Ceramic Magnets

A ceramic magnet, also known as a ferrite magnet, is a permanent magnet made by combining iron oxide and strontium carbonate. They are a man made magnet produced by heating the two elements to...

Please fill out the following form to submit a Request for Quote to any of the following companies listed on

This article takes an in depth look at alnico magnets.

You will learn more about topics such as:

An Alnico magnet is a form of permanent magnet engineered from a combination of aluminum, nickel, iron, cobalt, and other elements. These magnets are available in isotropic forms, which have no specific magnetic direction, and anisotropic forms, which are directionally focused. Once magnetized, alnico magnets exhibit magnetic strengths that are 5 to 17 times higher than those of naturally occurring magnetite or lodestone, substances renowned for their ability to attract iron.

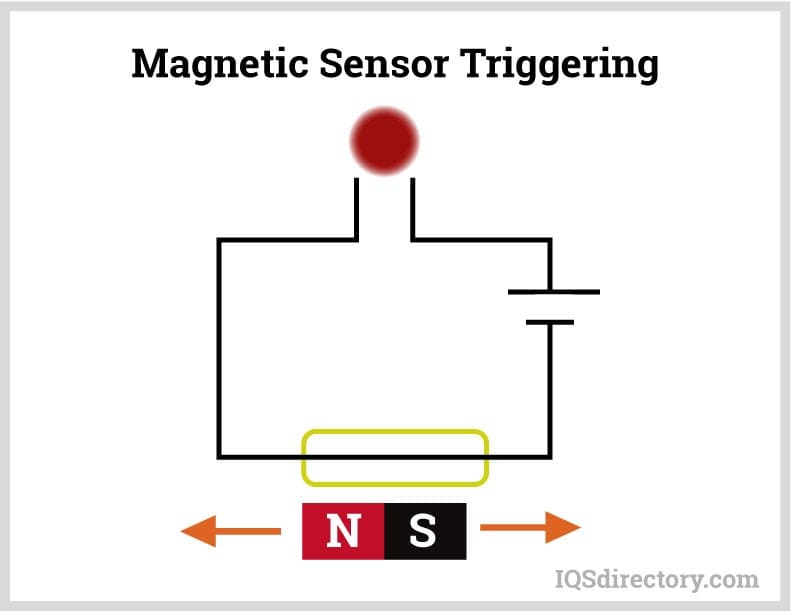

Alnico magnets are notable for their low temperature coefficient and the ability to be fine-tuned for high residual induction, making them ideal for high-temperature applications up to 930°F (500°C). They are frequently used in situations where corrosion resistance is essential and are also prominent in various sensor technologies.

First developed in the 1930s, alnico magnets are particularly prized in permanent magnet motors for their distinctive magnetic properties and stable temperature coefficient. These magnets maintain their magnetic field effectively, resist demagnetization, and retain their magnetism even at high temperatures. Unlike many other magnets, alnico magnets are not cold worked; instead, they are produced via sintering or casting methods.

Historically, naturally occurring lodestones were employed by explorers to find magnetic north. The advent of the first industrial revolution led to the creation of artificial magnets, culminating in the development of alnico magnets.

Alnico magnets combine aluminum, nickel, iron, cobalt, and sometimes copper or titanium. They are notable for high magnetic strength, stability at temperatures up to 930°F (500°C), and excellent resistance to demagnetization compared to natural magnets.

Cast alnico magnets are preferred for large, custom-shaped magnets in motors and scientific devices, while sintered alnico magnets are chosen for precise, high-volume applications like sensors and electronics due to their uniformity and cost-efficiency.

Industries such as aerospace, automotive, scientific instrumentation, and electronics depend on alnico magnets for sensors, motors, and components requiring stable magnetic strength at elevated temperatures or corrosive environments.

