Titanium Metal

Titanium metal, with the symbol Ti, is the ninth most abundant element in the earth‘s crust. It does not occur in large deposits, yet small amounts of titanium are found in almost every rock…

Please fill out the following form to submit a Request for Quote to any of the following companies listed on

An explanation of titanium, its uses and structure with a list of manufacturers

You will learn:

Titanium is a chemical element with an atomic number of 22 and can be alloyed with iron, vanadium, aluminum, and molybdenum. It is a strong, lightweight alloy with a high strength to weight ratio, low density, and ductility. The characteristics of titanium gives it a rare combination of mechanical, chemical, and physical properties. It is the 9th most abundant element on earth and is mined from ilmenite, sphene, and rutile. In many cases, titanium is alloyed with other elements to enhance its physical and chemical properties, especially its resistance to corrosion.

There are approximately 50 grades of alloyed and pure titanium that are divided into three classes. Grades 1, 2, 3, and 4 are pure titanium and are referred to as alpha titanium. Grade 5, workhorse titanium, is the most used grade and has significant amounts of aluminum and vanadium. Grades 7 and 11 are nearly pure grades of titanium with a half per cent of palladium added to give the alloys high resistance to corrosion.

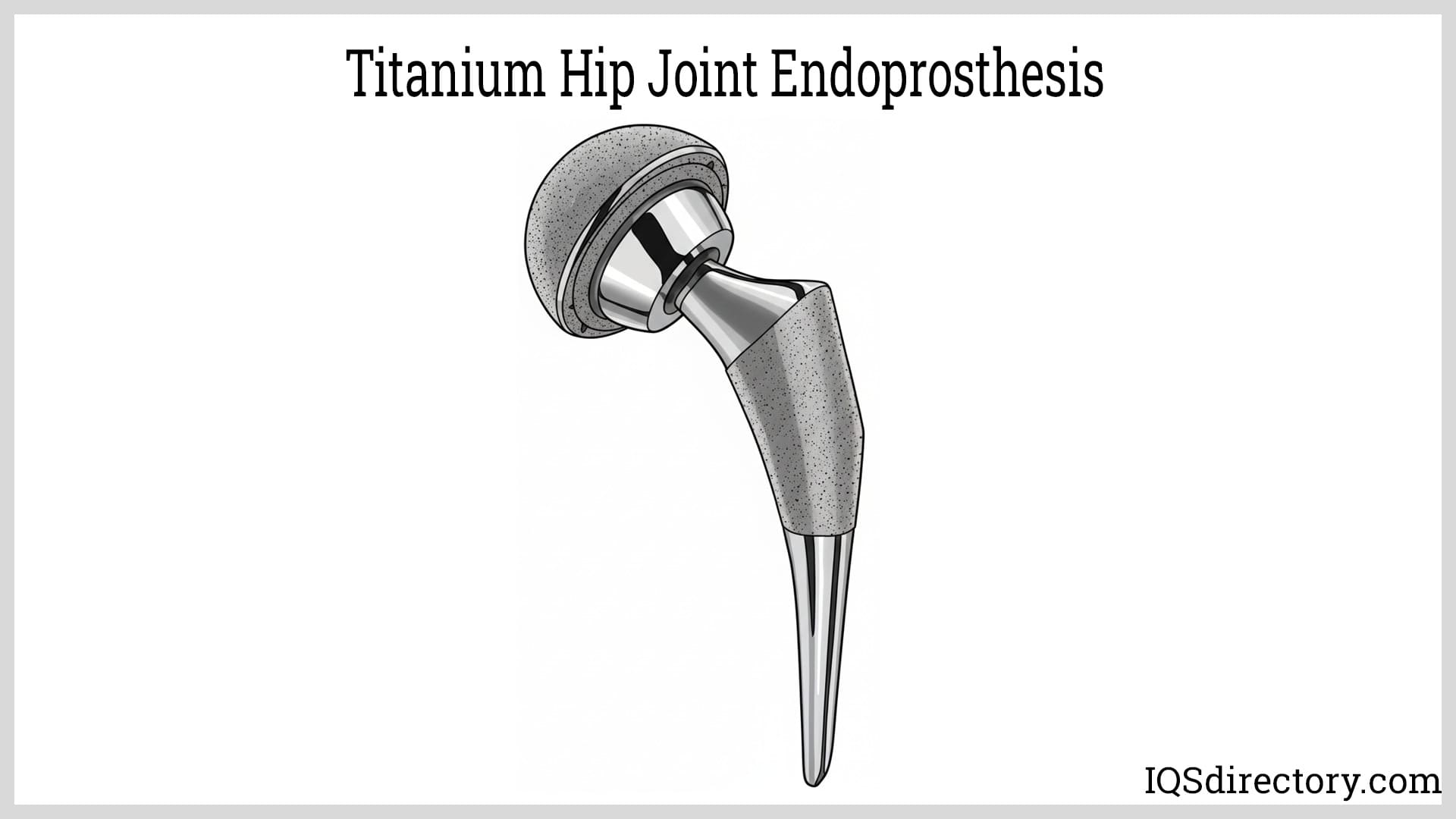

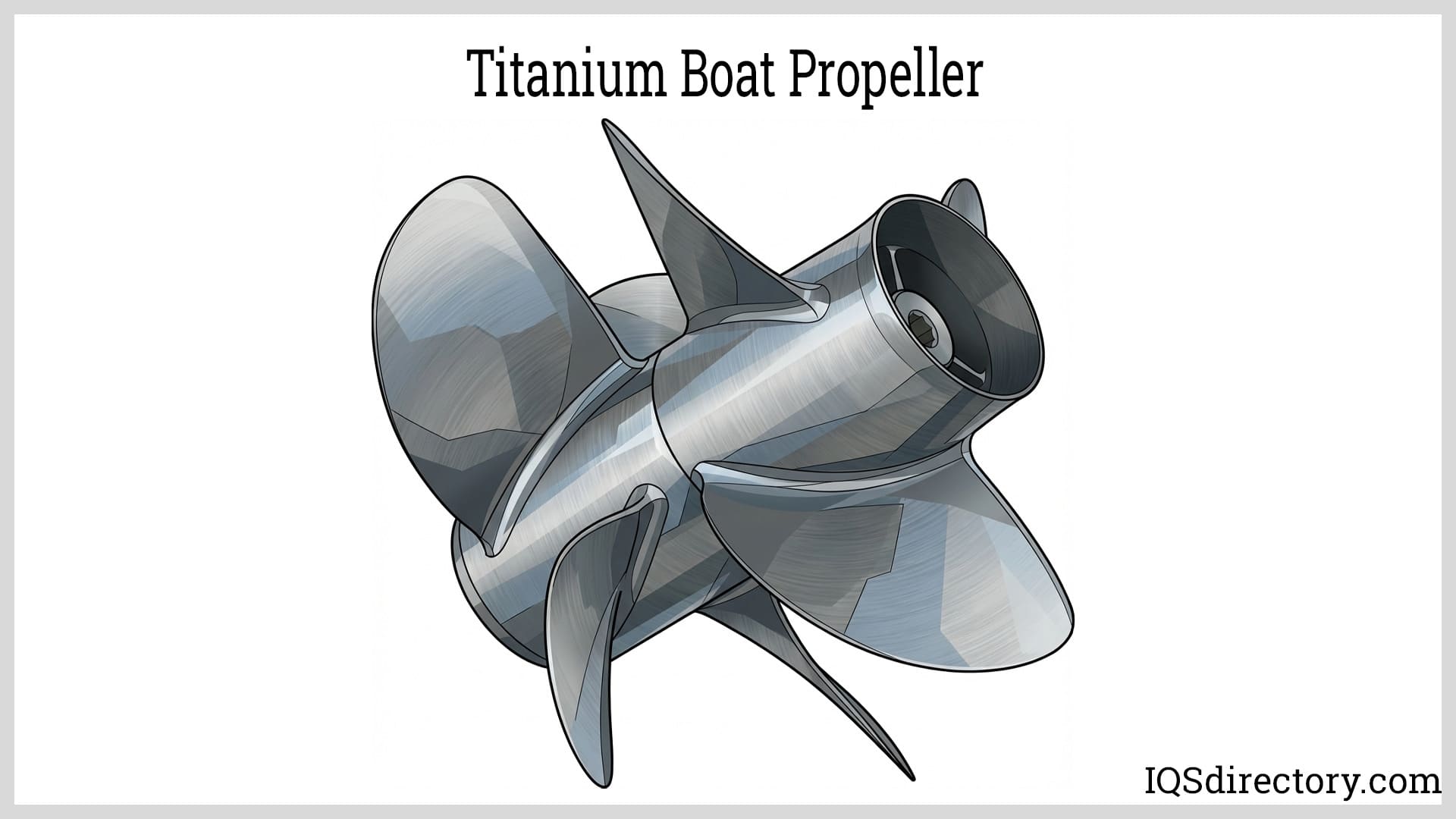

Titanium is a critical part of a wide range of products including aerospace components, jewelry, cookware, and medical implants. The two properties for which titanium is best known is its high strength to density ratio and its exceptional resistance to corrosion. Like aluminum, oxygen molecules combine with titanium to form titanium oxide, which is the same relationship that aluminum has with oxygen. The result of the combination is a passive titanium layer that does not flake and is resistant to chemical compounds, such as chlorine.

