AC Power Supplies

An AC power supply is a type of power supply used to supply alternating current (AC) power to a load. The power input may be in an AC or DC form. The power supplied from wall outlets (mains supply) and...

Please fill out the following form to submit a Request for Quote to any of the following companies listed on

This article will take an in-depth look at AC DC Power Supply.

The article will look at topics such as:

This chapter discusses fundamental topics including the idea of a power supply, characteristics and functions of AC and DC power supplies, and the construction and operation of AC/DC power sources.

A power supply is a device or circuit that translates electricity from the mains or different sources into precise voltage and current levels required for specific apparatus. These apparatus range from common household devices to large industrial machinery.

Each electrical device has certain voltage and current specifications necessary for proper functionality, usually indicated by the manufacturer. If these conditions aren't satisfied, the device might not function or could incur damage if exceeded. Some power supplies can cater to multiple devices at once, needing to maintain a steady output regardless of load or input variations, known as regulated power supplies. In contrast, unregulated power supplies' outputs fluctuate with input changes, as their output is a fixed portion of the input. Power supplies may appear as external units like chargers or as internal components in devices such as TVs and radios. They can convert both AC or DC input to DC or AC output.

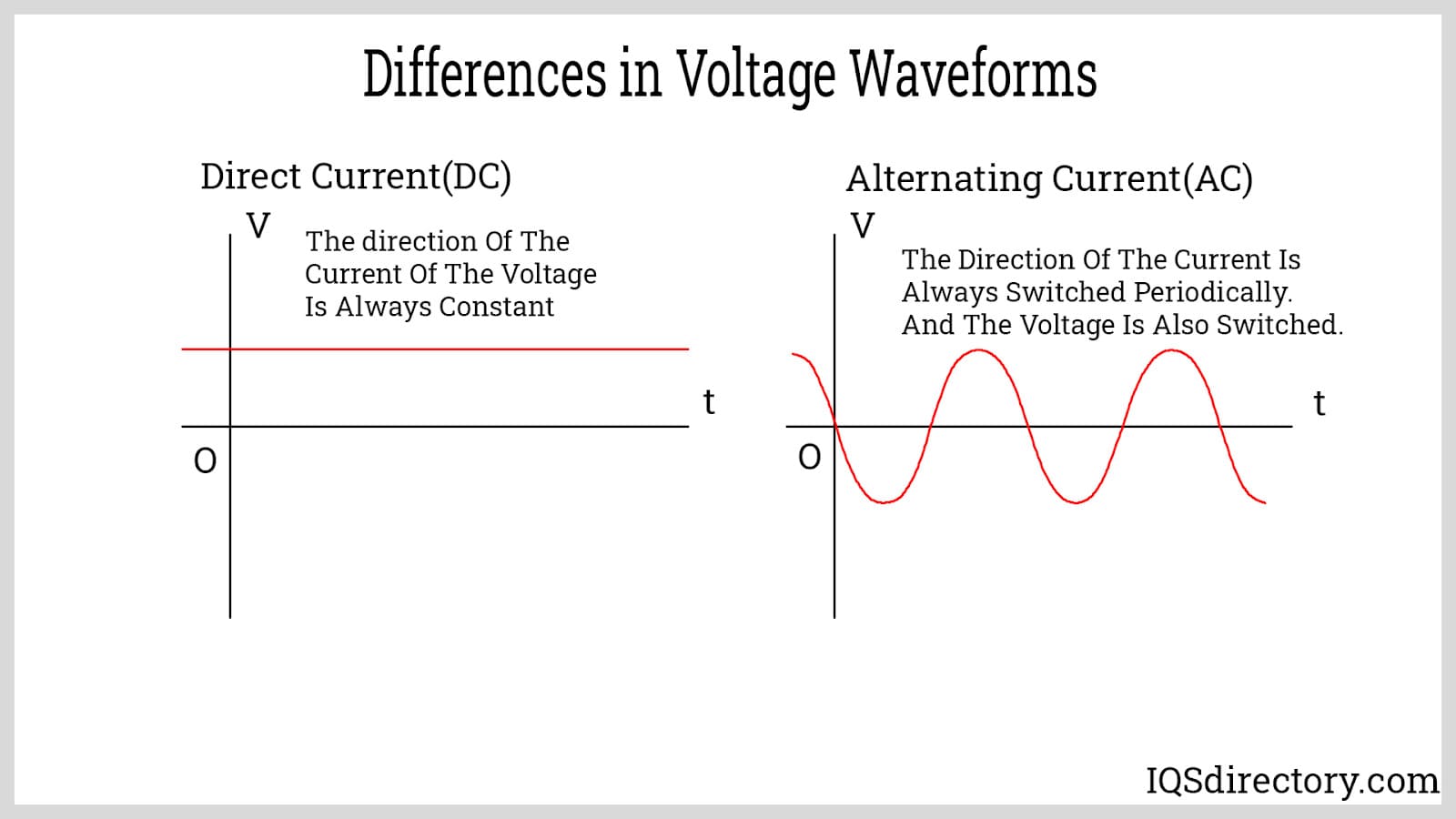

Direct current (DC) ensures a steady flow in one direction, typically provided by sources like batteries and solar panels.

Alternating current (AC) shifts between positive and negative cycles, altering the electrons' direction of flow intermittently.

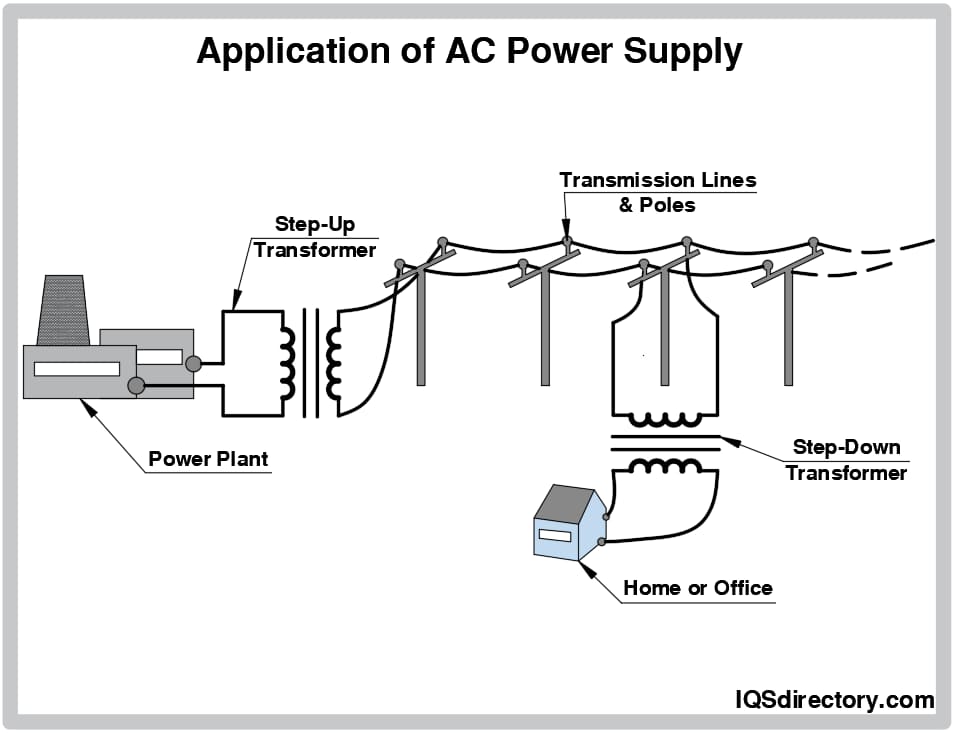

This describes electric current as delivered from a generator or power outlet. Electricity generated in power plants and transmitted to homes is provided as alternating current.

Direct current (DC) retains a stable voltage, flowing in a singular path. Alternating current (AC), on the other hand, involves a voltage that reverses, causing the current to change its directional flow as well.

In alternating current (AC), the current's direction continuously switches. If inductors or capacitors exist in the circuit, a phase shift might occur, leading the current to behave differently than the voltage. In contrast, both current and voltage in direct current (DC) maintain stability, ensuring component behavior remains predictable without phase shifts.

In AC circuits, because the current direction alternates, not all of it may reach the load, with some energy oscillating between the source and load, resulting in reactive power. With DC, the current flows unidirectionally, ensuring all current courses through the load, avoiding reactive power and optimizing power use.

Interrupting a DC circuit can be challenging, especially when a constant high voltage is involved, posing risks such as sparks. AC, which periodically reaches zero as the voltage alternates, tends to be safer to interrupt.

To alter DC voltage, it often undergoes conversion to AC and back again to DC, necessitating specialized equipment. Direct current is largely produced by storage means like batteries and best suits battery-dependent gadgets.

Though AC is prevalent in residential environments, electronic gadgets like computers and televisions rely on DC. AC is converted to DC via rectifiers in these devices. In settings like data centers, direct current use is advocated to prevent conversion-associated losses.

Each AC-DC power supply is crafted uniquely. Here are standard design elements commonly considered:

AC-DC power supplies vary based on their functional capabilities. Regulated power supplies offer consistent output regardless of load or input fluctuations. Unregulated power supplies have outputs that change with load or input alterations. Adjustability is a feature enabling users to set the output using controls like knobs or electronic inputs. Adjustable regulated power supplies combine regulation with flexibility. Isolated power supplies provide output that is electrically distinct from the input power, unlike others which have shared connections.