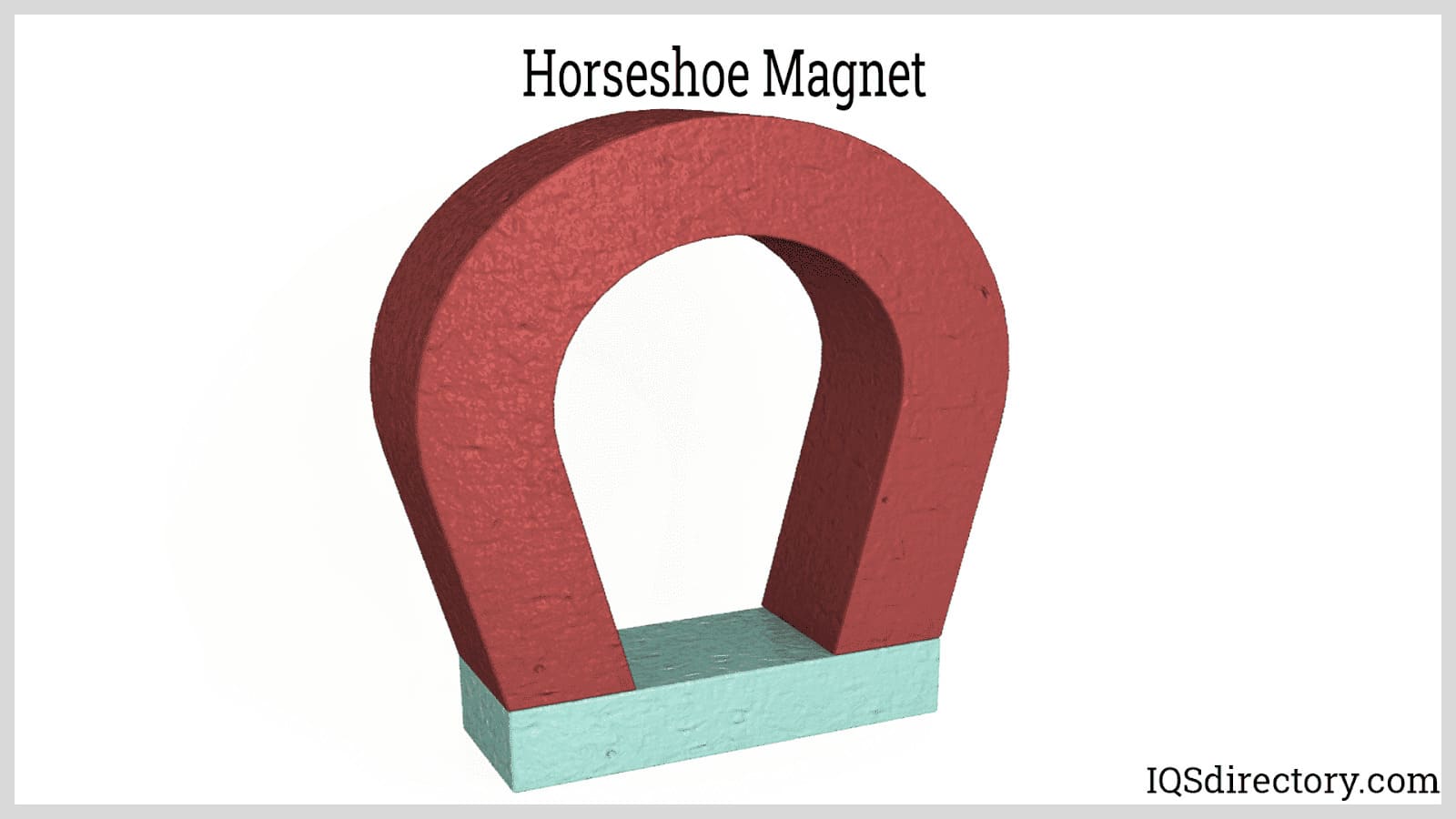

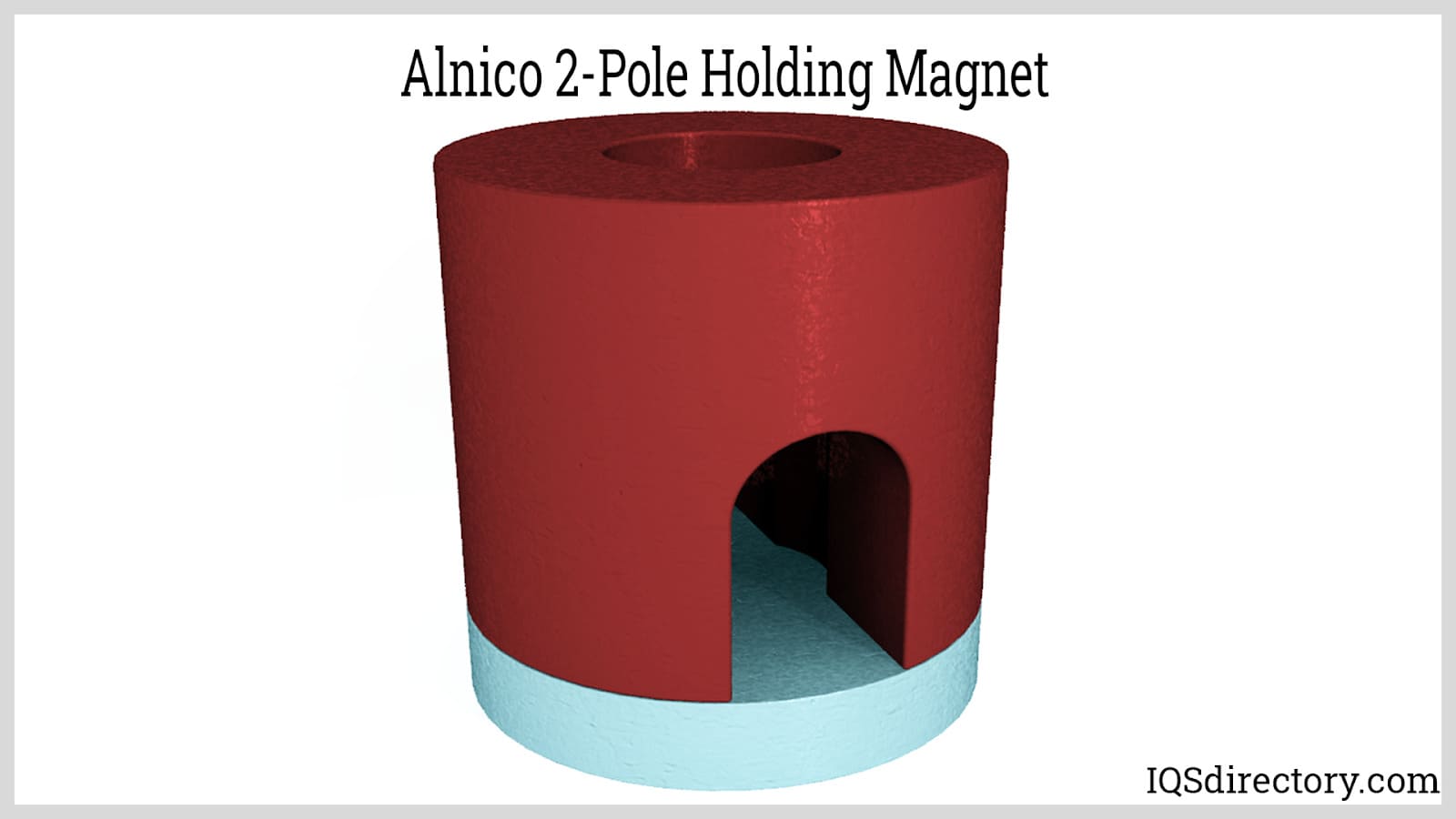

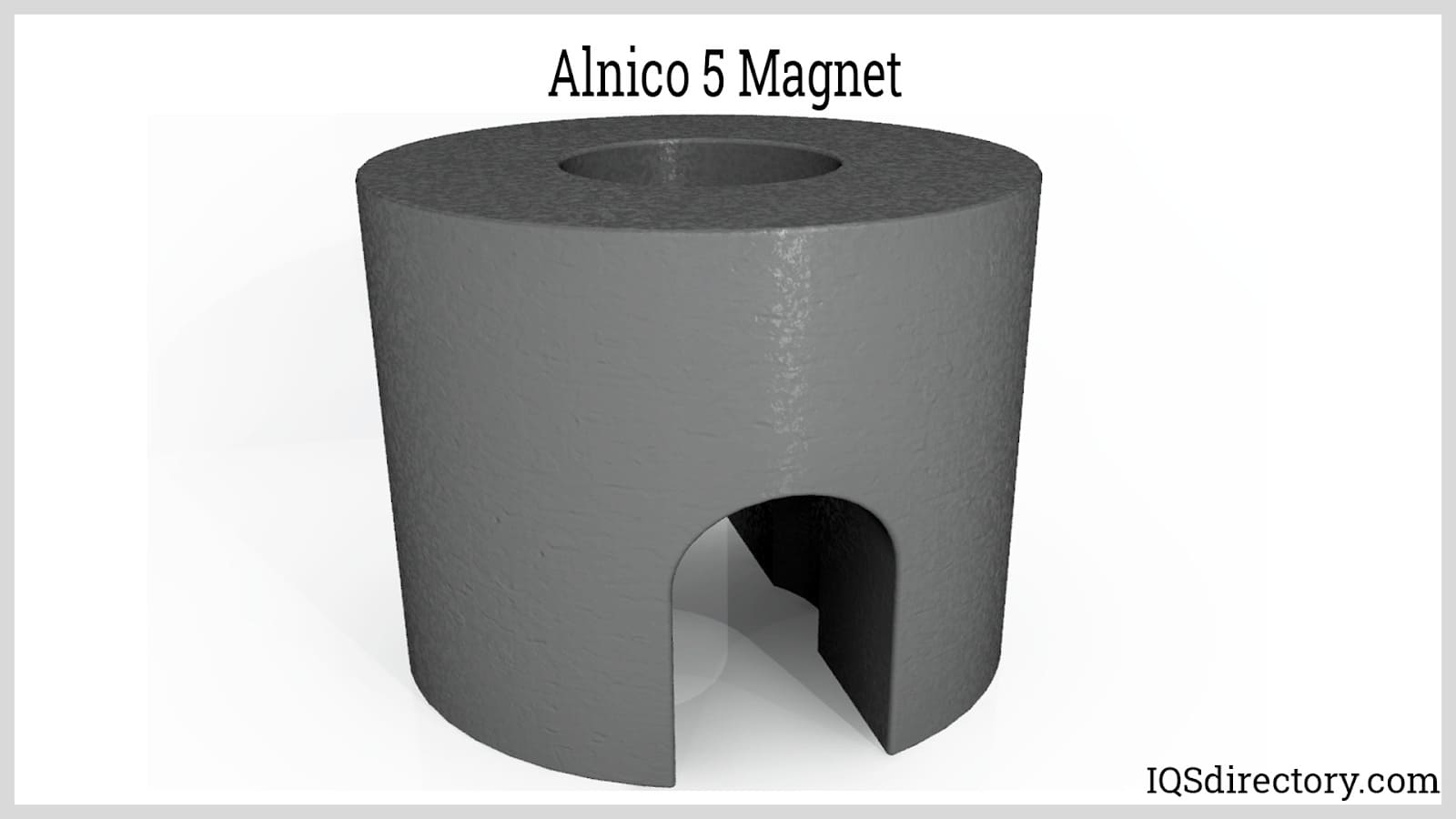

Alnico magnets come as bars, rods, cylinders, horseshoes, pots, and rings. Shapes like horseshoe and pot maximize strength for lifting or holding, while cylinders and rods excel in audio, medical, and automation devices.

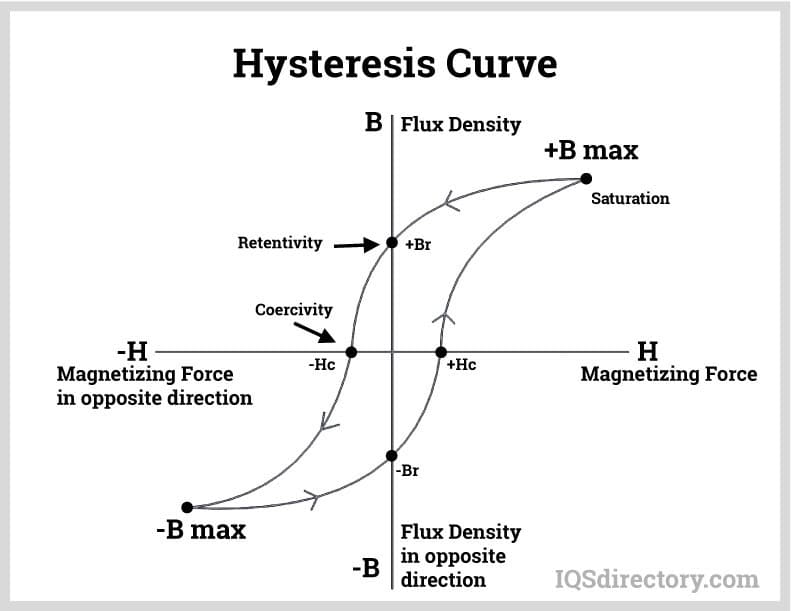

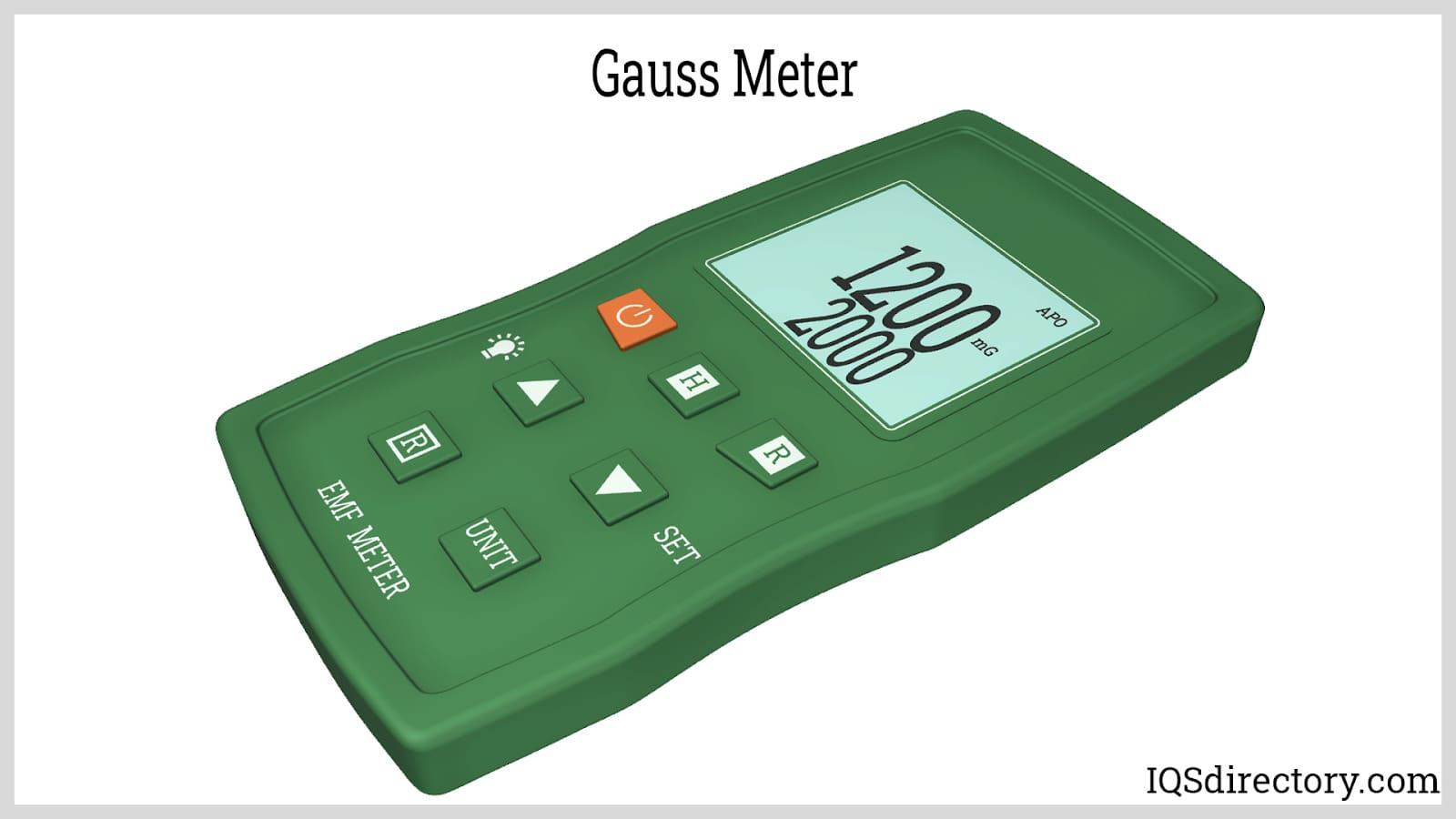

Quality is verified using hysteresis loop tests for retained magnetism, gauss meters to measure field strength, and fluxmeters for total flux—ensuring consistent magnetic output for demanding applications.

Although alnico magnets are naturally resistant to corrosion, special coatings like nickel or epoxy are applied for added protection in high-humidity, saline, or chemically aggressive settings, extending durability in marine and automotive uses.

