Ceramic Magnets

A ceramic magnet, also known as a ferrite magnet, is a permanent magnet made by combining iron oxide and strontium carbonate. They are a man made magnet produced by heating the two elements to...

Please fill out the following form to submit a Request for Quote to any of the following companies listed on

An explanation of SmCo magnets and their importance with a list of manufacturers and suppliers

You will learn:

SmCo magnets are strong rare earth permanent magnets that are used for a variety of industrial applications. They have two primary phases, which are SmCo₅ and Sm₂Co₁₇. The difference between the phases is in regard to their magnetic energy, temperature resistance, and the number of samarium and cobalt atoms.

SmCo magnets are known for their high magnetic strength with an MGOe range between 16 and 32 MGOe. The term MGOe is a unit measure, Maximum Energy Product, of a magnet. It is indicative of a magnet’s strength and efficiency. Strong powerful magnets have a high MGOe and a strong magnetic field that provides exceptional performance.

SmCo magnets have excellent magnetic stability in high or low temperature conditions. Unlike other types of magnets, SmCo magnets have high resistance to demagnetization and corrosion, without requiring a coating The stability and strength of SmCo magnets has led to their use in high performance motors, sensor systems, and various technical applications.

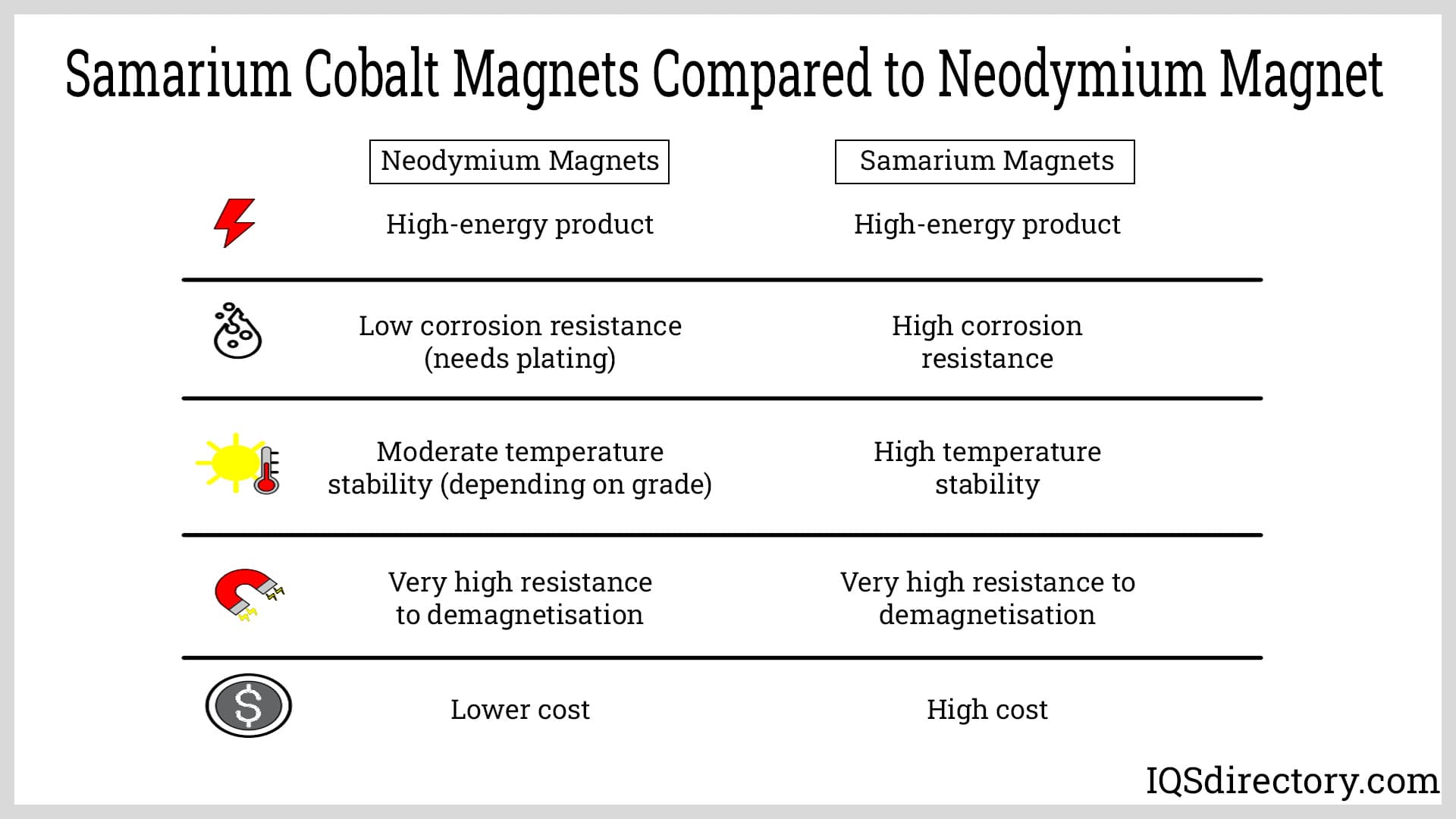

Although neodymium iron boron magnets are the strongest rare earth magnets, they lose their strength at extremely high temperatures and corrode easily, which necessitates that they be coated with electroplating or epoxy. SmCo magnets can withstand temperatures as high as 260°C (500°F) and are able to resist the effects of corrosion.

SmCo magnets were perfected in the 1960s and introduced to the world in the 1970s. They were the first rare earth magnet. Their introduction revolutionized magnets and replaced aluminum nickel cobalt (Anico) alloy magnets, which was the standard magnet at that time. SmCo magnets replaced Anico alloy magnets due to being three times stronger than Anico magnets.

Samarium cobalt magnets are rare earth magnets with high magnetic energy and a low temperature coefficient with an operating temperature that can reach as high as 350°C (662°F). When placed in conditions that exceed 180°C (356°F), the magnetic energy product (BHmax), coercivity, temperature stability, and chemical stability of SmCo magnetic exceeds that of NdFeB magnets.

Several manufacturing processes are used to produce SmCo magnets with the two most common being isostatic pressing with the second method being sintering. The differentiation between the methods is the form of SmCo powder that is used for the initial step in the processing. Isostatic pressing begins with SmCo powder that is mixed with a plastic carrier, while sintering involves heating the samarium cobalt powder to near its melting point.

Samarium is a rare earth element that is shiny. It is named after a Russian mine official, Colonel Vasili Samarsky Bykhovets. It comes from samarskite, a complex oxide mineral with concentrations of rare earth elements, uranium, and thorium. Samarskite was first discovered in the Ural Mountains of Russia but has been found all over the world. In its natural state, samarskite is a velvet black mass. Samarium makes up 2.8% of samarskite and other minerals. It is found in China, the United States, Brazil, India, Sri Lanka and Australia, with China being the world leader. Samarium (Sm) is a chemical element with the atomic number of 62.

Cobalt (Co) is referred to as a transition metal that is found naturally with copper and nickel with an atomic number of 27. It is sourced from cobaltite, erythrite, copper, and nickel. It is chosen for the production of magnets due to its high ferromagnetic properties. Cobalt is the part of SmCo magnets that is resistant to corrosion and capable of withstanding extremely high temperatures. Although cobalt is mainly used for battery technology, its strength and temperature resistance has made it valuable for 3D printing and different forms of renewable energy solutions.

To achieve the desired magnetic properties for SmCo magnets, samarium and cobalt are precision proportioned. The alloying process involves melting the metals in an induction furnace that contains argon. The inert properties of argon create a non-reactive environment that prevents contamination to ensure the purity and quality of the materials.

Although argon is expensive, it is used in the alloying process for SmCo magnets to ensure the integrity of the metals. During the process, samarium and cobalt are allowed to synergize to create magnets with exceptional strength and temperature stability, the main characteristics of SmCo magnets. To further enhance SmCo magnets, various alloys are added in small amounts, such as iron, copper, and zirconium. The use of the additional alloys is to alter the characteristics of SmCo magnets to match the requirements of a specific application.

The melted mixture is cast and formed into ingots that will be used for the raw materials to produce SmCo magnets. An essential part of the alloying process is the cooling of the ingots to form a solid metal piece. Various methods are used with water being the most common.

The milling process involves crushing the ingots to form a fine powder. Of the many steps in the manufacture of SmCo magnets, this aspect of the process is essential. The ingots have to be crushed in such a way that the result is a powder with a uniform particle size. To achieve a properly oriented magnet, the particles in the powder are required to have a size of 3 to 4 micrometers (μm). Concentrated size distribution with particles that are spherical or nearly spherical further assures the success of SmCo magnets.