Although titanium is a light weight metal, it has exceptional strength, such as grade 5 being as strong as mild steel. This property of titanium has made it a viable metal for use in aircraft and space ships, a factor that helps with fuel efficiency.

The extraction of titanium from the earth involves a number of processes, which vary in accordance with the application for which the metal will be used. The essence of the method for obtaining titanium is to change the microstructure of the ore to a necessary level. As the level of risk of failure increases, the microstructure is more studiously adjusted and followed to ensure the success of an application.

The history of titanium is rather interesting as regards its discovery and use. Titanium, or the ore from which titanium is extracted, was first discovered in 1791 by an English gentleman, whose achievement went unrecognized. Four years later, it was discovered a second time by a German chemist. Although the discoveries happened in the 18th century, the extraction of titanium was far too difficult for its practical use. It wasn’t until the end of the first industrial revolution that a practical method was used to isolate and extract the metal. From that time on, there have been improvements in the ways to access and refine the metal.

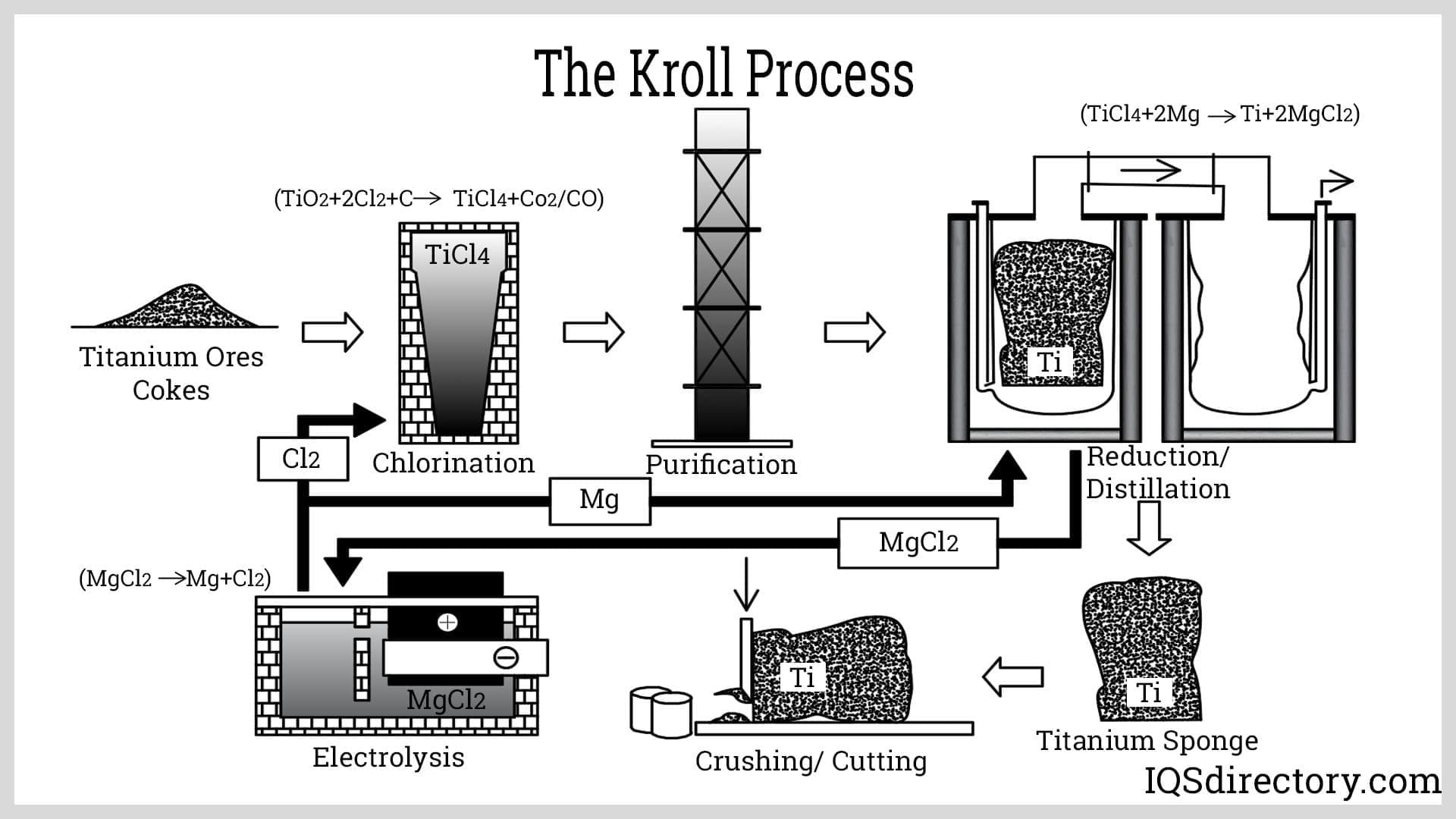

The method that is used today is the Kroll process, which was introduced during the Great Depression by William Kroll of Luxemburg. Over the years since, incremental changes have been made to the process that have led to an increase in the purity of titanium. The emphasis in the processing of titanium focuses on ensuring the purity of the metal, since the slightest defects in output can lead to catastrophic consequences.