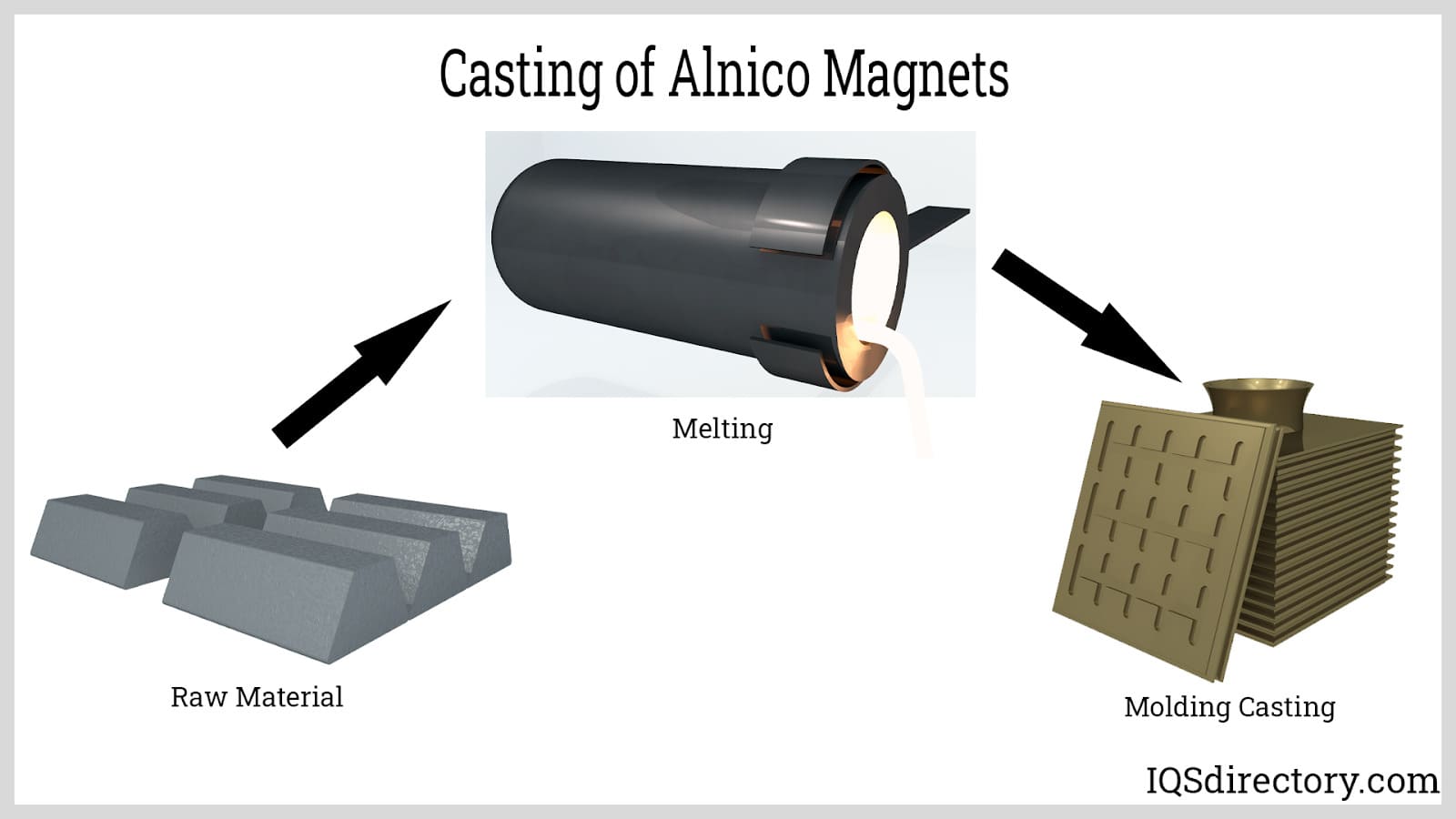

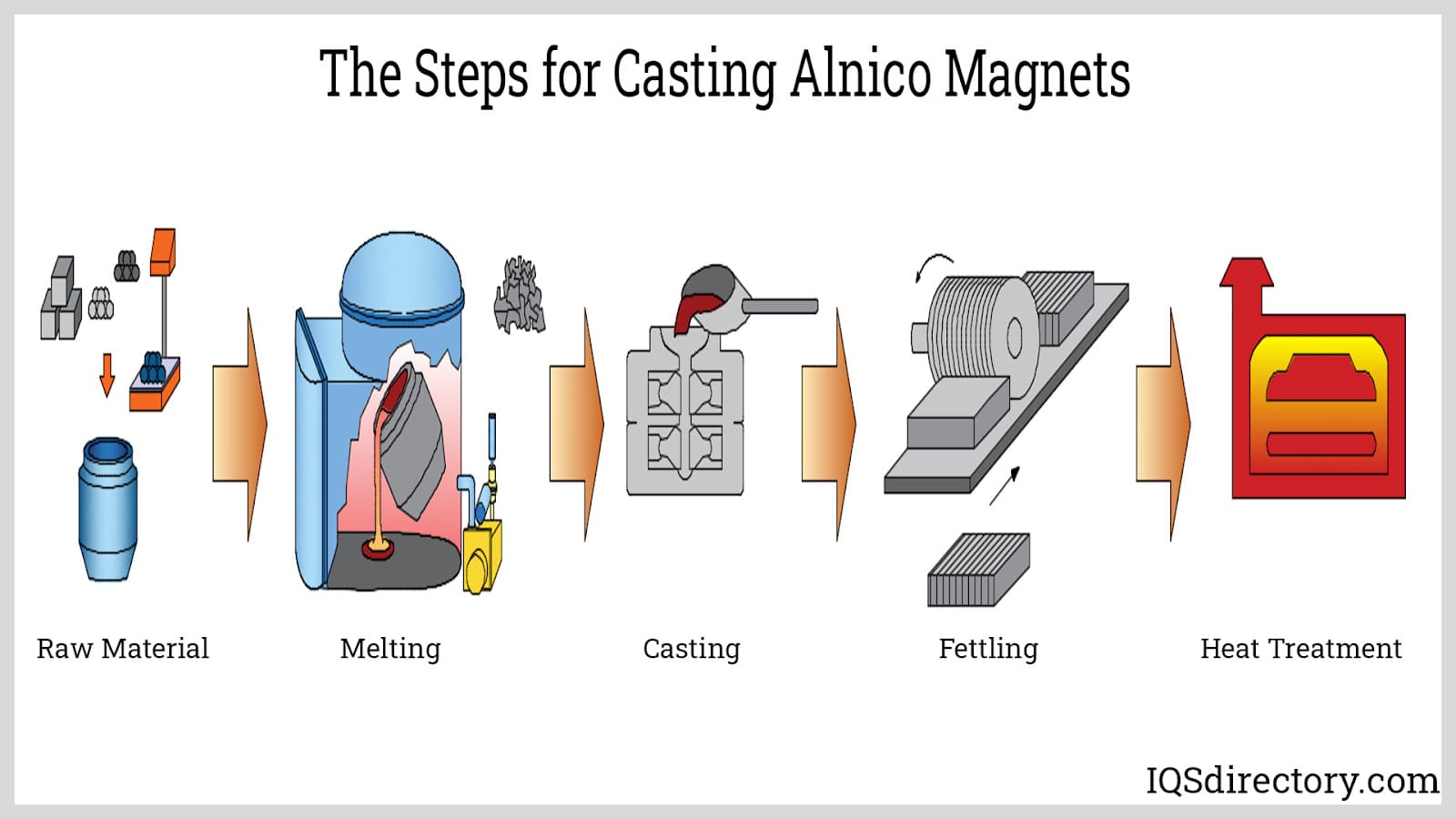

Alnico magnets, a class of permanent magnets composed primarily of aluminum (Al), nickel (Ni), and cobalt (Co), are manufactured using advanced metallurgical processes such as sintering or casting. These industrial magnet production methods enable manufacturers to leverage the unique properties of alnico alloys, combining elements like iron, copper, and titanium to increase magnetic energy product and overall magnetic strength. The alnico casting process involves pouring a molten alloy into precision-engineered molds—often crafted from resin-bonded sand—for optimal shape and density. Cast alnico magnets are typically larger and feature superior magnetic properties, high-temperature stability, and outstanding magnetic performance compared to sintered varieties, making them ideal for demanding industrial applications.

The casting technique provides tremendous versatility for customizing the geometry of alnico magnets, accommodating complex shapes and sizes that are impractical through conventional sintering. Regardless of the manufacturing process selected, industrial-grade alnico magnets are inherently brittle and cannot be cold worked—necessitating exclusive reliance on high-temperature forming and processing to achieve desired magnet specifications.

The grade of an alnico magnet—which influences applications in the automotive, aerospace, electronics, and sensor markets—is determined by its exact chemical formulation. Refer to the chart below for in-depth specification comparisons and performance data on popular alnico magnet grades.

| Dura Magnetics | ||||||||||

|---|---|---|---|---|---|---|---|---|---|---|

| Dura Magnet Grade | Residual Induction Br |

Coercive Force Hc |

Intrinsic Coercive Force Hci |

Maximum Energy Product (BH)max | Max Operating Temp | |||||

| Nominal | Nominal | Nominal | Minimum | Nominal | Nominal | |||||

| k-Gauss | Telsla | k-Oersted | KA/M | k-Oersted | KA/M | MG Oe |

KJ/m3 | °C | °F | |

| Alnico 5 | 12.2 | 1.22 | 600 | 48 | 630 | 50 | 5 | 40 | 500°C | 930°F |

| Alnico 5B | 12.22 | 1.22 | 650 | 52 | 660 | 53 | 5.5 | 44 | 500°C | 930°F |

| Alnico 5 DG | 12.5 | 1.25 | 690 | 55 | 700 | 56 | 6.5 | 52 | 500°C | 930°F |

| Alnico 5-7 | 13 | 1.3 | 700 | 56 | 740 | 59 | 7.5 | 60 | 525°C | 980°F |

| Alnico 8-HC | 7 | 0.7 | 1,750 | 139 | 1,750 | 139 | 4.5 | 36 | 525°C | 980°F |

| Alnico 8 | 8.2 | 0.82 | 1,500 | 119 | 1,600 | 127 | 5 | 40 | 525°C | 980°F |

| Alnico 8B | 8.8 | 0.88 | 1,500 | 119 | 1,650 | 131 | 5.5 | 44 | 525°C | 930°F |

| Alnico 8C | 9 | 0.9 | 1,380 | 110 | 1,440 | 115 | 7.5 | 60 | 525°C | 930°F |

| Alnico 9 | 10.5 | 1.05 | 1,410 | 112 | 1,440 | 139 | 9 | 72 | 525°C | 930°F |

The production technique for alnico magnets is selected based on parameters like final magnet size, weight, design complexity, and end-use application. For example, cast alnico magnets are favored for applications that necessitate large, custom-shaped, high-energy magnets—such as generators, electric motors, and scientific instrumentation—whereas sintered alnico magnets are preferred for manufacturing smaller magnets in significant volumes, such as sensors and electronic devices.

The creation of specific alnico magnet grades involves meticulously blending varying ratios of cobalt, aluminum, and nickel, along with trace elements like iron and titanium. For instance, the alnico 6 magnet formulation consists of 8% aluminum, 16% nickel, 24% cobalt, 3% copper, 1% titanium, and less than 1% assorted ferrous metals. All ingredients are loaded into an induction furnace and heated to 1750°C (3182°F), ensuring a homogeneous molten alloy. This high-temperature alloying is vital for optimal magnetic permeability and the long-term stability of the finished permanent magnet.

The casting process for alnico magnets utilizes green sand molds tailored to accommodate shrinkage and internal stresses. For some production runs, patterns are ganged together with intricate gating systems, allowing for efficient batch casting and precise control of casting volume. This methodology enables cost-effective manufacturing of large alnico magnet volumes with consistent material properties.

As the molten alloy is poured, careful regulation of mold temperature and sand properties influences the grain structure and surface finish. Upon cooling, the mold shell decomposes, leaving sand residue that is typically removed during finishing. Use of specialty shell molds—bonds of sand and resin—facilitates the formation of highly detailed and reproducible magnetic components, further reducing the need for secondary processing.

