Agitators

Agitators are equipment used in homogenizing media inside a tank. It works by rotating the impeller at its immersed end at a controlled speed or revolutions per minute (rpm). The work exerted by…

Please fill out the following form to submit a Request for Quote to any of the following companies listed on

An explanation of rotor stator technology with descriptions of its effects on products, mixtures, and materials

You will learn:

Rotor stator technology refers to high shear mixing involving emulsification, homogenization, blending, and dispersal of ingredients and matter. The central aspect of rotor stator technology is its reliance on high shearing forces that are used to achieve rapid, effective particle size reduction. As the rotor spins, particles are reduced and are forced through narrow gaps in the stator. The result of the shearing forces is particulate matter of submicron size. Particles are broken down such that they can be evenly distributed throughout a mixture to form a homogeneous and uniform blend.

The technology of rotor stator mixers provides ultra-high shearing for a wide range of industries. It has the ability to offer stable emulsions, ultra-fine dispersions, accelerated reactions, and eliminates fish eyes or lumps, hydrate polymers, and gums. It is an essential and necessary technology used by the mixing industry. The post mount version of rotor stator technology is available in different shapes and sizes for use in mixing containers with air or electric lift systems for easy maneuvering.

Rotor stator technology involves the use of a rapidly rotating rotor that is placed inside a stationary stator. The basic principle of the design is in regard to the rapid turning of the rotor as it relates to the stationary stator. As the tip speed of the rotor turns at 3000 up to 4000 feet per minute (fpm), it creates a vortex such that the product is forced through the gap between the rotor and stator. The process mechanically shears the product at high speeds creating a homogenous blend. The ability to vary the speed of the rotation of the rotor makes it possible to customize the amount of shearing force used for a mixing application.

Industrial mixing is an intriguing and fascinating aspect of modern America. It would seem on the surface that industrial mixing is as simple as placing two or more materials in a mixer and letting the process blend and homogenize them. In actuality, the process of mixing is far more complex and intricate than most people understand. The heart of the process is effectiveness, efficiency, and quality, with a great deal of emphasis on quality.

At the center of industrial mixing is rotor stator mixers, which are known for their precision, adaptability, and versatility. Emulsifying, homogenizing, blending, dispersing, and mixing are a few of the functions that a rotor stator mixer performs. The obvious main parts of a rotor stator mixer are the rotor and stator that work together to produce homogeneous fine mixes that have a smooth consistent texture.

A critical aspect of rotor stator mixers is the stator that comes in unique forms to meet the requirements of a variety of mixing challenges. As experts in industrial mixing know, the selection of the proper stator ensures optimum quality mixing that matches the specifications of an application. The determining factor in regard to the type of stator is the type of material to be handled. Stators are designed to enhance the mixing process and efficiently blend materials to the appropriate size.

Angle slot stators have vertical slots through which the rotor forces the mixture. The angle designed provides exceptional shearing action for shredding solids and powders. Angle slot stators are commonly used with post mount and batch rotor stators. They are rated for 10,000 centipoise (cPs) viscosity materials. The main benefit of the angled slots is to create suspensions and superior homogenization.

Emulser stators have small holes that are similar to a sieve or strainer. The fine mesh of an emulser provides ultra-high shearing. The design of emulser stators is for fine emulsions or suspensions that have low viscosity. They can be used with post mount or batch stator mixers. Emulser stators are known for breaking down ingredients into consistent fine textures, which makes them effective in food and cosmetic emulsions where precision droplet size is essential.

The holes in a general purpose stator can be round or square. They provide even high flow and efficient mixing. The openings on a general-purpose stator are larger than are found in slotted stators or emulser stators. General purpose stators are commonly used for soft solids where an even high flow is necessary. The product to be mixed is drawn from below the rotor stator before being forced through the square or round holes.

Round hole and large square hole general purpose stators have a high turnover rate and are used for disintegrating large solid pieces.