Power supplies have diverse packaging styles. Bench power supplies are stand-alone units used mainly in testing and developmental contexts. Open frame power supplies lack full mechanical covers, usually integrated within machinery. Rack mount power supplies are tailored to fit standard equipment racks, providing protection. Integrated power supplies share a circuit board with their load. External power supplies, recognized as AC adapters, are integrated within device power cords. Wall warts are compact external supplies incorporated into outlet plugs, optimizing safety by reducing main voltage to safer levels.

AC-DC power supplies are mainly categorized into switching and linear types. Linear supplies process voltages directly, with conversion apparatus working in linear regions. Switching supplies first transform input voltages to AC or DC pulses, using devices primarily in non-linear modes, ensuring devices spend minimal time in linear regions. Consequently, switching supplies are normally more efficient since less energy dissipates as heat compared to linear types.

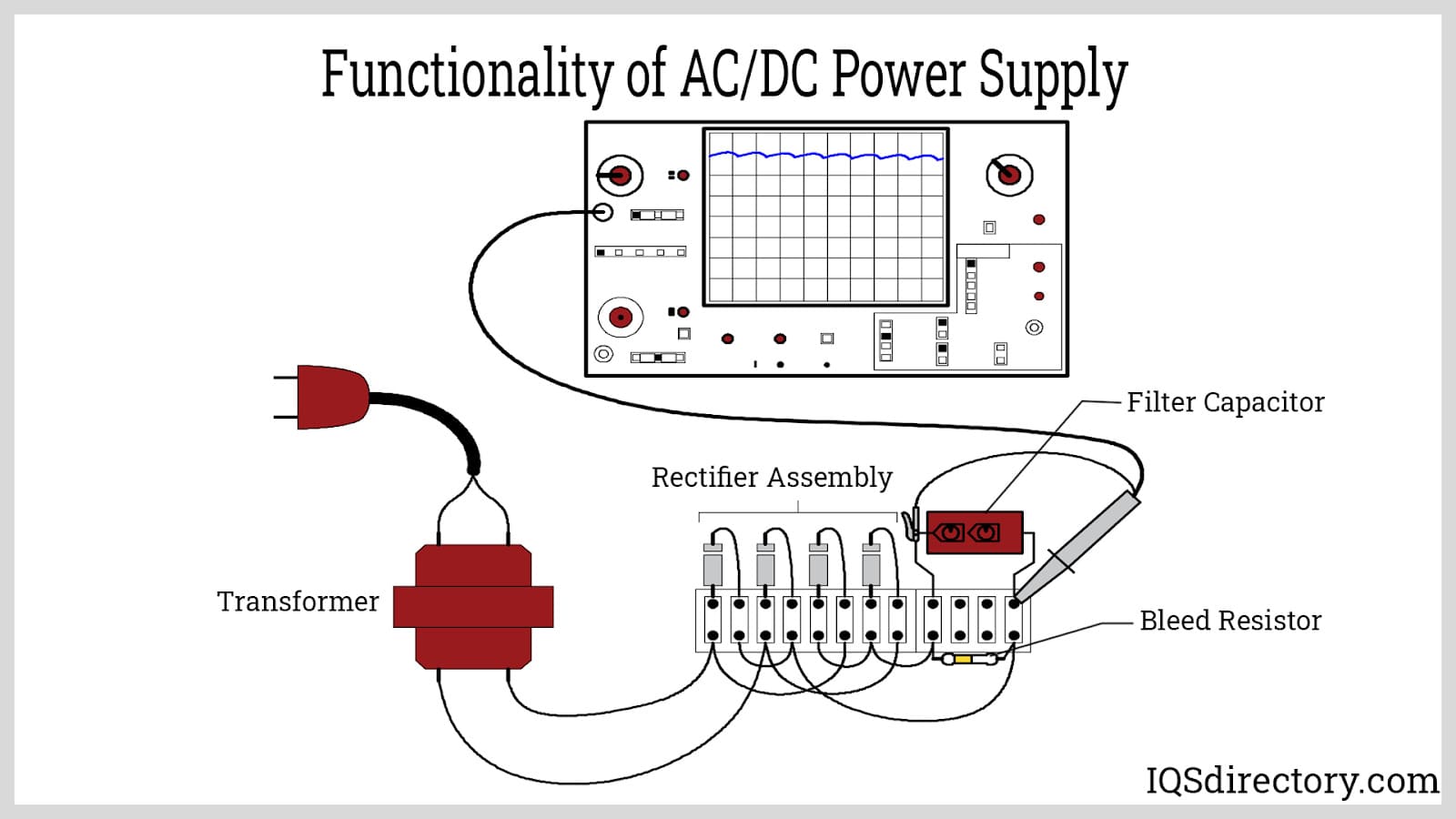

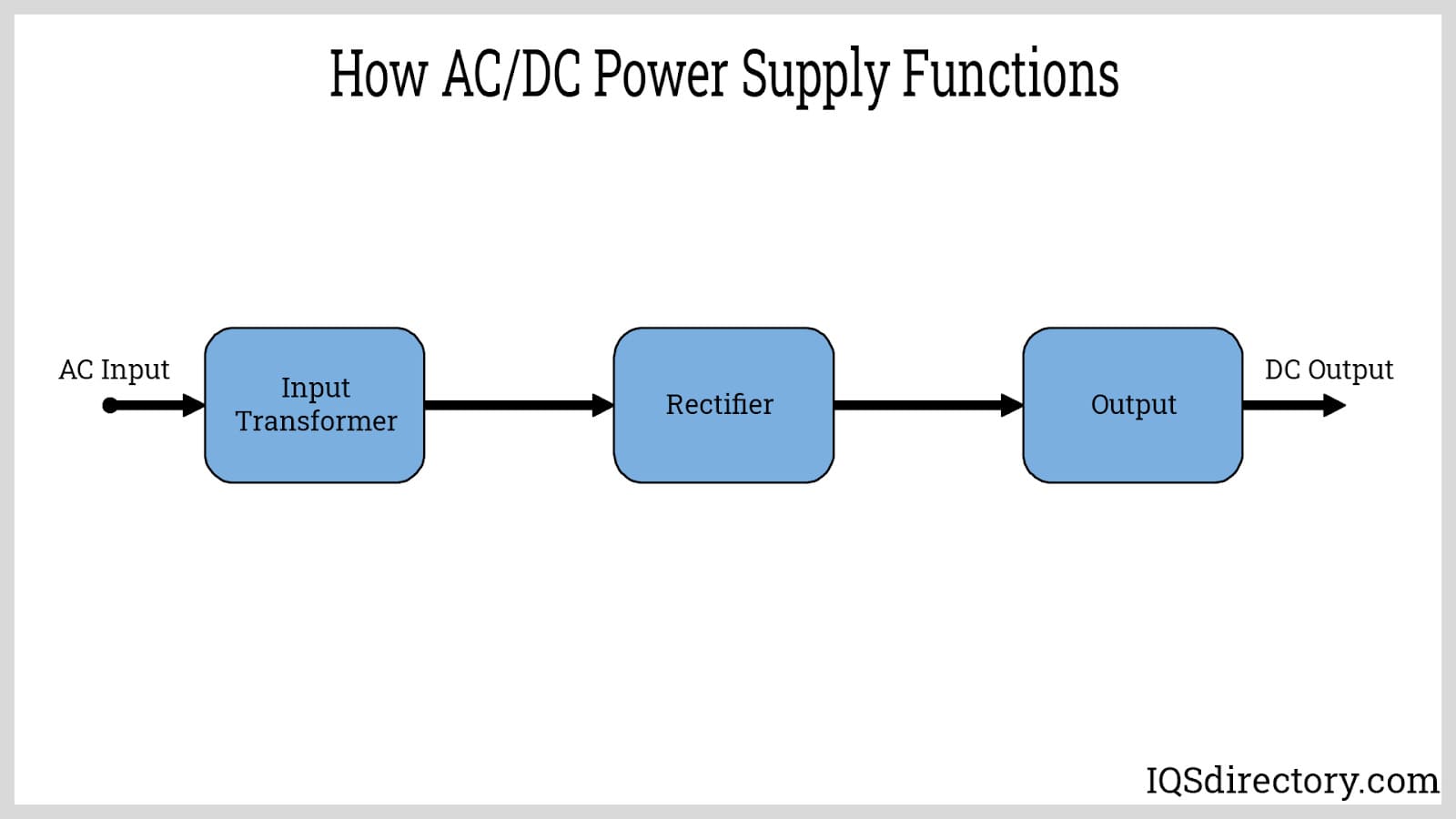

An AC-DC power supply initially receives an AC voltage of 230V, or a regional equivalent. Inside the unit, this voltage is stepped down to an appropriate level, typically between 9V and 24V for most applications, converting it then to DC. In linear supplies, diodes act on this conversion; switching mode supplies employ transistors. After transitioning to DC, the voltage smoothens out to remove ripples and undergoes regulation. Some supplies might bypass regulation. The resultant DC power activates household electronics, including computers and TVs.

AC Input Voltage Range (VIN) – Dictates the necessary AC input voltage range for the power supply, such as single-phase or three-phase AC. Recognizing both the appliance's and the supply's AC voltage range is essential when choosing an appropriate power supply. Many devices operate within a broad input range of 85 to 264 VAC at 47Hz to 60Hz. Some AC-DC power supplies offer interchangeable blades for adaptability to regional requirements.

Output Voltage Range (VOUT) – Specifies needed output voltage range. If variable voltage is crucial for applications like LED lighting or testing, selecting a power supply with adjustable output provides cost efficiency and convenience. Some uses might require fixed outputs like 12V or 48V.

Maximum Output Current (IOUT) – Understanding the peak current output is key, especially when current outputs may fluctuate. Power supplies capable of being paralleled might be necessary to boost power capacity.

