AC Power Cord

An AC power cord is a detachable way of providing an alternating current of electric energy from a mains power supply to an electrical appliance or equipment. Serving industries like...

Please fill out the following form to submit a Request for Quote to any of the following companies listed on

Here is everything you will need to know about NEMA Connectors.

You will learn:

NEMA connectors are essential for linking electronic devices to power sources, accommodating either alternating current (AC) or direct current (DC). AC is commonly used in residential, office, and commercial environments, whereas DC is usually supplied by batteries.

While household connectors often have two or three prongs, the global industry employs hundreds of varied connectors. Each type is tailored to specific amperage (A) and voltage (V) needs.

In America, connectors are designed for current ratings from 15 to 60 amps and voltage ratings spanning 125 to 600 volts. They come in numerous configurations with diverse blade shapes, sizes, and alignments to prevent interchangeability, ensuring they meet specific requirements for voltage, current capacity, and grounding.

All U.S. manufacturers comply with NEMA standards, facilitating uniformity across the industry. NEMA standardization delineates plug and receptacle pin configurations based on their respective amperage and voltage specifications.

Refer to the diagram illustrating NEMA 2-20, NEMA 6-50, and NEMA 24-15 models, each with unique pin setups. These models differ by amperage and voltage, with 2-20 and 6-50 rated for 250V, and 24-15 rated for 347V.

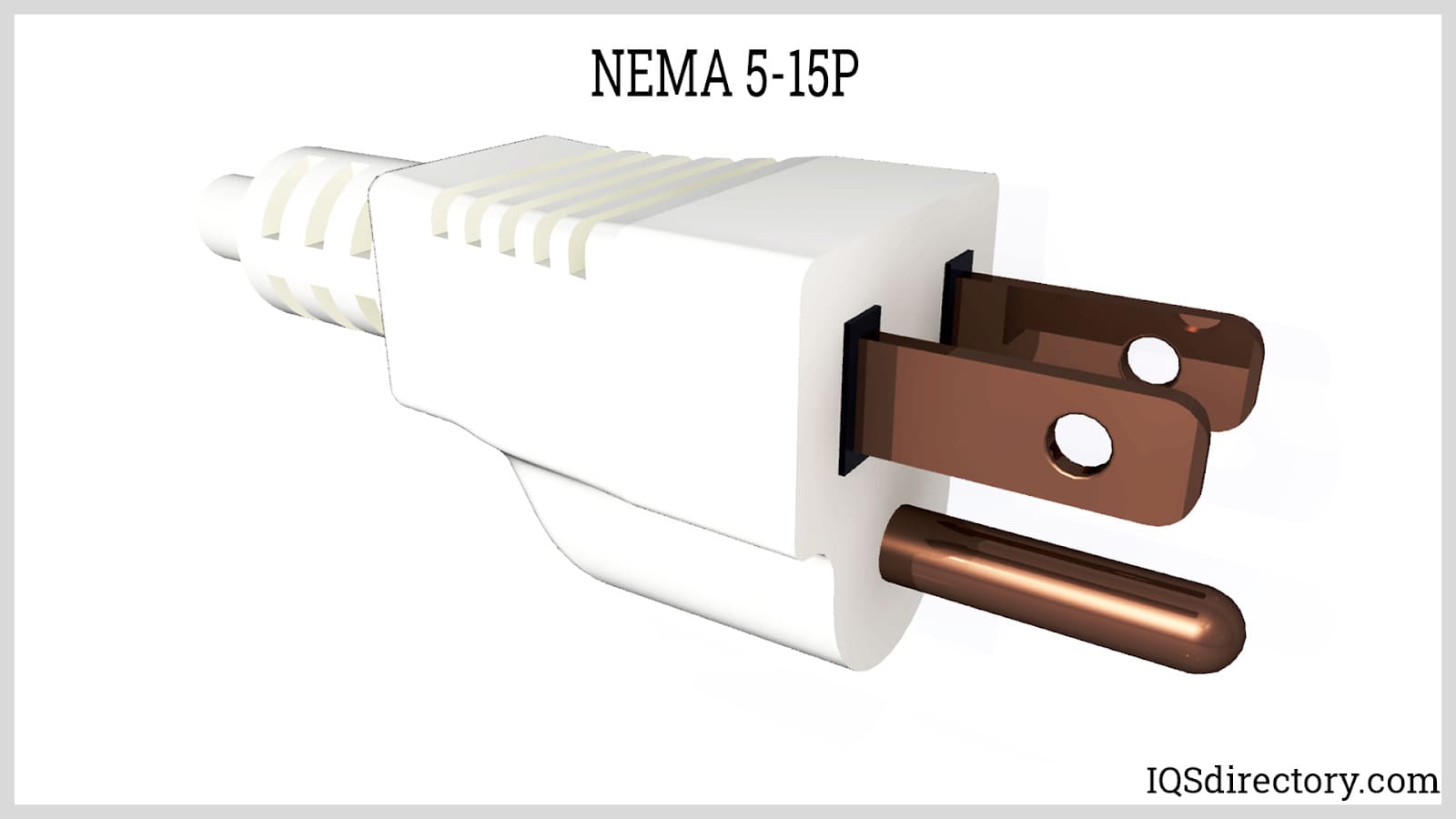

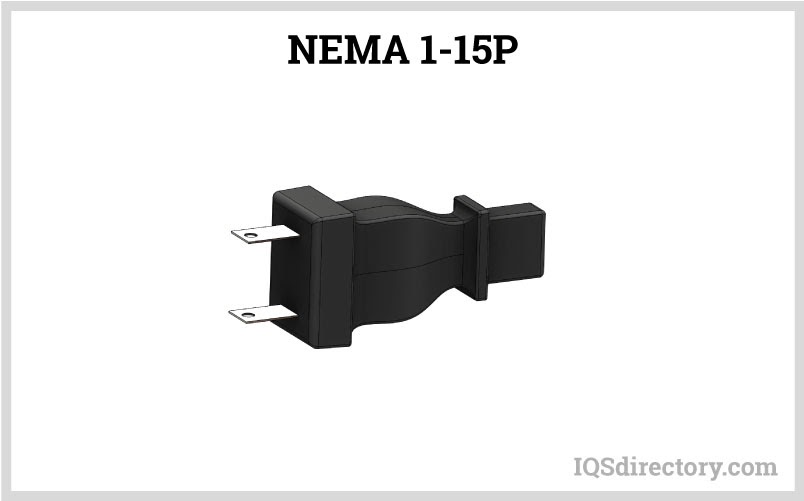

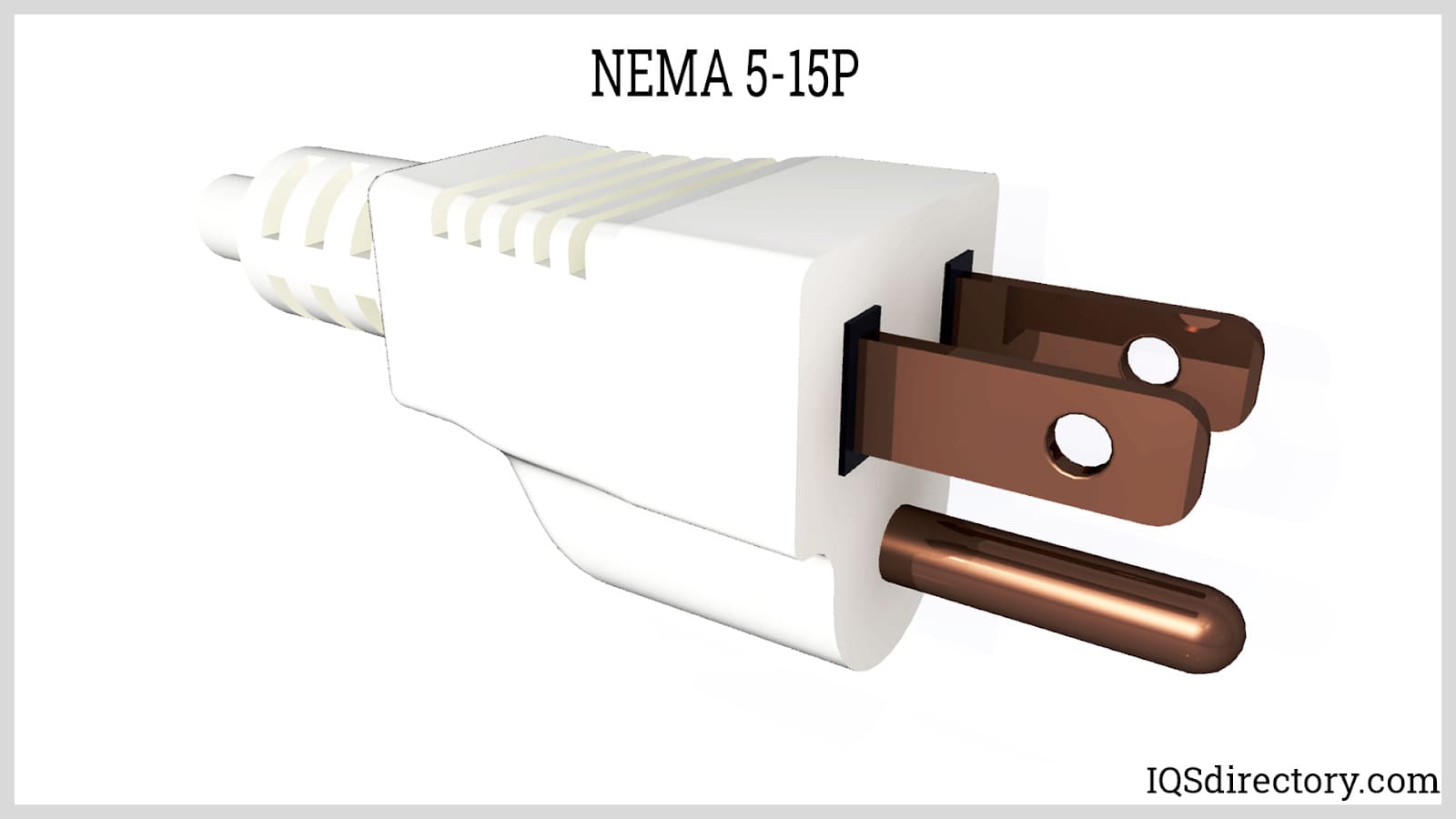

Electrical plugs and receptacles in the United States are manufactured according to strict quality and safety standards governed by the National Electrical Manufacturers Association (NEMA). Adhering to NEMA standards is critical for ensuring electrical compatibility, reliability, and proper grounding in residential, commercial, and industrial environments. The two most common NEMA connectors are NEMA 1-15P and NEMA 5-15P. These feature molded rubber housing and prongs constructed of steel or brass with protective coatings of zinc, tin, or nickel for enhanced conductivity and corrosion resistance. In addition to these, there are numerous other types of NEMA power plugs and receptacles, each designed for different voltage, amperage, and application requirements.

