Name Plates

Nameplates are plaque-like displays of information, specially designed with signs and symbols that identify things. Nameplate manufacturers fashion nameplates out of an extensive variety of materials for use in an equally extensive variety of applications. Office nameplates, desk nameplates and door nameplates are used in professional companies, industrial facilities and institutions to identify the occupants of desks and offices.

Note: Nameplates are not the same thing as labels. They differ from labels in that nameplates are usually designed for long term person or product identification, whereas labels are designed for fairly easy removal. In addition, labels almost always use adhesive, whereas adhesive is only one of the options available with nameplates. They are also not the same thing as tags or dog tags. Tags fall under the category of jewelry.

Quick links to Name Plates Information

Advantages of Name Plates

Name plates are advantageous for a number of reasons. First, they promote efficiency in the workplace by making it easier for visitors and new hires to navigate. With the guidance of nameplates, they can more easily and quickly find an office, a person or anything else they need. This lets employees focus on their responsibilities, rather than directing others around the workplace. Similarly, they create organization and structure. The less chaotic an environment, the easier it is to relax and get down to work. Next, it lends spaces a degree of professionalism, and helps infuse trust in the visitor, customer or patient. Finally, nameplates give people the recognition that they deserve and cement their respective roles in an organization.

Name Plate Production Processes

- Production Process

- Manufacturers make nameplates by inscribing a chosen material with words and/or symbols. Nameplate labeling methods include hot stamping, screen printing, sub-surface printing, etching, embossing, mechanical or laser engraving, photo anodizing and lithography.

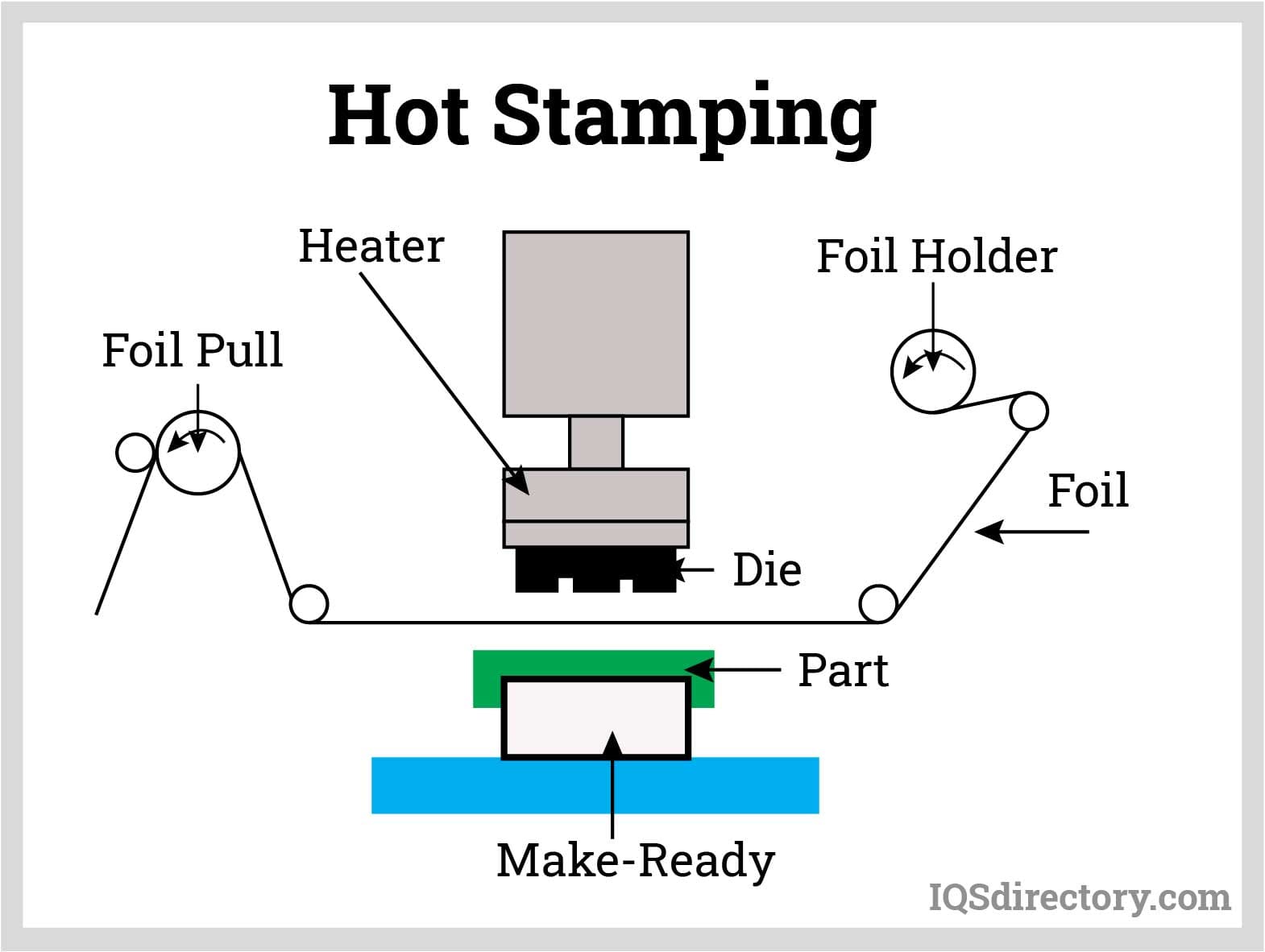

- Hot Stamping

- During hot stamping, name plates manufacturers heat an engraved image and then, using a metal marker die or metal stamp, force it against a part with a marking foil in between. Where the die meets the part, ink from the foil stays behind. Since hot stamping is a dry process, the parts can be handled right after stamping. Hot stamping is a popular method of serial number plate printing.