Output Regulation – For applications with risky high output ripple or current fluctuations, especially with load types like motor drives, ensuring solid output regulation is vital.

Space and Dimensions – As power supplies evolve to be more compact, ensure there’s enough room to fit the power supply and any additional elements, like parallel supplies, conduction plates, or cooling fans.

Enclosure and Cooling – Evaluate whether an enclosure with fans or an external cooling system is needed. Numerous power supplies incorporate over-temperature protection to avert heat-related damages.

Temperature Tolerance – Ensure the power supply can withstand extreme temperatures, ranging from -40 degrees Celsius to +50 degrees Celsius.

Derating Factors – Consider how environmental conditions, such as temperature and elevation, might affect performance, causing possible power derating.

Compliance Standards – Certain applications necessitate meeting standards like IP20, IP22, or 60601. Many power supplies undergo tests to meet general requirements, carrying certifications like TUV, EN, or UL.

Understanding these parameters is crucial in the process of selecting a suitable power supply to fit specific application needs.

AC-DC power supplies are essential components in electrical and electronic systems, converting alternating current (AC) from the power grid into direct current (DC) required by various devices and equipment. Understanding the types of AC-DC power supplies available and their features is crucial for selecting the right solution for industrial, commercial, residential, and consumer electronic applications. Below, we break down the primary categories of AC-DC power supply units (PSUs), including their operating principles, advantages, typical output voltages, and best-use scenarios.

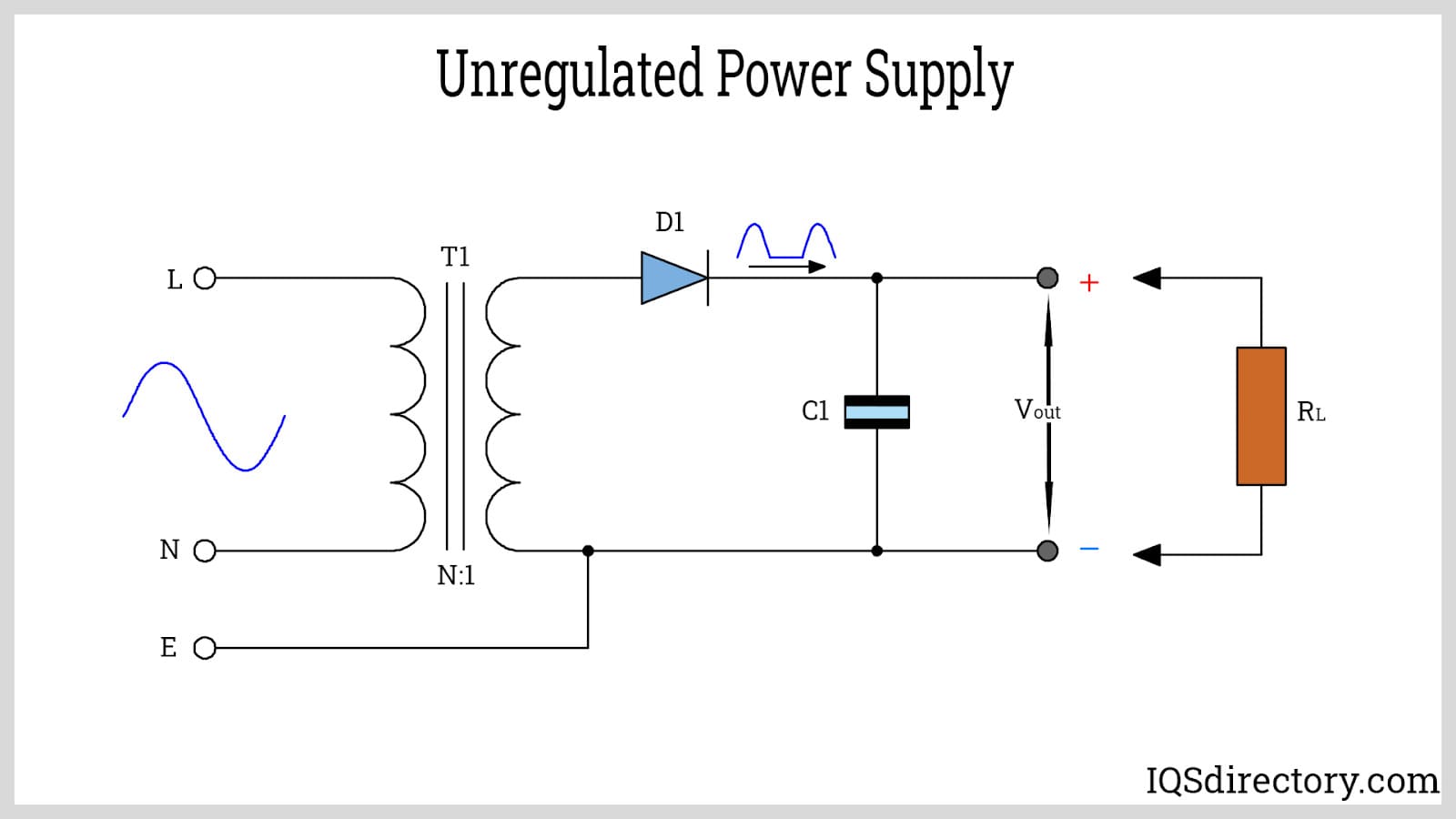

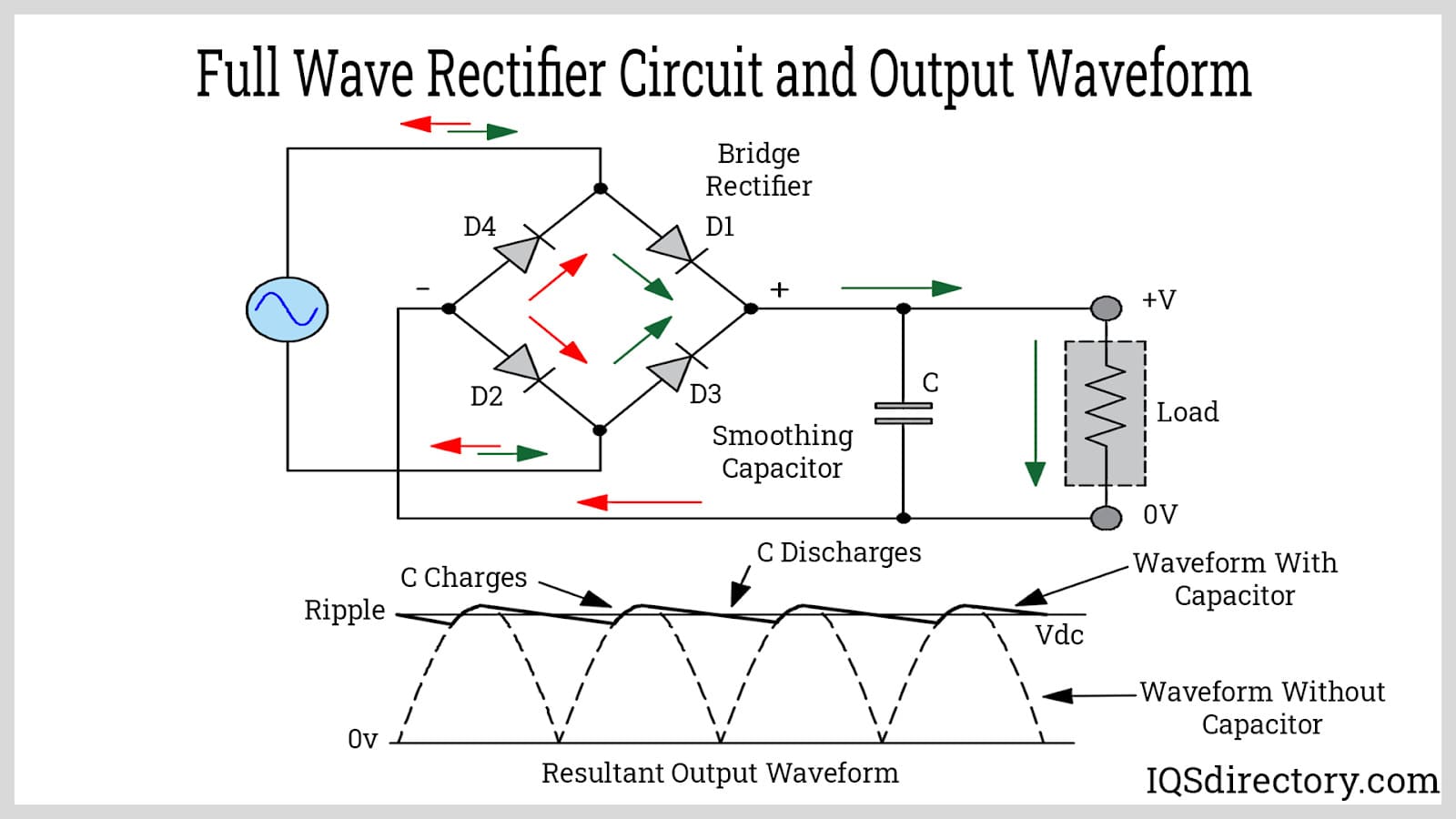

Unregulated power supplies use AC voltage as their input. The AC voltage first passes through a step-down transformer, which reduces the voltage and provides it across the secondary terminals. This voltage is then rectified by a bridge rectifier to convert it into DC voltage. Common output voltages include 9V, 12V, 15V, and 24V. A capacitor is used to smooth out the DC voltage from the rectifier. As indicated by its name, an unregulated power supply lacks a voltage regulator in its circuit.