A slotted stator is similar to an angled slotted stator with the difference being the slots on the stator are not placed at an angle. It is the most popular design for high-speed shearing and exceptionally efficient flow rates. Slotted stators are used for medium viscosity mixing for materials with a viscosity of 10,000 cPs. They are used for breaking down fibrous materials, resistant agglomerates, and the preparation and smoothing of slurries. The radial velocity of the rotor creates impact force that breaks down the particles as they are driven through the slots of the stator. Unlike the high shear blades of a mixer, the slotted design provides faster dispersion, which removes the need for further processing and reduces production time.

The rotor is the component of rotor stator technology that provides high shear mixing due to the speed of its rotation. It is the element that supplies the rotational force that rapidly moves materials through the stator. The combination of the fast moving rotor and the openings in the stator create the fine particles for the mixing process. The different forms of rotors are designed in accordance with the materials to be mixed and the type of stator.

As may be assumed, the nature of the work of the rotor requires exceptional durability and longevity. It is for this reason that rotors are made of stainless steel, normally grades 304 and 316. A very common type of rotor is the four blade version that has four blades or teeth projecting from a rod that is powered by the mixers motor. Four blade rotors are similar to typical mixing impellers with the differences being the size of the rotor and its placement in the stator.

Rotors come in a variety of shapes including two blade or two wing, four wing A, and four wing B. The function of all of the rotors is the same but in different configurations. The essential aspect is a set of blades, wings, or teeth that rotate at high speed to force materials through the openings in the stator.

Double and quad rotors are placed with matching stators. They can have two or four rows of blades in the rotor placed inside the stator. As with all forms of rotors, the acceleration of the teeth of the rotor forces the materials to be mixed out through the multiple teeth stator. The multiple teeth of the rotor and stator forces materials to endure multiple and increasing shearing forces before the material exits the rotor stator mechanism. The outcome of the process is droplets the size of one micron (µ) or less.

There are an endless number of rotors that apply rotational force to mixture ingredients. The types and designs are customized to meet the specific needs of a mixing function. The aspect of rotor stator technology that has to be considered is the interplay between the rotor and stator. In many cases, rotors are described in regard to their relationship with a stator. Rotor stator manufacturers supply data regarding the type and design of rotor stator technology that matches a particular process.

Electrical motors are the primary source of power for driving the rotor in a rotor stator mixer. The size of the motor varies in accordance with the requirements of an application. Electromagnetic induction motors are commonly used. The motor drives the shaft that rotates the rotor in the stator. Induction motors are commonly used due to their reliability and their ability to deliver constant torque, a necessity for industrial mixer applications.

For some applications, inverter drive motors are used that work with variable frequency drives (VFD), which allows the control of speed, torque, and energy use. The inverter controls input frequencies and voltage, make it possible to adjust motor speed. The design makes it possible to adjust the speed of the rotor to match the types of materials being mixed.

The components described above are the basic features of rotor stator technology. They are a general overview of rotor stator technology and provide an introduction to the features of this form of industrial mixer. The designs, configurations, types, and other aspects of rotor stator technology vary between manufacturers and processes. This general knowledge provides talking points for examining ways to implement the use of rotor stator technology in an industrial mixing operation.

The force and capabilities of rotor stator technology have enhanced the capabilities of industrial mixing. Rotor stator technology has radically improved the quality of the mixing process and opened the use of the technology to a wide range of processes and applications. Emulsification, homogenization, and other mixing applications require precision control and exceptional efficiency, which are the main reasons for the popularity of rotor stator technology.

As with all forms of mixing, rotor stator technology is used in the two basic forms of mixing, which are batch mixing and inline mixing. The two processes vary in how mixed materials are handled and the time involved in the process. Batch mixing is similar to traditional mixing in that ingredients are placed in a container to be combined. Once the desired level of homogenization has been reached, the mixture is poured from the container. Inline mixing is continuous and involves a flow of ingredients.

With batch mixing, set quantities are processed. The mixing process stops for loading, mixing, and unloading. It is a flexible method for small production runs, product experimentation, and the creation of unique formulations. Batch mixing is used to produce multiple product types in small quantities. The system is labor intensive and time consuming for large scale production.