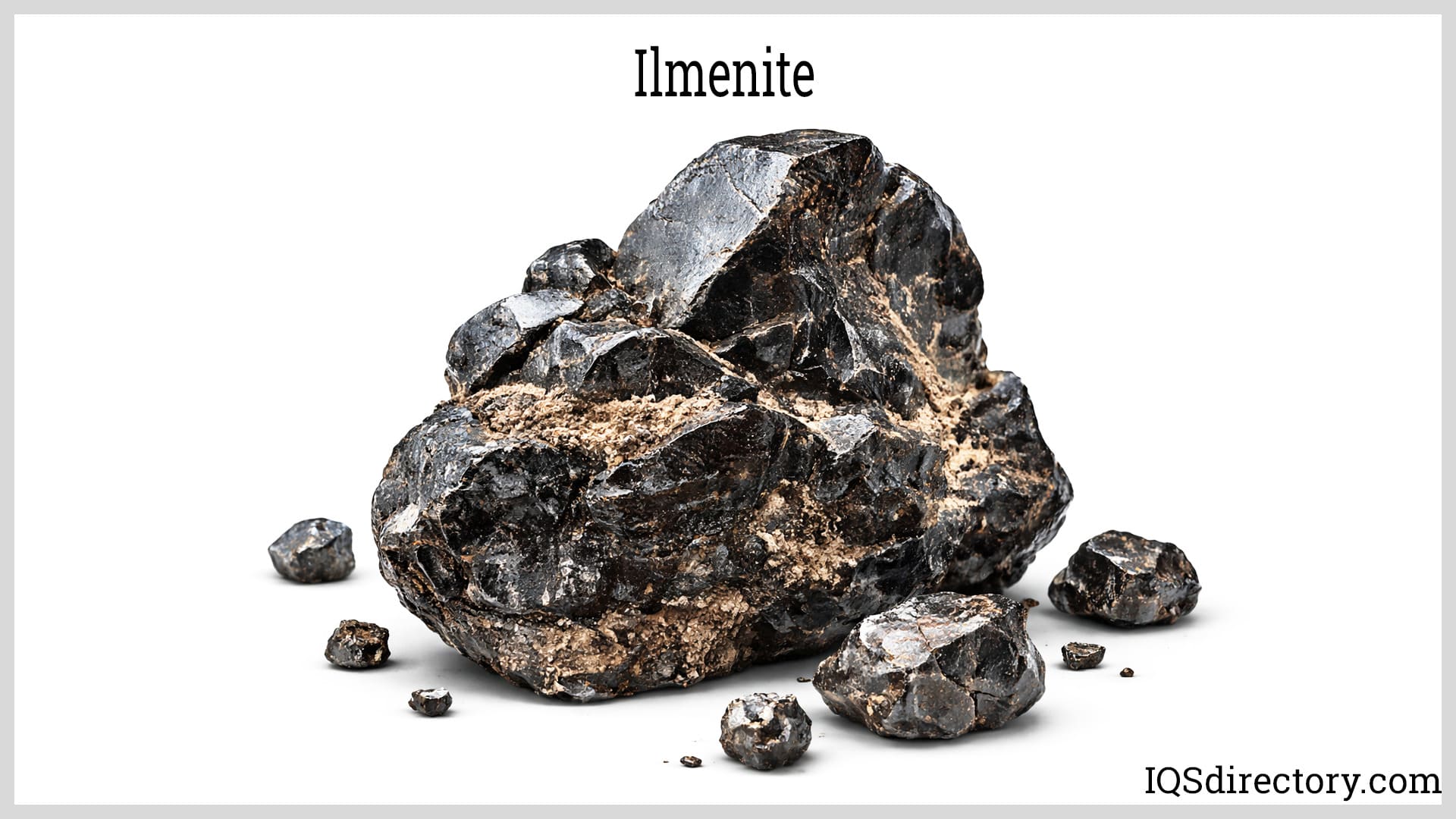

The Kroll process is a multistage extraction method that begins with the minerals ilmenite (FeTiO₃) or rutile (TiO₂), which are the most common sources of titanium. Other minerals with titanium content are anatase (TiO₂), leucoxene, perovskite (CaTiO₃), brookite (TiO₂) and titanite. The use of ilmenite and rutile is due to their availability and lower cost.

Ilmenite – Ilmenite is a magnetically weak mineral sand that is black and grey and has a triangular crystalline structure. It is named for the Il’menski Mountains of Russia where it was discovered. Iron and titanium ions appear in alternating layers perpendicular to the trigonal c axis. When ilmenite is changed, it forms the mineral leucoxene, which is a source for titanium. Ilmenite is found in igneous rocks, sediment, and sedimentary rocks. Rocks containing ilmenite weather, dispersing grains of ilmenite in the sediment, which causes them to accumulate as heavy mineral sand that is black and easily recognizable.

Rutile – Rutile, referred to as red schorl, crystallizes as grains, masses, prismatic crystals, and needle crystals. The term rutile is Latin for red, which was the color of the first specimen of the mineral. It is found in Sierra Leone, Brazil, Madagascar, Switzerland, and South Africa. Rutile is the most common and stable form of titanium oxide. Although red when rutile was first discovered, it can appear as reddish brown, pale yellow, pale blue, violet, grass green, and black. Rutile is surface mined and dredged from dense beach sand. It is the most common natural form of titanium. Rutile has a euhedral tetragonal crystalline structure with square or octagonal sections.