Any variations in the AC input voltage will directly impact the output voltage of an unregulated power supply. Due to its straightforward design, an unregulated power supply is generally durable and has an efficiency of about 60%. It is commonly used in electromechanical applications that do not require a fixed output voltage, such as powering contactors. The main types of unregulated power supplies include half-wave, full-wave center-tapped, and full-wave bridge rectifier configurations.

Key applications: Simple motors, relays, solenoid valves, and lamp circuits, where voltage precision is not critical. For cost-sensitive projects that prioritize robustness over fine voltage control, unregulated PSUs offer simplicity and reliability.

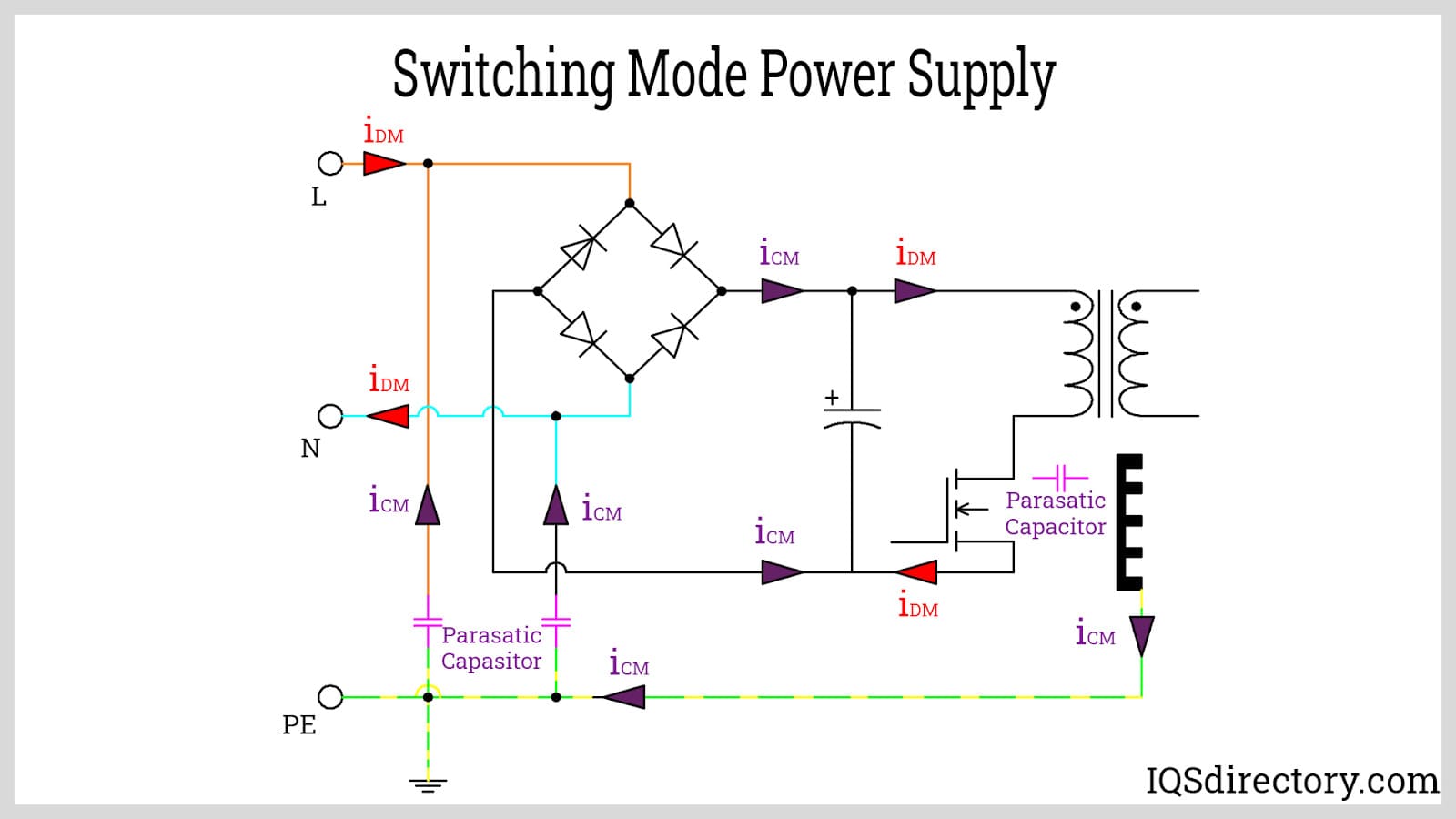

Advancements in semiconductor technology, particularly with fast-switching MOSFETs, have addressed issues like transformer size and voltage regulation found in linear AC DC transformers. This technology increases efficiency and reduces heat dissipation. MOSFETs can switch on and off rapidly even under high currents and voltages.

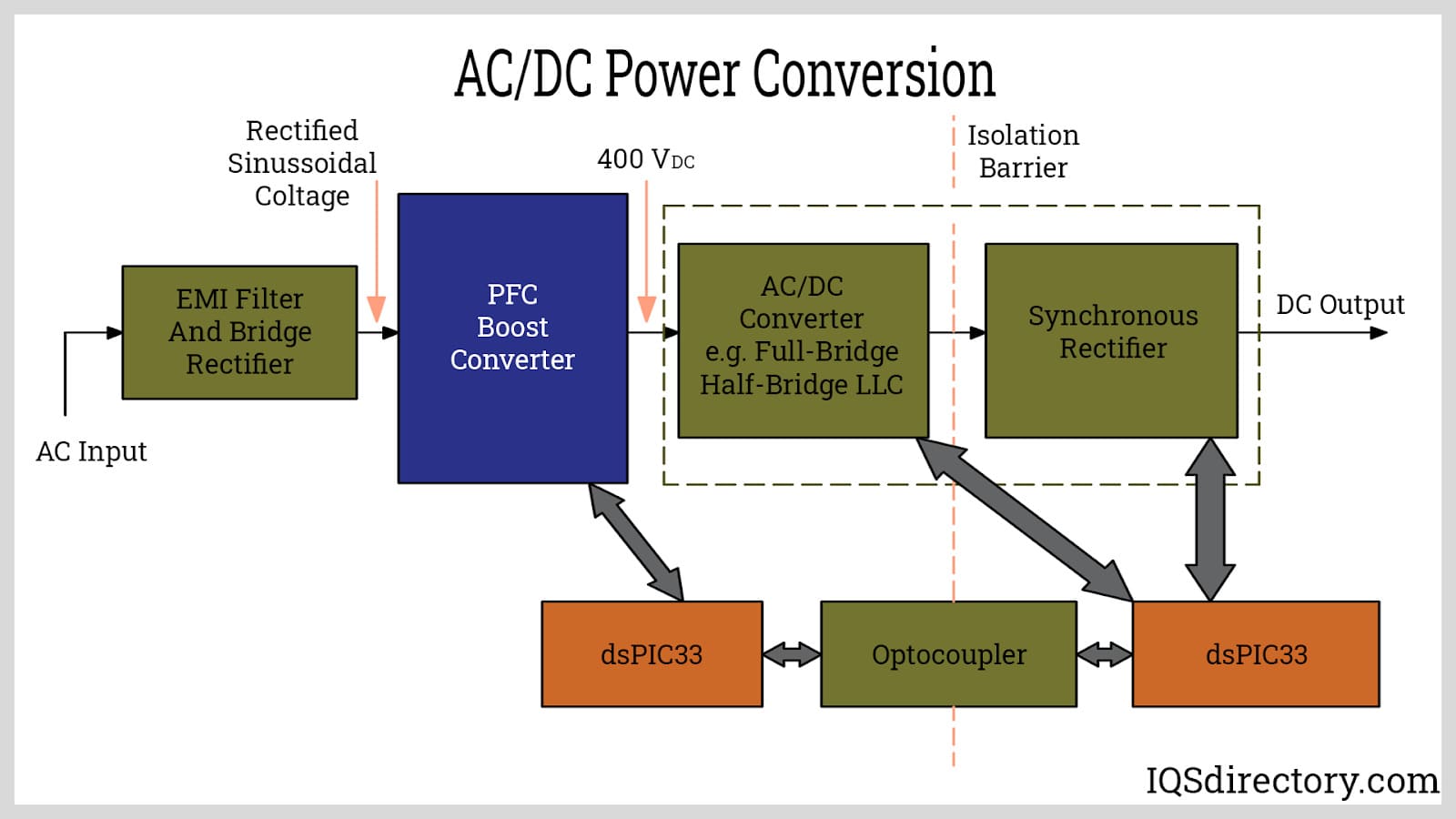

However, switch mode AC DC power supplies have a more complex design compared to linear AC DC power supplies. To avoid using large step-down transformers, the input voltage is rectified and filtered. A DC chopper (DC to AC converter) then transforms this DC voltage into a high-frequency pulse train, which is subsequently rectified and filtered to produce a DC output. This approach allows the use of smaller transformers that avoid saturation.

Benefits and features: Switch mode power supplies (SMPS) are widely used in computers, telecommunications equipment, LED lighting, and battery chargers. Their efficiency often exceeds 80–90%, reducing power loss, lowering operational costs, and minimizing the heat produced. Many modern SMPS meet global energy efficiency standards such as ENERGY STAR and Level VI, making them ideal for eco-conscious and high-performance applications.

Switching power supplies are available in open frame, enclosed, external desktop, DIN rail, and rack mounting styles to meet various integration and compliance needs across industries.

