AC DC Power Supply

Power supplies are electrical circuits and devices that are designed to convert mains power or electricity from any electric source to specific values of voltage and current for the target device...

Please fill out the following form to submit a Request for Quote to any of the following companies listed on

A description of the types of electrical connectors with a list of recommended manufacturers

You will learn:

Electronic connectors are essential devices used to link electronic circuits. They play a crucial role in the assembly, installation, and power supply of electrical devices. These components are pivotal in a range of applications, including industrial equipment, consumer electronics, communication systems, and household appliances. Often underestimated, connectors are vital in ensuring that electronic products operate effectively. While some connectors are designed for permanent connections, the majority are intended to be temporary and easily detachable.

An electrical connector comprises two primary parts: the contacts and the housing, commonly known as plugs or receptacles. The housing secures the terminals, maintaining steady connections and providing insulation to prevent unwanted interactions with other electronic elements, thus avoiding short circuits. Plugs and receptacles shield the terminals from the environment and are typically constructed from insulating materials like molded plastics or ceramics.

Depending on the specific application, additional features may be incorporated into a connector. Keyed connectors are designed to fit in a singular orientation to prevent mismatched connections. Some connectors are equipped with locking mechanisms to avoid accidental disconnection. There are also connectors that are meticulously sealed to function efficiently in underwater conditions.

Connector terminals are the contact pins that create an uninterrupted pathway for electrical current to traverse between circuits. These are crafted from conductive materials, including brass, phosphor bronze, beryllium copper, and high-copper alloys.

Understanding the terminology associated with electronic connectors is essential for selecting the right component for your electronic systems. This terminology covers the key properties, construction features, and performance metrics that define connector types and compatibility. Knowledge of these electronic connector terms aids in design decisions, procurement, and troubleshooting for a broad range of applications in electrical engineering, electronics assembly, and industrial automation.

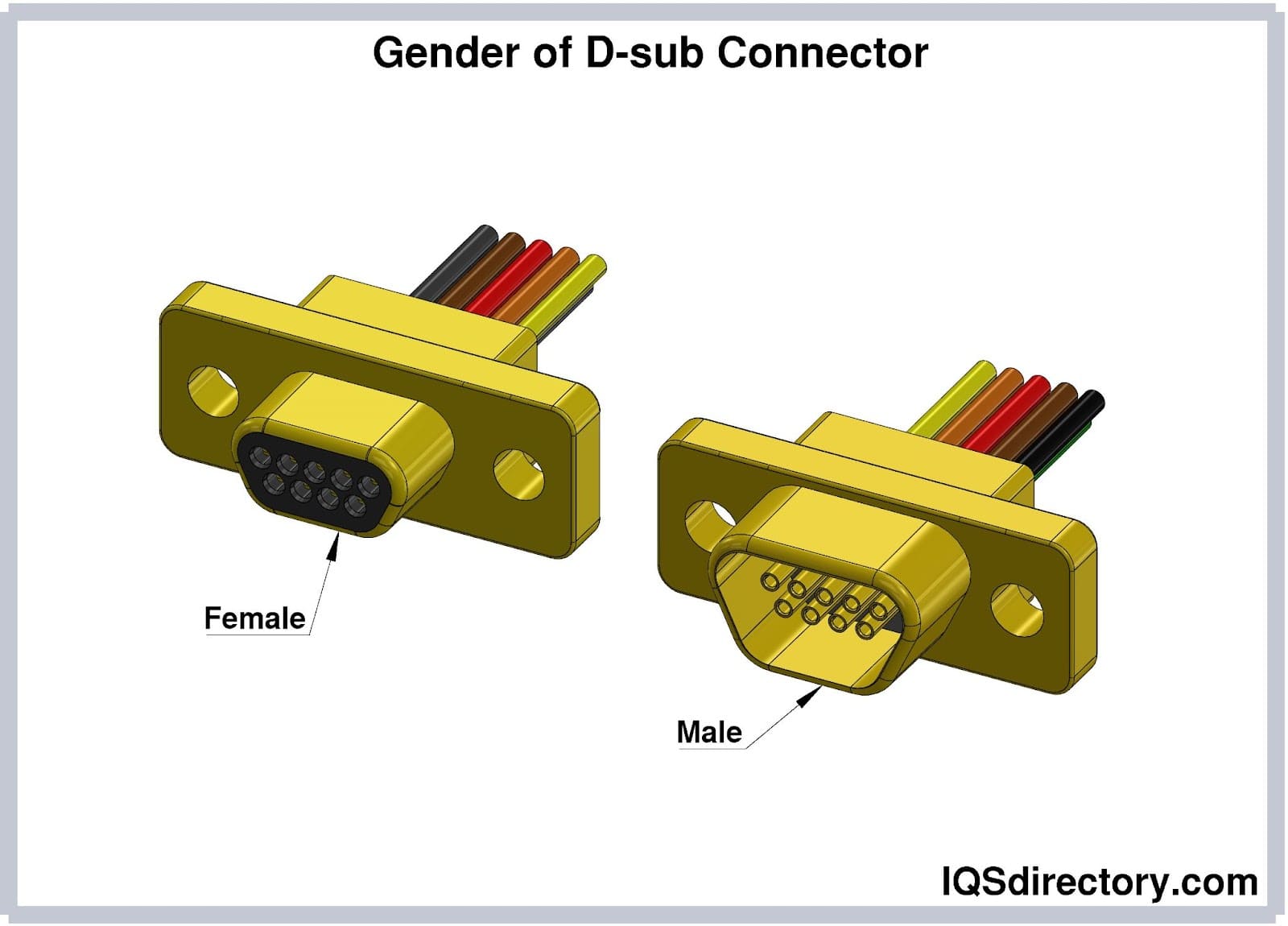

For electronic connectors, gender is a foundational classification used to differentiate mating connectors—those that fit together based on size, shape, and pin configuration. The plug or male connector contains pins (also called blades or contacts), designed to insert into a female connector, which features a receptacle, jack, or socket with mating contacts. Female connectors have socket holes with terminals attached to conductors, wires, or cables. When the male connector’s pins are inserted into the female jack or socket, they complete the electrical signal path or power connection. Correct selection of connector gender ensures reliable, secure mating and electrical integrity across a wide range of electronic devices and PCB (printed circuit board) assemblies.

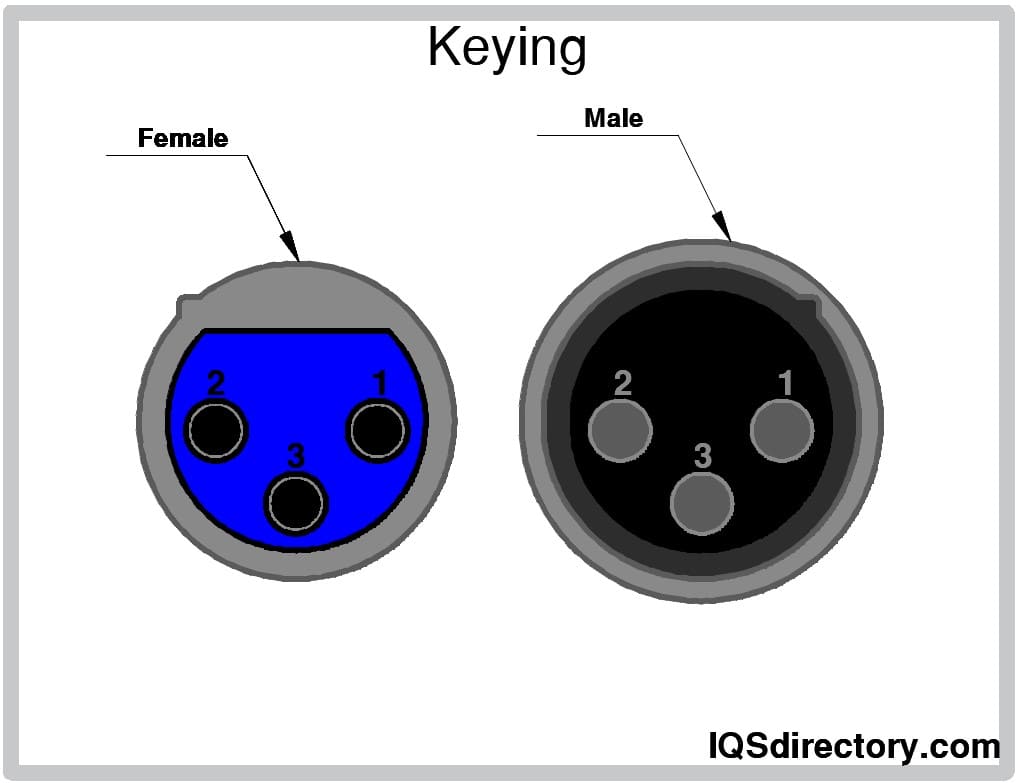

Keying is a critical design feature in electronic connectors aimed at preventing incorrect mating, which could cause electrical failures or mechanical damage. Keying involves unique physical elements—such as keys, keyways, or notches—that make it physically impossible to mate connector pairs in the wrong orientation. This is especially important in multi-way or symmetrical connectors where misalignment could damage components or lead to short circuits. Proper keying ensures connector compatibility and enhances reliability in data, signal, and power connectivity.

Locking mechanisms secure mated connectors, preventing accidental disconnection that could disrupt an electronic system. Locking methods include push-pull connectors, bayonet couplings, and fine thread screw couplings, each chosen based on application needs. These mechanisms offer vibration resistance, mechanical retention, and environmental sealing for connectors exposed to demanding industrial, automotive, or aerospace environments. Selecting the right locking feature is crucial in preventing signal loss and maintaining electrical continuity.

The number of contacts specifies the total number of pins or terminals that establish individual electrical connection points within a single connector. This value varies widely, from simple 2-pin connectors used for power or signal, up to advanced multi-pin connectors exceeding 200 contacts for high-density circuit applications. The contact count is determined by the device requirements, signal complexity, and interface standard, influencing connector size, footprint, and signal routing capabilities.

Contact pitch, or simply pitch, describes the center-to-center spacing between adjacent pins or terminals of a connector, typically measured in millimeters or inches. Contact pitch impacts connector compatibility with PCBs and cable harnesses, affecting signal integrity and miniaturization. Larger pitches allow greater voltage isolation, reducing risk of electrical arcing (when current jumps between too-close pins), while smaller pitches enable high-density layouts in space-constrained designs. Accurate specification of contact pitch is vital in electronic connector selection and assembly for consumer electronics, industrial controls, and communications equipment.

A larger pitch means fewer terminals per connector area, which decreases the risk of arc-over between pins. Careful calculation of contact pitch during electrical connector assembly ensures optimal electrical performance and design compatibility.

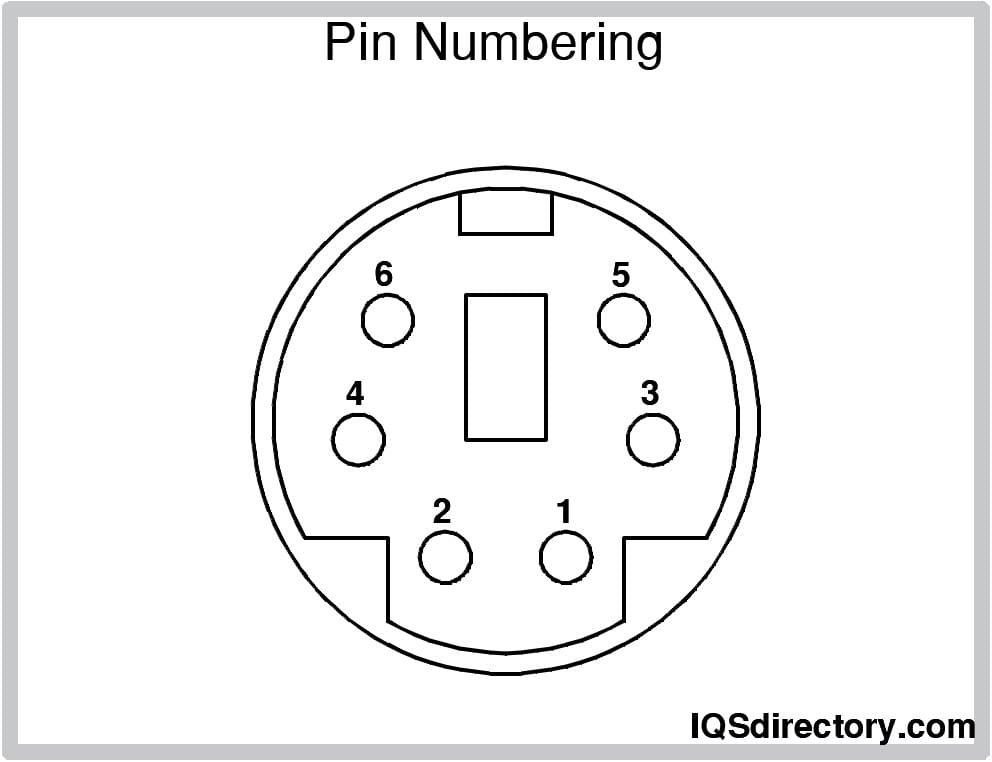

Pin numbering is the standardized method for identifying each terminal or pin within an electronic connector. Numbering schemes—such as left-to-right, top-to-bottom, or specific industry conventions—streamline wire routing and prevent wiring errors, critical in complex multi-pin connectors and custom cable assemblies. Consistent pin identification is essential for schematic diagrams, connector documentation, and successful harness manufacturing for automotive wiring, industrial systems, and PCB layouts.