Inline mixing is referred to as continuous mixing in that materials are blended and mixed as they flow through a production line. It is an unending process that operates without stopping and requires raw materials to be constantly fed, mixed, and output. The inline process is widely used for the manufacture of cosmetics, chemical formulations, and high viscosity foods. It is a fast process that produces uniform, homogeneous results. Inline mixing is ideal for high demand production and the maximization of throughput.

Single stage rotor stator mixers are used for batch and inline mixing. The batch design is permanently mounted in a mixing tank or can be portable and mobile. In both forms, the position of the mixer can be positioned in the container for fine tuning and the handling of a variety of materials. The inline version is used with process lines that have frequent changeovers.

The use of single stage rotor stators is for products that are up to 10,000 cPs using a four blade rotor that turns with a tip speed of 4000 feet per minute (fpm) with high energy units capable of rotating at speeds over 16,000 fpm. Single stage rotor stators are used for homogenization, solid size reduction, and emulsification.

Multiple stage rotor stators are available in different configurations. The uniqueness of the designs is in regard to the type of rotor and stator, the number of blades in the rotor, and the number of stages in the rotor stator, which can vary from two up to several rows of blades. The purpose of the multiple stage rotor stator design is to disintegrate materials to droplet form rapidly.

Quad Slot System – Quad slot systems normally have two motors for greater torque and acceleration. After materials enter the rotor stator, they pass through a succession of shearing levels before leaving the rotor stator. The result of the multiple stages is micron sized materials in the form of droplets. Quad slot rotor stator assemblies have high head shear rates for the creation of sub-micron particles. They are used for size reduction, emulsification, and homogenization. The use of quad slot systems provides high shear emulsification in a single pass for exceptional efficiency.

Intermeshing Teeth Rotor Stator – Intermeshing teeth rotor stator consists of concentric rows of teeth that provide extremely high shear rates that operate at speeds up to 18,000 fpm. The teeth of the rotor are matched by teeth on the stator to create intense mechanical and hydraulic shearing. As with the quad slot system, intermeshing teeth rotor stator mixers produce sub-micron particles and droplets for achieving the proper stability and texture for a mixture. Exceptionally high flow rates and shearing increases overall production, operating efficiency, and profitability. Intermeshing teeth rotor stators complete the mixing process in a single pass.

Ultra-High Shear Rotor Stator – Ultra-high shear rotor stator mixers are used for homogenizing dispersions and disintegrating large particles or droplets suspended in liquids. They are an inline rotor stator design that has tip speeds over 11,000 fpm. Ultra-high shear rotor stator mixers generate complex and intricate flow patterns without hindering throughput. The popularity of ultra-high shear rotor stator mixers is due to their lower cost, shorter cycle times, no clogging, and easy maintenance.

The design of ultra-high shear rotor stator mixers consists of opposed, semi-circular, cylindrical grooves placed on the rotor and the face of the stator. As fluid flow enters the cylinders, counter flow is created that splits and redirects flow against itself to produce turbulent collisions. The result of the turbulent action is sub-micron sized droplets. The 15,000 fpm spin of the rotor creates the intense hydraulic, shear, and centrifugal forces that disintegrates materials.

In tank rotor stators consist of a shaft with the rotor and stator placed at the end of the shaft. In some ways, they are similar to a home appliance in that the mechanism is placed in a tank with the ingredients to be mixed. The action of an in tank rotor stator pulls materials into the mixing from above and below. Inside the mixing head, materials are exposed to multiple shear zones before being forced out through the stator. The downward and upward draw of the ingredients produces an optimal flow pattern. The rapid action has made it an alternative to traditional mixers that take hours to mix materials.

The speed, efficiency, and shearing forces of rotor stator technology enables it to perform a wide range of mixing functions. The rapid rotation of the rotor creates a vortex that circulates the product through the gap between the rotor and stator, mechanically shearing material to create a homogenous blend. The different mixing functions of a rotor stator are performed using unique rotor configurations. The most common use is for emulsification and the reduction of particle size. The extreme shearing forces of rotor stator technology creates shearing conditions capable of disintegrating any form of material.