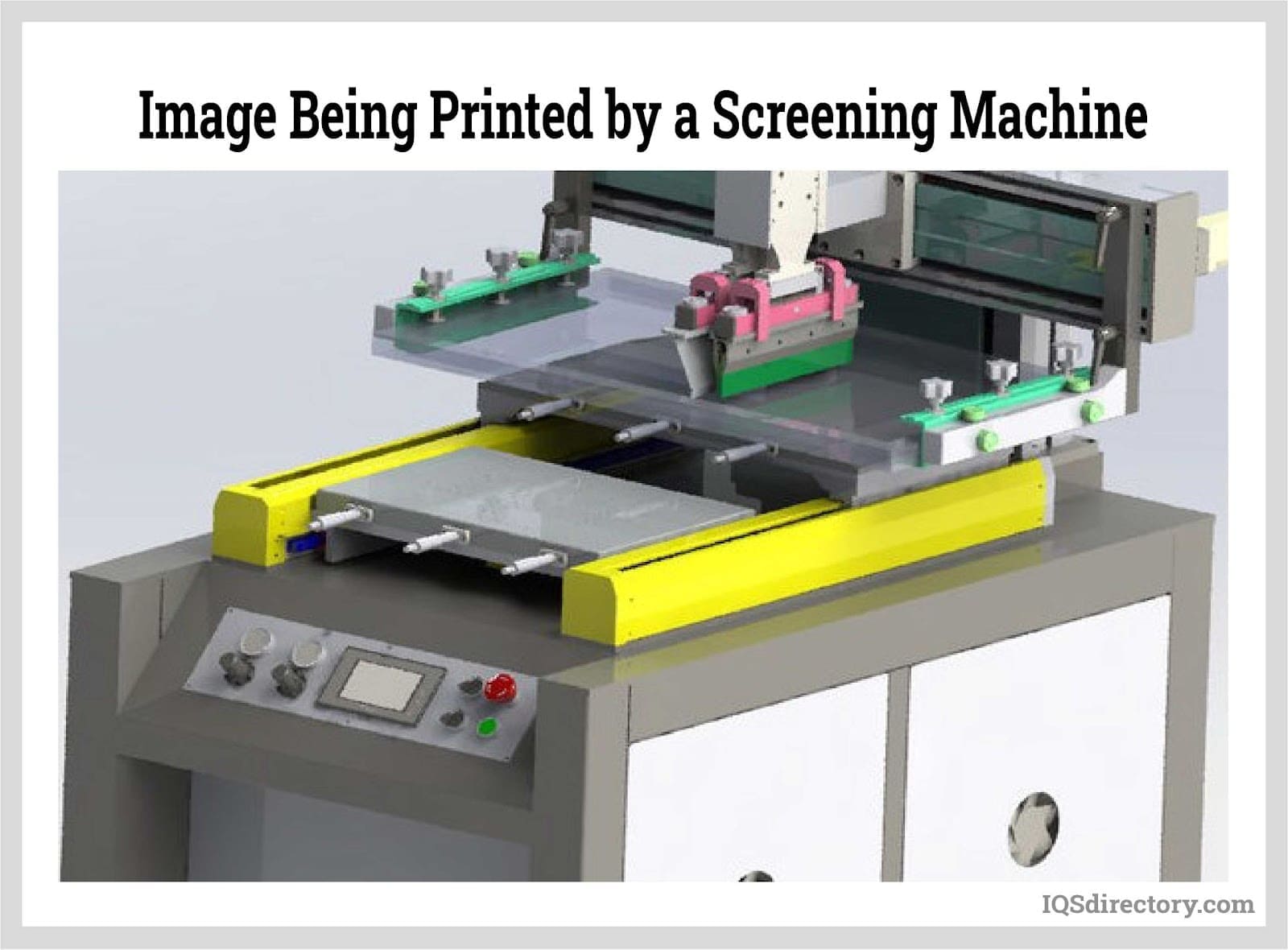

- Screen Printing

- Involves applying a photographic stencil to a piece of porous, tightly stretched polyester through which enamel colors are forced.

- Sub-Surface Printing

- A process during which ink is processed on the underside of transparent plastic materials. This way of printing creates symbols that are abrasion, oil and chemical resistant. This is a popular way to print durable and resistant serial numbers that are fully protected from abrasions and solvents.

- Etching Nameplates

- Chemically etched nameplates are manufactured by masking certain areas of metal with an acid resistant material. The uncovered areas are then exposed to a corrosive material, which creates engraved words based on the configuration of the stencil while preserving the covered area.

- Embossing Process

- Involves squeezing a nameplate material between a female metal die and a male counter using heat and pressure.