The pin sequence of an electronic connector establishes the order in which individual contacts make electrical contact during mating. This arrangement is engineered to prioritize the engagement of ground or shield contacts before signal or power pins, thereby minimizing the risk of device damage from stray voltages or static discharge. Specifying pin sequence is especially relevant for high-speed data, signal, and power connectors used in sensitive instrumentation, computer hardware, and telecommunications infrastructure.

Mating cycles define connector durability, referring to the number of times a connector can be properly connected and disconnected without mechanical or electrical failure. Different connector types—such as USB, FFC (Flat Flexible Cable), and FPC (Flexible Printed Circuit) connectors—offer varying mating cycle ranges based on their material quality, terminal plating, thickness, and mating style (e.g., snap-fit, lever lock). High-mating-cycle connectors are essential for test equipment, consumer electronics, and devices requiring frequent reconnections, while lower cycle ratings may be suitable for permanent or infrequent connections.

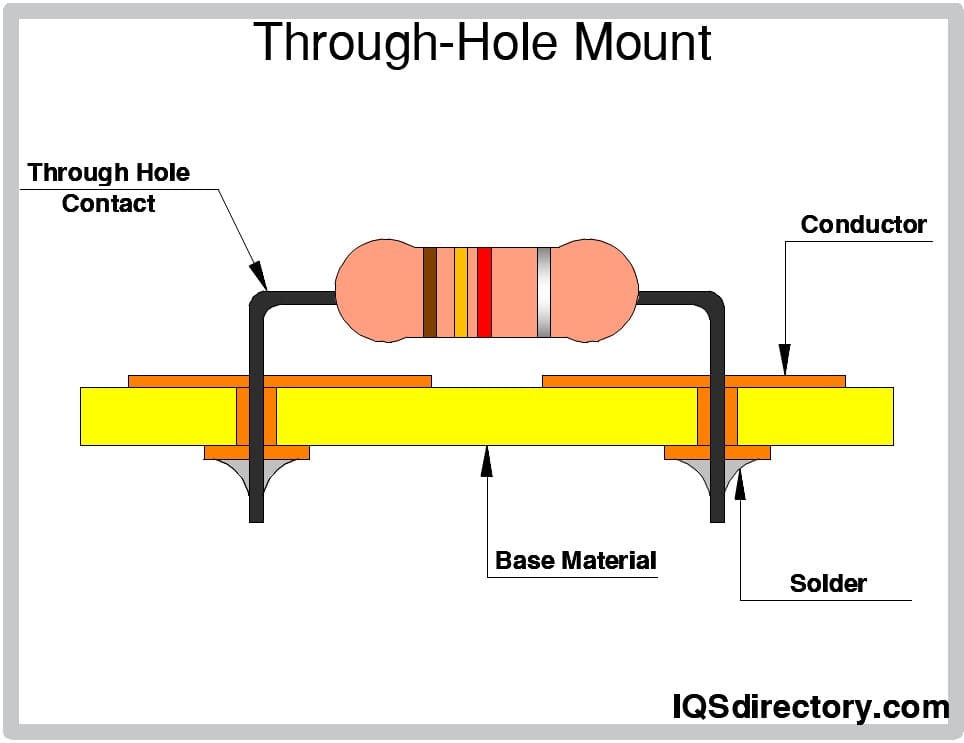

Mounting refers to how an electronic connector is attached to a device or circuit board. Common mounting types include PCB (through-hole or surface-mount), edge mount, panel mount, and cable mount. Proper mounting impacts connector strength, ease of assembly, electrical performance, and field serviceability. For circuit board connectors, PCB mounting standards ensure reliable solder connections and electrical integrity. Panel and chassis mounts are essential in industrial enclosures, aerospace, and telecommunications equipment.

Termination is the process of electrically connecting wires to a connector’s contact points. Common termination methods include crimping, soldering, and screw terminals. Each method offers different advantages regarding mechanical strength, reliability, and field-serviceability. Choosing the proper termination technique is critical in ensuring signal integrity, consistent contact resistance, and safe modular wiring in cable assemblies, control panels, and harness fabrication.

Strain relief describes the mechanical support structures, such as fittings or bushings, that dissipate forces acting on an electronic connector or cable assembly. Effective strain relief prevents cable flexing, pull-out, or twisting forces from transferring directly to the terminals, which can cause intermittent electrical contact or conductor breakage. This feature is indispensable in industrial automation, robotics, and outdoor installations where connectors and cables are subject to frequent motion or environmental stress.

The performance parameters of an electronic connector provide critical data for evaluating suitability under operational and environmental conditions. These include:

Evaluating these specifications allows engineers and buyers to choose ruggedized connectors for harsh environments or high-reliability connectors for mission-critical systems.

Some electronic connectors offer specialized features tailored for demanding environments or applications, which include:

Additional advanced features may include polarization, quick-disconnect latches, alignment guides, and overmolded housings for further protection and ease of use. Selecting electronic connectors with suitable features ensures efficient performance, long-term reliability, and minimal maintenance in your application.

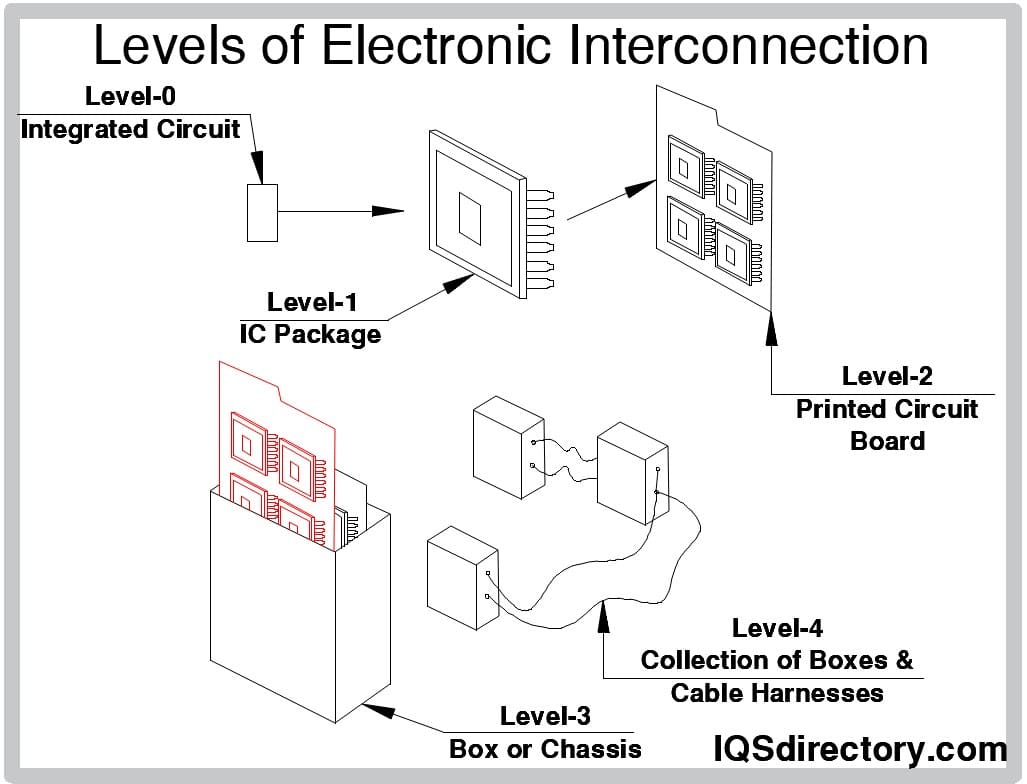

Electronic connectors are essential hardware components that facilitate the reliable electrical and data transmission between electronic circuits, devices, and systems. The wide array of connectors available is categorized according to the level of electrical interconnection required for a project or system:

The world of electronics is rapidly evolving, and the demand for advanced, high-speed data and power interconnections has resulted in a diverse range of electronic connector types. Connectors are foundational in creating dependable pathways for power, signal, and data, with modern electronic connectors supporting robust, efficient, and seamless connectivity across a broad spectrum of electronic devices, printed circuit boards (PCBs), and industrial control systems. Selecting the correct connector type ensures proper circuit performance, system safety, and hassle-free upgrades or maintenance.