It’s important to account for casting shrinkage from the earliest design stages. Proper mold design ensures that the finished alnico magnets meet application-specific tolerances, minimizing post-casting waste and machining time. This precision is one reason cast alnico magnets are preferred for high-performance sensor magnets and scientific devices.

Fettling, the process of removing excess material such as gate remnants and flash from cast magnets, is essential to achieve dimensional accuracy and surface integrity. Given the brittle nature of alnico, careful precision machining and grinding reduce the risk of fracturing or chipping. This finesse in post-casting finishing is crucial for specialty magnet assemblies and customized industrial magnets.

Developing the final magnetic characteristics of alnico magnets demands a rigorous heat treatment regimen. Magnets are heated to temperatures as high as 1250°C (2282°F), then placed in strong external magnetic fields during cooling (hardening). This “magnetic annealing” locks the crystal structure into an orientation optimized for magnetic flux density, alignment, and coercivity. The final tempering phase in a controlled oven ensures long-term performance and resistance to thermal demagnetization, a key asset for high-temperature magnet applications such as sensors, scientific equipment, and aerospace electronics.

To attain exacting dimensional tolerances and specified surface finishes, select cast alnico magnets undergo finish grinding. This step is vital for magnets designed for precision assemblies, instrumentation, or where automated mounting is a requirement. By delivering magnets that meet strict engineering parameters, manufacturers ensure optimal integration into magnetic sensing, separation, and electrical machinery applications.

Stringent quality assurance and magnetic property evaluation are fundamental to industrial alnico magnet production. Multiple tests verify magnetic performance, consistency, and compliance with application standards. This includes the hysteresis loop test for assessing retained magnetism, the gauss meter for quantifying field strength, and the fluxmeter for measuring total magnetic flux—each crucial for applications requiring predictable, stable magnetic output.

Hysteresis Loop Test - The hysteresis loop provides a detailed view of material coercivity and residual flux density. For high-spec alnico permanent magnets, an ideally wide hysteresis loop signifies robust magnetic retention and minimal loss under operational reversal—essential traits for electric motor magnets and power generation components. Alnico is one of only a handful of materials that satisfy advanced hysteresis criteria for high-performance permanent magnets.

Gauss Meter - A gauss meter, utilizing Hall effect sensors, measures the strength, direction, and uniformity of a magnet’s field. This data confirms alnico magnets meet critical technical specifications for military, aerospace, and engine sensor applications, where reliable and predictable magnetism is non-negotiable.

Alnico magnets are naturally resistant to oxidation and corrosion due to their alloy composition. However, for environments with exposure to high humidity, saline, or aggressive chemicals, protective coatings (such as nickel, zinc, or specialized epoxy paints) are sometimes applied. These coatings are particularly beneficial in marine, automotive ignition, and laboratory magnet applications where long operational life is necessary.

In educational or laboratory environments, painted surfaces (often bright red) are applied for easy identification. While functional performance is generally unaffected, such coatings or aesthetic finishes are common in demonstration kits and magnet learning tools.

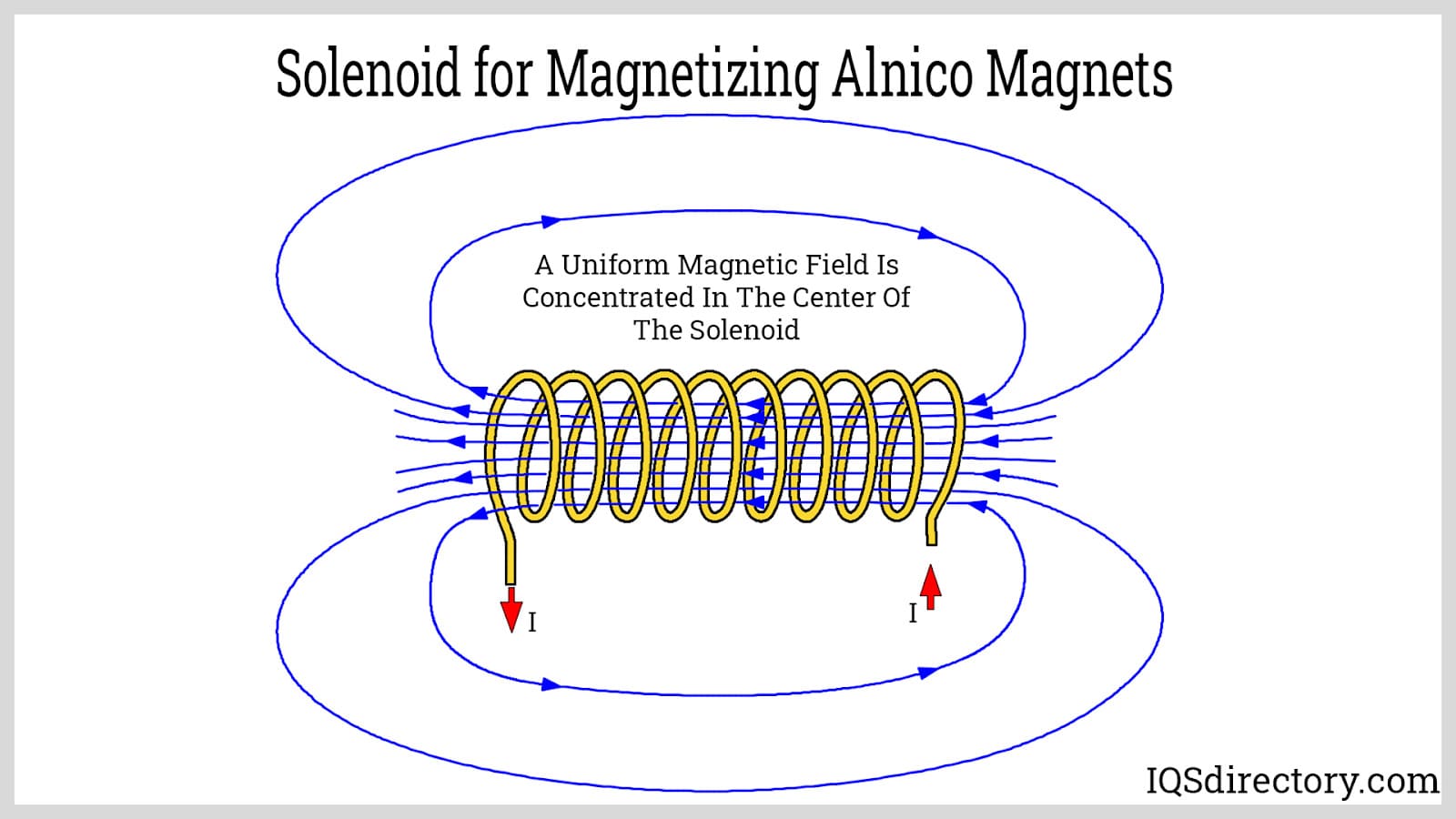

Prior to shipment and integration into equipment, alnico magnets undergo a dedicated magnetization process. Using state-of-the-art pulsed magnetizing equipment or static fields, the magnetic domains within the magnet are aligned according to the required magnetic orientation. Most commercial alnico magnets are anisotropic—magnetized in a single axis—for superior field strength and directivity. Precision magnetizers deliver very high current pulses, assuring full saturation and optimal performance for use in custom sensor magnets, actuator magnets, or other industrial permanent magnet assemblies.

Proper magnetization ensures each magnet’s north and south poles are clearly defined, supporting consistent function in rotating machinery, sensors, and measuring devices. For best results, state-of-the-art pulse magnetizing technology that can deliver high-intensity short-duration electrical pulses enables reliable, repeatable magnetic saturation.

