Agitators

Agitators are equipment used in homogenizing media inside a tank. It works by rotating the impeller at its immersed end at a controlled speed or revolutions per minute (rpm). The work exerted by...

Please fill out the following form to submit a Request for Quote to any of the following companies listed on

This article contains everything you will need to know about emulsifiers and their use.

You will learn:

An emulsifier is a specialized device designed to create stable emulsions by dispersing droplets of liquids that do not naturally mix, using an emulsifying agent. This device supports the mixing of liquids or solutions that would typically separate after being combined. During the emulsification process, the liquid is broken into very small droplets or particles, employing techniques such as rotating propeller mixers, vacuum systems, rotor-stator arrangements, and high shear mixers. These processes reduce droplet sizes to less than one micron (µ), forming a finely textured emulsion. Emulsifiers use high-pressure methods to achieve the necessary droplet dimensions.

There are various types of emulsifier machines or vacuum emulsifying mixers that can mix, disperse, homogenize, emulsify, and aspirate both viscous ingredients and immiscible liquids. These machines are engineered with a construction that prevents dead zones and operate electronically. They also have the capability to emulate a vacuum and manipulate temperatures by heating or cooling the environment. Emulsifiers are frequently employed to mix products like creams, lotions, ointments, medications, and liquid creams, thanks to their expertise in handling substances that don't naturally blend.

Emulsification is a crucial process in diverse industries such as food production, pharmaceuticals, cosmetics, and chemical manufacturing, aimed at producing the smallest possible droplet size so that typically immiscible materials, like oil and water, can blend into a stable, homogeneous emulsion. By increasing the energy input into the mixture—through processes like mechanical mixing, high-shear blending, or ultrasonic homogenization—smaller droplets are generated. This results in a finer emulsion, directly impacting the consistency, mouthfeel, and quality of the final product. Importantly, the efficiency of the emulsion process significantly influences not only product stability and shelf life, but also its sensory attributes and performance. Although various synthetic and natural emulsifying agents (or surfactants) can be used to achieve emulsification, a mixer or homogenizer often proves more effective in attaining the desired droplet size and emulsion stability, especially for commercial-scale production.

Emulsification involves a dynamic two-phase system where one phase, known as the internal or dispersed phase (such as oil droplets), is transformed into minute droplets and dispersed within the other phase, called the external or continuous phase (such as water). Energy is necessary to generate emulsions and establish this two-phase system—whether by mechanical agitation, ultrasonication, or chemical techniques. The careful balance of these phases and understanding the type of emulsion desired (oil-in-water or water-in-oil) are essential for product functionality across industries.

The objectives of emulsification include:

Emulsification is the process where one immiscible liquid is dispersed within another immiscible liquid, such as oil droplets within water or vice versa. Unlike colloidal solutions that contain particles suspended in a liquid, emulsification specifically pertains to the mixing of two or more immiscible liquids. This process can involve chemical, physical, and mechanical methods, often necessitating the use of high-shear mixers, inline homogenizers, dispersers, or even ultrasonic emulsification equipment to reduce droplet size and promote a finer emulsion.

Mechanical emulsification relies on three fundamental scientific theories that explain how stable emulsions are achieved:

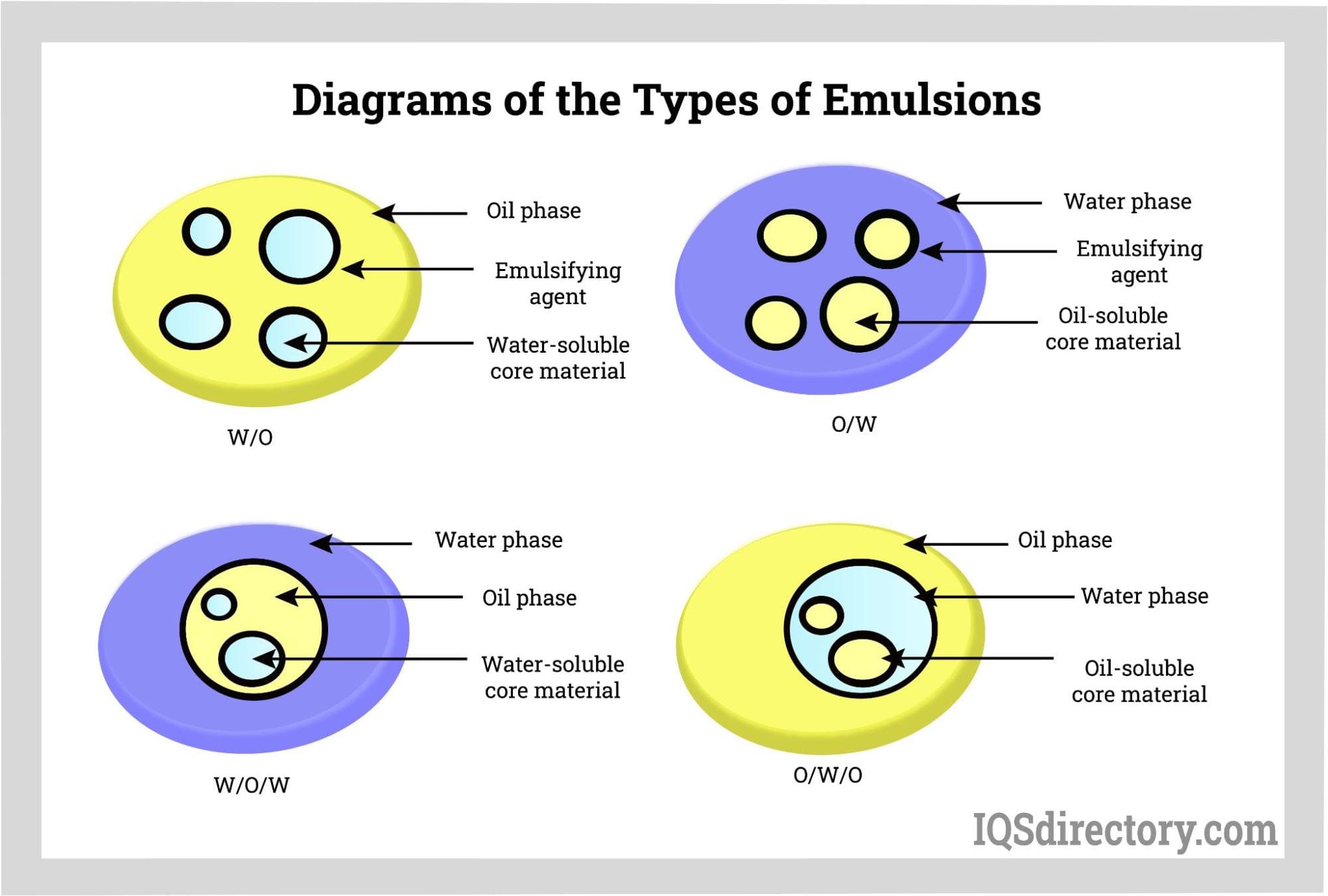

Emulsions are categorized based on their phase distribution and complexity, critical for tailoring properties for specific applications such as food science, personal care, or industrial processing. The two principal types of emulsions encountered are simple and complex (multiple) emulsions:

Emulsifiers, or surfactants, are key ingredients used to enhance emulsion stability by reducing interfacial tension and preventing phase separation. These stabilizing agents typically feature both hydrophilic (water-attracting) and hydrophobic (oil-attracting) molecular components, enabling them to position themselves at the oil-water interface and decrease the likelihood of droplets merging.

Common emulsifiers used in industry and the food sector include lecithin (extracted from soy or egg yolks), soy lecithin, sodium phosphates, monoglycerides, diglycerides, and sodium stearoyl lactylate. Additional popular food grade and industrial emulsifiers include polysorbates, sorbitan esters, stearic acid derivatives, and glycerol monostearate. Selecting an appropriate emulsifier is essential for product quality, influencing droplet size, viscosity, flavor profile, appearance, and shelf-life.

Emulsifier selection is guided by the Hydrophilic-Lipophilic Balance (HLB) system, which rates emulsifiers on their water solubility versus oil solubility, optimizing compatibility with oil-in-water or water-in-oil emulsions.

While emulsification is a core technique in food manufacturing for producing products like dressings, ice cream, sauces, and dairy, its applications extend to pharmaceuticals (emulsified drug delivery systems, topical creams), cosmetics (moisturizers, creams, lotions), paints, adhesives, and more.