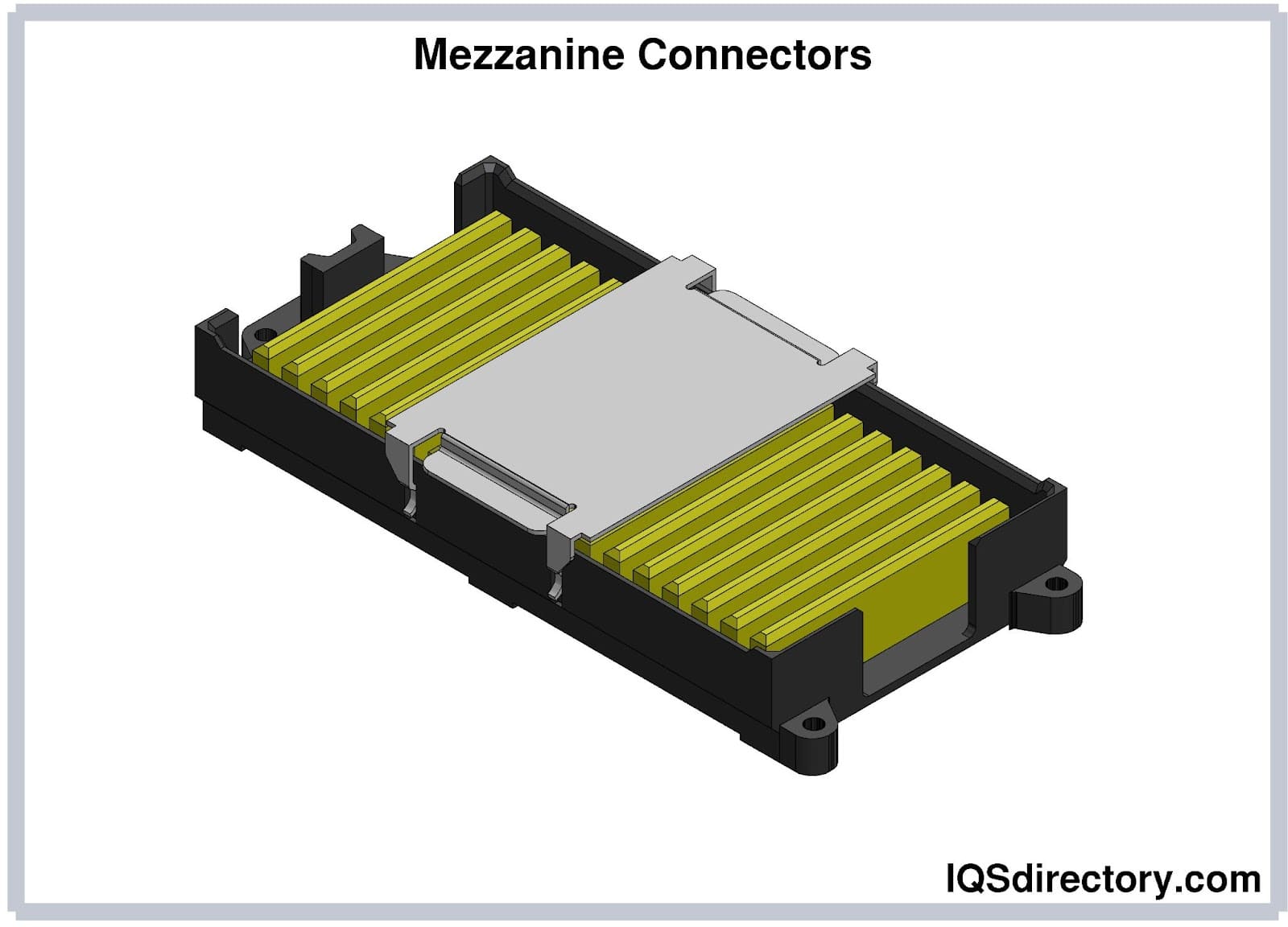

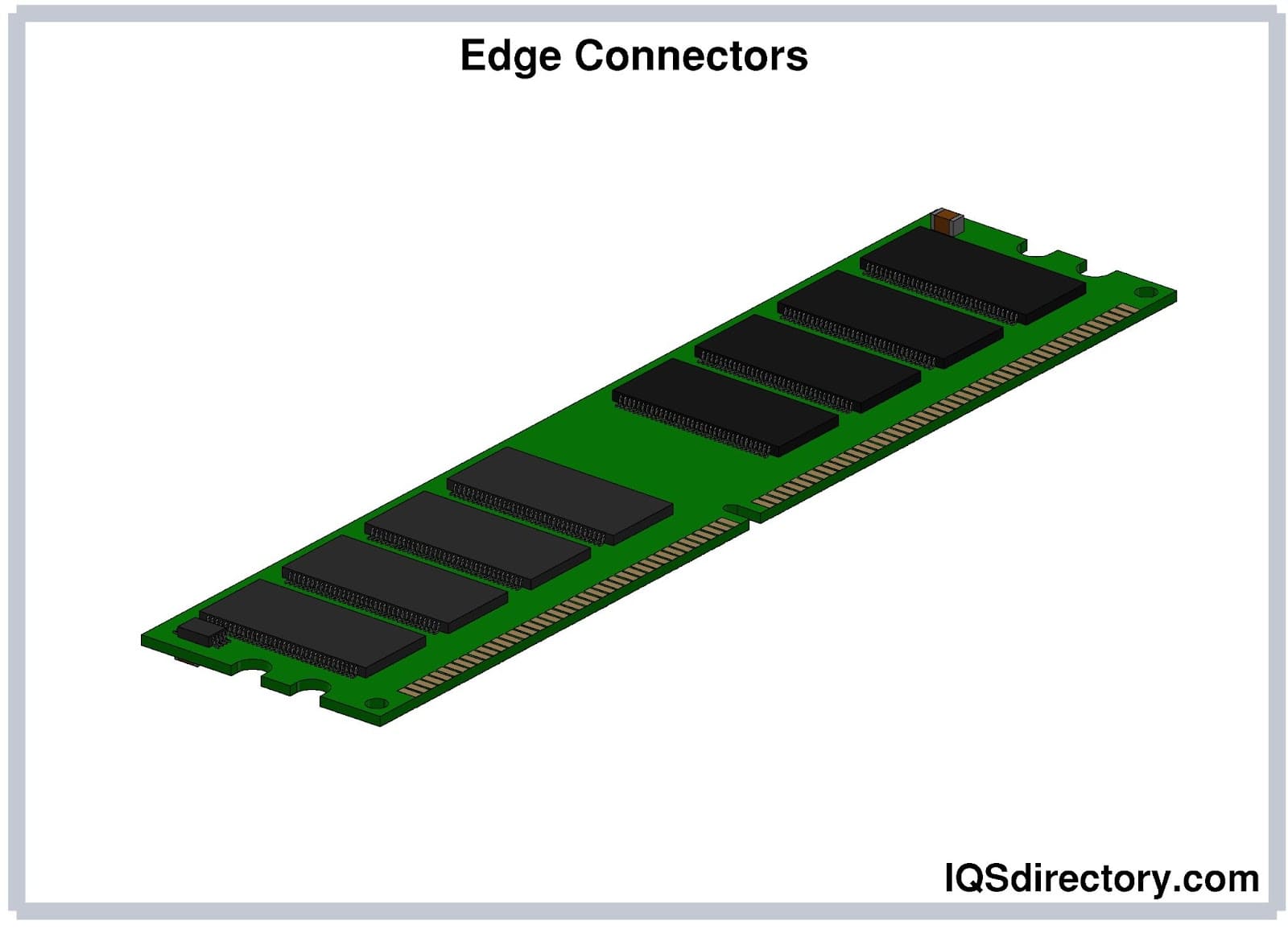

Board-to-board connectors are specialized connector solutions that join printed circuit boards without requiring cabling. These electronic connectors enable reliable electrical and signal transfer between PCB assemblies by using plug and socket interfaces, which can be implemented via through-hole or surface-mount technology (SMT). PCB connections can be arranged perpendicularly, in stacking configurations (using mezzanine connectors), or in parallel with edge connectors that interface directly at the PCB edge. Board-to-board connections are essential in consumer electronics, automotive modules, and industrial control systems, offering high-density interconnections, reduced assembly times, and improved miniaturization in complex designs.

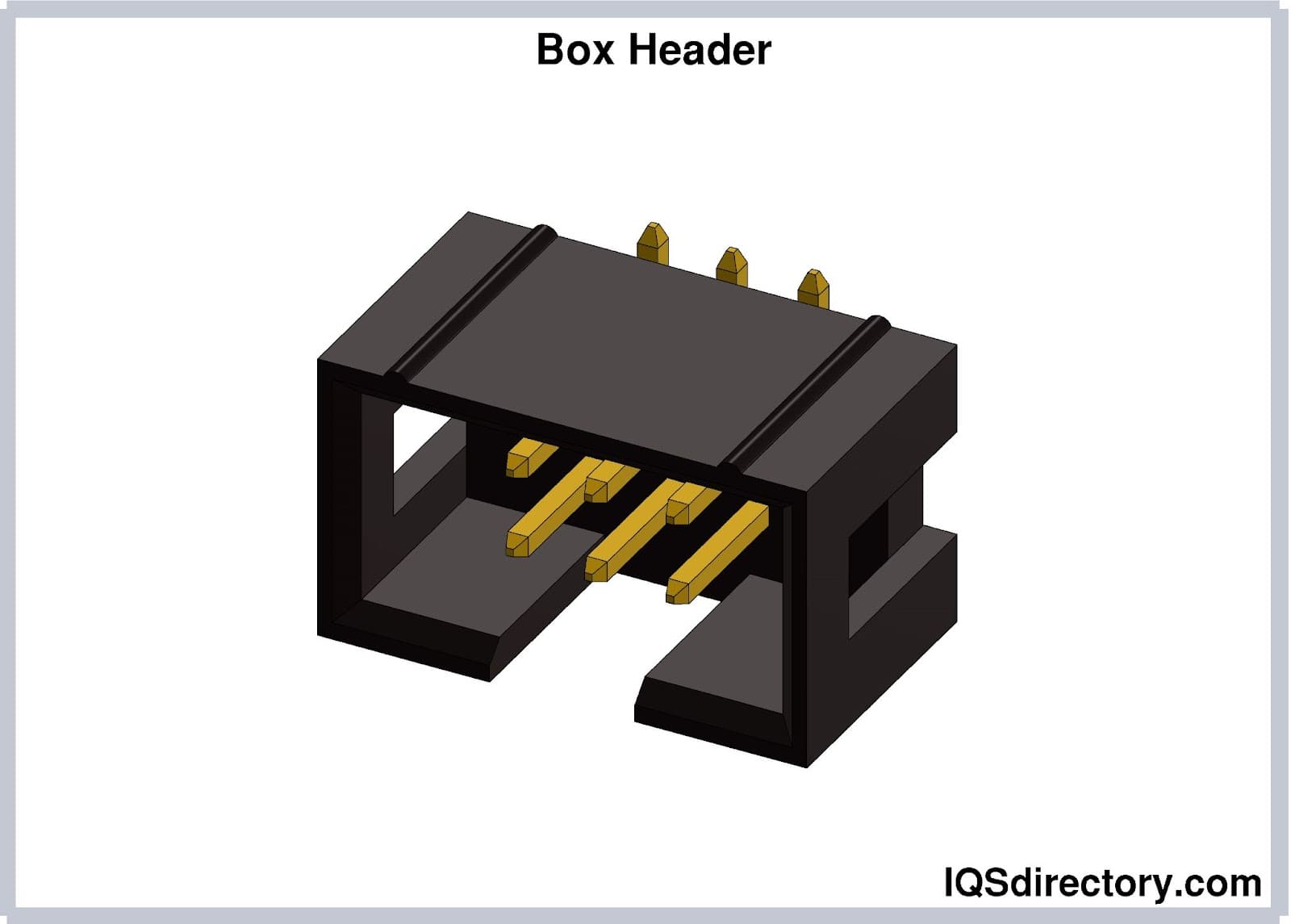

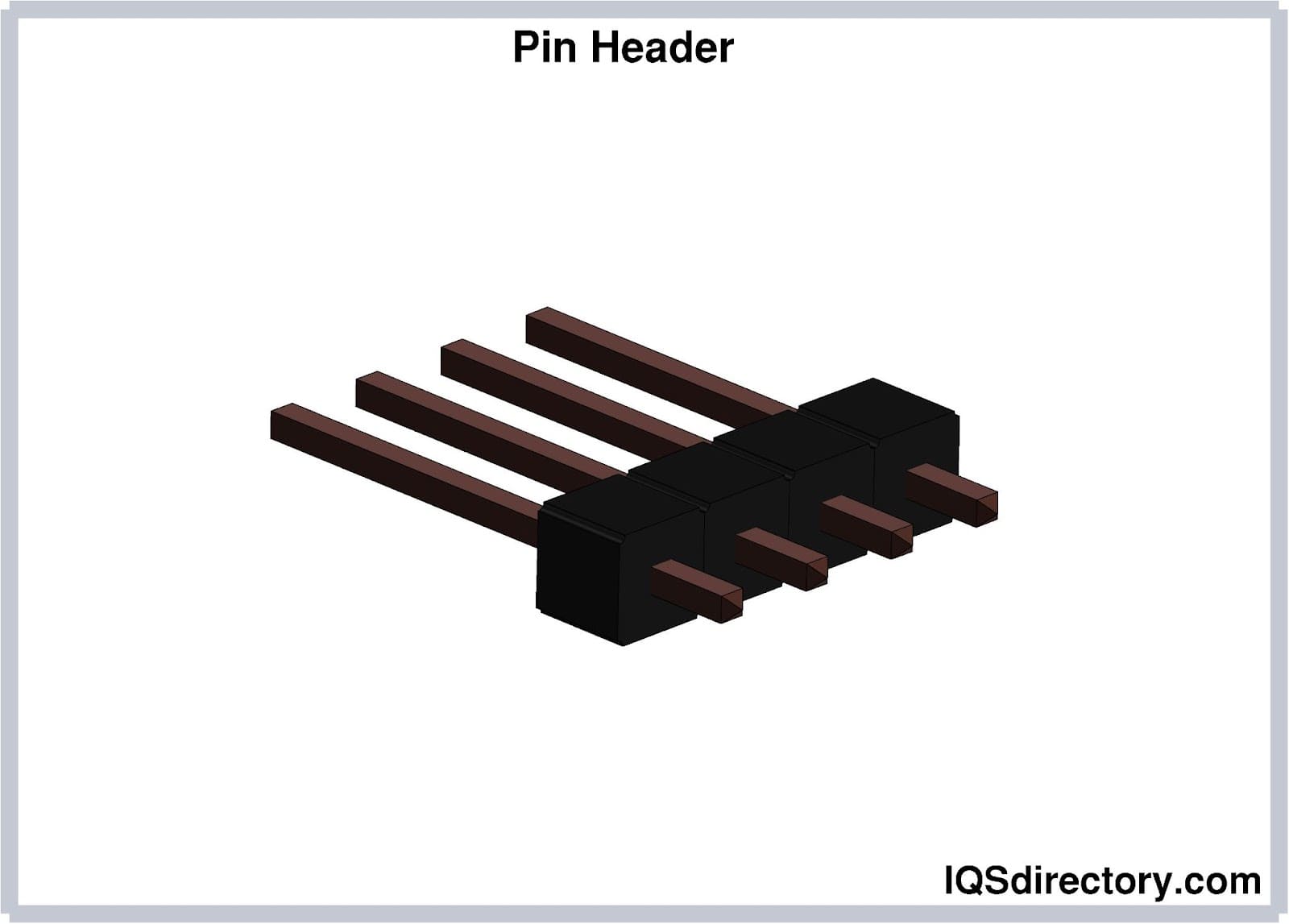

Box header connectors, sometimes referred to as shrouded headers, are a form of board-to-board connector widely used in electronic circuits for providing signal, data, or power pathways between PCBs. Box headers feature exposed pins housed in a plastic guide box for easy, proper alignment and mating. Integrated keying and notches prevent mismating, which makes these connectors a reliable choice for complex electronic assemblies, embedded systems, and modular equipment swaps.