Emulsification is a mixing process that forces liquids that do not combine, referred to as immiscible liquids, to mix together to form a uniform homogenous solution. The best example of immiscible liquids are oil and water that are unable to mix. The action of rotor stator technology breaks down oil into sub-micron droplets that remain suspended in water. The process of emulsion happens when the small droplets of a solution, referred to as the dispersed solution, is dispersed in a continuous solution. In most cases, the dispersed solution is oil based while the continuous solution is water based.

Emulsion solutions are categorized by their phase distribution and complexity. Simple solutions are oil-in-water and water-in-oil or O/W and W/O. Complex solutions require multiple emulsions and require the dispersion of an emulsion in another emulsion. They are referred to as oil-in-water-in-oil (O/W/O). These complex emulsions allow for controlled ingredient release, improved encapsulation, and the creation of unique textures.

Although rotor stator technology provides the force for emulsification, the process requires an agent that coats the created droplets to keep them separated. Referred to as emulsifiers, these substances are molecules with fat and water soluble parts. The fat part sticks to oil while the water soluble part sticks to water. These attachments create a barrier around the droplets to prevent them from reconnecting. The water and oil molecules assist in retaining the configuration of an emulsified substance.

In technical terms, dispersion is the distribution of particulates of a material in the continuous phase of another material. The goal is to mix solids in liquids or liquids with other liquids. The result of the process is very fine particles spread evenly in a liquid. Rotor stator technology uses rotational force to break down particles or de-agglomerate them to create a homogeneous mixture. For the particles to remain agglomerated, their surface area is made inaccessible by the liquid solution. Rotor stator technology breaks down particles exposing their surface area, a process referred to as wetting.

Rotor stator technology is the main mechanism for achieving dispersion due to its shear driven process. The rotor’s edge, rotating rapidly, produces the action necessary to disperse particles through the stator. The high shear forces produce wetting, deagglomeration, and un-clumped stable particles.

As with emulsion, dispersion includes a dispersant substance or chemical that improves the dispersion for uniform distribution of particles. The dispersant prevents agglomeration or clumping causing particles to remain dispersed. The long list of dispersants includes organic and inorganic substants, such as surfactants and polymeric dispersants.

Rotor stator technology is ideal for dispersion due to its ability to produce high speed rotation to produce the intense shearing and turbulence necessary to break down particle lumps. Prior to being inserted into the rotor stator, particles are wetted. In the rotor stator, the wetted particles are deagglomerated before passing on to stabilization.

Homogenization is used to create uniform and consistent mixtures by breaking down particles and dispersing them evenly. The processes that depend on homogenization are food, beverages, cosmetics, pharmaceuticals, and chemical manufacturing. In those industries, homogenization is used to enhance the stability of products, produce an even texture, and enable a long shelf life.

The basic aspect of homogenization is the formation of a liquid suspension of fluids with low miscibility rates. The formation of a suspension requires that droplet size be sub-micron, which is the reason for the use of rotor stator technology. As with dispersion and emulsion, surfactants are used to hold the suspension and serve as glue to hold a mixture together.

Rotor and stator technology is at the heart of homogenization due its high level of shearing that transforms materials into tiny, minute droplets. Of the various homogenization processes, rotor stator technology is the fastest, most economical, and efficient.

Suspensions involve two types of matter, solid and liquid. In a suspension, solids are undissolved and visible. In many cases, solids are large and heavy and fall to the bottom of a container in layers, which is referred to as sedimentation. In order to transform a suspension into a mixture, it has to endure some form of mixing process with rotor stator technology being the first choice.

In essence, a suspension is a heterogeneous mixture with liquid and solid particles. The function of rotor stator technology is to transform a suspension into a viable, stable, homogeneous mixture. The immiscible components of a suspension, with a surfactant, are subjected to the high rotation of the rotor in the gap before being forced through the openings in the stator to form a homogeneous solution.

