Alnico Magnets

An Alnico magnet is a permanent magnet made by combiming aluminum, nickel, iron, cobalt, and other elements. They come in isotropic, non-directional, or anisotropic, mono-directional, form...

Please fill out the following form to submit a Request for Quote to any of the following companies listed on

This article takes an in depth look at ceramic magnets and their use.

You will learn more about topics such as:

A ceramic magnet, often referred to as a ferrite magnet, is a type of permanent magnet formed by combining iron oxide with strontium carbonate. This human-made magnet is crafted by heating the mixture to temperatures surpassing 2000° F, initiating a chemical transformation that converts the components into a ferrite substance exhibiting a magnetic field.

Ceramic magnets provide an economical substitute for natural magnets and are extensively utilized in both consumer goods and industrial applications. These magnets are the most widely used worldwide, featuring in about 75% of magnet-based products. Their cost-effectiveness is further enhanced by their excellent corrosion resistance.

During the 1960s, as industries sought affordable alternatives to traditional metal magnets, the manufacturing of ceramic magnets emerged as a breakthrough solution. This innovation coincided with the rapid expansion of the electronics industry, where the high cost of rare earth and metal magnets significantly impacted the production of consumer electronics, electric motors, audio equipment, and recording devices. The adoption of ceramic magnets offered a cost-effective, corrosion-resistant, and thermally stable option that revolutionized magnet technology by providing excellent magnetic performance at a fraction of the cost.

Ceramic magnets, also known as ferrite magnets, are widely utilized in diverse industrial applications due to their impressive magnetic strength and resistance to demagnetization. Common uses include DC motors, magnetic separators, speakers, magnetic resonance imaging (MRI) scanners, sensors, and consumer electronics. The core composition of ceramic magnets is ferrite—a composite material made by combining iron oxide with strontium carbonate, or sometimes barium carbonate, to optimize magnetic performance and cost efficiency.

If you’re seeking strong, reliable, and cost-efficient magnets for industrial, automotive, or medical applications, understanding the ceramic magnet manufacturing process—and the advantages gained through each step—can help guide purchasing decisions and ensure you select the best magnet type for your requirements.

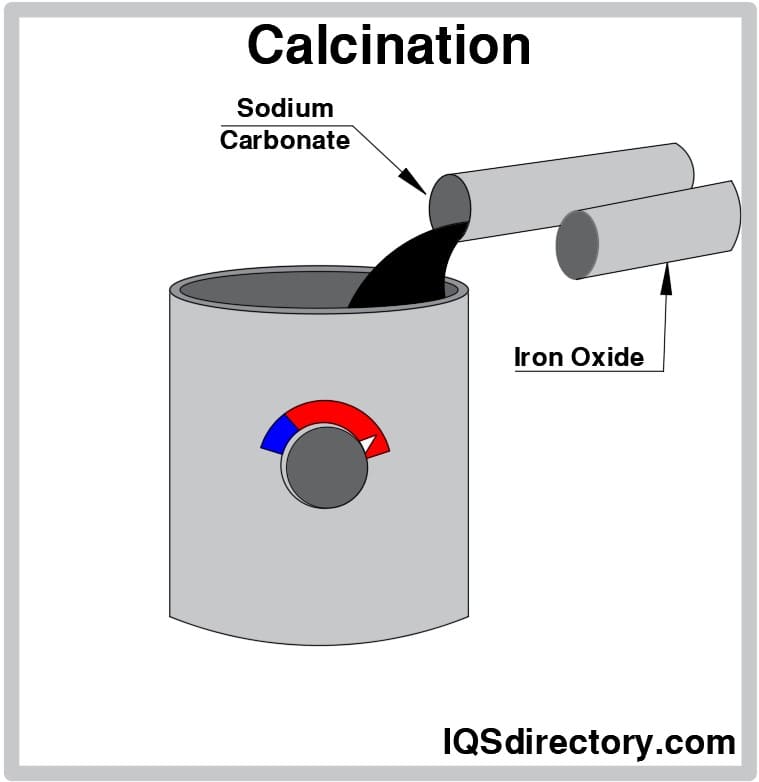

The initial stage in producing ceramic magnets is calcination—a high-temperature process in which iron oxide powder and strontium carbonate (or barium carbonate for certain formulations) are blended and heated in specialized furnaces. Calcination alters the chemical and physical characteristics of solid materials by exposing them to intense heat, commonly over 1800°F (1000°C). This process is essential for forming the ferrite compound (e.g., SrO-6 (Fe2O3)) that provides the base magnetic properties.

During calcination, manufacturers may introduce additional elements such as cobalt, lanthanum, or rare earth additives to enhance the performance characteristics—like coercivity and remanence—of the resulting ceramic magnet. This chemical transformation lays the foundation for the high-quality, high-coercivity ferrite magnets required in demanding modern applications.

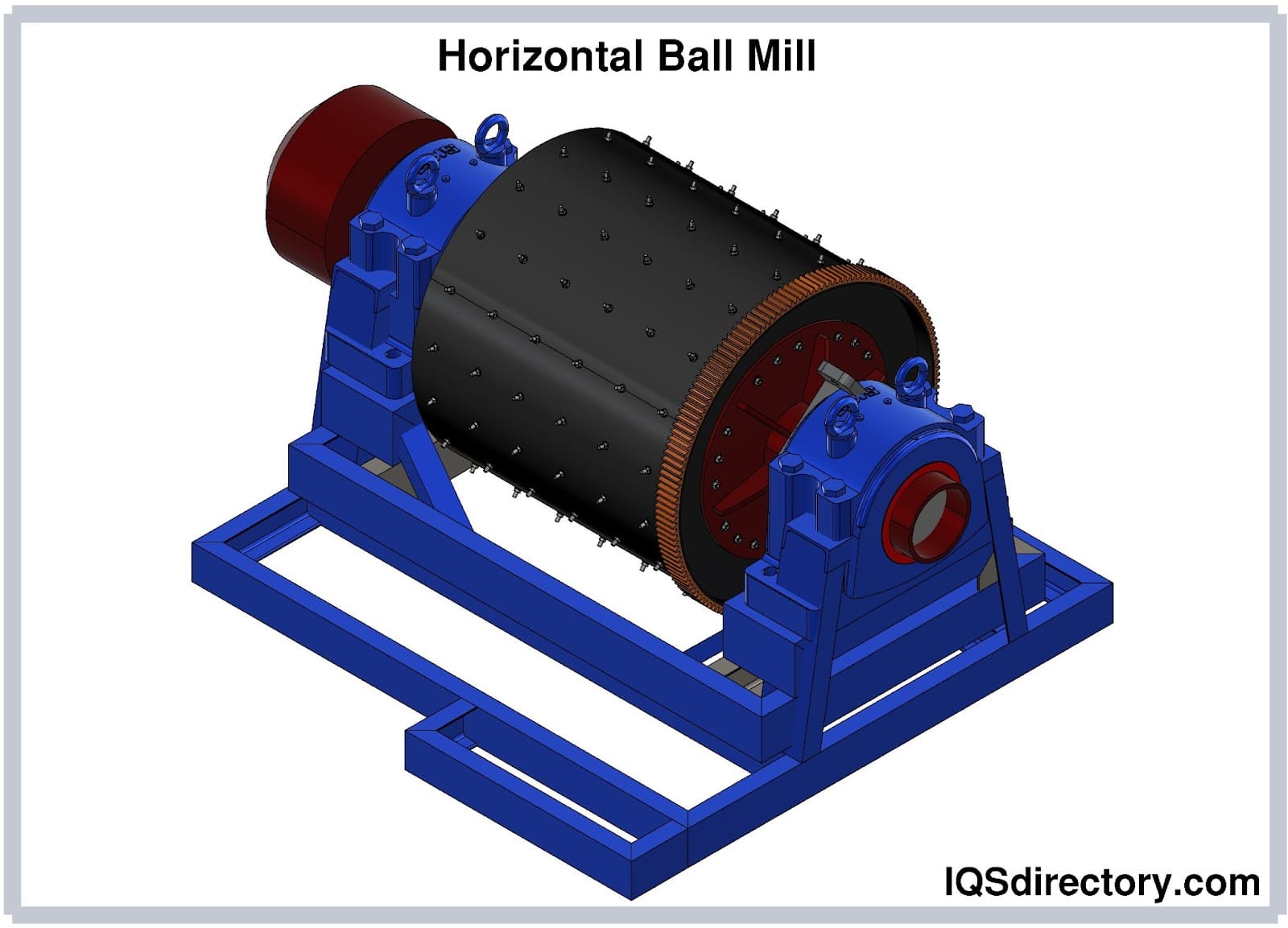

Milling is a critical stage that determines the magnetic and mechanical properties of the final ceramic product. The purpose of milling, or pulverization, is to reduce the ferrite or ceramic powder into extremely fine particles, often as small as two micrometers (µ) or less. These finely milled particles each host a single magnetic domain, promoting homogeneous magnetization and enhanced energy product in finished magnets. Particle uniformity is key for consistent magnetic field output and the production of high-performance ferrite magnets.

A widely adopted milling technique is the ball mill, which uses steel or ceramic balls within a rotating drum to grind the ferrite material. Through repeated impacts and friction, the ball mill transforms granulated ferrite into a consistent, ultrafine powder. The resulting material supports the creation of complex, custom magnet geometries for specialized industrial needs, ranging from loudspeakers to electric vehicle drive motors.

Transforming the ultrafine ferrite powder into a manageable medium is vital for downstream processes. To achieve this, a precise amount of water or binder is mixed in to form a slurry—a homogeneous, mud-like suspension. This step ensures even distribution of particles, optimal packing density, and improved handling during pressing or molding. Proper slurry consistency is critical for achieving desired magnet density, shape accuracy, and minimizing unwanted air pockets.