A backplane serves as a structural backbone for connecting multiple PCBs in electronic systems, typically aligning an array of pins on one board to matching receptors on another. Backplane connectors are crucial in high-reliability applications such as computers, network switches, telecommunications, data centers, and electronic instrumentation. They support high-speed data transfer and power distribution, enabling modular upgrades. Modern backplane connector designs optimize for bandwidth, signal integrity, and electromagnetic compatibility (EMC), making them essential in top-of-rack switches, hybrid storage clusters, servers, and automation systems.

Power connectors are specialized components engineered to safely transmit electrical current—either alternating current (AC) or direct current (DC)—from a power source to an electronic device or system. Selecting the right type of power connector is critical for ensuring safety, reliability, and optimal energy efficiency in power delivery for consumer electronics, industrial machines, and automation systems.

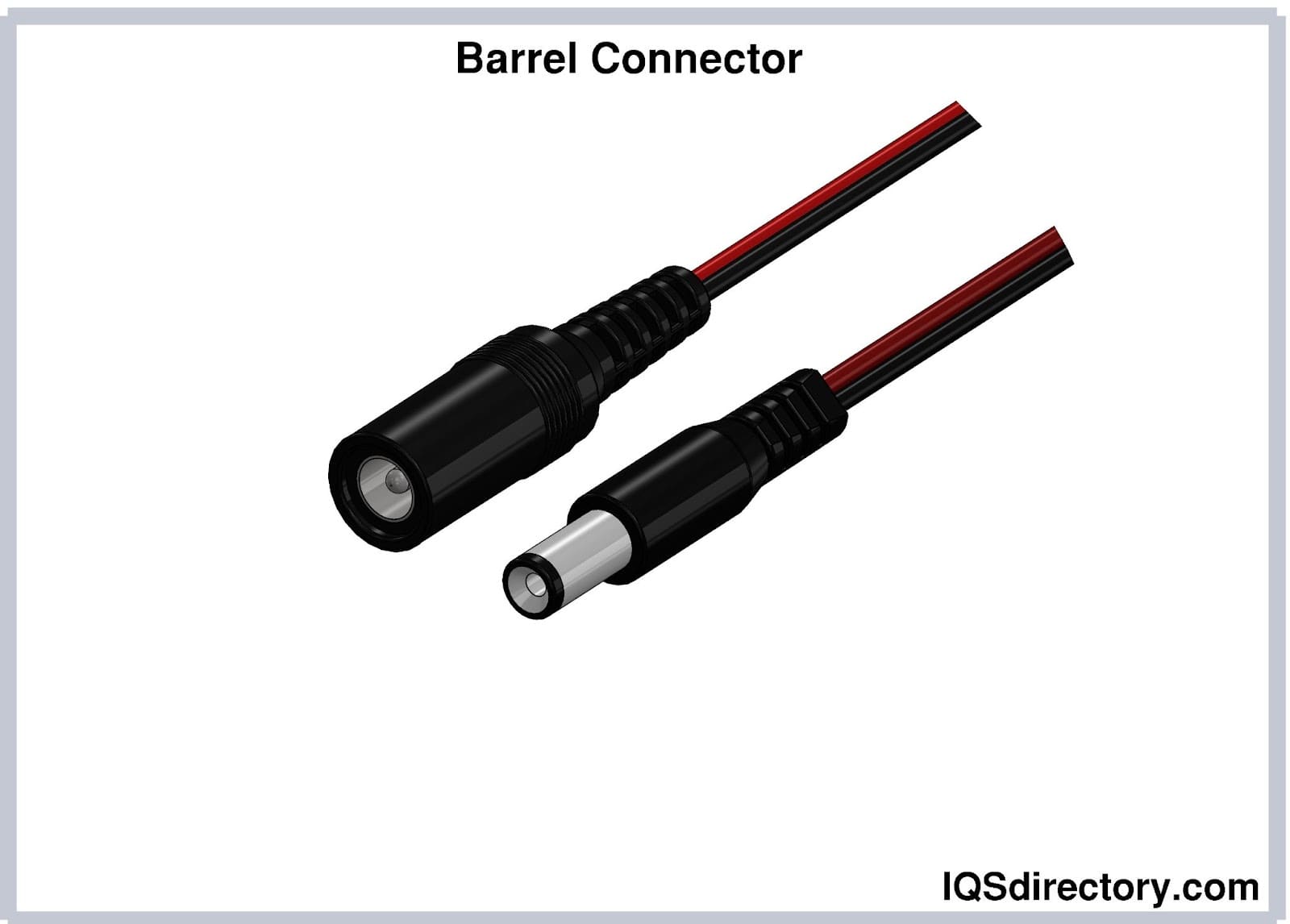

Barrel connectors, also known as coaxial DC power connectors, deliver low-voltage DC power from external power adapters to electronic devices. Popular in consumer electronics and small appliances, standardized barrel connectors simplify compatibility and device charging. Key considerations include plug diameter, polarity, voltage, and current rating to ensure proper fit and safe operation.

The barrel plug has concentric metal cylinders separated by insulation; the inner cylinder accommodates the central pin for electrical contact. Barrel jacks may be mounted onto PCBs, panels, or cables. Inside, a cantilevered spring contacts the plug’s outer sleeve, providing secure, low-resistance connections. Secure engagement helps prevent accidental power loss or arcing.

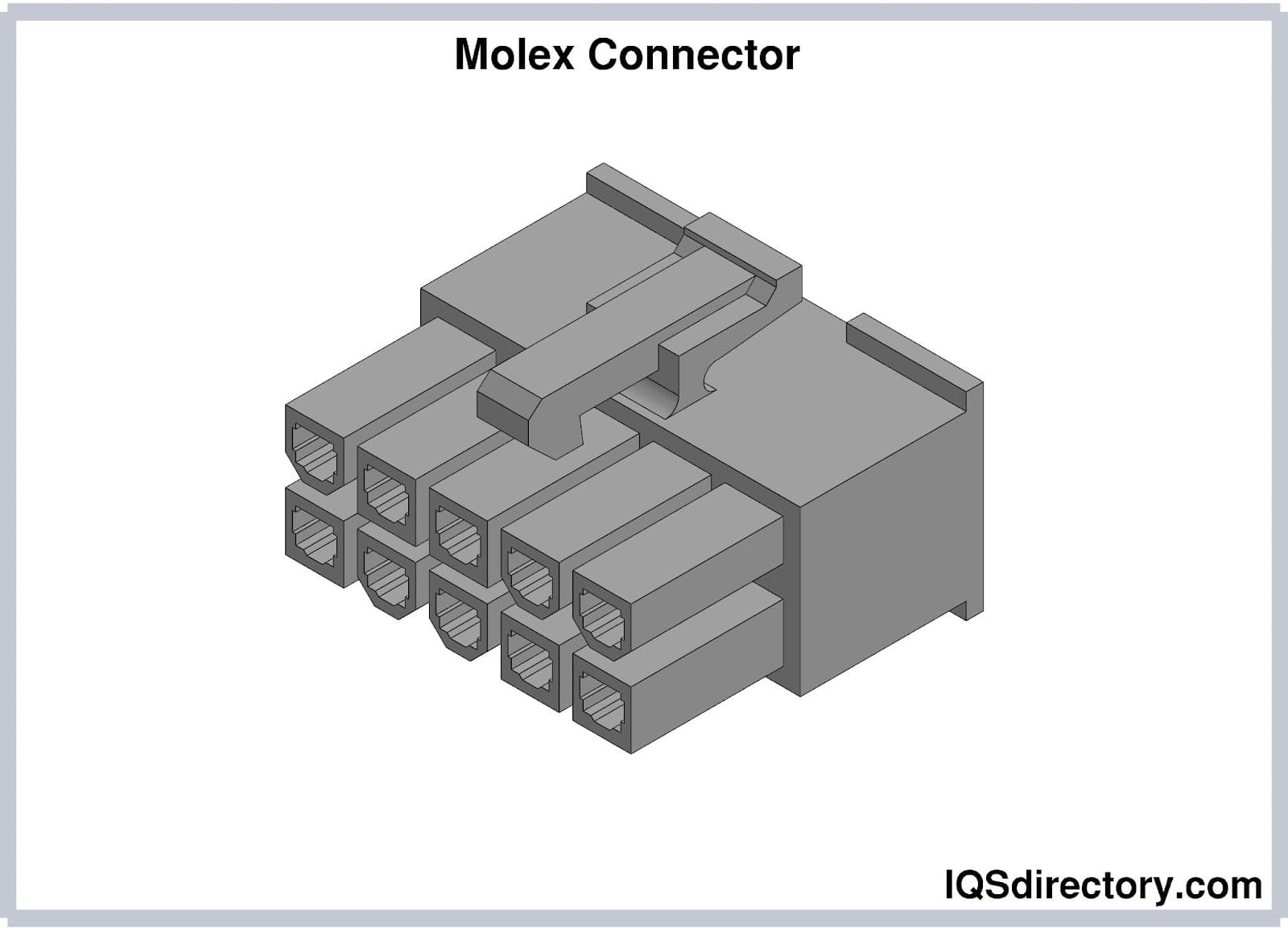

Invented and patented by the Molex Connector Company, Molex connectors are widely used in IT hardware for powering internal computer components such as hard drives, optical drives, and motherboards. Molex connectors utilize cylindrical spring metal pins and sockets in plastic housings for consistent, high-current connections. These connectors are valued in PC, automotive, and industrial applications due to their keyed alignment, robust locking mechanisms, and configurations supporting from two up to 24 contacts—providing flexible solutions for many wiring harnesses.

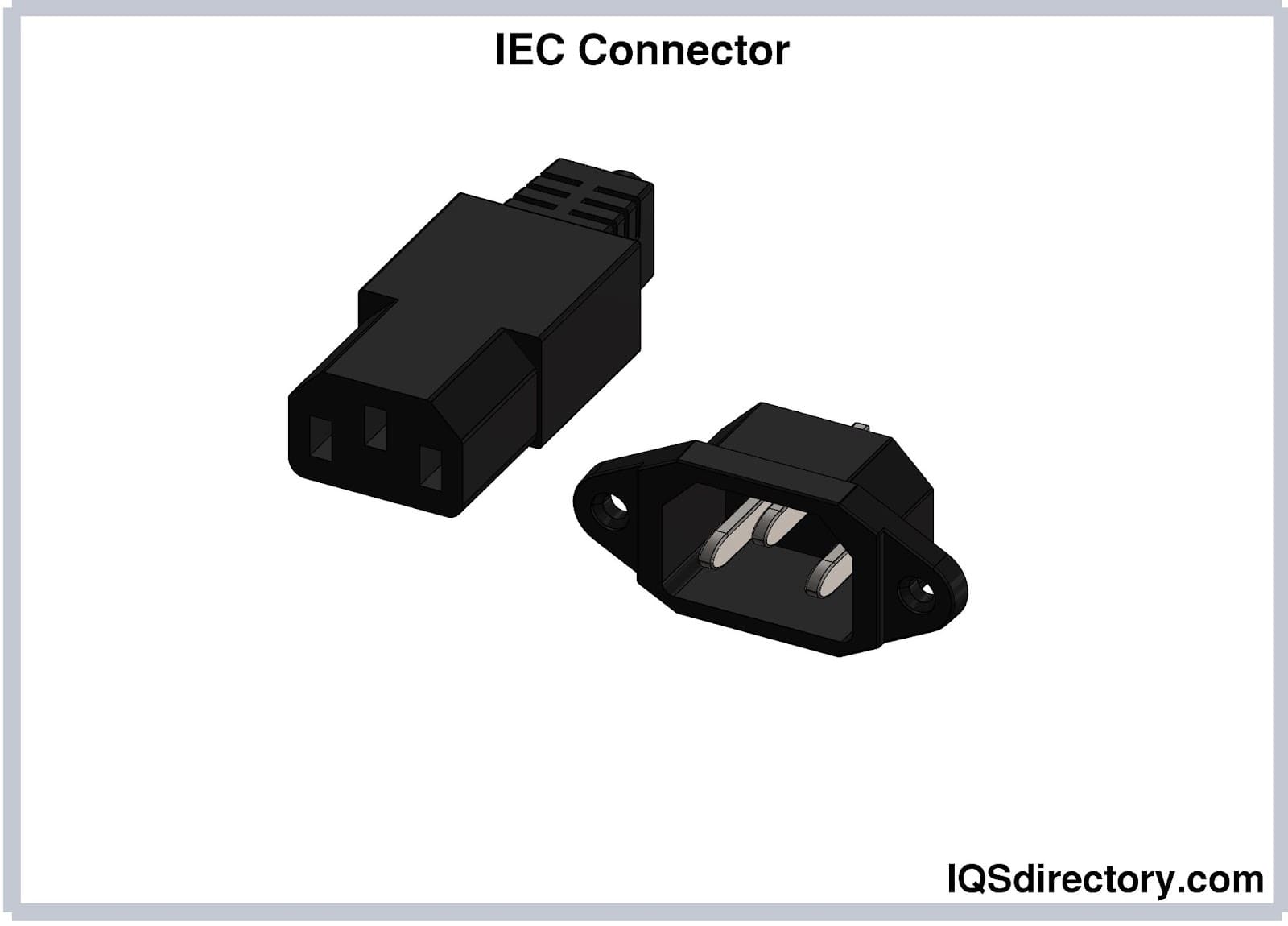

IEC connectors are power connection solutions governed by international standard IEC 60320. Used for connecting power supply cords to equipment, IEC connectors are common in IT hardware, test equipment, and household electronics worldwide. They are rated up to 250V and 16A, with their precise component designation (e.g., C13 connector for C14 inlets) simplifying selection for global compatibility. IEC connectors’ variety supports desktop computers, monitors, medical devices, laboratory equipment, and more.

