Automation Systems

Industry runs on machines, equipment, and motors that have been developed to produce products and services. Many varieties of manufacturing machinery are available to perform functions from cleaning and finishing to shaping and forming. Each type and design are essential to the success of an operation, as well as providing a valuable service.

There is a long list of the types of machines that help and assist producers to provide products and ensure quality. To understand manufacturing machinery, it is important to explore all types, from the most common ones that perform specialized services to those that are complex and important to manufacturing production. Included in this group are centrifuges, car wash equipment, rebuilders, paint finishing, and tube forming, to name a few.

The cleaning of a car has become an important part of preserving an investment as well as removing road debris and chemicals. Many manufacturers recommend that a car should be cleaned once a week to keep it in top operating condition. Car wash equipment manufacturers provide the tools and equipment for commercial and industrial car cleaning.

There are several forms of car wash equipment. In some cases, manual pre scrubbing is necessary prior to putting a car through the cleaning equipment. On the other hand, there are fully automated systems that do not require any preparatory cleaning. Regardless of the equipment, car wash equipment manufacturers are capable of producing equipment to specifically meet the demands and requirements of their customers. From the smallest operation designed for commercial use to large operations for the cleaning of semi-trucks, car wash designers are able to produce individualized and unique systems.

One of the necessities of production operations is the ability to separate combined substances and isolate them. This process can be accomplished by a centrifuge that rapidly spins causing heavier particles to be trapped against the side of the spinning container. The types of materials that can be processed include granules, liquids, solids, or a combination of each type.

There are several types of materials that can be used to manufacture a centrifuge with plastic, metal alloys, and other metals being the most common. Centrifuges are powered by a motor that uses a rotor to rapidly turn the centrifuge container. As the container turns, it creates a gravitational well that separates substances. There are several uses for a centrifuge, which include the refining of ingredients for cooking.

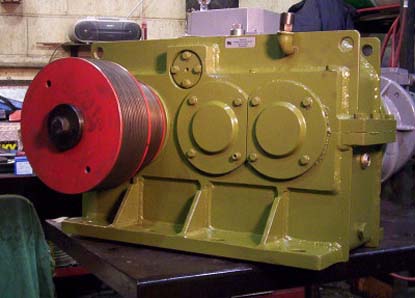

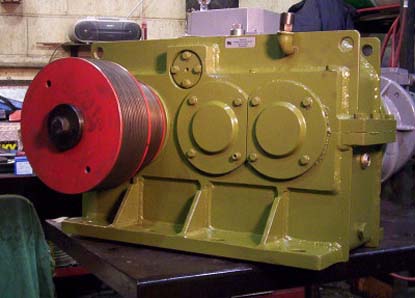

A necessary part of equipment maintenance and sustainability is the use of machinery rebuilders that revitalize and repurpose supposedly used and worn equipment. Investment in equipment and machinery is a major part of a company‘s cost. To control that cost, many producers use machinery rebuilders to preserve and sustain their equipment. The process of rebuilding includes identifying and replacing worn parts, disassembling, cleaning, and repairing. The cost of the process is far less than replacing equipment and helps add to the life span of vital machinery.

Several industries depend on painting and finishing equipment as a step in the manufacturing process. The types of machines that perform this important function vary from ones that are small and designed to process small parts, to ones that are large enough for a car or truck.

The purpose of the finishing and painting operation is to add a protective coating to the surface of a complete assembly or part. Each form of finishing machinery is configured to meet the needs of the part and its design. For intricate designs, the finishing equipment may be equipped with several forms of applicators to ensure a smooth and uniform application.

One of the more complex types of manufacturing machinery is a tube forming machine, which takes tubing and configures, forms, stresses, and fabricates it into complex shapes. There are very few limits to the types of tubing a tube forming machine can produce.

The purpose of tubing goes beyond being a means of transport. It can also be used as a decoration, safety protection, and railings. To achieve each of the different functions, a tube forming machine is required. In today‘s modern production methods, tube forming machines have become an invaluable method for producing tubing designs rapidly and efficiently.

The machines described above are a few of the many types of manufacturing machinery that assist in producing new products and performing valuable services.