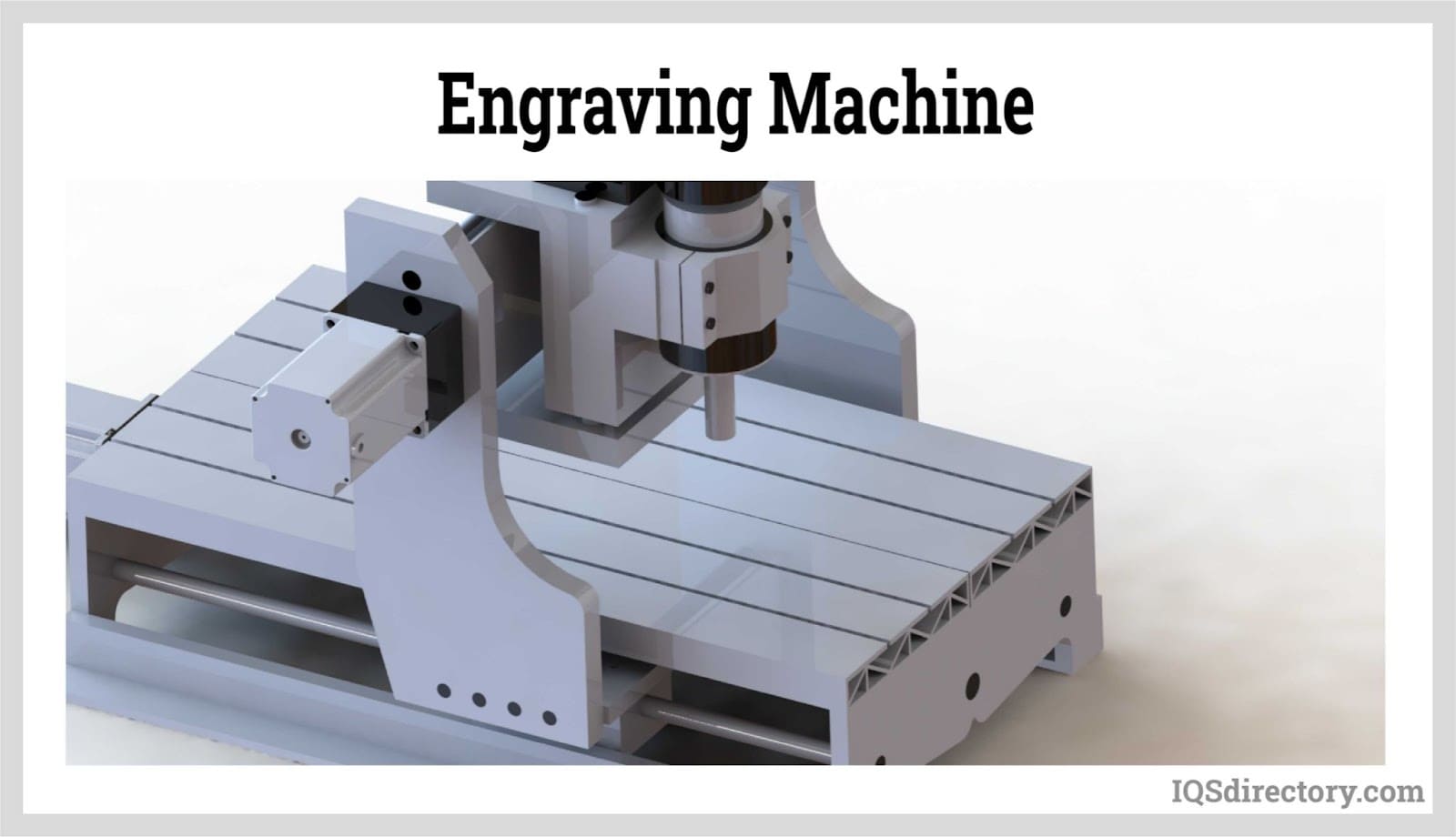

- Mechanical and Laser Engraving

- Mechanical and laser engraving involves cutting a nameplate with a rotary tool, engrave plate or a laser beam. Suppliers choose to laser engrave when they are looking for extreme precision.

- Photo Anodizing

- Like developing a picture on a specialized aluminum sheet.

- Lithography

- A printing press is used to move a master image to a nameplate using an ink-transferring roller device.

Name Plate Design and Materials

Nameplates are not meant to be viewed from a distance, nor should they require more than a few seconds of attention to convey their complete meaning. Office nameplates, for example, are usually limited to one or two lines of information. A typical desk-mounted nameplate will feature a name and possibly a job title. When designing a standard or custom nameplate, manufacturers will keep this in mind, seeking to make it clear and legible. Of course, that doesn’t mean a name plate has to be plain, as illustrated by graphic overlays and personalized nameplates.

Manufacturers personalize plate designs based on customer specifications, including words, symbols and material. Nameplate material, thickness, printing method and other properties also vary depending on a name plate's application. All nameplates, even mass-produced nameplates, are characterized by some degree of customization; every nameplate is a custom name plate, as each variety features its own instructions, messages, labels and other information.

- Nameplate Materials

- Materials used by nameplate manufacturers include wood, metal and brush metal and plastics. Examples of metal nameplate materials include: gold, aluminum, stainless steel, stainless steel alloys, brass and alloy metal. Examples of plastic materials used for nameplate construction include: polycarbonate, Mylar®, rigid PVC or plastic, MetalPhoto®, vinyls, foils and more. Metal nameplate varieties are generally the most expensive and require the most maintenance. For instance, brass metal nameplates that are mounted outside must be coated with a protective layer of weather-resistant chemicals to keep the brass from becoming tarnished.

Features of Name Plates

Nameplates can be affixed to surfaces in three ways. They can 1) be drilled with holes at each end and affixed with pins, screws or other fasteners, 2) coated on one side with strong adhesives and pressed onto their surfaces, or 3) supported by a stand or other structure.