Connectors are categorized into locking and non-locking types to suit specific electrical needs. Locking connectors are engineered with curved prongs that twist and lock into place, providing a secure connection ideal for heavy-duty, high-vibration, or industrial uses to prevent accidental disconnection or displacement. Non-locking connectors, distinguished by their straight blade design, are widely used for computers, office equipment, small appliances, and other everyday electrical applications. Understanding the proper type of NEMA connector is essential when selecting wiring devices for safe and consistent power distribution.

This chapter provides a comprehensive overview of the most common and important NEMA plug and receptacle types found in both residential and industrial environments, with a focus on their electrical ratings, safety features, and distinct applications.

Among non-locking electrical connectors, NEMA 1 and NEMA 5 are by far the most widely used types in North America. NEMA 1 is a two-blade plug without a ground, recommended for low-power, non-critical appliances, while NEMA 5 incorporates two blades with a dedicated grounding pin, enhancing user safety and meeting current National Electrical Code (NEC) regulations. Due to increased emphasis on electrical safety and proper grounding, most new construction projects require installation of NEMA 5 receptacles, contributing to the gradual replacement and phase-out of the older NEMA 1 series.

The NEMA plug and receptacle standardization system uses the first number to indicate the plug or receptacle configuration, specifying the number of poles, wires, and intended voltage. Grounded and non-grounded options exist, including two-pole three-wire or four-pole five-wire grounding designs. Non-grounded variants simply match the wire count to the number of poles as no ground wire is necessary. Each connector then adds a number for ampacity, followed by "P" (plug) or "R" (receptacle)—for example, a NEMA 5-15R is a 125V, two-pole, three-wire receptacle rated for 15 amps, commonly found in household wall outlets.

A standard installation practice positions the ground pin upward in wall outlets. This layout helps prevent metal objects from contacting the live line, minimizes the risk of short circuits, and protects users and electronics from electrical shock hazards. Complying with NEMA code is crucial for safe, efficient energy delivery, particularly in environments where electrical disturbances must be minimized.

NEMA 1 plugs are defined by a classic two flat prong design, offering a two-pole, two-wire, non-grounded configuration with a 125 V rating. They are mostly used for lamps, chargers, and other low-power devices, but due to a lack of grounding, usage is declining in favor of grounded plug types. Depicted below is the most prevalent NEMA 1-15 P type.

The NEMA 2 series is obsolete and no longer produced. It was a two-wire, 250V plug and receptacle system used in limited, historic applications.

NEMA 3 is a planned series designed for high-voltage applications with a two-wire, ungrounded design rated at 277 V, addressing certain commercial lighting requirements.

The NEMA 4 series, an upcoming type, targets higher capacity needs, offering a 600 V rating with two-wire, ungrounded configurations, primarily for future industrial usage.

NEMA 5 connectors feature two poles, three wires, and a distinctive grounding pin alongside two flat blades (one wider for polarity). Typical voltage is 125V, with amp ratings that include NEMA 5-15, NEMA 5-20, and NEMA 5-30. These are the current default for residential wall receptacles and extension cords, supporting most small and medium appliances.

NEMA 6 connectors are designed for higher voltage (208 or 240 V) and heavy-duty applications, particularly in commercial and industrial settings. With three-wire grounding and various configurations, they are optimal for powering large equipment, including HVAC units, air compressors, and certain kitchen appliances, providing robust performance and high reliability.

NEMA 7 connectors offer a two-pole, grounded design rated for 277 V, typically serving single-phase fluorescent lighting and specialized building circuits. They feature angled current-carrying pins and a U-shaped ground for added safety.

NEMA 8 is a proposed, high-voltage connector rated for 480 V, with three wires and two poles along with grounding, suiting it for specialized industrial equipment.

NEMA 9 is designed similarly to NEMA 8 but is rated at 600 V, meeting the requirements for even more demanding electrical systems.

NEMA 10 connectors, now obsolete, were traditionally installed for dryers and ranges, but have since been replaced by grounded alternatives like NEMA 14-30 and NEMA 14-50 to comply with modern electrical codes.

NEMA 11 connectors accommodate three-phase, 250 V loads with three-pole, three-wire, and ungrounded setups, available in 20, 30, and 50 amp capacities for legacy industrial equipment.

NEMA 12 is an upcoming connector designed for three-phase, 480 V, three-wire, three-pole, ungrounded configurations, expected to address emerging industrial applications.

NEMA 13 shares a configuration with NEMA 12 but is engineered for even higher voltage at 600 V, targeting future heavy-industrial needs.

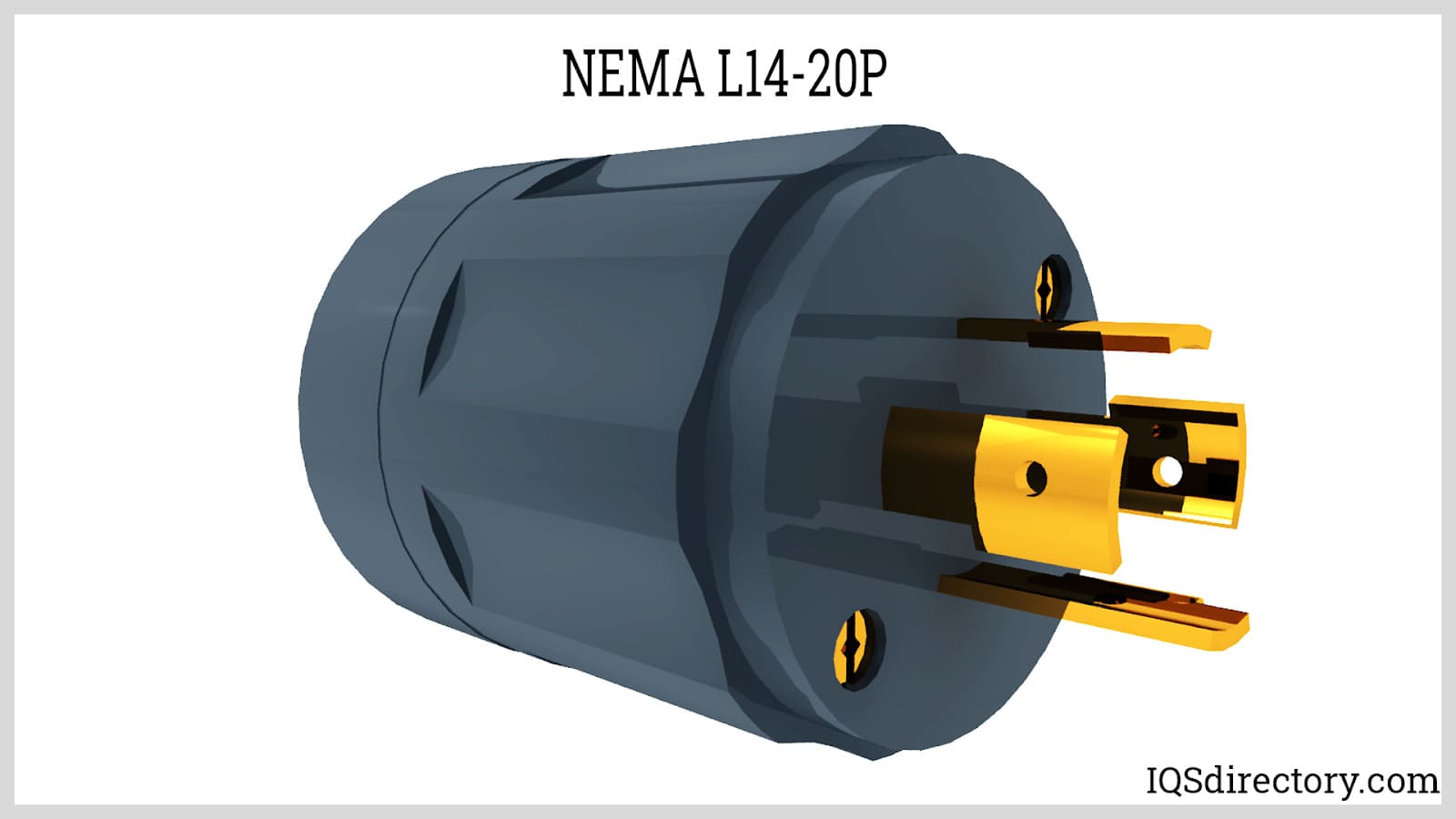

NEMA 14 is a four-wire, grounded outlet design with amp ratings from 15 to 60 A and is commonly used for electric vehicle charging (EVSE), electric ovens, and ranges. Its inclusion of a separate ground and neutral makes these plugs suitable for both 240 V and split phase circuits.

NEMA 15 is similar in application to NEMA 14 but designed for three-phase power without a neutral line, enabling robust support of large-scale machinery.

NEMA 16, not yet widely available, will feature a four-wire, three-pole, grounded, three-phase design with a 480 V rating optimized for upcoming high-demand installations.

NEMA 17 mirrors the NEMA 16 but supports a higher voltage at 600 V for greater industrial utility.

NEMA 18 is a specialized alternative to NEMA 14 and 15, delivering a 120Y208V, three-phase, ungrounded configuration for tailored commercial electrical needs.

NEMA 19, a forthcoming type, is rated for 277/480Y V and offers a four-wire, three-pole, ungrounded design, targeting advanced electrical distribution systems.

NEMA 20 is similar to NEMA 19 but increases voltage handling to 247/600Y, providing additional flexibility for evolving infrastructure requirements.

NEMA 21 is a planned connector offering a 120/208Y, five-wire, three-pole configuration with neutral and grounding, suited for complex power distribution networks in commercial settings.

NEMA 22 is comparable to NEMA 21, specifically designed for 277/480Y system implementations.

NEMA 23 is equivalent in function to NEMA 22, supporting 277/480Y voltage levels for expanded application scenarios.

NEMA 24 connectors are two-pole, grounded outlets with a 347 V rating, and are used primarily in Canadian power systems.

The NEMA TT-30 plug, commonly called the "travel trailer plug," is engineered for recreational vehicles and campgrounds. Providing 120 V and 30 A of power, it reliably supports RV air conditioning, microwaves, and other demanding appliances. Its unique plug configuration prevents misconnection with standard residential or commercial receptacles, ensuring safety for users and equipment.