Powder dispersion rotor stator technology is used to mix powders that are difficult to disperse in a liquid and require the high shear power of a rotor stator to create a high-quality dispersion. High molecular weight hydrocolloids, xanthan gum, cellulose gums, starches, and proteins normally require the use of rotor stator technology in order to meet the proper consistency. Powders can float on the surface of a liquid, which makes them difficult to mix and increases batch time. In other instances, powders clump into large sticky masses affecting batch time and the quality of a batch.

Rotor stator technology is used in powder dispersion due to its ability to eliminate floating powder and dust in the mixing process. The high shearing of rotor stator technology simplifies the process and prevents the formation of lumps or fish eyes. The unique nature of powders and their reactions to liquids necessitates the efficiency of rotor stator technology that can draw powders into the mechanism and break them down into sub-micron droplets suitable for further processing.

Conventional methods are incapable of dealing with the characteristics of powders since they are unable to force the path of powders. Rotor stator technology draws powder masses into the mechanism, pulverizes it with the rotor in the gap, and forces it through the openings in the stator to form a homogeneous and viable mixture. The rapid wet out and the shearing action instantly transforms the powder into the liquid preventing the forming of floating, undissolved fish eyes.

As with the many different forms of rotor stator technology, wet milling is designed to reduce particle size. The process breaks down particles to sub-micron size for emulsion and dispersion. High shear rotor stator wet mills have a special configuration with intermeshing teeth or blade rotor stators. The intense hydraulic shear forces material through the narrow gaps in the stator and rotor. In a single pass, a rotor stator facilitates mixing, emulsification, and particle size reduction. In the end, fine particle size is achieved with uniform distribution using rapid rotation. The use of rotor stator technology enhances product quality and consistency.

The ability of rotor stator technology to change easily and achieve uniform dispersion while reducing particle size makes it ideal for the pharmaceutical, food processing, and paints and coating industries. These factors make high shear wet mills the preference over traditional rotor stator technology. They provide exceptional performance with precision as well as efficiency and versatility. High shear wet milling is used in applications where fine particle size control and uniformity are the goal.

The types mixing, described above, is a partial list of the mixing processes where rotor stator technology is used. Rotor stator manufacturers and users have perfected a wide range of methods for which the mechanism is used with new ones being developed. It is safe to say that rotor stator technology is a crucial part of industrial mixing operations.

The uses of rotor stator technology in laboratories and industrial mixing operations are radically different although the structure of the rotor stator mixers have the same components and structure. The key differences are the amount of energy and force used by each form of rotor stator.

In laboratories, rotor stator technology is used for R&D testing and does not require the amount of force that an industrial mixer needs to break down large masses. Lab mixers are produced and configured for small batch projects such as one milliliter up to 50 gallons. In contrast, industrial rotor stator technology is capable of handling 30,000 liters (7925.16 gal) efficiently and quickly.

Laboratory rotor stator high shear mixers have a single stage four blade rotor that rotates within a stationary stator. As with all forms of rotor stator technology, the rotation of the rotor mechanically shears materials through the stator into sub-micron particles and droplets. The mixing process is crucial for lab experiments where uneven mixing wastes time, causes experiment failure, and inaccurate data.

Rotor stator technology oriented to lab experiments can provide consistent homogeneous mixtures. Viscous liquids, powders, and biological samples are treated in accordance with the requirements of an experiment.

Bench rotor stator mixers are designed to create emulsions, suspensions, and homogeneous mixtures. The high shearing force of rotor stator mixers enables researchers to test pharmaceuticals, cosmetics, and food products. The compact bench top design allows R&D experts to test new products, evaluate product quality, and develop unique production methods.

There is an endless number of rotor stator technology designs that are used by industrial mixing. The high shearing force and efficiency of rotor stator technology makes the process ideal for a wide range of products and processes. Milling, dispersion, wet grinding, and emulsion are essential aspects of a wide range of industries.