Typically, IEC connector systems include male (outlet) and female (inlet) components, designed with thermal, electrical, and mechanical safety in mind. The C13/C14 pair, for example, supports three conductors with a 10A rating and a temperature tolerance up to 700°C, making them a staple in power cords and infocomm installations.

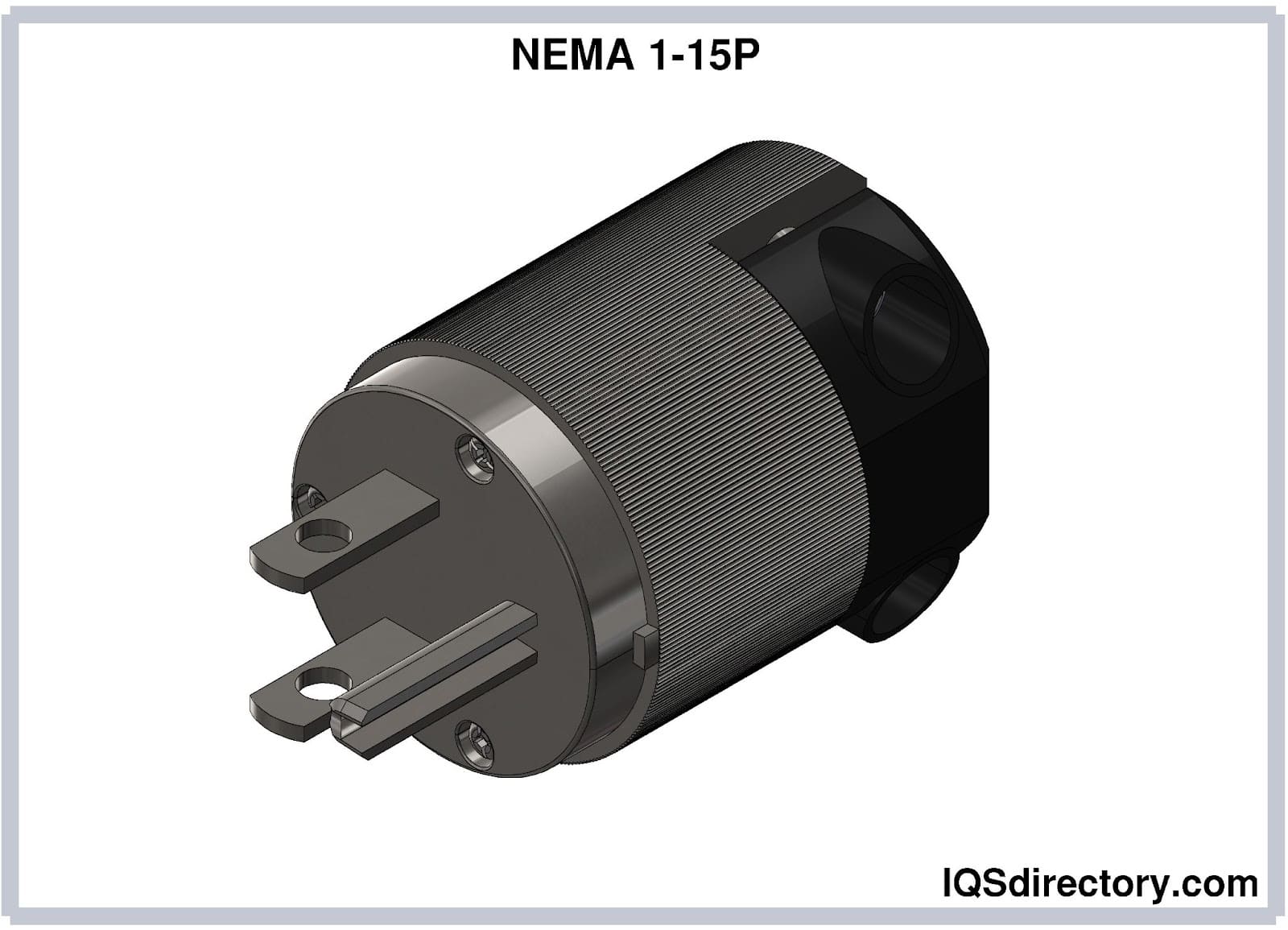

A NEMA connector is a standard for AC power plugs and receptacles defined by the National Electrical Manufacturers Association. These connectors are prevalent in North America and recognized globally in certain industries. NEMA connectors are found in residential, commercial, and industrial settings, where their codes identify features such as voltage, current capacity, wiring configuration, and locking mechanism (for example, twist-locking connectors for secure engagement).

The coding scheme distinguishes between plug types: codes beginning with "L" indicate locking connectors; others are non-locking with straight blades. Letter/number identifiers reflect the application, such as amperage and voltage support. Non-locking NEMA connectors offer rapid disconnection for household appliances, while twist-lock variants ensure a safe, vibration-resistant connection in power distribution panels, manufacturing equipment, and mobile systems.

RF connectors are precision adapters designed for high-frequency, low-loss signal transmission along coaxial cables. Delivering exceptional shielding and robust signal integrity, RF connectors are vital in radio communications, broadcasting, wireless networks, antenna systems, and microwave equipment. Common types include BNC, SMA, TNC, and F connectors. Engineering for both male and female versions, RF connectors ensure minimal insertion loss, high vibration resistance, and effective EMI shielding. Their spring-loaded, threaded, or bayonet mechanisms facilitate secure, repeatable mating and unmating—even in demanding environments.