Adhesives vary in terms of the weather and temperature resistance. Typically, these adhesives are heavier than adhesives used for labels. Adhesive-backed nameplates, depending on their adhesive composition, may be more appropriate for indoor use (to prevent accelerated degradation of the adhesive). Others, though, like vehicle nameplates (hood and trunk ornaments) are very well suited for outdoor use. Nameplates that are not affixed with fasteners or adhesives must be supported by a stand or other structure. Many desk and office nameplates, which can be heavy, are placed in metal, plastic or wooden stands in order to make them visible. The method by which a nameplate is affixed depends on the name plate's application.

Name Plate Images, Diagrams and Visual Concepts

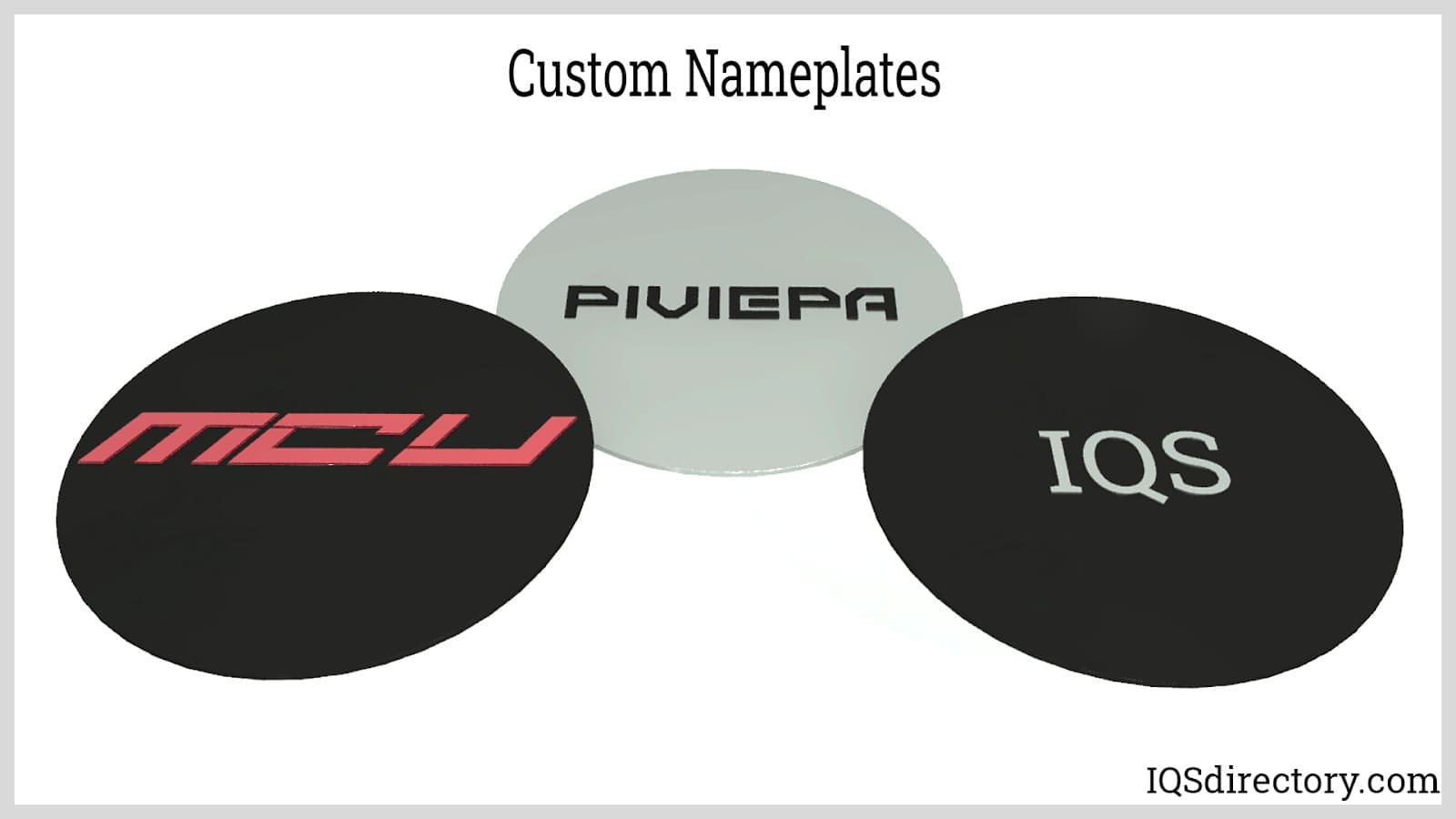

Name plates serves as a long term identifier for a name of a person, logo, product, or mechanism.

Name plates serves as a long term identifier for a name of a person, logo, product, or mechanism.

