Electrical Plugs

Electrical plugs, commonly known as power plugs, are devices responsible for supplying and drawing current from a receptacle to the circuitry of an electrical appliance...

Please fill out the following form to submit a Request for Quote to any of the following companies listed on

This article will take an in-depth look at AC power cords.

The article will bring more detail on topics such as:

This section explores the basic principles of AC power cords, detailing their construction and operational functionality.

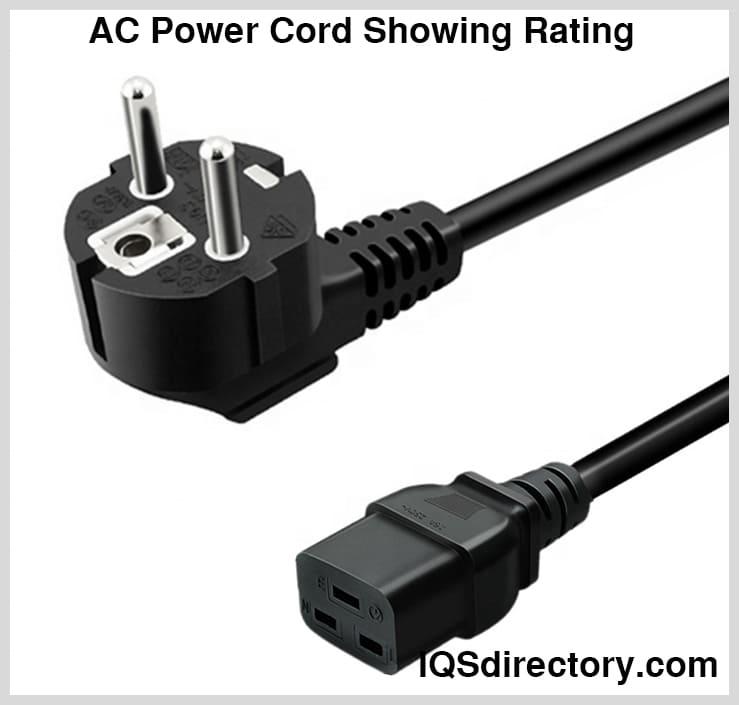

An AC power cord is a detachable device that delivers alternating current (AC) from a mains supply to electrical devices and appliances. Utilized across a wide range of sectors like retail, industrial, electronics, entertainment, and residential, these cords power applications such as lighting, power tools, home appliances, shop equipment, and musical instruments, among other uses.

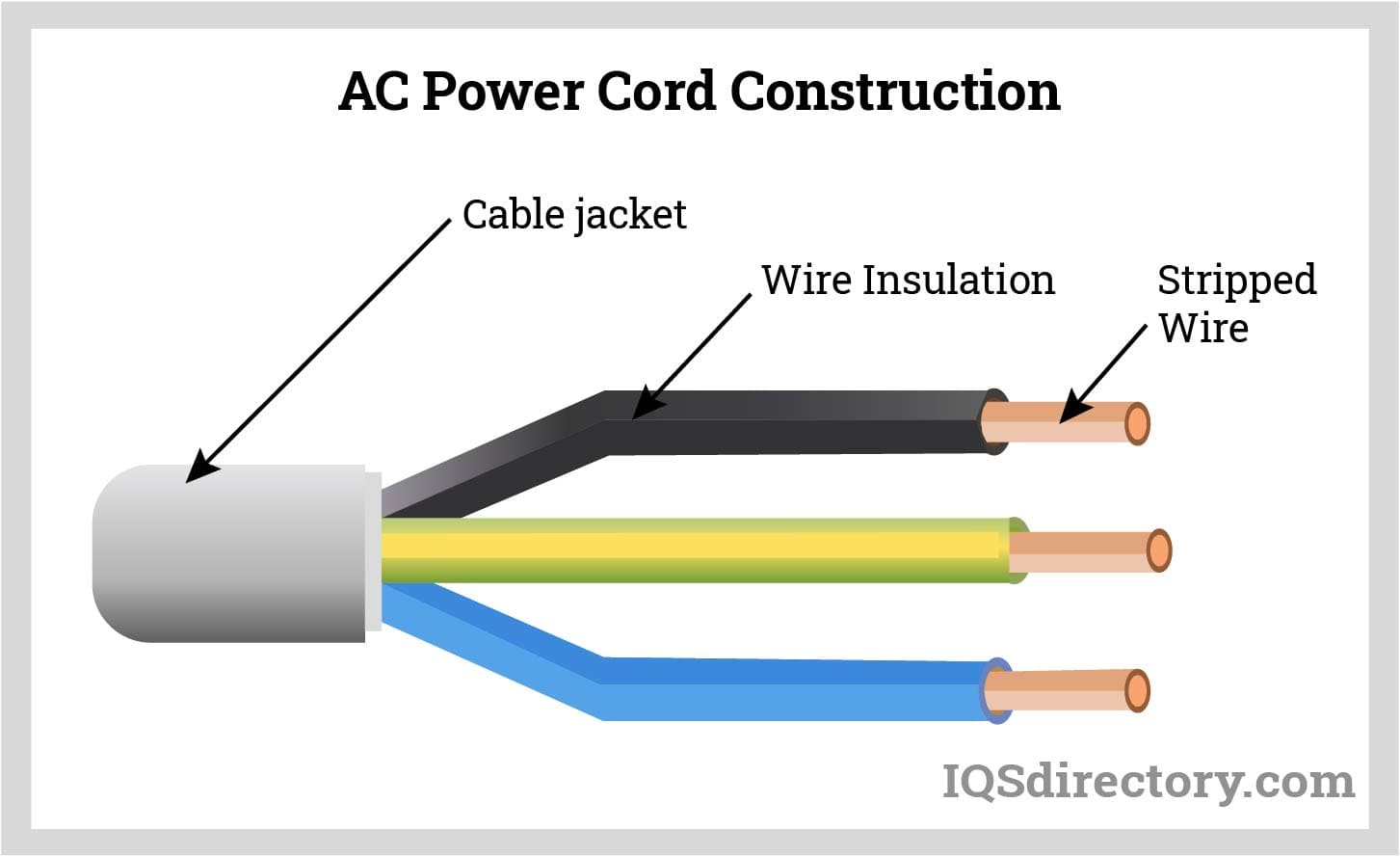

AC power cords facilitate alternating current (AC), with electrons changing direction periodically, transferring energy from the power source to the intended device. The cords comprise conductive wires, often copper, shielded in insulation and encased in an outer jacket made from rubber or polymers. Cord construction can vary based on specific application needs.

Key considerations in the construction and material selection for AC power cords include:

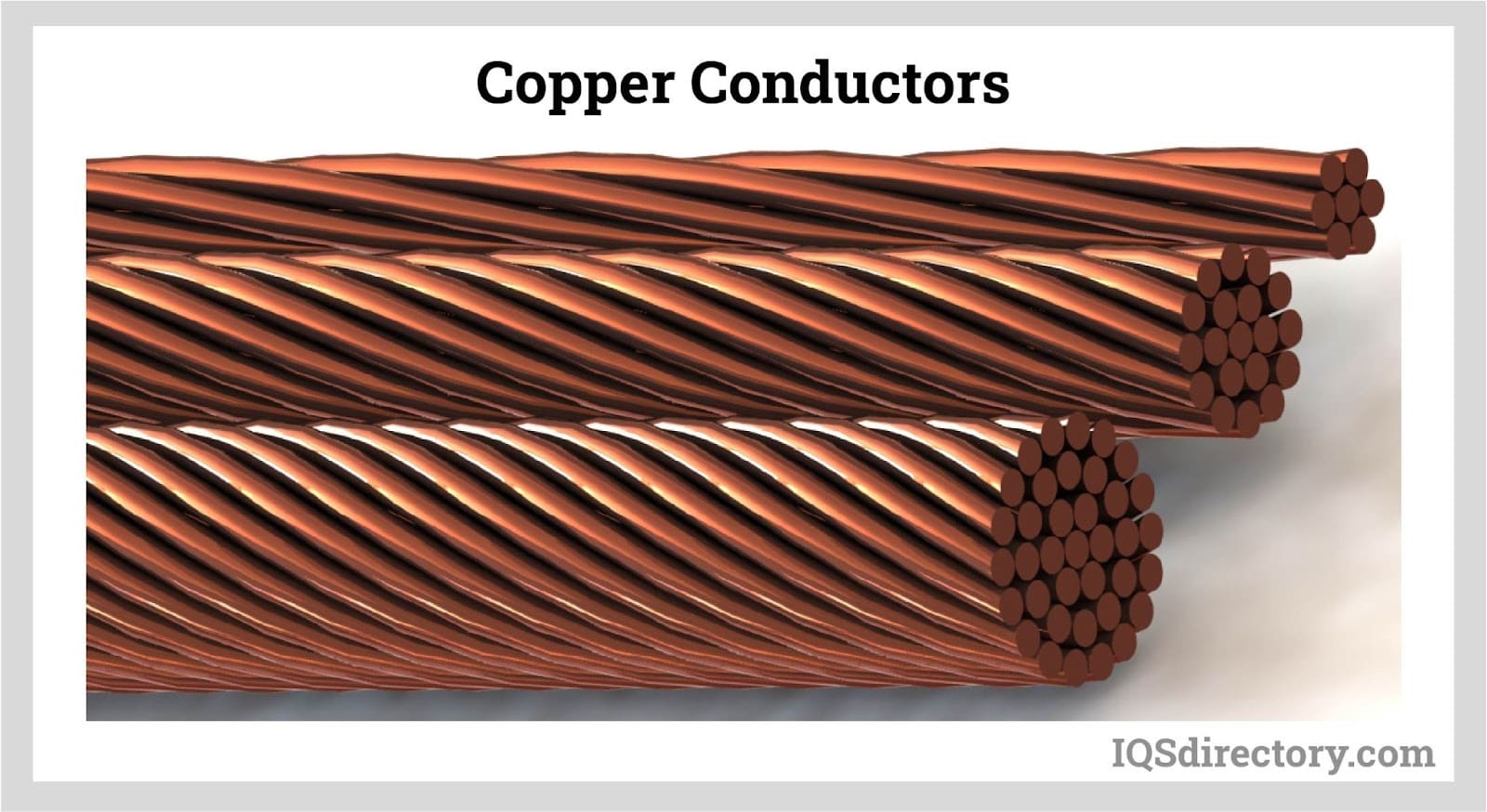

Copper serves as an electrical conductor in diverse wiring applications, essential for power generation and transmission, electronic circuitry, telecommunications, and manufacturing electrical contacts. Construction wiring dominates the market for copper wires, with nearly half of mined copper transformed into wires and cable conductors.

Copper wires within cords are frequently stranded by braiding, twisting, or bonding, enhancing the cable's flexibility.

Copper wires can be bare or plated with tin to minimize oxidation, and sometimes coated with silver or gold to extend their longevity and aid in soldering. Coaxial and twisted pair cables are designed to lower electromagnetic interference, maintain signal integrity, and improve transmission properties. Shielding with wire mesh or foil further safeguards these cables.

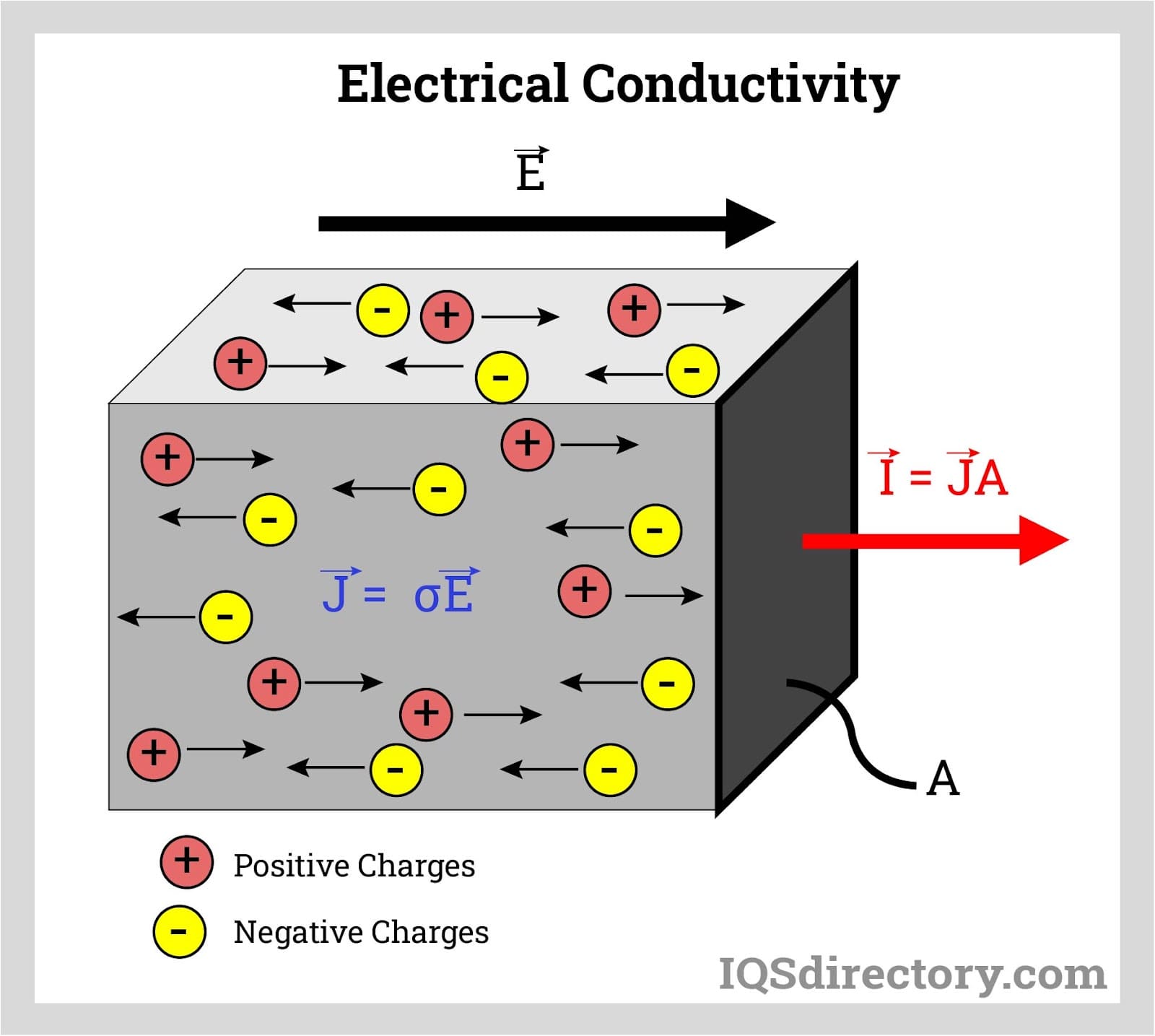

The material's electrical conductivity is key, as it measures the efficiency of electric charge transfer. Copper, renowned for outstanding conductivity, presents a resistivity of 16.78 nΩm at 20°C. According to solid-state metal theory: copper’s conduction band is partially filled, allowing numerous electrons to transport electric current. When electricity is introduced to copper, electrons flow towards the positive end, initiating the current.

Electrons encounter resistance due to impurities or lattice interference, known as "mean free path" inversely related to resistivity. Copper's excellent conductivity serves as a benchmark. Electrolytic-tough pitch (ETP) copper, with reduced oxygen, is often selected for its conductivity efficiency.

Despite copper’s denser nature, it remains optimal for conductive capacity without needing extensive cross-sectional width, unlike aluminum, which requires a cross-section 1.56 times larger due to its 0.6x conductivity.

Silver outperforms copper only slightly in conductivity, with a resistivity of 15.9 nΩm at 20°C.