The alloying, casting, and milling of samarium and cobalt, described above, is the process that is used the most for preparing the raw materials for SmCo magnet production. After this initial stage, the manufacturing of SmCo magnets takes different forms, with bonding or isostatic pressing and sintering being two of the most used.

Bonded or isostatic pressing samarium cobalt magnets are an alternative to sintered samarium cobalt magnets. The alloying process includes the mixing of the powder with a binding agent, such as an epoxy resin, and compressing the mixture into the final shape of the magnet. With the hot press method, the powder is placed under high pressure with heat. Due to the heat, the powder particles fuse to create a solid compact cohesive shape. The application of heat, in the presence of a magnetic field, orients the powder particles.

The use of heat to produce bonded SmCo magnets orients the powder particles, which makes most bonded samarium cobalt magnets anisotropic, where the magnetization is in one direction. This aspect of the bonded samarium cobalt magnets gives them stronger magnetic properties than isotopic magnets. In addition, isostatic compression magnets have close tolerances, eliminating the need for machining, and can be configured into complex shapes.

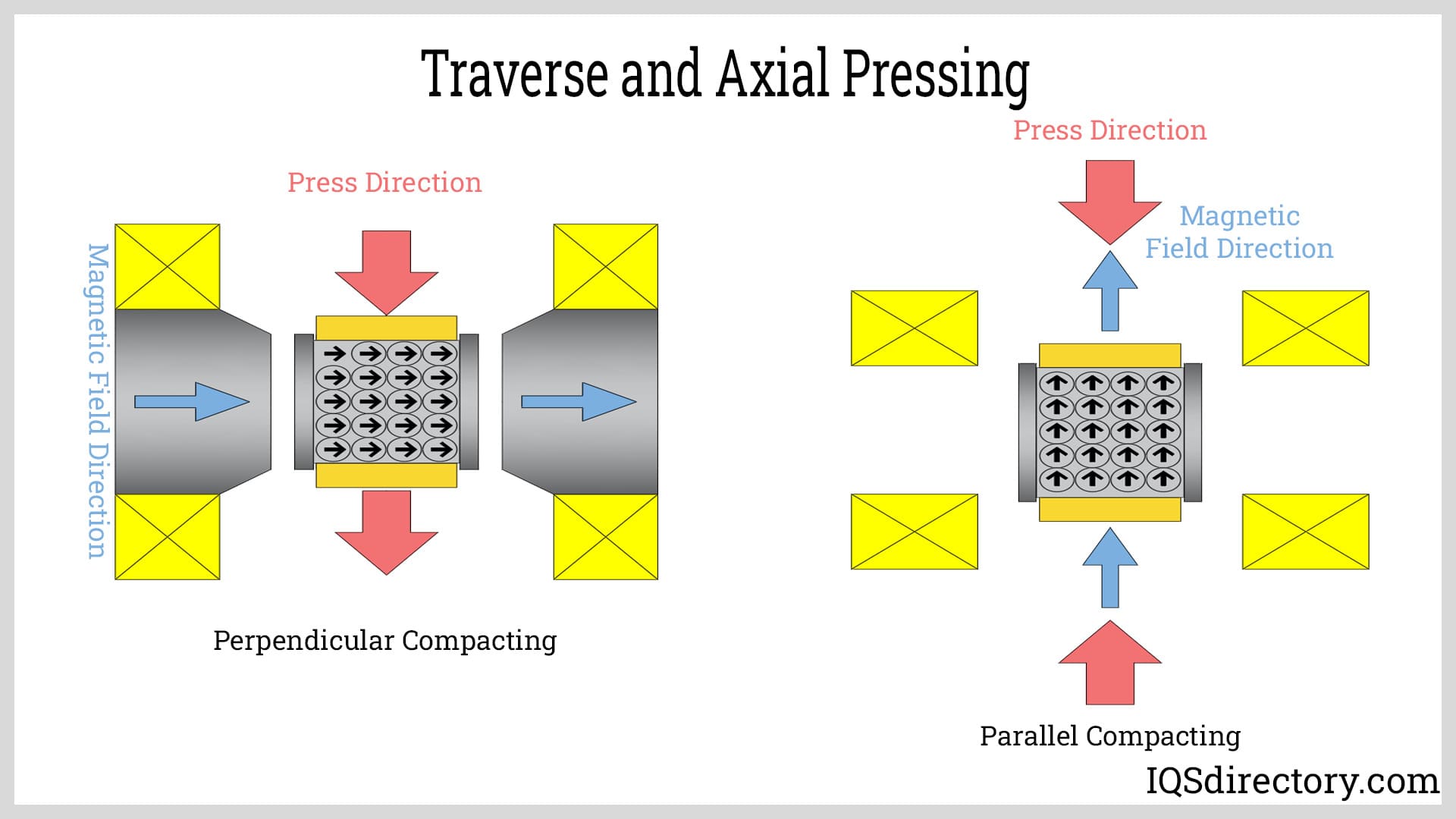

The compacting of the powder to form SmCo magnets takes several forms, each having distinguishing characteristics. The method chosen for producing SmCo magnets is dependent on the manufacturer and the type of magnet that is required.

Magnetic field compacting uses the interaction between the powder and magnetic field to align the powder’s magnetization direction to make it consistent with the final magnetization direction. The use of magnetic field orientation is used to produce anisotropic magnets.

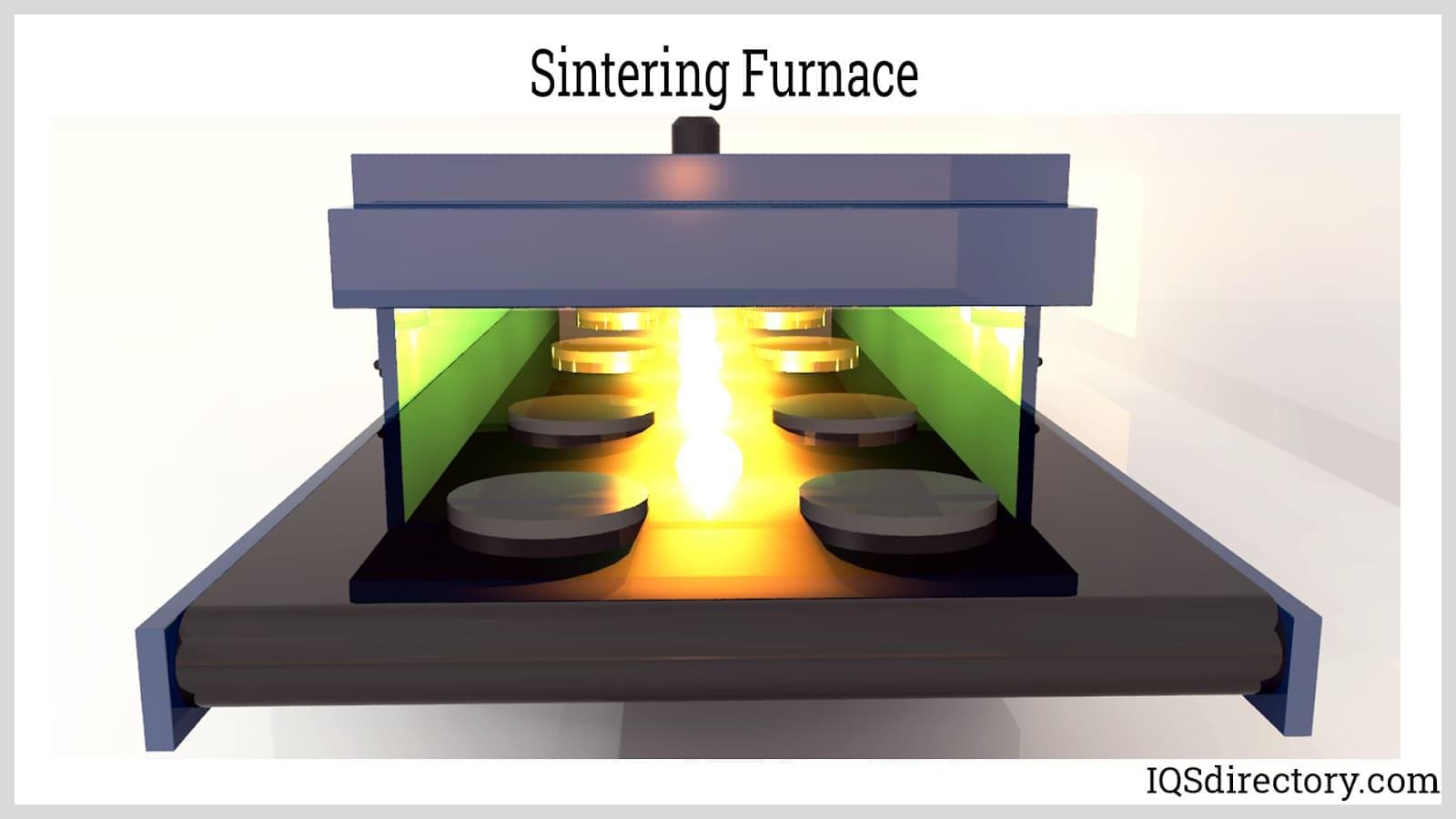

The initial steps for the manufacture of sintered samarium cobalt magnets are the same as those for bonded samarium cobalt magnets. The differentiation in the processes is the following steps where additional chemicals are added to the process. The sintering process heats the powder mixture to just below its melting point to bond and form a solid structure.