An essential part of the industrial emulsion process is stabilization, which is especially critical for pharmaceuticals, cosmetics, and shelf-stable foods. Most emulsions are thermodynamically unstable and will eventually separate if not properly stabilized. Thus, emulsifier choice and process parameters such as shear force, temperature, order of ingredient addition, and emulsification time are crucial to ensure long-lasting stability, appropriate viscosity, and targeted texture. Advances in high-pressure homogenization and microfluidizer technology are enabling even greater control over emulsion particle size distribution for specific product requirements.

The use of force or energy arises because emulsification is rarely a spontaneous process; it requires energy in the form of mechanical shear, cavitation (ultrasound), or pressure. The ultimate droplet size—and thus stability and appearance—is dictated by the amount and type of energy applied during processing. Coarse emulsions with droplet diameters above 10 µm can be formed with simple agitation or paddle mixers, while fine and nanoemulsions (for advanced pharmaceutical, cosmetic, or food applications) require high-shear mixers or rotor-stator systems capable of producing droplets below 1 µm.

Unlike simple blending techniques for combining two non-mixable liquids, certain specialized emulsifiers—classified as lipophilic (oil-loving) or hydrophilic (water-loving)—are utilized especially in surface treatment processes to extract or remove excess emulsifiable penetrants without disturbing desired surface applications. These emulsifiers, lacking traditional surfactants, efficiently remove surplus penetrant residues in applications like non-destructive testing (NDT) or metal finishing, while preserving penetrant adherence where it is needed.

Lipophilic emulsifiers interact specifically with oil-based penetrants, enabling their removal from a component's surface using a water spray or rinse. By penetrating residual oil, these emulsifiers facilitate rapid and complete removal, essential to avoid over-emulsification and loss of the intended penetrant. Their action is fast and controlled.

Hydrophilic emulsifiers, typically available as concentrated solutions, are diluted with water and applied by spray or immersion. They act much like detergents, emulsifying residual penetrants so they can be washed away. The process often includes an initial water rinse, followed by emulsifier application and a final rinse, ensuring thorough cleaning and preparation of the treated parts.

Laser diffraction is a state-of-the-art particle sizing technique employed to assess the size and distribution of droplets created during the emulsification process. This analytical method is crucial for food scientists, pharmaceutical formulators, and industrial chemists, as droplet size distribution directly influences the flavor, texture, stability, mouthfeel, appearance, and overall processing efficiency of emulsified products. Precise droplet size control also affects emulsion shelf life, viscosity, and consumer acceptance.

The laser diffraction method relies on the principle that the scattering angle of laser light passing through an emulsion is directly related to the size of the droplets present. When droplets of various sizes are present, a complex diffraction pattern results. By analyzing this diffraction pattern using advanced algorithms, the size distribution of droplets within the emulsion can be rapidly and accurately determined. Such real-time particle size monitoring allows manufacturers to optimize emulsifier concentration, processing conditions, and formulation parameters for better process control and quality assurance.

Conclusion: Understanding the emulsification process—from the selection of surfactants and type of mixers to particle size analysis and stability control—is fundamental for producing high-quality, stable emulsions. Employing proper emulsification techniques enables innovation and improved product performance across food processing, pharmaceuticals, cosmetics, and specialty chemicals, meeting diverse consumer, industrial, and regulatory needs.

Emulsification is a fundamental process in industries such as food manufacturing, pharmaceuticals, cosmetics, chemicals, and more. It necessitates the application of energy in various forms to blend immiscible liquids—most commonly oil and water—into a stable emulsion. While the overall process follows specific chemical principles, the mechanical mechanisms and energy sources involved can vary significantly. These may include the use of vacuums, ultrasonic waves, high-pressure homogenizers, and advanced, high-efficiency emulsification equipment. Choosing the right emulsification method is crucial for product quality, operational efficiency, and production scale.