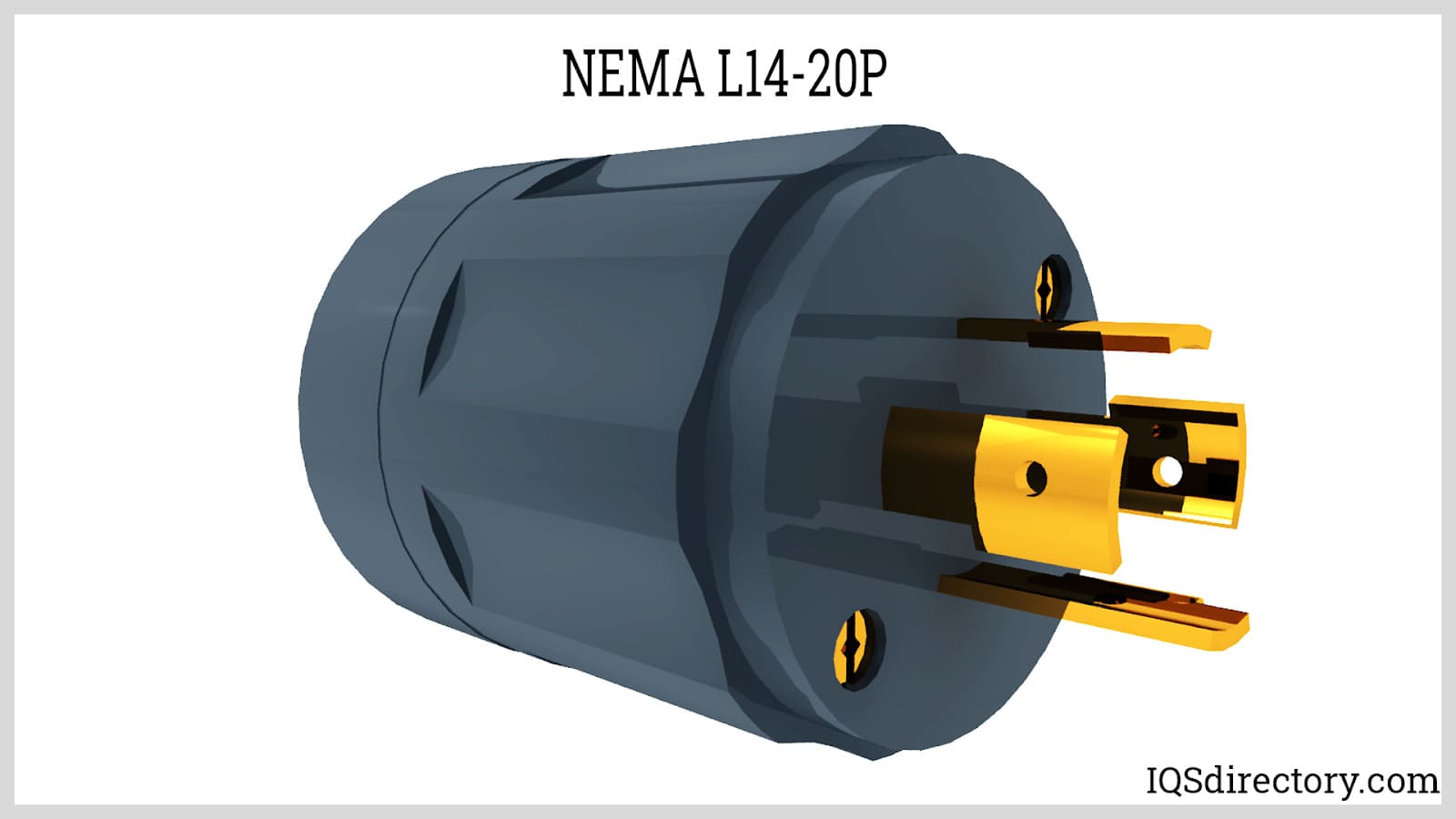

Locking connectors, also known as Twist-Lock® plugs and receptacles, provide a secure, vibration-resistant connection for mission-critical electrical circuits. Their distinctive curved blades allow users to insert the plug and twist it into the locking position, preventing the accidental unplugging common with standard straight-blade (non-locking) connectors. Locking plugs are essential for commercial construction, stage lighting, industrial machinery, portable generators, and environments with frequent movement or heavy equipment vibration.

Most locking connectors are designed to handle high amperage and ensure stable power delivery in demanding applications. Midget locking connectors—marked “ML”—are available where compact connection is necessary, offering easy installation in confined panel spaces. Midget locking plugs come in varieties including:

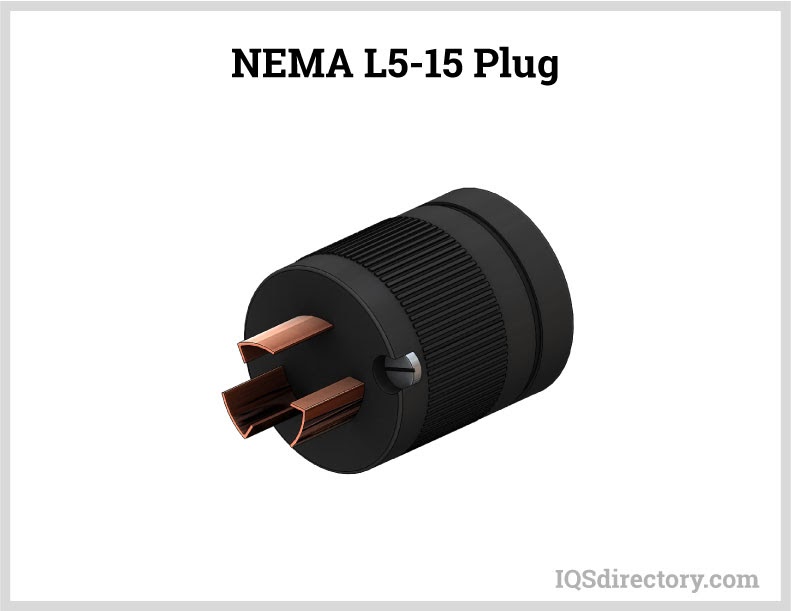

Locking connector types are indicated by an “L” before the series number, such as NEMA L5, NEMA L6, or NEMA L14. Understanding locking plug designations helps professionals properly match receptacles within power distribution systems and select the right connector for environmental and load requirements.

NEMA L1 connectors supply a single-pole plus neutral, two-wire, ungrounded connection for 125 V single-phase circuits, rated up to 15 amps. Their use is limited to specialized or legacy equipment.

NEMA L2 connectors deliver a two-pole, two-wire ungrounded circuit rated at 250 V for 20 amp single-phase applications in select industrial settings.

Neither NEMA L3 nor NEMA L4 was developed or standardized; these series have no commercial implementation.

NEMA L5 connectors are two-pole, grounded types rated for 125 V, with common applications ranging from marine shore power and campsites to RV parks. They provide secure, reliable connections for outdoor and wet locations.

The NEMA L6 series is rated for 250 V and features a robust two-pole, three-wire grounded design, supporting loads from 208 to 240 V without a neutral. These twist-lock connectors are standard in data centers, industrial control cabinets, servers, uninterruptible power supplies (UPS), and high-powered IT equipment.

NEMA L7 plugs are grounded, two-pole twist-lock connectors rated for 277 V, regularly installed in commercial lighting and select industrial machinery circuits where stability is critical.

NEMA L8 provides a two-pole, grounded, three-wire solution rated for 480 V, serving specialty industrial and HVAC power requirements.

NEMA L9 resembles NEMA L8 but with a 600 V voltage rating, suited for intense industrial electrical loads.

NEMA L10 connects two-pole plus neutral, three-wire, ungrounded, single-phase systems at 125/250 V, but this older series is now deprecated in favor of grounded alternatives.

NEMA L11 equips three-pole, three-wire, ungrounded, 250 V, three-phase circuits, available in 15, 20, and 30 amp power levels for heavier industrial equipment.

NEMA L12 offers a configuration matching the L11 but supports 480 V, enabling advanced three-phase system integration.

NEMA L13 supplies three-pole, three-wire, ungrounded connectivity at a 600 V rating for severe power loads in rugged environments.

NEMA L14 connectors combine three-pole, grounded construction with a 125/250 V, four-wire capability, bringing together two hot wires, a neutral, and ground. Common applications include generator transfer switches, amplifier racks, and heavy-duty portable equipment requiring versatile power. They are especially valued for powering residential backup power units safely.

NEMA L15 is a 250 V, 30 A locking connector with four prongs and a unified grounding system, offering water-resistant and polarized options. These are essential in environments where safety and electrical code compliance are paramount.

NEMA L16 provides three-pole, grounded, locking capability for 480 V, supporting robust three-phase circuits for high-demand machinery.

NEMA L17 replicates the L16 configuration but with a 600 V rating, accommodating the highest industrial voltage requirements.

NEMA L18 connectors are four-pole, ungrounded units for 120/208 V, three-phase, four-wire installations—ideal in specialized commercial settings.

NEMA L19 delivers three-pole, four-wire, ungrounded terminations suitable for three-phase 277/480 V applications, in either 20 or 30 amp versions.

NEMA L20 mirrors the L19 design but is rated for even higher voltage at 347/600 V, for advanced industrial and utility power distribution.

NEMA L21 locking connectors feature four poles and a ground, rated for 120/208 V three-phase wye circuits. They are specifically built to maintain secure connections in dusty, damp, and wet environments, featuring industry-leading watertight seals—ideal for outdoor power distribution panels, entertainment venues, and commercial construction.

NEMA L22 features four poles and a ground, rated for 277/480 V, three-phase, four-wire circuits. The unique pin configuration includes a center ground and a right-angle neutral pin, supporting complex, balanced loads.

NEMA L23 is comparable in layout to L22, but enhanced for 347/600 V, serving large commercial power distribution panels or industrial automation equipment.