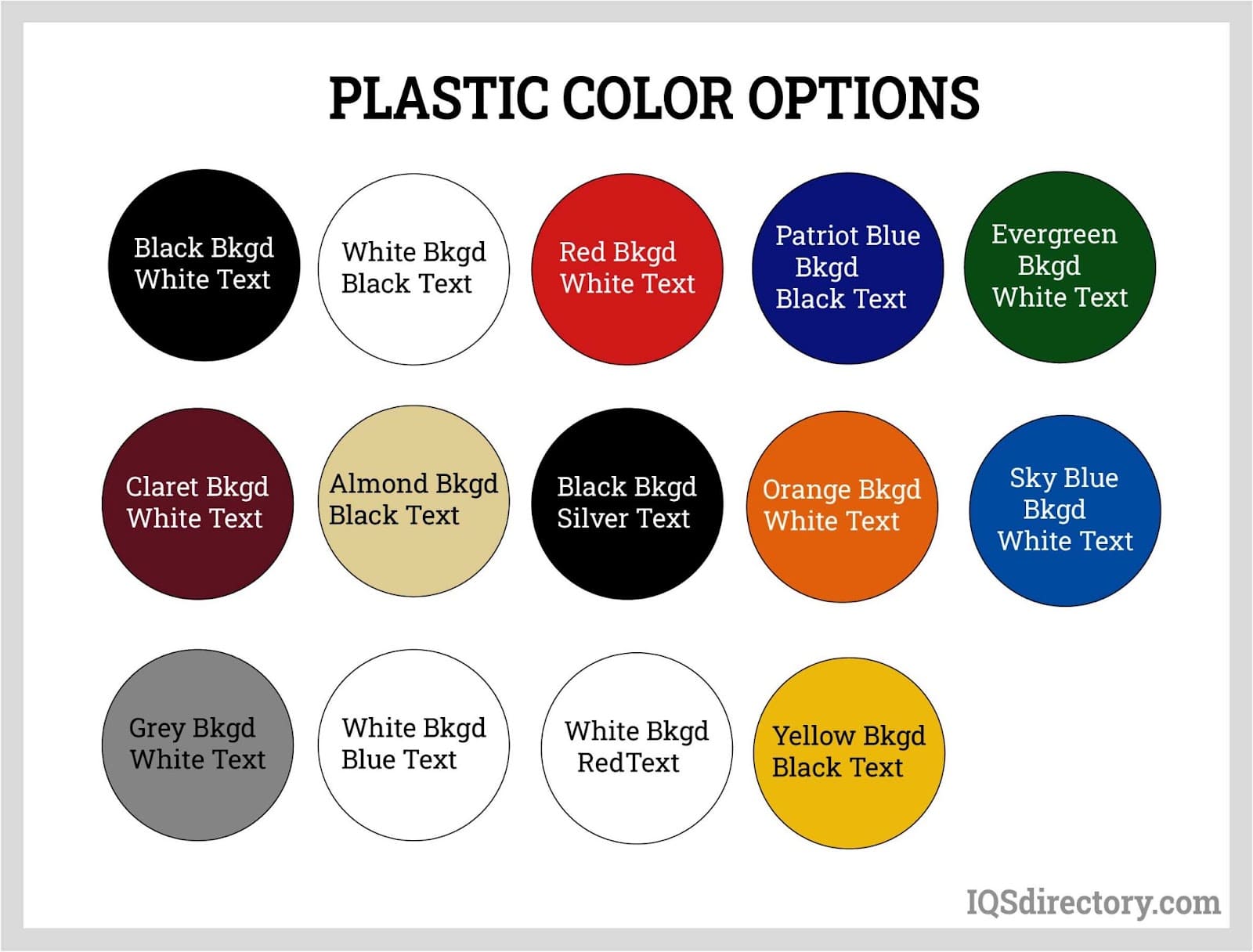

Plastic polymers used for manufacturing name plates can be engineered and designed in any shape, color, texture, and configuration to meet customized specifications.

Plastic polymers used for manufacturing name plates can be engineered and designed in any shape, color, texture, and configuration to meet customized specifications.

Etched name plates have a recessed image created by acid which eats away the surface to produce a recessed design in fine detail.

Etched name plates have a recessed image created by acid which eats away the surface to produce a recessed design in fine detail.