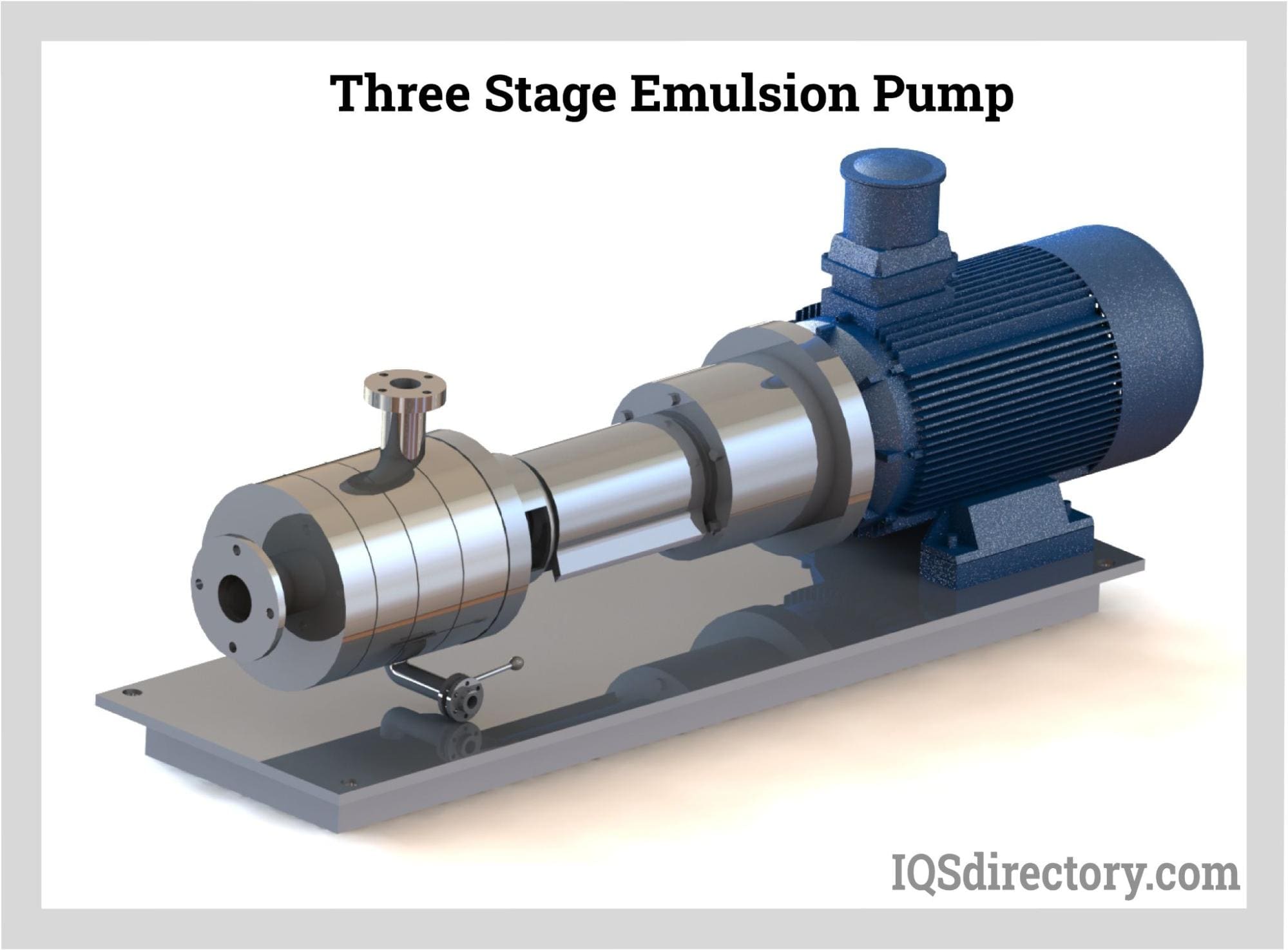

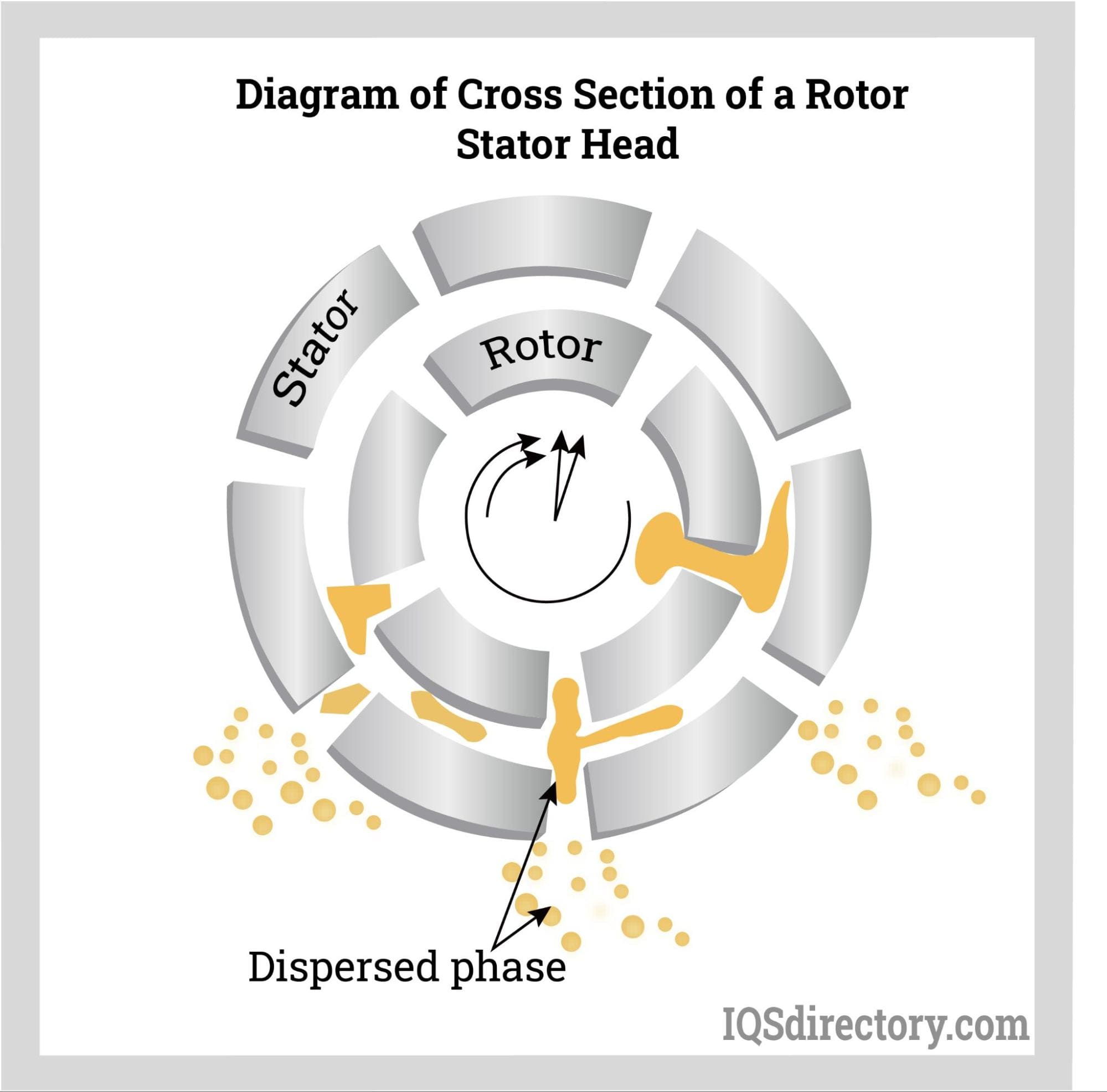

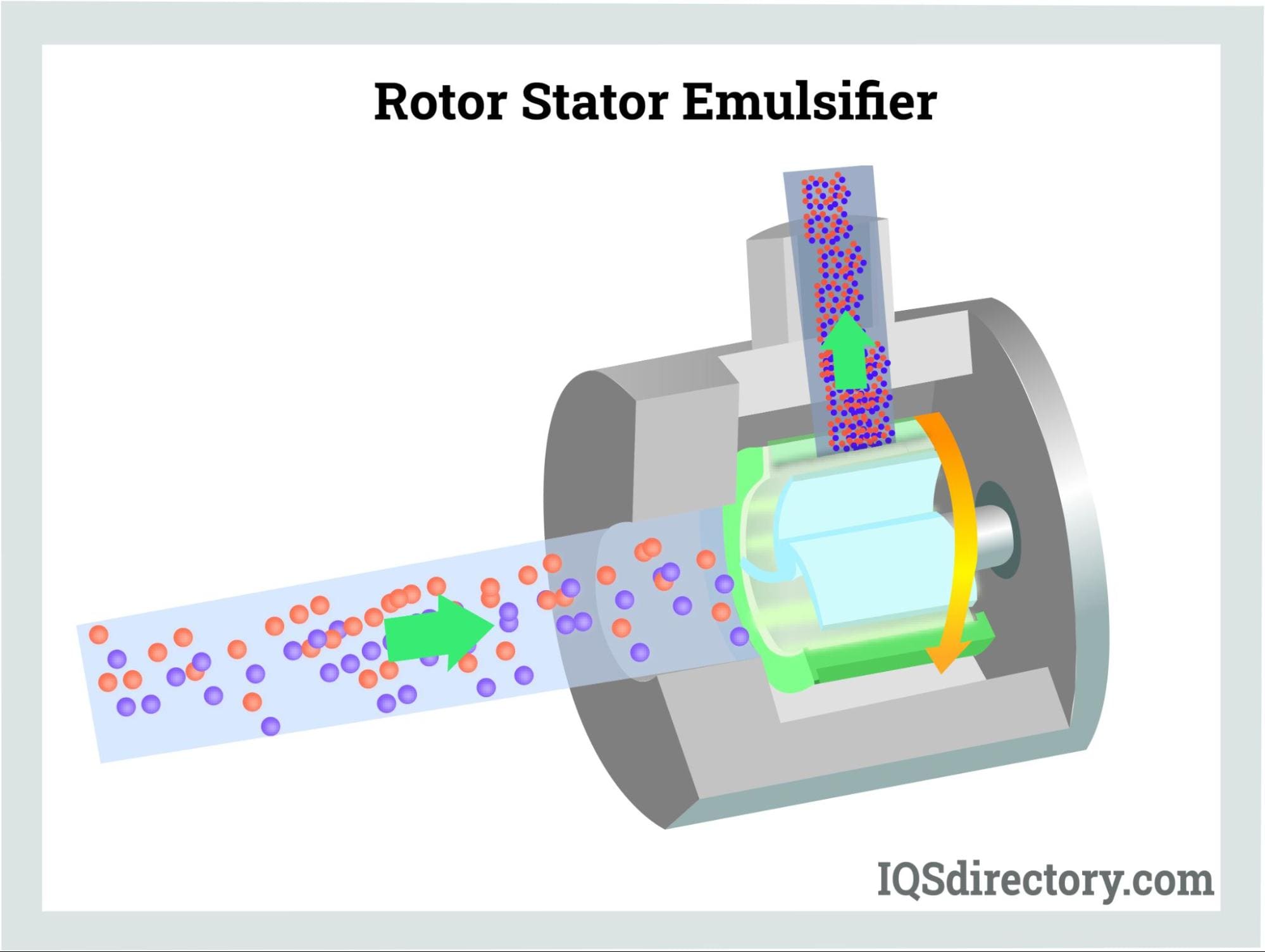

The emulsification process relies on reducing liquids into fine droplets to achieve effective mixing and a homogeneous emulsion. Rotor-stator mixers are industrial mixers valued for their ability to deliver high-speed dispersion and efficient droplet size reduction. In these machines, the rotor spins at extremely high speeds, acting as a centrifugal pump that draws in the product and subsequently breaks it down into much smaller particles.

Rotor-stator mixers operate in two distinct modes: batch and continuous processing. The batch mode uses both pumping action and shaft power, while continuous processing allows for uninterrupted blending—ideal for large-scale production lines. The mixture is forced through a narrow gap between the rotor and the perforated stator, and the corresponding shearing forces further decrease droplet size.

These mixers deliver significant shear stress, elongation forces, and high turbulence. The rotor’s kinetic energy transfers to the stator, resulting in high local energy dissipation and rapid mixing—conditions not achieved with conventional mixing equipment. This unique combination enables the production of fine, stable emulsions with extended shelf life and enhanced texture.