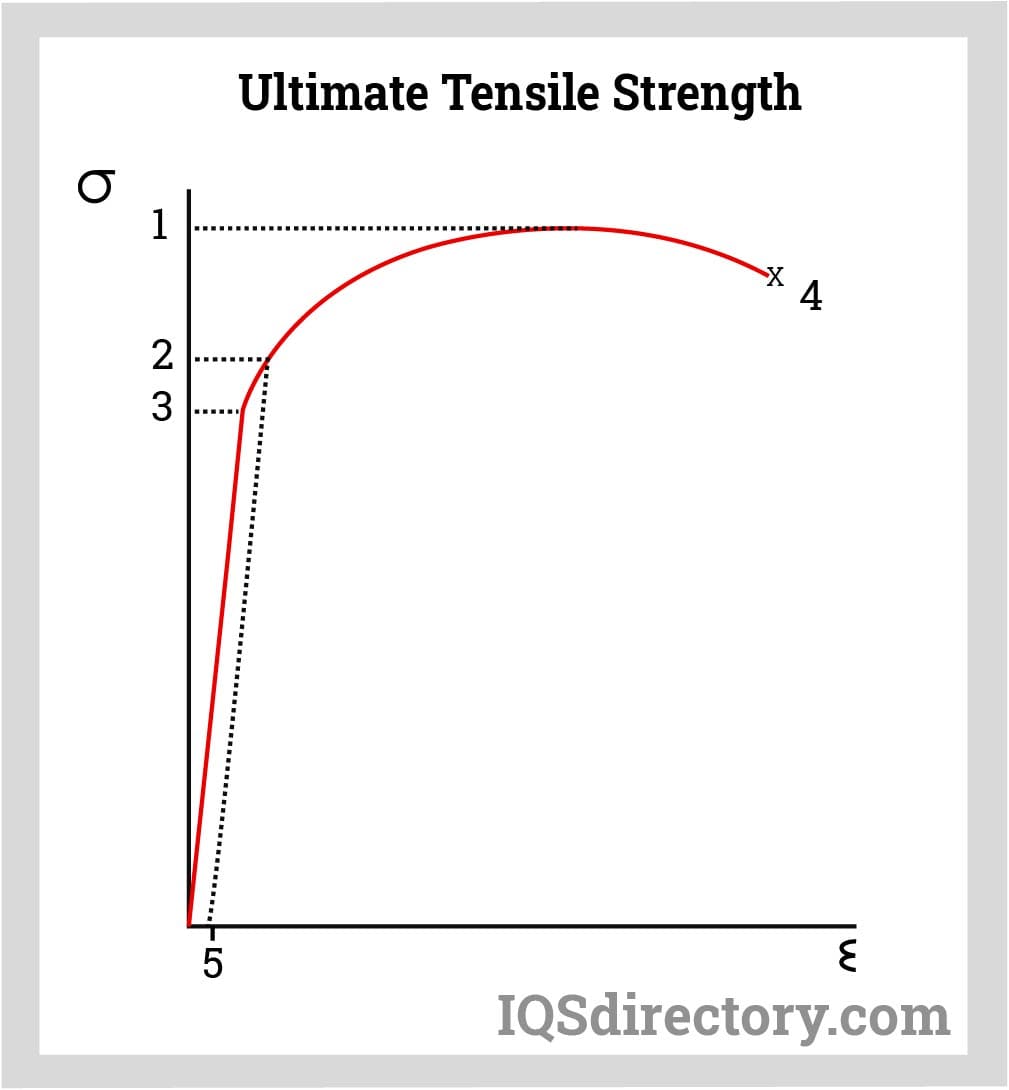

Tensile strength indicates the maximum force a material withstands before failure. Copper's high tensile strength inhibits stretching, breaking, and deformation.

Copper’s tensile strength resists necking and creep but adds weight compared to similarly conductive aluminum wires, which might counteract its strength once installed.

Ductility reflects a material's ability to handle tensile stress, allowing it to be drawn into a wire form. Copper ranks high in ductility, only surpassed by silver and gold, facilitating very fine wiring with precise specifications.

Copper’s advantageous mix of hardness, flexibility, and ease of handling supports straightforward installation without special tools for joining or adjustments. It permits bending and twisting during installation without breaking, and it has secure connections, eliminating the need for fittings or lugs.

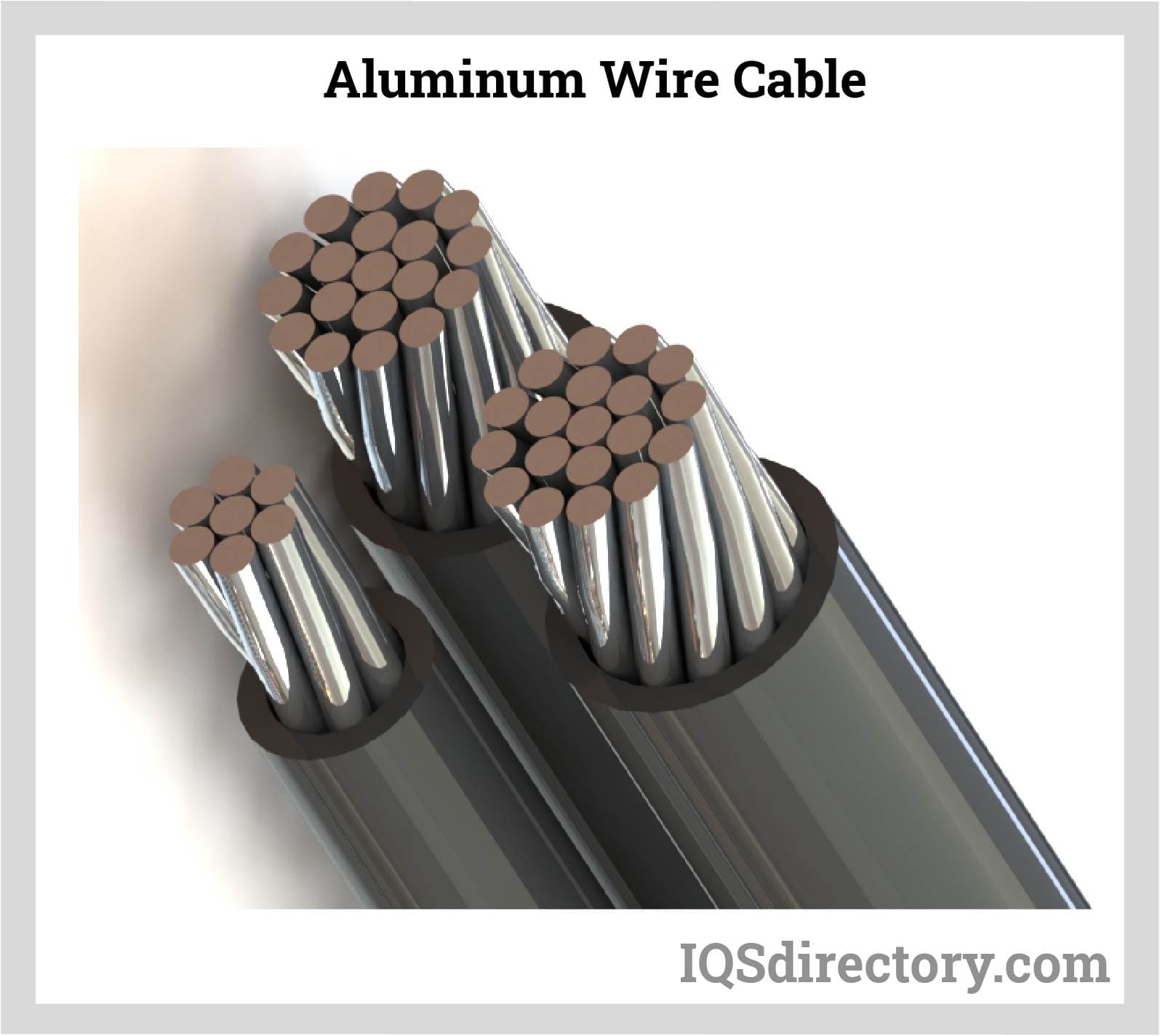

Aluminum wire, an electrical conduit for residential applications, is used widely for power grid infrastructure like distribution and transmission lines. Aluminum offers better conductivity per weight than copper, presenting an effective cost-efficient alternative in specific applications.

Its commendable electrical and thermal conductivity, about 60% relative to copper, combined with lower density makes aluminum susceptible to AC magnetic fields and eddy current issues.

Yet, aluminum’s use is limited by potential fire risks from loose connections. It has higher electrical resistance, requiring thicker wires to perform equivalently to copper.

Aluminum's higher resistance means it requires thicker wires than copper for the same current load, affecting installation space and circuit design.

Aluminum’s reduced ductility leads to faster fatigue under stress, causing internal wire problems and heat buildup due to increased resistance.

Moisture exposure exposes aluminum to galvanic corrosion in contact with certain metals, posing safety hazards.

Aluminum oxidizes more readily than copper, resulting in an oxide less conductive than copper oxide, threatening connection integrity and increasing fire risk.

Increased malleability can cause aluminum to compress and deform, leading to loosening and increased resistance, creating hazards.

Higher thermal changes compared to copper can degrade connections, especially in long-term setups, affecting performance.

Sensitivity to vibration leads to loosening over time, affecting aluminum's suitability in high-vibration environments.