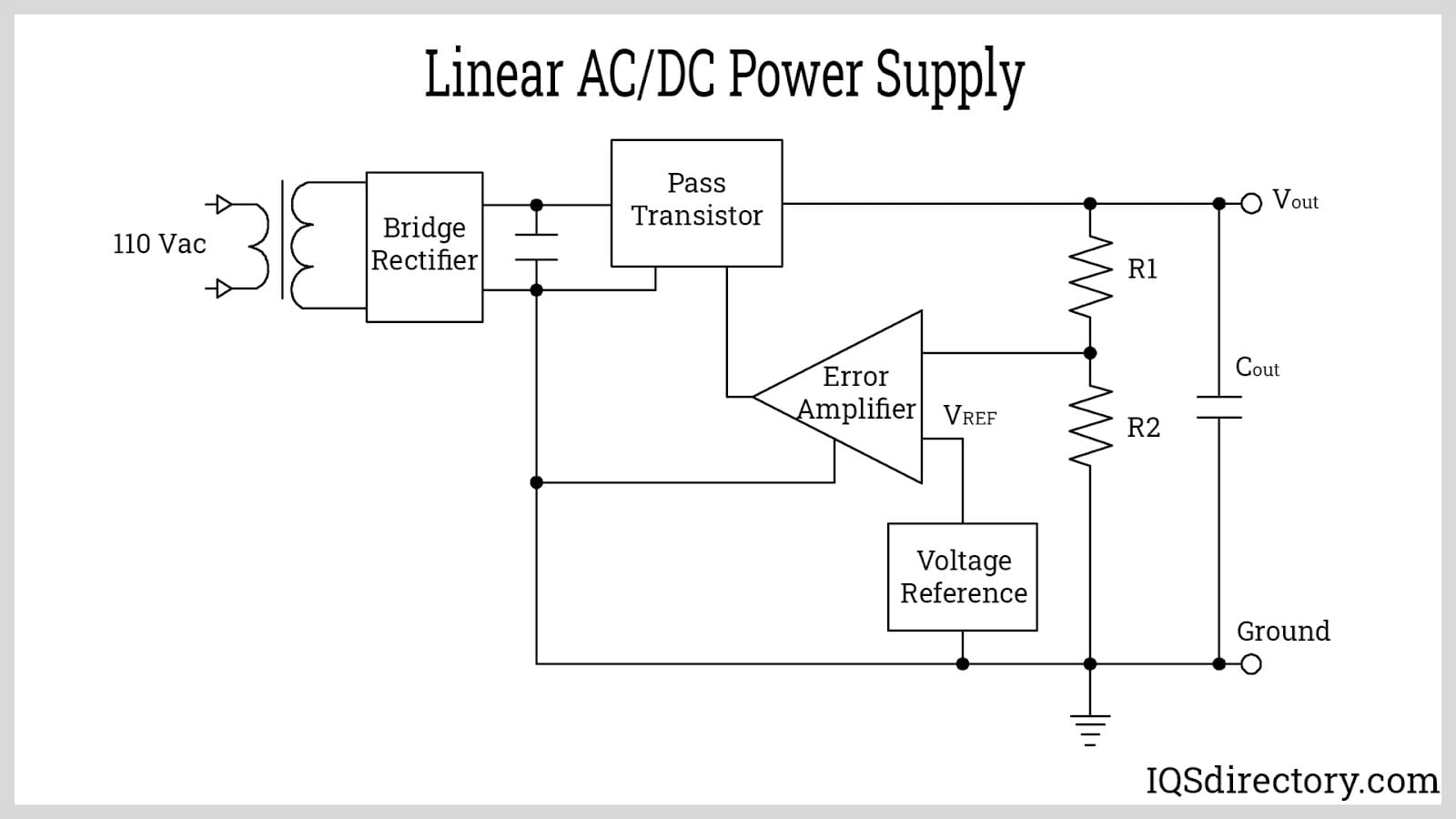

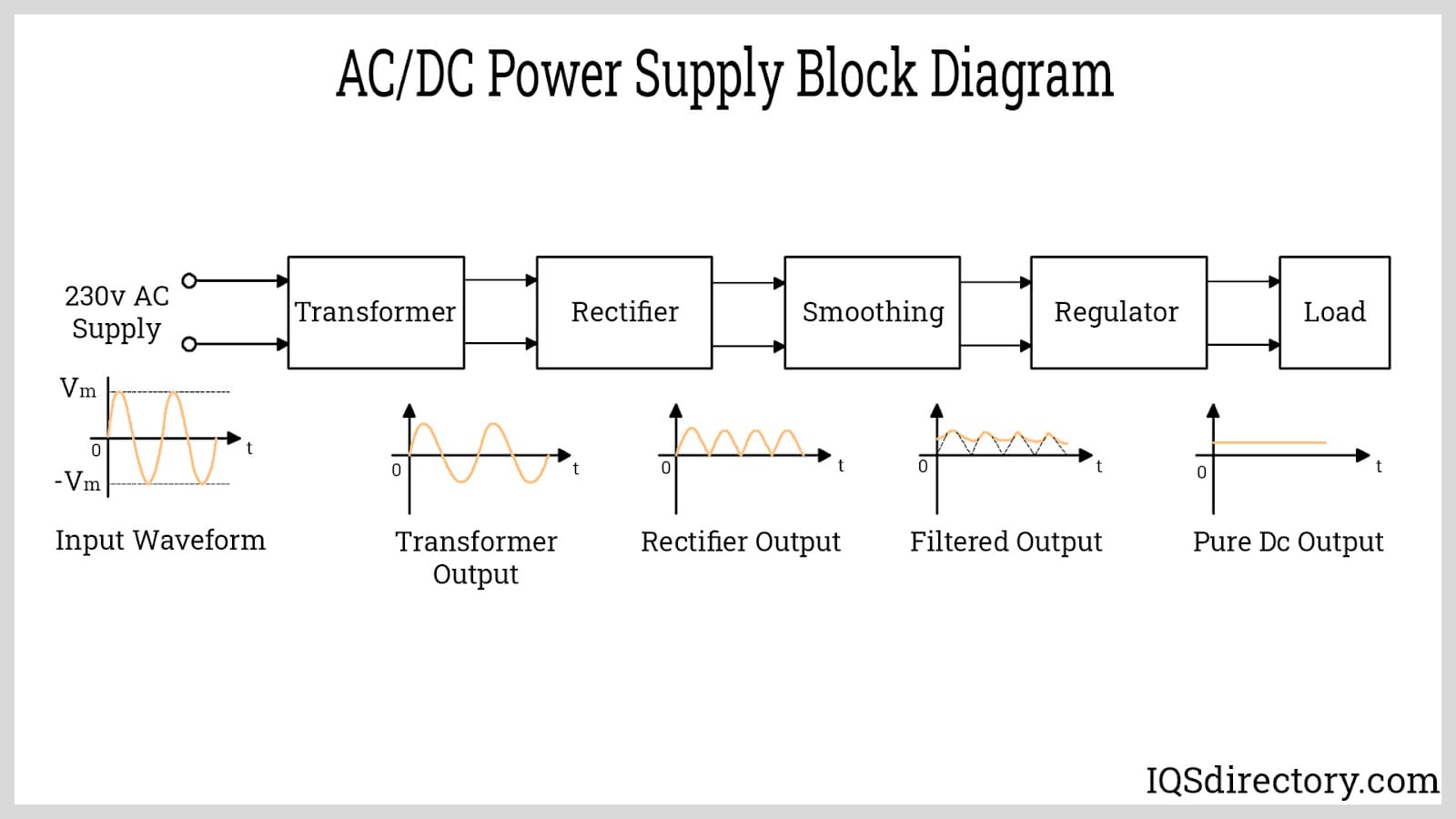

This represents the simplest design for AC DC power supplies. They have long been a reliable method for converting AC power from the grid into DC power for household appliances.

A transformer reduces the AC voltage to a lower, more suitable value for home use. The reduced voltage is then rectified into DC and filtered to remove ripples.