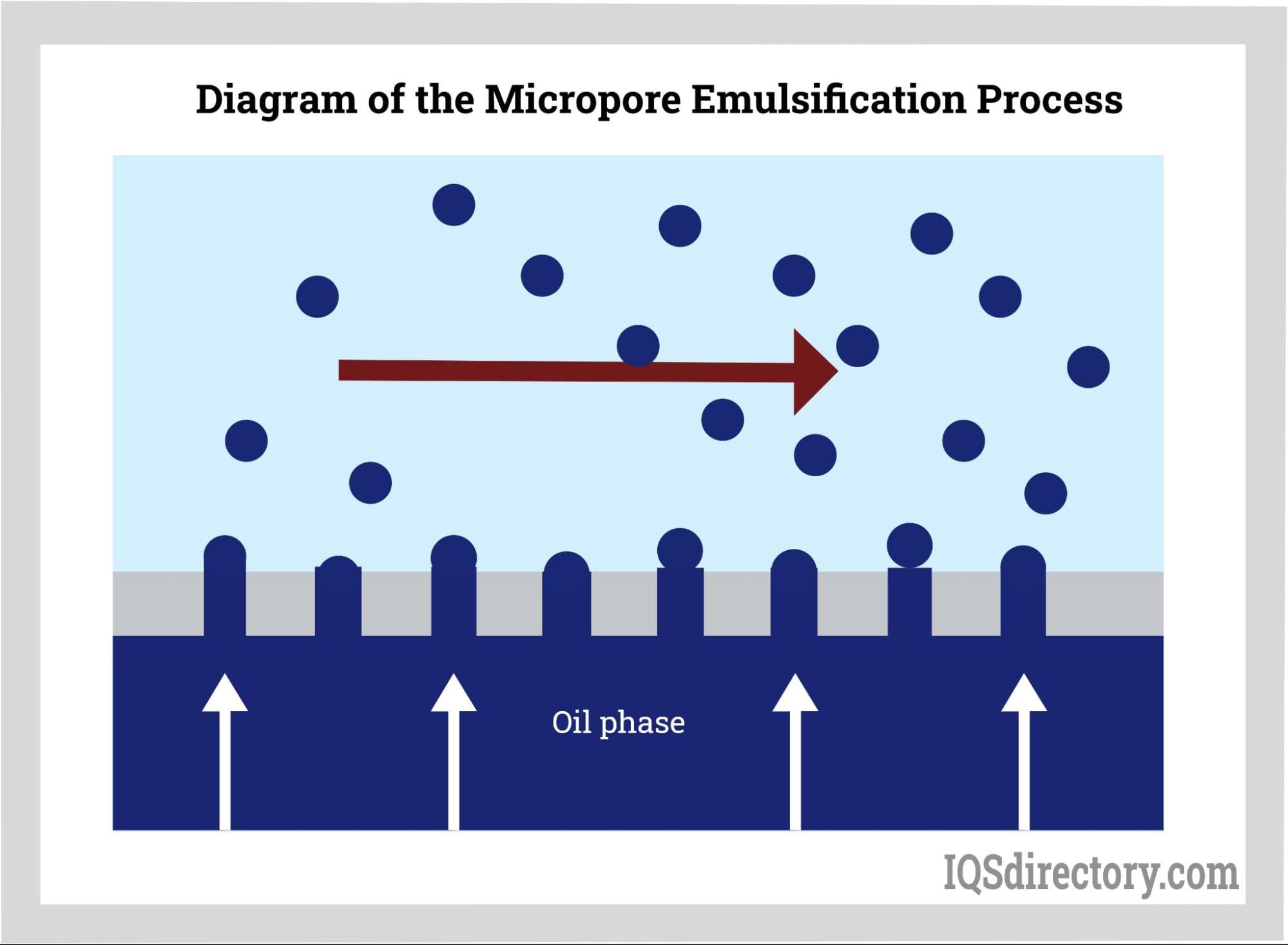

Micropore emulsification is a sophisticated emulsion technology for achieving highly uniform droplet sizes, resulting in exceptionally stable emulsions. This technique is particularly effective in handling high-viscosity ingredients, such as oils, gels, and polymers, ensuring consistent production critical for food, pharmaceutical, and cosmetic manufacturing.

Through precision engineering, the dispersed phase is introduced via microscopic pores in a stainless-steel membrane, allowing for controlled formation of near-perfect spherical droplets within the continuous phase. These well-dispersed droplets significantly improve the quality and shelf stability of the finished emulsion. Controlled shear forces in the system help detach the droplets from the membrane’s surface, yielding a uniform particle size distribution and minimizing waste and variability between production batches—a leading challenge in traditional mixing methods.

Ultrasonic emulsifiers leverage the power of ultrasound-driven cavitation to physically disrupt oil and water droplets, forming both oil-in-water (O/W) and water-in-oil (W/O) emulsions with droplets in the micron and nano size ranges. This ultrasonic emulsification technique is highly effective for creating nanoemulsions needed in industries requiring ultra-fine distribution—such as pharmaceutical drug delivery, advanced coatings, paints, food science, and polymer synthesis.

The exceptionally small droplet size achieved with ultrasound means faster absorption and stability, making nanoemulsions less prone to sedimentation, coalescence, and flocculation. Vigorous ultrasonic mixing promotes thorough dispersion without reverting to phase separation. Modern ultrasonic emulsifiers commonly use surfactants or emulsifying agents to aid stability and performance, meeting the strict requirements for pharmaceutical and food-grade emulsions.

High pressure homogenizers are industrial emulsifiers engineered for high-throughput production—capable of producing nano-sized droplets for stable, high-quality emulsions. During the homogenization process, immiscible emulsion phases are forced together under extreme pressure (often exceeding 10,000 psi) through a narrow orifice or a porous membrane, generating intense shearing and cavitation that homogenizes the mixture at the microscopic level.

Compared to ultrasonic emulsifiers, high-pressure homogenizers excel in handling large batch volumes, making them indispensable in the dairy industry for processes like milk homogenization, as well as in food processing, chemical manufacturing, and pharmaceutical formulation. These homogenizers can be easily adjusted to process different flow rates and pressure ranges, catering to a variety of application requirements. The equipment requires rigorous cleaning protocols—particularly vital in food and beverage and bioprocessing settings—to prevent contamination and maintain product integrity.

There are multiple types of high-pressure homogenizers, each designed for specific workflows. Some are dedicated to batch production, while others support continuous processing. When selecting a homogenizer, factors such as processing volume, energy efficiency, sanitation requirements, and compatibility with specific product viscosities must be considered. Although high-pressure equipment demands a higher upfront investment, its scalability, ability to achieve submicron droplet sizes, and long-term process efficiency justify the cost for industrial users seeking superior emulsion quality.

It is important to note the distinction between homogenization and emulsification: homogenizers are best for blending similar (miscible) liquids, while emulsifiers are designed specifically for mixing immiscible liquids. Ultimately, the choice of emulsification equipment influences final product quality, shelf life, and cost-efficiency.