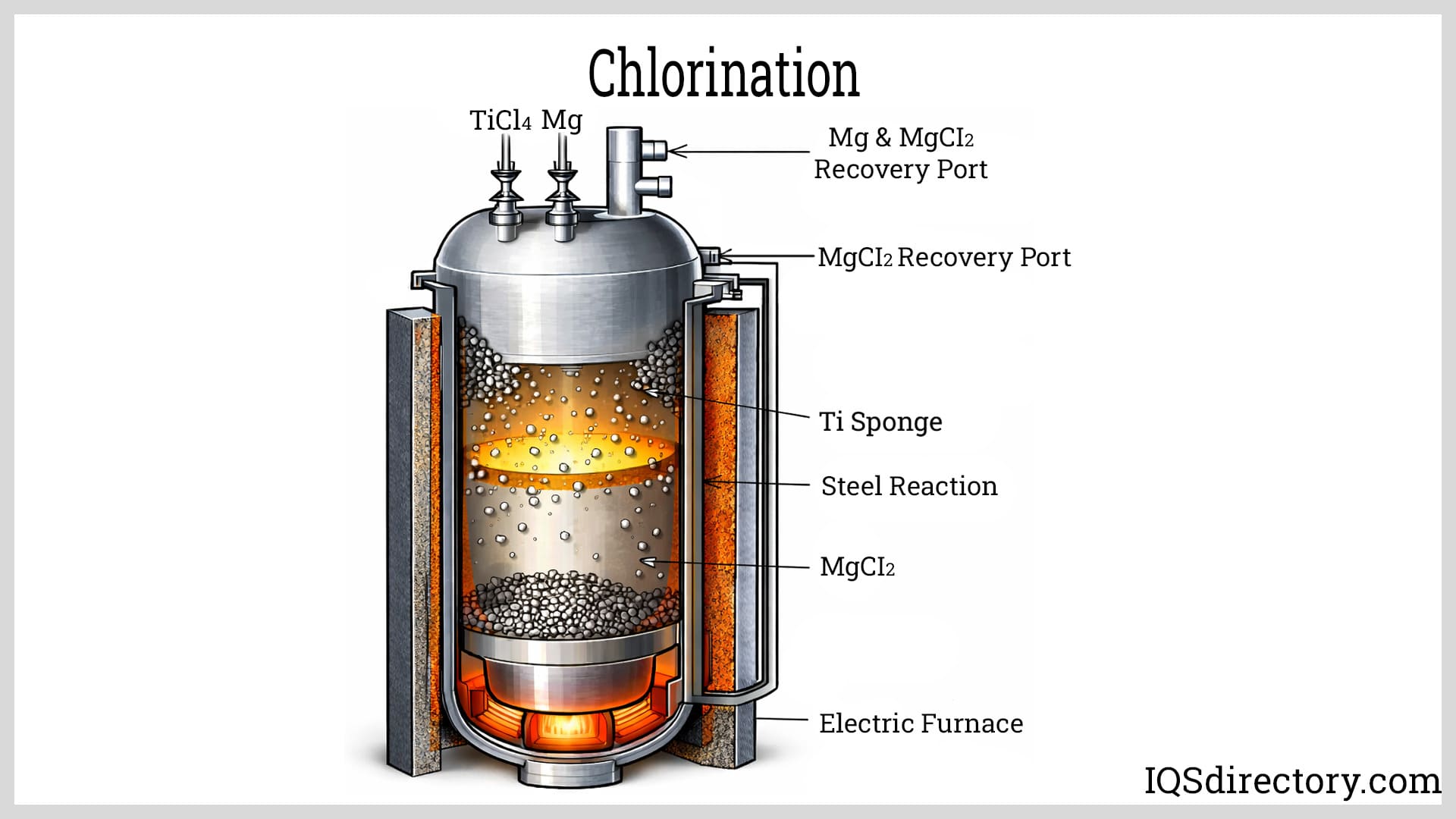

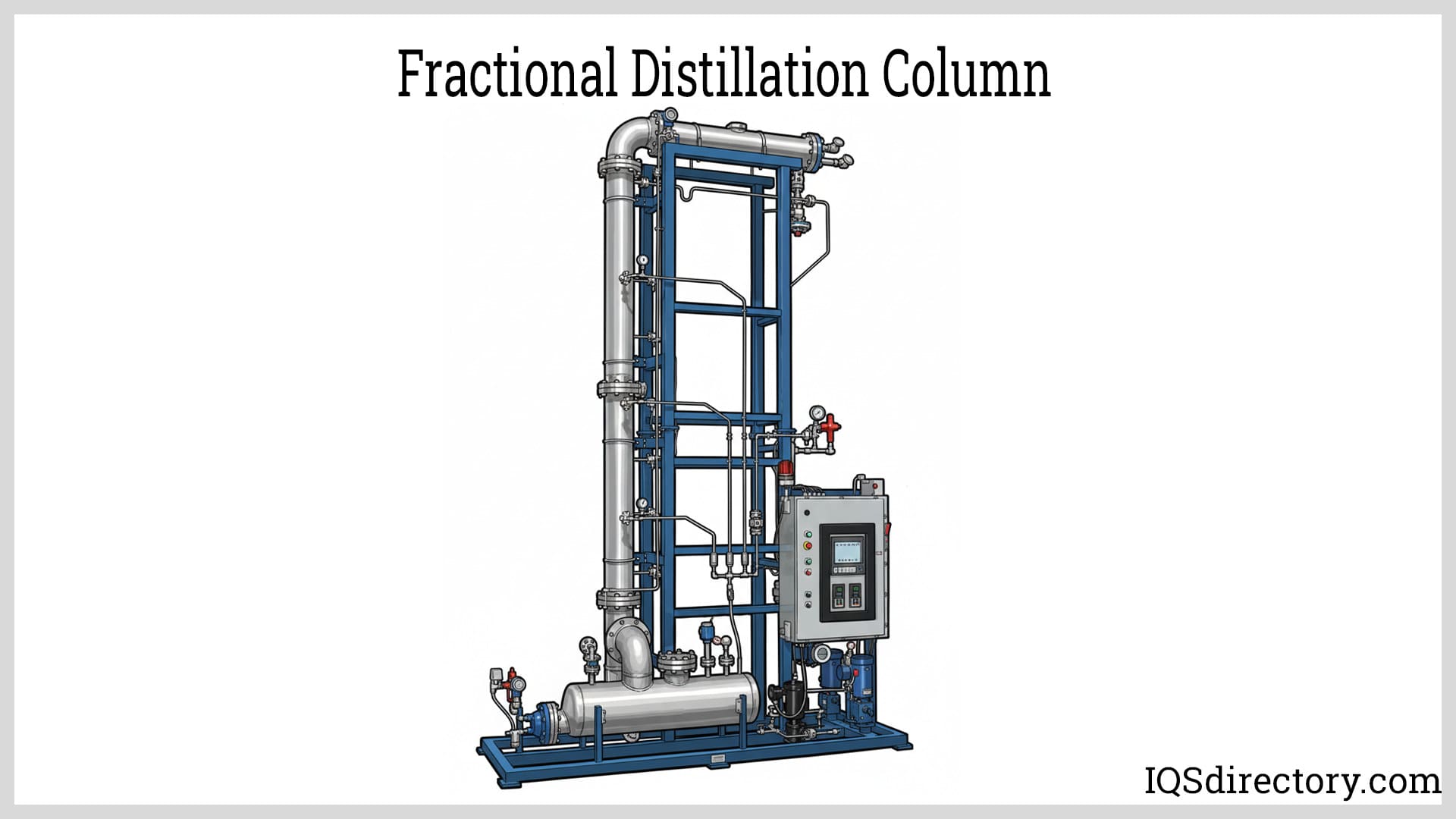

The conversion process involves placing the ore in a chlorinator where an electric charge is applied to the ore. Chlorinators are steel containers that infuse chlorine gas into the ore to convert titanium oxide ore into titanium tetrachloride. The chlorination chemical reaction requires 800°C up to 1000°C (1472°F up to 1832°F) to complete the process. Any impurities are fractionally distilled in order to produce a pure mixture of titanium. The created titanium gas is a colorless and volatile liquid with a pungent odor. The result of the process is titanium that has been isolated from oxygen without impurities and titanium in a chlorinated state.