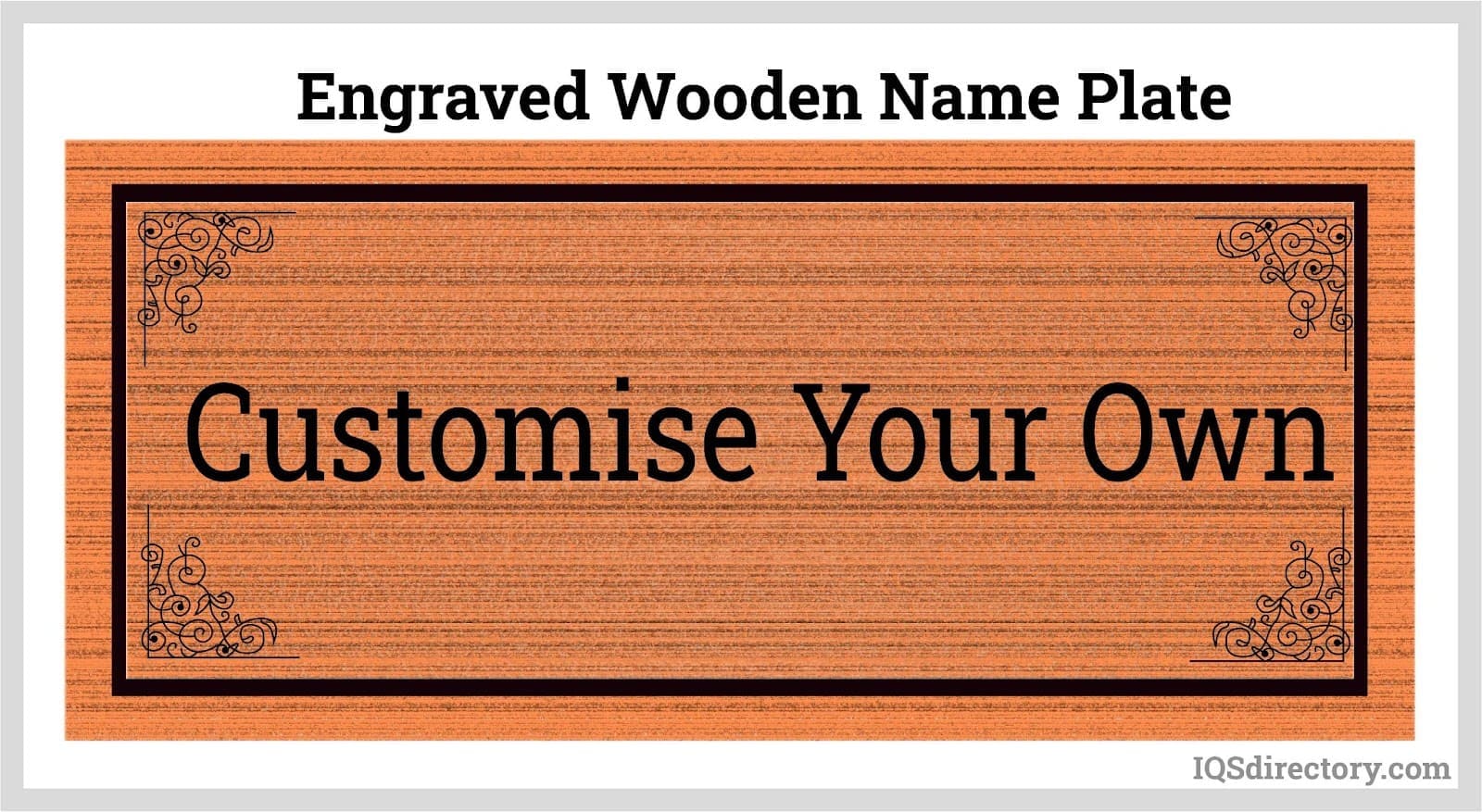

Engraving a wooden name plate is mainly uses computerized machinery.

Engraving a wooden name plate is mainly uses computerized machinery.

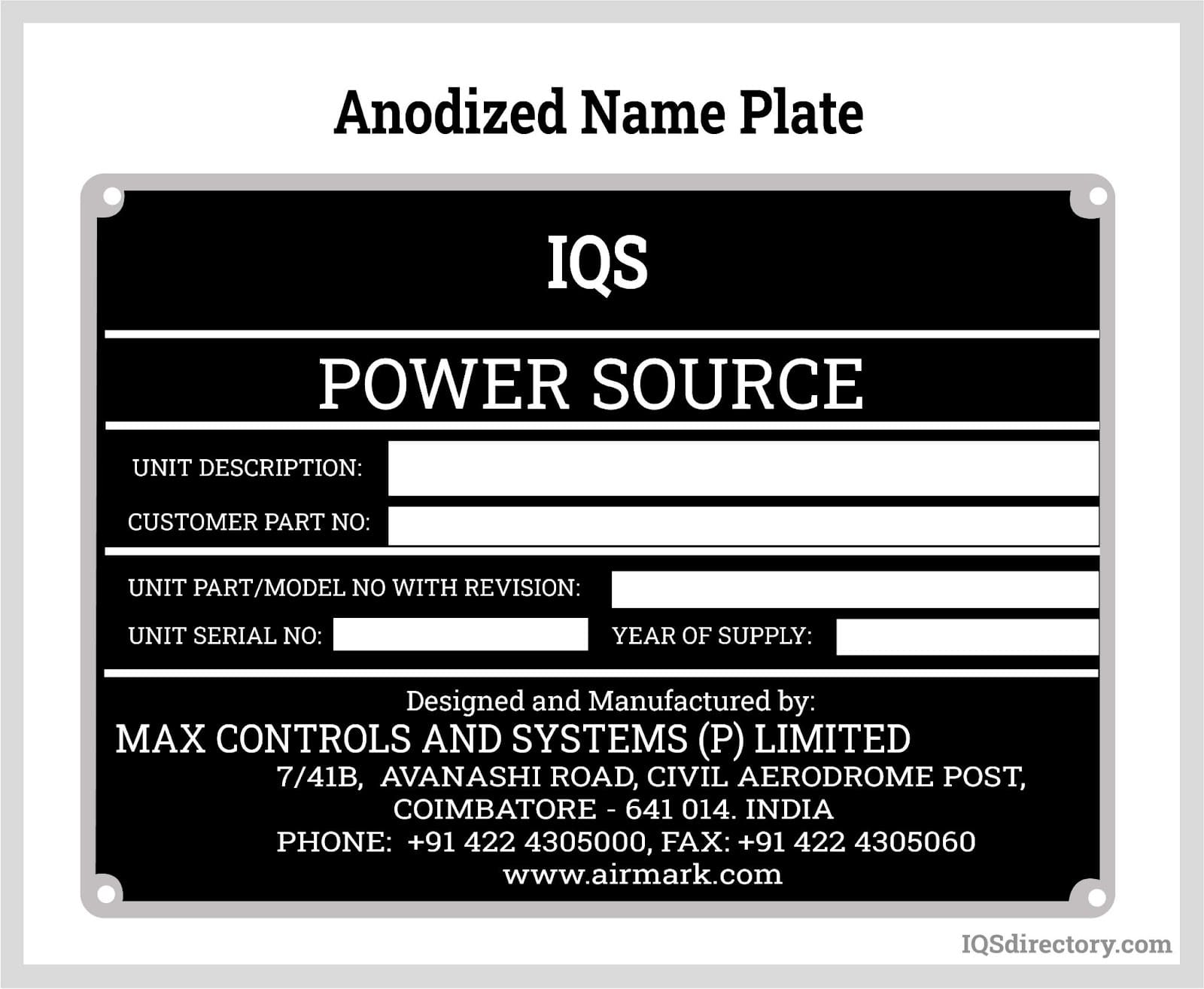

Anodizing, a forced oxidation of aluminum using sulfuric acid and directed electrical current opens the pores of the aluminum and introduce various colored dies.