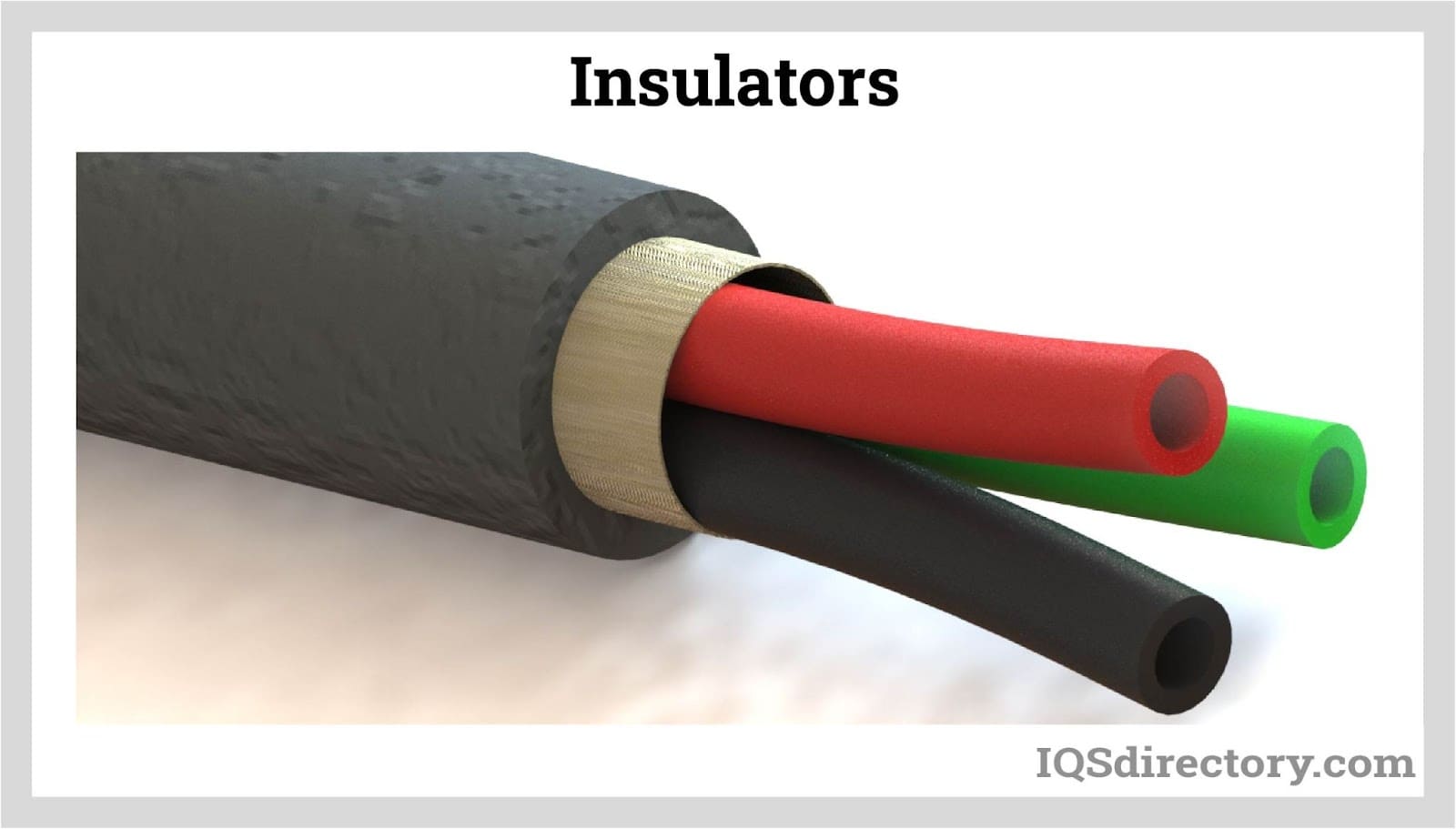

Insulation serves as a protective measure against current leakage, environmental threats, and external damage to the conductor. High-quality insulation is essential for durability and performance.

Different insulation types cater to specialized applications—rubber, plastic, and fluoropolymer are primary materials. Insulation covers either individual conductors or multi-wire cords, and choice depends on the intended application and environmental challenges.

Plastic options such as:

PVC offers an economical and versatile insulating choice suitable for a range of temperatures from -55°C to 05°C. It is resistant to flames, abrasion and moisture, and withstands chemicals and solvents.

PVC's nontoxic nature makes it suitable for medical and food applications. However, its limitations include limited flexibility and unfavorable performance in low temperatures. Its higher attenuation and capacitance loss can negatively impact energy efficiency.

SR-PVC offers primary insulation with high abrasion resistance, providing a defense against chemicals, heat, and flame.

Meeting stringent fire safety requirements, plenum PVC is ideal for air-circulating voids like ceilings or floors.

Favored for low-capacitance wires and coaxial cables, PE's low dielectric constant offers high-speed transmission capability. Cross-linking enhances durability against grading and solvents, useful for broader temperature ranges.

With structural stiffness, it is flammable, but flame retardants raise dielectric loss, impacting energy transmission.

Similar to PE with a broader temperature range, PP is utilized in thin-wall applications, offering improved electrical insulation by foaming.

Widely used where flexibility and chemical resistance are key, such as military cords. Flammable as an insulator but viable as a jacket material.

Environmentally friendly with robust resistance qualities for industrial control and power cables.

Nylon is strong and durable against chemicals and cuts but susceptible to moisture absorption, impacting some electrical properties.

Rubber offers an array of options:

An evolution from thermoset, TPR improves processing rates and color options, though cut-through resistance is less compared to alternatives.

Suits portable cord applications and military products, thanks to its excellent cut-through, flame, and oil resistance capabilities.

Silicone withstands high operational temperatures with average abrasion resistance and flexibility, useful across electrical spaces.

Favored for high-voltage use due to small cross-sectional accommodation, possesses excellent versatility but requires thoughtful management during installation due to its relatively soft nature.

Combining natural rubbers with SBR provides mixed properties suitable for general applications depending on thermal demands or electrical resistance.

With options such as:

High temperature-ready with limited applications, representing a more expensive insulating solution.

Flexible and resistant to chemicals and high temperatures, PTFE is valuable where mechanical flexibility prevails.

By merging rubber’s elasticity and plastic’s processing, TPE serves in homes and automobiles, though challenged by heat and chemical resistance.

AC power cords convey alternating current to devices, ensuring a secure current flow. The live wire supplies voltage, alternating at regular intervals, to the appliance. The neutral wire returns current to the ground or busbar in the distribution box, maintaining a steady circuit flow. Earth wires safeguard from electric shocks, directing faults to the ground, and activate safety breaks in emergencies.

When it comes to choosing AC power cords, consider these aspects:

A cord's current rating shows its capacity to handle maximum current without overheating, influenced by insulation, current frequency, resistance, and ambient conditions.