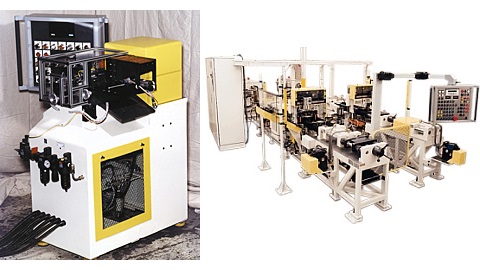

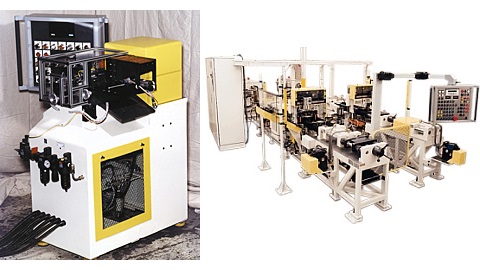

Many manufacturing functions such as material handling, product forming, welding, milling, grinding, cleaning, assembly, and packaging are accomplished through the use of computer controlled, automated, and robotic machinery.

Automated systems sort mail, packaged goods, and food products.

Many manufacturing functions such as material handling, product forming, welding, milling, grinding, cleaning, assembly, and packaging are accomplished through the use of computer controlled, automated, and robotic machinery.

Automated systems sort mail, packaged goods, and food products.

These systems may be partially manned, supervised by a production manager, or totally automated, operating without any human guidance or intervention beyond the initial programming and necessary maintenance. Learn more about automation equipments.

Car washing is the manufacturer-recommended process of cleaning a vehicle.

It can be performed manually, with equipment as simple as a bucket and a rag, although there are many products on the market to facilitate hand washing, spraying, scrubbing, waxing, and drying. These include pressure washers, natural or chemical cleaners and waxes, sponges, brushes, nozzles, and natural or synthetic cloths.

Car washing is the manufacturer-recommended process of cleaning a vehicle.

It can be performed manually, with equipment as simple as a bucket and a rag, although there are many products on the market to facilitate hand washing, spraying, scrubbing, waxing, and drying. These include pressure washers, natural or chemical cleaners and waxes, sponges, brushes, nozzles, and natural or synthetic cloths.

Hand washing of cars is still done commercially, but automated car washing technology has made the manual process, or at least most of the steps involved, all but obsolete, except for the die-hard hand washing fan.

Automated car washes may be completely automatic or may have attendants who perform certain steps in the process. They may be coin or credit card operated, manned by an attendant who monitors the machinery and equipment, or manned by multiple attendants who perform such steps as interior detailing and drying.

A car wash equipment manufacturer is a company that provides the equipment and material necessary for various kinds of commercial and sometimes industrial car washes. When starting a car wash business, many businesses purchase used car wash equipment. There are many different kinds of car wash systems; some work without employees and some operate with many. Automated car washes have gained significant popularity in recent years. They are very common and come in two different varieties: touchless and cloth friction. Touchless car washes use high-powered water pressure sprayers to clean cars, which either move around the parked car or are stationary through which the car passes. Only the water and cleaning agent come in contact with the car, which prevents scratching and marking the car's finish. The alternative, cloth friction, uses soft yet powerful cloth to clean the car, which are large, rotating brushes that use soap to scrub the car exterior clean. Both forms of auto car washes use sensors called eyes that trigger a digital control system to enable the washing sequence and adjust to the car's size. Near the end of auto car washes is usually a drying station, where high-pressure compressors blow air over the surface of the vehicle, drying it before exiting the car wash. Learn more about car wash equipments.

A centrifuge system is designed to separate different elements within a particular substance by way of a high speed rotation known as centrifugal force.

The simplest and perhaps crudest demonstration of centrifugal force can be witnessed in a laundry washer or dryer that is typically found in a residential home. As the washer spins, dirt is separated from the clothing.

A centrifuge system is designed to separate different elements within a particular substance by way of a high speed rotation known as centrifugal force.

The simplest and perhaps crudest demonstration of centrifugal force can be witnessed in a laundry washer or dryer that is typically found in a residential home. As the washer spins, dirt is separated from the clothing.