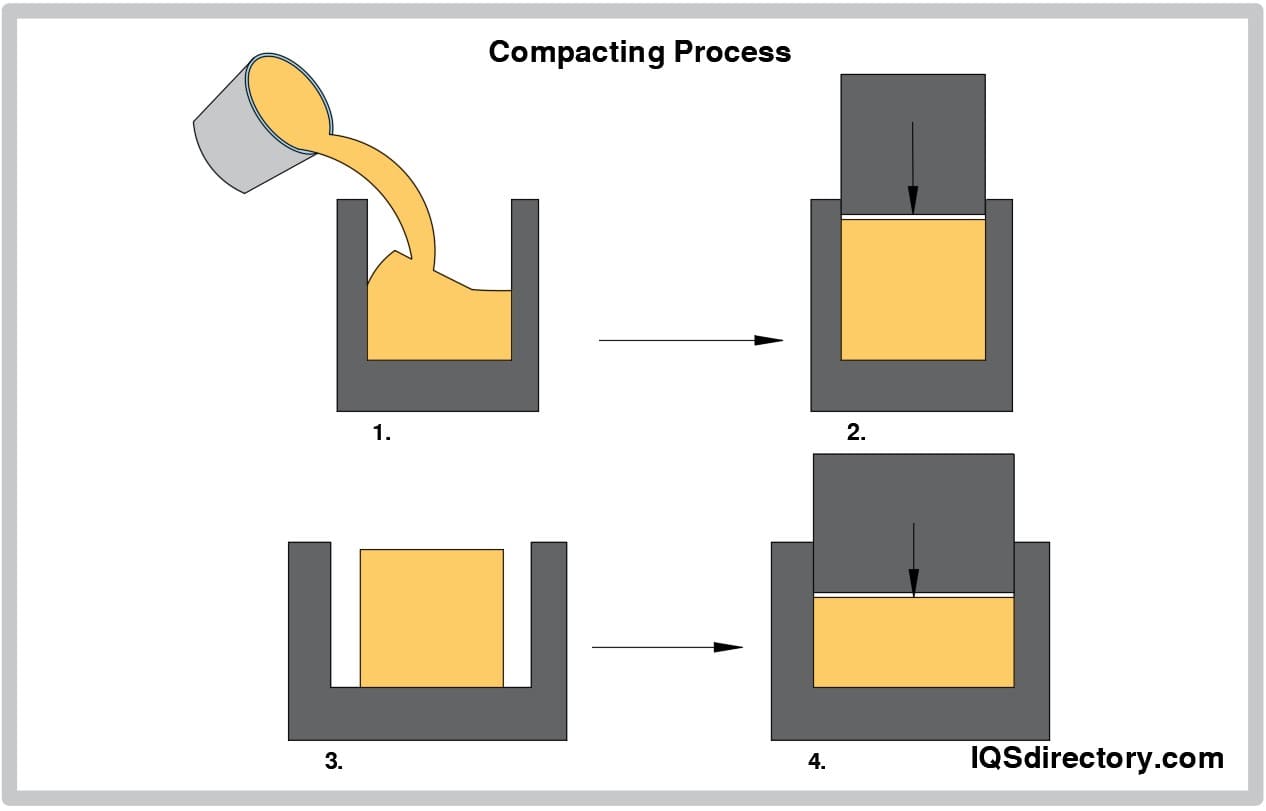

Compacting is where the ceramic magnet begins to take its final shape. In this stage, the wet slurry is pressed using hydraulic or isostatic presses into custom molds matched to standard or bespoke magnet shapes (disks, rings, blocks, arcs, etc.). For high-performance magnets, an external magnetic field is applied during pressing, which aligns the anisotropic magnetic domains for maximum magnetic directionality—a key factor for powerful permanent magnets. This process is used to create oriented (anisotropic) ferrite magnets with superior energy density.

Alternatively, dry pressing without field alignment results in isotropic ceramic magnets, which can be magnetized in any direction, but generally display lower energy product. The choice between isotropic and anisotropic magnets depends on the end use: anisotropic types are preferred for demanding applications like electric motors and high-efficiency magnetic assemblies.

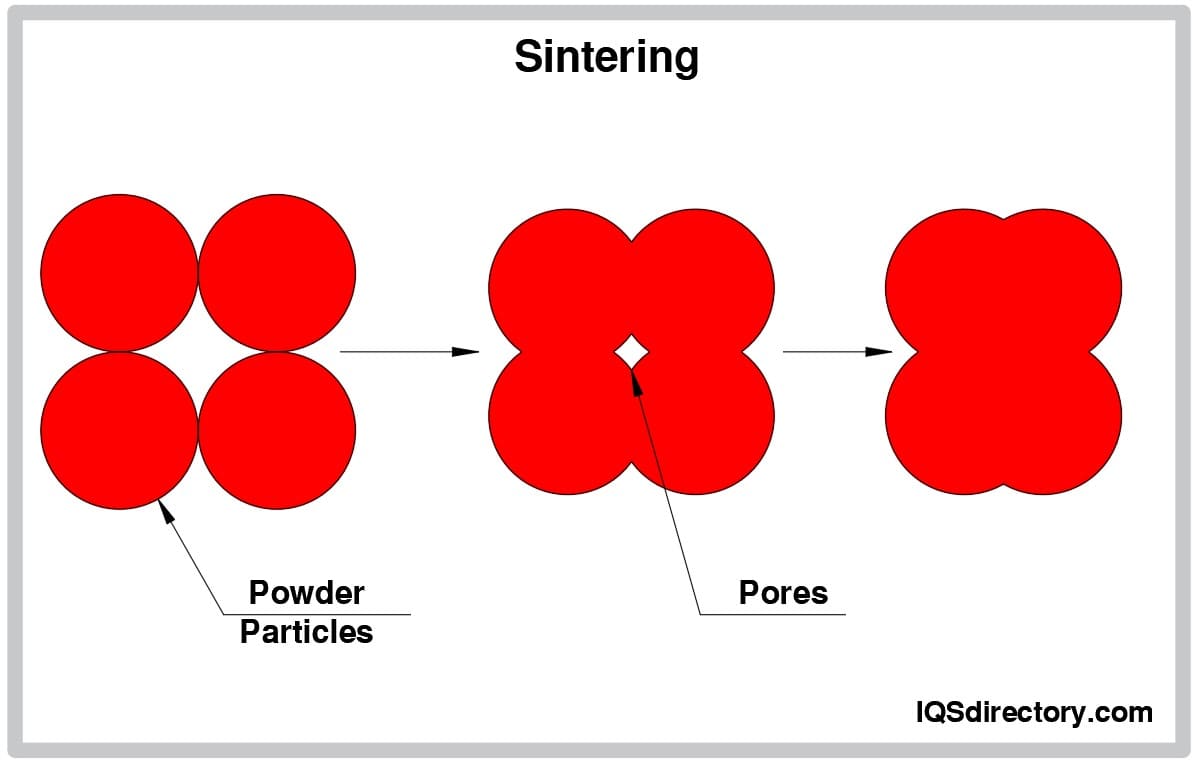

Sintering, also known as ceramic firing or frittage, is essential for transforming compacted powder into a dense, robust magnetic solid. In specialized kilns or high-temperature ovens, the pressed magnets are heated from 482°F (250°C) up to 1652°F (900°C) for durations of 20 to 36 hours, depending on quality requirements and magnet volume. This controlled high-temperature environment encourages atomic diffusion and solid-state bonding, closing gaps between powder particles and dramatically increasing magnet strength, durability, and resistance to demagnetization.

Unlike conventional melting, sintering bonds particles without liquifying the materials, thus maintaining shape integrity while yielding a cohesive, hard ceramic magnet. Real-time control of the sintering profile ensures tight tolerances and repeatable performance needed for critical applications such as automotive sensors and power generation equipment.

The diagram below shows the transition of ferrite particles through the sintering process, highlighting densification and grain growth at each stage.

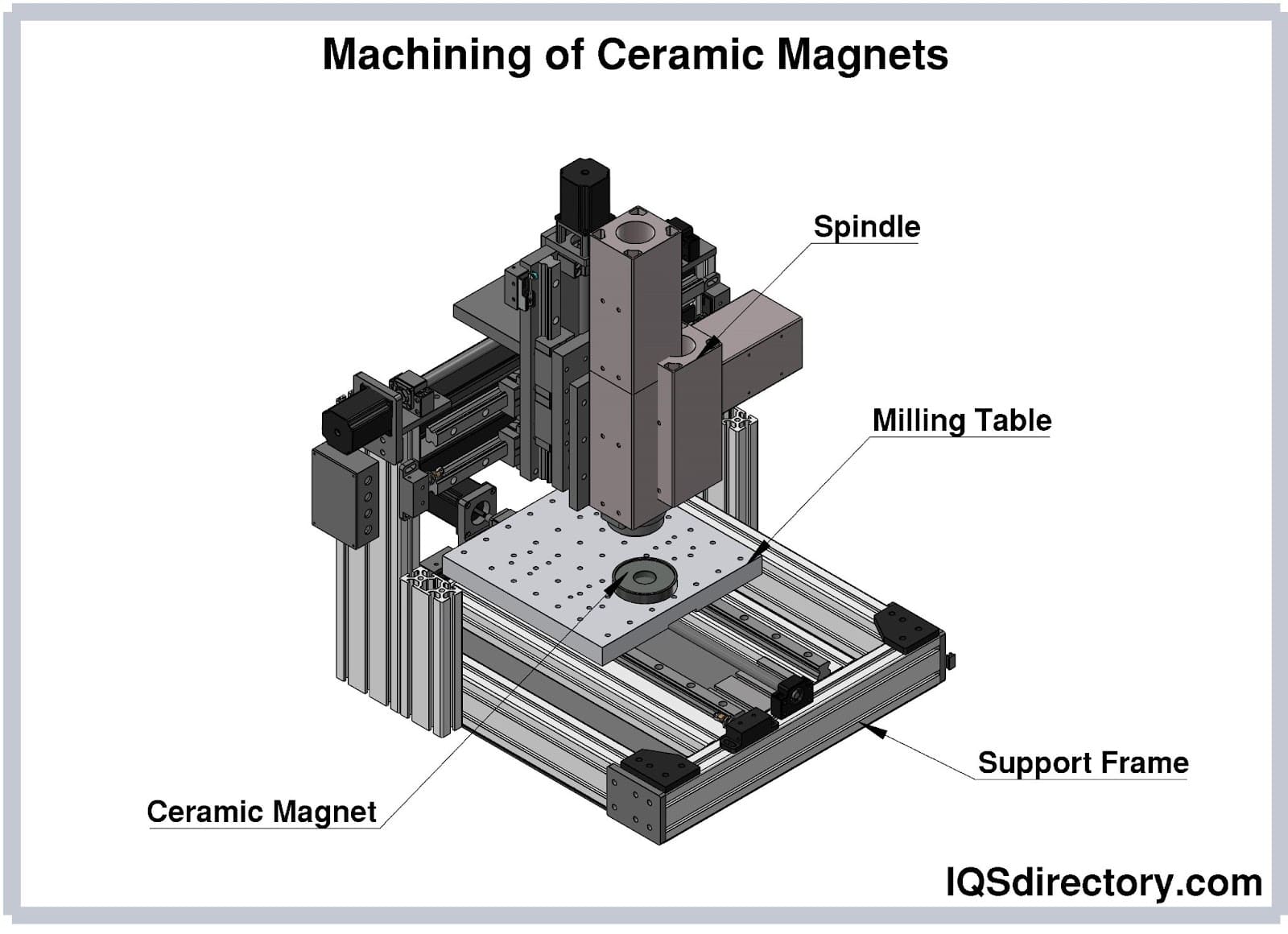

Once sintering is complete, ceramic magnets must be cooled to room temperature and processed to strict dimensional specifications. Their brittle, hard structure requires diamond-coated grinding and cutting tools for precision shaping, hole drilling, or surface finishing. Advanced CNC machining methods are often used to achieve intricate forms and ultra-precise measurements, enhancing performance and compatibility with automated assembly systems. Each pass of the diamond tool carefully removes millimeters of material to achieve desired tolerances, ensuring magnets fit seamlessly into today’s high-speed manufacturing operations.