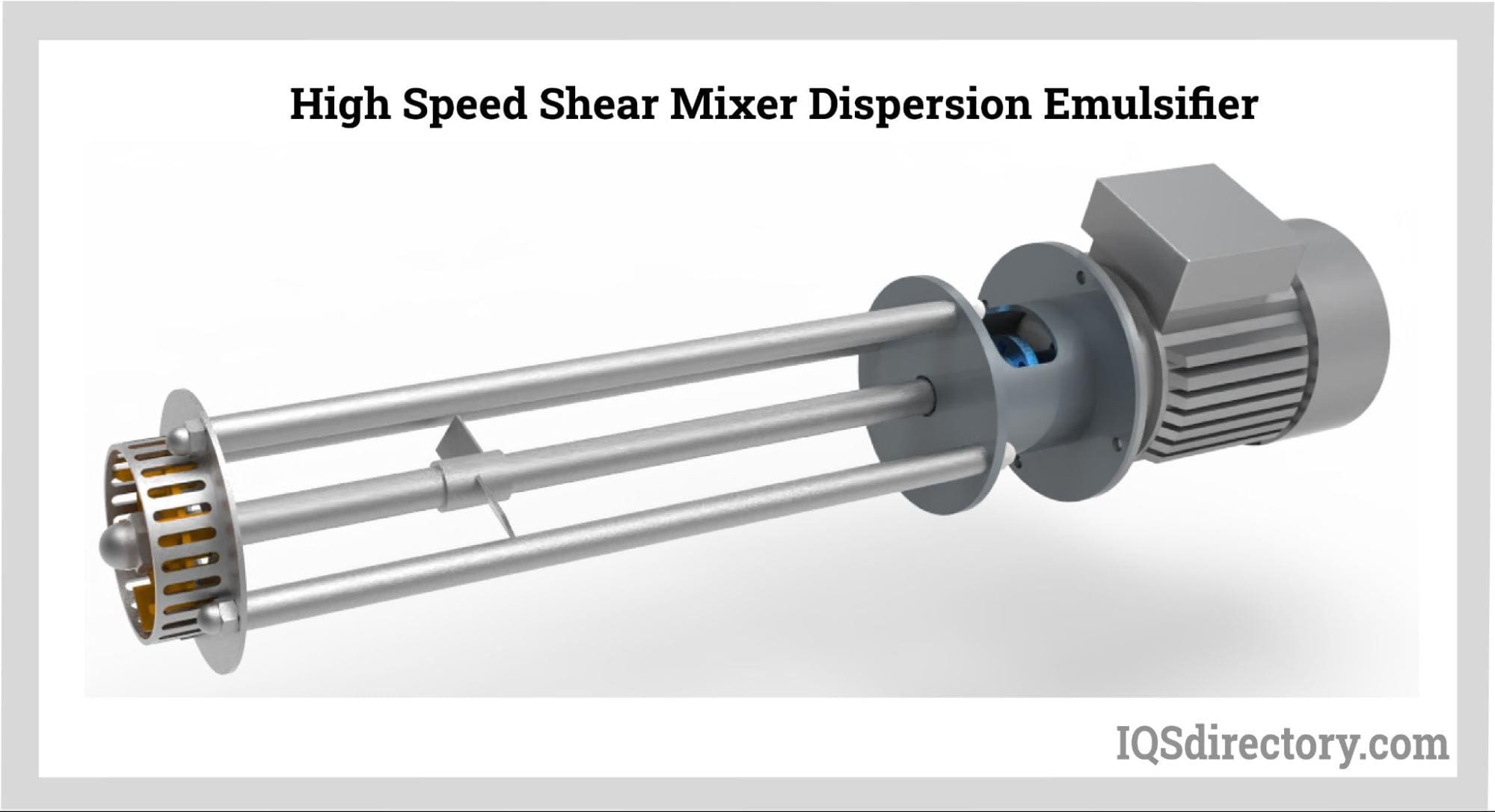

High shear mixers, including rotor-stator mixers, shear reactors, and high shear homogenizers, are essential for applications involving emulsification and dispersion. Known for their high rotor tip speeds, intense shear rates, and elevated localized energy dissipation, these mixers facilitate rapid droplet size reduction and uniform distribution.

Shearing is fundamental for destabilizing the boundary between immiscible liquids, such as oil and water, allowing for the formation of stable, fine emulsions in food production, personal care products, and chemical manufacturing. Adjustable rotor speeds enable flexible shearing energy levels suitable for different viscosities and end-use requirements. Unlike high-pressure homogenizers, which depend on intense applied pressure, high-shear mixing achieves excellent emulsion quality via mechanical forces, efficiently reaching submicron particle sizes suitable for both laboratory-scale and industrial-scale emulsification processes.

An inline emulsifier is a specialized high-shear mixing system featuring a robust rotor-stator assembly. Inline emulsification enables continuous, efficient processing of immiscible liquid systems, ensuring consistent product quality and reducing processing time. As the rotor quickly spins, it draws materials through the stator where they are subjected to powerful, uniform shearing forces, ultimately dispersing fine droplets evenly and resulting in highly stable emulsions.

Inline emulsifiers are widely used in process industries for the manufacture of creams, lotions, sauces, pharmaceuticals, adhesives, and chemical formulations due to their reliability and ease of integration into existing production lines. Despite the variety in size and configuration, all inline emulsifiers share critical characteristics designed for professional-grade emulsification.

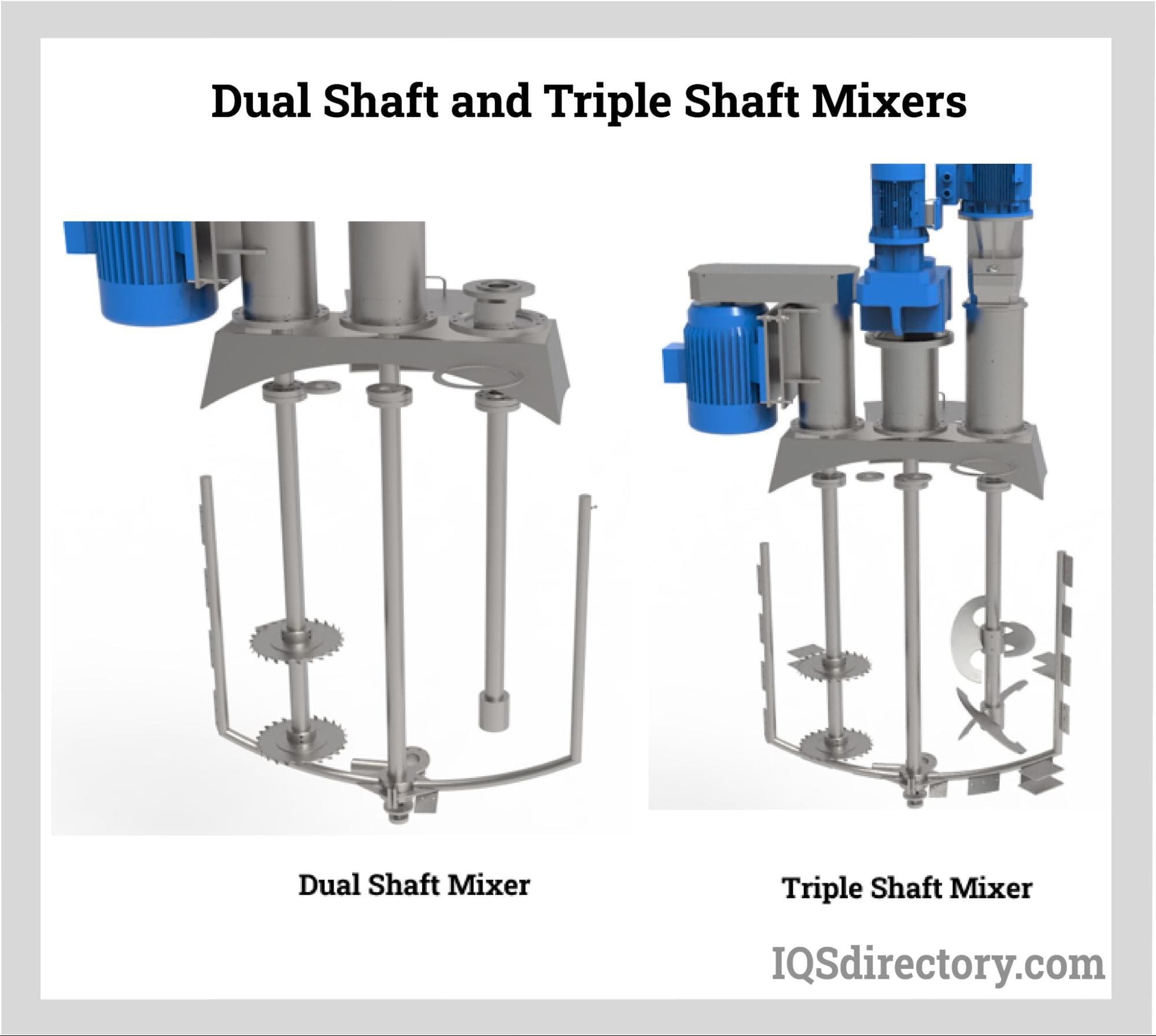

Multi shaft mixers are industrial-scale emulsification systems utilizing two, three, or even four individual mixing shafts. Their versatile mixing elements—ranging from classic blades and paddles to helical agitators—enable them to efficiently blend highly viscous or heterogeneous materials, tackling complex fluids where conventional mixers may fail. Multi shaft mixers are ideal for industries requiring tailored emulsions, such as cosmetics, adhesives, paints, and specialty chemicals. Blades, paddles, or helical shapes can be specifically selected or customized for unique applications, providing unmatched emulsion process flexibility.