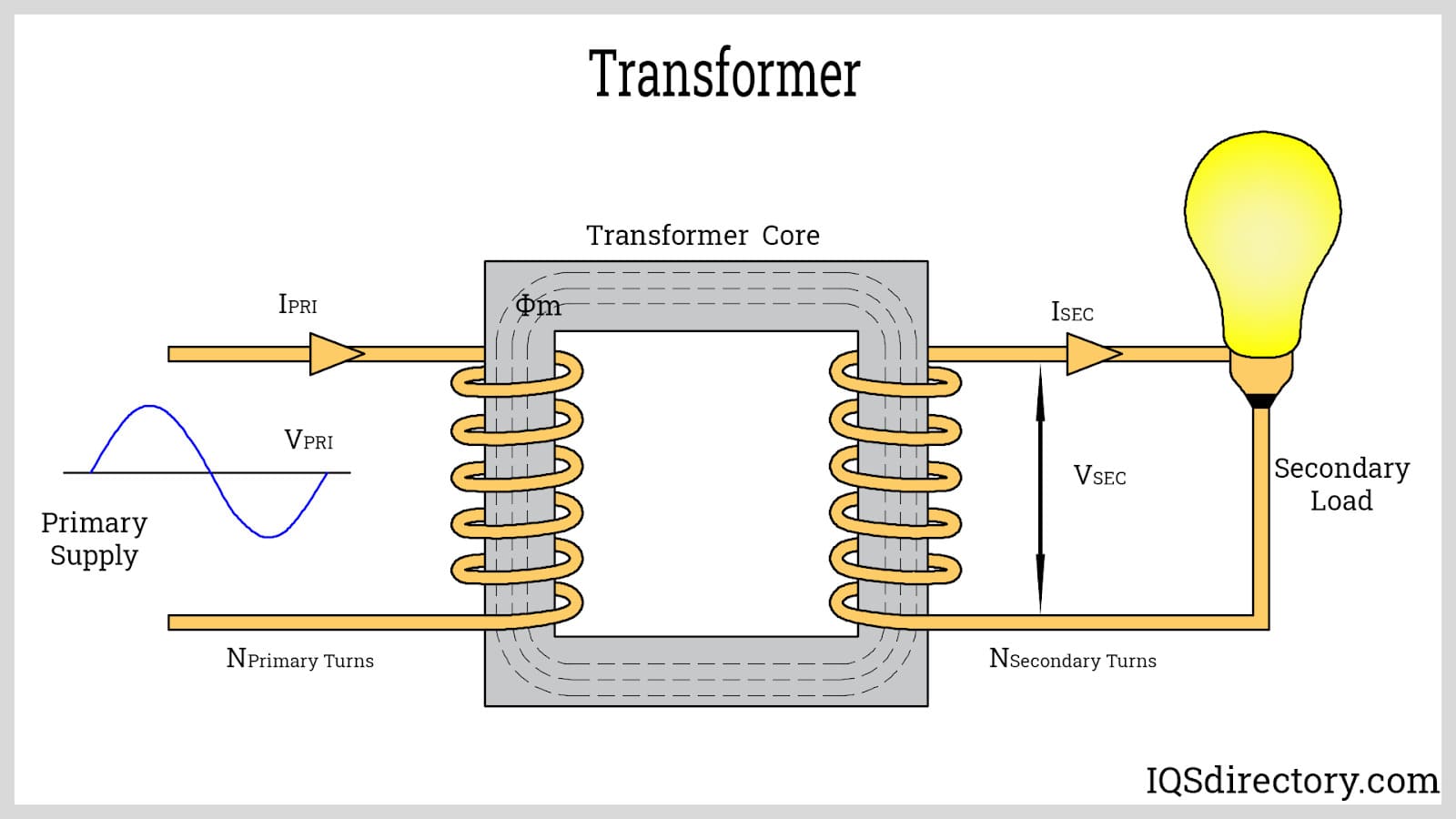

The image above illustrates its structure and the changes in output voltage at each stage. A transformer steps down the main supply voltage from 230V.

The output voltage of the transformer is determined by the turns ratio of the primary to the secondary coil, calculated using the equation Vs/Vp = Ns/Np. Transformer operation relies on electromagnetic induction principles. An alternating current in the primary coil generates a magnetic flux, amplified by the core, to induce an alternating current in the secondary coil. The waveform shape is preserved but with reduced amplitude.

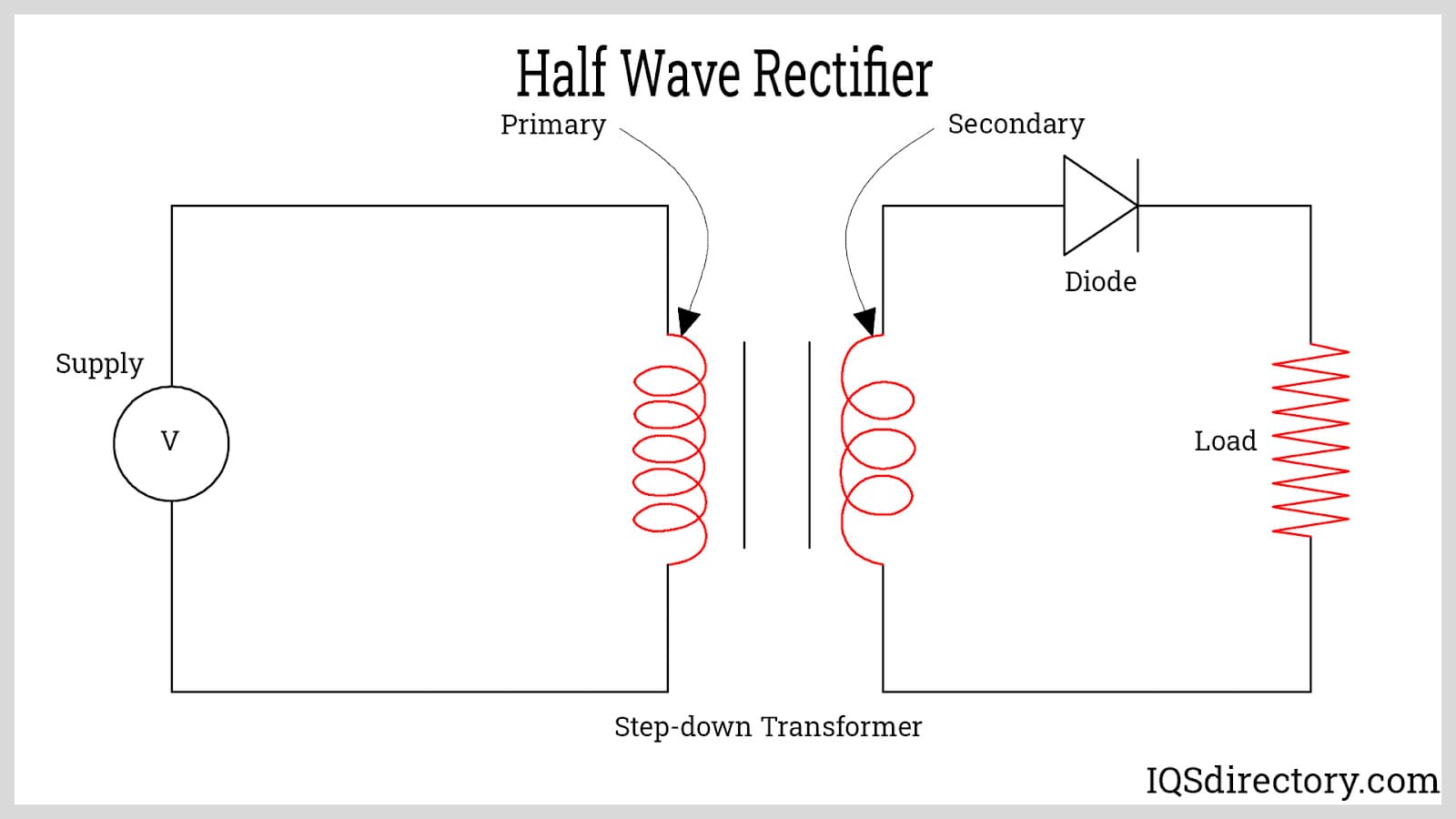

The stepped-down voltage is then passed through a rectifier to remove the negative halves of the waveform. There are two types of rectifiers: half-wave and full-wave.

The half-wave rectifier uses two diodes to eliminate the negative half cycle by restricting current flow in that direction. It conducts current only in the positive direction, resulting in a pulsating DC waveform with zero value during the negative half cycle.

The full-wave rectifier, in contrast, converts negative half cycles into positive ones. It redirects the negative half cycle current to pass through the load in the same direction as the positive current.

After rectification, smoothing is performed to remove ripples from the wave and approximate the DC voltage. The smoothed waveform is then regulated to maintain a constant output level despite variations in input voltage.

Typical use cases: Audio equipment, laboratory instruments, and sensitive analog devices benefit from the low electrical noise of linear power supplies. While less efficient and bulkier than switch mode designs, linear PSUs are prized where precise, noise-free DC output is required.