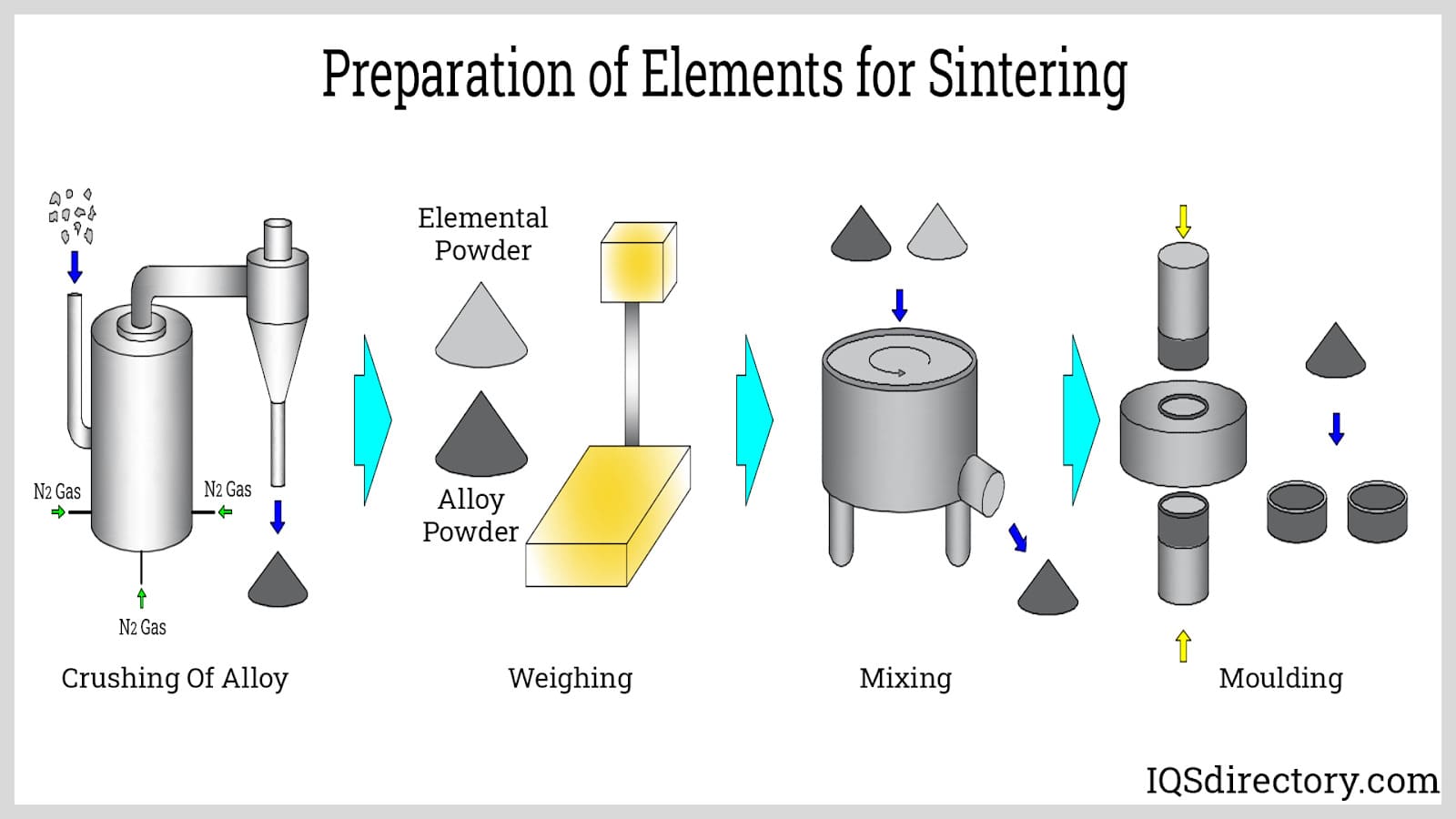

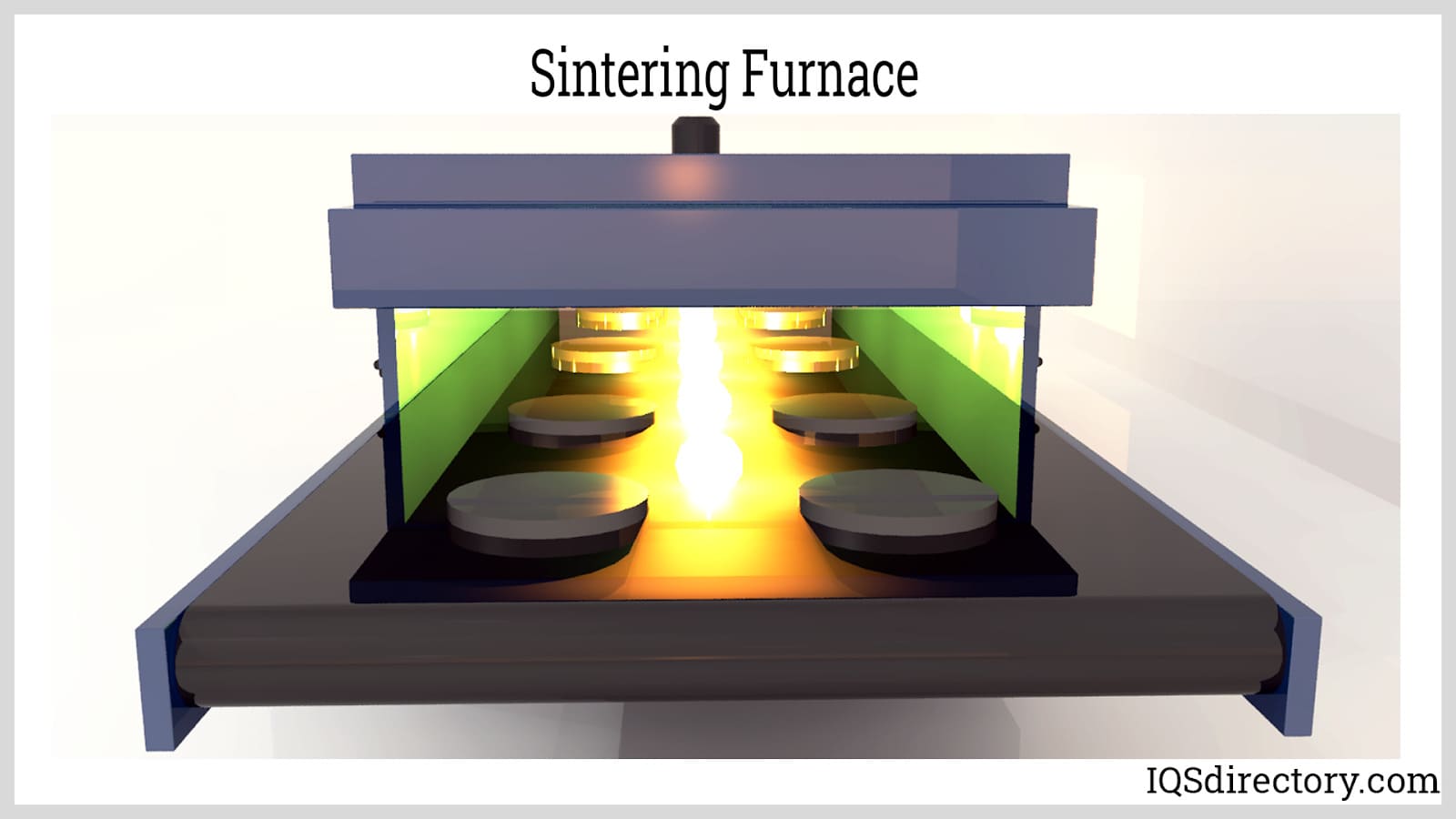

The sintering of alnico magnets, ideal for small- to medium-sized components or when complex production automation is required, begins with the formulation of a precise powder blend of constituent metals. Advanced powder metallurgy techniques allow the use of fine particles of aluminum, nickel, cobalt, iron, and supplemental elements. These powders are measured and homogenously mixed to exacting standards for properties like coercivity and remanence required in high-sensitivity sensor magnets.

The mixed alloy powder is pressed at high pressure in molds—perpendicular or parallel orientations may be selected to optimize the resultant energy product for specific device or assembly requirements. This method supports the high-volume, cost-efficient production of miniature alnico devices for automation, automotive, and electronics markets.

Sintering (frittage) consolidates the pressed powder into a solid, dense form via controlled heating below the melting point. As the compact is exposed to approximately 2300°F (1260°C) in a hydrogen or inert atmosphere furnace—often constructed of stainless steel and protected by molybdenum—they achieve the grain growth and bonding necessary for high coercive force and magnetic stability. The outcome is a finely-grained, structurally robust magnet ideal for relays, switches, and miniature electric motors.

Sintered alnico magnets are preferred when precise, repeatable dimensions or automated assembly line production is essential. The resulting magnets possess excellent corrosion resistance, mechanical integrity, and consistent magnetic properties across large batches, fulfilling requirements for automotive sensing devices, transducers, and medical equipment.

Following sintering, alnico magnets are cooled—often while exposed to a controlled external magnetic field—enabling the magnets’ internal magnetic domains to align directionally (anisotropy), which is optimal for applications where strong, focused magnetic fields are crucial. Absent a directional field during cooling, the resulting isotropic magnets have lower uniform magnetic characteristics.

Coating is rarely required for sintered alnico magnets due to their solid, chemically-stable surfaces. Nonetheless, light coatings may be utilized for color coding, part tracking, or aesthetic identification in complex assemblies or for educational demonstration sets. Functional coatings are added only when environmental exposure warrants additional protection.

The final operation for sintered magnets is precise magnetization. This is achieved using a pulse magnetizer or high-field solenoid, subjecting the magnet to the required magnetic field intensity (often 3 kOe or higher). This phase is indispensable for ensuring each magnet fulfills its role in high-reliability sensor assemblies, control devices, or medical diagnostic tools.

Choosing Between Cast and Sintered Alnico Magnets

When evaluating alnico magnets for your project, consider the trade-offs between casting and sintering. Cast alnico magnets offer maximum geometric flexibility, high magnetic performance, and are regularly chosen for applications requiring custom magnet shapes and powerful permanent magnets in motors and industrial equipment. Sintered alnico magnets, on the other hand, excel in low-tolerance, high-volume production for electronic componentry, sensor arrays, and automotive electronics where cost efficiency and uniformity are critical.

If you are sourcing alnico magnets for sale or comparing them to other permanent magnet materials (such as neodymium, samarium cobalt, or ferrite magnets), it’s important to assess key parameters including operating temperature range, corrosion resistance, remanence, and total cost of ownership. Consulting with leading alnico magnet manufacturers and experienced magnet suppliers will help deliver the most suitable solution for your application, ensuring industry compliance, technical reliability, and long-term operational performance.

Alnico magnets are available in a diverse range of shapes and sizes to suit various applications. They are used in everything from small toys and electric guitars to industrial machinery in factories. These magnets can be shaped through either sintering or casting, with casting being the more prevalent method.

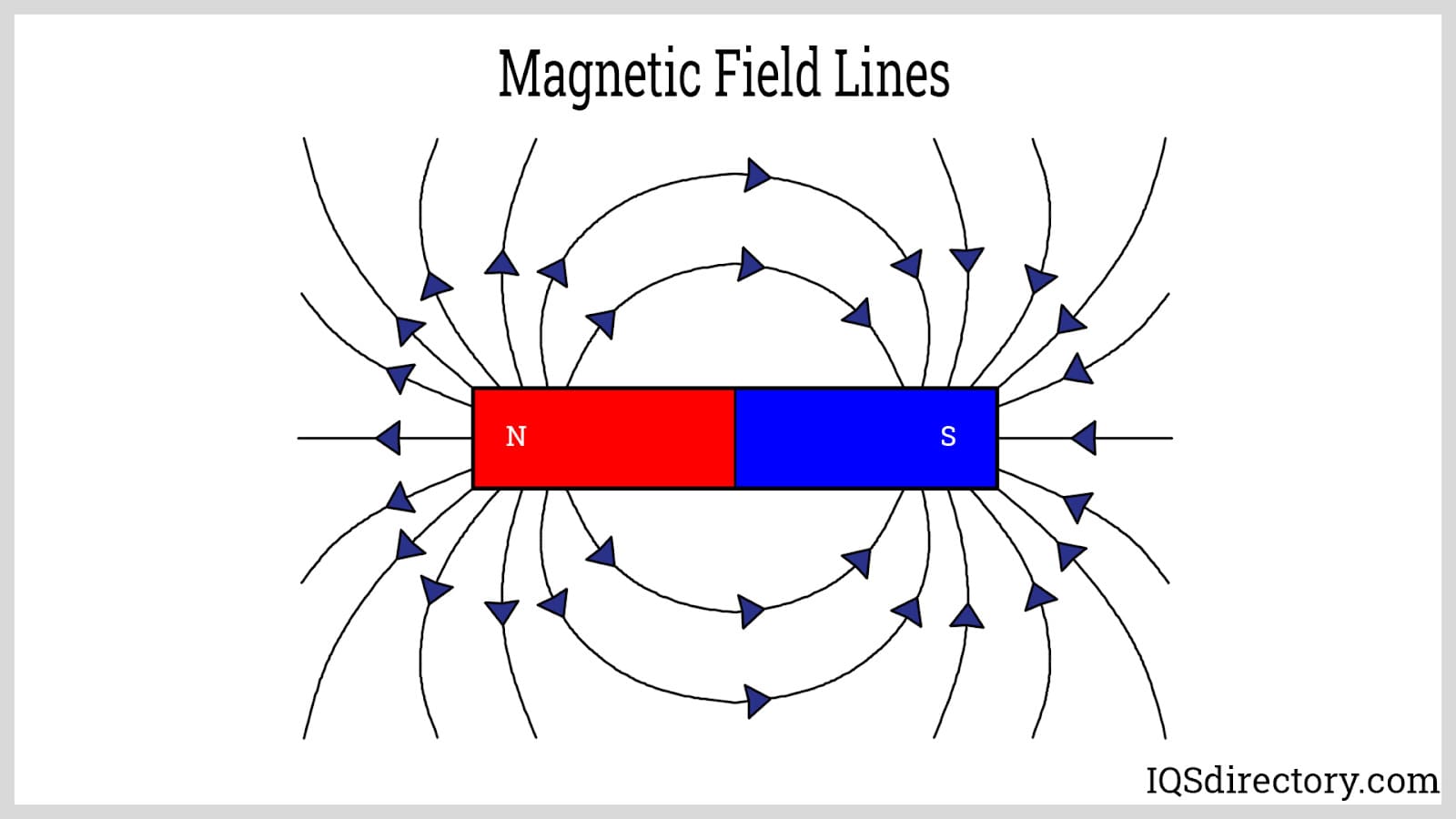

Bar or block magnets are used in schools for experiments, such as demonstrating magnetic fields. They are the weakest shape because of the small area of the poles but are the most common shape. Bar magnets can be used in automation, separation, and holding applications.