Most modern multi-shaft mixers combine a disperser to initiate high-speed mixing and a rotor-stator assembly that finishes the process, refining the particle size and texture of the emulsion. This configuration enables efficient production of fine, uniform, and stable emulsions, even in high-volume or highly viscous product formulations. Customization options—such as heating, cooling, or vacuum integration—allow these mixers to meet the specific needs of end-users across various industries.

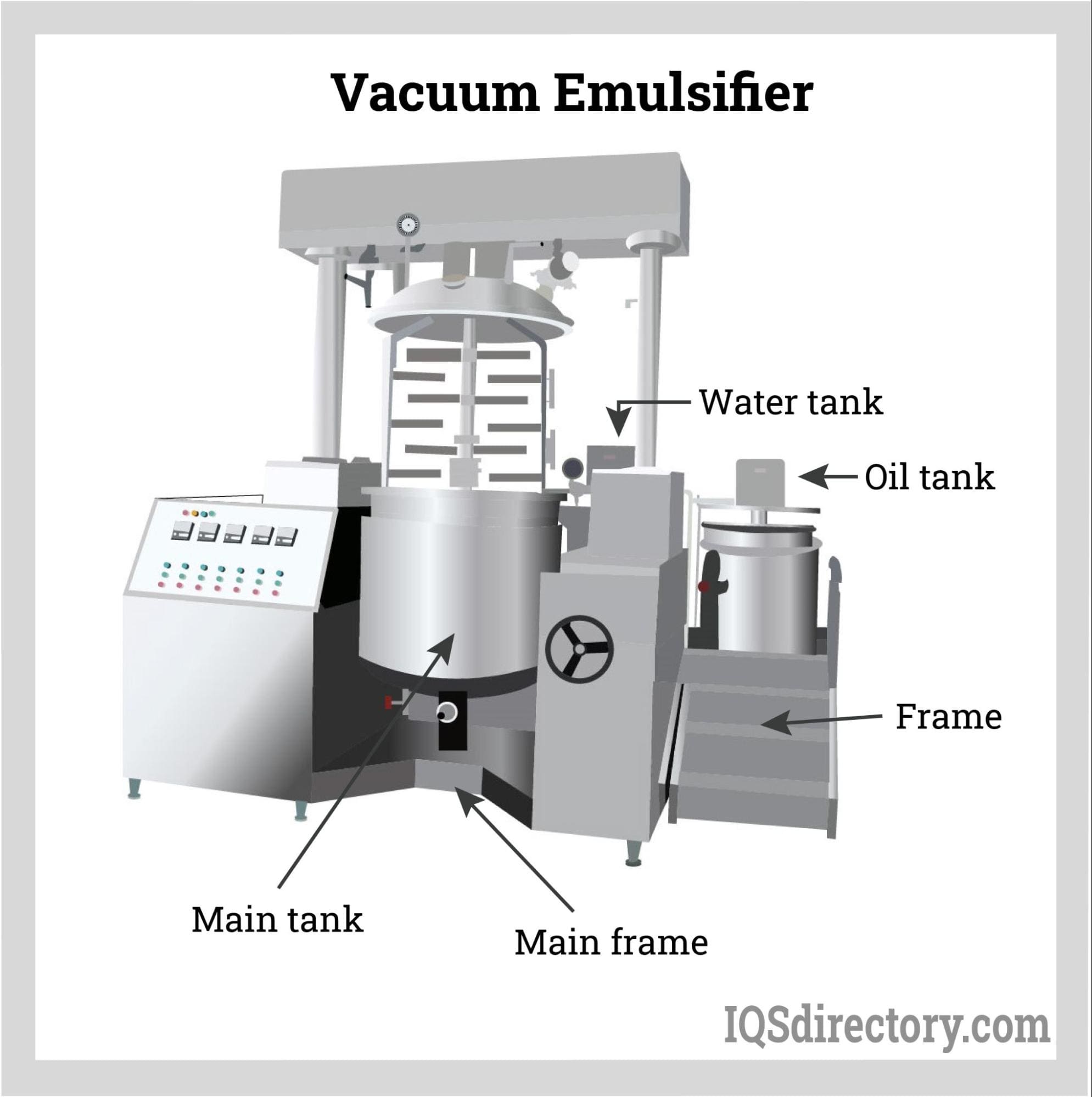

Vacuum emulsifiers utilize airless mixing chambers to optimize emulsion formation and product integrity—critical where air bubbles or oxidation can undermine product quality, such as in cosmetics, pharmaceuticals, and high-purity chemical products. In a vacuum emulsification system, materials are placed in a sealed mixing tank equipped with fixed, perforated impellers. These impellers rotate at adjustable speeds, with one driving the product upwards and another driving it downward, ensuring comprehensive blending in both directions.

A vacuum pump removes air from the chamber, creating negative pressure and facilitating the formation of smooth, void-free emulsions. A pressure sensor continually monitors internal conditions, optimizing processing and protecting sensitive ingredients from degradation. This approach prevents aeration, enhances product homogeneity, and preserves volatile or heat-sensitive components. The result is a consistently smooth, high-purity emulsion suitable for demanding applications requiring strict quality assurance.

An emulsifier disperses immiscible liquids, such as oil and water, into stable, fine emulsions by reducing droplet size through high-pressure, shear, or vacuum mixing. This ensures uniformity, texture, and extended shelf life in products.

The choice of equipment—rotor-stator mixers, ultrasonic emulsifiers, high-pressure homogenizers, or vacuum mixers—directly impacts droplet size, emulsion stability, processing efficiency, and the consistency of the final product in various industries.

Stable emulsions are achieved through surface tension reduction, repulsion theory, and viscosity modification. Emulsifying agents or surfactants enhance these effects by preventing droplet coalescence and increasing system viscosity.

Ultrasonic emulsifiers and high-pressure homogenizers are preferred for nanoemulsions, while multi shaft and micropore emulsifiers effectively handle high-viscosity and complex formulations requiring precise particle size control and stability.

Laser diffraction is used to analyze droplet size and distribution in emulsions. This technique ensures product consistency, optimal texture, and stability by providing real-time monitoring and enabling precise process adjustments.

Vacuum emulsifiers eliminate air and oxidation, producing void-free emulsions critical for cosmetics, pharmaceuticals, and high-purity applications where product homogeneity and protection of sensitive ingredients are paramount.

Emulsifiers play a vital role in numerous industrial processes by enabling the mixing of liquids to create various products. In manufacturing, certain products require the blending of ingredients with differing densities, which is achievable only with the use of an emulsifier. This component ensures that the ingredients remain stable until they are ready for final application.

The use of emulsifiers in the food, pharmaceutical, cannabis, and cosmetic industries is subject to the regulations set by the Food and Drug Administration (FDA), which oversees commercial products intended for public use. Any substance or material used in the production of these products must be approved by the FDA. For the food industry, acceptable emulsifiers include sorbitan esters and polysorbates derived from natural fatty acids.

Emulsifier machines and emulsifiers are extensively used in the food industry, as many food products are in an emulsified state, such as dressings, sauces, spreads, dips, creams, and beverages. Emulsifiers maintain ingredient stability, which helps extend the product's shelf life. The appropriate surfactant ensures that materials remain evenly mixed. In the meat industry, emulsifiers are employed to cut and mix meat for sausage production.

The pharmaceutical sector relies on emulsion technology to create palatable medications by better dispersing their ingredients. Without emulsification, drugs could be too bitter and ineffective, as dosages might become inconsistent. Emulsification blends and mixes ingredients to ensure medicines are produced with accurate proportions and dosages.

In the cosmetics industry, emulsions are crucial for achieving the desired appearance and ensuring even application of products. Emulsification breaks down substances into very small droplets, enabling the production of cosmetics with a smooth texture and ease of absorption. By significantly reducing particle size, emulsification enhances product stability and longevity.

The cannabis industry benefits from emulsification by improving the flavor of its products. Emulsification ensures product consistency by reducing the size of cannabinoid molecules, facilitating better absorption by the body, and providing a uniform delivery of active ingredients.

Paint consists of pigment, which provides color, a binder, and a solvent that keeps the paint liquid and spreadable. Emulsification is essential in paint production because the ingredients need to blend completely. The process involves dispersing the pigment and binder into the solvent, with the pigment and binder acting as oil and the solvent as water.

When paint is applied, the pigment and binder droplets coat the surface. As the solvent evaporates or dries, the droplets of pigment and binder consolidate and adhere to form a solid, colorful layer. This transformation is facilitated by the emulsification of the paint.