The set temperature and the presence of a vacuum or inert gas determines the type and grade of SmCo magnet being made. The purpose of the vacuum is to prevent the forming of an oxide film that would lower the quality of the final magnets. During the heating process, the SmCo magnets are heated to a sintering temperature that densifies the mixture. The powder is pressed into a die and is heated to 1250°C (2282°F), which solidifies and fuses the powder. The length of the sintering time affects grain growth and has to be sufficient to achieve proper density.

When the material is at the highest temperature, it is given a solutionizing treatment. At the completion of the sintering, the SmCo magnets are tempered between 700°C and 900°C

(1292°F and 1652°F). After they have cooled, they have their magnetic field applied. During sintering, the magnets shrink, linearly, by 15% to 20% and have a rough surface with no evident magnetic field.

Unlike bonded samarium cobalt magnets, sintered samarium cobalt magnets are ground and finished using a water cooled diamond coated grinding machine. The sintered material is very hard and brittle at Rockwell C57 up to C61, which is the reason for the use of diamond coated grinding tools. The grinding process takes different forms, which can include grinding them smooth and parallel, OD and ID grinding, or slicing the magnet blocks into smaller portions. When the slicing process is performed, with exacting precision, other grinding may not be necessary.

There are several factors that are meticulously controlled during the grinding process to avoid damaging the final SmCo magnets. Care in the process is necessary to avoid chipping and cracking the magnets. When the final shapes are being produced in low volume, electrical discharge machining (EDM) can be used for simple dimensional profiles.

Machined SmCo magnets have sharp edges that chip easily. Since coating is difficult, other measures are taken to remove the sharpness. A common method for high volume magnet production is vibratory tumbling that includes an abrasive media.

SmCo magnets do not require a surface like the coatings that are applied to Neodymium magnets, which can rust and react to chemicals. The mixture of samarium and cobalt is naturally resistant to corrosion. Regardless of this factor, there are occasions when epoxy, electrolytic nickel, and aluminum IVD is applied. Conversion coatings are also used but provide temporary protection.

At the end of the casting, heating, and machining, the magnets need to be charged to produce a magnetic field. Magnetization aligns the magnetic dipoles, which is achieved by applying a magnetic field or exposing the material to a magnetic field. The strength of the magnetization and magnetic field depends on the type of material and the strength of the applied magnetic field.

The magnet field applied to a SmCo magnet is 2 to 3 times stronger than its coercivity. With high coercivity magnets, magnetization fields may reach as high as 30,000 to 40,000 oersted (Oe), the unit measure of the strength of a magnetic field. During magnetization, the domains of a magnet are aligned permanently in the desired direction and give the magnet its full potential.

Magnetization can be accomplished in a solenoid or with fixtures designed to pass magnetic properties. In most cases, magnetization is completed by a magnetizer that has coil wire with electric current. When a magnetizer is turned on, it discharges a magnetic field that activates the magnetism of a SmCo magnet slug.

Two common forms of magnetization are:

There are special cases where SmCo magnets will require stabilization and calibration. Stabilization is a treatment to prevent demagnetizing influences that could change the performance of a magnet. Calibration is a treatment that narrows the performance range of a magnet to achieve a tight tolerance for the requirements of an application. Stabilization and calibration ensure that a magnet can perform within a specified temperature and have tight tolerances on flux output.

SmCo magnets provide exceptional performance until they are driven beyond their parameters, which leads to irreversible loss. When loss may come from elevated temperatures, then thermal stabilization is performed. If demagnetization is possible, then magnetic stabilization is performed.

Flux output is an aspect of magnets that is unavoidable. SmCo magnets are known to have a high flux output, the strength of a magnet’s magnetic field. In the majority of cases, flux output has little effect on an application. In special cases, where tight tolerances are required, magnets need to be calibrated to a specific range of temperatures. In those instances, SmCo magnets with pulses per minute (ppm) of less than 50 ppm are used.

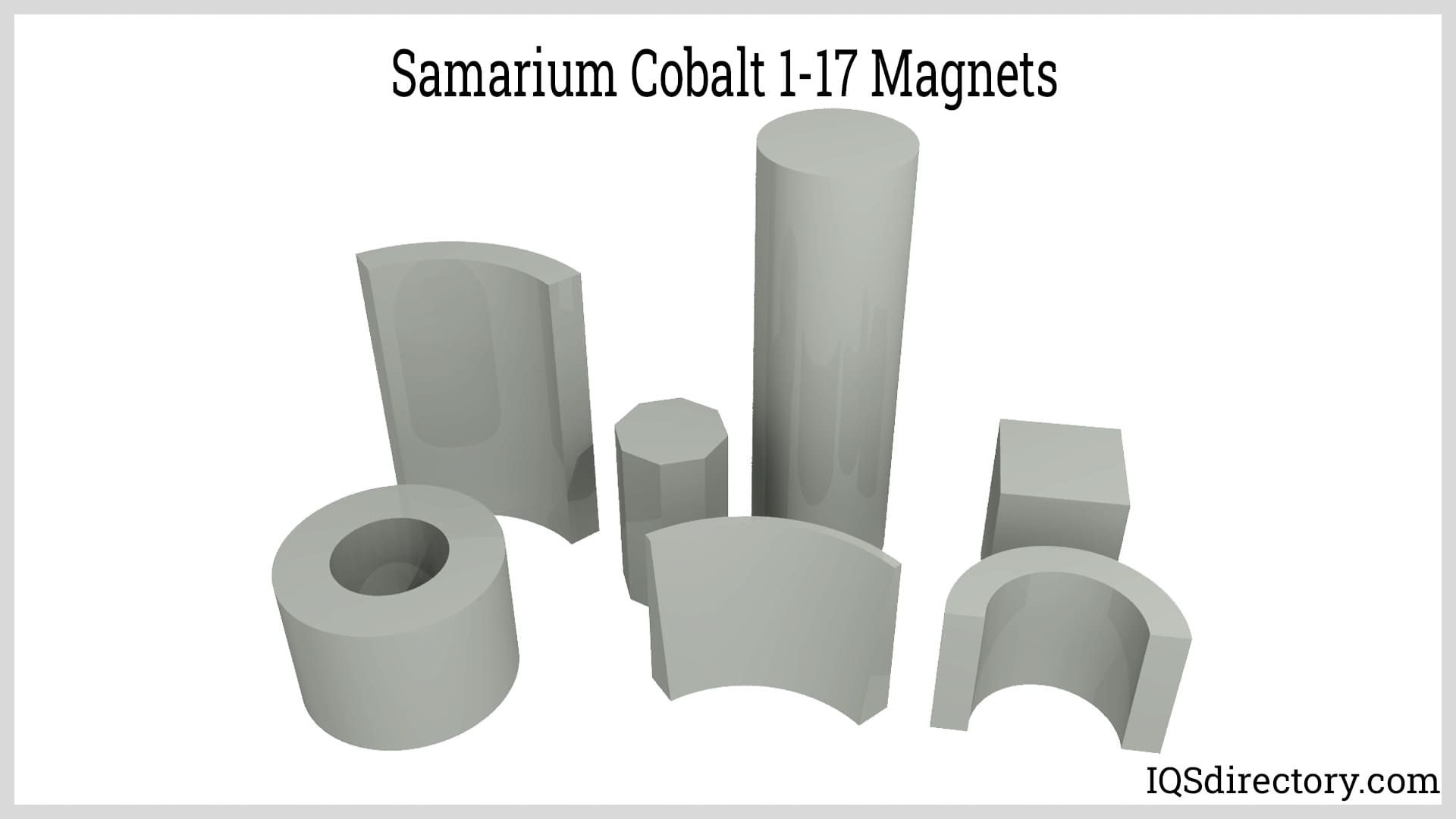

There is a wide variety of samarium cobalt magnets that are designed to support general and specialized industrial applications. The range of grades extends from 16 MGOe to 32 MGOe. The many types make it possible to optimize cost, performance, and resistance to temperature. The two main types of samarium cobalt magnets are 1-5 and 2-17, which are differentiated by the number of samarium atoms to cobalt atoms.