Centrifuges traditionally are made out of plastic, metal alloy, and metal, and are powered by an electric motor that uses a rotor. The substances placed within a centrifuge can be either liquid or solid, and include those found in the medical field, such as blood, as well as industrial solutions, products, and fuels. In some cases, centrifuges are also used to create or refine certain food products. In general, centrifuges work by creating a temporary but very strong gravitational well that separates elements based on their density. In most cases, the process must be a continual one that is synced to a particular cycle of varying speeds; if the cycle is interrupted, the separation will not be complete, and may damage the equipment. There are numerous types of centrifuges designed for specific environments, including laboratory centrifuges, industrial centrifuges, and decanter centrifuges. However, the two principal types of centrifuges are referred to as preparative and analytical. An analytical centrifuge is traditionally used for research applications where the components of a particular substance are being identified, while a preparative centrifuge is used to separate particles from a given slurry or liquid. Learn more about centrifuges.

Lasers produce beams of monochromatic, coherent radiation (light) and are designed to concentrate high amounts of energy over a defined point.

The term laser is an acronym for Light Amplification by Stimulated Emission of Radiation. This helps us understand that, through stimulated emission, lasers release a beam of electromagnetic radiation (beam of light).

Learn more about lasers.

Lasers produce beams of monochromatic, coherent radiation (light) and are designed to concentrate high amounts of energy over a defined point.

The term laser is an acronym for Light Amplification by Stimulated Emission of Radiation. This helps us understand that, through stimulated emission, lasers release a beam of electromagnetic radiation (beam of light).

Learn more about lasers.

Machinery rebuilders are service companies that disassemble, clean, repair and/or replace machine components in order to increase their service life.

While rebuilding is considered to be an old-fashioned term in some industries, having been replaced in common use by the term "remanufacturing," other industries such as the railroad industry have maintained the term in common usage.

Learn more about machinery rebuilders.

Machinery rebuilders are service companies that disassemble, clean, repair and/or replace machine components in order to increase their service life.

While rebuilding is considered to be an old-fashioned term in some industries, having been replaced in common use by the term "remanufacturing," other industries such as the railroad industry have maintained the term in common usage.

Learn more about machinery rebuilders.

Paint finishing equipment is the broad category of tools and machines that includes all devices used in the paint finishing process.

By definition, the paint finishing process is the application of coats of paint or a finish to a surface. There are many different types of paints and finishes that vary in characteristics such as color, hardness, durability, sheen and other attributes. Finishes can be applied both for visual appeal and function and the methods used to apply them differ greatly as well.

Learn more about paint finishing equipments.

Paint finishing equipment is the broad category of tools and machines that includes all devices used in the paint finishing process.

By definition, the paint finishing process is the application of coats of paint or a finish to a surface. There are many different types of paints and finishes that vary in characteristics such as color, hardness, durability, sheen and other attributes. Finishes can be applied both for visual appeal and function and the methods used to apply them differ greatly as well.

Learn more about paint finishing equipments.