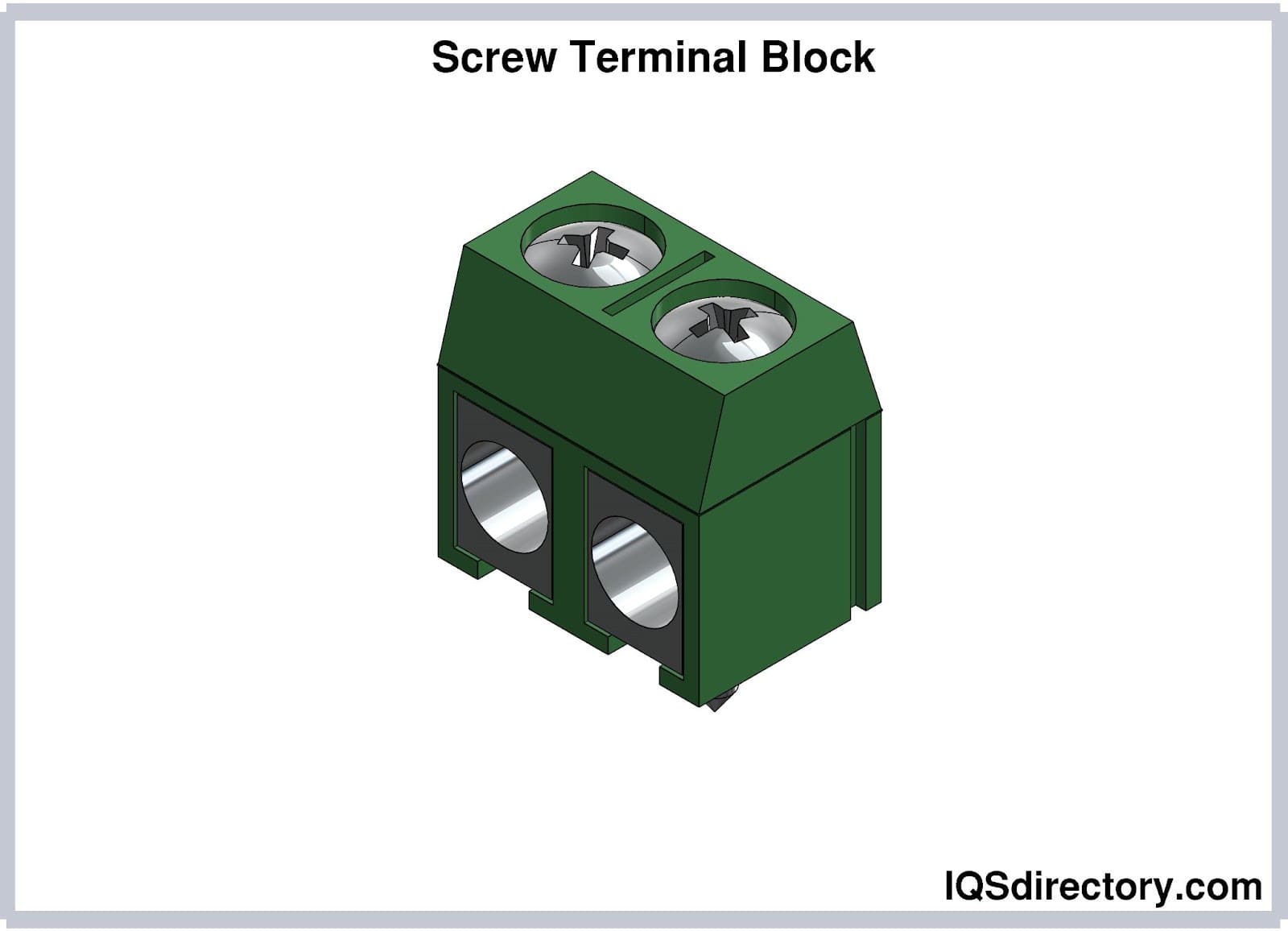

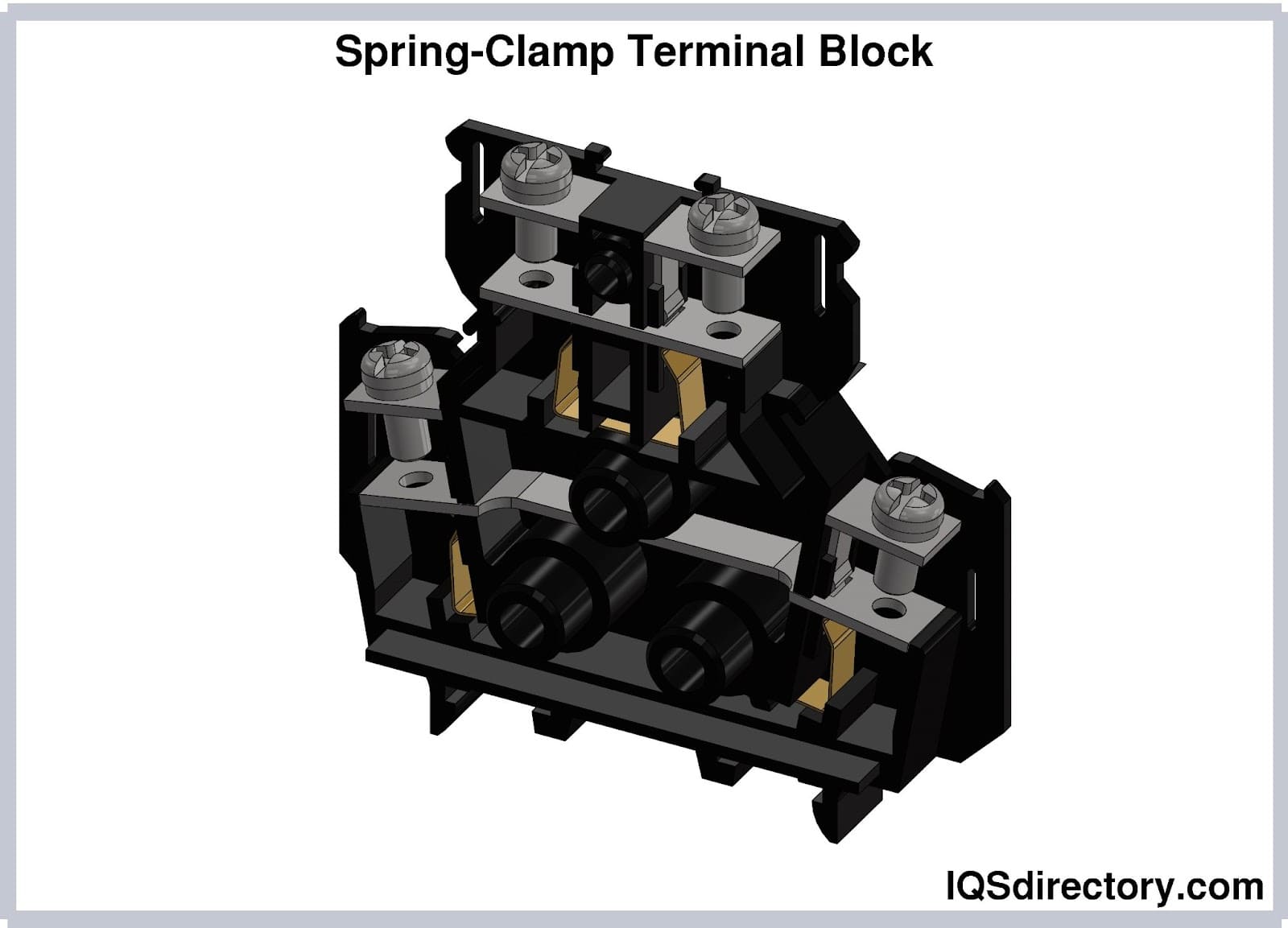

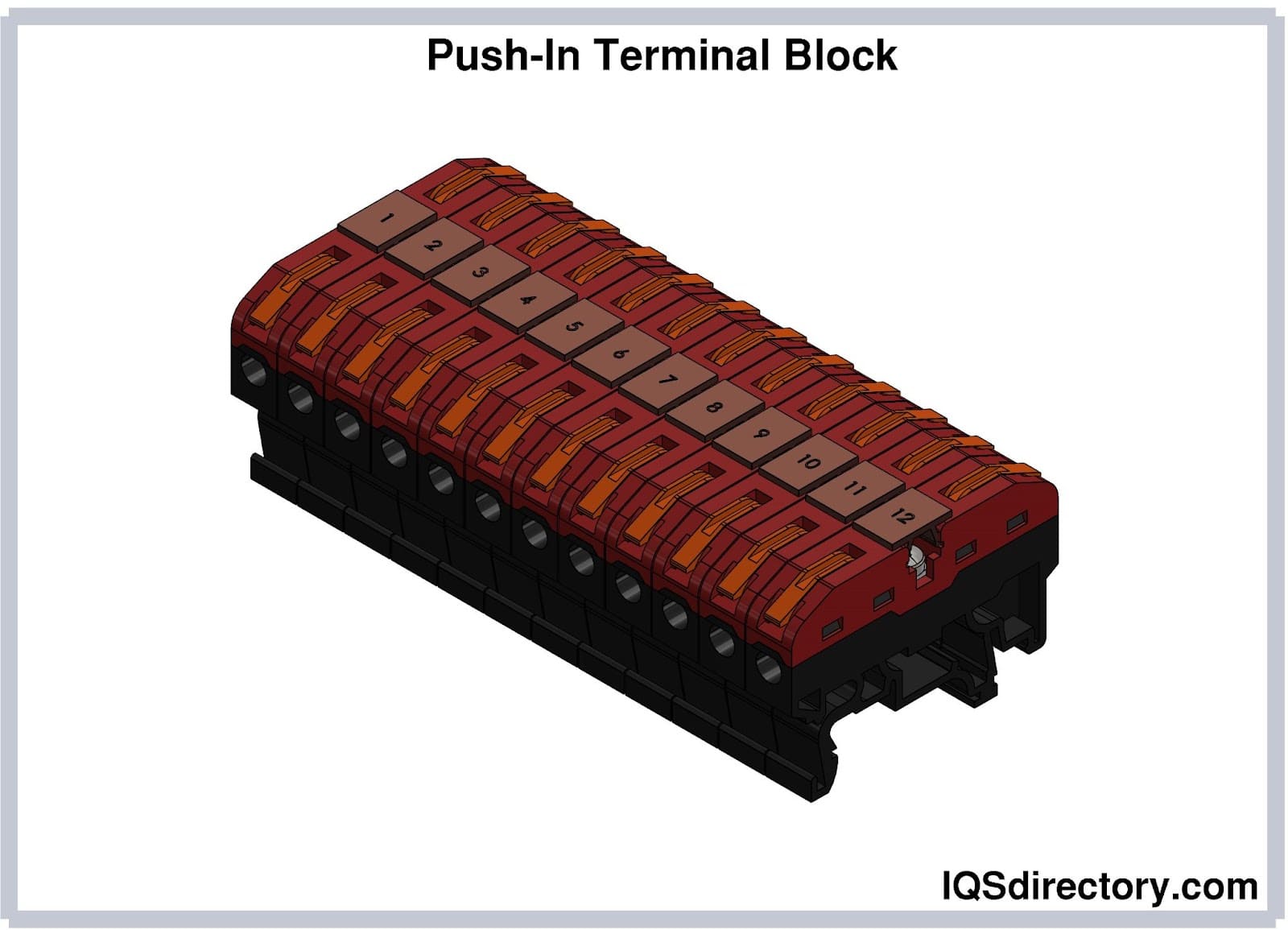

A terminal block is a modular, insulated connection system used to organize, secure, and distribute wiring in industrial control panels, automation equipment, and power distribution assemblies. Comprising a strip of metal terminals with clamping mechanisms, terminal blocks facilitate safe, reliable connections for multiple wires—streamlining installation, maintenance, and troubleshooting. Terminal blocks help ensure compliance with electrical codes, optimize space utilization, and provide clear identification for wiring junctions. Their ability to withstand high current, voltage, and temperature variations makes them indispensable for industrial and commercial electrical infrastructure.

Their Structure

Their Application

Screw terminal blocks are the industry-standard choice for wire-to-board and wire-to-wire connections, favored for their flexibility and strong, vibration-resistant electrical contacts. The clamping mechanism uses a screw to press down on a metal strip, securing the wire in place. For stranded wires, a ferrule—a tubular metal sleeve—improves connection reliability and reduces fraying. Screw terminal blocks are common in control cabinets, HVAC systems, lighting controls, and industrial power applications as they accommodate a wide range of conductor sizes and are easy to install, modify, and maintain.

Spring-clamp terminal blocks utilize spring pressure instead of screws to hold conductors securely. These blocks provide quick, tool-free installation, making them ideal for high-density wiring, vibration-prone environments, and maintenance-friendly systems. Available in single, double, or triple-level formats, spring-clamp designs save space and are highly reliable in control panels, automation equipment, and signal wiring for process instrumentation. They maintain strong electrical connections even with repeated wiring cycles.

Push-in terminal blocks, also known as quick-disconnect blocks, feature a tool-less design for swift, secure wire insertion. Compatible with both solid and stranded wires (with ferrules), push-in blocks are designed to optimize assembly line efficiency and support frequent modifications. Available in male (tab) and female (receptacle) styles, push-in terminal blocks are applied in PLCs, sensor interconnections, building automation, and modular equipment architectures. Integrated locking mechanisms ensure high connection reliability and minimize contact resistance.

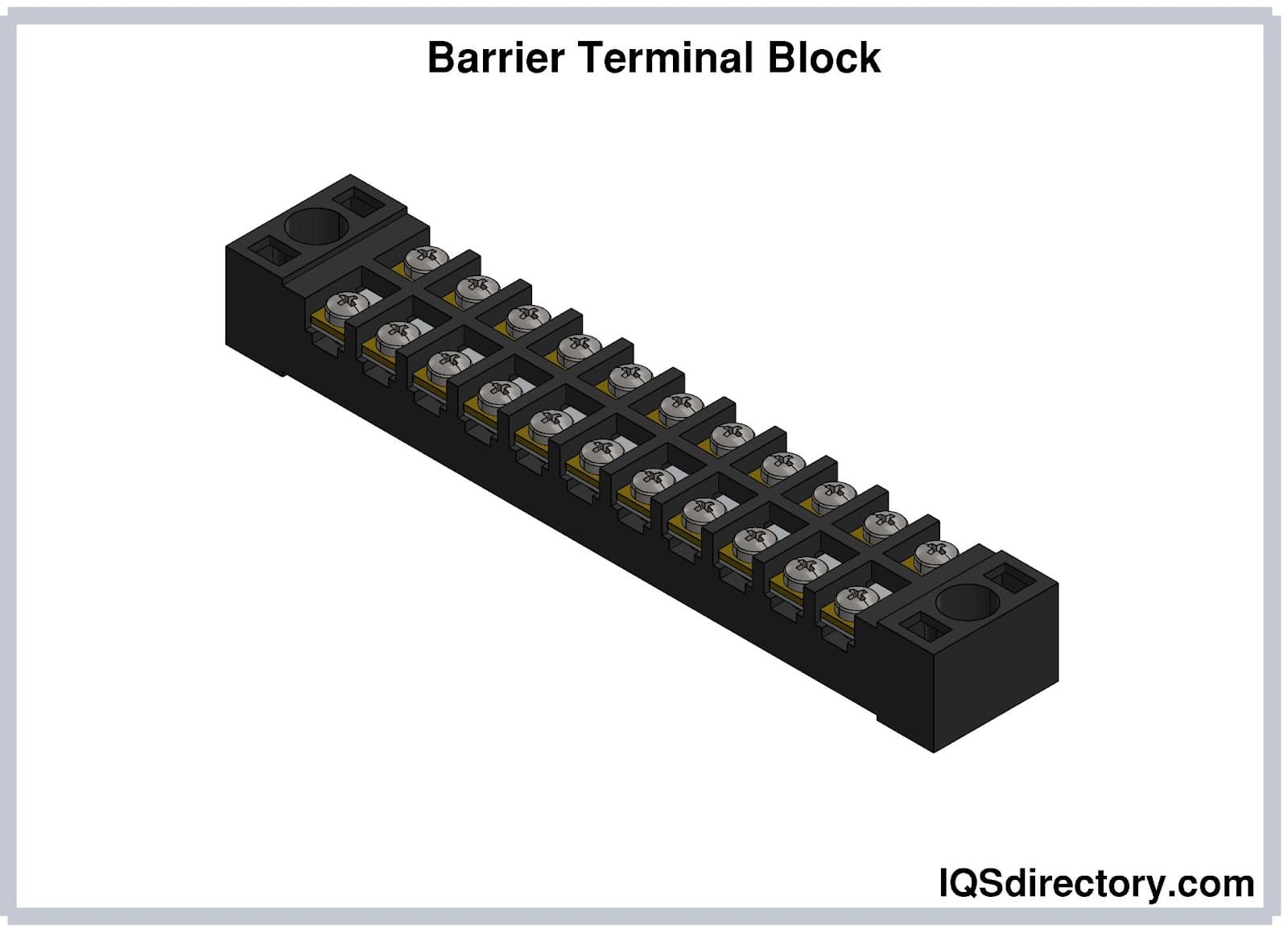

Barrier terminal blocks employ insulating barriers to segregate adjacent connections, reducing the risk of short circuits and improving safety. These blocks typically use pressure plates or screw-down mechanisms for strong, vibration-resistant contacts, supporting both bare and terminated wires. Barrier terminal blocks feature in industrial controls, heavy equipment, audio systems, and marine wiring where secure, high-current connections with easy access are priorities. Their modularity and resilience enable fast installation and simplified maintenance in complex wiring setups.