Samarium cobalt (1-5) is an older version of samarium cobalt magnets. It is designated as 1-5 due to its structure, which is one samarium atom per five cobalt atoms. The energy product of 1-5 ranges between 15 MGOe and 24 MGOe. This form of SmCo magnet can operate in temperatures up to 250°C (482°F) and is 35% samarium and 65% cobalt.

Samarium cobalt (2-17) is a newer samarium cobalt magnet material that has two samarium atoms and 14 to 17 cobalt atoms, with the 14-17 atoms being a mix of transition metals that include copper and iron with cobalt being the most abundant. The energy range of 2-17 magnets is between 21 MGOe and 32 MGOe with operating temperatures between 300o C up to 350°C (572°F up to 662°F). Samarium cobalt alloy for 2-17 is 25% samarium and 75% transition metals that are composed mostly of cobalt. The higher energy density and operating temperatures for this magnet alloy makes it an ideal choice for a wide variety of applications.

The main types of samarium cobalt magnets, SmCo₅ and Sm₂Co₁₇, are divided into 11 subgrades with each group given its name in accordance with their ratio of samarium atoms to cobalt atoms. The grades of SmCo magnets are identified by their strength, which range from 16, 18, 20, 22, 24, 26, 28, 30, and 32 MGOe.

When examining a table for magnets, there are letters placed after some grades, which represent a magnets ability to withstand demagnetization, temperature, and other forces that work against a magnet. Each magnet manufacturer has a different system for defining coercive force with the lettering system being the most widely used.

The identifiers for SmCo₅ and Sm₂Co₁₇ grades include three parts. Letter 1, which is a single or set of letters, indicates material type, which is followed by a number that is the (BH) max MGOe level value. The final letter, letter 2, is the Hci level or coercivity level. Sintered SmCo magnets are identified by letter 1 being XG or XGS with XG for SmCo5 and XGS for Sm₂Co₁₇. The letter 2 or Hci levels are identified by default, H, L, M, and LT. An example of a label for a Sm₂Co₁₇ magnet is XGS28H where XGS means sintered, and 28 is the magnets maximum MGOe level with H specifying the Hci or coercivity level.

| Samarium Cobalt Materials Chart for SmCo Sintered Magnets | |||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|

| Grades | Remanence | Coercivity | Max Energy | Max Working Temperature | |||||||

| Br | HcB | HcJ | (BH)max | TwMax | |||||||

| T | kGs | kA/m | k0e | kA/m | k0e | kJ/m³ | MG0e | °C | |||

| Sm₁Co₅ | Sm1Co5-20 | 0.89-0.93 | 8.9-9.3 | 684-732 | 8.6-9.2 | ≥1830 | ≥23 | 151-167 | 19-21 | ≤250 | |

| Sm1Co5-22 | 0.92-0.96 | 9.2-9.6 | 710-756 | 8.9-9.5 | ≥1830 | ≥23 | 159-175 | 22-24 | ≤250 | ||

| Sm1Co5-24 | 0.96-1.00 | 9.6-10.0 | 740-788 | 9.3-9.9 | ≥1830 | ≥23 | 175-191 | 22-24 | ≤250 | ||

| Sm₂Co₁₇ | Sm2Co17-30L | 1.08-1.10 | 10.8-11.0 | 541-796 | 6.8-10.0 | 636-955 | 12-Aug | 223-239 | 28-30 | ≤250 | |

| Sm2Co17-32L | 1.10-1.15 | 11.0-11.5 | 541-812 | 6.8-10.2 | 636-955 | 12-Aug | 231-255 | 29-32 | ≤250 | ||

| Sm2Co17-30M | 1.08-1.10 | 10.8-11.0 | 676-835 | 8.5-10.5 | 955-1433 | 18-Dec | 223-239 | 28-30 | ≤300 | ||

| Sm2Co17-32M | 1.10-1.15 | 11.0-11.5 | 676-852 | 8.5-10.7 | 955-1433 | 18-Dec | 231-255 | 29-32 | ≤300 | ||

| Sm2Co17-28 | 1.03-1.08 | 10.3-10.8 | 756-812 | 9.5-10.2 | ≥1433 | ≥18 | 207-223 | 26-28 | ≤300 | ||

| Sm2Co17-30 | 1.08-1.10 | 10.8-11.0 | 788-835 | 9.9-10.5 | ≥1433 | ≥18 | 223-239 | 28-30 | ≤300 | ||

| Sm2Co17-32 | 1.10-1.15 | 11.0-11.5 | 812-860 | 10.2-10.8 | ≥1433 | ≥18 | 231-255 | 29-32 | ≤300 | ||

| Sm2Co17-28H | 1.03-1.08 | 10.3-10.8 | 756-812 | 9.5-10.2 | ≥1990 | ≥25 | 207-223 | 26-28 | ≤350 | ||

| Sm2Co17-30H | 1.08-1.10 | 10.8-11.0 | 788-835 | 9.9-10.5 | ≥1990 | ≥25 | 223-239 | 28-30 | ≤350 | ||

| Sm2Co17-32H | 1.10-1.15 | 11.0-11.5 | 812-860 | 10.2-10.8 | ≥1990 | ≥25 | 231-255 | 29-32 | ≤350 | ||

A critical factor for all forms of magnets is their temperature rating, which is indicated by one or two letters. When letter or letters are placed after a grade, it is an indication that the magnet has the ability to fight against demagnetization. Since heat is a major factor and most common force that affects magnets, there are certain acceptable general rules to indicate temperature considerations. The letters used are M, H, SH, UH, EH, and TH with M meaning an operating temperature of 100°C (212°F) from which the temperatures progress to TH for 220°C (428°F).

The combination of samarium and cobalt provides SmCo magnets with natural resistance to corrosion, eliminating the need for protective coatings in most applications.

SmCo magnets perform better than neodymium magnets in high temperature environments, maintaining magnet strength at temperatures up to 350°C, while neodymium magnets lose strength and require coatings to prevent corrosion.

SmCo 1-5 magnets have a 1:5 samarium to cobalt ratio, operate up to 250°C, and have max energy products from 15 to 24 MGOe. SmCo 2-17 magnets have a 2:14–17 ratio, operate up to 350°C, and reach energy products of 21 to 32 MGOe.

China is the world leader in samarium mining and supply, making it a primary source for the samarium used in SmCo magnet manufacturing worldwide.

Isostatic pressing allows for uniform density and close tolerances in SmCo magnets, supporting precise complex shapes and stronger magnetic orientation, reducing the need for additional machining.

Letters such as M, H, SH, UH, EH, and TH in SmCo magnet grades show their temperature rating, progressing from 100°C (M) up to 220°C (TH) for higher heat resistance.

As with all forms of industrial magnets, samarium cobalt magnets are available in different forms. Each of the different shapes are designed for a specific application and purpose. The many shapes of SmCo magnets are common to all forms of magnets with differentiating factors being their strength and magnetic field.