Metalworking fluids and industrial lubricants are typically oil-in-water (O/W) emulsions. Emulsifiers allow metalworkers to benefit from the lubricating properties of oil combined with the cooling effects of water. Anionic and nonionic emulsifiers are commonly used in metalworking, whereas cationic emulsifiers are less frequently used due to their instability in alkaline conditions.

Emulsifiers are crucial for the emulsification process, enabling the mixing and blending of immiscible substances. To effectively combine materials, an emulsifier that matches the chemical properties of the substances is required. During emulsification, the emulsifier lowers the interfacial tension between the materials and forms a film around the droplets. This action prevents the droplets from clumping together and helps maintain a consistent emulsion.

Anionic emulsifiers dissolve in water to create hydrophilic groups. Suitable for alkaline or neutral conditions, they are not effective with acidic substances. These emulsifiers can be combined with nonionic types and are commonly found in products like laundry detergents, handwashes, kitchen cleaners, and body washes. They are also widely used in industrial applications such as architectural coatings, industrial coatings, and water-based coatings.

Cationic emulsifiers ionize in water to form cationic hydrophilic groups and are used with acidic compounds. They carry a positive charge and are effective in emulsifying water within oil-based coatings. Cationic emulsifiers are utilized in the production of wood finishes, metal coatings, and oil-based coatings.

Nonionic emulsifiers are the second most commonly used type. Their molecules do not carry a charge. These emulsifiers are used to blend oils with water, in emulsion polymerization, and as dispersing agents in various applications. They are present in cleaning products, personal care items, and disinfectants. Nonionic emulsifiers do not ionize in water.

Sorbitan monooleate is utilized in food processing and is classified as a low polyol nonionic emulsifier in the lipophilic group. It serves as an additive in food and medicines, and is soluble in both water and ethanol. Sorbitan monooleate is employed as a stabilizer, dispersant, and emulsifier in the production and processing of food, medicines, cosmetics, and textile printing.

Lecithin, widely used in the food industry, is derived from sources such as soybeans, egg yolks, milk, sunflower seeds, and rapeseeds. It is often combined with other emulsifiers to form a mixed emulsifier that aids in stabilizing the emulsion process. Lecithin, available in liquid, granule, powdered, and gel capsule forms, is a versatile emulsifier with a broad range of applications.

Polysorbates are derived from sugar alcohols found in fruits. They have a yellow hue and exhibit viscous properties after being processed with ethylene oxide.

Mono and diglycerides, also known as partial glycerides, are fatty acids commonly present in food and are highly soluble in dense solvents.

Sodium stearoyl lactylate, derived from sodium salt, is a natural emulsifier approved by both the FDA and the EU.

The Sonolater is a high-pressure emulsifier designed to achieve extremely small droplet sizes through fluid acceleration, inline cavitation, and turbulent flow. It features a comprehensive system that includes a positive displacement pump, electric motor, and PLC controls. The Sonolater’s fixed orifice and blade are engineered to generate intense turbulence to break down oil phase droplets or deagglomerate solids within a liquid medium. It can be tailored to meet specific production requirements.

The Makwell vacuum emulsifying mixer is equipped with a high-speed rotor and stator. As these components spin rapidly within the homo-head, a pressure differential is created between the mixer’s top and bottom. The material is processed through the homo-head, undergoing shearing, breaking, mixing, and emulsification. Once the upward force ceases, the emulsified material exits through the top of the head and is reintroduced by the downward pressure of the blades. The integrated vacuum system ensures smooth operation by preventing bubble formation.

The high shear batch mixer from Silverson is designed to emulsify, homogenize, solubilize, suspend, disperse, and disintegrate solids. It features a rotor-stator work head that reduces processing time by 90%, enhancing quality, product consistency, and process efficiency. Capable of processing up to 8000 gallons (30283 L), this mixer excels in reducing particle sizes and producing highly stable emulsions. Its multistage mixing and shearing action allow efficient material processing through the work head.

The inline high shear mixer from Ross is utilized for reducing particle and droplet sizes to create emulsions that are scalable and reproducible. It includes a single, dual, or four-stage rotor-stator setup that mechanically shears materials as they pass by the stator. The mixer is either floor-mounted or placed on a platform, with materials gravity-fed into the mixing chamber. The rotor generates shearing force at speeds of up to 3000 to 4000 ft/min and expels the mixture through stator holes. It can handle high viscosity materials without needing a pump system.

The PerMix emulsifier and inline homogenizer mixer is a high-shear device designed for continuous inline operation. Its design allows easy integration into existing production lines through its inlet and outlet connections. For low viscosity liquids, it can pump materials without requiring an additional pump. Products can be processed in a single pass or circulated for multiple passes to achieve better quality. The PerMix mixer significantly reduces processing time, enhancing efficiency and lowering costs.

Given the complexity of the emulsification process, issues can arise. An emulsifier's role is to ensure the formation of a stable emulsion. The effectiveness of this process relies on the composition rate and the concentration of emulsifiers used. Factors that can lead to emulsion destabilization include coalescence, sedimentation, Ostwald ripening, creaming, flocculation, aggregation, and phase inversion.

Ostwald ripening occurs when smaller particles in a solution dissolve and deposit onto larger particles to achieve a more thermodynamically stable state. The molecules on the surface of smaller particles are less stable and dissolve, increasing the concentration of free molecules in the solution. Over time, this leads to the emulsion becoming unstable and eventually undergoing phase separation. Ostwald ripening typically happens in water-in-oil emulsions where oil molecules migrate through the water phase and coalesce with larger oil droplets.

Coalescence involves the merging of droplets into progressively larger droplets until the distinct phases of oil and water separate. This issue may arise from insufficient emulsifier levels, the precipitation of water-soluble emulsifiers, an excessive concentration of base or acid, or the use of incompatible anionic and cationic emulsifiers in the same mixture. Selecting an incorrect emulsifier can also contribute to this problem.

Flocculation happens when droplets clump together to form flocci. While clumping can be beneficial in some processes, in emulsions it leads to poor stability. This issue can be addressed by increasing agitation, boosting the concentration of the emulsifier, or incorporating a higher hydrophilic-lipophilic balance (HLB) emulsifier.

Sedimentation, or creaming, occurs when less dense oil droplets rise to the top of the emulsion, forming a fatty layer. This can result from an imbalance in the size of the oil or water phases relative to each other, a small dispersed droplet size, or insufficient viscosity of the continuous phase. Adjustments can be made to rectify these issues and restore emulsion stability.

Agitators are equipment used in homogenizing media inside a tank. It works by rotating the impeller at its immersed end at a controlled speed or revolutions per minute (rpm). The work exerted by...