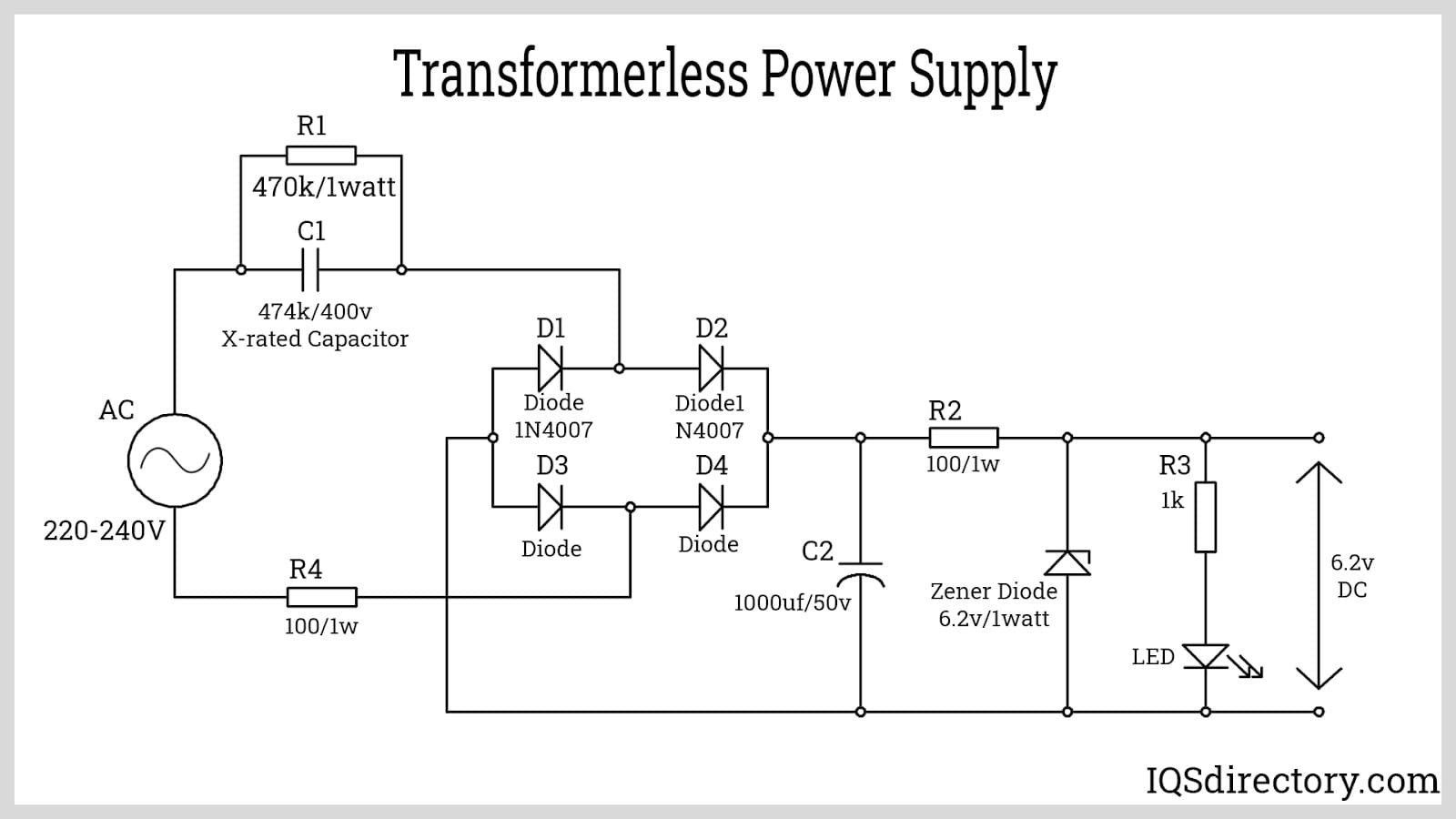

Capacitive power supplies, also known as capacitive droppers, use a capacitor’s capacitive reactance to reduce mains AC voltage. Due to high voltage tolerance requirements and the need for high capacitance to achieve the desired current output, these supplies are practical only for low-power applications.

The capacitance required increases with the current drawn; high-capacitance AC capacitors are bulky and expensive. A capacitive power supply typically includes a rectifier and filter to generate DC current from the reduced AC voltage.

This type of supply features a capacitor (C1) with reactance that limits current flow through the bridge rectifier (D1). A series resistor (R1) with the capacitor (C1) prevents voltage spikes during switching. An electrolytic capacitor (C2) smooths the DC voltage and handles switching currents. The figure shows a voltage regulator made by resistor (R3) and a shunt regulator (Zener diode, IC1). If precise voltage stabilization is not critical, a Zener diode can serve as the regulator. The two-terminal components (R5 and R4) are used as a voltage divider in the circuit above.

Best suited for: Compact, low-current devices such as LED indicators, small sensor modules, or night lights that require minimal DC power directly from mains voltage. Not recommended for high-power or safety-critical electronics due to the lack of galvanic isolation.

AC DC wall adaptors, also known as wall warts or wall plug-in transformers, convert 120Vac (or 220Vac) to a lower DC voltage. They are commonly used with electronic devices in homes and businesses and are among the most recognizable types of external AC-DC power supplies.

Typical applications: Mobile phone chargers, routers, home automation devices, and medical equipment. Wall adaptors can be selected based on voltage, current, connector type, energy efficiency standards, and certification requirements.

Wall warts and junction boxes can be categorized into the following types:

These AC DC wall adaptors eliminate the need for internal cooling devices, allowing for smaller and lighter designs while keeping heat away from sensitive circuits. They provide a lower and safer output to the end product. Modern switch-mode wall adaptors are designed for high efficiency and low power standby, meeting international regulatory standards and safety certifications such as UL, CE, and FCC.

These versatile adaptors feature four styles of interchangeable plugs for use in the United Kingdom, European Union, North America, and Australia. They operate at 100-240V input and provide 24W at 5-24 VDC. This flexibility makes them ideal for global product distribution.

These junction boxes are designed for hard-wiring stationary electronic equipment, reducing tangled cords and minimizing accidental disconnections. They are typically available in 24VDC/0.75A and 12VDC/1.5A models. Junction boxes support industrial automation, HVAC systems, and control panel solutions that demand reliable, long-term power delivery.

These power supplies meet Level VI efficiency standards set by the U.S. Department of Energy, consuming 25% less power compared to previous 60 Hz models. They are ideal for applications like battery backup systems, security locks, HVAC systems, lighting, and camera controls where standby efficiency and regulatory compliance are essential.

Designed for commercial and industrial environments, these wall adaptors are available in unregulated models at 60 Hz. They often require agency approvals due to their numerous agency listings, and may be customized for unique voltages, currents, connectors, and safety requirements as specified for OEMs and system integrators.

How to choose the right AC-DC Power Supply? Selecting the ideal AC-DC power supply depends on several critical factors, including output voltage and current, efficiency, form factor (open frame, enclosed, rack mount), certification (UL, CE, RoHS compliance), power quality (regulation, ripple, and noise specifications), and environmental operating conditions. For medical and industrial uses, look for supplies meeting IEC safety and EMC standards. For consumer electronics or IoT devices, prioritize compactness, energy efficiency, and universal input compatibility. Reviewing datasheets, application notes, and manufacturer references can help guide the purchasing process and ensure reliable power delivery for your specific project or equipment needs.

AC DC wall adaptors, also known as wall warts, wall plug-in transformers, or AC to DC adapters, are electrical devices engineered to convert standard household alternating current (AC) voltage—typically 120V AC or 220V AC—into a lower, safer direct current (DC) output voltage suitable for electronic devices. Compact and highly versatile, AC DC wall adaptors are widely used for powering a vast array of consumer electronics, office equipment, security devices, and industrial automation systems in both residential and commercial settings. By offering reliable voltage conversion, these power adapters help protect sensitive circuits and ensure optimal device performance.

Wall warts and junction boxes can be categorized into the following types, each suited for particular electronic power supply needs:

Wall plug-in adapters featuring switch-mode power supply (SMPS) technology eliminate the need for bulky internal cooling systems commonly found in traditional power supplies. SMPS wall plug-in adaptors are lightweight and compact, efficiently converting AC power to a regulated DC output while minimizing heat dissipation. This design not only enhances energy efficiency but also provides a lower, safer output voltage to downstream electronics—making them ideal for charging smartphones, tablets, IoT devices, and portable gadgets where thermal management and size constraints are critical.

Interchangeable input AC/DC wall adapters deliver exceptional flexibility, enabling seamless international compatibility with four different removable plugs tailored for power sockets in the United Kingdom, European Union, North America, and Australia. These travel-friendly power supplies support a broad input range of 100-240V AC, making them suitable for global use. With selectable output voltages between 5V and 24V DC and a 24W maximum power rating, they are an excellent choice for powering global electronics, medical devices, or test equipment that require adaptable, multi-region power solutions.

The JSU Series power supply junction boxes are engineered for securely hard-wiring stationary electronic systems, such as security cameras, industrial sensors, and building automation equipment. These robust junction boxes help eliminate cord clutter and accidental unplugging by providing a reliable, fixed power connection. Standard models offer outputs of 24VDC/0.75A and 12VDC/1.5A, supporting a variety of professional and commercial electronics installations that require dependable, high-quality DC power delivery.

AC power supplies that meet Level VI efficiency standards represent the latest advancement in energy-efficient power adapters, as defined by the U.S. Department of Energy. These highly efficient units consume up to 25% less power than previous 60 Hz linear AC power supplies, significantly reducing standby and no-load power consumption. Typical applications include uninterruptible power supplies (UPS), battery backup systems, smart home devices, security system locks, access control, HVAC control systems, LED lighting, and surveillance camera controls. Choosing Level VI certified adapters ensures compliance with current energy regulations and lowers operating costs for both businesses and homeowners.

DC and AC wall plug-in power supplies tailored for industrial and commercial applications are engineered for dependable operation in challenging environments. These adapters operate exclusively at 60 Hz frequency in unregulated AC or DC models, offering rugged construction and critical agency approvals to comply with UL, CE, FCC, or other regulatory bodies. Industrial-grade power adapters are well-suited for machinery, control panels, data communications, process automation, and large-scale facility management systems, where reliability, safety, and compliance are paramount.

AC/DC plug-in power supplies and wall adapters serve the same fundamental purpose—delivering safe, regulated DC power from a standard wall outlet—but they can differ in form and function. Wall adaptors are typically designed for permanent installation, offering a fixed voltage and current output ideal for lower-power devices such as phone and tablet chargers, wireless routers, or LED drivers. In contrast, many modern AC/DC plug-in power supplies are built for flexibility, allowing users to select adjustable output voltages and currents to match specific device requirements, and are available with various connector tips for compatibility with a wide range of electronic equipment.

Available in diverse form factors—from ultra-compact travel adapters to high-output industrial units—plug-in power supplies cater to everything from laptops, external hard drives, networking gear, and gaming consoles to laboratory instruments, test benches, and high-performance specialty equipment. Their robust design and power capacity are ideal for devices demanding higher wattage output or precise voltage regulation. This makes them foundational to both everyday household electronics and mission-critical industrial processes.

Beyond charging portable electronics, modern AC/DC plug-in adapters are frequently used to power home automation devices, Wi-Fi extenders, smart thermostats, small appliances, LED strip lighting, industrial controllers, and backup battery packs. For users in regions with unreliable mains power, energy-efficient plug-in supplies can help safeguard devices from voltage fluctuations and reduce utility costs, especially when paired with surge protectors or battery management systems.