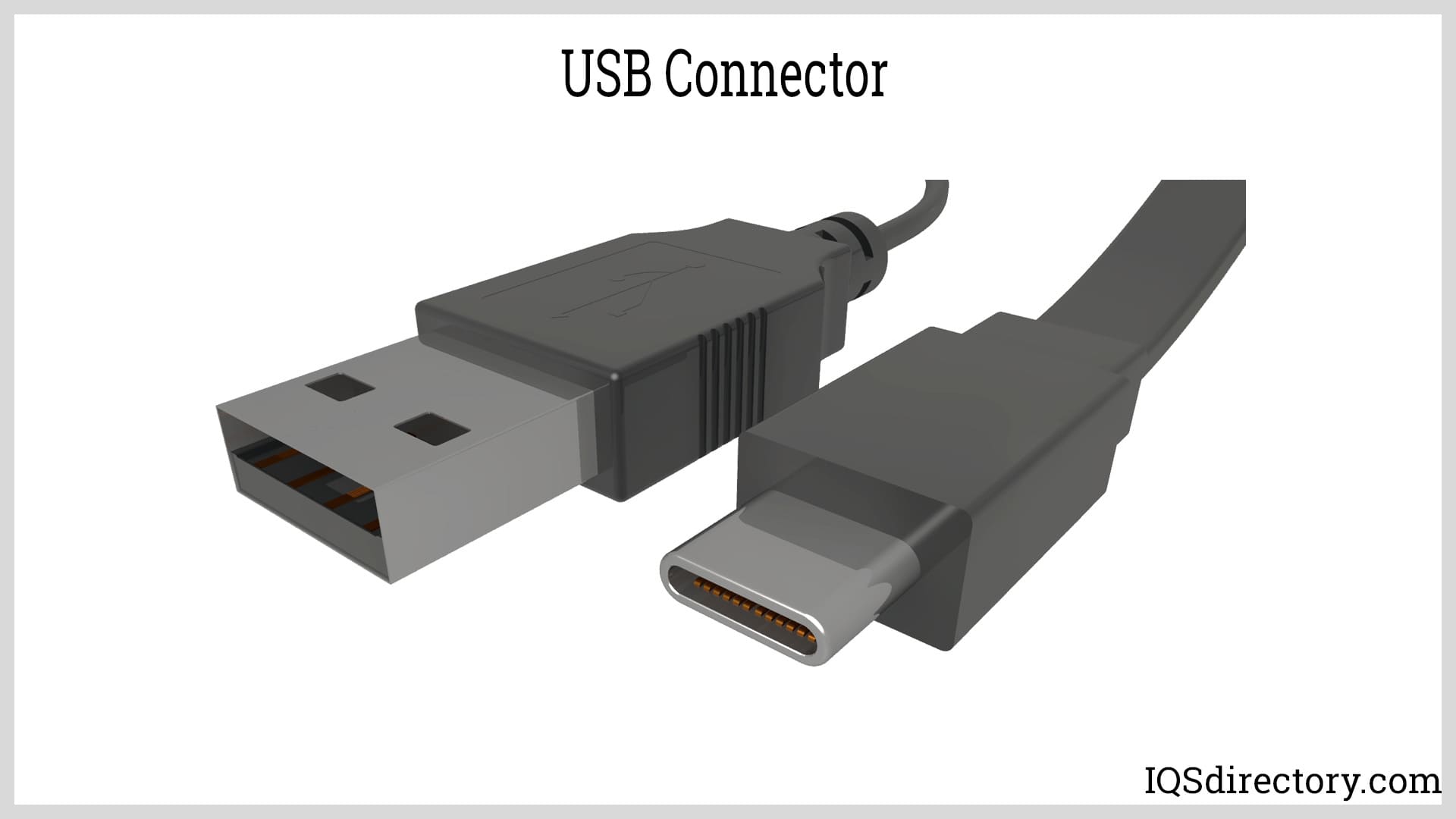

Universal Serial Bus (USB) connectors are ubiquitous interface solutions for both data transfer and DC power delivery across personal computers, smartphones, storage devices, and industrial electronics. Each USB connector consists of male and female contacts enclosed in a protective housing—incorporating keying and shielding features for robust electrical performance. With support for backward compatibility, USB standards (from USB 1.0 to USB 3.2) ensure reliable, high-speed communication and intelligent device charging.

USB connectors are classified according to style (Type-A, Type-B, Type-C), size (Standard, Mini, Micro), orientation, and application. USB-A is most common for host ports, supporting peripherals such as keyboards, mice, and drives. USB-B connectors, larger and well-suited for board mount or industrial interfaces, offer dependable connections for printers and instrumentation. Mini and Micro USB variants enable miniaturization for portable electronics, while advanced USB-C connectors support reversible plug orientation, fast charging (Power Delivery), and high-speed data throughputs for next-generation devices and hubs.

As USB standards evolve, features such as USB-OTG (On-The-Go) and USB Power Delivery enable flexible roles for devices and unified charging solutions—making USB connectors a key element in the design and function of modern electronic products.

Audio and video (AV) connectors are a comprehensive class of electronic connectors designed to transmit analog or digital audio and video signals across consumer electronics, studio equipment, and professional AV systems. These connectors come in myriad forms for supporting single-channel (mono) or multi-channel (stereo) signals—and for integrating both analog and digital interfaces within modern entertainment, broadcast, and data communication technology.

Understanding the types, performance characteristics, and use cases for different AV connectors helps engineers and DIY enthusiasts select optimal solutions for home audio setups, studio wiring, multimedia projects, and networked AV infrastructure.

Phone Connectors (also called TS/TRS/TRRS “tip-ring-sleeve” jacks) use coaxial contacts and are available in 2.5 mm, 3.5 mm, and 6.35 mm diameters. Found in headphones, musical instruments, and telephony, phone connectors support mono, stereo, and even combined microphone/audio channel configurations in modern portable devices.

DIN Connectors are multi-pin interfaces standardized by the Deutsches Institut für Normung (DIN) for analog signal transmission. These connectors enable reliable wiring in vintage audio gear, MIDI devices, and data networks and are available as both standard and mini-DIN variants for compact equipment. Keyed designs prevent misalignment and support durability in frequent-use scenarios.

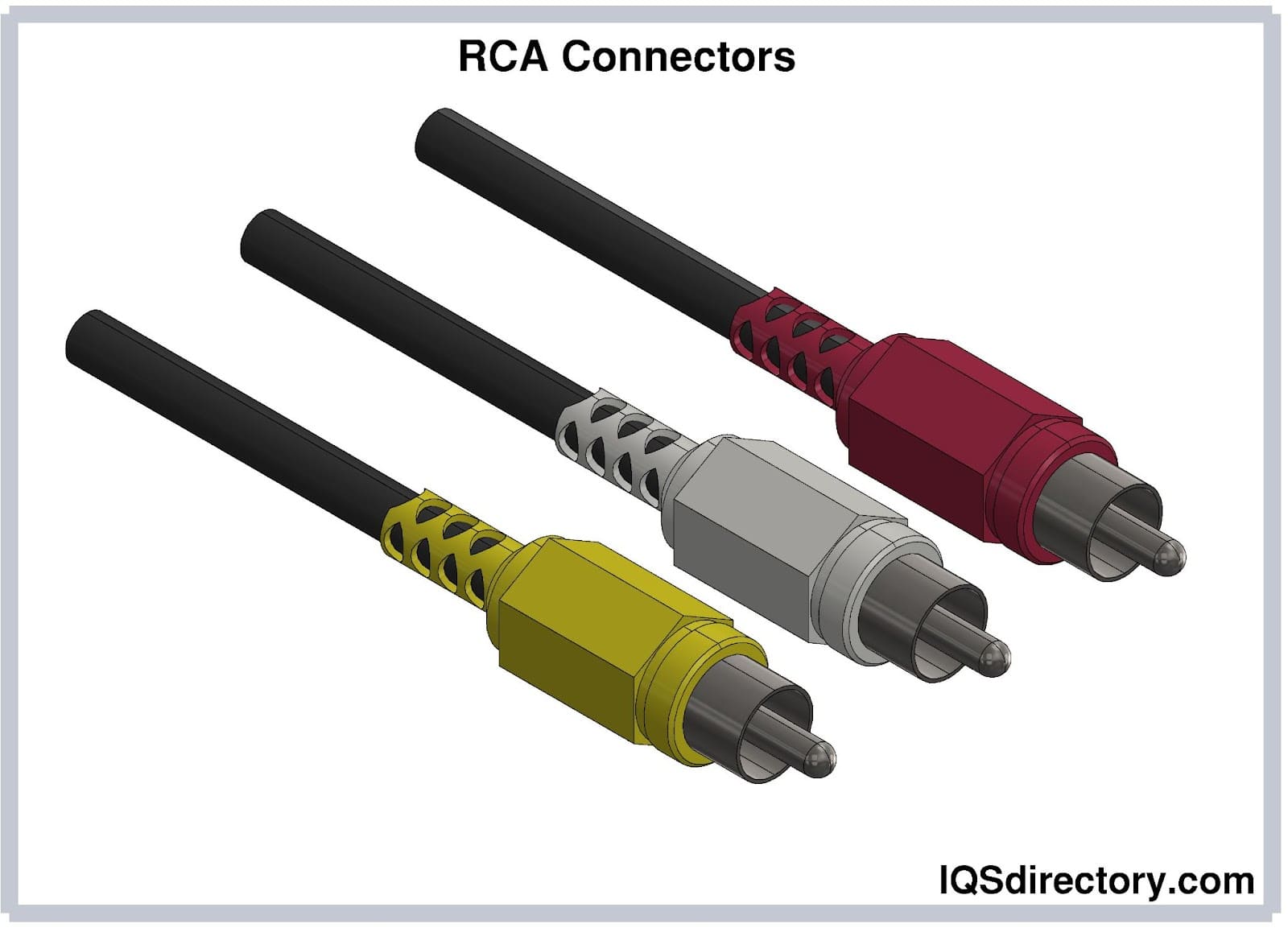

RCA Connectors (phono connectors) are color-coded interfaces for stereo audio (red/white) and composite video (yellow). Used in legacy home entertainment, speaker wiring, and analog video transmission, RCA connectors are valued for their convenience, affordability, and ability to integrate with other connector types via adapters or converter cables.

XLR Connectors are rugged, balanced connectors with three to seven pins, designed to resist electromagnetic interference and voltage drops over long cable runs. XLR connectors are the professional standard in live sound, recording studios, stage lighting systems, and intercom applications, with phantom power support (up to 48 V) built in for microphones and audio equipment.

High-Definition Multimedia Interface (HDMI) Connectors have become the go-to digital interface for transmitting high-definition video and audio. HDMI connectors use Transition-Minimized Differential Signaling (TMDS) for high-bandwidth transmission, supporting advanced video formats and multi-channel audio in home theaters, gaming consoles, and AV receivers. Different HDMI connector types—Standard (A), Dual-link (B), Mini (C), Micro (D), and Automotive (E)—accommodate various device sizes and environments.