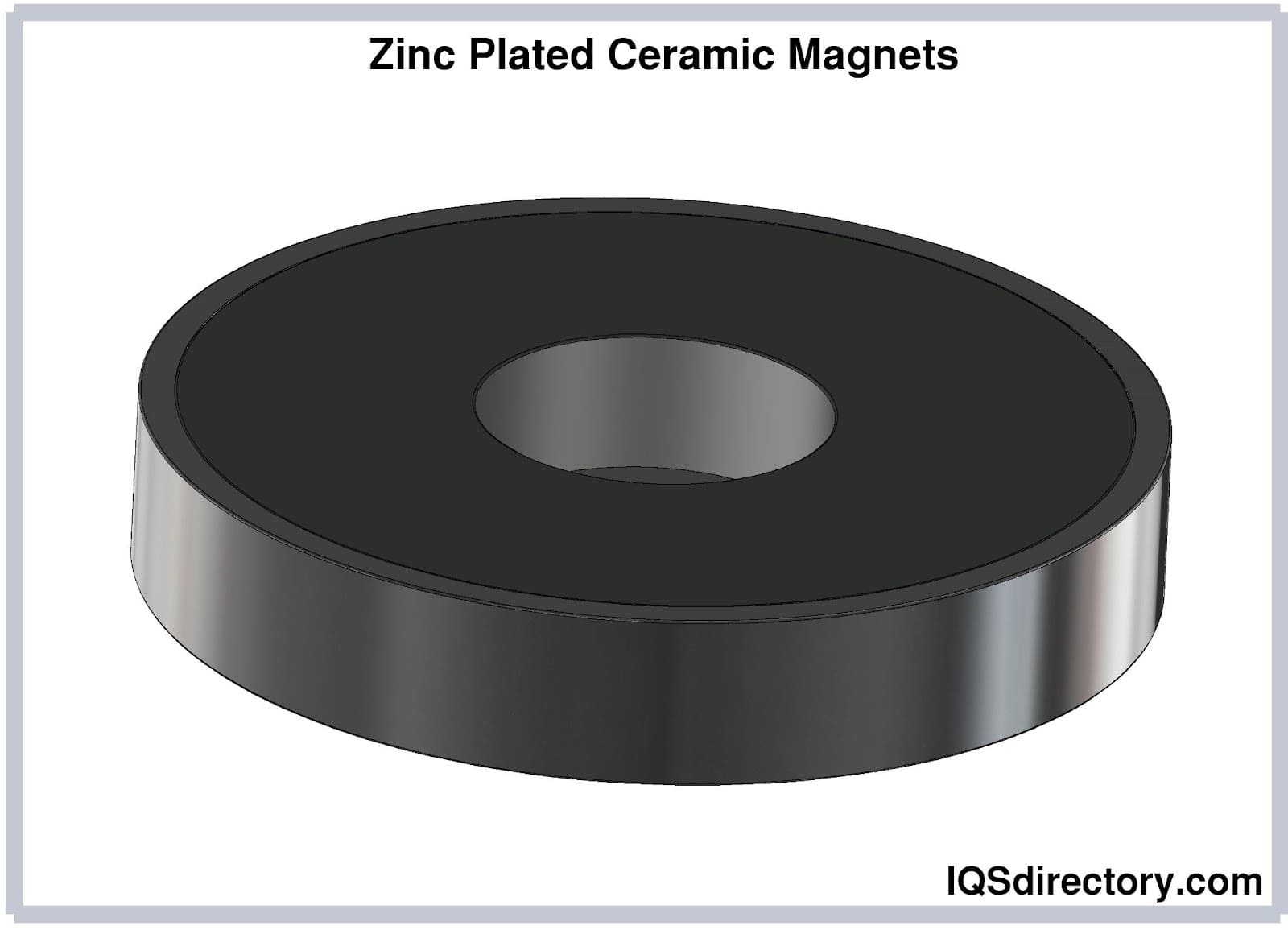

While ceramic magnets are naturally corrosion-resistant, surface coatings or platings are often applied to improve wear resistance, prevent chipping, or enhance electrical insulation. Selecting the right finish is vital for applications requiring frequent handling, exposure to moisture, or contact with sensitive electronic components. Here are common ceramic magnet coatings and their benefits:

A triple-layer nickel-copper-nickel coating, also known as nickel coating, delivers excellent corrosion protection and forms a smooth surface finish favored in medical devices and precision magnetic assemblies.

Epoxy coatings offer durable, chemical-resistant protection ideal for magnets exposed to harsh environments or direct contact with liquids, thereby extending magnet lifespan and preserving magnetic properties.

Zinc coatings provide economical corrosion protection and act as a moisture barrier, suitable for general-purpose applications or magnets used in humid or salty conditions.

PTFE (Teflon) coatings significantly boost impact resistance, guarding against breakage and improving the handling of brittle ceramic magnets during assembly and usage.

Gold-plated ceramic magnets are hypoallergenic, making them ideal for medical and therapeutic devices, such as those in magnetic therapy, where direct skin contact is routine. The thin 22-carat gold layer is inert, ensuring user safety and long-term reliability.

Other advanced coatings include silver plating, parylene, and polyurethane, each tailored for specific operational environments or regulatory requirements. The optimal coating depends on factors like operating temperature, exposure to chemicals, and the need for electrical insulation.

For engineers, designers, and procurement teams: Understanding the entire manufacturing process and available customization options for ceramic magnets can help inform selection criteria, cost comparisons, and performance evaluations, while also providing opportunities for increased efficiency and product innovation within your operations. To learn more about custom ceramic magnet manufacturing, specifications, and current pricing from leading suppliers, consult with the companies below or visit our comprehensive product guides linked throughout this page.

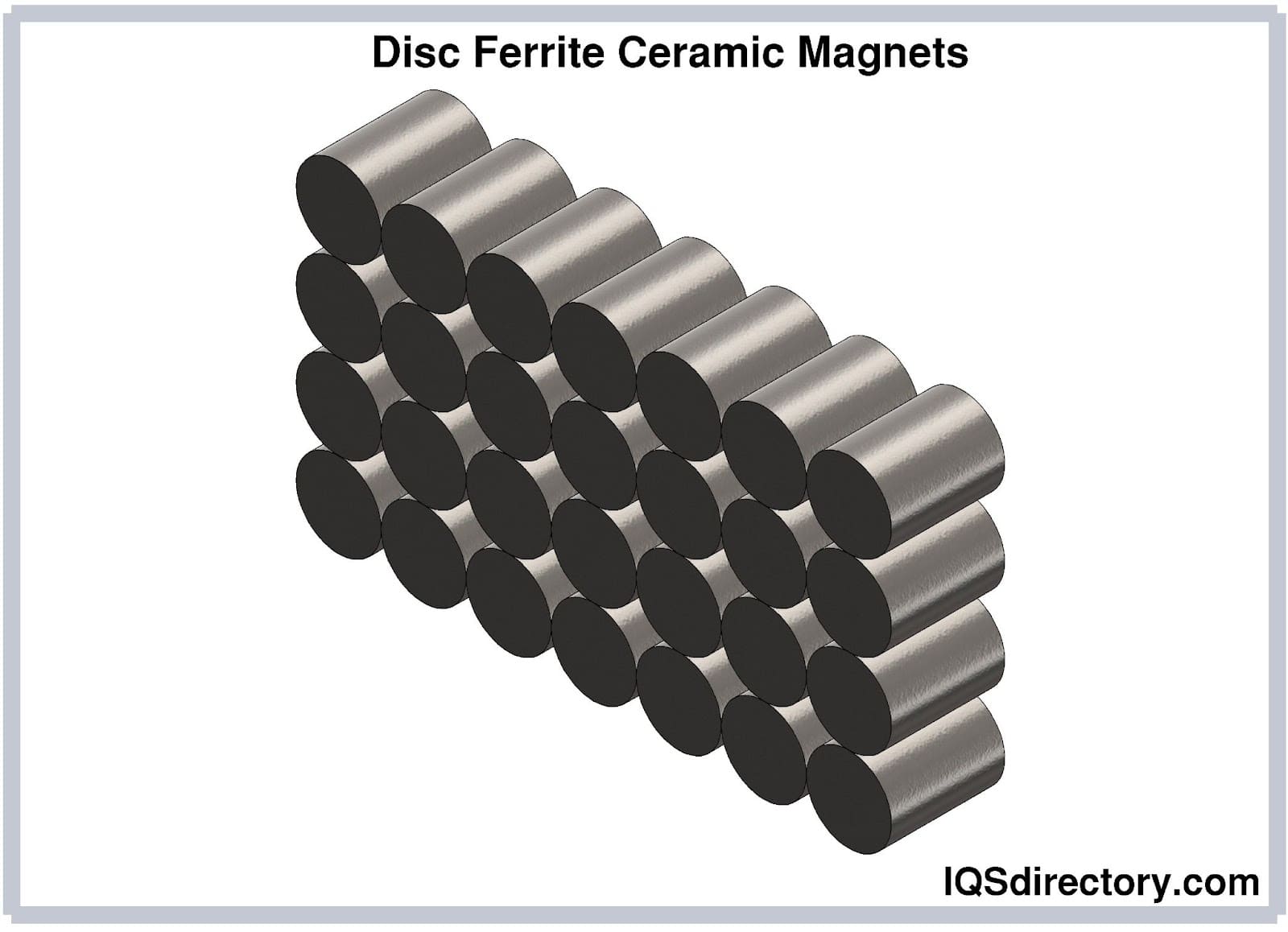

Ceramic magnets, also known as ferrite magnets, are among the most widely used permanent magnets thanks to their versatile magnetic properties, cost-effectiveness, and corrosion resistance. The flexible manufacturing process allows ceramic magnets to be produced in various shapes and sizes, such as small ceramic block magnets, discs, rings, or puck-like forms, making these industrial magnets suitable for a diverse range of applications across industries from automotive to electronics. This adaptability, combined with the low production costs, has led to their extensive adoption in commercial and industrial environments.