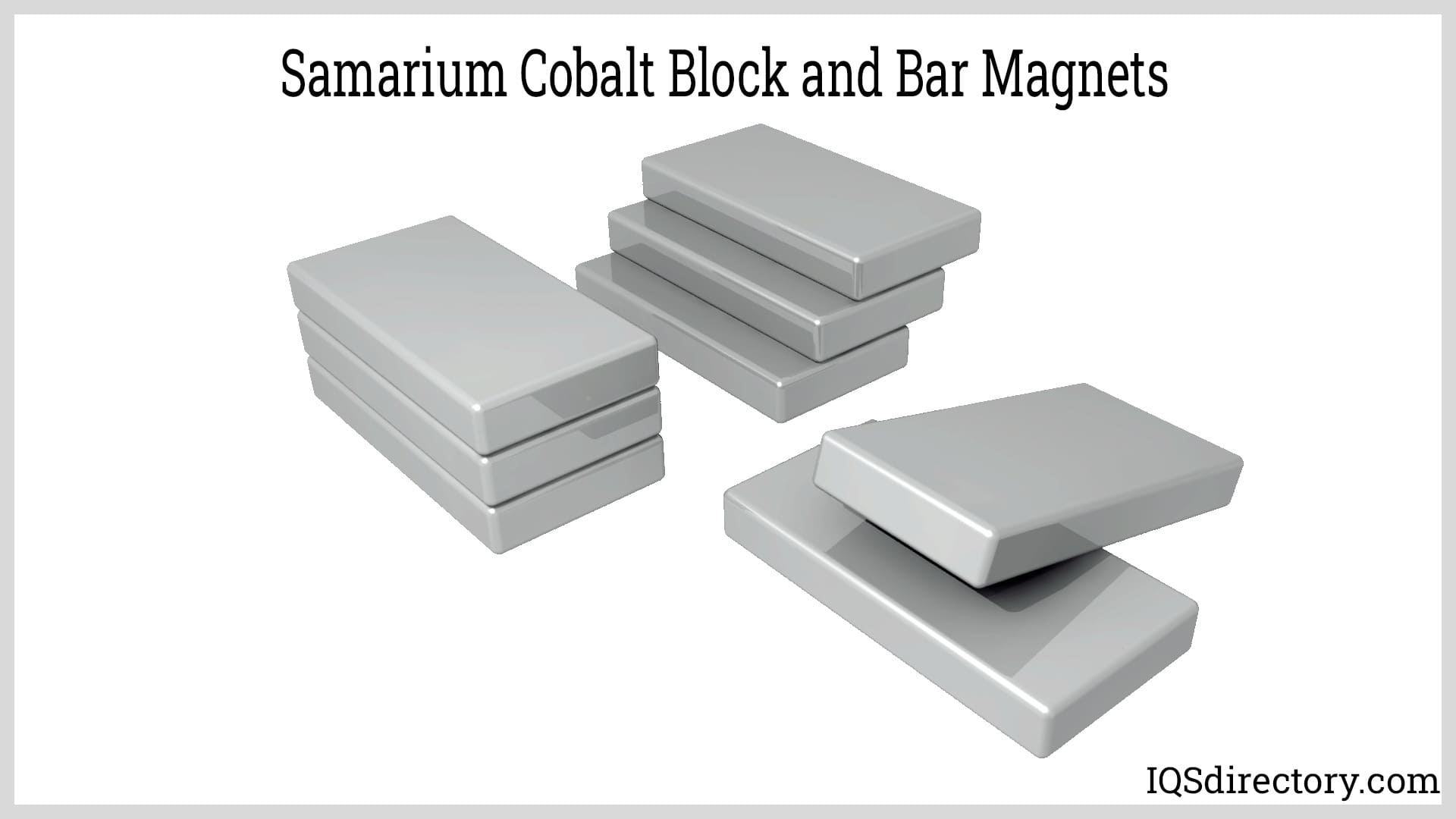

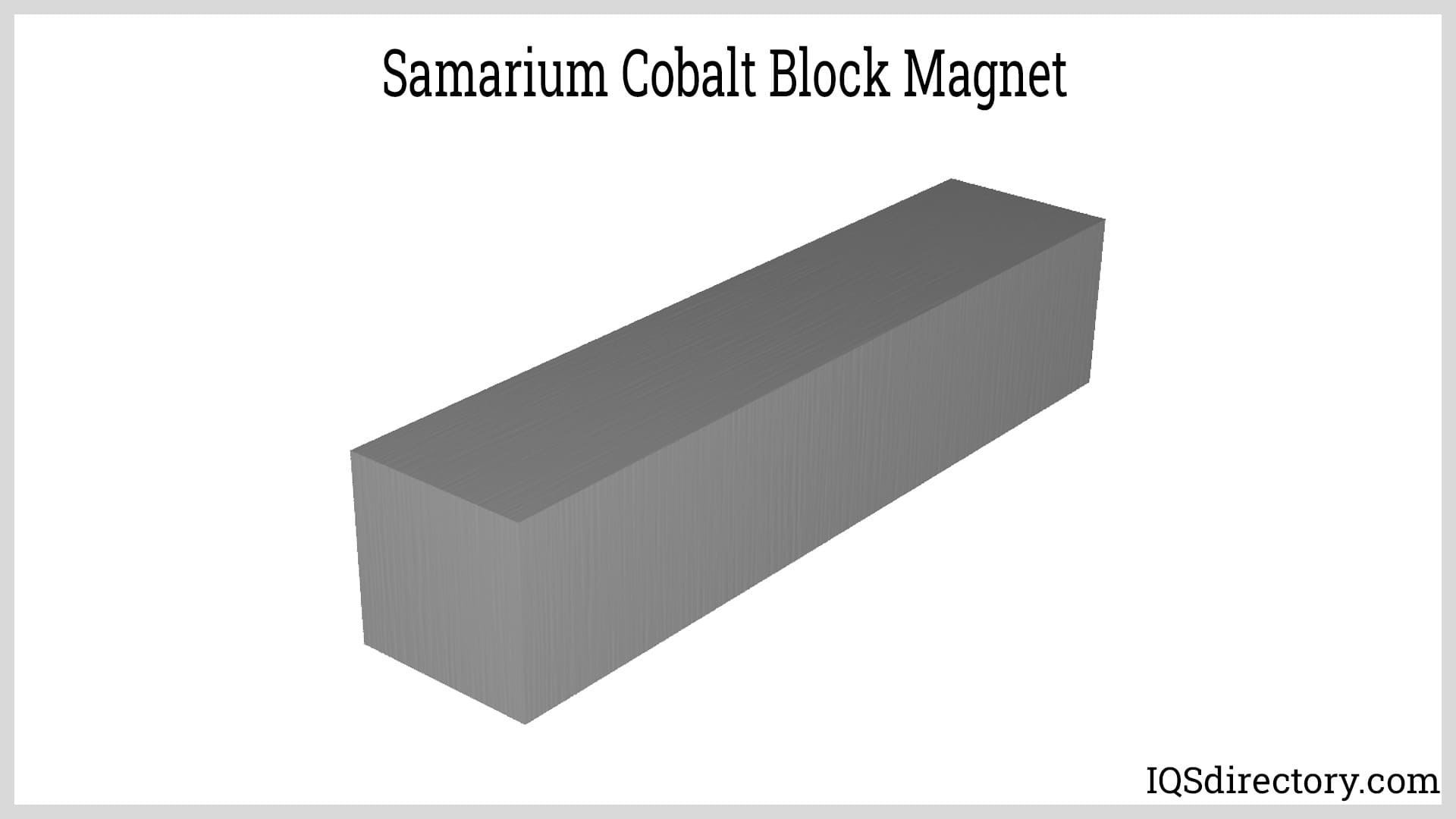

Block magnets are six sided magnets with straight sides that meet at a right angle. Each of the sides are parallel and give the appearance of a block of wood. The wide use of SmCo block magnets is due to their magnetic strength, temperature stability, high coercivity, and exceptional resistance to corrosion. SmCo block magnets are available in a wide assortment of sizes and grades, which can be tailored to meet the needs of a specific application.

SmCo block magnets are used where magnets have to endure high temperatures, such as critical sensors. In addition, they are utilized in speakers, reed switches, motors, rotors, wind turbines, AC/DC motors, drive motors, and servo motors.

Samarium cobalt disc magnets are flat, circular, coin shaped magnets that are available in varying diameters and thicknesses to meet the specific requirements of an application. The compactness of SmCo magnets makes them ideal for applications that require small magnets but able to endure high temperatures in corrosive environments. SmCo disc magnets are used for coreless motors, variable frequency air conditioners, dewaxing motors for the oil industry, sensors, computer disc drivers, and linear actuators. They are chosen for applications where low-carbon and energy savings are essential.