The titanium tetrachloride from chlorination has byproducts that influence and corrupt its purity. To remove the impurities, the titanium tetrachloride undergoes fractional distillation that uses differences in boiling points to remove the impurities. The process begins with cooling the titanium tetrachloride vapor to condense it into a liquid. The liquid is fed into columns that have different boiling points. The less volatile impurities condense while the more volatile titanium tetrachloride rises to the top.

The purification of titanium tetrachloride is a necessity to prepare the element for the next steps of the process. Any elements that are close to the titanium are separated further by precipitation.

The purified titanium tetrachloride, retrieved from fractional distillation, is placed in a sealed reactor where it is combined with molten magnesium. The titanium tetrachloride reacts with the magnesium to produce a porous titanium metal sponge and magnesium chloride. As with all aspects of the Kroll process, precision and control are necessary to achieve the desired results.

The titanium sponge is a light grey sponge like mass that is the raw material for the manufacture of titanium. Sponges are classified into seven grades that range from MHT 95 up to MHT 200. The numbers in the classification refers to the Brinell hardness maximum value. Titanium sponge has a titanium purity level of 98.5% up to 99.8% with impurities at 0.05% up to 0.30%.

To achieve necessary purity, the titanium sponge material has to be cleaned to remove leftover magnesium chloride. There are several methods used to remove the unnecessary elements, including vacuum distillation, the FFC Cambridge method, the ITP Armstrong process, and leaching.

Vacuum distillation uses the varying vapor pressures of metals to separate the magnesium chloride. Different vapor pressures used to separate the metals, along with increases in temperature, causes the metals to separate. Metals with high vapor pressure evaporate while low pressure metals remain. The process causes the unwanted metals to vaporize, preserving the pure titanium.

Leaching involves the use of various processes including pressure, atmospheric process, and ultrasound assistance. The efficiency of the process is enhanced through the use of high temperatures. The method commonly used to purify titanium involves the use of acids or other chemical solvents that extract titanium and remove the magnesium.

The purification process is an essential part of the manufacture of titanium to ensure its stability in regard to certain conditions and exposure to impurities. The purer forms of titanium are used for space craft and the aerospace industry.

The purified titanium is crushed to form small granules, destroying the sponge form. The pure titanium of the granules is normally mixed with other metals to form titanium alloys. The different types of alloys are added to improve the properties and characteristics of the pure titanium in order to conform to the application for which the titanium is being produced. Extreme pressure is used to compact the granule mixture to form blocks, which are welded together to make electrodes.

The electrodes are melted using an arc melting process in a vacuum or some form of inert atmosphere. During the melting process, an arc forms between the titanium electrode and a crucible. As the electrode melts, the titanium flows into the crucible where it cools to form the first ingot. To ensure the purity of the titanium, the first ingots are used as electrodes a second time for remelting.

The completed ingots can be heated and forged to create a wide array of products. Common alloying elements for titanium are aluminum, vanadium, and molybdenum, which are added to improve the properties of titanium, such as its strength to weight ratio, toughness, and resistance to corrosion.

As with most metals, the grades of titanium are classified by their chemical composition and mechanical properties. Each grade is designed to fulfill the requirements of an application or a specific purpose. The American Society for Testing and Materials (ASTM) has developed the specifications and details regarding each of the various grades. Pure grades of titanium are classified as alpha titanium as one of the three classifications of titanium.

Titanium Grade 1 is the softest, most ductile, and formable of the different grades of titanium. In essence, Grade 1 is pure titanium that has exceptional resistance to corrosion and is easy to weld with average impact toughness. The ductility of Grade 1 enables it to be easily formed and shaped, making it ideal for products that are bent or molded. Its resistance to corrosion has led to its wide use in marine applications. Like other titanium grades, Grade 1 is biocompatible enabling it to be used for implants and medical devices.

Titanium Grade 2 is valued for its moderate strength, ductility, and resistance to corrosion. It is used in environments containing calcium chloride, cupric chloride, ferric chloride, concentrations of acetic acid, high temperature seawater, and organic media. Due to Grade 2’s resistance to chlorine, it is used to make chlorine dioxide mixers, pipes, and fasteners in bleach production plants. Grade 2 is stronger than Grade 1 but has the same level of resistance to corrosion as Grade 1. It is referred to as the workhorse of titanium due to its wide industrial use

The factor that differentiates Grade 2 titanium from other grades, and the reason for its common use, is its lower cost. As with Grade 1 titanium, Grade 2 is used for applications in chemical processing, aerospace, marine environments, and desalination plants.

Grade 3 titanium is another form of pure titanium. It is stronger than titanium Grades 1 and 2 but is flexible and has the same corrosion resistance. Grade 3 titanium is found in applications that require high strength but need flexibility. It has the highest American Society of Mechanical Engineers (ASME) design stress rating for any form of commercial titanium.

As with all pure titanium grades, Grade 3 is biocompatible and exceptionally resistant to corrosion with good formability and impact properties at low temperatures. It is 98.8% pure titanium with small amounts of iron, carbon, nitrogen, and hydrogen. The applications for which Grade 3 titanium is used are the same as those for Grades 1 and 2 with the addition of parts for the auto industry, power generation, and specific types of industrial machinery.

Titanium Grade 4 is reputed to be the strongest of the pure titanium grades but is the least moldable. It is commonly cold formed to produce medical devices and is highly valued for its strength, durability, and weldability. As with all forms of pure titanium grades, Grade 4 is resistant to corrosion and is widely used in environments containing seawater and various chemicals.

The inability to shape Grade 4 titanium makes its use for different applications challenging. This aspect of Grade 4 is balanced against its ability to be easily welded using any of the normal welding techniques. The dependency on Grade 4 titanium is built on its strength, corrosion resistance, and its easy weldability. Grade 4 titanium is used as parts of heat exchangers and turbine blades for power plants, which depend on its strength.

Grade 4 titanium is the last of the pure titanium grades, which are known as the Commercially Pure (CP) Titanium or Alpha (α) titanium. As is evident from the discussion, the grades of these pure titanium differ in accordance with their corrosion resistance, strength, ductility, and flexibility. Of the four, Grade 1 titanium has the highest corrosion resistance and formability but the lowest strength, while Grade 4 titanium has the highest strength but limited ductility.