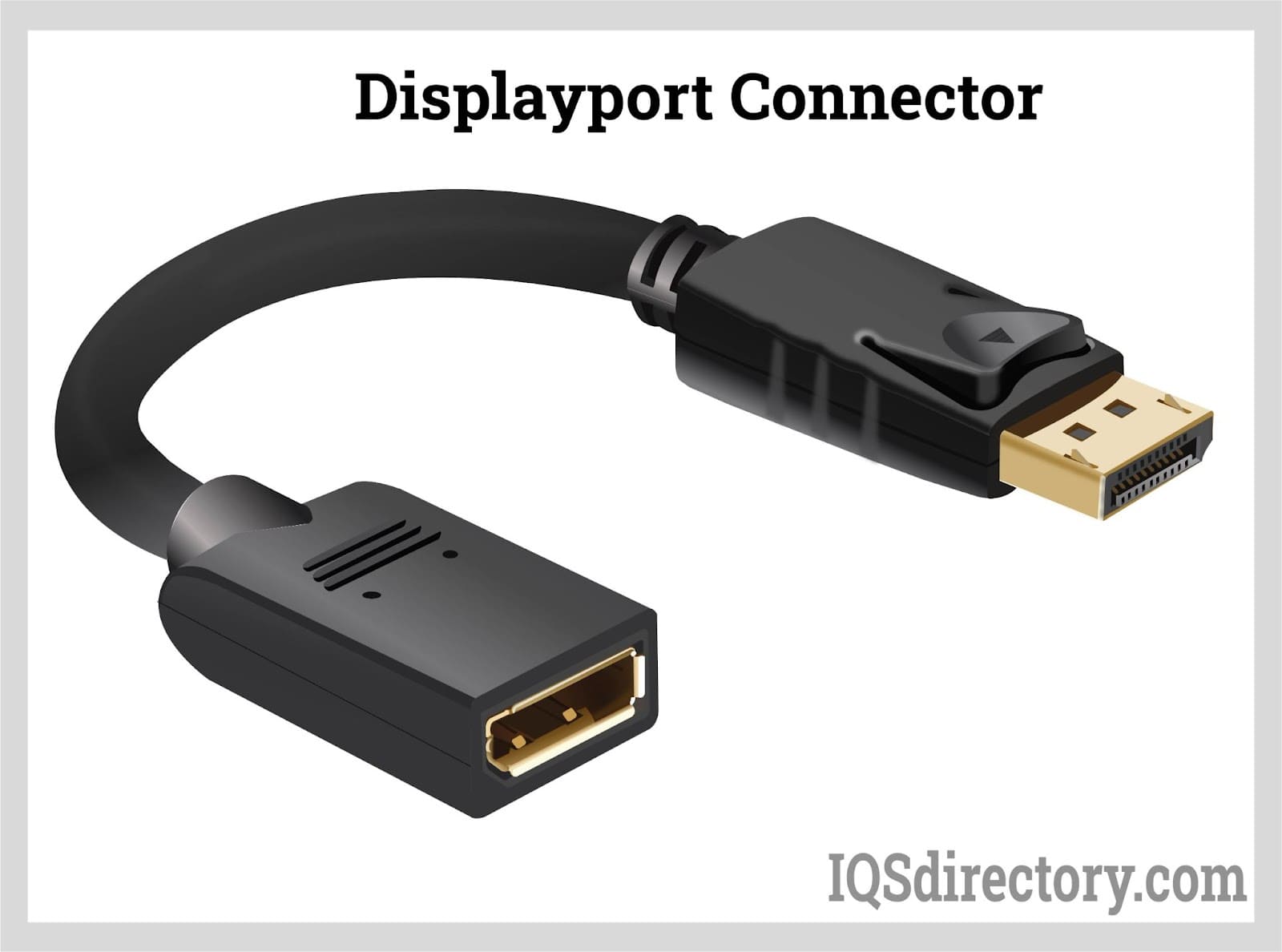

DisplayPort (DP) Connectors are designed for state-of-the-art high-definition video and multi-channel audio transfer between computers, monitors, and projectors. Supporting resolutions beyond 4K and featuring secure locking mechanisms, DisplayPort connectors are available in standard and mini sizes. DP cables are commonly used in professional graphics displays, workstation setups, and high refresh rate gaming systems, standing out for their long transmission distance and robust, multi-stream transport capabilities.

Digital Visual Interface (DVI) Connectors deliver both analog and digital video signals and are widely applied in desktop computers, monitors, and projection systems. DVI connectors, serving as a transition from analog (VGA) to digital (HDMI) standards, provide reliable, interference-resistant connections but require separate cabling for audio.

Video Graphic Array (VGA) Connectors have been the historic standard for analog video signal connectivity in computers and display equipment. Featuring a 15-pin arrangement, VGA connectors have been largely succeeded by digital standards like DVI and HDMI but remain essential for legacy equipment compatibility, KVM switches, and industrial automation displays.

Keying prevents incorrect mating by using unique physical features such as keys or notches. This ensures connectors fit only in the correct orientation, protecting against misalignment, short circuits, or component damage, especially in multi-pin or symmetrical connectors.

Locking mechanisms like push-pull, bayonet couplings, or screw couplings prevent accidental disconnections, enhance vibration resistance, and provide mechanical retention. They are vital in demanding environments to ensure ongoing electrical continuity and system performance.

Connector terminals are crafted from conductive materials such as brass, phosphor bronze, beryllium copper, and high-copper alloys. These materials provide reliable electrical pathways and support consistent current flow between circuits.

Contact pitch, the spacing between adjacent terminals, impacts connector compatibility, electrical isolation, signal integrity, and miniaturization. A correct pitch choice reduces arc-over risk and facilitates optimal performance in electronic assemblies.

Hermetically sealed, water resistant, moisture and oil resistant, EMI/RFI filtering, and ESD shielded connectors offer protection from extreme conditions, contaminants, and interference. Such features ensure reliability in industrial, military, and outdoor applications.

NEMA connectors are the standard for AC power plugs and receptacles in North America, found in residential, commercial, and industrial environments. They include non-locking and twist-lock types for varied application needs.

There are several choices when it comes to connector mounting, which is how leads of the connector mount or fasten to a circuit board. The different types of mountings include surface mounting (SM), through the hold, hanging, cutout, and through the board. Although the terms termination and mounting are used interchangeably, there are distinct differences between them.

The term mounting refers to the overall project and how the connectors interface, fasten, and attach. Termination refers to how the connection is being made and may indicate how the connector is attached at either end.

The term mount can be confusing in regard to what it is referring to. In general, mount or mounting is an all encompassing term that describes how connectors are attached. The many varieties of connectors require different types of mounting methods, which vary according to the terminating leads and type of connector.

Pin Through Hole - Pin through hole mountings are used when terminating leads are attached to a circuit board through holes or vias placed in a board.

Termination methods vary depending on personal preference with some terminations requiring a specific type. The determining factors are the needs of an application and the stipulations of a project.

In board-to-board and wire-to-board connections, solder terminations are used on through-hole mount or surface mount devices. In through-hole terminations, the terminals are inserted into drilled holes and soldered on the contact pads located on the other side of the board.

With surface mount terminations, the leads and mounting pads are on the same side of the board. Components are placed by hand and soldered using reflow or wave soldering. Terminals are soldered on contact pads on the same side as the connector.

Crimp connections involve compressing electrical wires and cables against a crimp termination or splice band. The compression reshapes the wire strands to create a low-resistance electrical connection, akin to a cold weld.

Crimping is crucial for reliable terminal connections. Improper crimping can result in electrical failures or even fires. Ensuring correct wire preparation, sizing, and using appropriate termination types, tools, and settings are vital for dependable and permanent connections. The crimping process starts with evaluating and measuring the wire's cross-section.

The crimping tool is either a ratchet or manual crimper. The jaws of the crimper cover the entire surface area of the connector and are equipped with crimping dies designed to match the gauge of the wire. Dies are color coded to indicate correct placement of the wire.

The wire to be crimped fits in the barrel of the connector, which is typically 0.25 inches (0.64 cm) in diameter. Once placed, the jaws of the crimper close and apply pressure to the barrel and wire. The compression removes the insulation from the wire exposing the conductors.

A strong connection between the connector and wire is critical for preventing connection failure and collateral damage. A final step in the crimping process involves twisting and tightening the exposed wire to ensure a secure fit.

The stripped exposed wire is inserted into the barrel of the connector until the insulation of the wire touches the barrel. None of the exposed wire should be visible at the entrance of the barrel or past the barrel into the tongue of the terminal.

The connector and stripped wire are placed back in the crimper die in a horizontal position with the barrel side facing upward and the flat side downward. The color of the die on the crimper should match the color of the insulation wire. The slot or die must match the gauge of the wire.

The crimper is placed perpendicular to the connector and stripped wire such that the crimper can firmly hold them. The jaws of the crimper should be placed closer to the tongue of the connector than to the insulation of the wire. Once positioned, the jaws of the crimper are closed with great force such that the wire cannot be removed when it is pulled away from the terminal.

Electrical tape or a heat shrink seal are used to protect the wire and connector of the terminal against exposure to the elements. The adhesive of the electrical tape makes a tight connection while heat shrinking involves applying heat melts plastic material and causes it to deform to the shape of the terminal.

Crimping eliminates the need for soldering wire connections and avoids potential failure associated with soldered joints that become brittle and crack. Terminal manufacturers supply information regarding the appropriate tooling and materials for completing a connection that should be followed to prevent wiring failures.

Ratchet crimp tools provide tactile evidence that the terminal crimp has been fully compressed and have color coding for easy identification of the proper die. Additionally, the jaws of a ratchet crimp tool will not open until the crimp between the connector and wire is sufficiently snug and tight.

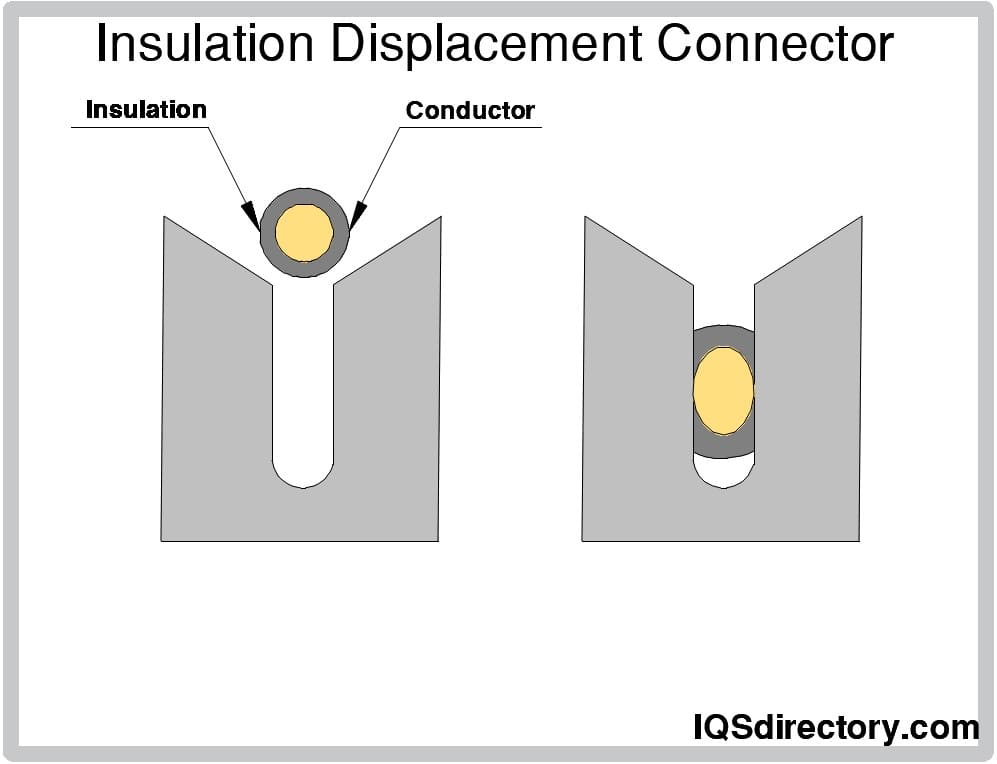

Insulation Displacement Connectors (IDCs) have sharp blades that strip the wire insulation as the wire or cable is inserted. Once properly placed, the exposed area of the wire is cold-welded to the connector terminal, creating a secure and reliable connection. The insulation displacement is commonly used on ribbon cable connectors and telephone and network plugs.

Push-in terminations are reliable and rugged terminations that can be temporary or permanent. Wires are stripped and pushed into the connector or locked in. Although the push-in and locked in methods are most common, there are several variations of push-in terminations. They are quite common and used with several types of connectors. Push-in terminations are restricted to applications that do not have any vibrations that could break or loosen the connection. A vibration rating of an application is required for the use of push-in terminations.

Power supplies are electrical circuits and devices that are designed to convert mains power or electricity from any electric source to specific values of voltage and current for the target device...

An AC power cord is a detachable way of providing an alternating current of electric energy from a mains power supply to an electrical appliance or equipment. Serving industries like...

An AC power supply is a type of power supply used to supply alternating current (AC) power to a load. The power input may be in an AC or DC form. The power supplied from wall outlets (mains supply) and...

A DC DC power supply (also known as DC DC Converter) is a kind of DC power supply that uses DC voltage as input instead of AC/DC power supplies that rely on AC mains supply voltage as an input...

A DC power supply is a type of power supply that gives direct current (DC) voltage to power a device. Because DC power supply is commonly used on an engineer‘s or technician‘s bench for a ton of power tests...

An electric switch is a device – usually electromechanical – that is used to open and close an electric circuit. This disables and enables the flow of electric current, respectively...

Electrical plugs, commonly known as power plugs, are devices responsible for supplying and drawing current from a receptacle to the circuitry of an electrical appliance...

By definition a power supply is a device that is designed to supply electric power to an electrical load. An electrical load refers to an electrical device that uses up electric power. Such a device can be anything from...

A NEMA connector is a method for connecting electronic devices to power outlets. They can carry alternating current (AC) or direct current (DC). AC current is the typical current found in homes, offices, stores, or businesses...

A power cord is an electrical component used for connecting appliances to an electrical utility or power supply. It is made from an insulated electrical cable with one or both ends molded with connectors...

A programmable power supply is a method for controlling output voltage using an analog or digitally controlled signal using a keypad or rotary switch from the front panel of the power supply...

Push button switches are electrical actuators that, when pressed, either close or open the electrical circuits to which they are attached. They are capable of controlling a wide range of electronic gadgets...

Thomas Edison developed the power distribution system in 1882. He wrapped a copper rod in jute, a soft shiny fiber from plants, as an insulator. The jute wrapped copper rod was placed in a pipe with a bituminous compound...