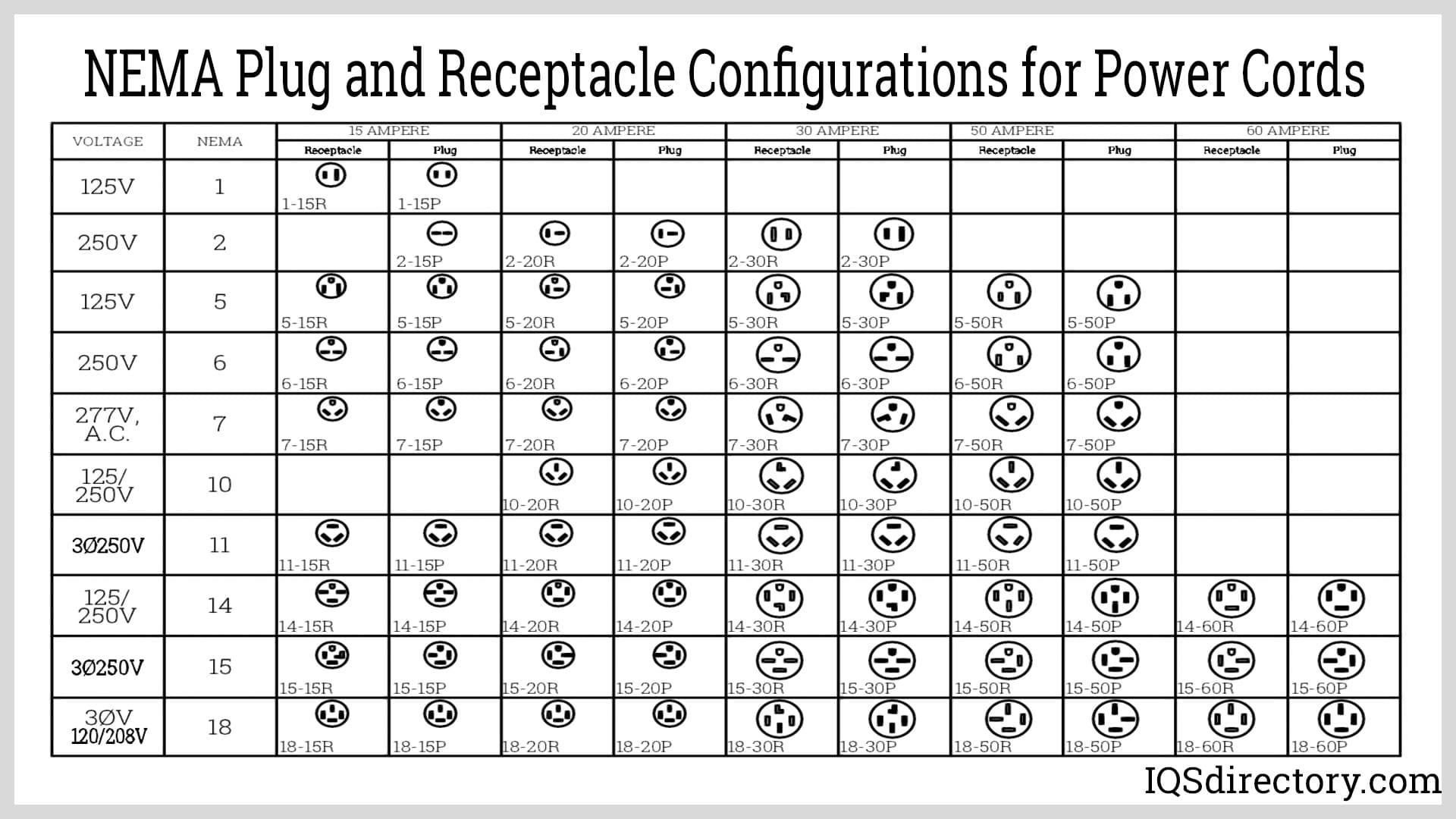

The chart below provides a visual summary of the many NEMA plug and receptacle configurations for quick reference and selection guidance.

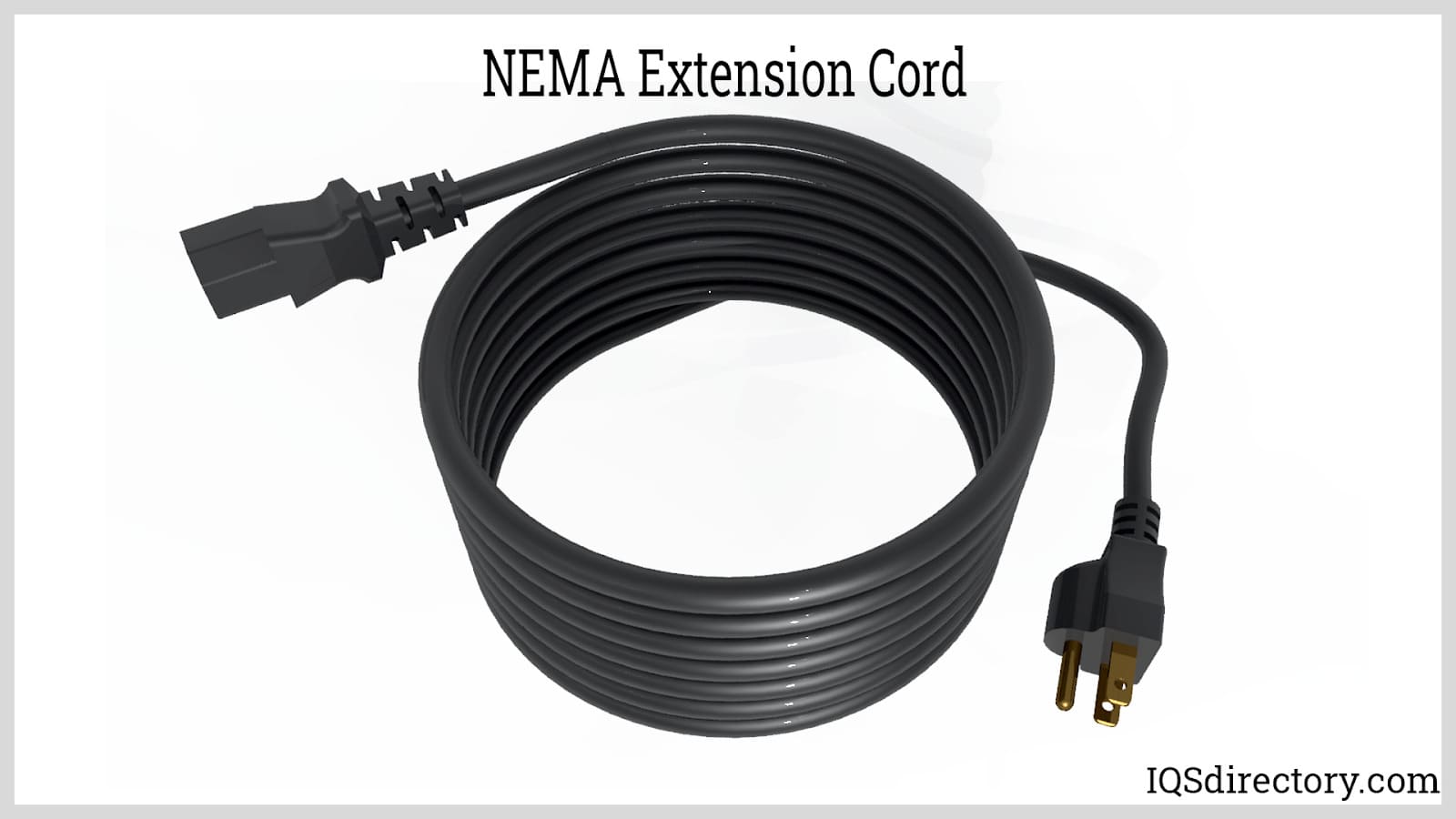

Power cords are a vital component in any electrical wiring system, playing an essential role in safely transmitting current from a main power source to the end device. NEMA power cords are specifically designed and rated for compatibility with NEMA plugs, receptacles, and unique application requirements across industry verticals including information technology, healthcare, manufacturing, and consumer electronics.

Each power cord is constructed with copper wiring housed in an insulating sheath and an outer non-conductive protective jacket. The full power cord assembly typically includes a plug for connecting to the power source, a socket for device connection, and durable, flexible cordage. Some power cord sets, especially in industrial or healthcare environments, incorporate integrated locking mechanisms to minimize accidental disconnections during critical operations.

Key technical considerations for choosing the right NEMA-rated power cord include voltage (or kilovolt) rating, amperage (amp) rating, American Wire Gauge (AWG), cord length, and intended use environment. Voltage rating specifies the cord’s safe operational limits, while ampacity is determined by the thickness of internal conductors, number of current-carrying wires, and total cord length. Safety and energy efficiency are impacted by both amp rating and wire gauge, so it's critical to consult NEMA standards or a qualified electrical engineer for selection.

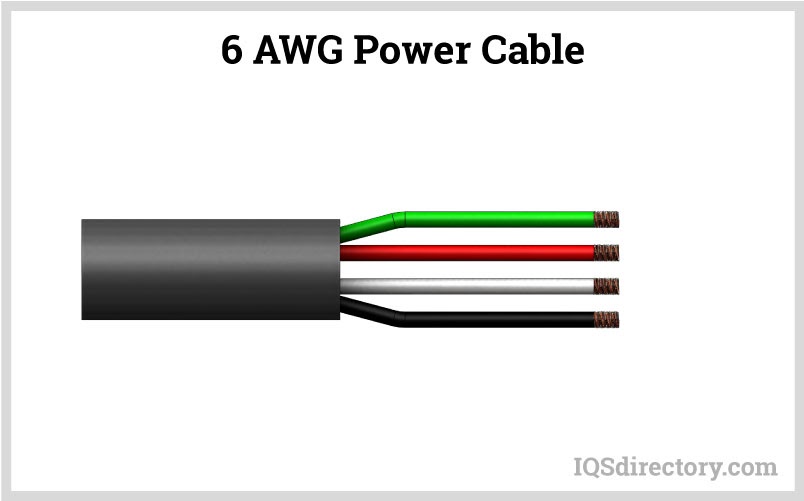

Wire gauge is measured by the American Wire Gauge (AWG) system, where a lower AWG number signifies a thicker conductor capable of greater current flow and reduced voltage drop. For example, a 12 AWG wire is standard for 120-volt residential or light commercial circuits, whereas heavier duty connections—such as for air conditioners or industrial equipment—may require 10 AWG or lower. Specialized cords, such as a 6 AWG cable with 4 conductors and ground, are rated for up to 45 amps, making them suitable for high-wattage devices like arc welders or large EV chargers.

The image below demonstrates a 6 AWG cable construction, featuring heavy-duty insulation and multi-stranded copper conductors with grounding for safety.