When classifying ceramic magnets, different categories are based on their intrinsic magnetic properties and intended applications within specific sectors. Industry professionals usually group ceramic magnets into five main types: soft ceramic magnets, permanent ceramic magnets (hard ferrites), spin ceramic magnets, moment magnets, and piezomagnetic magnets. Understanding these categories can help users choose the optimal magnet type for their unique engineering, manufacturing, or consumer product requirements.

Hard ceramic magnets, also referred to as hard ferrites, are characterized by their high coercive force and strong magnetic retention. This means they are highly resistant to demagnetization, ensuring their magnetic strength and stability even under demanding conditions. As a result, hard ceramic magnets are preferred in applications where reliability and consistent performance are critical, such as in automotive sensors, electric motors, loudspeakers, and particularly in critical telecommunications equipment where magnetic failure is unacceptable. Compared to rare earth magnets like neodymium, hard ceramic magnets offer an exceptional balance of strength, thermal stability, and low cost.

Ceramic moment magnets are specialty magnets that display rectangular hysteresis loops. This property allows them to become magnetized and quickly reach saturation under a low magnetic field, while retaining magnetization after the external field is removed—classifying them as remanent magnets. Manufactured from advanced materials like magnesium manganese ferrite and lithium manganese ferrite, moment magnets are essential for high-speed memory devices and are used extensively within computer memory cores, magnetic storage solutions, and emerging spintronic devices.

Permanent ceramic magnets, which are typically composed of strontium or barium ferrite, possess a uniaxial anisotropic hexagonal crystalline structure. This molecular arrangement grants them exceptional magnetic strength and stability, helping them maintain strong remanent magnetization over long periods. Thanks to their enduring and consistent power, permanent ceramic magnets are ideal for consumer products such as refrigerator magnets, microphones, cordless device motors, and a broad range of automotive applications. Their low cost and corrosion resistance make them an economical and durable solution for manufacturers seeking reliable permanent magnets without sacrificing quality.

Piezomagnetic ceramic magnets are unique for their ability to change dimensions in the direction of a magnetic field upon magnetization, a phenomenon driven by mechanical stress or deformation. This distinctive property, caused by distortions or lattice deficiencies in the crystal structure, allows piezomagnetic materials to convert mechanical energy into magnetic energy and vice versa. As a result, piezomagnetic ceramic magnets are vital in high-sensitivity sensors, medical transducers, industrial actuators, and magnetostrictive components for ultrasound imaging and precision audio systems. Their non-conductive nature also minimizes energy loss, making them ideal for advanced electronics and acoustic applications.

Soft ceramic magnets are a core element within the ferrite magnet category and are prized for their ease of magnetization and demagnetization. Featuring a cubic crystal structure and typically composed of materials such as manganese zinc ferrite or nickel zinc ferrite, soft magnets have low coercivity, which allows them to respond rapidly to external magnetic fields. This property is crucial for use in alternating current (AC) electromagnetic devices such as electronic filters, power transformers, inductor cores, radio frequency devices, and both tape and video heads. Due to their high electrical resistivity and minimal eddy current losses, soft ceramic magnets support high-frequency operation, making them essential in modern electronics and electrical engineering applications.

By evaluating their magnetic hysteresis loop or magnetization curve, engineers determine the most suitable ferrite composition and grade for each use case, ensuring optimal performance in signal processing, wireless communication, and energy conversion.

Spin ceramic magnets are engineered to exploit the rotary magnetism effect, which is based on the interplay of two perpendicular stable magnetic fields and a time-varying electromagnetic wave magnetic field. This dynamic interaction generates continuous rotational motion at the atomic or molecular level, leading to specialized magnetic phenomena. Although some metallic magnets can demonstrate spin magnetism, they often suffer from high eddy current losses and thermal instability. Spin ceramic magnets, however, are preferred for their superior resistance to energy loss, making them well-suited to high-frequency and microwave applications such as radar, magnetic resonance imaging (MRI), and advanced RF components.

When evaluating ceramic magnets for your application, consider the unique properties, performance requirements, and environmental conditions—such as operating temperature and electrical insulation needs. Working with an experienced ceramic magnet supplier or magnetic materials manufacturer can ensure you select the correct specifications, grade, and shape to optimize performance and cost-effectiveness. Whether you're designing consumer products, industrial systems, or advanced electronics, understanding the advantages of ceramic magnets—including their affordability, thermal stability, and electrical resistivity—will enable more informed and effective engineering decisions. For more detailed product data or to explore custom magnet solutions, consult with a magnetics industry expert or read our FAQ for guidance tailored to specific use cases.

A ceramic magnet, or ferrite magnet, is a permanent magnet made by combining iron oxide with strontium carbonate. The process involves heating the mixture at high temperatures to create a ferrite substance with strong magnetic properties.

Ceramic magnets are produced through steps including calcination, milling, slurry preparation, compacting with potential magnetic alignment, sintering, precision machining, and optional protective coatings for wear, corrosion, or insulation.

The main ceramic magnet types are hard ceramic (hard ferrite), soft ceramic, moment magnets, permanent ceramic magnets, piezomagnetic magnets, and spin ceramic magnets. Each type is engineered for specific magnetic, structural, or electronic properties and use cases.

Ceramic magnets are widely used in consumer electronics, electric motors, audio equipment, MRI scanners, automotive components, sensors, and other industrial applications due to their strength, cost-effectiveness, and resistance to corrosion.

Ceramic magnets are the most widely used magnet type due to their low cost, excellent corrosion resistance, electrical insulation, and stable magnetic performance—making them ideal for high-volume industrial and consumer products.

Yes. While ceramic magnets are inherently corrosion-resistant, applying additional coatings such as zinc, epoxy, or PTFE can further protect them for use in humid, salty, or chemically aggressive environments.

Ceramic magnets are utilized in a diverse range of products, including speakers, recorders, and large communication systems. Their affordability and versatility make them an excellent choice for providing magnetism. Ceramic magnets are primarily categorized into soft and hard types, with hard magnets exhibiting high coercivity and soft magnets having low coercivity.

Before the advent of ceramic magnets in the 1960s, cost-effective options for generating a magnetic field were limited, as most magnets were metal-based. The introduction of ceramic magnets significantly reduced the cost of many products and made them widely accessible.

In a speaker, the voice coil moves in and out in response to the audio signal, generating a magnetic field. A ceramic magnet positioned near the voice coil helps regulate its movement, influencing the overall sound quality of the speaker. To achieve superior sound quality, ceramic magnet speakers are often heavier, which enhances their punch and clarity.

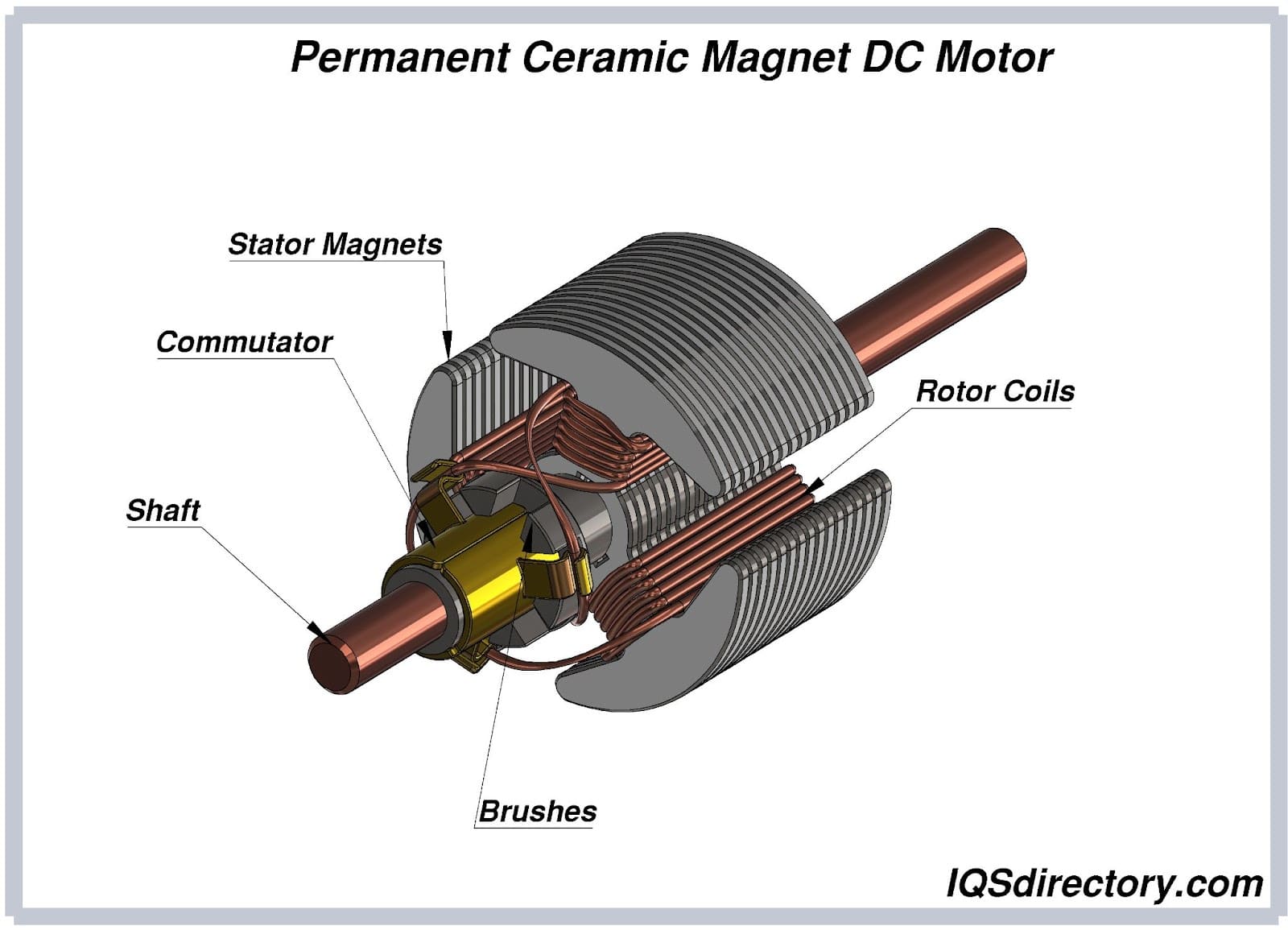

Direct current (DC) motors utilize the magnetic field's force to generate rotational motion. An armature within the magnetic field rotates due to this force, producing DC current. In a permanent ceramic magnet DC motor, a permanent ceramic magnet creates the necessary magnetic field.

Permanent ceramic magnet motors are commonly found in automobile starters, windshield wipers, washers, and air conditioners. These motors are ideal for applications where speed control is not required, as speed regulation typically involves adjusting the magnetic field.