When selecting the best AC/DC power supply adapter, factors such as compatibility (output voltage & current), connector size (polarity, plug type), efficiency rating (such as Energy Star or Level VI), reliability, portability (for travel needs), and durable housing (for industrial work environments) should be carefully considered. Incorrect voltage or connector types can damage your electronics, so always confirm the technical requirements of your device before connecting. For devices with unique power or connector specifications, universal adapters with selectable tips can simplify device management and reduce the number of adaptors needed.

Proper maintenance of AC/DC plug-in power supplies extends their working life and ensures electronic safety. Regularly check all cables, connectors, and adapters for fraying, splitting, overheating, or loose components. Promptly replace any worn or damaged parts to avoid electrical hazards. Never overload a power adapter beyond its rated output, and always use certified recycling programs or electronic waste facilities to dispose of old or obsolete units. Adhering to these best practices will keep your power supplies operating efficiently and your devices protected from power-related failures.

Regulated power supplies maintain a constant output voltage despite changes in input or load, providing stability. Unregulated supplies let output voltage fluctuate with input or load variations, making them suitable only where voltage precision is not critical.

Switching power supplies convert and regulate power using high-frequency switching elements, resulting in higher efficiency and compact size. Linear power supplies use simpler, transformer-based conversion, offering low noise but are bulkier and less efficient.

AC DC wall adaptors, or wall warts, convert household AC to lower DC voltages for devices like mobile chargers, routers, home automation, security and medical equipment, providing reliable power for consumer, commercial, and industrial electronics.

Key factors include input voltage range, output voltage/current, regulation quality, device size, cooling/enclosure needs, temperature tolerance, compliance standards, and expected environmental conditions like elevation or temperature extremes.

Industrial and commercial settings often use rugged wall plug-in power supplies with agency approvals, available in both regulated and unregulated versions, supporting high reliability and compliance with safety standards for machinery and automation.

Interchangeable wall plug-ins provide removable plugs for various regions, supporting 100-240V AC input and adaptable DC output, making them ideal for global distribution and travel with electronics requiring flexible power solutions.

This chapter will explore the various applications and benefits of AC DC power supplies.

Switched-mode power supplies (SMPS) in home appliances like computers often feature universal inputs, allowing them to operate with mains supplies worldwide. However, manual switches for adjusting voltage ranges might still be necessary. SMPS can handle a wide range of power voltages and frequencies.

Cell phone chargers, due to their high volume, are typically cost-sensitive. Initially, linear power supplies were used, but they have since transitioned to more efficient switched-mode power supply designs, such as the ringing choke converter. Recent trends towards lower no-load power consumption have popularized flyback topologies, and primary-side sensing controllers are reducing material costs by eliminating secondary-side components like optocouplers.

Switched-mode power supplies are also used for DC/DC conversion. In vehicles, for instance, heavy trucks with a 24V cranking system may use DC/DC converters to provide 12V for accessories. This setup allows for even distribution of loads across 24V battery cells. In industrial settings, such as telecommunications, power may be distributed at low DC voltages from backup systems, with DC/DC converters supplying the necessary voltages.

Switched-mode power supplies are commonly used as low-voltage supplies for lighting, sometimes referred to as "electronic transformers."

Linear power supplies are often employed in applications where cost is a major concern and efficiency is less critical. They are valued for their simple design and fewer components compared to SMPS. Capacitive power supplies are utilized in low-power applications such as LEDs and small DIY projects due to their simplicity.

The advantages of AC DC power supplies include:

Unregulated power supplies are valued for their simplicity and low cost. They are suitable for applications that do not require precise voltage output. Often, a linear power supply is equipped with an unregulated front stage followed by a voltage regulator.

The primary advantage of a switched-mode power supply is its high efficiency, which can reach up to 96%. This is notably superior to that of linear regulators because the switching transistor generates minimal heat when functioning as a switch.

Additional benefits include a compact size, reduced noise, and lightweight design, achieved by eliminating the need for large line frequency transformers and minimizing heat generation. The standby power loss is often significantly lower compared to traditional transformers. Moreover, the transformer in a switched-mode power supply is more compact than those in standard line frequency transformers (whether operating at 60 Hz or 50 Hz depending on the region) and requires less expensive raw materials, such as copper.

Linear power supplies offer several advantages, including a relatively low cost and a straightforward design. They are known for their simplicity, reliability, and low noise generation, making them cost-effective to produce. The reduced number of components in linear power supplies leads to more streamlined designs and lower manufacturing expenses. These characteristics often make them a preferred choice for engineers and designers.

In accordance with electronics and mechanical guidelines, the fewer components in a linear power supply generally result in fewer potential issues. This inherent simplicity contributes to their increased reliability, which is a significant benefit of using linear power supplies.

Capacitive power supplies are advantageous due to their simplicity and low cost. They are the most straightforward and least expensive AC DC power supplies to manufacture.

Some drawbacks of AC DC power supplies include:

Unregulated power supplies are sensitive to variations in mains AC voltage, which can affect the output voltage. Changes in load current can also cause fluctuations in the output voltage due to the inherent impedance in the power supply’s components.

Drawbacks of switched-mode power supplies (SMPSs) include their complexity and the generation of high-frequency, high-amplitude energy. This energy requires a low-pass filter to prevent electromagnetic interference (EMI), manage harmonic frequencies, and mitigate ripple voltages at the switching frequency.

Inexpensive SMPSs may introduce electrical switching noise back into the mains power supply, potentially causing interference with equipment on the same phase, such as A/V systems. Additionally, SMPSs without power factor correction (PFC) can result in harmonic distortion.

Linear power supplies are known for generating significant heat and having lower efficiency, which results in energy loss. A major drawback in high-power applications is their size and weight, attributed to the large transformers and other substantial components required for their construction. Additionally, the design necessitates a heatsink to manage the thermal stress caused by high current output and excessive heat loss during high-power load regulation.

Efficiency is a significant concern with linear power supplies. Their lower efficiency leads to a considerable difference between input and output voltage, which is crucial when evaluating their suitability for a design. Besides efficiency, other factors such as dropout voltage and load voltage should also be considered. Overall, when selecting a power supply for a specific application, it is important to weigh all relevant factors, including efficiency, cost, and size.

Capacitive power supplies lack electrical isolation between the input and output. Proper insulation of devices drawing power from these supplies is essential to prevent the risk of electric shock.

Comparing linear power supplies to switched-mode power supplies (SMPS) highlights several differences:

Linear power supplies and SMPS differ in their methods of converting mains AC voltage to output DC voltage. An SMPS uses a power transistor to create high-frequency voltage that passes through a small transformer and is then filtered to remove AC noise. In contrast, a linear power supply uses a transformer to step down the primary AC voltage before filtering to eliminate AC noise.

SMPS units are lighter, more compact, and more efficient, offering a broader input voltage range. They are more durable and generally have higher efficiency compared to linear power supplies, which tend to be larger, heavier, and less efficient.

Linear power supplies typically operate at around 60% efficiency, whereas SMPS can achieve efficiencies of 80% or higher.

Linear power supplies have a longer performance history but come with trade-offs. Ultimately, the choice between linear and SMPS depends on the specific needs and requirements of the application.

AC and DC can be interchanged in order to suit the required input to a device. There are many aspects that have to be considered, from the device’s voltage, current and power limits to the areas in which they are operated to come up with the most appropriate power supply. Also, simple circuits may be able to supply the required power, but they have massive losses and dissipate a lot of heat. The better and more efficient solutions are more complex and consist of more expensive components. AC power supplies are usually preferred in large industries to power heavy load equipment. They are very efficient and minimize losses.

An AC power supply is a type of power supply used to supply alternating current (AC) power to a load. The power input may be in an AC or DC form. The power supplied from wall outlets (mains supply) and...

A DC DC power supply (also known as DC DC Converter) is a kind of DC power supply that uses DC voltage as input instead of AC/DC power supplies that rely on AC mains supply voltage as an input...

A DC power supply is a type of power supply that gives direct current (DC) voltage to power a device. Because DC power supply is commonly used on an engineer‘s or technician‘s bench for a ton of power tests...

An electromagnetic interference or EMI Filter is an electrical device or circuit that filters specific unwanted frequencies in power lines or offending frequencies that are detrimental to a system. They receive AC or main power...

By definition a power supply is a device that is designed to supply electric power to an electrical load. An electrical load refers to an electrical device that uses up electric power. Such a device can be anything from...

A programmable power supply is a method for controlling output voltage using an analog or digitally controlled signal using a keypad or rotary switch from the front panel of the power supply...

An AC power cord is a detachable way of providing an alternating current of electric energy from a mains power supply to an electrical appliance or equipment. Serving industries like...

Electrical plugs, commonly known as power plugs, are devices responsible for supplying and drawing current from a receptacle to the circuitry of an electrical appliance...

Electronic connectors are devices that join electronic circuits. They are used in assembling, installing, and supplying power to electrical devices. Connectors are an important component of every electronic equipment used in...

An electric switch is a device – usually electromechanical – that is used to open and close an electric circuit. This disables and enables the flow of electric current, respectively...

A NEMA connector is a method for connecting electronic devices to power outlets. They can carry alternating current (AC) or direct current (DC). AC current is the typical current found in homes, offices, stores, or businesses...

A power cord is an electrical component used for connecting appliances to an electrical utility or power supply. It is made from an insulated electrical cable with one or both ends molded with connectors...

Push button switches are electrical actuators that, when pressed, either close or open the electrical circuits to which they are attached. They are capable of controlling a wide range of electronic gadgets...

Thomas Edison developed the power distribution system in 1882. He wrapped a copper rod in jute, a soft shiny fiber from plants, as an insulator. The jute wrapped copper rod was placed in a pipe with a bituminous compound...