The rated voltage dictates critical design elements like insulation type and thickness, harmonizing safety standards with performance needs for high-voltage scenarios.

```An AC power cord includes conductive wires (usually copper or aluminum), insulation made of plastic, rubber, or fluoropolymer, and an outer jacket. It may have shielding, connectors (couplers or plugs), and optional grounding wires for safety.

C13/C14 connectors are used for computers, monitors, and similar devices, supporting up to 10A or 15A. C19/C20 connectors allow higher amperage (16A or 20A), are robust, and power data centers, servers, and industrial-grade equipment.

Select a cord matching your device’s voltage and amperage, and ensure the plug or coupler is compatible with your country’s socket standards, such as the Type G plug used in the UK and other Commonwealth countries.

Common insulation materials include polyvinyl chloride (PVC), semi-rigid PVC, polyethylene (PE), polypropylene (PP), polyurethane (PUR), chlorinated polyethylene (CPE), nylon, thermoplastic rubber, neoprene, silicone, and fluoropolymers like PTFE.

AC power cords are used in data centers, power tools, lighting, shop equipment, refineries, chemical plants, public buildings, airports, manufacturing, and server farms, supporting both IT infrastructure and heavy-duty industrial operations.

Regularly inspect cords, keep them organized, avoid moisture, and ensure usage within the manufacturer’s specified amperage. Dust cords often and store in dry environments to extend their lifespan and reliability.

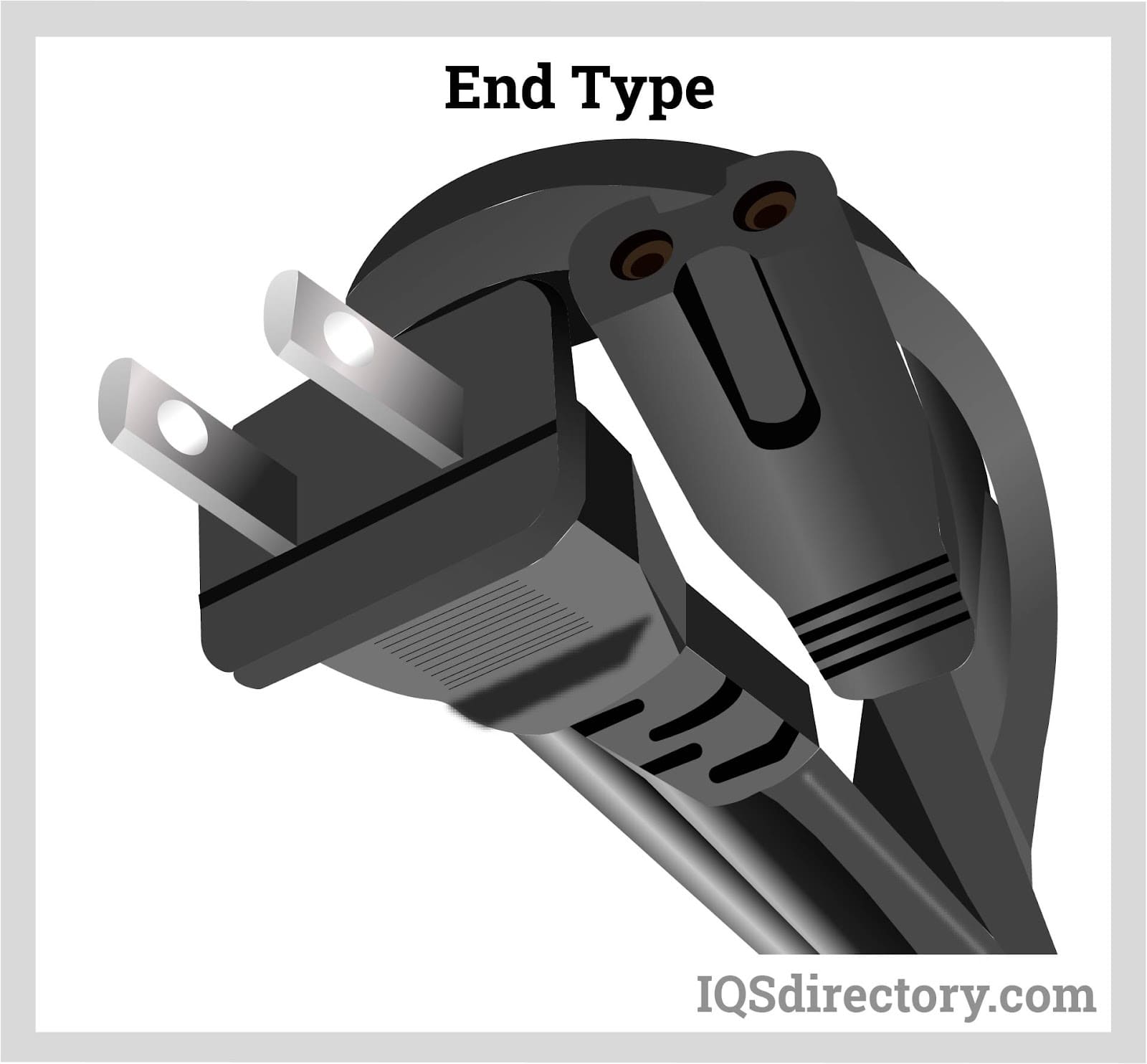

AC power cords, also known as mains power cables or line cords, are essential components for safely delivering electricity from wall outlets to a variety of electronic devices and electrical appliances. These cords are distinguished by their connectors—commonly called couplers—which facilitate a secure and reliable link between the device and the available power source. In addition to the connectors, the type of plug used at the end of the cord is also important. There are many varieties of connectors and plugs that comply with international and regional standards, each tailored for specific voltage, current requirements, and device compatibility. Understanding the differences among these AC power cord types is crucial for selecting the right cable for your application, ensuring not only effective power transmission but also safety and compliance with electrical regulations.

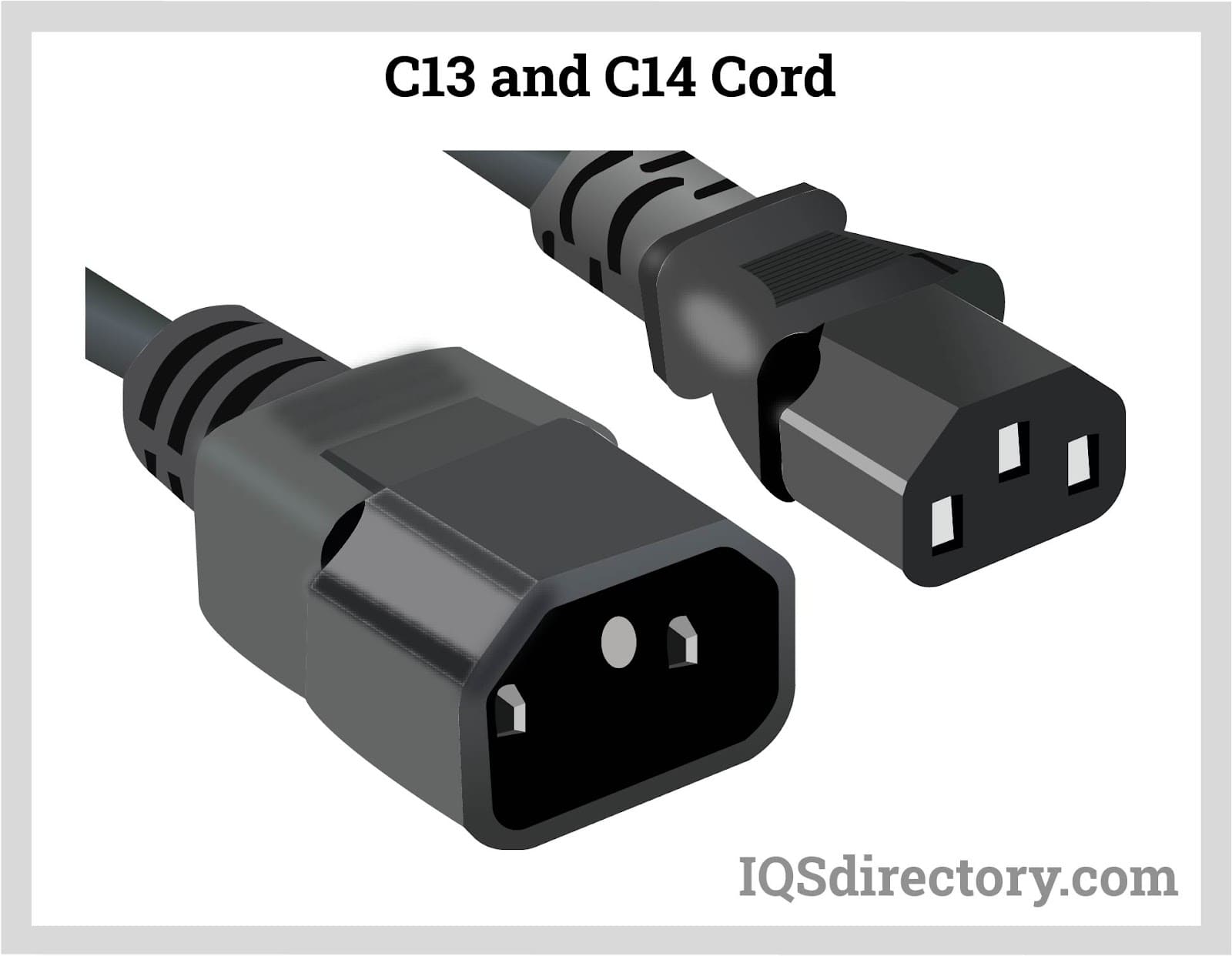

The International Electrotechnical Commission (IEC) established the IEC 320 C13/C14 connector standard for AC power cords, which is officially designated as IEC 60320. Frequently used in the IT, data center, and office equipment industries, this connector type is prevalent in power cables for computers, printers, monitors, power distribution units (PDUs), and networking equipment. The C13 line socket is the most widely used female connector in desktop computer power cords, while the C14 plug, as the male component, is typically mounted on recessed panels or chassis found on power supplies and uninterruptible power supplies (UPS).

The C13/C14 combination supports currents up to 10A (in the US) or 15A (in many international regions) and voltage ratings of up to 250V, making it suitable for a broad spectrum of low- to medium-power electronic devices. Its globally recognized design ensures widespread compatibility and safety in power delivery for electronics and appliances.

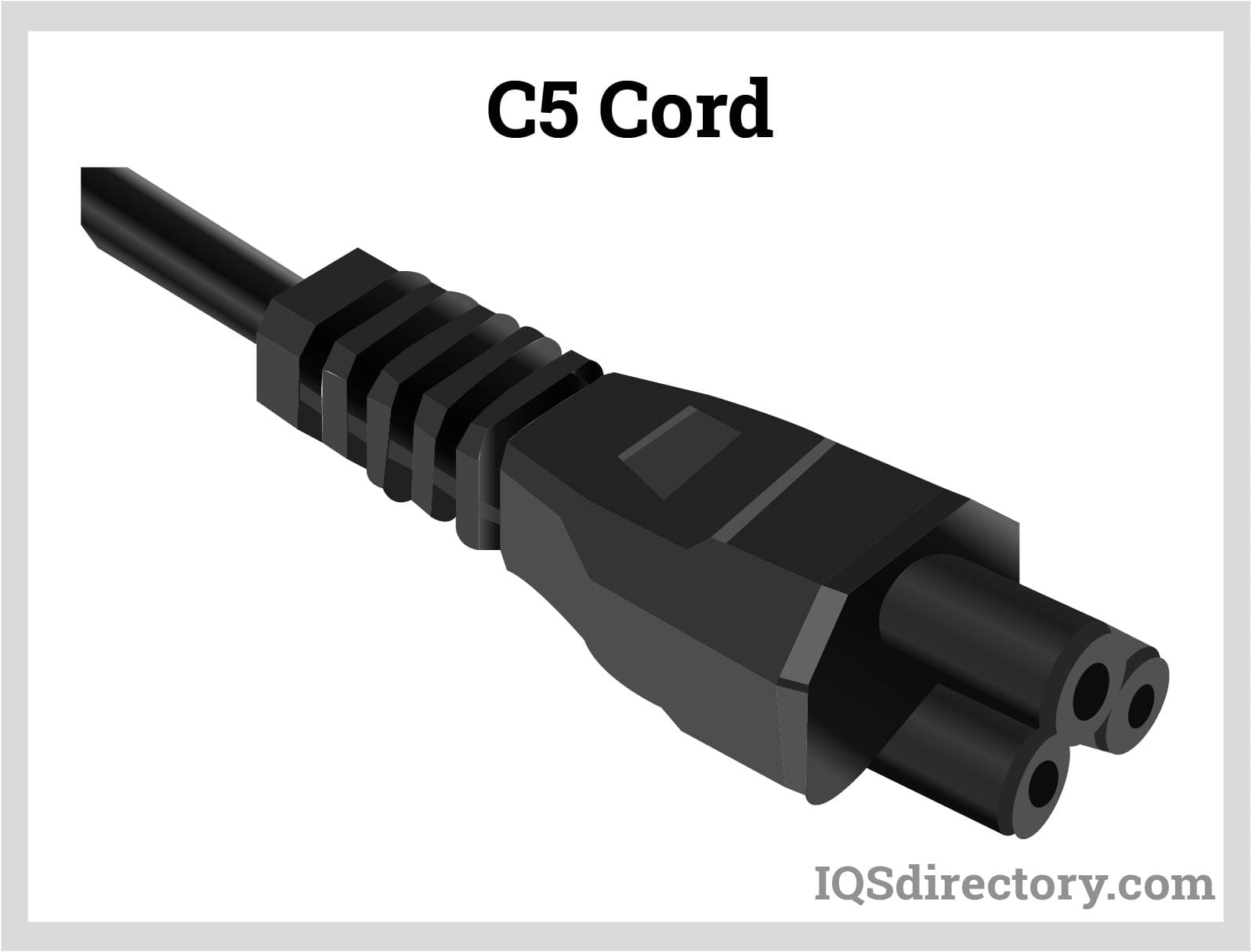