MRI scanners utilize magnetic fields and radio waves to create detailed images of the human body, aiding in medical diagnoses. They come in different sizes and configurations, with some models featuring side openings to alleviate feelings of claustrophobia.

The core component of an MRI system is its extremely strong magnet, which generates a stable magnetic field along the length of the MRI tube. This uniform magnetic field ensures clear and high-quality imaging of the internal structures of a patient's body.

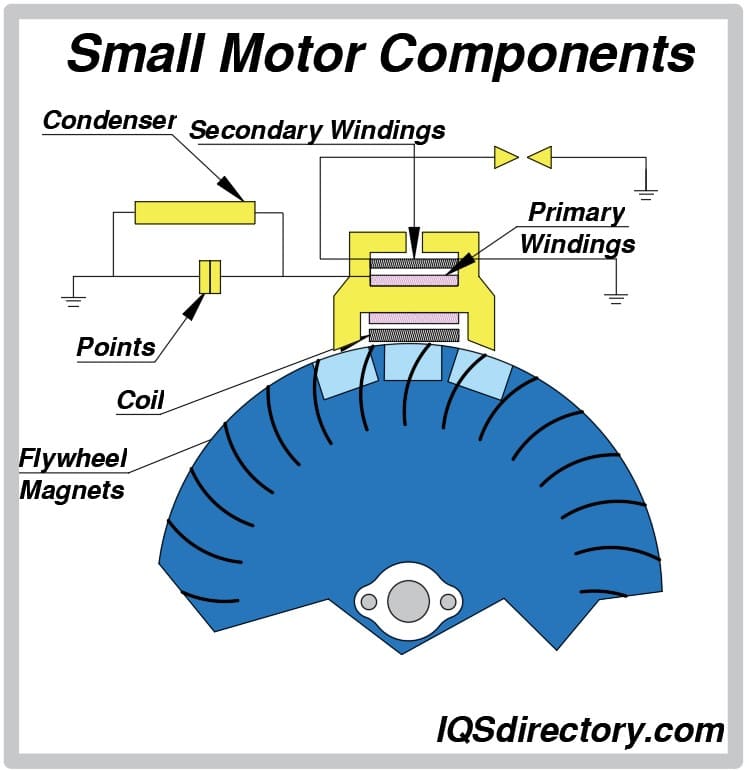

Small motors do not require a battery. They generate power for the spark plugs using a magneto. The voltage from the magneto creates a spark that jumps the spark plug gap that ignites the engine’s fuel. The function of the magneto is to supply current to the ignition system and produce voltage for the spark plugs. For the motor to work properly, the magneto must be precisely placed in relation to the flywheel to generate the correct magnetic field.

A magneto integrates the functions of a distributor and a generator, differing from a traditional distributor by generating its own spark without requiring external voltage. In this system, rotating ceramic magnets disrupt the electrical field, which induces current in the primary windings, as illustrated in the image below.

The term "ceramic magnet" refers to a broad category of 27 different types, each designed for specific applications, from operating MRI scanners to starting lawnmowers. Their resistance to high temperatures and corrosion, combined with their affordability, makes them a popular choice.

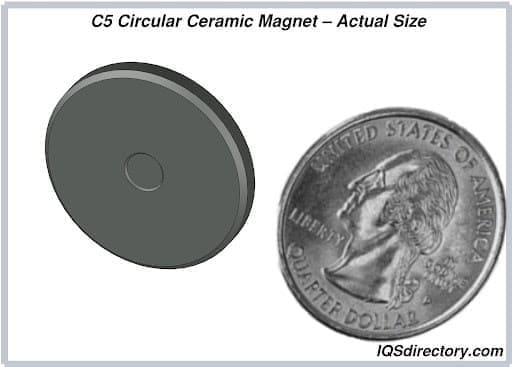

The most frequently used grades of ceramic magnets are C1, C5, and C8, known for their straightforward construction due to their manufacturing process. The variations between these grades are based on their ferromagnetic properties.

The traditional “C” labeling system for ceramic magnet grades has been replaced by a “Y” system. In this new system, grades are indicated by the letter Y followed by a number or a combination of numbers and letters. The numbers after the "Y" denote the magnet’s energy, while the letters provide additional details about its characteristics.

The “Y” labeling system is gradually becoming the standard for ceramic magnets and is now widely adopted in most countries. However, the transition has been gradual, so the “C” labeling system remains common in the United States.

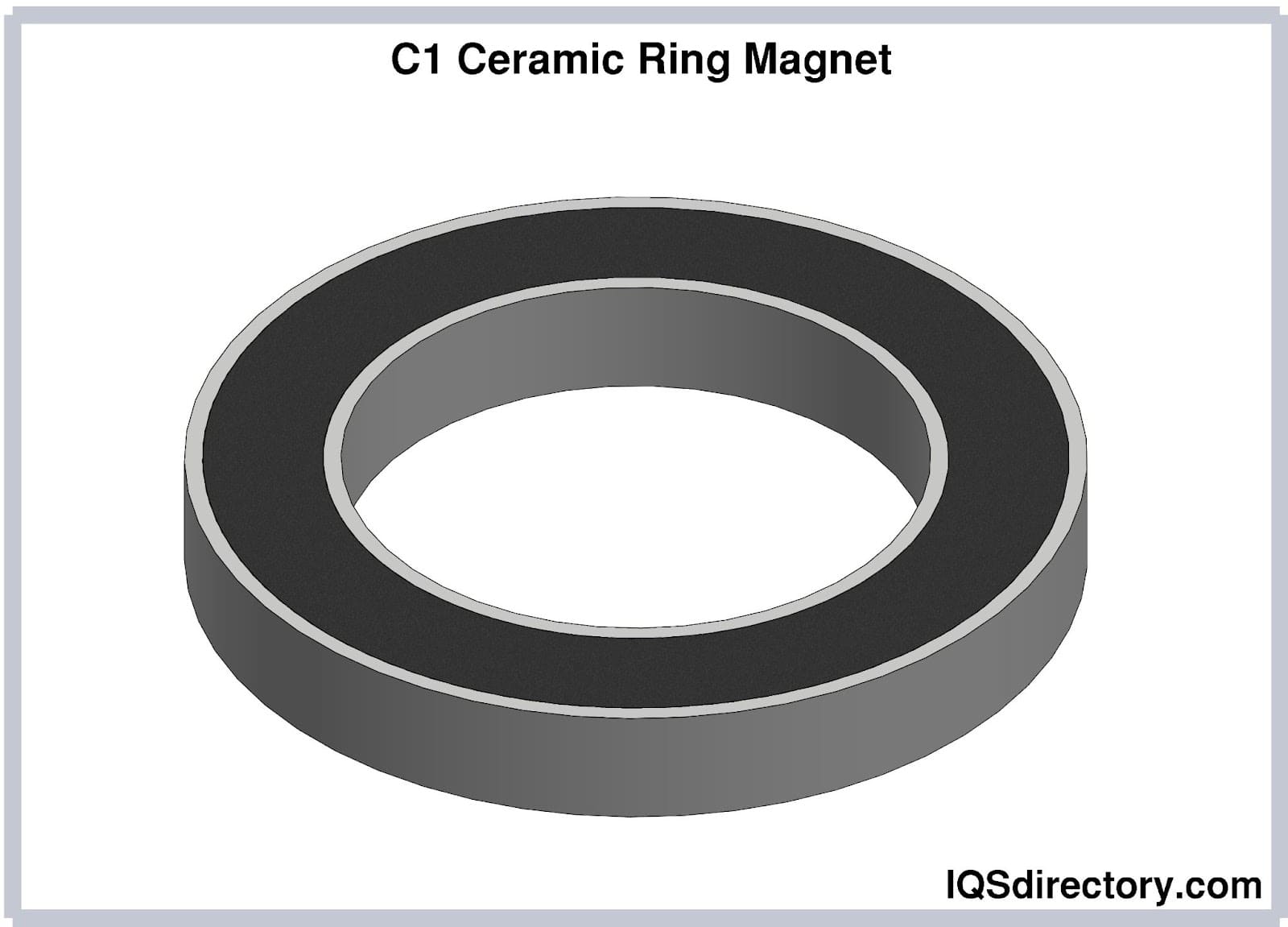

C1 ceramic magnets are small and relatively weak, designed to fit into compact spaces. With an operating temperature of up to 480°F (249°C), they are well-suited for high-temperature environments. These magnets are commonly used in speakers, small motors, and reed switches.

C5 ceramic magnets are among the most commonly used ceramic magnets and are magnetized according to their orientation. While they offer broad applicability, they can be demagnetized, which limits their use in certain applications.