The list of applications includes paints and coatings, printing inks, food and drink products, cosmetic and personal care products, and pharmaceutical products. Rotor stator technology plays a crucial role in the development and manufacture of a long list of everyday consumer items.

For industrial use, rotor stator technology can be used for inline mixing where materials are fed into a rotor stator before moving on to another application. With batch mixing, rotor stator technology can take different forms, such as the main mixing element or a portion of a mixer where ingredients have to be broken down before being mixed or blended.

Inline powder induction rotor stator mixers are flexible, capable, and portable, enabling them to serve any mixer of any size. Used with a vacuum pump and hopper, inline rotor stator mixers are able to easily place powders into a liquid stream. Unlike conventional mixers, rotor stator high shear mixers are exceptionally capable of processing ingredients that tend to form agglomerates.

Rotor stator technology plays a key part in high shear granulators where the rotor mixes powders after a binder is added and breaks up lumps to achieve a necessary smaller particle size. The function and design of rotor stator technology make it ideal for the processing of granule materials. The high shearing force and the elimination of fish eyes is part of its design.

Many commercial products depend on rotor stator technology to break down ingredients, mix immiscible materials, create suspensions, and avoid fish eyes and lumps. Rotor stator technology is at the heart of the mixing industry and is designed to improve the quality of products and ensure uniformity. The industrial applications described above are a small portion of the uses of rotor stator technology.

Agitators are equipment used in homogenizing media inside a tank. It works by rotating the impeller at its immersed end at a controlled speed or revolutions per minute (rpm). The work exerted by…