Anodizing, a forced oxidation of aluminum using sulfuric acid and directed electrical current opens the pores of the aluminum and introduce various colored dies.

Aluminum is an exceptionally resilient metal capable of enduring nearly any environment and when alloyed with other metals, its basic qualities are immensely enhances the strength of the material.

Aluminum is an exceptionally resilient metal capable of enduring nearly any environment and when alloyed with other metals, its basic qualities are immensely enhances the strength of the material.

Hot stamping uses a die, press, and stamping foil, which the press heats up the die and transfers the ink from the foil onto the piece.

Hot stamping uses a die, press, and stamping foil, which the press heats up the die and transfers the ink from the foil onto the piece.

Metal engraving carves, etches, or incises an image or design by cutting, digging, scraping, or gouging the metal‘s surface.

Metal engraving carves, etches, or incises an image or design by cutting, digging, scraping, or gouging the metal‘s surface.

Screen printing, an economical process where a mesh screen is used as a stencil and is placed over a metal plate, which seals the colors, image, and surface.

Screen printing, an economical process where a mesh screen is used as a stencil and is placed over a metal plate, which seals the colors, image, and surface.

Types of Name Plates

- Industrial Nameplate

- Used around industrial facilities in order to identify different work areas and equipment. When attached to equipment, an industrial nameplate can alternatively be called an equipment nameplate.

- Office Name Plate

- A nameplate used around the office. It is used to identify the occupants of desks and rooms within that workspace. Office name plates include a variety of nameplates, such as the wall name plate, desk name plate or door name plate, all of which are named for the surface to which they are to be affixed.

- Graphic Overlay Nameplate

- Nameplates that are chemical and corrosion resistant, with transparent window displays, embossing and selective texturing. Graphic overlay nameplates are typically placed over switches, control panels, LEDS or windows.

- Brass Nameplate

- This type of metal nameplate is attractive, but due to the properties of brass, not durable enough for aerospace applications. Instead, brass nameplates are best affixed to outdoor statues or buildings to identify them.

- Gold Nameplate

- Among the most expensive nameplate varieties and can be affixed to doors, paintings and plaques, usually in the offices of professional companies or in institutions like universities.

- Aluminum Nameplate

- Among the least expensive and most widely used nameplate varieties. Because you can anodize aluminum, aluminum nameplates can be quite thick. Aluminum nameplates can be used to identify offices, or it can be affixed to consumer products like washing machines and lawn mowers to provide instructions for use and warnings of operational hazards.

- Plastic Nameplate

- The least expensive nameplate variety and require the lowest amount of continuing maintenance.

- Wooden Nameplate

- Most often used as personalized nameplates. One of the most common places you will see them is on the door of a child’s bedroom or playroom. Because they’re made for children, manufacturers tend to offer these nameplates in playful shapes, such as animals, baseball bats or the child’s name. A wooden nameplate is also usually much more colorful than a professional or industrial nameplate.

- Desk Name Plates

- Used to identify the occupants of desks in all kinds of industrial and commercial settings.

- Custom Nameplates

- Manufactured to a customer's design specifications. Depending on material and application, custom options could be limited or unlimited.

- Door Name Plates

- Nameplates affixed to doors in offices, industrial facilities and institutions to identify the contents or occupant of a room.

- Engraved Nameplates

- Typically produced using mechanical engraving, laser engraving, whittling or photo-chemical etching processes to permanently cut out lettering or a design.

- Equipment Nameplates

- Bound to the machinery that they identify. Small and rectangular or square, they can simply include the machinery manufacturer’s name and logo or offer details like location, phone number, power capacity, size, complementary machinery or components and model, make, stock or job number.

- Metal Nameplates

- Usually made out of aluminum, stainless steel, brass, bronze, copper, zinc, titanium or alloys.

- Personnel Nameplates

- Any tags, badges or plates that identify employees or members of a company or organization, usually used as clearance or admittance for certain areas.

- Nameplates

- Design and produce nameplates. Nameplates are specially designed signs and symbols that are used to identify things.

Name Plate Applications

Nameplates are used to display snippets of pertinent information, as opposed to the display of large amounts of information. Objects used to display larger volumes of information fit more appropriately into the category of signs.

Nameplates indicate information such as: the occupants and contents of desks, the occupants and contents of offices, directions, the location of emergency exists, the brand name of consumer products like cars and lawn mowers, and instructions and warnings relevant to the operation of consumer and industrial equipment. In addition, they can be used to identify work areas.

They are also used to indicate the name, origins and authorship of works of art, and they are very commonly used as title plates on commemorative plaques (trophies, memorials) to indicate the recipients of awards. Meanwhile, to identify brand name and ownership, nameplates can be found affixed to suitcases, briefcases, trunks and chests. Finally, they can be found on aircraft brakes, Navy destroyers and even the International Space Station.

Industries in which nameplates are used include: office supply, healthcare, sports, education, transportation, travel, museum and art, commemorative products, aerospace, consumer products and food and beverage.

Standards and Specifications for Name Plates

While office nameplates aren’t really beholden to any standards, many industrial nameplates are. In addition, many nameplates have to meet certain requirements for print life, as well as any environmental tolerances the location in which the nameplate is used may require. The National Electric Manufacturers Association (NEMA) sets requirements for motor nameplates, including electric motor nameplates.