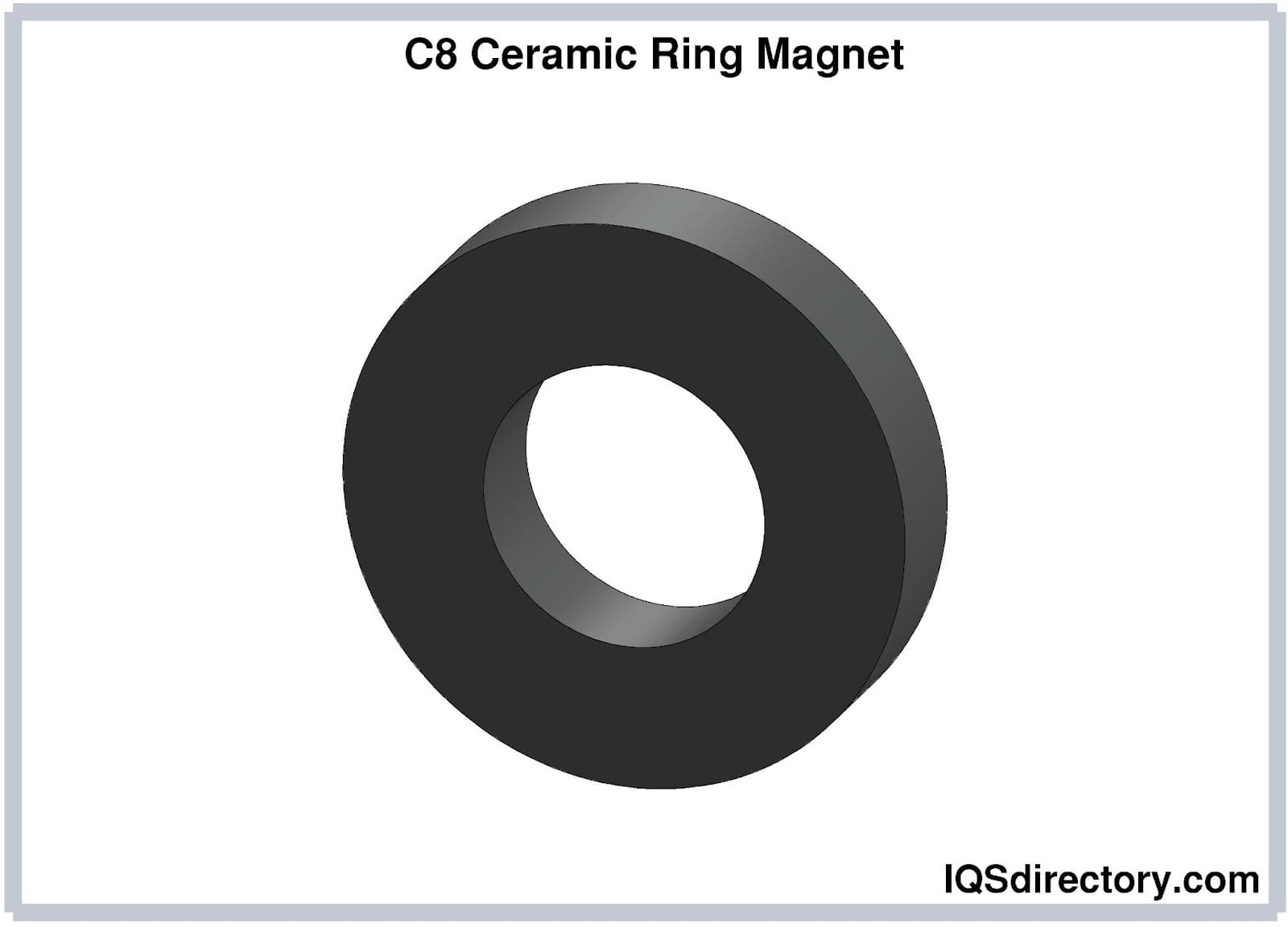

C8 ceramic magnets are valued for their high energy and strong resistance to demagnetization. They are frequently employed in applications where the magnet's length could be an issue or where there is a risk of demagnetization.

Ceramic magnets C1, C5, and C8 are among the most commonly used and can be found in a wide range of products. However, they are just a few of the 27 different types available from manufacturers. The list below highlights some of the more popular ceramic magnets, along with their properties and characteristics.

| Grades of Ceramic Magnets | |||||

|---|---|---|---|---|---|

| Grade | Br (Kg) | HcB (KOe) | Hci (KOe) | BHmax (MGOe) | T max |

| C | 2.30 | 1.86 | 3.50 | 1.00 | 250C / 482F |

| C | 3.30 | 2.40 | 2.50 | 3.40 | 250C / 482F |

| C7 | 4.30 | 3.23 | 4.00 | 2.75 | 250C / 482F |

| C8 | 5.30 | 2.95 | 3.05 | 3.50 | 250C / 482F |

| C8B | 6.30 | 2.91 | 2.96 | 4.12 | 250C / 482F |

| C9 | 7.30 | 3.52 | 4.01 | 3.32 | 250C / 482F |

| C10 | 8.30 | 3.62 | 3.51 | 3.82 | 250C / 482F |

| C11 | 9.30 | 2.51 | 2.56 | 4.32 | 250C / 482F |

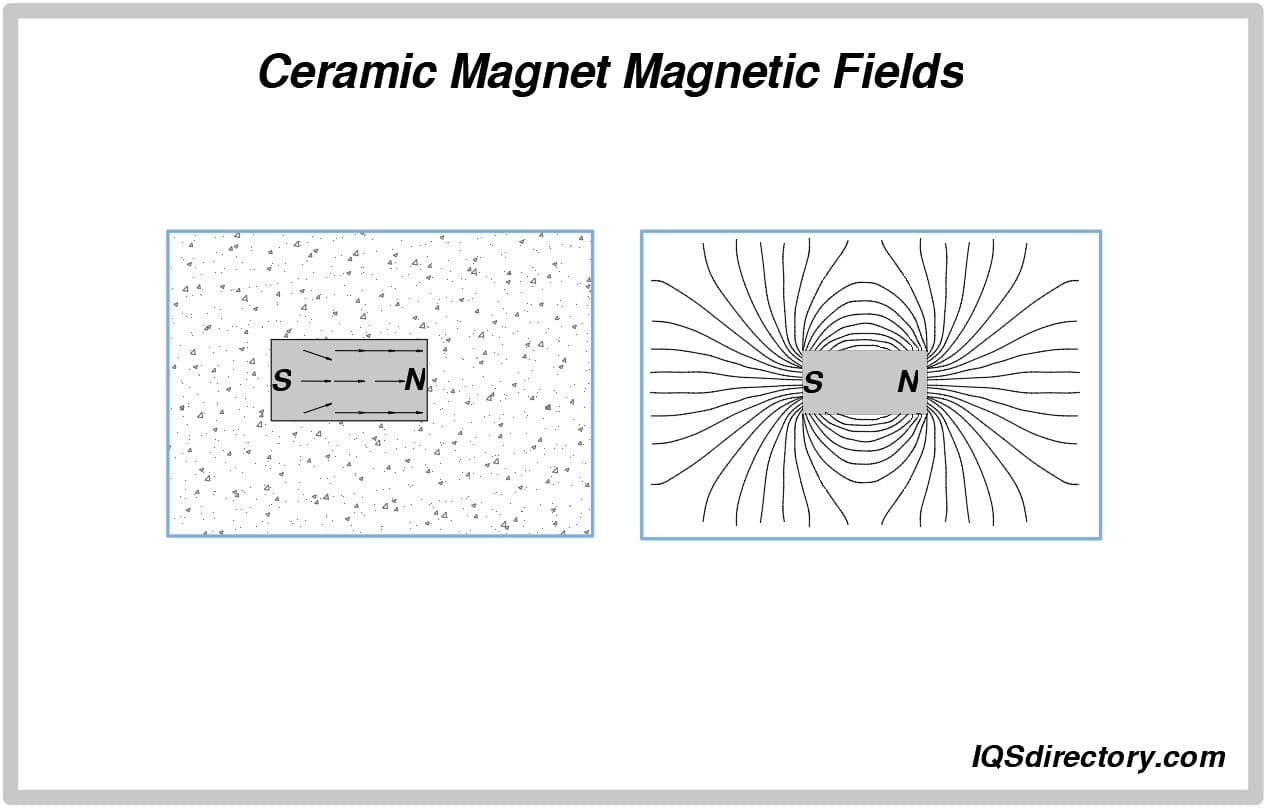

The magnetic field describes the force exerted by a magnet and is characterized by its poles, which are either attracting or repelling. The vector method represents a magnetic field with dots on a grid, where each vector points in the direction of the magnetic force and its length corresponds to the strength of the field. Alternatively, the field lines method visualizes the magnetic force pattern using smooth, curved lines to illustrate the field's behavior.

Two key parameters used to measure a magnetic field are its strength and direction. Among these, direction is the simpler parameter to measure. Determining the strength of a magnetic field is more challenging and has been possible for only about 30 years.

A magnetic field arises when a charge is in motion. The stronger the charge and its movement, the more intense the magnetic field. Electromagnetic force, which includes magnetism and magnetic fields, is one of the four fundamental forces of nature.

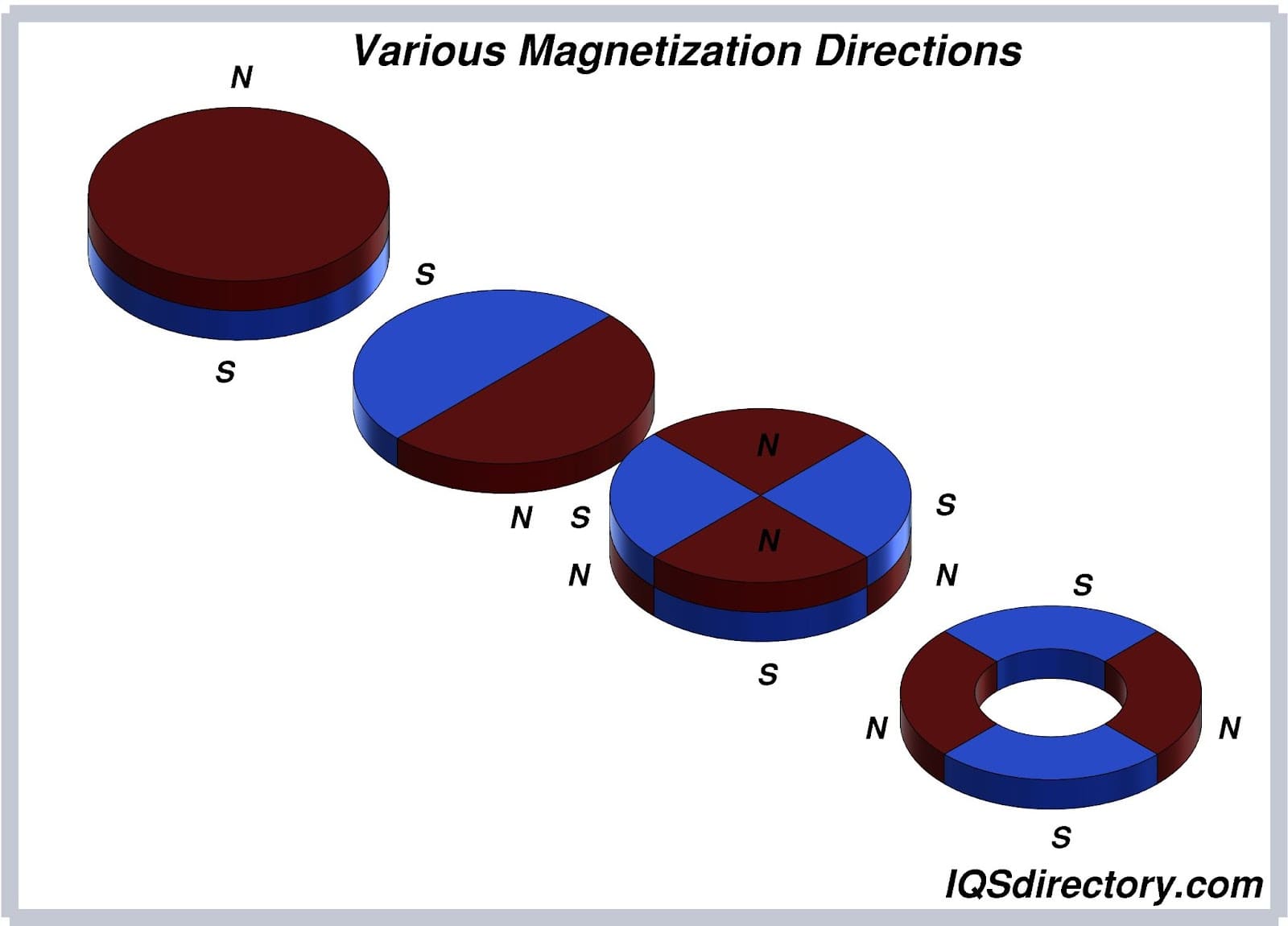

Magnetization directions vary and are primarily limited by the magnet's size. As illustrated in the images below, magnetization can be axial, running along the axis of the magnet, or diametrical, extending across its length. Additionally, there are multiple pole configurations, including multipole axial and multipole diametrical magnetizations.