The C5 polarized power connector—often called the "Mickey Mouse" or cloverleaf connector—is primarily used in AC power cords for notebook computers, projectors, and portable power adapters. Its three circular prongs, arranged in a triangular pattern, resemble the silhouette of the famed Disney character, hence its nickname. The C5 power cord is highly popular among OEM laptop manufacturers due to its compact design and secure fit. Typical use cases include supplying power to laptops, some game consoles, portable speakers, and select printer models.

C5 AC power cords comply with global electrical safety regulations, providing a safe and efficient connection for modern consumer electronics. For users seeking reliable power solutions for portable or mobile applications, the C5 power cord provides flexibility, strong electrical contact, and wide compatibility.

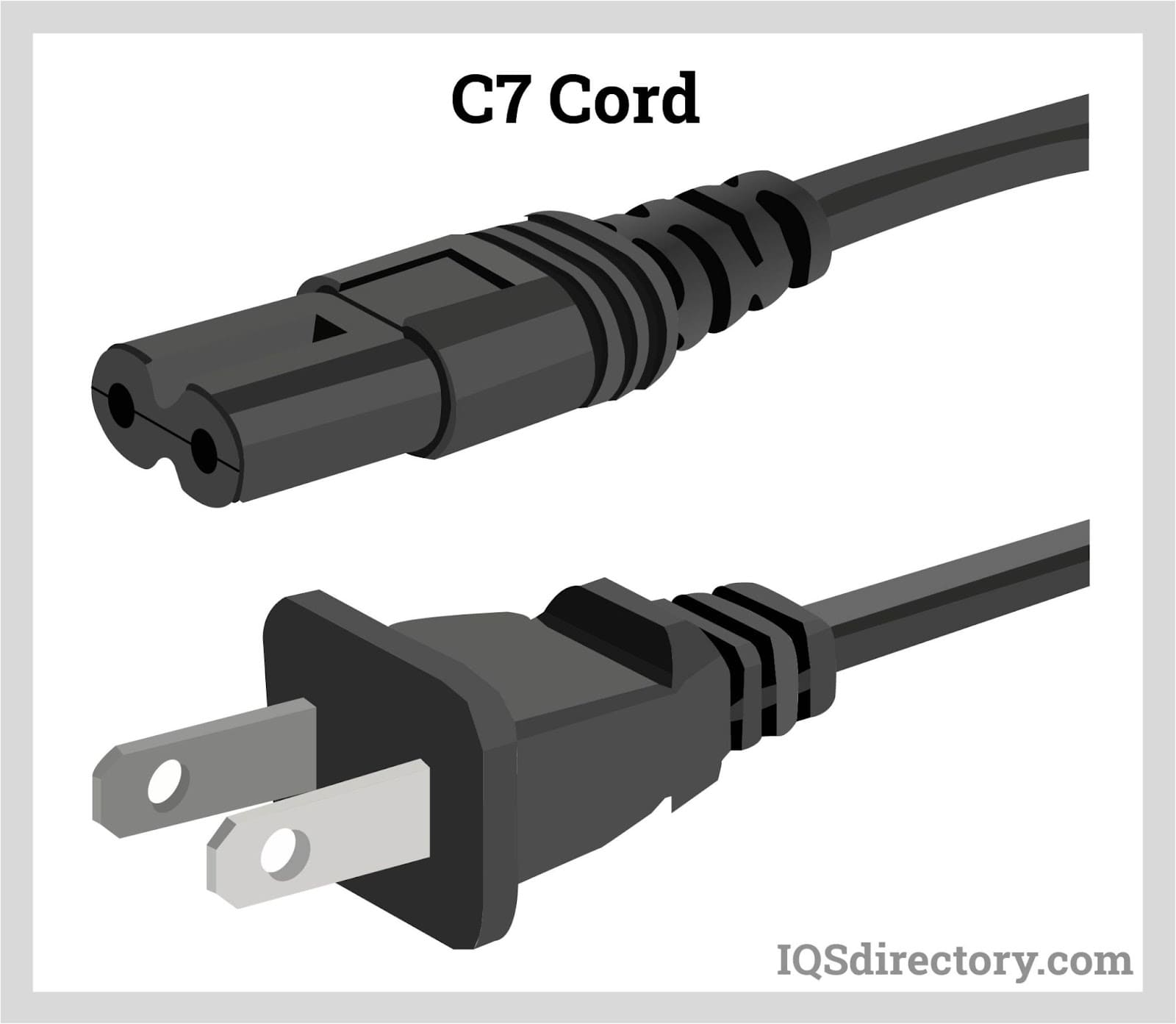

The C7 power connector is a 2-pronged, non-polarized plug commonly used in AC power cords for various electronic devices, including radios, power transformers, shavers, and small appliances. Also referred to as the "figure-8" or "shotgun" connector due to its shape, the C7 features two round pins placed side-by-side. This type of AC power cord is typically used to power low-voltage equipment such as portable laptop power supplies, CD and DVD players, game consoles, audio devices, and AV equipment. Its slim, lightweight design makes it a popular choice for consumer electronics requiring moderate electric current and a simple, no-ground connection.

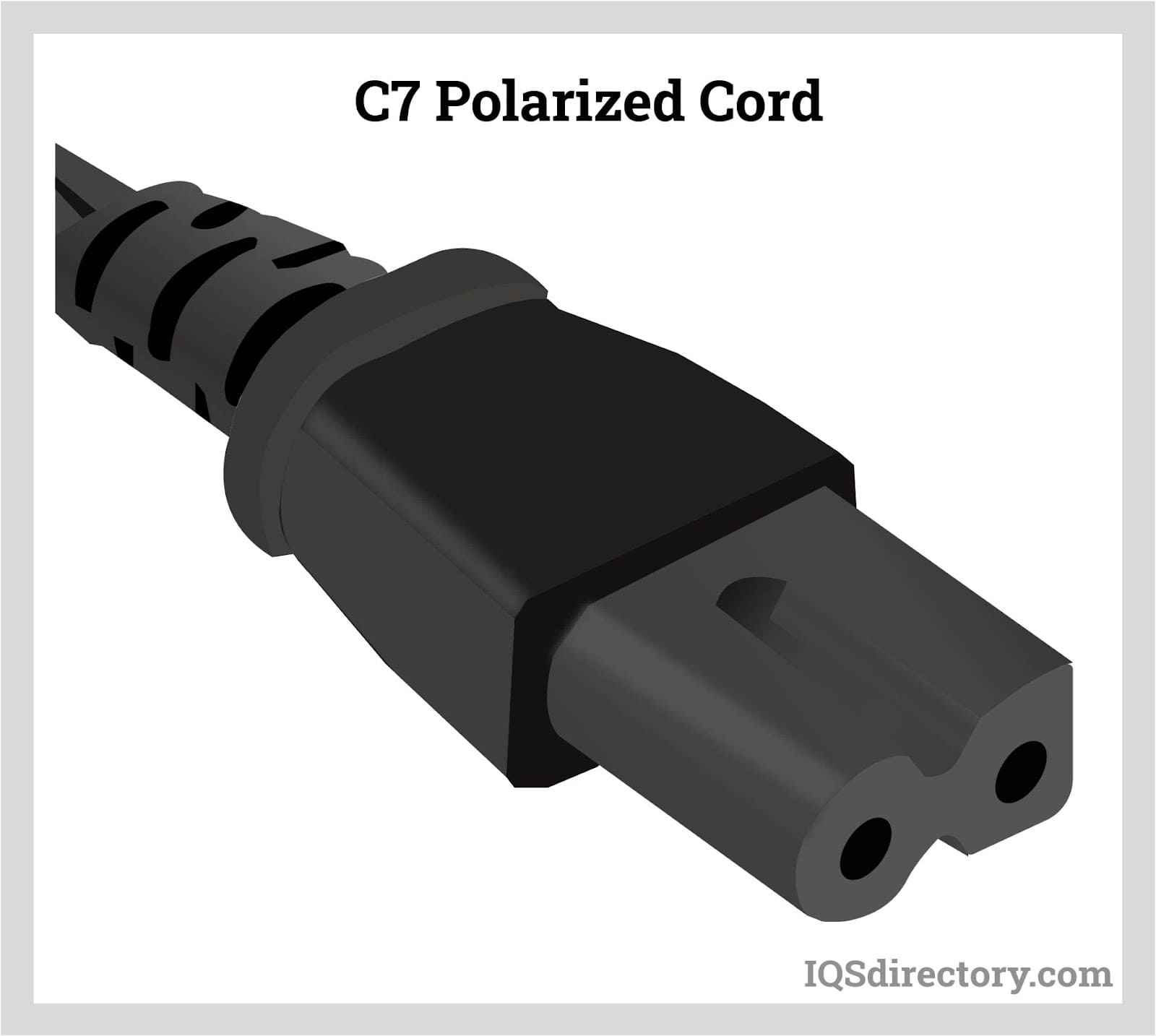

The C7 connector also has a polarized version, designed to enhance safety and prevent mismatched connections. The main characteristic of the polarized C7 AC power cord is the presence of a square-shaped overmold along one of the pins, ensuring that the prongs are oriented correctly when plugged in. This structural difference guarantees that the neutral terminal of your device is reliably connected to the neutral wire of the AC power supply, reducing the risk of electrical faults or reversed polarities in sensitive equipment. These cords are a popular choice for devices where correct polarity is critical for safe operation.

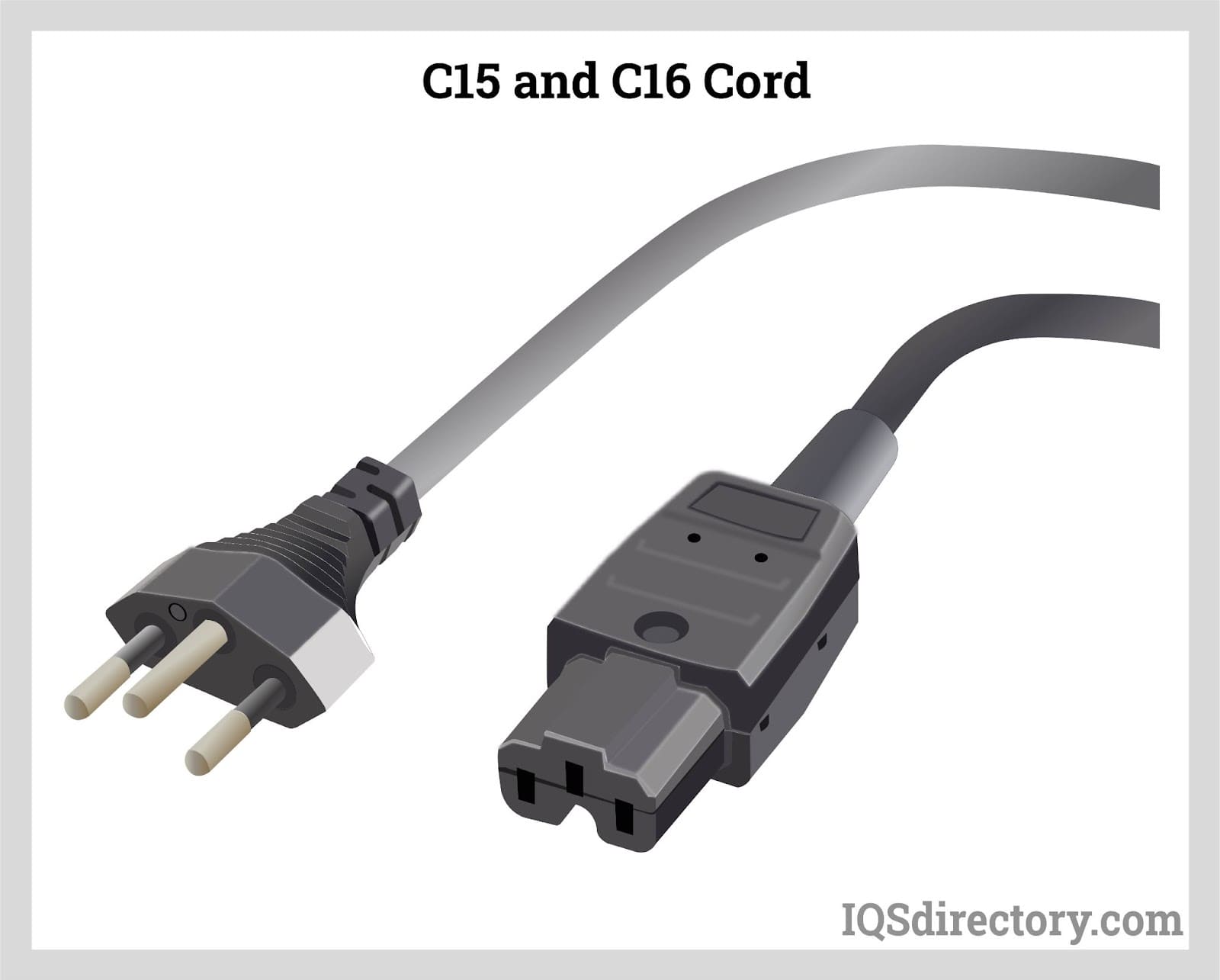

The C15 and C16 connectors are advanced IEC connectors specifically designed for use in high-temperature environments and heavy-duty applications. These connectors are commonly found in data centers, server rooms, and industrial facilities where devices are closely packed, generating significant heat. The C15 model is often used for electric kettles, networking gear, hot-pluggable rack equipment, and advanced power distribution systems. What sets the C15/C16 apart is an additional notch or key, which prevents improper insertion and ensures a correct matching of "cold" and "hot" orientation.

The C15 and C16 connectors have a higher temperature rating (up to 120°C) compared with the standard C13/C14 connectors, making them ideal for mission-critical applications. There is also a C15A/C16A variant for even higher temperature environments (up to 155°C), featuring a unique rectangular ridge at the upper end of the molding. These power cords are vital in enterprise-level power management and industrial electrical setups, where safety and reliability are paramount.

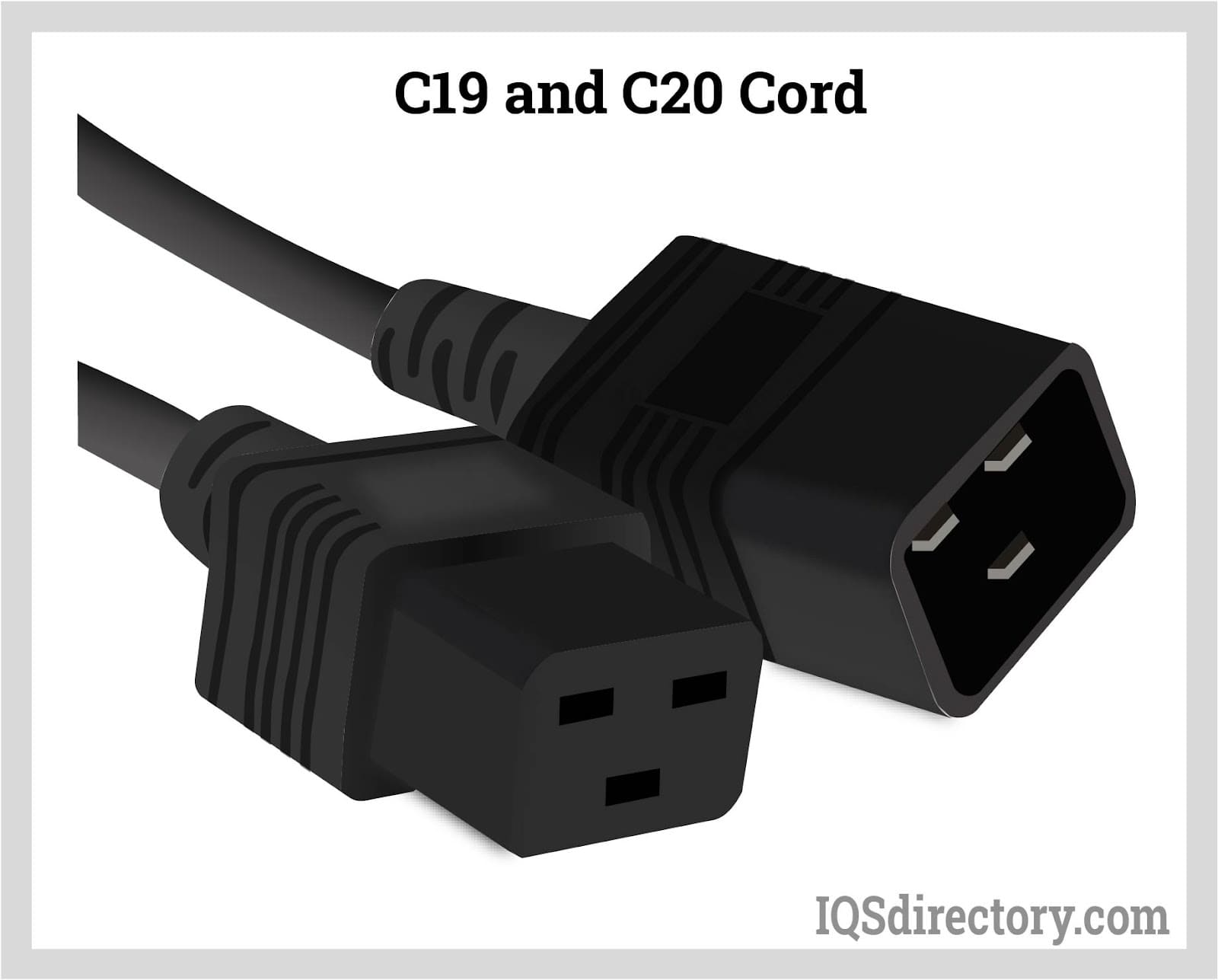

The C19 and C20 power connectors represent heavy-duty AC power cord solutions with a horizontal terminal orientation and a robust, rectangular shape with rounded edges. Commonly deployed in data centers, server farms, network infrastructure, and professional IT equipment, the C19/C20 connector is designed to deliver higher amperage—up to 16A internationally and 20A in US specs—at voltages up to 250V. These connectors are used for powerful devices that exceed the capacity of C13/C14 cords, such as servers, large power supplies, blade enclosures, industrial-grade power distribution units, and mission-critical medical equipment.

