In the intricate web of industrial operations, facility management emerges as the linchpin of success, orchestrating the seamless support and maintenance crucial to complex manufacturing processes. Behind every industry's curtain lies a myriad of processes and applications, silently ensuring each production step glides with precision and efficiency.

At the heart of industrial efficiency lies inventory control, commencing with the meticulous storage and management of diverse components—from boxed goods to bulk powders and granular materials. Central to this process are advanced conveyor systems, ingeniously crafted to effortlessly transport materials, alleviating workers from the burden of handling cumbersome loads manually.

Shelving is a prominent storage method, ranging from towering racks that reach the ceiling to compact units nestled in parts rooms. This category extends to encompass drums, plastic pallets, and both small and large storage tanks, each tailored to house raw materials, parts, assemblies, and equipment efficiently.

These storage methods are significant because they maintain organization and facilitate seamless access. By systematically arranging materials, these methods not only ensure convenience but also streamline the retrieval of essential items when needed.

Numerous factors impact manufacturing processes, significantly influencing both environmental health and working conditions. A critical issue involves maintaining air quality within production facilities and regulating emissions. Every industrial operation prioritizes reducing its environmental impact. Consequently, companies have implemented advanced air filtration systems to mitigate air pollution and prevent environmental contamination by removing hazardous particulates generated during manufacturing processes.

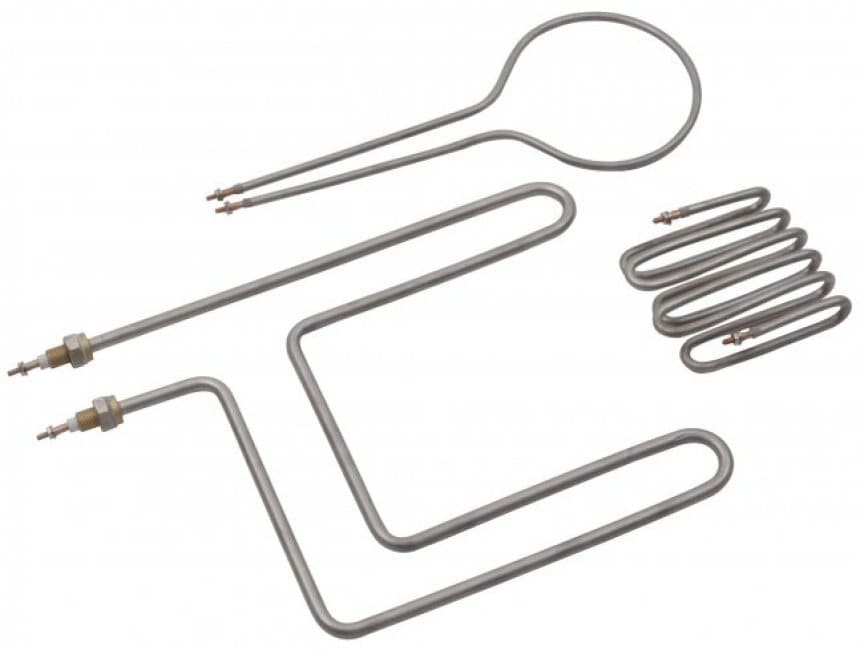

Diverse manufacturing processes rely on electric heaters to precisely regulate fluid temperatures. Unlike conventional residential units, industrial electric heaters span a broad spectrum of sizes and types, ranging from those submerged in vats of liquid to models designed to heat raw material drums. Choosing the right heater for each application is crucial to maintaining material temperature integrity and ensuring employee safety.

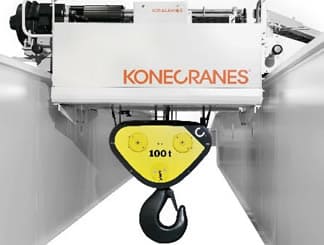

In the realm of manufacturing, the seamless flow of raw materials is pivotal to operational success. This crucial function is overseen by the supply chain manager, tasked with the meticulous management and accessibility of raw materials essential for various processes and assemblies. The logistics encompass a diverse range of methods, from forklifts and AGVs to cranes and hydraulic lifts, ensuring efficient transportation to and from production lines. Smooth integration of materials, from receipt to assembly, is indispensable for optimizing manufacturing output and product delivery.

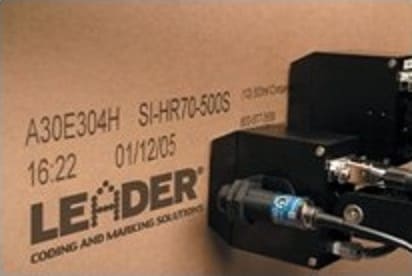

Within the realm of manufacturing, a diverse array of equipment and applications harmoniously supports operations. At the forefront, manufacturing equipment stands as a cornerstone, meticulously maintained to sustain uninterrupted production flow. Effective labeling and identification methods are imperative to guarantee precise material utilization throughout processes. Upon completion, meticulous packaging and preparation methodologies ensure products are primed for seamless shipment and delivery.

In the intricate dance of product manufacturing, every element plays a vital role, from the janitorial team to the skilled operators of technical equipment driving production forward. Each facet and component harmonizes to uphold the company's commitment to timely delivery, ensuring cohesive coordination across operations, applications, and methodologies.