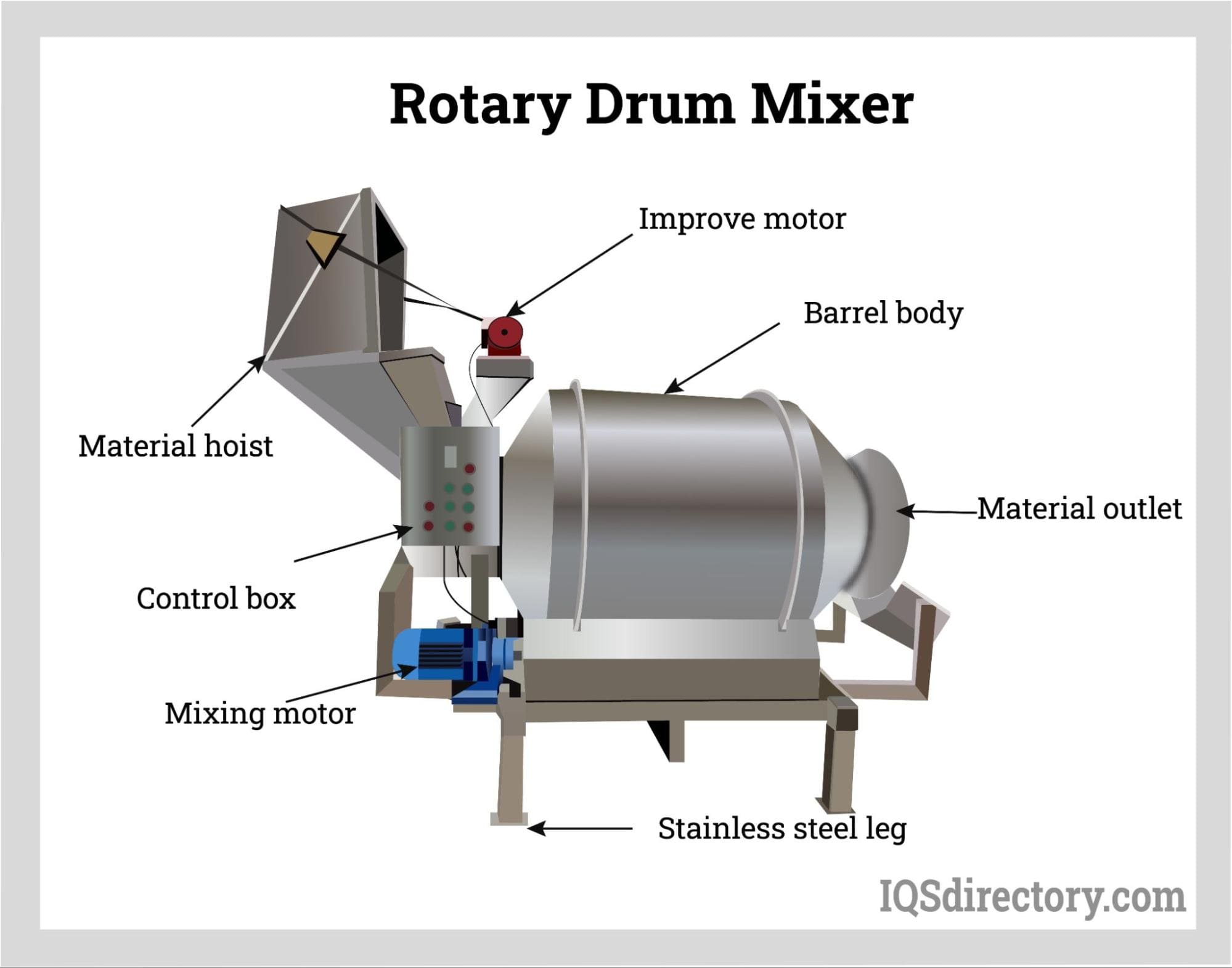

Drum mixers are mixers that are used for mixing free flowing materials by rotating them forward and reverse with welded chutes or flights that fluidize the mixture. The design of drum mixers gives them...

High shear mixers, also known as high shear reactors (HSRs), rotor-stator mixers, and high shear homogenizers, are used to emulsify, homogenize, disperse, grind and/or dissolve immiscible mixtures with components of the same or different phases...

A homogenizer is a type of mixing equipment used to create a uniform and consistent mixture. It works by breaking the components and evenly distributing them throughout the solution. The components are either immiscible, have varying sizes, or are in different phases from each other...

An industrial blender is a machine for large-scale production that consists of a large tank capable of mixing and blending batches of manufacturing materials to create a reaction between the materials. The many uses for industrial blenders are due to their capacity and...

A mill is a mechanical device that is often a structure, appliance, or machine that is used to break down solid materials into smaller pieces by cutting, grinding, or crushing them. Many industrial processes involve...

A tank mixer is a mixing device that blends several different ingredients in a single tank to make a single solution. It is a mixing process capable of mixing wettable powders, liquids, emulsifiable concentrates, and surfactants. They mix and blend...

A mixer is a complex and precise tool that is used in combining and mixing of substances and chemicals for manufacturing, production, and industrial use. There are many types of industrial mixers including...

A plastic tank is a large capacity liquid or granular storage unit that can be vertical, horizontal, below or above ground, as well as movable. They are designed to hold several gallons of a variety of substances for long periods without experiencing wear, weathering, or deterioration...

A plastic water tank is a large capacity container designed to store water for household, agricultural, irrigation, and industrial manufacturing use. There are various types of water tanks produced to meet the needs of specific applications, with...

A poly tank is a plastic storage tank used to store, transport, and collect water, other liquids, and granular or powder materials. They are made of polyethylene or polypropylene and are a cost effective, lightweight, and easy to handle...

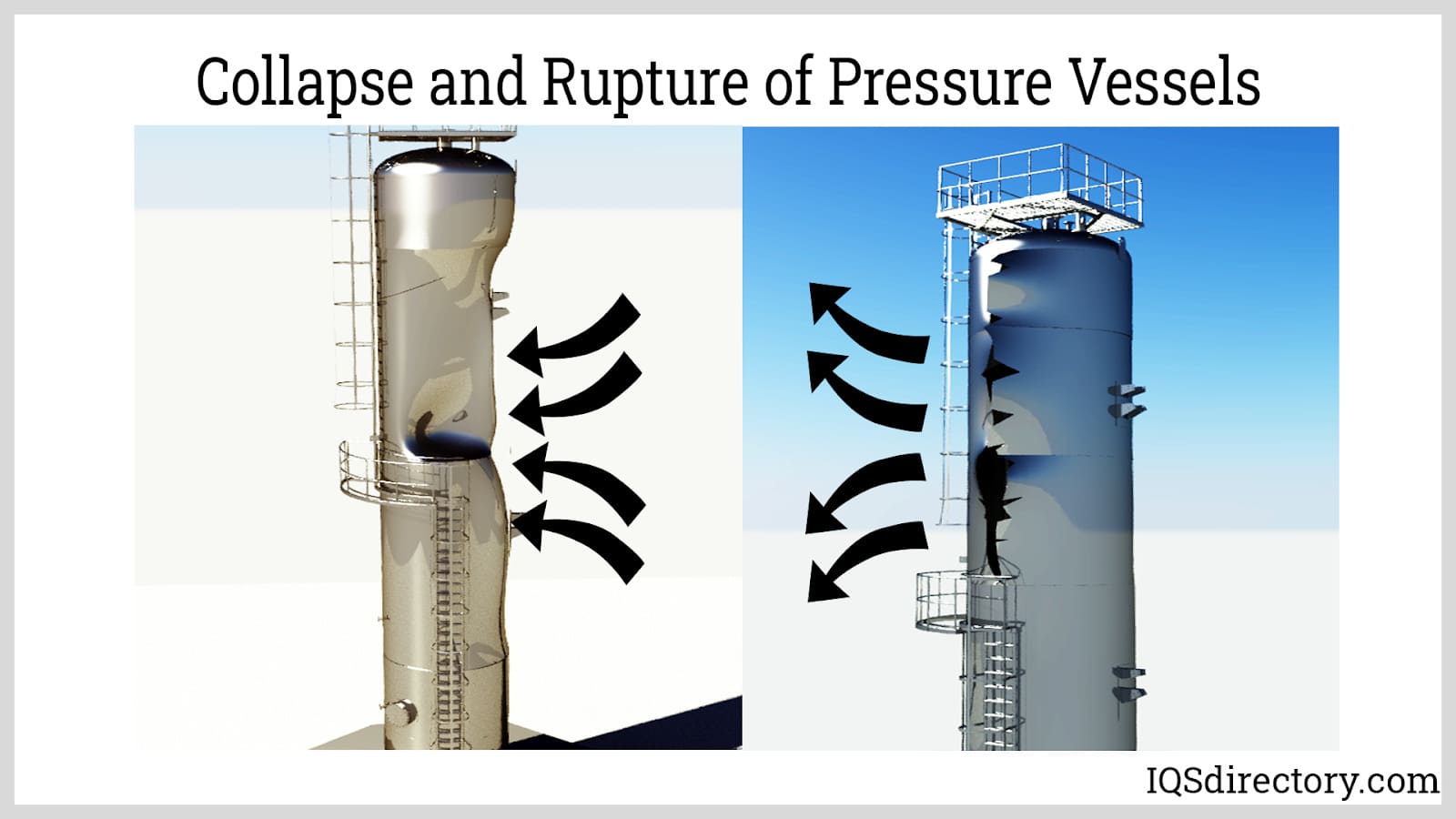

Pressure tanks are vessels that are used to store, hold, and/or convey gasses, vapors and fluids at pressures greater than atmospheric pressure, also known as high pressures...

Pressure vessels are enclosed containers used to hold liquids, vapors, and gases at a pressure significantly higher or lower than the ambient pressure. They are widely used in various industries such as...

Stainless steel tanks are widely used in food, beverage, dairy, medicine, cosmetics, and other manufacturing processes where cleanliness and purity are important. These are also used in industrial plants for storing chemicals and gases where strong resistance from chemical degradation is required...