The C19/C20 AC power cord offers a secure connection for high-power electrical appliances, helping prevent accidental disconnects, overheating, or electrical faults in demanding environments. It supports Class I equipment that requires grounding and ensures compliance with rigorous safety standards for professional environments.

The Type G plug—standard in the United Kingdom, Ireland, and several Commonwealth countries—features three rectangular prongs and a built-in fuse, typically rated at 13A. This fuse protects the power cord and the connected electrical appliance from overload, providing added safety. The Type G socket is compatible with some other plug types (such as Type C in rare instances), but using such adapters or non-compliant plugs is considered unsafe and can void equipment warranties or damage devices.

The primary standard for Type G plugs and sockets is British Standard BS 1363, which is widely adopted for residential and commercial wiring in the UK and other regions. Additional standards derived from BS 1363 follow strict regulations for plug/socket safety, durability, and compatibility with fused AC power cords. When choosing a power cord for international travel, or for devices sold in different countries, checking the compatibility with socket standards like Type G is essential.

With so many types of AC power cords and connectors, it can be challenging to determine which option best fits your device and region. It’s critical to match the voltage and amperage requirements of your equipment with the electrical ratings of the cord (such as 125V, 250V, 10A, 16A, or 20A), and to ensure you select a compliant plug type for your country’s electrical outlets. When purchasing AC power cords online or from local distributors, always check for third-party safety certifications (such as UL, CSA, VDE, or RoHS compliance) to guarantee long-term reliability and regulatory adherence. Many manufacturers and suppliers offer customized power cords to address specific needs, such as cord length, shielding, or specialty connectors for industrial and medical applications.

For bulk ordering, OEM requirements, or international sourcing, consult with leading AC power cord manufacturers or authorized distributors. Knowledgeable suppliers can offer guidance on the best products for data centers, IT infrastructure, household electronics, and specialized environments—ensuring compatibility, safety, and energy efficiency. To learn more or compare options, visit our Leading Manufacturers and Suppliers section below for reputable sources of high-quality AC power cords.

This chapter will explore the applications and advantages of AC power cords.

AC power cords are used in a variety of applications, including:

When dealing with materials that transfer electrical current, it's crucial to observe safety considerations. Polarization and grounding are especially important for higher-voltage electrical equipment and appliances, which may pose a greater risk of electric shock. Polarizing an electric plug ensures that the appliance is properly connected to the ground or neutral side of the circuit, reducing the risk of electric shock for users. Sensitive electrical products and equipment should always be used with properly grounded or polarized AC power cords.

AC power cords require minimal maintenance since they are passive devices with no moving parts. However, several practices can help extend their lifespan. Ensure that the power cord is used within the manufacturer's specified amperage to prevent overheating. In environments with numerous power cords, such as server rooms, they should be organized and tied to avoid entanglement. It's also important to use AC power cords in dry areas to prevent moisture from entering the connectors. Regular dusting of the power cords helps keep them clean and in good condition.