To meet NEMA requirements, all motor nameplates must include:

- Manufacturer's Type

- Rated Voltage

- Full-Load Current

- Rated Frequency

- Number of Phases

- Rated Full Load RPM

- Rated Temperature Rise, or Insulation System Class

- Time Rating

- Horsepower

- Locked Rotor Code Letter

- Service Factor

- Efficiency

- Frame Size

- Design Letter

Outside of the USA, the most commonly used motor nameplate standards are put out by the International Electrotechnical Commission (IEC).

There are also nameplate standards for generators, centrifugal pumps and PV modules, which are roof-mounted solar panels. PV module nameplate standards are maintained by the Solar America Board for Codes and Standards (Solar ABCs).

Things to Consider When Purchasing a Name Plate

To find a nameplate that really works for you, turn to an experienced nameplate manufacturer. There are a lot of manufacturers out there, so it’s important to be discerning. The last thing you want is a set of nameplates that are poorly engraved or made with a cheap material. Get a leg up by starting with the providers we’ve listed near the top of this page.

All of those with whom we work are well vetted and experienced. To narrow it down, visit each of their websites and take note of the services they offer, their prices and standard certifications. Choose three or four in whom you’re most interested, then reach out to each of them. Make sure to get a production lead time quote. Once you’ve spoken with each of them, compare and contrast their responses, keeping in mind not only prices, but also customer service. No matter how inexpensive a nameplate is, it’s not a deal unless it’s what you really want. A nameplate manufacturer that listens to you and takes your needs into consideration is key to your success. Once you’ve determined which supplier that is, reach back out to them and get started on your custom nameplate order.

Name Plate Alternatives

- Barcode

- Serial number and model number plates offer encoded numbering systems for identification of each and every part, product or piece of equipment. Manufacturers can either provide the encoding or go with what their client gives them.

- Decals

- Made of light-weight, non-metallic material such as heavy duty paper, polyester, vinyl or soft plastic or rubber and are usually made with backing to be torn off to reveal adhesive. Many customization options are available for these products, and they can generally be made in any size.

- Dial Faces

- Labels, panels or plates that identify the calibration or measurements on dials or scales.

- Panel Fronts

- Or front panels are thinner plates made to fit over specific control or instrumentation panels with openings and identifications for buttons or lighted displays.

- Safety Labels

- Contain instructions for the proper use of the labeled object.

- Tags

- Pieces or strips of strong paper, plastic, metal or leather that attach by one end to something as a mark or label. These ID tags can be used when not a lot of surface area is available for items like valves, wire rope or cable.

- Unique Identification (UID) Labels

- Permanent, machine-readable, inscribed with a dot matrix and attached to qualifying items. They are part of a system of distinguishing one object from another to allow for Department of Defense tracking.

- Warning Labels

- Stand out in bright colors like orange or yellow or red and have big bold words like "Warning!" and "Danger!" on them.

Name Plate Accessories

Common name plate accessories include: a name plate holder, nameplate inserts (for changing out names while keeping the holder intact), a snap on label holder, a nameplate frame, pins, hangers, chains, hooks and wall mount adhesives.

Name Plate Terms

- Anodizing (or Anodising)

- A technique used to coat the surface of a metal with an oxide layer. It may be used to increase corrosion resistance, increase wear resistance, allow dyeing or to prepare the surface for other processes and coatings including paint.

- Embossing

- The process of creating an image or design in ductile materials by combining heat and pressure. This is achieved by using a metal die (female) and a counter die (male) that fit together and squeeze the fibers.

- Etching

- The process of using strong acid to cut into the unprotected parts of a metal surface to create a design.

- Hot Stamping

- A process in which an engraved image is heated then forced against a part with a marking foil in between. Ink from the foil is left behind where the die meets the part; it is a dry process and the parts can be handled right after stamping.

- Laser Engraving

- A process that can precisely and quickly engrave very fine details using a laser beam combined with a CNC driver.

- Lithography

- An offset printing process where a rubber cylinder "blanket" rolls over a metal printing plate, picks up the master image and transfers it to another area of the press where the nameplate is located. It is possible to achieve extremely fine detail in both direct and reverse print but does not weather well when placed outdoors or in other harsh environments.

- Mechanical Engraving

- A high-speed rotary tool cuts into the surface of a metal or plastic. Then enamel paint is filled into the engraved area.

- MetalPhoto®

- An anodized, photosensitive aluminum offering a sharp print quality that’s highly durable and extremely resistant to abrasion, corrosion and high temperatures. This material doesn’t fade or chip and is used in many military applications because it meets strict government regulations.

- Mylar®

- A strong laminated polyester film suited for sub-surface printing that has good temperature, chemical and abrasion resistance.

- Photo Anodizing

- Exposing an image onto specially coated aluminum that is developed much like a piece of photographic film and then sealed, thus trapping the image in the metal under an anodized layer. This method can produce small quantities of highly durable nameplates with a fast turn-around time.

- Polycarbonate

- A particular group of thermoplastic polymers easily worked, molded, and thermoformed. This material is extremely resistant to chemicals, corrosion and temperature; it also has excellent durability and light transmission.

- Screenprinting (also Silkscreening or Serigraphy)

- A printmaking technique that creates a sharp-edged image using a stencil.

- Sub-Surface Printed

- Processed with the ink on the underside of transparent plastic materials, making it abrasion, oil and chemical resistant.

- Vinyl

- A non-laminated polyester suited for surface printing. This material has good chemical and abrasion resistance for normal indoor use.