Bar magnets can also be used to magnetize other objects. When a bar magnet is rubbed against a metal item, it aligns the electrons within the metal, thereby inducing magnetism. This magnetization is not permanent but can persist for a certain period.

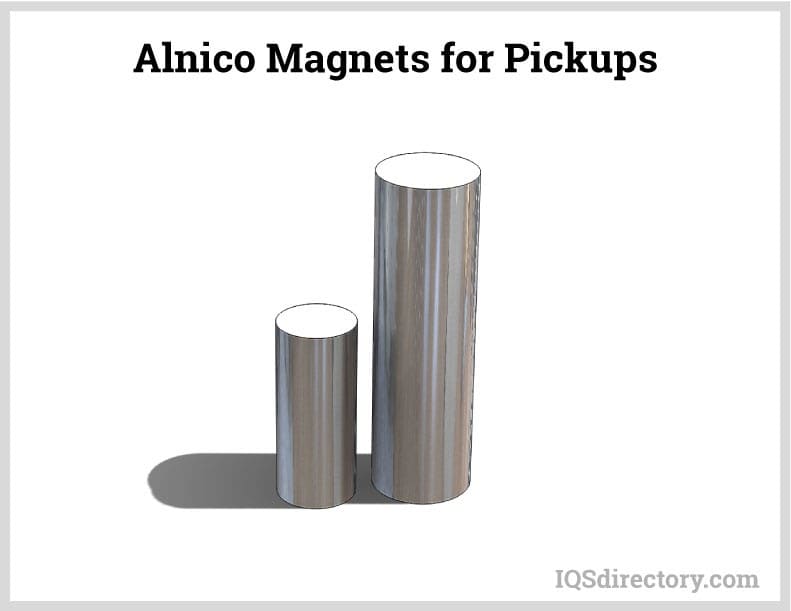

Cylinder magnets feature straight, parallel sides, a circular cross-section, and a hollow core aligned with their length. They are utilized in a variety of applications including seals, sensors, coin collection machines, and guitar pickups. Cylinder alnico magnets are particularly valued in amplifiers, actuators, and motor applications for their high flux density. In the medical field, their strength and adjustability make them useful for specialized applications.

Rod alnico magnets are cylinder shaped and are used in tools and parts. They have high coercivity, strong flux output, and remain stable at high temperatures up to 1000°F or 537°C. Alnico rod magnets have higher residual energy induction and low coercive force compared to ceramic and rare earth materials.

Horseshoe magnets are essentially bar magnets bent into a U shape, enhancing their strength by aligning the poles in the same direction. This configuration makes them effective at picking up metal objects of various sizes, depending on their strength.

Pot, holding, or mounting magnets are designed for various holding applications, serving as alternatives to traditional fixtures and fasteners. These magnets offer the advantage of easy removal and repositioning, unlike permanent fastening solutions.

Ring magnets are cylindrical with a central hole and are sometimes called donut magnets. The orientation of their north and south poles is determined by their polarization method. Typically, one half of the magnet is north, and the other is south, but some polarizations divide the magnet into quarters or eighths.

Ring magnets find applications in scientific experiments and medical fields. For individuals with implanted cardioverter defibrillators (ICDs), which deliver shocks to correct irregular heart rhythms, ring magnets can be used to temporarily disable the device if it malfunctions. Placing a ring magnet on the patient’s chest, directly over the ICD, can stop the device from delivering unnecessary shocks.

Alnico magnets exhibit excellent resistance to oxidation and corrosion, typically eliminating the need for protective coatings, plating, or surface treatments. They are highly resistant to damage from oils, solvents, gasoline, and alcohol. However, their iron content makes them susceptible to surface corrosion if exposed to water for prolonged periods, as well as to alkali solutions and inorganic acids.

While a coating is generally unnecessary for protection, manufacturers often paint alnico magnets to enhance their appearance and mask their natural dark gray color. Red is the most commonly used color, though chrome or nickel coatings are also options.

Alnico magnets can be coated or plated with a variety of materials, depending on the application requirements. Coatings may be applied for aesthetic purposes, to improve bonding, for internal applications, or to increase surface hardness.

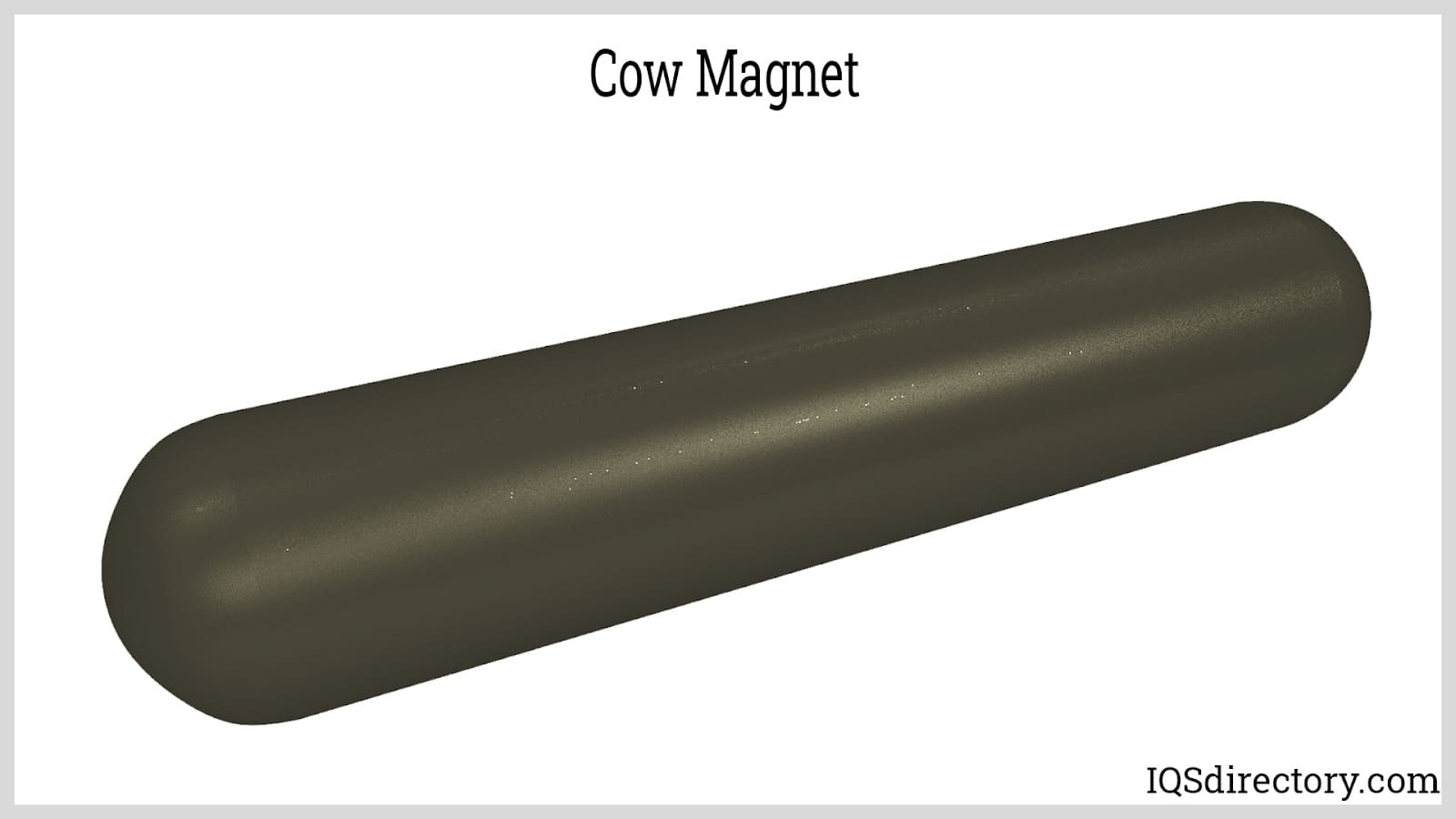

Alnico magnets are used for applications with high operating temperatures. They are used where a strong permanent magnet is required. such as electric motors, electric guitar pickups, microphones, sensors, loudspeakers, and cow magnets.

Alnico magnets are a preferred choice for many applications due to their high flux density and strong magnetic lines of force, offered at a reasonable cost. They also feature the lowest reversible temperature coefficient of any magnet, at just 0.02% per degree Celsius, ensuring excellent temperature stability.

Alnico rotor magnets are designed with multiple poles of alternating polarity and include a central hole for mounting on a shaft. They are highly effective in applications such as synchronous motors, dynamos, and air turbine generators.

Cow magnets are used to protect cattle from ingesting metal objects like nails, staples, and bits of baling wire while grazing. These foreign objects can lead to "hardware disease," which poses a risk to the cow's vital organs by causing irritation and inflammation. To prevent this, a magnet is given to the cow orally, usually around one year of age. The magnet then settles in the cow's second stomach, where it attracts and holds onto any stray metal, preventing further health issues.

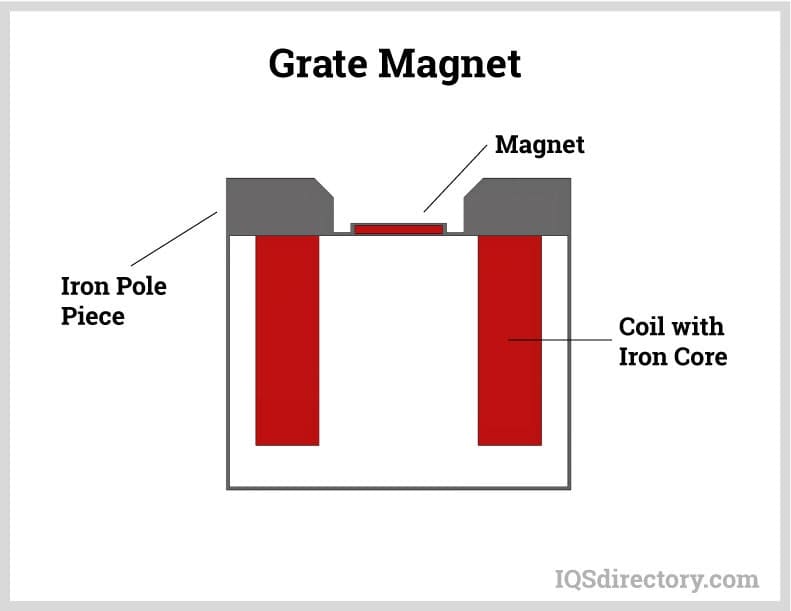

Alnico magnets are favored in speaker systems due to their ability to precisely tune the magnetic field in the air gap, leading to optimal acoustic performance. The air gap is the space between the poles of the magnet or between the magnet and the adjacent surface. In speakers, one pole of the magnet typically envelops the other pole. The strong magnetic field in this air gap demands precise control, which is effectively achieved with alnico magnets.