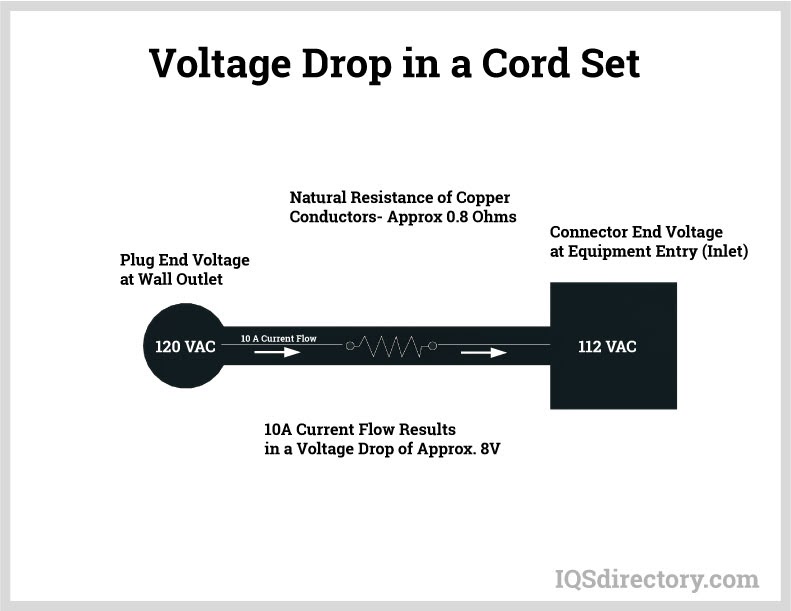

As power cord length increases, so does voltage drop—a phenomenon where electrical current weakens due to resistance over extended cable runs. For cords exceeding 50 feet, upgrading to a larger (lower AWG) wire is generally recommended to maintain efficiency and prevent hazardous heat buildup. Adhering to NEC and NEMA guidelines, and referencing manufacturer charts, is necessary to properly match power cord length, gauge, and load to avoid damage or fire risk associated with excessive voltage drop and overheating.

Voltage drop and power loss generate heat. Excessive heat can compromise wire insulation, degrade performance, and present a fire hazard. The chart below shows how power drop can occur in a 100-foot cord set, highlighting the need to select the appropriate NEMA cord set or extension cord to suit your application.

When evaluating or purchasing power cords, extension cords, or NEMA-compatible cord sets, consider not just electrical ratings, but also environmental factors (wet/dry locations), end-use application (medical, data center, construction, home appliance, vehicle charging), certification requirements (UL, CSA, ISO), and compliance with local and international electrical codes. Consulting with expert manufacturers or suppliers can help streamline the selection process and ensure reliable, code-compliant power connections for your project.

Electrical enclosures, also known as electrical cabinets, control panels, or junction boxes, are critical components used to house and shield sensitive electrical equipment, such as circuit breakers, switches, PLCs, and transformers. These enclosures are engineered from durable materials like plastic, steel, stainless steel, or aluminum, and receive standardized ratings to define their resilience against hazards, harsh environments, and foreign contaminants. In addition to safeguarding against tampering, impact, or accidental electrical shock, properly rated enclosures minimize risks related to fire and moisture and provide effective barriers against electromagnetic interference (EMI) and radio frequency interference (RFI). As a result, selecting the right NEMA enclosure is essential for compliance, equipment reliability, and workplace safety in electrical installations across manufacturing, utilities, commercial buildings, and industrial automation facilities.

The National Electrical Manufacturers Association (NEMA) classifies enclosures by assigning specific "NEMA ratings"—codes that detail the level of environmental protection each enclosure type offers. There are thirteen NEMA enclosure types, each rated for different usage conditions such as dust, water, ice, corrosion resistance, and hazardous locations. This precise classification allows engineers, facility managers, and buyers to select enclosures that meet their operational and regulatory requirements. Understanding the core characteristics of these NEMA types is critical for making informed decisions when specifying or purchasing enclosures for challenging environments or specialized applications. Here are six of the most common NEMA enclosure types used in commercial and industrial sectors:

| NEMA Enclosure Types | |

|---|---|

| Rating | Protects against |

| NEMA1 | General Purpose Indoor, prevents accidental contact of personnel with the enclosed equipment |

| NEMA 3R | Windblown dust, vertical rain, severe external corrosion |

| NEMA 4 | dust, watertight, splashing rain, hose directed water, severe external condensation |

| NEMA 4X | dust, rain, splashing rain, hose directed water, ice, corrosion resistant |

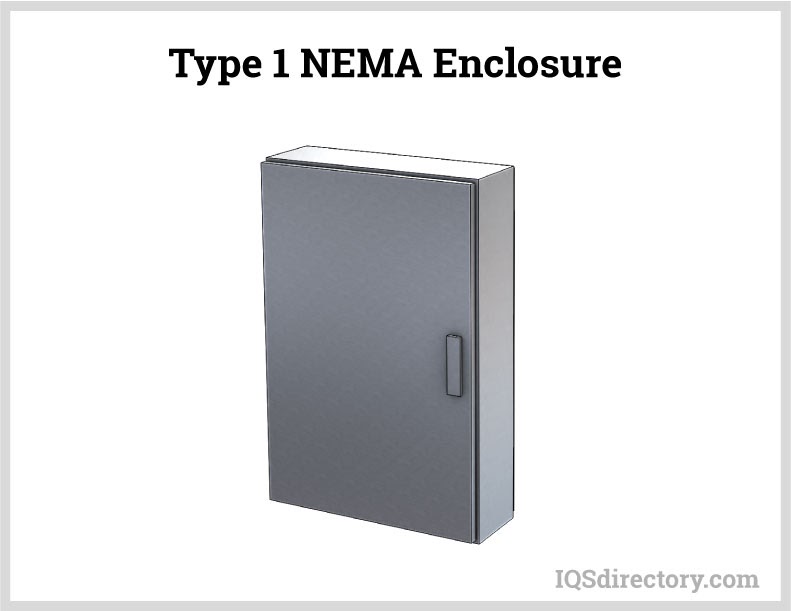

A Type 1 enclosure is a general-purpose indoor enclosure designed to protect against dirt, dust, and accidental contact with people or tools. These enclosures are widely used in institutional, office, and basic factory environments to safeguard control panels, wiring junctions, and electrical switchgear from ingress of solid foreign objects and unauthorized access. They are not suitable for wet or outdoor conditions.

Type 3R enclosures are engineered for outdoor applications, delivering protection against rain, sleet, snow, and ice formation. Crafted from galvanized steel or weather-resistant metals, 3R enclosures excel as meter cabinets, filtered fan housings, utility boxes, and outdoor power distribution panels. Their sloped roofs and effective drainage features ensure superior water resistance, making them ideal for utility, telecom, and renewable energy installations exposed to challenging weather.

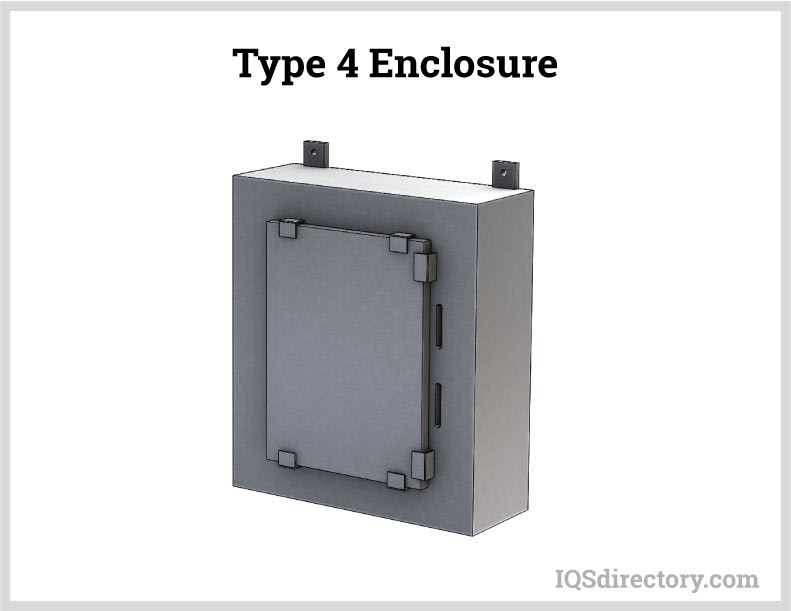

A Type 4 enclosure is specifically designed for both indoor and outdoor environments where complete protection against accidental contact, airborne dust, rain, sleet, snow, splashing water, hose-directed water, and extreme weather is required. Enhanced with gasketed, clamp-down doors on multiple sides, these watertight enclosures are favored in automation, wastewater, and food processing applications requiring resilience to periodic washdowns or harsh cleaning protocols. Type 4 units are routinely chosen for wiring enclosures, hydraulic and pneumatic controls, and heavy-duty operator stations exposed to demanding conditions.

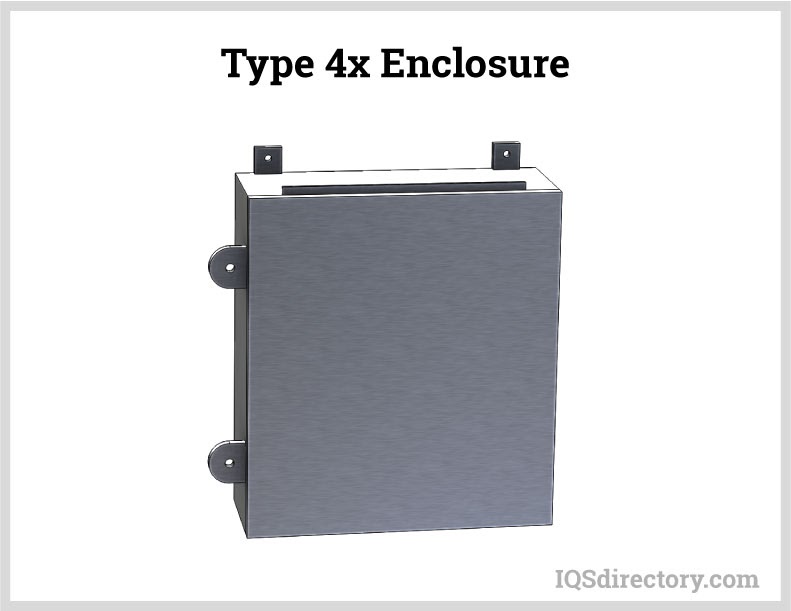

Type 4X enclosures extend Type 4 protection standards by offering additional defense against corrosion, rust, and chemical exposure—features essential for applications in marine settings, pulp and paper manufacturing, dairy and food production, chemical processing, pharmaceutical processing, oil and gas drilling, and water and wastewater treatment plants. These stainless steel or nonmetallic enclosures resist aggressive environments, high-pressure cleaning, saltwater spray, and cleaning agents, thereby ensuring equipment longevity and regulatory compliance in highly corrosive or sanitary environments.