Titanium alloys are mainly pure titanium mixed with other metals or chemicals to change the characteristics and properties of titanium. Although pure titanium is strong, with strength that is the same as steel, it becomes even stronger with the addition of alloys. Titanium alloys are divided into three classes, which are alpha, beta, and alpha beta. These three classifications represent fifty different grades of titanium alloys, with only 31 being recognized by ASTM. Titanium alloys have been developed to meet the specific requirements of a variety of applications.

The alpha class of titanium consists of four elements that are composed of pure titanium with small percentages of other elements including aluminum. They are known for their weldability and exceptional corrosion resistance. Alpha alloys maintain their strength regardless of the temperature, which is due to their creep resistance, a tendency to deform under stress. The strength of alpha titanium can not be enhanced through heat treatment.

The beta class of titanium includes the alloys vanadium, chromium, and molybdenum with a titanium content of 99% and all of the positive properties of titanium. Unlike alpha class titanium, beta class titanium can be heat treated to achieve exceptional tensile strength, which makes beta titanium ideal for the aerospace industry. The formability of beta class titanium enables it to be used for shaping complex components with high strength.

With the alpha beta class of titanium, the percentage of titanium decreases to 88% up to 90% with certain grades having a slightly higher titanium content. The alpha beta class of titanium provides the best features of the alpha and beta classes. This class of titanium is described as the workhorse of titanium.

| Comparison of the Three Classes of Titanium | |||

|---|---|---|---|

| Family | Weldability | Strength (Heat Treated) | Formability |

| Alpha (α) | Excellent | Low | Good |

| Beta (β) | Fair | Highest | Excellent |

| Alpha-Beta (α-β) | Good | High | Good |

Of the long list of titanium alloys, only a few are widely used. This aspect of titanium is in regard to the specialized alloys that are manufactured for a specific purpose. The short list of alloys that are used in a wide range of products is in regard to their cost, availability, versatility, and formability. The many positive properties of titanium come at a cost, which is why manufacturers carefully consider the use of titanium in a product.

Grade 5 is an alpha beta class titanium alloy that contains aluminum and vanadium, elements that make Grade 5 adaptable, versatile, and highly reliable. The aluminum content adds to the strength of titanium improving its strength in high temperature applications and its creep resistance. In essence, aluminum serves as the structural backbone of the alloy. Vanadium stabilizes the alloy, which is crucial during heat treatment. It adds toughness and other strength capabilities.

The property of Grade 5, also known as TC4, that is most valued is its strength, which can reach 1000 MPa with a yield strength of 900 MPa. As with all forms of titanium, Grade 5 has exceptional corrosion resistance that is reflected in its ability to withstand oxidation, nitration, and chlorination. Grade 5, in its powder form, is used for the 3D printing of aircraft parts.

Grade 5 titanium includes 6% aluminum (Al), 0.25% iron (Fe), 90% titanium, and 4% vanadium (V). The hardness of Grade 5 as well as its high strength is indicated by a Brinell hardness number of 334, which is comparable to steel.

Grade 9 titanium has a similar content as that of Grade 5 but with a decrease in its aluminum and vanadium content. Unlike Grade 5, Grade 9 is cold formable, which makes it ideal for forming or welding parts that require more strength than alpha class titanium. The superior fatigue strength of Grade 9 makes it a great choice for applications that are cyclically loaded. Although Grade 9 is an alpha beta class titanium, it leans strongly toward an alpha classification due to its low beta stabilizer content. Grade 9 is referred to as a medium strength alloy that is a bridge between CP titanium and Grade 5 titanium.

The level of strength of Grade 9 is approximately 20% to 30% greater than Grade 2 titanium. The formability of Grade 9 enables it to be used to produce tubing for aerospace and sports equipment and sheets for stamping and deep draw parts. Grade 9 tubing is used in chemical and power plants for heat exchangers that operate at high pressure and require corrosion protection.

Titanium Grade 7 is more resistant to corrosion than other grades of titanium due to its palladium content. The structure of Grade 7 is similar to that of Grade 2, such as its medium strength and ductility. Grade 7 has a tensile strength of 485 MPa with a yield strength of 350 MPa. It is made up of small amounts of iron, carbon, nitrogen, and hydrogen as well as 0.12% up to 0.25% palladium. The titanium content of Grade 7 is over 99%.

Grade 7 titanium is very weldable due to its microstructure being unaffected by thermal treatments. An unusual aspect of Grade 7 is its ability to be annealed, which is not common for titanium. Annealing is performed at 650°C up to 760°C (1202°F up to 1400°F) for six minutes up to two hours. When stress relief is necessary, Grade 7 is heated to 480°C up to 595°C (896°F up to 1103°F) for 15 minutes up to 4 hours. In both cases, air cooling is used.

The list of uses for Grade 7 extends through a wide range of components and capabilities. Included in the applications for which Grade 7 is used are cathodes, air pollution control equipment, paper bleaching, hydrometallurgical extraction, and desalination. The high titanium content matched with palladium gives Grade 7 an unusual set of beneficial and productive properties.

Grade 11 titanium, as with Grade 7 titanium, is a product of the alloying of titanium and palladium. It is categorized as part of the CP group of titanium with a titanium content of 99% and a palladium content of 0.12% up to 0.25%. As with Grade 7, the addition of palladium improves Grade 11’s resistance to corrosion. The alloying of Grade 11 gives it higher strength than alpha titanium. Compared to Grade 7 titanium, which has the same palladium content, Grade 11 is more weldable, costs less, and is more accessible for industrial use.

The palladium content of Grade 11 titanium increases its resistance to harsh conditions, such ones that contain hydrochloric acid or sulfuric acid. The temperature stability of Grade 11 enables it to be used in multiple types of environments, minimizing potential equipment failures. As with other forms of titanium, Grade 11 titanium is widely used in desalination, chemical processing, and marine industries. When being prepared for shipping, Grade 11 titanium is shaped into rods or tubes.

Grade 12 titanium has strength that is similar to series 300 steels. Its weldability and formability enable it to be used for fabricating heat exchangers, marine equipment, and various aerospace components. The addition of molybdenum and nickel increases the corrosion resistance of Grade 12 at lower cost than that of Grades 7 and 11 that contain palladium. Although it is stronger than alpha titanium, it is formable regardless of its Brinell hardness of 235 and Rockwell C hardness of 11.

The use of Grade 12 titanium is similar to the other grades of titanium that are used in chemical processing, heat exchangers, valves, and pumps. The resilience and strength of titanium make an ideal metal for applications that demand high endurance and stability.

Grade 23 titanium is similar to Grade 5 titanium but with a lower oxygen, nitrogen, and iron content but with the same ductility and fracture toughness. It is made up of small amounts of carbon, oxygen, nitrogen, hydrogen, vanadium, aluminum, and iron. As with all forms of titanium, it is highly resistant to corrosion and is available in bars, wire, plates, sheets, and welding wire.

Along with its high corrosion resistance, Grade 23 titanium is known for its mechanical properties of low density and high strength. In its powder form, Grade 23 titanium is used to 3D manufacture parts, which can be machined, shot peened, and polished. Parts manufactured using Grade 23 have good elongation and toughness.