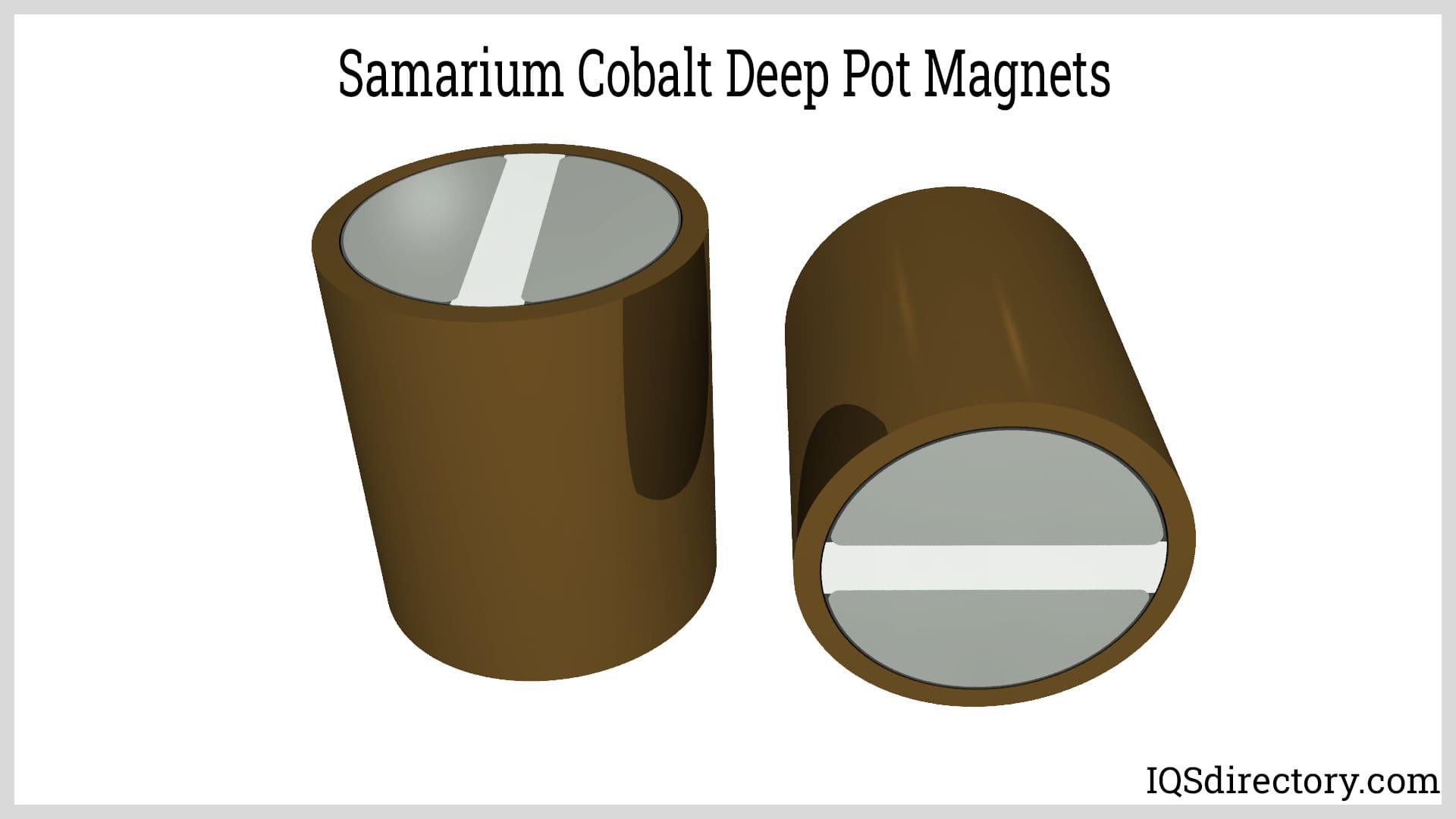

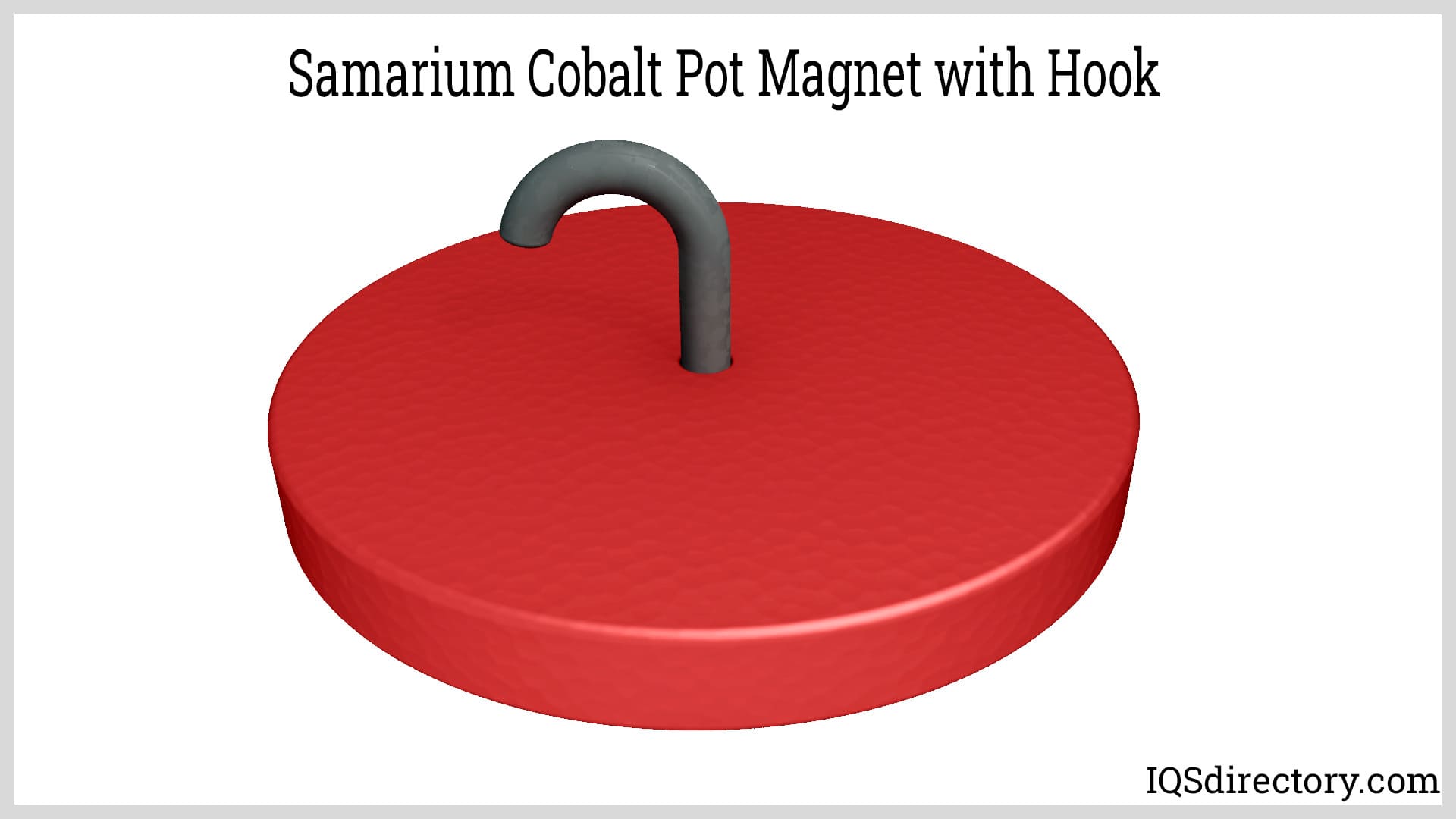

Samarium cobalt pot magnets have one exposed surface with a magnetic field that creates concentrated force. The magnet is contained within a housing or casing that is referred to as a shell or pot. The design of pot magnets enhances their magnetic force, a factor that radically influences their attracting power, while protecting the magnet from damage and outside forces.

SmCo pot magnets are widely valued due to their exceptional temperature and corrosion resistance. They are shipped with a keeper plate that protects the magnet during shipping or when they are handled. The ferromagnetic housing of SmCo pot magnets is available in different shapes and designs, which allows them to include threaded bars, tapped threaded holes, countersunk holes for screws, and blind ends for gluing into place. These aspects of SmCo pot magnets differentiates them from the configuration of traditional magnets.

Both compositions of SmCo magnets, SmCo₅ and Sm₂Co₁₇, are used in the manufacture of pot magnets, with Sm₂Co₁₇ having the highest energy product of MGOe 30. The design and strength of SmCo pot magnets has made them a highly valued magnet for industrial use.

Ring magnets are similar to SmCo disc magnets in that they are round circular magnets. What differentiates them from disc magnets is a hole in the center of the magnet. SmCo ring magnets come in a wide variety of sizes with differing outer diameters (ODs) and inner diameters (IDs), which makes the magnets very versatile and able to be used for a wide range of applications. A common use for ring SmCo ring magnets is in aerospace and medical devices. The fact that SmCo ring magnets do not require a coating is the reason they are chosen for applications in hostile environments.

Cylinder magnets are long, round, circular magnets where their length exceeds their diameter. Often referred to as rod magnets, SmCo cylinder magnets are recessed into drilled holes to provide a strong magnetic field in applications that have limited space. SmCo cylinder magnets have straight parallel sides with a circular or round cross section. Their dimensions are determined by their length or height and diameter, which is also used as a descriptor. The design of rod or cylinder SmCo magnets allows them to generate a strong magnetic field from the small surface of their pole area.