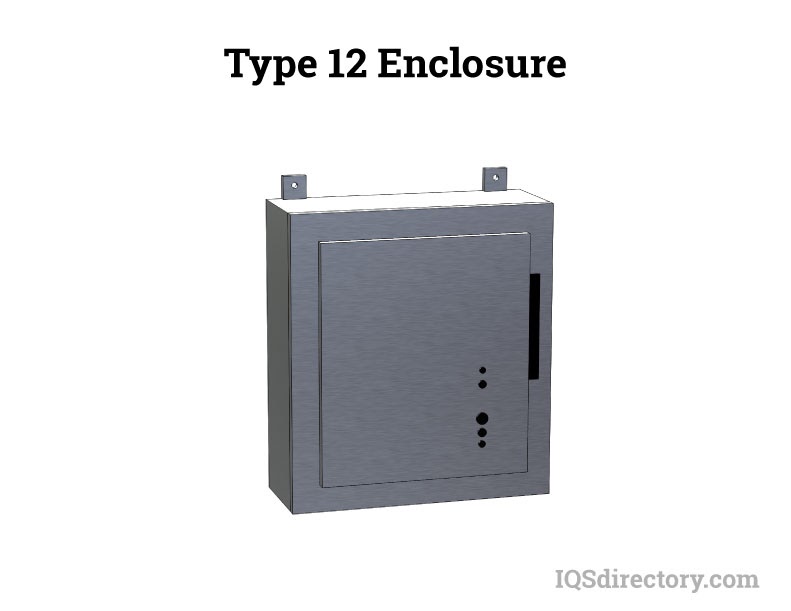

Type 12 enclosures can be either wall-mounted or freestanding and are constructed with 14-gauge steel and reinforced welded seams to prevent entry of dust, dirt, lint, and dripping liquids. These enclosures are non-corrosive and specially designed for indoor industrial environments like CNC machinery rooms, manufacturing floors, and control circuits where airborne particulates and light splashing are a concern. Optional knockouts offer installation flexibility to accommodate cables and conduit, ensuring a secure fit for sensitive control systems, relays, and power distribution equipment.

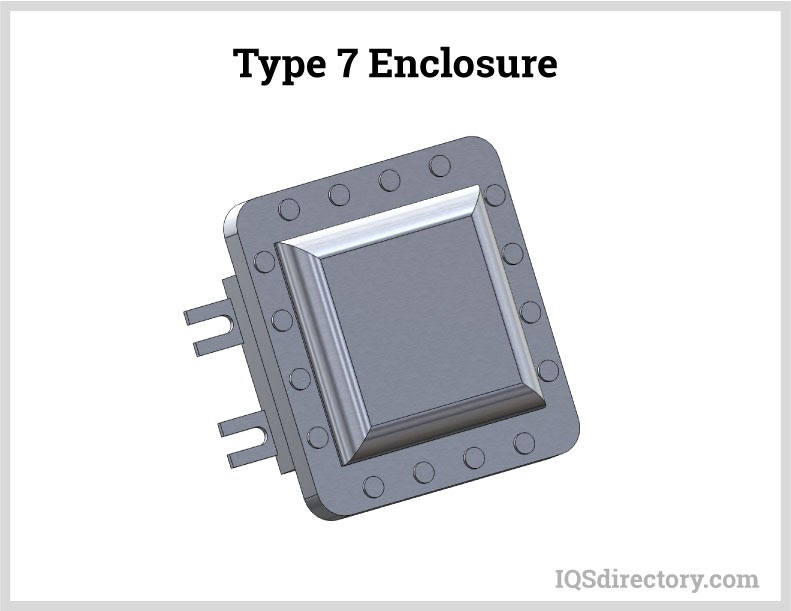

Type 7 enclosures are rigorously engineered for hazardous locations classified by the National Electrical Code (NEC) Articles 500 to 506, particularly for environments with elevated risks of fire or explosion due to the presence of flammable gases and vapors. Often described as explosion-proof or flame-proof, these indoor enclosures are built for Class I, Groups A, B, C, and D areas—including paint spray booths, refining operations, petrochemical processing, and other high-risk zones. Their robust construction contains internal explosions without allowing flames or hot gases to escape, ensuring worker safety and regulatory compliance with OSHA and NEC standards.

When specifying or selecting a NEMA enclosure, it’s crucial to consider the operational environment, exposure to environmental hazards, and installation location (indoor vs. outdoor). Key factors include the presence of dust, water, oil, chemicals, corrosion agents, and the potential for mechanical impact or unauthorized access. For industrial automation, process control, and electrical distribution systems, matching the enclosure’s NEMA rating to your site’s conditions optimizes uptime and reduces the risk of equipment failure or safety incidents. Evaluate options based on thermal management (cooling or venting requirements), ease of maintenance, compatibility with cable and conduit entries, and certifications for hazardous or sanitary zones. Manufacturers often provide tech specs, custom fabrication, and value-added accessories such as climate control, viewing windows, and lockable doors to meet specific project needs.

When evaluating the protection of electrical components, fixtures, or enclosures, understanding ingress protection (IP) ratings is essential for ensuring equipment performance and safety. The International Protection (or IP) code system measures the effectiveness of enclosures against the intrusion of solids (like dust and tools) and liquids (such as rain or jetting water). Many electrical enclosures feature both a NEMA rating and an IP rating due to industry overlap, particularly for applications involving international standards, industrial control panels, and export equipment.

Although their rating scales differ, both NEMA and IP classifications offer guidance on enclosure quality and the anticipated protection provided against environmental conditions. Below is a simplified overview of IP classifications to aid in comparison and specification:

| Ingress Protection Classification | |||

|---|---|---|---|

| First Number | Second Number | ||

| IP | Protection Provided | IP | Protection Provided |

| 0 | No Protection | 0 | No Protection |

| 1 | Protected against solid objects up to 50mm e.g. accidental touch by hands | 1 | Protected against vertically falling drops of water e.g. condensation |

| 2 | Protected against solid objects up to 12mm e.g. fingers | 2 | Protected against direct sprays of water up to 15 degrees from the vertical |

| 3 | Protected against solid objects up to 2.5mm e.g. fingers | 3 | Protected against direct sprays of water up to 60 degrees from the vertical |

| 4 | Protected against solid objects up to 1mm e.g. fingers | 4 | Protected against water sprayed from all directions - limit ingress permitted |

| 5 | Protected against dust - limit ingress (no harmful deposit) | 5 | Protected against low pressure jets of water from all directions - limited ingress permitted |

| 6 | Totally protected against dust | 6 | Protected against strong jets of water e.g. for use on ship decks - limited ingress permitted |

| 7 | Protected against the affects of immersion between 15cm and 1m | ||

| 8 | Protected against long periods of immersion under pressure | ||

NEMA connectors are electrical plugs and receptacles standardized for safe, reliable power connections. They prevent accidental interchangeability and ensure compatibility, making them critical for compliance in residential, commercial, and industrial applications.

Locking NEMA connectors have curved prongs that twist to secure the plug, preventing accidental disconnects in high-vibration or industrial settings. Non-locking types use straight blades and are common for household electronics and general appliances.

Selecting a NEMA power cord depends on voltage and amperage ratings, American Wire Gauge (AWG), cord length, environment, and certification requirements. Using the correct gauge for the cord’s length and load minimizes voltage drop and improves safety.

NEMA enclosures house and protect electrical equipment. Their ratings, such as NEMA 1, 3R, 4, and 4X, specify protection levels against hazards like dust, water, corrosion, or explosion risks, ensuring safety and compliance with operational requirements.

Yes, NEMA 24 connectors are two-pole, grounded outlets rated for 347 volts, primarily used in Canadian power systems.

A lower AWG number means a thicker conductor, which carries more current and reduces voltage drop. Correct gauge selection is vital to avoid overheating and ensure efficiency, especially for long or high-load cords.

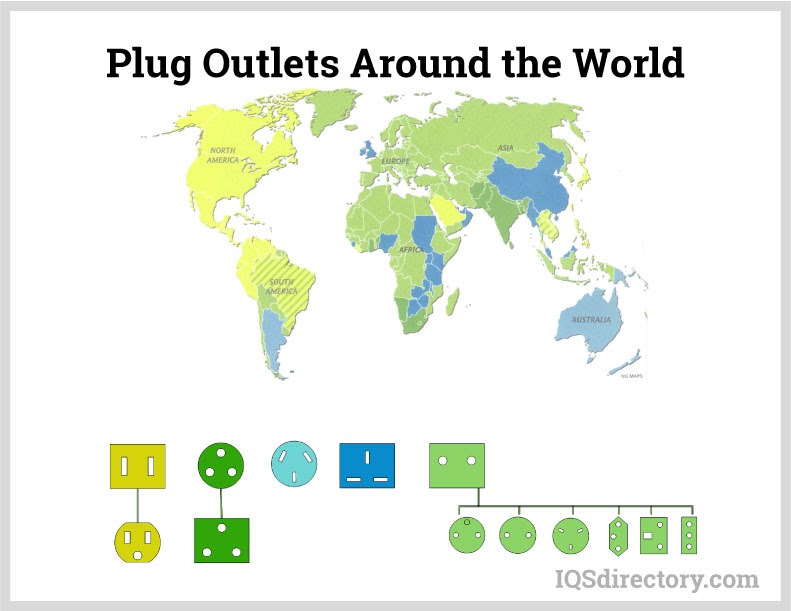

The United States, as outlined by NEMA standards, offers a diverse range of plugs and sockets to meet the needs of appliances, machinery, heavy-duty equipment, and unique electrical requirements. This variety suggests that there are ample options available to accommodate the needs of other countries as well.