The list of titanium grades described above are a small sampling of the over 50 grades of titanium available on the market. Of the six grades discussed, Grade 5 titanium, referred to as the workhorse alloy, accounts for 50% of the usage of titanium in the world. Its aluminum and vanadium content gives it high strength, low weight, and enables it to be heat treated, a critical factor for parts produced for the aerospace, automobile, and medical industries.

An alpha class grade that is also widely used is Grade 2 titanium, which is known for its exceptional resistance to corrosion and weldability. Although other grades of titanium are used by marine applications and the manufacture of heat exchangers, Grade 2 titanium leads the list of materials preferred for such products.

In order to appreciate the versatility and reliability of titanium, it is important to examine all of the different forms of titanium, especially in incidences when it is being used to produce a product. The chemical adjustments that have been made to titanium structure it to perfectly match the specific requirements of an application.

| Titanium Grades and Applications | |||

|---|---|---|---|

| Composition | Applications | Key Properties | |

| Grade 1 | Pure Titanium | Chemical Processing, Marine Application | High Corrosion Resistance Softest Grade |

| Grade 2 | Pure Titanium | Aerospace, Desalination Plant, Architecture | Excellent Corrosion Resistance, Moderate Strength |

| Grade 3 | Pure Titanium | Heat Exchangers, Industrial Applications | High Strength, Moderate Corrosion Resistance |

| Grade 5 (TI-6AL-4V) | Titanium-Aluminum-Vanadium | Medical Implants, Aerospace, Sporting Goods | High Strength-to-Weight Ratio, Widely Used |

| Grade 7 | Titanium-Palladium | Chemical Processing | Enhanced Corrosion Resistance |

| Grade 9 (TI-3AL-2.5V) | Titanium-Aluminum | Automotive, Aerospace Tubing | Good Weldability, Medium Strength |

| Grade 11 | Titanium-Palladium | Chemical Processing | Superior Corrosion Resistance in Oxidizing Environments |

| Grade 12 | Titanium-Molybdenium-Nickel | Power Generation, Chemical Processing | Enhanced Corrosion Resistance |

| Grade 16 | Titanium-Palladium | Desalination, Marine Environments | Enhanced Corrosion Resistance |

| Grade 23 (TI-6AL-ELI) | Titanium-Aluminum-Vanadium | Medical Implants, Surgical Devices | High Strength, Improved Fracture Toughness |

One of the issues that is regularly discussed regarding the use of titanium is its cost, which varies in accordance with the grade of titanium. The constant changes of the prices of metals and their quality makes it difficult to determine the cost of titanium. When exploring the purchase of titanium, it is essential to understand the factors that influence its pricing.

Titanium is priced by the pound or kilogram with per pound costs ranging from $3 up to $16 while kilogram prices range from $4 up to $150. Industrial Grade 2 pure titanium has a kilogram cost of $15 up to $30 while Grade 5 can be as high as $75 to $150 per kilogram. The purity, grade, supply, quality, certification, and other factors all influence the pricing. As any manufacturer can attest, the purchase of titanium is a complex and intricate process that requires careful consideration and up to date information.

The most important factors that influence the price of titanium are its grade and purity. The alpha and beta classifications are further categorized by their crystalline structure, grain sizes, and their properties. In addition, high purity titanium demands a higher price due to the absence of any impurities.

The normal factors that influence the demand for a product also apply to the demand for titanium. Aerospace, automobile, chemical processing, and medical fields play an important role in determining the demand for titanium. In addition to these industrial needs, governmental regulations and requirements further influence the price of titanium. As with many raw materials, the cost of titanium is influenced by a complex and intricate set of factors that cause the fluctuations in its cost.

The manufacture of titanium takes place all over the world, which adds to the complexity of its cost. As anyone who has traveled overseas can tell you, currency values are constantly changing, a factor that impacts the cost of titanium. Economics, politics, international relations, and a list of other factors further complicate the purchase of titanium.

Each metal industry develops pricing benchmarks based on demand trends for all metals. The interplay between other metals and titanium allows experts to decide on the price of a kilogram or pound of titanium. There is a list of metal exchanges, such as the London Metal Exchange, around the world that decide on the benchmark pricing for titanium. Such organizations study supply and demand trends, market directions, and the fluctuations in pricing.

Titanium, as with other metals, are certified after being tested in regard to chemical properties, mechanical properties, and dimensional accuracy. Each grade of titanium is quality tested to ensure it meets the highest standards. As with all metals, titanium certification is in accordance with the stipulations of ASTM, MIL, and ISO. Titanium dealers are certified and approved regarding the quality of the titanium they offer.

The Kroll process is a high energy method for extracting titanium. Although titanium is the 9th most common element on earth, the ores that contain titanium are less common and are present in specific regions of the planet. The transportation of the ore to processing further adds to the cost of the product.