Alnico magnets are commonly used in electric guitar pickups, where they play a crucial role in converting the vibrations of the guitar strings into electrical signals. These signals are then sent to an amplifier to enhance the volume of the guitar. The magnetic properties of alnico 2, 3, 4, and 5 magnets are particularly well-suited for this purpose, allowing the electric guitar to be clearly heard even in noisy environments.

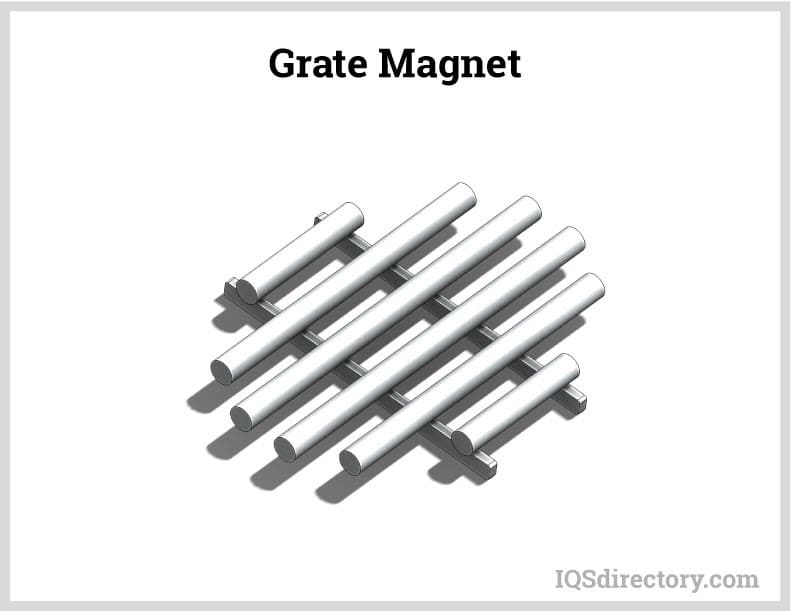

Grate magnets are protective devices used in hoppers, floor openings, vertical chutes, and ducts to capture and retain fine iron contaminants. They are specifically designed to trap weakly magnetic or very fine iron particles. Once captured, these contaminants are later removed from the grate.

Highly sensitive and precise equipment relies on the electrical conductivity of alnico magnets to control electrical circuits. In alarm systems, alnico magnets complete the circuit when the system is closed and in the activated position. If unauthorized access occurs, the circuit is interrupted, triggering the alarm. In some cases, the system can also turn off devices or other equipment as part of its response.

Alnico magnets come in various formulations with differing levels of aluminum, nickel, and cobalt. The changes in the proportions of these base metals affect the magnet's strength, leading to variations in their individual magnetic fields.

There are 29 distinct grades of alnico magnets: seventeen are cast, ten are sintered, and two are bonded. These grades are determined by factors such as the magnet's chemical composition, residual induction, coercive force, maximum energy, cobalt content, and operating temperature. Generally, as the operating temperature increases, so does the grade of the magnet.

Most alnico magnets are anisotropic, which are known for their superior strength compared to other grades. The following discussion explores various alnico grades and their applications.

The chart below offers a summary of some alnico magnet grades and their respective properties.

| Grades of Alnico Magnets | ||||||||||

|---|---|---|---|---|---|---|---|---|---|---|

| Dura Magnet Grade | Residual Induction Br |

Coercive Force Hc |

Intrinsic Coercive Force Hci |

Maximum Energy Product (BH)max | Max Operating Temp | |||||

| Nominal | Nominal | Nominal | Minimum | Nominal | Nominal | |||||

| k-Gauss | Telsla | k-Oersted | KA/M | k-Oersted | KA/M | MG Oe |

KJ/m3 | °C | °F | |

| Alnico 5 | 12.2 | 1.22 | 600 | 48 | 630 | 50 | 5 | 40 | 500°C | 930°F |

| Alnico 5B | 12.22 | 1.22 | 650 | 52 | 660 | 53 | 5.5 | 44 | 500°C | 930°F |

| Alnico 5 DG | 12.5 | 1.25 | 690 | 55 | 700 | 56 | 6.5 | 52 | 500°C | 930°F |

| Alnico 5-7 | 13 | 1.3 | 700 | 56 | 740 | 59 | 7.5 | 60 | 525°C | 980°F |

| Alnico 8-HC | 7 | 0.7 | 1,750 | 139 | 1,750 | 139 | 4.5 | 36 | 525°C | 980°F |

| Alnico 8 | 8.2 | 0.82 | 1,500 | 119 | 1,600 | 127 | 5 | 40 | 525°C | 980°F |

| Alnico 8B | 8.8 | 0.88 | 1,500 | 119 | 1,650 | 131 | 5.5 | 44 | 525°C | 930°F |

| Alnico 8C | 9 | 0.9 | 1,380 | 110 | 1,440 | 115 | 7.5 | 60 | 525°C | 930°F |

| Alnico 9 | 10.5 | 1.05 | 1,410 | 112 | 1,440 | 139 | 9 | 72 | 525°C | 930°F |

| Alnico 2 | 7 | 0.7 | 500 | 40 | 540 | 43 | 1.5 | 12 | 450°C | 840°F |

| Alnico 5 | 11.0 | 1.1 | 600 | 48 | 600 | 48 | 4.25 | 34 | 450°C | 840°F |

| Alnico 8 | 8.8 | 0.88 | 1530 | 121 | 1,600 | 127 | 5.25 | 42 | 450°C | 840°F |

Alnico 2 is the second weakest among alnico magnets, characterized by its low cobalt content. It is isotropic and has a lower magnetic output compared to other types. Alnico 2 magnets are commonly used in electric guitars, where they are valued for their ability to enhance sound clarity in audio recording and performance. Despite their lower strength compared to alnico 4 and 5 magnets, alnico 2 magnets can produce a cleaner and more defined sound when used in guitar pickups.

Alnico 3 is the weakest of the alnico magnets and contains no cobalt. Like Alnico 2, it is isotropic and has a low magnetic output. Alnico 3 magnets are also used in electric guitars and offer similar sound characteristics to Alnico 2 magnets.

Alnico 4 is a relatively weak magnet, comparable to Alnico 2 and 3. It is isotropic with a low magnetic output and is primarily used in sound recording and performance applications.

Alnico 5 is the most commonly used alnico magnet, available in four cast versions and one sintered version. It provides efficient magnetic energy to circuits and is a high-grade anisotropic magnet with exceptional magnetic output. The magnetic direction of Alnico 5 is established by its crystal alignment during the molten phase. These magnets can produce large magnetic fields, but for optimal performance, they should be magnetically long and incorporate iron or steel components to minimize demagnetization.

Alnico 8 boasts the highest coercive resistance among alnico grades and offers excellent energy density with a low reversible temperature coefficient. It is ideal for applications subject to demagnetizing fields or where a compact magnetic length is needed.

Alnico 9 features strong magnetic properties and a single crystal structure. It is employed in geological detection instruments as well as in defense and aerospace technologies. Like most alnico magnets, Alnico 9 maintains its resistance to high temperatures.

A ceramic magnet, also known as a ferrite magnet, is a permanent magnet made by combining iron oxide and strontium carbonate. They are a man made magnet produced by heating the two elements to...

Flexible magnets are composite materials with magnetic components arranged in an elastomer matrix. They are made from a combination of rubber polymer resin and ferrite powder by forming it through...

Magnets are materials that exert a noticeable force on other materials without physically contacting them. This force is called a magnetic force. The magnetic force can either attract or repel. Most known materials...

A Neodymium (Nd-Fe-B) magnet is a common rare earth magnet composed of neodymium (Nd), iron (Fe), boron (B), and transition metals. They have superior performance in applications because of their strong...

ermanent magnets are materials that generate a magnet field based on the internal structure of the material that forms them. With most materials, magnet fields point in random directions that cancel out the fields. The electrons of such materials spin…

SmCo magnets are strong rare earth permanent magnets that are used for a variety of industrial applications. They have two primary phases, which are SmCo₅ and Sm₂Co₁₇. The difference between the phases is in regard to their magnetic energy…

Power supplies are electrical circuits and devices that are designed to convert mains power or electricity from any electric source to specific values of voltage and current for the target device...

An AC power supply is a type of power supply used to supply alternating current (AC) power to a load. The power input may be in an AC or DC form. The power supplied from wall outlets (mains supply) and...

A bowl feeder is a mechanism for supplying small parts and components to a production line or for sorting bulk items for rapid use. A self contained bowl feeder system has a bowl that sets on a spring loaded base that moves vertically...

A DC DC power supply (also known as DC DC Converter) is a kind of DC power supply that uses DC voltage as input instead of AC/DC power supplies that rely on AC mains supply voltage as an input...

A DC power supply is a type of power supply that gives direct current (DC) voltage to power a device. Because DC power supply is commonly used on an engineer‘s or technician‘s bench for a ton of power tests...

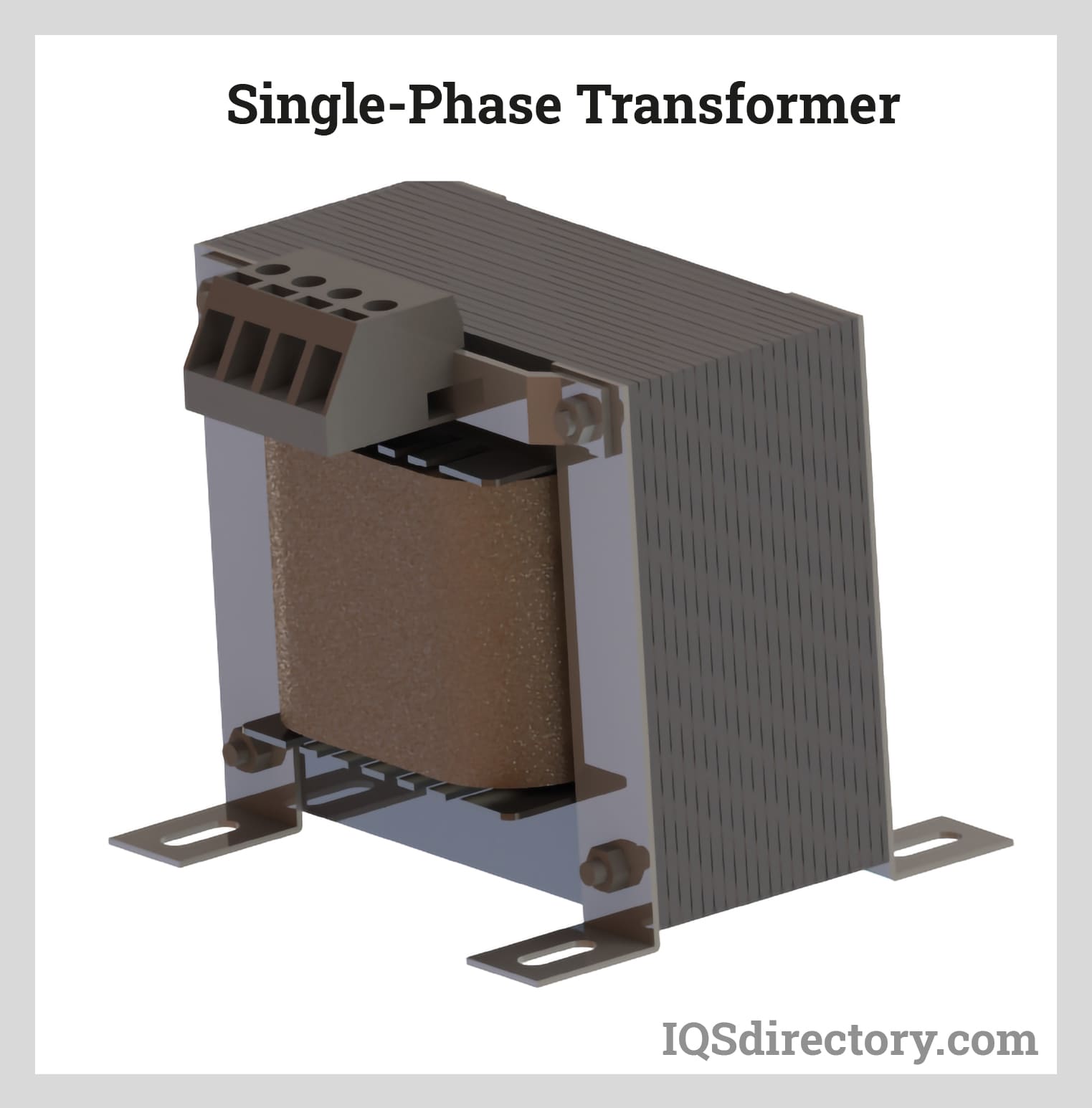

Electric transformers are static electrical machines that transform electric power from one circuit to the other without changing the frequency. An electrical transformer can increase or decrease the voltage with...