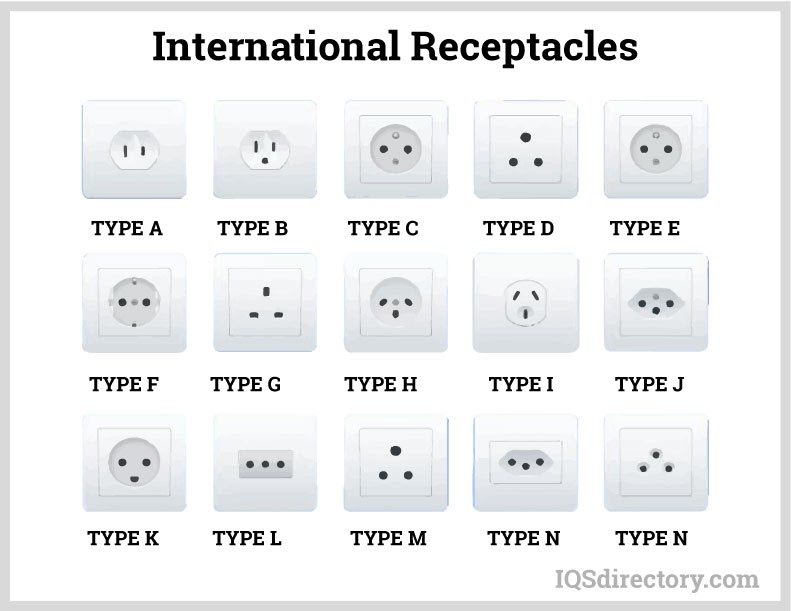

Despite the numerous plugs and receptacles in North America, many different types exist globally, each with varying voltage and amp requirements. To simplify this, the U.S. Department of Commerce International Trade Administration has assigned letters from A to O to different connector types, as shown on the map below.

As international travel increases and reliance on electronic devices grows, manufacturers have created adapters to meet the needs of various countries. While standardization would simplify things, it’s unlikely to happen in the near future.

The first two types of international plugs, A and B, are commonly used in the United States, Canada, Mexico, and Japan. These are the plugs and receptacles we encounter daily. However, as shown in the diagrams, plugs and receptacles in other countries differ significantly from what we are used to.

The United States, Canada, Mexico, and Japan use two-pin, ungrounded configurations.

The United States, Canada, Mexico, and Japan – three-pin configuration with grounding.

Europe, South America, and Asia – features two pins and is ungrounded.

India – features three pins with grounding.

France, Belgium, Poland, Slovakia, and Czechia – two-pin and grounded.

Europe and Russia, excluding the United Kingdom and Ireland – two-pin, grounded plugs.

The United Kingdom, Ireland, Malta, Malaysia, and Singapore use a three-pin, grounded configuration.

Israel, the West Bank, and the Gaza Strip – three-pin and grounded

Australia, New Zealand, China, and Argentina – options include two-pin ungrounded or three-pin grounded configurations.

Switzerland & Liechtenstein – features three pins with a grounded design.

Denmark & Greenland – three-pin configuration with grounding.

Italy & Chile – three-pin configuration with grounding.

South Africa – three-pin, grounded configuration

Brazil and South Africa – three-pin configuration with grounding.

Thailand – three pins and grounded

Here is the international plug chart from Webber Electronics, located in North Ridge, OH.

As electronics began to advance in the early 20th century, manufacturers recognized the need for standardized safety and uniformity in electrical components. In response, the International Electrotechnical Commission (IEC) was established in 1906 as a non-profit, non-governmental organization to develop standards for electrotechnical devices.

In 1926, the Electric Power Club and the Associated Manufacturers of Electrical Supplies merged to create the National Electrical Manufacturers Association (NEMA), aiming to standardize electrical equipment for consumer safety. NEMA now sets standards specifically for North America.

The IEC, an international organization with over 80 member countries including the United States, develops standards through the expertise of thousands of electrical and electronics professionals. IEC standards are numbered from 60000 to 79999, such as IEC 60548. Below is a selection of some IEC standards.

Below are examples of NEMA standards. Each code is prefixed with letters such as EWS, MG, or ICS, representing water service (EWS), motors and generators (MG), and industrial control systems (ICS). Other letter combinations specify the particular applications for each code.

Although the IEC and NEMA have similar goals, they differ in several key aspects. Here are some of the main differences.

NEMA simplifies selection by focusing on horsepower and voltage. In contrast, IEC standards demand more detailed specifications.

NEMA products offer broader applications, while IEC products are smaller, more affordable, and designed for specific operating conditions.

NEMA products come fully assembled, whereas IEC products feature a modular design.

NEMA products feature an open design and require safety covers, while IEC contactors are designed to be finger-safe.

NEMA does not certify products directly but collaborates with the National Institute of Standards and Technology (NIST) and ASTM International. In contrast, IEC partners with certifying organizations like the System for Conformity Testing and Certification of Electrotechnical Equipment and Components (IECEE) and the International Organization for Standardization (ISO).

Using IEC and NEMA guidelines offers various benefits based on your specific needs. The chart below outlines some of the key differences between them.

| IEC vs. NEMA | |

|---|---|

| IEC vs. NEMA: Pros and Cons | |

| Less expensive | Less expensive |

| Less versatile (Designed to meet life/current requirements in specific applications) | More versatile (Rating are broad and apply to many different applications) |

| More compact device | Large sized device |

| Caters to global market | Specific to North American market |

| Reacts faster to overloads | Better at withstanding short circuits |

| Finger safe | Requires safety covers |

Common NEMA connectors are often overlooked but play a crucial role in specialized applications. These connectors are designed to offer enhanced protection and safety, ensuring reliable performance in various settings.

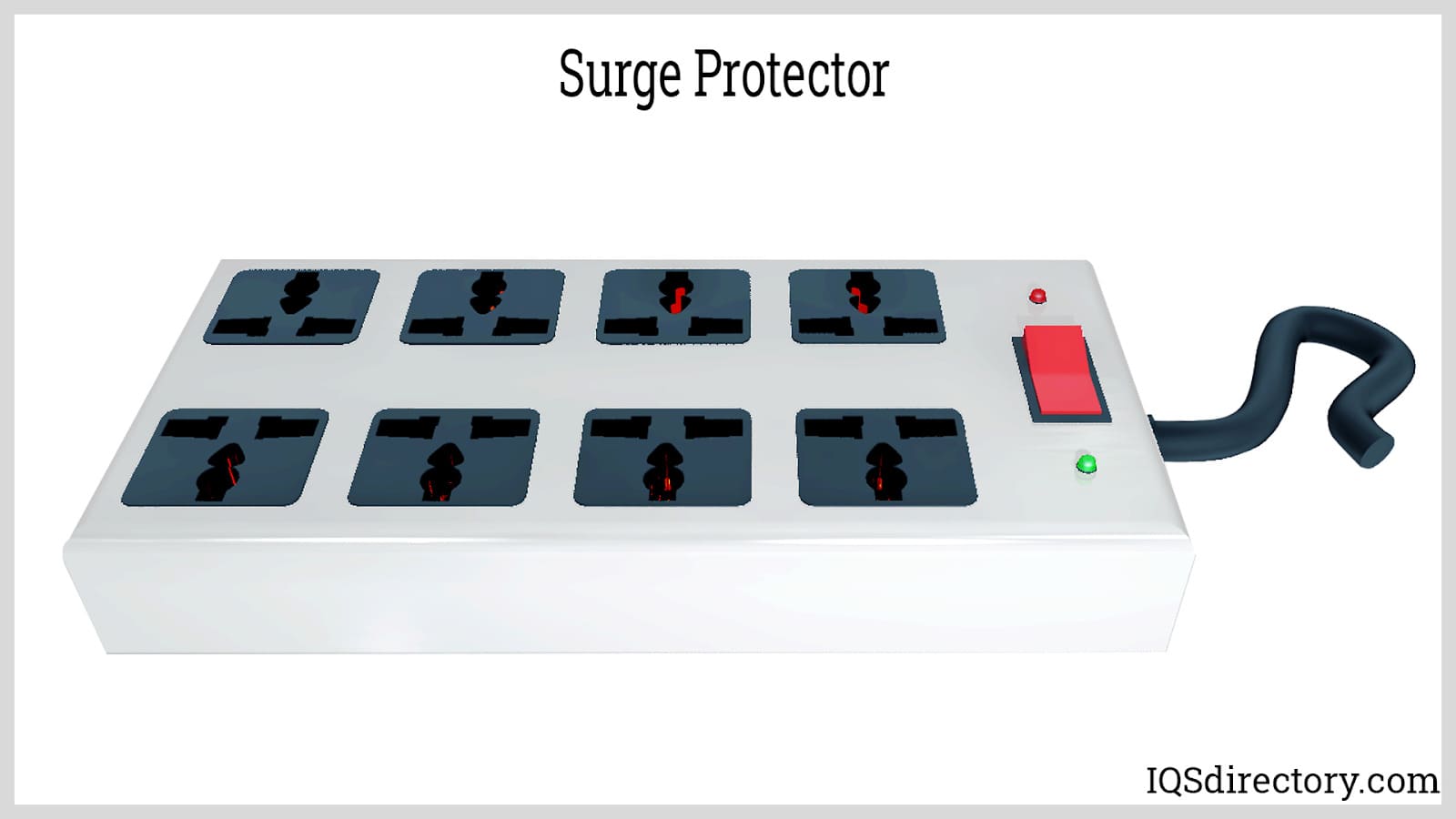

When working with electrical outlets, power surges are a major concern as they can damage electrical components and devices. Power surges are a common issue in electrical systems, and every location must address them by providing adequate protection to prevent damage.

Although power surges are brief, lasting only a millisecond, they can cause significant damage if not properly protected against. The most common solution is a surge protector, which can either be easily connected to any electronic device or integrated into the device itself.

Surge protectors are classified by their joule rating, which indicates the amount of energy they can dissipate. A higher joule rating means the surge protector can absorb more energy, offering better protection.

Simply put, a surge protector shields electronic or electrical equipment from damage caused by power surges, voltage spikes, or brief bursts of energy. Also called a transient suppressor, it is installed on an alternating current (AC) line.

A surge protector allows current to flow to connected devices. If voltage exceeds safe levels, it redirects the excess to the outlet's ground, which runs alongside the hot and neutral wires. Grounding wires offer a safe pathway for current in case of system failure.

The PoE (Power over Ethernet) is a groundbreaking device that enables both power and data transmission through a single cable. This innovation reduces the need for additional wiring, enhances safety, and simplifies installation, saving both time and cost. By delivering DC power via Ethernet cables, it eliminates the need for separate outlets.

A servo motor needs a stable, reliable, and straightforward power supply to effectively manage power flow to and from the motor. The primary challenge for a servo motor supply is its ability to endure harsh operating conditions, including voltage fluctuations, high spikes, electromagnetic interference (EMI), shocks, vibrations, and extreme temperatures.

A PDU, or Power Distribution Unit, manages and distributes electrical power. At its most basic, it's a power strip without surge protection. On a larger scale, PDUs serve as a crucial link between the power source and various types of equipment in buildings. Essentially, a PDU is an industrial-grade power strip with broader and more critical functionalities.

On a work site, plugging all necessary devices into a single power supply isn't feasible. To power multiple devices simultaneously, a PDU is needed. It transforms one power source into several outlets, enabling all devices to operate at once.