The terms axial and diametrical describe magnetization directions in cylindrical, disk, ring, and arc-shaped magnets. In axial magnetization, the magnetic force aligns with the end planes of the magnet, whereas in diametrical magnetization, the field is oriented along the inner and outer arcs.

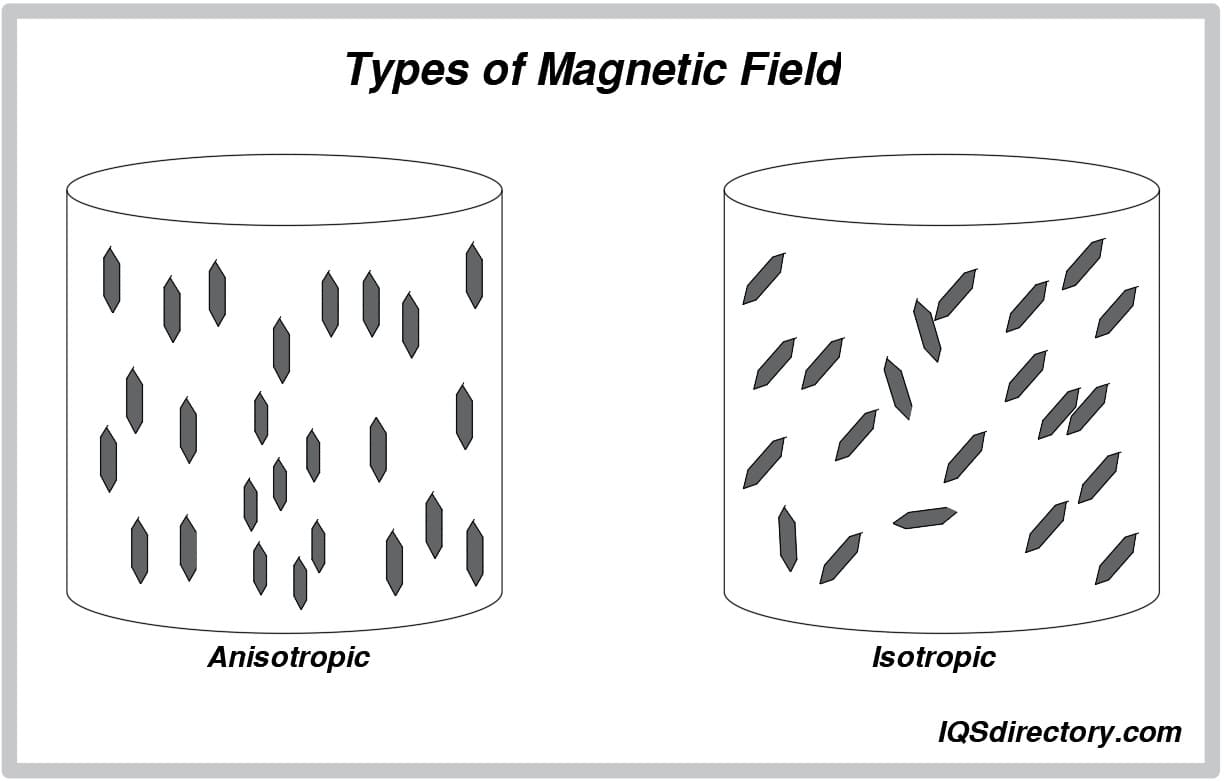

Magnetic fields are classified into two categories: isotropic and anisotropic. Isotropic magnets have a random magnetization direction, resulting in generally weaker magnetic fields. In contrast, anisotropic magnets have a specific, predetermined magnetization direction, which provides them with a stronger magnetic force.

The distinction between isotropic and anisotropic magnets is clearly illustrated in the image below. Isotropic magnetization appears scattered and random, while anisotropic magnetization is more directional and uniform.

Since their invention, ceramic magnets have found a growing number of applications. They are permanent magnets known for their durability and strength, largely due to their high magnetic permeability.

Approximately 75% of all magnets globally are ceramic magnets. Their widespread use can be attributed to several factors, with their low cost being a primary reason.

The most frequently highlighted advantage of ceramic magnets is their cost, which is significantly lower compared to other types of magnets. The production process for ceramic magnets is more efficient, and their magnetic field strength often exceeds that of natural magnets. Their affordability primarily stems from their composition, as they are made from nonmetallic materials.

The effectiveness of a magnet is assessed by its ability to retain magnetism under challenging conditions. While many magnets can demagnetize due to vibrations or high temperatures, ceramic magnets are notably more resilient. They can endure extreme temperatures and still maintain their magnetization.

Ceramic magnets exhibit remarkable magnetic permanence even in the harshest environments. Their resistance to electrical exposure makes them particularly suitable for use in DC motors.

The combination of iron oxide and strontium carbonate in ceramic magnets provides inherent corrosion resistance. The natural properties of these materials are retained in the magnets, making them highly resistant to corrosion. This quality is essential for their use in industrial and manufacturing settings.

Once a ceramic magnet is magnetized, it remains nearly impossible to demagnetize. This durability is crucial for applications that rely on the consistent performance of magnets.

Beyond their ease of magnetization, ceramic magnets can be magnetized in various directions, making them versatile for a wide range of applications.

Because ceramic magnets are made from compacted powdered materials, they can be manufactured in virtually any shape, size, or configuration. This versatility allows ceramic magnets to be used in a diverse range of applications, from small toys to large MRI scanners.

An Alnico magnet is a permanent magnet made by combiming aluminum, nickel, iron, cobalt, and other elements. They come in isotropic, non-directional, or anisotropic, mono-directional, form...

Flexible magnets are composite materials with magnetic components arranged in an elastomer matrix. They are made from a combination of rubber polymer resin and ferrite powder by forming it through...

Magnets are materials that exert a noticeable force on other materials without physically contacting them. This force is called a magnetic force. The magnetic force can either attract or repel. Most known materials...

A Neodymium (Nd-Fe-B) magnet is a common rare earth magnet composed of neodymium (Nd), iron (Fe), boron (B), and transition metals. They have superior performance in applications because of their strong...

ermanent magnets are materials that generate a magnet field based on the internal structure of the material that forms them. With most materials, magnet fields point in random directions that cancel out the fields. The electrons of such materials spin…

SmCo magnets are strong rare earth permanent magnets that are used for a variety of industrial applications. They have two primary phases, which are SmCo₅ and Sm₂Co₁₇. The difference between the phases is in regard to their magnetic energy…

Power supplies are electrical circuits and devices that are designed to convert mains power or electricity from any electric source to specific values of voltage and current for the target device...

An AC power supply is a type of power supply used to supply alternating current (AC) power to a load. The power input may be in an AC or DC form. The power supplied from wall outlets (mains supply) and...

A bowl feeder is a mechanism for supplying small parts and components to a production line or for sorting bulk items for rapid use. A self contained bowl feeder system has a bowl that sets on a spring loaded base that moves vertically...

A DC DC power supply (also known as DC DC Converter) is a kind of DC power supply that uses DC voltage as input instead of AC/DC power supplies that rely on AC mains supply voltage as an input...

A DC power supply is a type of power supply that gives direct current (DC) voltage to power a device. Because DC power supply is commonly used on an engineer‘s or technician‘s bench for a ton of power tests...

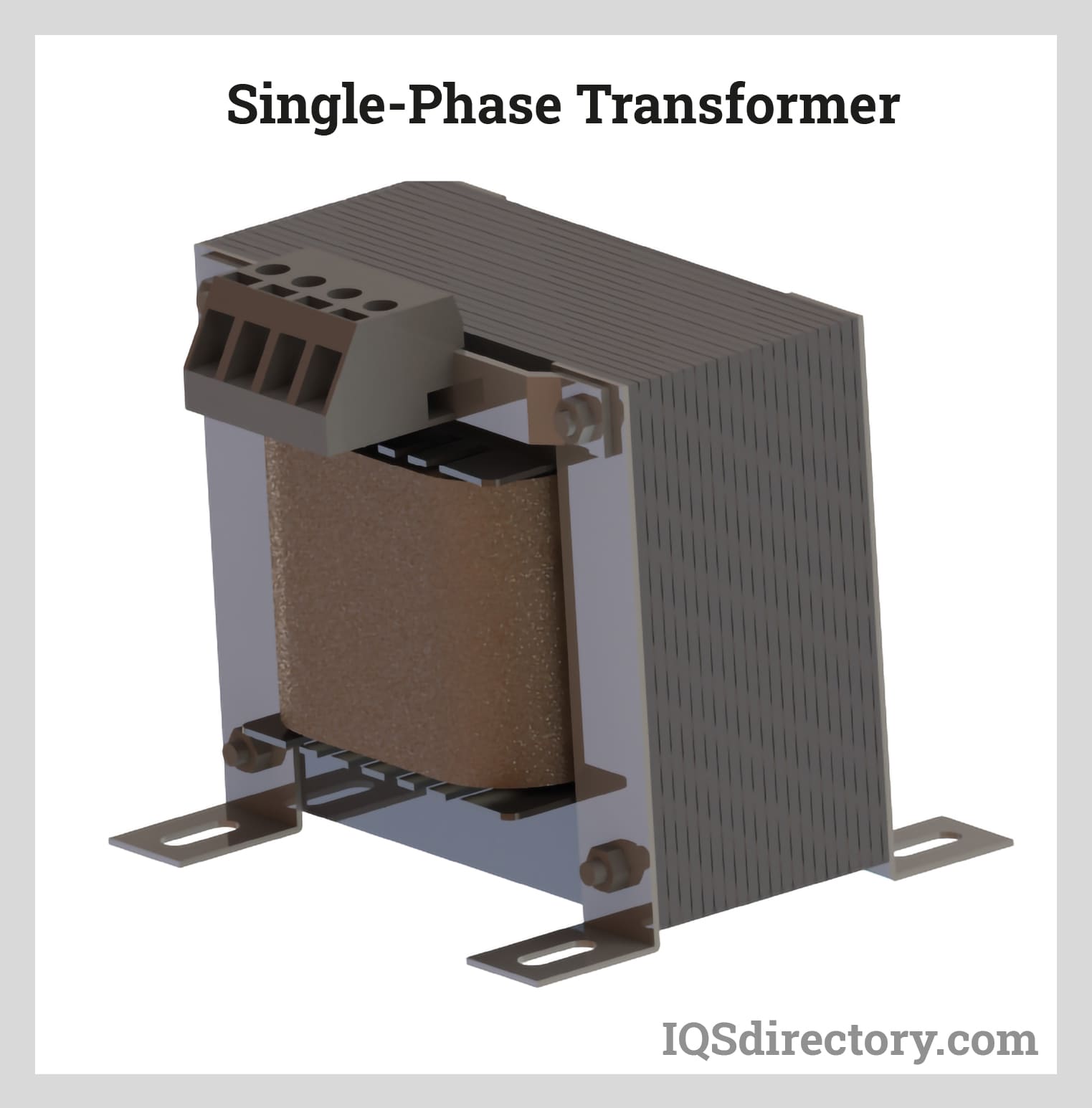

Electric transformers are static electrical machines that transform electric power from one circuit to the other without changing the frequency. An electrical transformer can increase or decrease the voltage with...