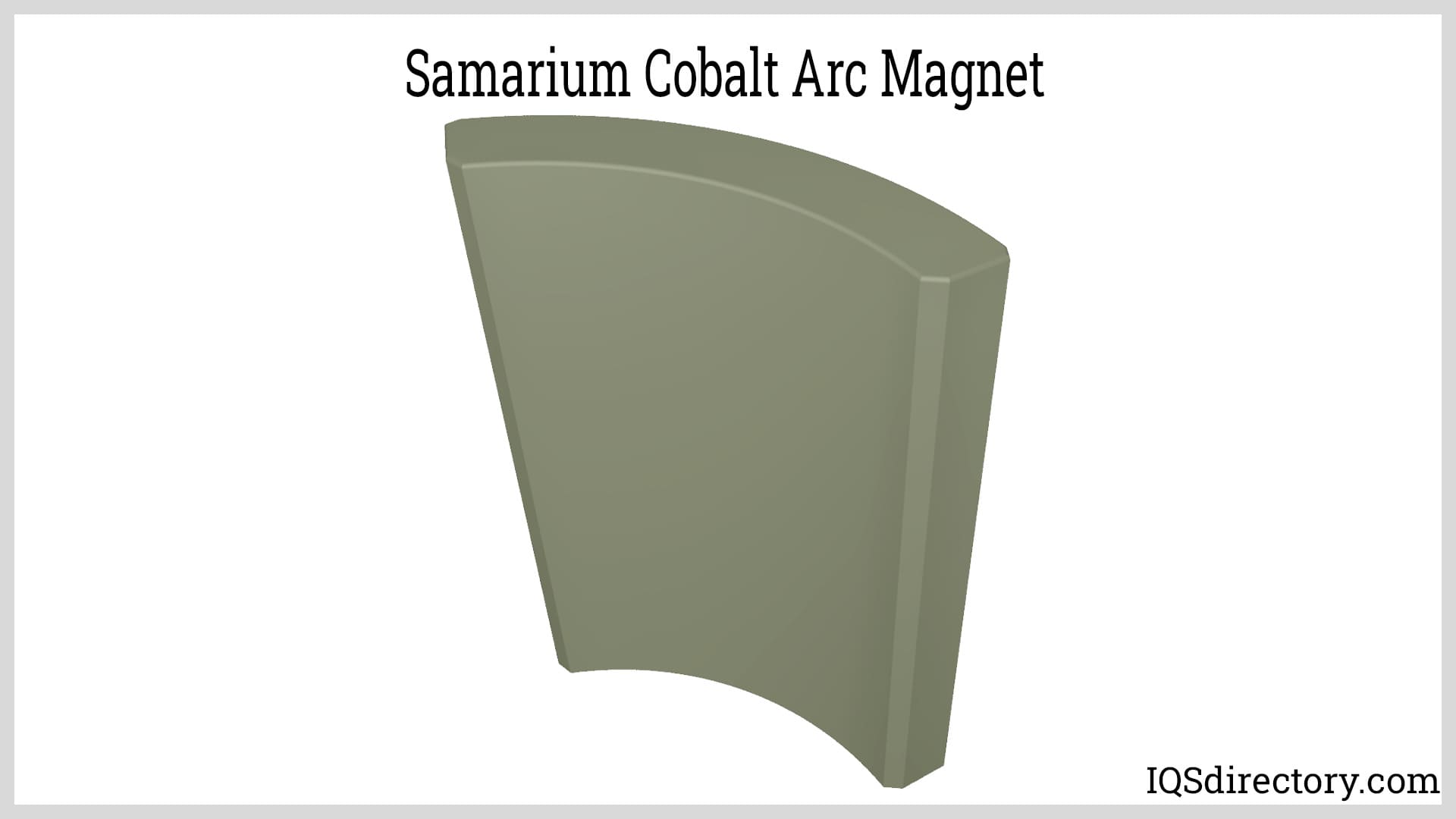

Samarium cobalt arc magnets are a special form of SmCo magnet that has a curved shape to be used in rotating machinery, like rotors and stators. They are produced in tile form segments in order to align with circular systems and provide focused magnetic force. Known as curved, tile and segment magnets, SmCo arc magnets are a crucial part of magnet motors, generators, and magnetic couplings.

As with all other uses for SmCo magnets, arc magnets are added to applications that endure high temperatures. They supply the type of reliable service required for an application to be successful. SmCo arc magnets are not as widely known as Neodymium arc magnets but have many of the same characteristics as NdFeb magnets. They have similar magnetization directions, machining processes, and geometries that boost equipment performance. Where SmCo arc magnets excel over NdFeb magnets is in hostile conditions with high temperatures and the potential of demagnetization.

Samarium Cobalt and Neodymium Iron Boron magnets are the most important industrial magnets. Although NdFeb magnets outperform SmCo magnets in many applications, there are characteristics of samarium cobalt magnets that make them superior to Neodymium magnets in certain circumstances.

The similarities between SmCo and NdFeb magnets include their strong magnetic fields with a very high BH Max and exceptional coercivity, resistance to demagnetization. Since their discovery, SmCo and NdFeb magnets have become an essential part of multiple industrial processes.

A large portion of SmCo magnets is composed of cobalt, about 65%, which is a major part of stainless steel. It makes SmCo magnets highly resistant to corrosion. In contrast, 65% of NdFeb magnets is the ferromagnetic metal iron, which has very limited resistance to corrosion. To improve NdFeb magnets resistance to corrosion, they have a small amount of cobalt added, about 1.5%. In addition, for further protection, they are electroplated or coated. The service life of a NdFeb magnet depends on the quality and effectiveness of its coating.

SmCo magnets are well known for being able to operate at extreme temperatures, far beyond those that NdFeb magnets can endure. SmCo magnets lose less field strength per degree of temperature increase than NdFeb magnets. This factor makes it easier for engineers to adjust temperature effects since the effects are so small. Temperature is one of the causes for magnets to demagnetize and is an area that SmCo magnets excel.

Of the two magnets, neodymium iron boron magnets are the strongest at room temperature up to 180°C (356°F). Their strength rapidly declines as the temperature rises. After NdFeb magnets reach their optimum performance temperature, SmCo magnets easily outperform them.

Coercivity, resistance to demagnetization, is high for both SmCo and NdFeb magnets compared to other forms of magnets. NdFeb’s vulnerability to high temperatures is the major factor in their use.

The applications for which neodymium iron boron magnets are used include motors, generators, and miniaturization. Other applications are:

Applications for which samarium cobalt magnets are used include ones with high temperatures and heavy loads. Other applications include:

Neodymium magnets are more affordable than samarium cobalt magnets due to the abundance of their elements. Neodymium, iron, and boron are readily available and inexpensive. Samarium and cobalt are scarce and more costly to acquire. In addition, the manufacturing methods used to produce SmCo magnets is highly technical, complex, and requires a great deal of energy.

The iron content of neodymium magnets makes them stronger and resistant to cracking and braking. Samarium cobalt magnets are brittle and crack or chip easily if handled incorrectly.

A ceramic magnet, also known as a ferrite magnet, is a permanent magnet made by combining iron oxide and strontium carbonate. They are a man made magnet produced by heating the two elements to...

Flexible magnets are composite materials with magnetic components arranged in an elastomer matrix. They are made from a combination of rubber polymer resin and ferrite powder by forming it through...

Magnets are materials that exert a noticeable force on other materials without physically contacting them. This force is called a magnetic force. The magnetic force can either attract or repel. Most known materials...

A Neodymium (Nd-Fe-B) magnet is a common rare earth magnet composed of neodymium (Nd), iron (Fe), boron (B), and transition metals. They have superior performance in applications because of their strong...

ermanent magnets are materials that generate a magnet field based on the internal structure of the material that forms them. With most materials, magnet fields point in random directions that cancel out the fields. The electrons of such materials spin…

Power supplies are electrical circuits and devices that are designed to convert mains power or electricity from any electric source to specific values of voltage and current for the target device...

An AC power supply is a type of power supply used to supply alternating current (AC) power to a load. The power input may be in an AC or DC form. The power supplied from wall outlets (mains supply) and...

A bowl feeder is a mechanism for supplying small parts and components to a production line or for sorting bulk items for rapid use. A self contained bowl feeder system has a bowl that sets on a spring loaded base that moves vertically...

A DC DC power supply (also known as DC DC Converter) is a kind of DC power supply that uses DC voltage as input instead of AC/DC power supplies that rely on AC mains supply voltage as an input...

A DC power supply is a type of power supply that gives direct current (DC) voltage to power a device. Because DC power supply is commonly used on an engineer‘s or technician‘s bench for a ton of power tests...

Electric transformers are static electrical machines that transform electric power from one circuit to the other without changing the frequency. An electrical transformer can increase or decrease the voltage with...

An electromagnetic interference or EMI Filter is an electrical device or circuit that filters specific unwanted frequencies in power lines or offending frequencies that are detrimental to a system. They receive AC or main power...

By definition a power supply is a device that is designed to supply electric power to an electrical load. An electrical load refers to an electrical device that uses up electric power. Such a device can be anything from...

An isolation transformer, just like typical transformers, is a non-moving device that transmits electrical energy from one circuit to another without requiring any physical contact. It works on the idea of magnetic...

Power transformers are electrical instruments used in transmitting electrical power from one circuit to another without changing the frequency. They operate by the principle of electromagnetic induction. They are used in transmitting electrical power between...

A programmable power supply is a method for controlling output voltage using an analog or digitally controlled signal using a keypad or rotary switch from the front panel of the power supply...