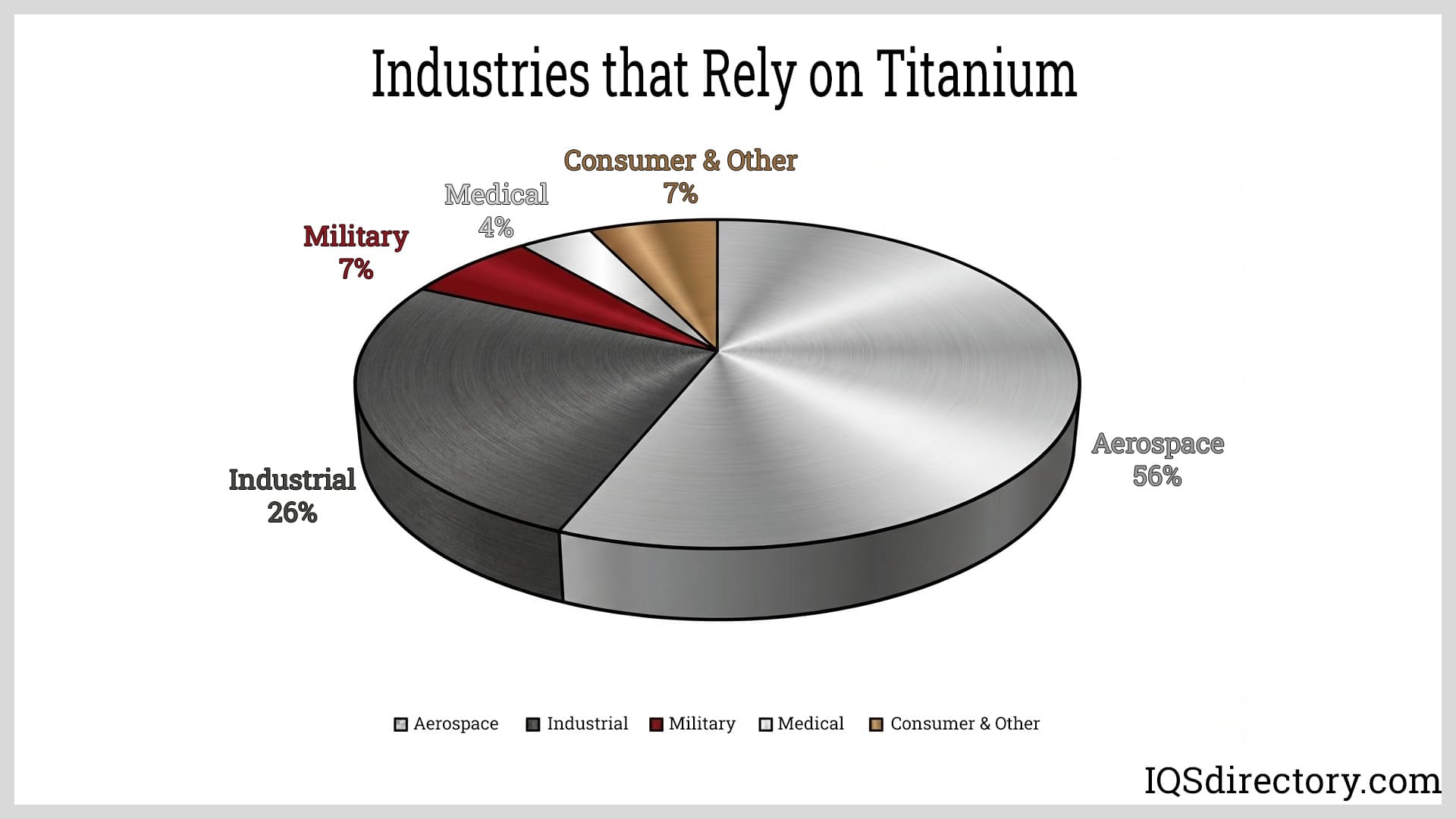

Several industries rely on titanium as a raw material for the production of their products or the completion of an application. Rutile titanium is the most widely traded type of titanium with an average cost of $1772 up to $2100 per metric ton. The variations in the cost are in regard to the origin of the titanium. Sponges, ingots, and alloy ingots vary in price and are constantly fluctuating with market value. This aspect of the pricing adds to the complexity of purchasing titanium.

Titanium is sold as a cost per pound, which is the generally accepted pricing method.

| Titanium Grades and Applications | |

|---|---|

| Type/ Grade | Price Per Pound (USD) |

| Grade 1 & 2 (Pure) | $6 - $10 |

| Grade 2 & 4 (Pure, Stronger) | $7 - $12 |

| Grade 5 (TI-6AL-4V) | $10 - $16+ |

| Titanium Powder | $20 - $35 |

| Titanium Scrap | $2 - $6 |

Although cost per pound is widely used, in the age of the metric system, sellers also offer titanium at prices per gram or per kilogram. The conversion of pounds to kilograms involves the formula of a pound being equal to 0.453 kilograms. For example, three pounds would be 1.36 kilograms.

| Titanium Grades and Applications | |

|---|---|

| Unit | Price Range |

| Titanium Cost Per Pound (lb) | $2 - $16 |

| Titanium Cost Per Kilogram (kg) | $4.40 - 35.20 |

| Titanium Cost Per Gram (g) | $0.0044 - $0.035 |

Titanium is the most expensive of the metals used for industrial applications. Aluminum, brass, copper, stainless steel, and nickel, which are also industrial metals, cost far less and are readily available. Although titanium is less expensive than gold and silver, of the three metals, titanium is the only metal that is widely used in automobiles, airplanes, chemical processing, and power plants.

The cost of titanium is the reason that manufacturers carefully consider its use as an alternative to other metals, since its inclusion in a product radically increases the cost of a product. The upside of titanium is its mechanical properties and characteristics that add to the life expectancy of a product.

Titanium metal, with the symbol Ti, is the ninth most abundant element in the earth‘s crust. It does not occur in large deposits, yet small amounts of titanium are found in almost every rock…

Aluminized steels are steels that have been hot-dip coated with pure aluminum or aluminum-silicon alloys. This hot-dip coating process is termed hot-dip aluminizing (HAD)...

Aluminum 1100 is the softest of the aluminum alloys, which makes it easy to shape and form into a wide range of products for industrial and home use. It can be cold and hot worked but is frequently shaped by...

The term "aluminum coil" describes aluminum that has been flattened into sheets where their width is significantly higher than their thickness and then "coiled" into a roll. Stacks of individual aluminum sheets are difficult to...

Aluminum piping and tubing is silvery-white, soft, and ductile. The metal belongs to the boron group. Aluminum is the third most abundant element present on earth. Aluminum has low density. When exposed...

Beryllium Copper is a versatile copper alloy that is valued for its high strength and hardness, combined with good electrical and thermal conductivity. It is a non-ferrous, non-magnetic, and non-sparking metal alloy...

A variety of copper-zinc alloys are referred to together as brass. Different ratios of brass and zinc can be used to create alloys, which produce materials with various mechanical, corrosion, and thermal properties...

Copper is a ductile, malleable, and reddish-gold metal with the capacity to effectively conduct heat and electricity. Brass and bronze, two commonly used alloys, are created when copper is combined with...

The copper sheet is a highly malleable and workable metal with outstanding electrical and thermal conductivity and corrosion resistance. Copper (Cu) is a reddish, very ductile metal that belongs to Group 11 of the periodic table...

Metals are a group of substances that are malleable, ductile, and have high heat and electrical conductivity. They can be grouped into five categories with nickel falling in the category known as transition metals...

Stainless steel grade 304 is an austenite stainless steel that is the most widely used and versatile of the various grades of stainless steel. It is a part of the T300 series stainless steels with...

Stainless steel is a type of steel alloy containing a minimum of 10.5% chromium. Chromium imparts corrosion resistance to the metal. Corrosion resistance is achieved by creating a thin film of metal...

Stainless steel grades each consist of carbon, iron, 10.5%-30% chromium, nickel, molybdenum, and other alloying elements. It is a popular metal used in various products, tools, equipment, and structures that serve in many industrial, commercial, and domestic applications...

Steel service centers are companies that specialize in procuring steel directly from mills and manufacturers and supplying them to the customers. They are fundamental to the steel supply chain...

Stainless steel can be fabricated using any of the traditional forming and shaping methods. Austenitic stainless steel can be rolled, spun, deep drawn, cold forged, hot forged, or stippled using force and stress...

Stainless steel tubing is a multifaceted product that is commonly utilized in structural applications. Stainless steel tubing diameters and variations vary greatly based on the application requirements and are...

Tungsten is a rare naturally occurring chemical element on earth. It is known to be one of the toughest metals on the earth. It is usually a tin white or a steel gray metal. Tungsten is common for its high tensile...

Aluminum is the most abundant metal on the Earth’s crust, but it rarely exists as an elemental form. Aluminum and its alloys are valued because of their low density and high strength-to-weight ratio, durability, and corrosion resistance...