An AC power cord is a removable means of offering alternating current of electric energy from a mains power supply to an electrical appliance or equipment. Serving industries like retail, commercial, industrial, electronics, entertainment, and residential, AC power cords are utilized for applications such as lighting, electrical power tools, household appliances, shop equipment, musical instruments, and many personal uses. They offer a low resistance path for alternating current to flow through. Live wire carries the 230V/120V AC from the power supply to the appliance. The current alternates periodically at 50 times per second. The cord is a cable made of a conducting wire, generally copper, covered by cord covers, insulation, and an outer rubber or polymer jacket which protects the wire. AC power cords are differentiated by their connectors or more formally known as couplers. AC power connectors enable the connection between electronic devices and appliances to available power outlets. Besides connectors, plugs are also used. The choice of an AC power cord is determined by rated current and voltage.

Electrical plugs, commonly known as power plugs, are devices responsible for supplying and drawing current from a receptacle to the circuitry of an electrical appliance...

A NEMA connector is a method for connecting electronic devices to power outlets. They can carry alternating current (AC) or direct current (DC). AC current is the typical current found in homes, offices, stores, or businesses...

A power cord is an electrical component used for connecting appliances to an electrical utility or power supply. It is made from an insulated electrical cable with one or both ends molded with connectors...

Thomas Edison developed the power distribution system in 1882. He wrapped a copper rod in jute, a soft shiny fiber from plants, as an insulator. The jute wrapped copper rod was placed in a pipe with a bituminous compound...

Power supplies are electrical circuits and devices that are designed to convert mains power or electricity from any electric source to specific values of voltage and current for the target device...

An AC power supply is a type of power supply used to supply alternating current (AC) power to a load. The power input may be in an AC or DC form. The power supplied from wall outlets (mains supply) and...

A DC DC power supply (also known as DC DC Converter) is a kind of DC power supply that uses DC voltage as input instead of AC/DC power supplies that rely on AC mains supply voltage as an input...

A DC power supply is a type of power supply that gives direct current (DC) voltage to power a device. Because DC power supply is commonly used on an engineer‘s or technician‘s bench for a ton of power tests...

Electronic connectors are devices that join electronic circuits. They are used in assembling, installing, and supplying power to electrical devices. Connectors are an important component of every electronic equipment used in...

An electric switch is a device – usually electromechanical – that is used to open and close an electric circuit. This disables and enables the flow of electric current, respectively...

By definition a power supply is a device that is designed to supply electric power to an electrical load. An electrical load refers to an electrical device that uses up electric power. Such a device can be anything from...

A programmable power supply is a method for controlling output voltage using an analog or digitally controlled signal using a keypad or rotary switch from the front panel of the power supply...

Push button switches are electrical actuators that, when pressed, either close or open the electrical circuits to which they are attached. They are capable of controlling a wide range of electronic gadgets...