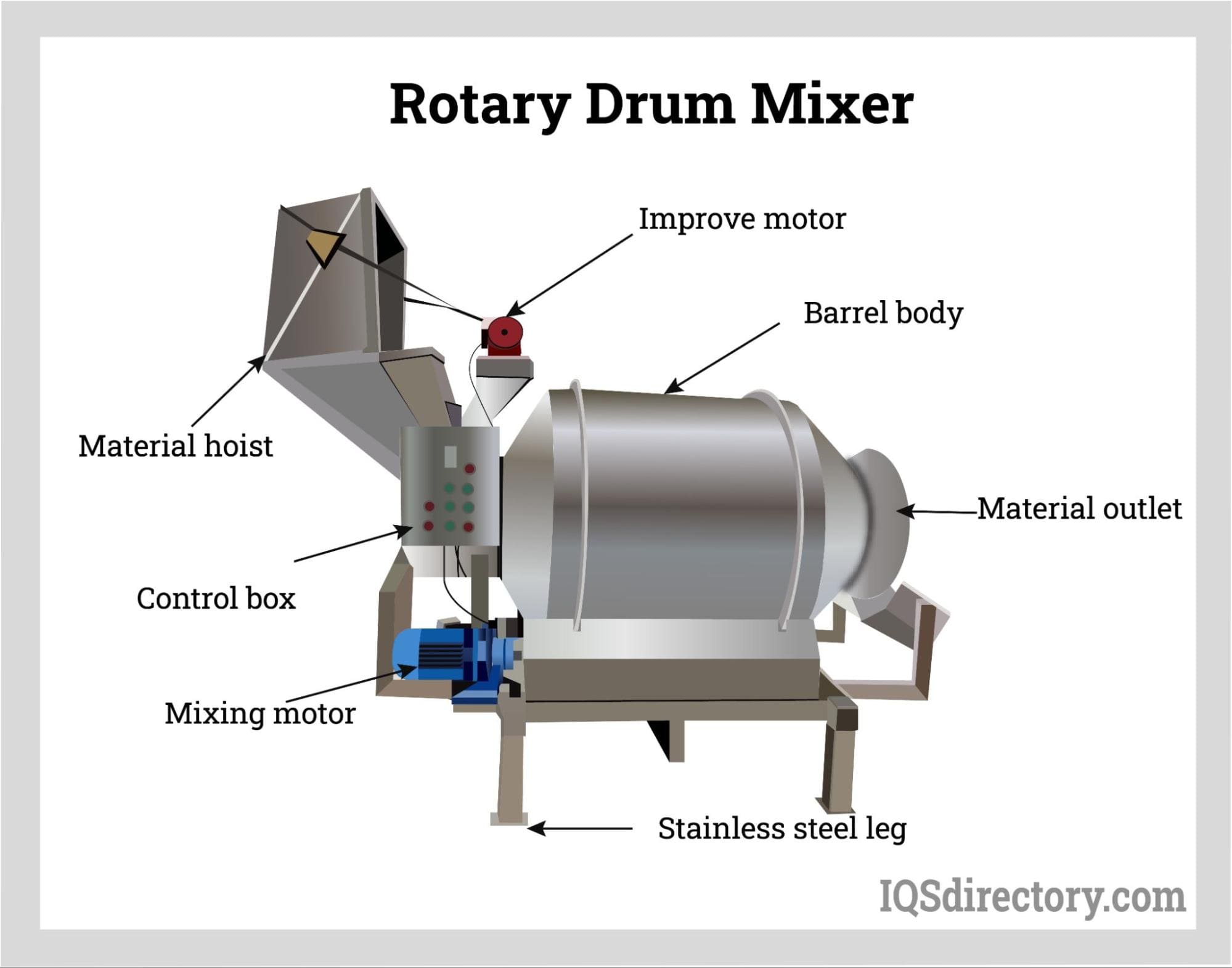

Drum mixers are mixers that are used for mixing free flowing materials by rotating them forward and reverse with welded chutes or flights that fluidize the mixture. The design of drum mixers gives them...

An emulsifier is an emulsion device used for colloidal dispersion of liquid droplets of immiscible liquids in the presence of an emulsifying agent. It enables the combining of non-soluble solutions or liquids...

High shear mixers, also known as high shear reactors (HSRs), rotor-stator mixers, and high shear homogenizers, are used to emulsify, homogenize, disperse, grind and/or dissolve immiscible mixtures with components of the same or different phases...

A homogenizer is a type of mixing equipment used to create a uniform and consistent mixture. It works by breaking the components and evenly distributing them throughout the solution. The components are either immiscible, have varying sizes, or are in different phases from each other...

An industrial blender is a machine for large-scale production that consists of a large tank capable of mixing and blending batches of manufacturing materials to create a reaction between the materials. The many uses for industrial blenders are due to their capacity and...

A mill is a mechanical device that is often a structure, appliance, or machine that is used to break down solid materials into smaller pieces by cutting, grinding, or crushing them. Many industrial processes involve...

A tank mixer is a mixing device that blends several different ingredients in a single tank to make a single solution. It is a mixing process capable of mixing wettable powders, liquids, emulsifiable concentrates, and surfactants. They mix and blend...

A mixer is a complex and precise tool that is used in combining and mixing of substances and chemicals for manufacturing, production, and industrial use. There are many types of industrial mixers including...

A plastic tank is a large capacity liquid or granular storage unit that can be vertical, horizontal, below or above ground, as well as movable. They are designed to hold several gallons of a variety of substances for long periods without experiencing wear, weathering, or deterioration...

A plastic water tank is a large capacity container designed to store water for household, agricultural, irrigation, and industrial manufacturing use. There are various types of water tanks produced to meet the needs of specific applications, with...

A poly tank is a plastic storage tank used to store, transport, and collect water, other liquids, and granular or powder materials. They are made of polyethylene or polypropylene and are a cost effective, lightweight, and easy to handle...