A PDU, surge protector, and power strip all serve to protect against power surges. The key difference lies in the level of protection they offer, measured in joules.

Among the various electrical components, power strips are the most common and widely used. Typically, they include a surge protector or circuit breaker to cut off current when a certain voltage is reached. Power strips consist of multiple electrical sockets connected to a cable, allowing several devices to be plugged in. Essentially, they function as miniature PDUs and come in both surge-protected and non-surge-protected designs.

When selecting a power strip, it's crucial to match it to the devices you'll plug in. Power strips are equipped with 15 or 20 amp circuit breakers to protect against dangerous overloads.

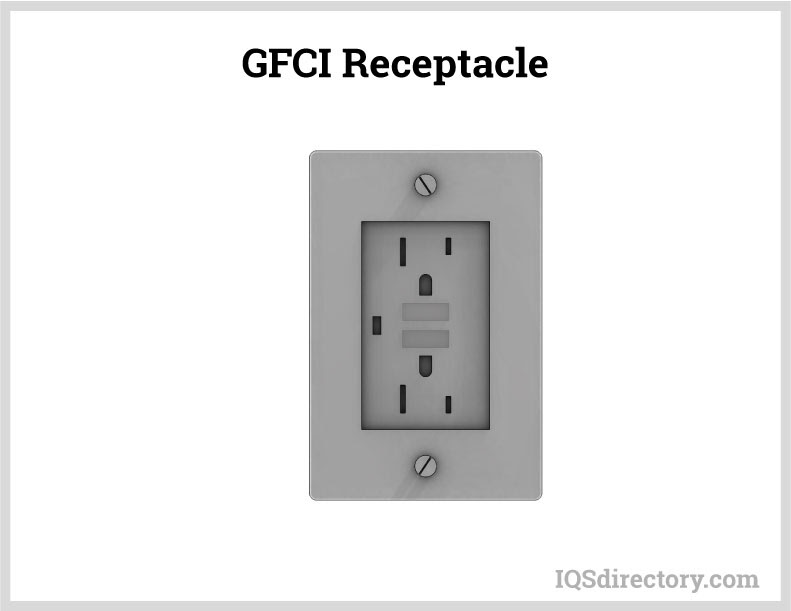

All our items need easy access to electricity, as electronics are present in every room, from the kitchen to the bedroom. Regulatory agencies like IEC and NEMA set standards and guidelines for safe electrical use. Below are some essential safety devices that have become standard for powering electrical equipment.

A GFCI prevents electric shock by monitoring the current flow between the hot and neutral wires. If it detects a deviation of just 4 milliamps, it immediately cuts off the power supply.

TR receptacles are designed to prevent electrical shocks by ensuring that nothing plugged in can be energized unintentionally. They feature spring-loaded shutters that block the contact openings and only open when both shutters are pressed simultaneously, offering effective protection against electrical hazards.

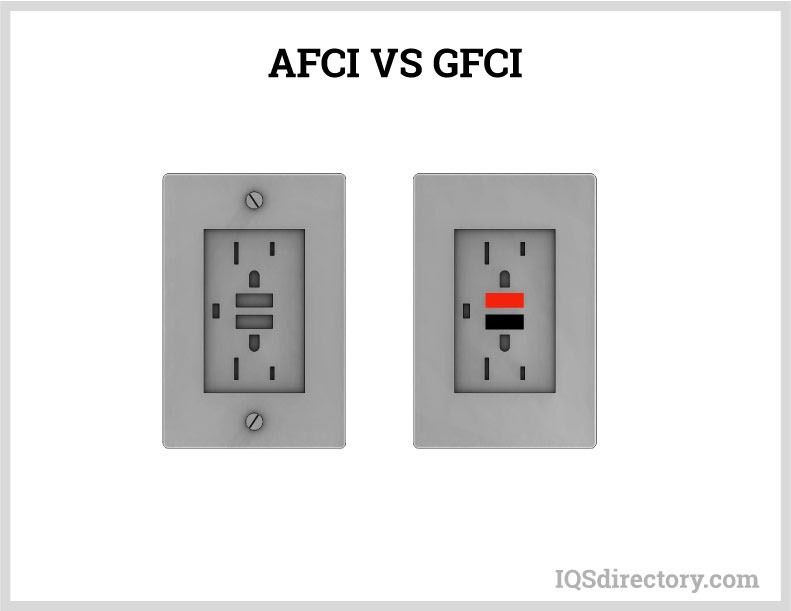

An arc fault occurs when current flows through an unintended path, generating intense heat at the arc's location, which can ignite nearby materials. An Arc Fault Circuit Interrupter (AFCI) is designed to detect these arcs and reduce the risk of fire. Although GFCI and AFCI devices may look similar, they serve different purposes: GFCIs protect against electrical shock, while AFCIs guard against fires.

Surge protectors prevent voltage spikes that can harm electronics like TVs, computers, and smart appliances. Although a voltage surge may last only microseconds, it can reach up to 1000 volts. Surge protectors block or divert this excess current to protect your devices.

When regular electrical current flows through the circuit, choke coils or capacitors connected to the hot wire help direct it through the device. During voltage spikes or surges, the excess is diverted into the green ground wire, as illustrated in the diagram, to protect the power outlet and connector from potential damage.

Weather-resistant receptacles are designed to endure rain, snow, humidity, ice, and other forms of moisture. They safeguard the outlet from corrosion and other potential hazards. You can identify weather-resistant receptacles by the "WR" marking on the faceplate, as shown in the example below.

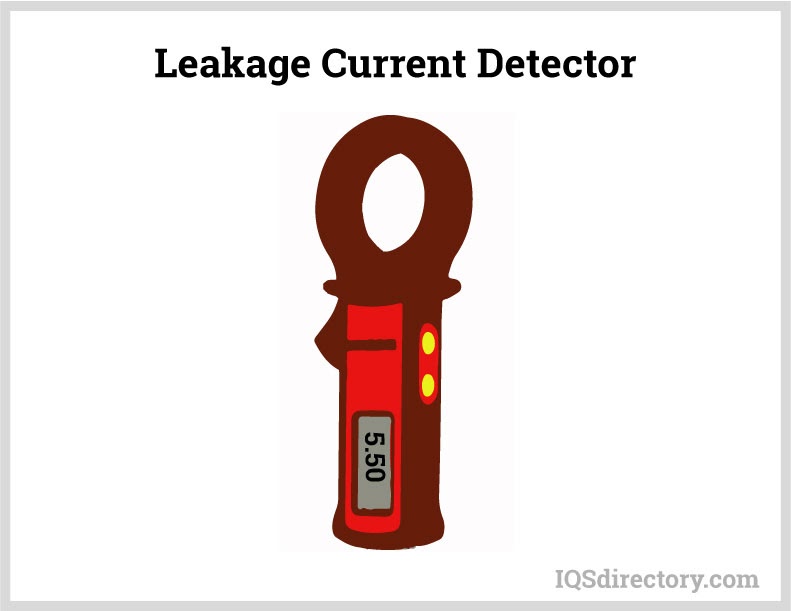

In an electrical connection, some current may flow through the ground conductor, a phenomenon known as leakage. Most of this leakage occurs through the insulation around the conductors and the protective filters. If leakage goes undetected, it can cause a GFCI to trip. To identify the source of the leakage, a leakage detector is used. This device is clamped onto a conductor to measure the current value and pinpoint the leakage source.

Wiring for AC and DC power is color-coded to simplify identification. The IEC provides color codes for AC branch circuits, and the chart below outlines common color codes used in the United States. However, since these codes are not standardized nationwide, variations may exist depending on the region.

| Color Coding | |||

|---|---|---|---|

| Function | Label | Common Color | Alternate Color |

| Ground | PG | Bare, Green or Green-Yellow | Green |

| Neutral | N | White | Grey |

| Line, Single Phase | L | Black or Red (2nd Hot) | |

| Line, 3-Phase | L1 | Black | Brown |

| Line, 3-Phase | L2 | Red | Orange |

| Line, 3-Phase | L3 | Blue | Yellow |

Black electrical wires are commonly used to transfer power and can also serve as switch legs.

Red electrical wires serve as secondary live wires and can function as switch legs. They are also used to connect hardwired smoke detectors to the power system.

Blue and yellow electrical wires are not used for outlet wiring. Instead, they serve as live wires within conduits. Yellow wires can act as switch legs for ceiling fans, structural lights, and outlets controlled by light switches. Blue wires are typically used as travelers in three- or four-way switch configurations.

White and gray electrical wires are both neutral wires, with white being the most commonly used.

Green electrical wires serve as the grounding component for electrical circuits, connecting to the grounding terminal. They provide a failsafe mechanism for safely directing electricity away in case of a fault.

An AC power cord is a detachable way of providing an alternating current of electric energy from a mains power supply to an electrical appliance or equipment. Serving industries like...

Electrical plugs, commonly known as power plugs, are devices responsible for supplying and drawing current from a receptacle to the circuitry of an electrical appliance...

A power cord is an electrical component used for connecting appliances to an electrical utility or power supply. It is made from an insulated electrical cable with one or both ends molded with connectors...

Thomas Edison developed the power distribution system in 1882. He wrapped a copper rod in jute, a soft shiny fiber from plants, as an insulator. The jute wrapped copper rod was placed in a pipe with a bituminous compound...

Power supplies are electrical circuits and devices that are designed to convert mains power or electricity from any electric source to specific values of voltage and current for the target device...

An AC power supply is a type of power supply used to supply alternating current (AC) power to a load. The power input may be in an AC or DC form. The power supplied from wall outlets (mains supply) and...

A DC DC power supply (also known as DC DC Converter) is a kind of DC power supply that uses DC voltage as input instead of AC/DC power supplies that rely on AC mains supply voltage as an input...

A DC power supply is a type of power supply that gives direct current (DC) voltage to power a device. Because DC power supply is commonly used on an engineer‘s or technician‘s bench for a ton of power tests...

Electronic connectors are devices that join electronic circuits. They are used in assembling, installing, and supplying power to electrical devices. Connectors are an important component of every electronic equipment used in...

An electric switch is a device – usually electromechanical – that is used to open and close an electric circuit. This disables and enables the flow of electric current, respectively...

By definition a power supply is a device that is designed to supply electric power to an electrical load. An electrical load refers to an electrical device that uses up electric power. Such a device can be anything from...

A programmable power supply is a method for controlling output voltage using an analog or digitally controlled signal using a keypad or rotary switch from the front panel of the power supply...

Push button switches are electrical actuators that, when pressed, either close or open the electrical circuits to which they are attached. They are capable of controlling a wide range of electronic gadgets...