An electromagnetic interference or EMI Filter is an electrical device or circuit that filters specific unwanted frequencies in power lines or offending frequencies that are detrimental to a system. They receive AC or main power...

By definition a power supply is a device that is designed to supply electric power to an electrical load. An electrical load refers to an electrical device that uses up electric power. Such a device can be anything from...

An isolation transformer, just like typical transformers, is a non-moving device that transmits electrical energy from one circuit to another without requiring any physical contact. It works on the idea of magnetic...

Power transformers are electrical instruments used in transmitting electrical power from one circuit to another without changing the frequency. They operate by the principle of electromagnetic induction. They are used in transmitting electrical power between...

A programmable power supply is a method for controlling output voltage using an analog or digitally controlled signal using a keypad or rotary switch from the front panel of the power supply...

An electrical transformer is a passive machine that transfers electrical energy from one circuit to another using a magnetic flux to induce an electromotive force. Transformers are used to increase (step-up) or decrease (step-down) voltages without changing the frequency of the electric current...

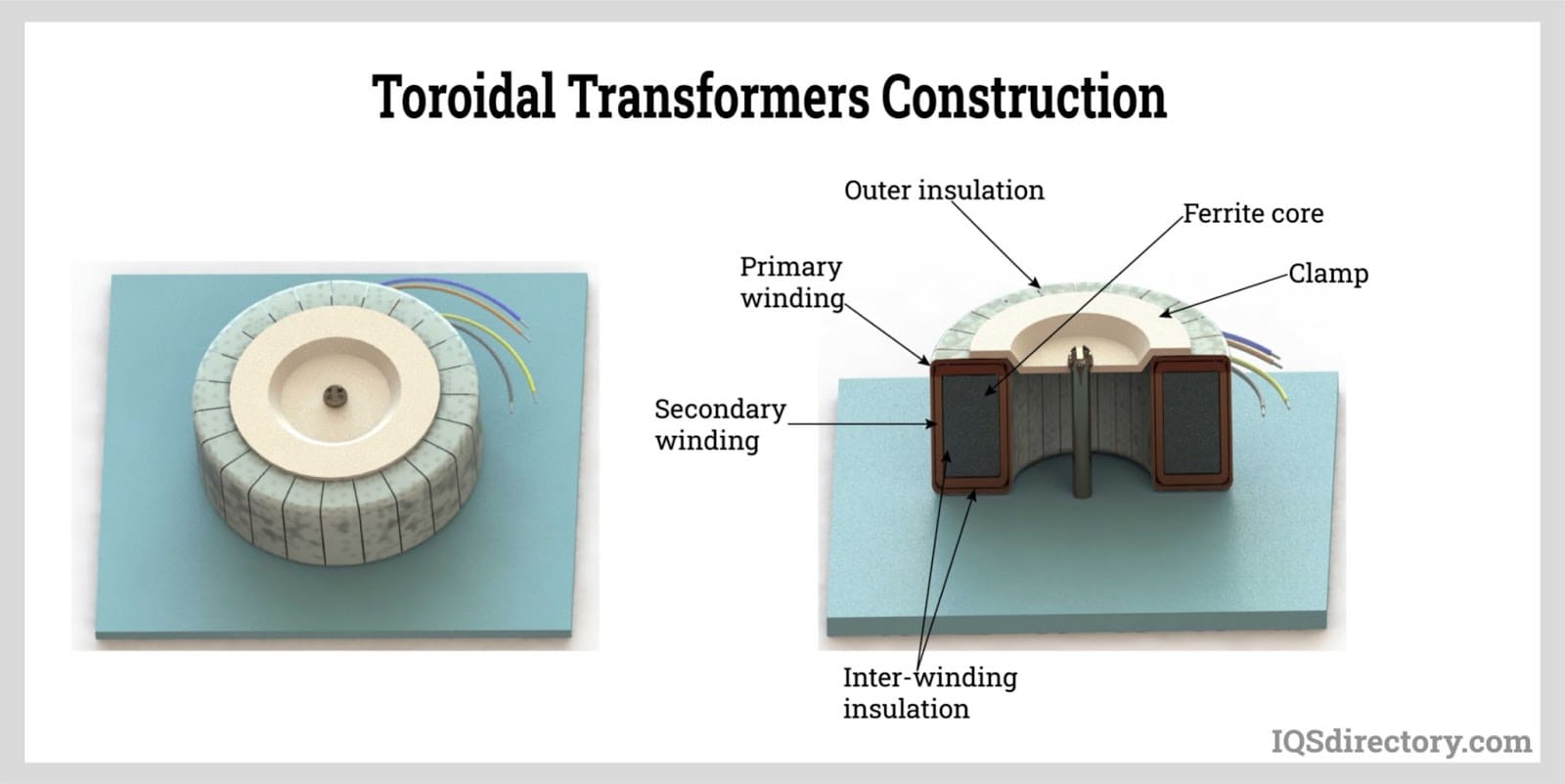

A toroidal transformer is a type of electrical transformer constructed with a torus or donut-shaped core. Its primary and secondary windings are wound across the entire surface of the torus core separated by an insulating material...

Vibratory conveyors are material-handling equipment used to transport fine to coarse-grained bulk materials. These vibratory conveyors are strong conveying equipment utilized for bulk commodities with fine to coarse graininess...

Vibratory feeders are short conveyors used to transport bulk materials utilizing a controlled vibratory force system and gravity. The vibrations impart a combination of horizontal and vertical acceleration through tossing, hopping, or sliding-type of action to the materials being handled...

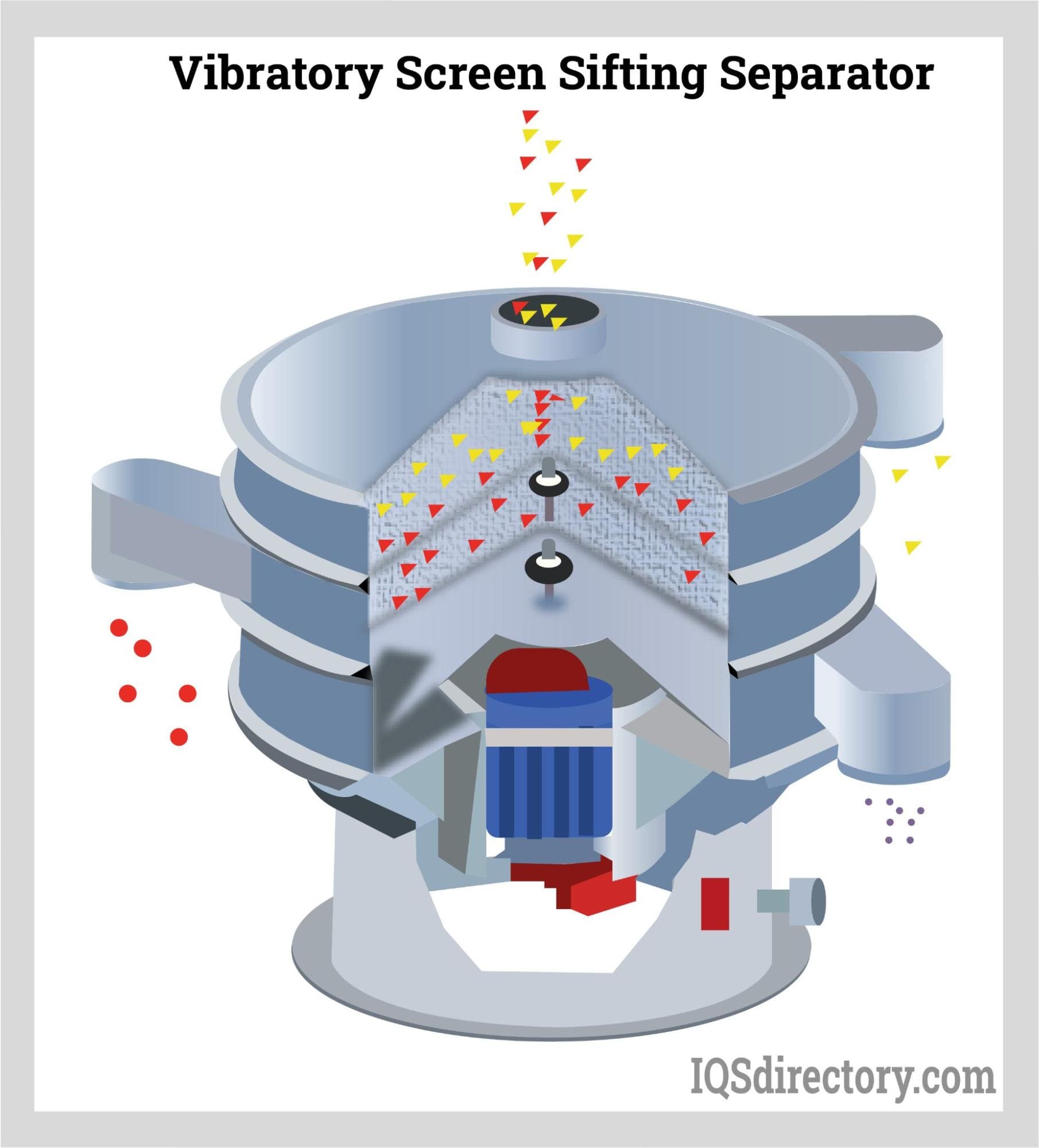

A vibratory screening is a process that separates bulk solid materials from solids and slurries using inertial vibration that causes various sizes of particles to pass through openings in a screen or...

Electronically operated equipment depends on power transformers to convert electrical currents into voltage. Current transformers store and transport energy through power lines and grids...