An electromagnetic interference or EMI Filter is an electrical device or circuit that filters specific unwanted frequencies in power lines or offending frequencies that are detrimental to a system. They receive AC or main power...

By definition a power supply is a device that is designed to supply electric power to an electrical load. An electrical load refers to an electrical device that uses up electric power. Such a device can be anything from...

An isolation transformer, just like typical transformers, is a non-moving device that transmits electrical energy from one circuit to another without requiring any physical contact. It works on the idea of magnetic...

Power transformers are electrical instruments used in transmitting electrical power from one circuit to another without changing the frequency. They operate by the principle of electromagnetic induction. They are used in transmitting electrical power between...

A programmable power supply is a method for controlling output voltage using an analog or digitally controlled signal using a keypad or rotary switch from the front panel of the power supply...

An electrical transformer is a passive machine that transfers electrical energy from one circuit to another using a magnetic flux to induce an electromotive force. Transformers are used to increase (step-up) or decrease (step-down) voltages without changing the frequency of the electric current...

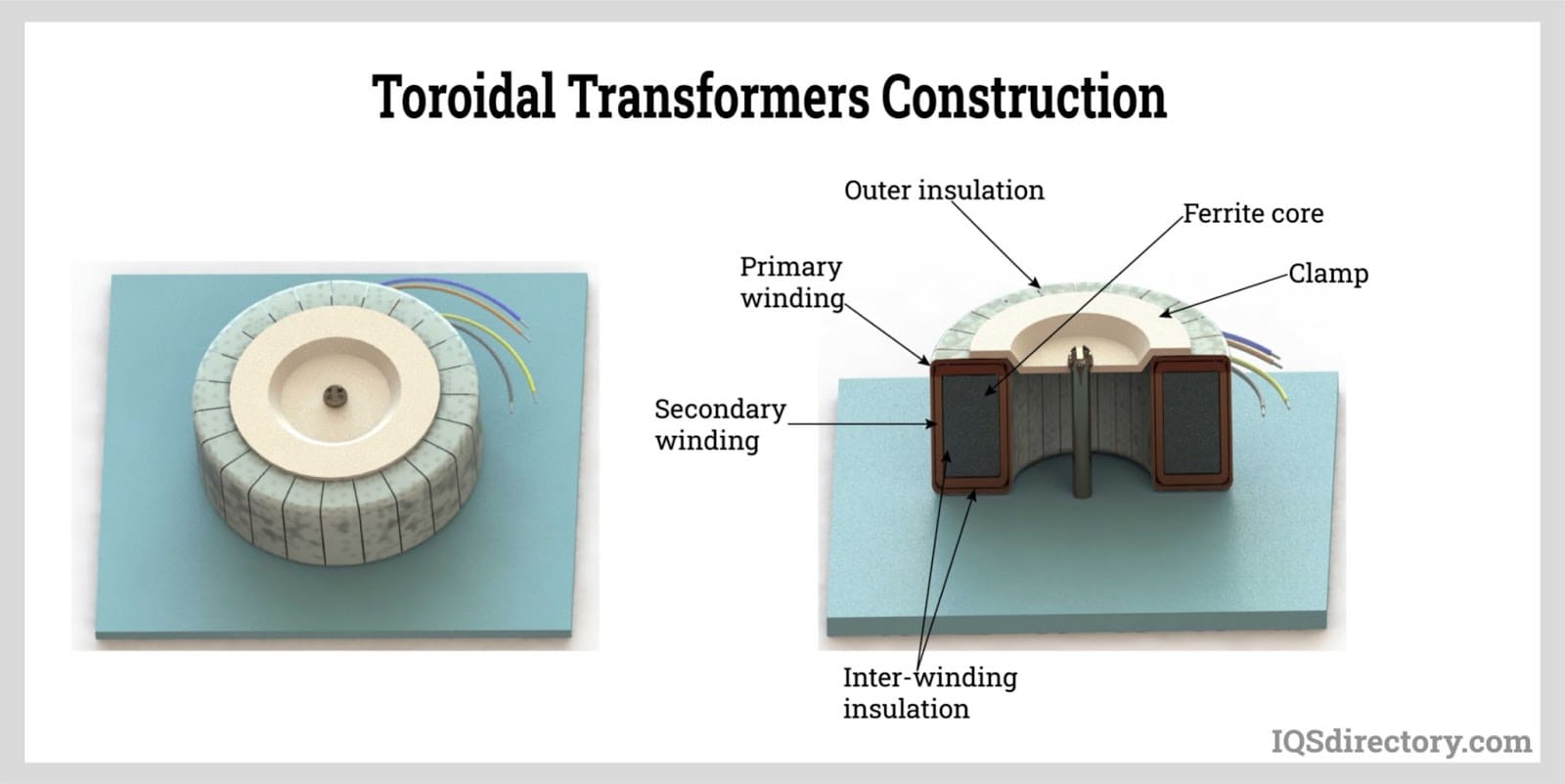

A toroidal transformer is a type of electrical transformer constructed with a torus or donut-shaped core. Its primary and secondary windings are wound across the entire surface of the torus core separated by an insulating material...

Vibratory conveyors are material-handling equipment used to transport fine to coarse-grained bulk materials. These vibratory conveyors are strong conveying equipment utilized for bulk commodities with fine to coarse graininess...

Vibratory feeders are short conveyors used to transport bulk materials utilizing a controlled vibratory force system and gravity. The vibrations impart a combination of horizontal and vertical acceleration through tossing, hopping, or sliding-type of action to the materials being handled...

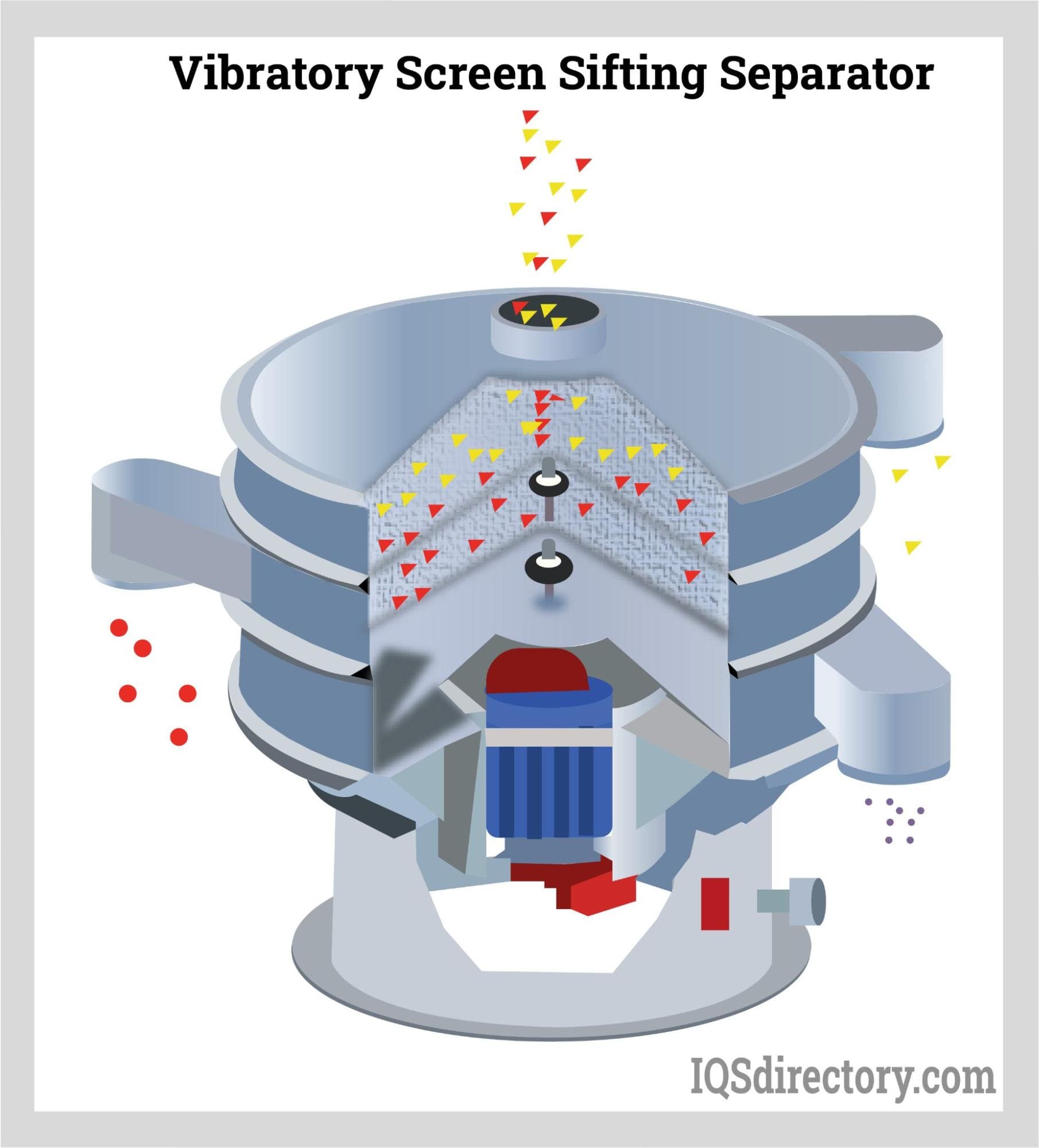

A vibratory screening is a process that separates bulk solid materials from solids and slurries using inertial vibration that causes various sizes of particles to pass through openings in a screen or...

Electronically operated equipment depends on power transformers to convert electrical currents into voltage. Current transformers store and transport energy through power lines and grids...