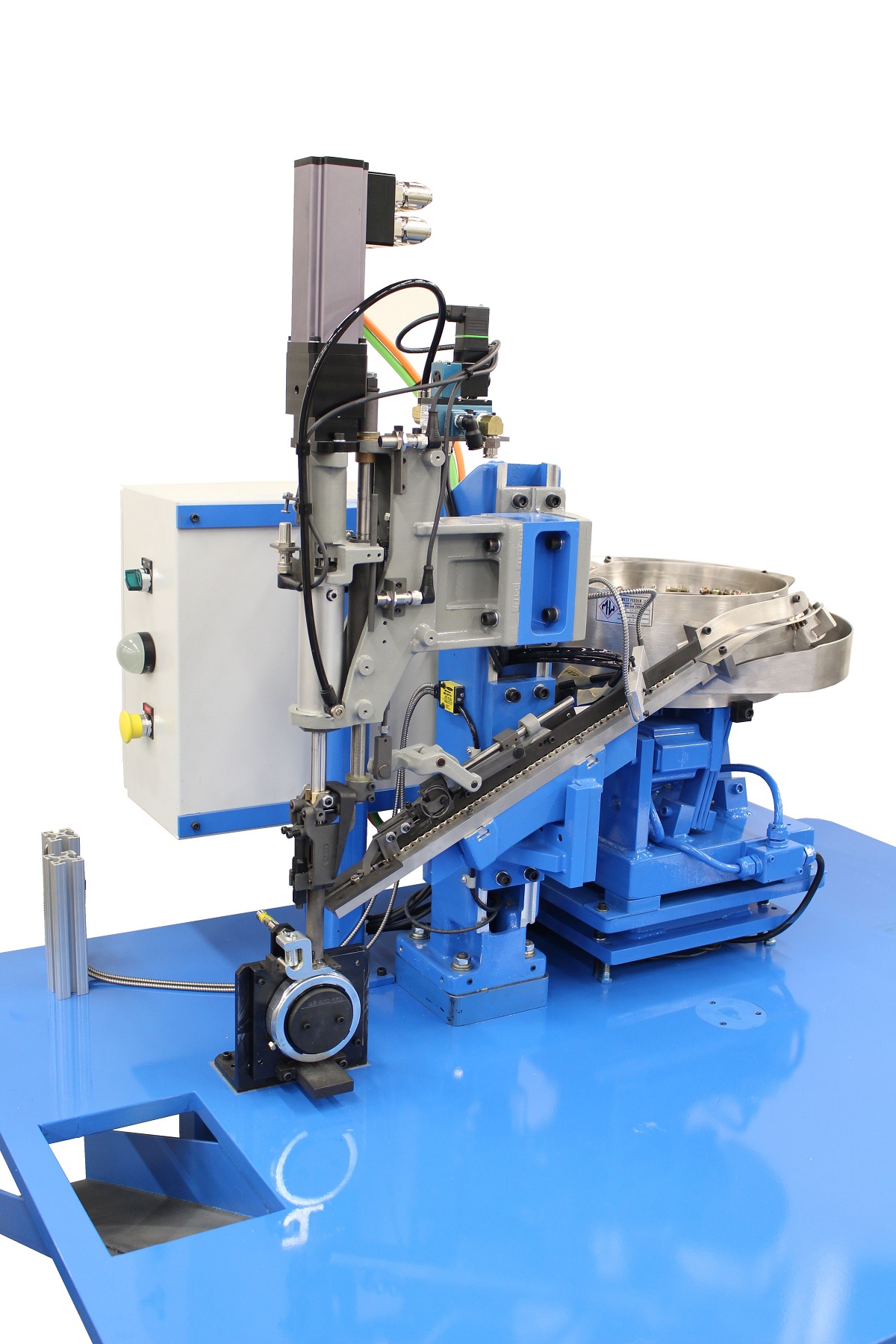

Tube forming machines refer to various types of equipment that are used in order to form tubing, which is the process of altering tubing into complex shapes.

A tube is defined as a long and thin hollow cylinder that is most commonly used to either convey a fluid or gas, or to function as a passage. Typically cylindrical, tubes can also be formed into square or rectangular shapes as well.

Tube forming machines refer to various types of equipment that are used in order to form tubing, which is the process of altering tubing into complex shapes.

A tube is defined as a long and thin hollow cylinder that is most commonly used to either convey a fluid or gas, or to function as a passage. Typically cylindrical, tubes can also be formed into square or rectangular shapes as well.

Tube forming differs from tube fabrication, which is the manufacturing of tubing, and is considered to be a secondary process to tube fabrication. The machines that perform tube forming processes must be able to maintain a high level of accuracy due to the complexity of the various shapes required. As a result, tube forming machines are generally either dedicated machines or automated manufacturing cells. While dedicated machines are built for a specific job and thus, cannot accommodate any design changes, automated manufacturing cells are able to provide high production rates as well as the ability to be versatile in design. Some examples of applications and industries that utilize tube forming machinery include: marine, for use in exhaust products, heat exchangers, piping systems and more; automotive, to be used for structural components, coolant systems, exhaust manifolds and more; industrial manufacturing, for applications such as various automation equipment and tubing assemblies; and medical, for use in complex components such as glass capillary tubes, epidural needles and arthroscopic drivers. Learn more about tube forming machines.