An electrical transformer is a passive machine that transfers electrical energy from one circuit to another using a magnetic flux to induce an electromotive force. Transformers are used to increase (step-up) or decrease (step-down) voltages without changing the frequency of the electric current...

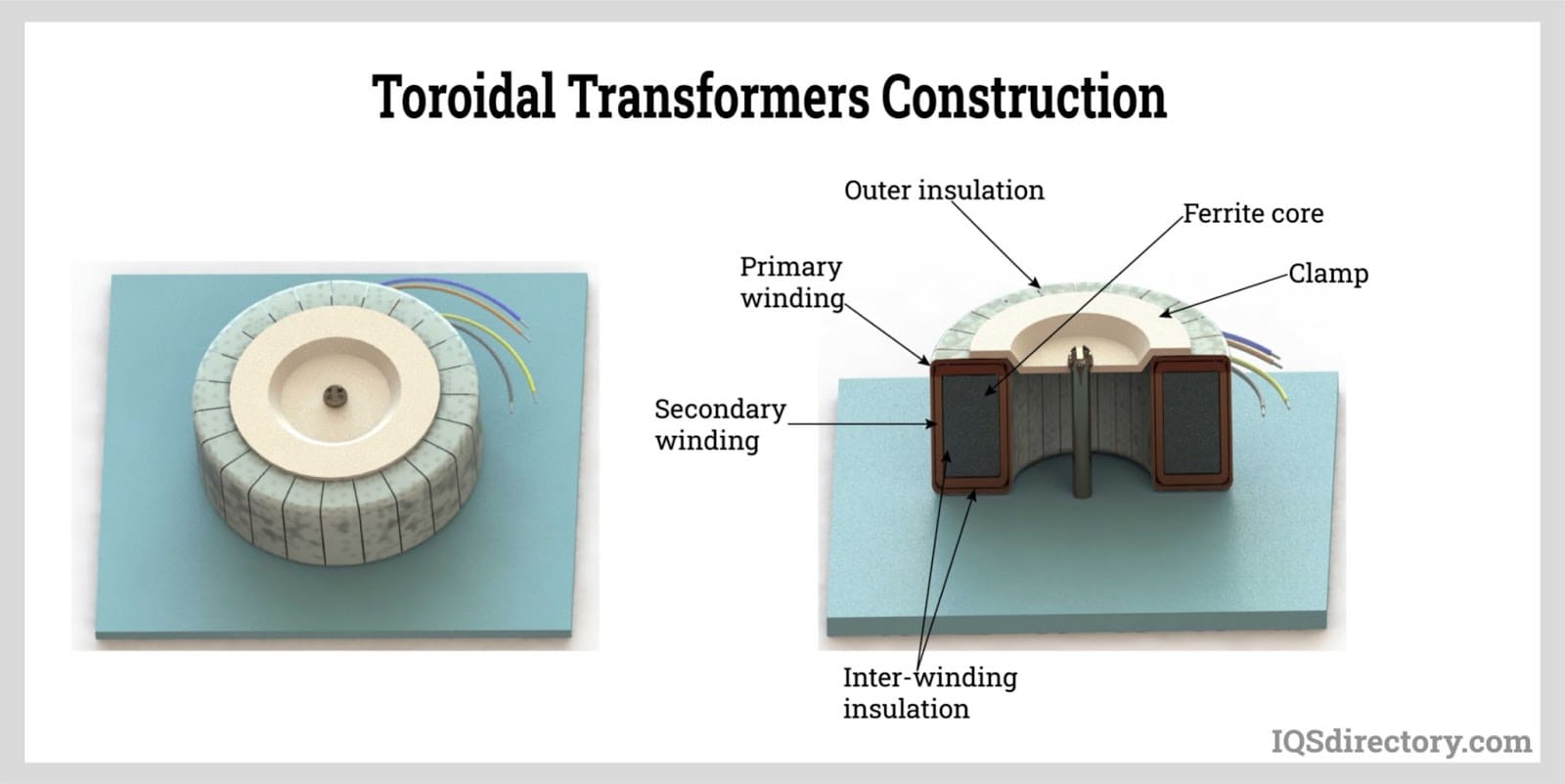

A toroidal transformer is a type of electrical transformer constructed with a torus or donut-shaped core. Its primary and secondary windings are wound across the entire surface of the torus core separated by an insulating material...

Vibratory conveyors are material-handling equipment used to transport fine to coarse-grained bulk materials. These vibratory conveyors are strong conveying equipment utilized for bulk commodities with fine to coarse graininess...

Vibratory feeders are short conveyors used to transport bulk materials utilizing a controlled vibratory force system and gravity. The vibrations impart a combination of horizontal and vertical acceleration through tossing, hopping, or sliding-type of action to the materials being handled...

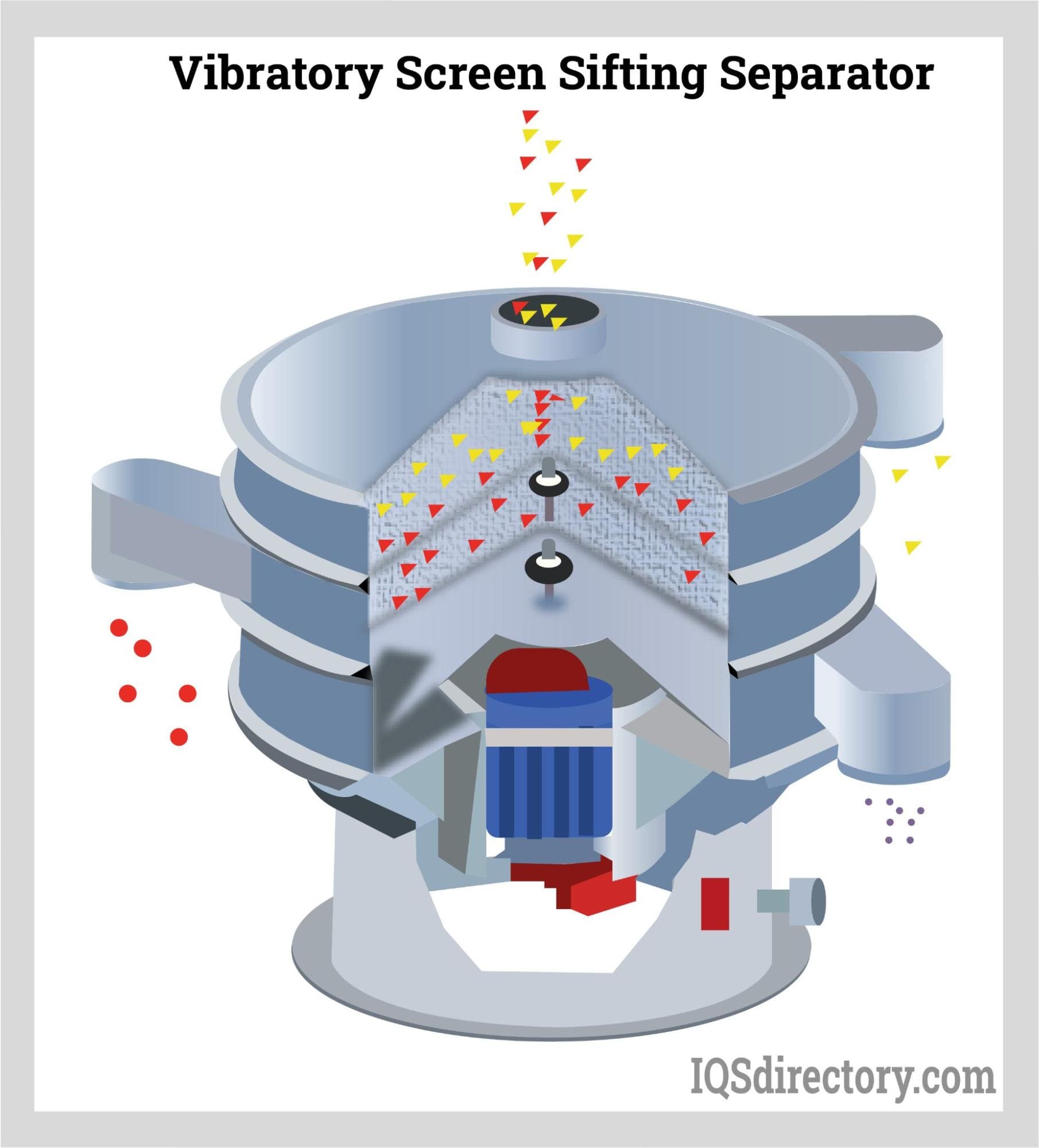

A vibratory screening is a process that separates bulk solid materials from solids and slurries using inertial vibration that causes various sizes of particles to pass through openings in a screen or...

Electronically operated equipment depends on power transformers to convert electrical currents into voltage. Current transformers store and transport energy through power lines and grids...