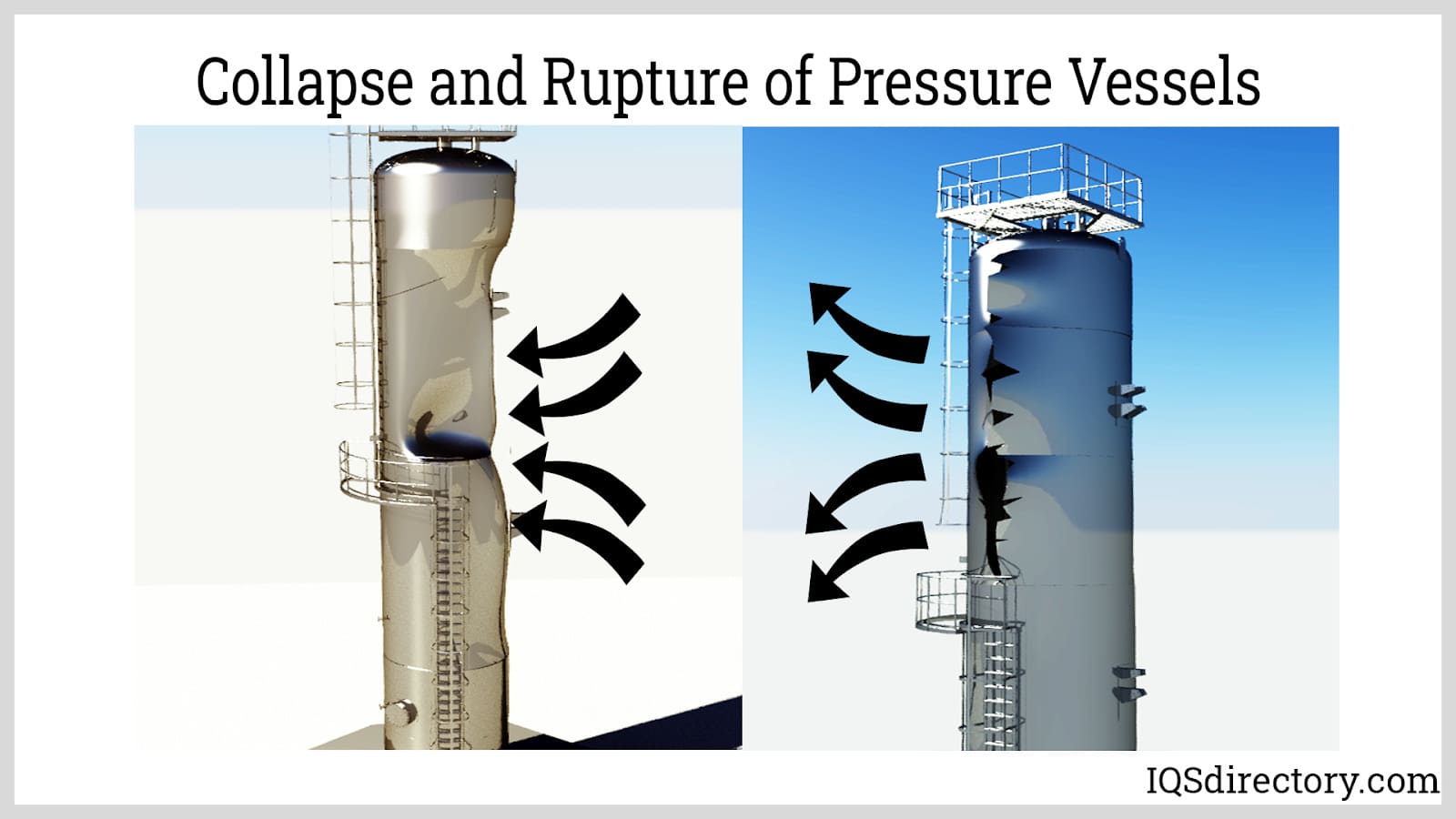

Pressure tanks are vessels that are used to store, hold, and/or convey gasses, vapors and fluids at pressures greater than atmospheric pressure, also known as high pressures...

Pressure vessels are enclosed containers used to hold liquids, vapors, and gases at a pressure significantly higher or lower than the ambient pressure. They are widely used in various industries such as...

Stainless steel tanks are widely used in food, beverage, dairy, medicine, cosmetics, and other manufacturing processes where cleanliness and purity are important. These are also used in industrial plants for storing chemicals and gases where strong resistance from chemical degradation is required...