Pressure Tanks

Pressure tanks are vessels that are used to store, hold, and/or convey gasses, vapors and fluids at pressures greater than atmospheric pressure, also known as high pressures...

Please fill out the following form to submit a Request for Quote to any of the following companies listed on

This article presents all the information you need to know about Pressure Vessels. Read further and learn more about:

Pressure vessels are enclosed structures designed to hold liquids, gases, or vapors at pressures significantly differing from the surrounding atmosphere. They play a crucial role across diverse industries, such as petrochemical, oil and gas, chemical processing, and food manufacturing. Typical examples include reactors, flash drums, separators, and heat exchangers.

Pressure vessels must adhere to several standards and regulations. The ASME Boiler and Pressure Vessel Code (BPVC) is highly regarded, offering detailed guidelines for the design, construction, installation, testing, inspection, and certification of boilers, pressure vessels, and nuclear plant components. Specifically, ASME BPVC Section VIII specializes in pressure vessels and is segmented into three parts:

Another significant standard is the API 510 - Pressure Vessel Inspection Code: In-Service Inspection, Rating, Repair, and Alteration. This standard emphasizes the ongoing maintenance, inspection, and repair of operational pressure vessels, ensuring their sustained integrity and safety.

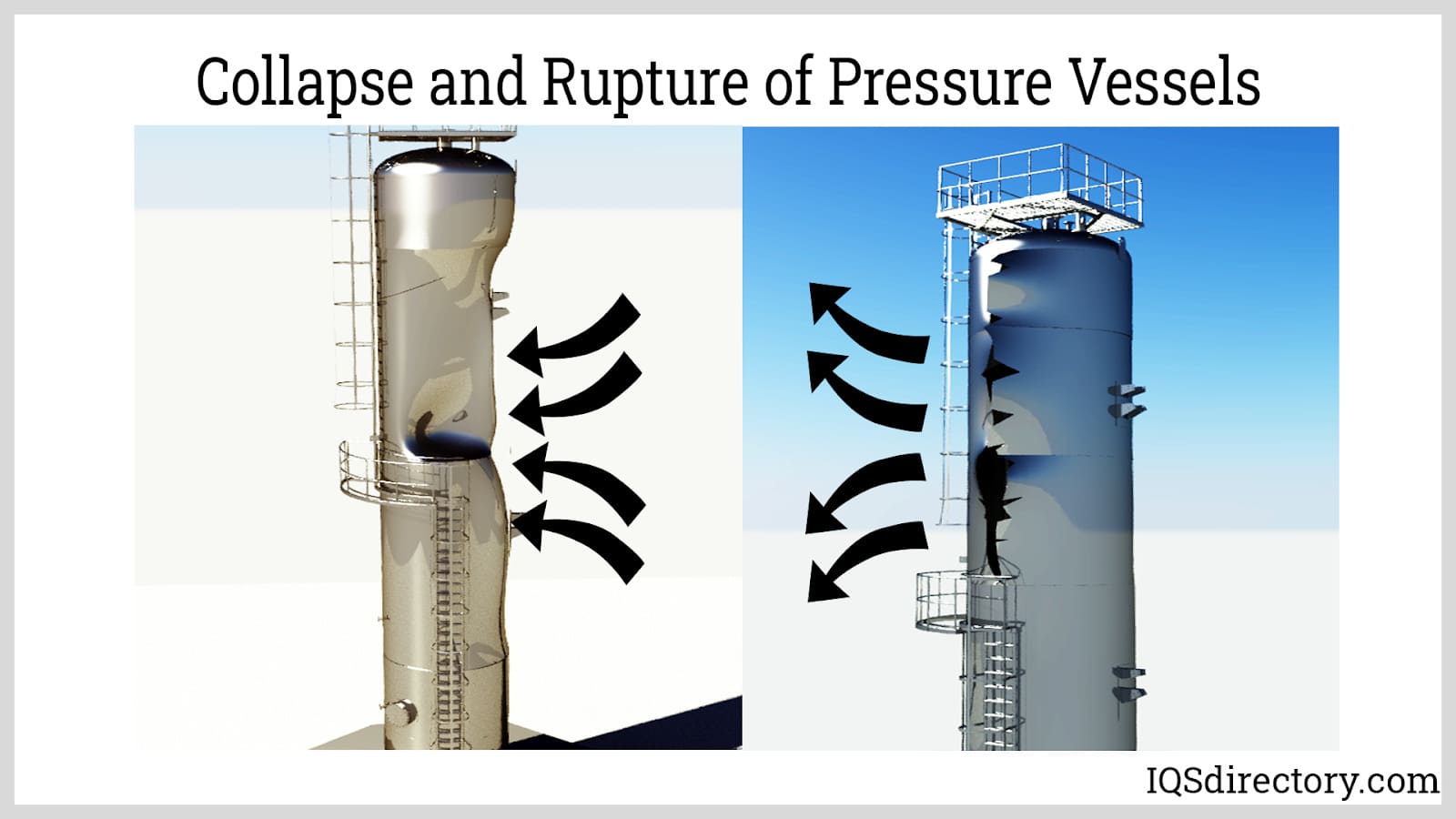

Pressure vessels must be operated within prescribed safety parameters, like maximum allowable working temperature and pressure. All operations involving pressure vessels should be conducted by certified professionals, as any accidental release or leakage could present substantial hazards to the environment.

Pressure vessels are specialized containers designed to safely hold liquids, gases, or vapors at pressures significantly different from ambient pressure. These critical components are foundational in industries such as chemical processing, oil and gas, power generation, pharmaceuticals, and food and beverage manufacturing. Pressure vessels can be categorized based on their function (purpose of use) or geometric shape, each with specific advantages and industry applications. Understanding the various types of pressure vessels, along with their construction materials and pressure ratings, is essential for equipment selection, plant safety, and regulatory compliance.

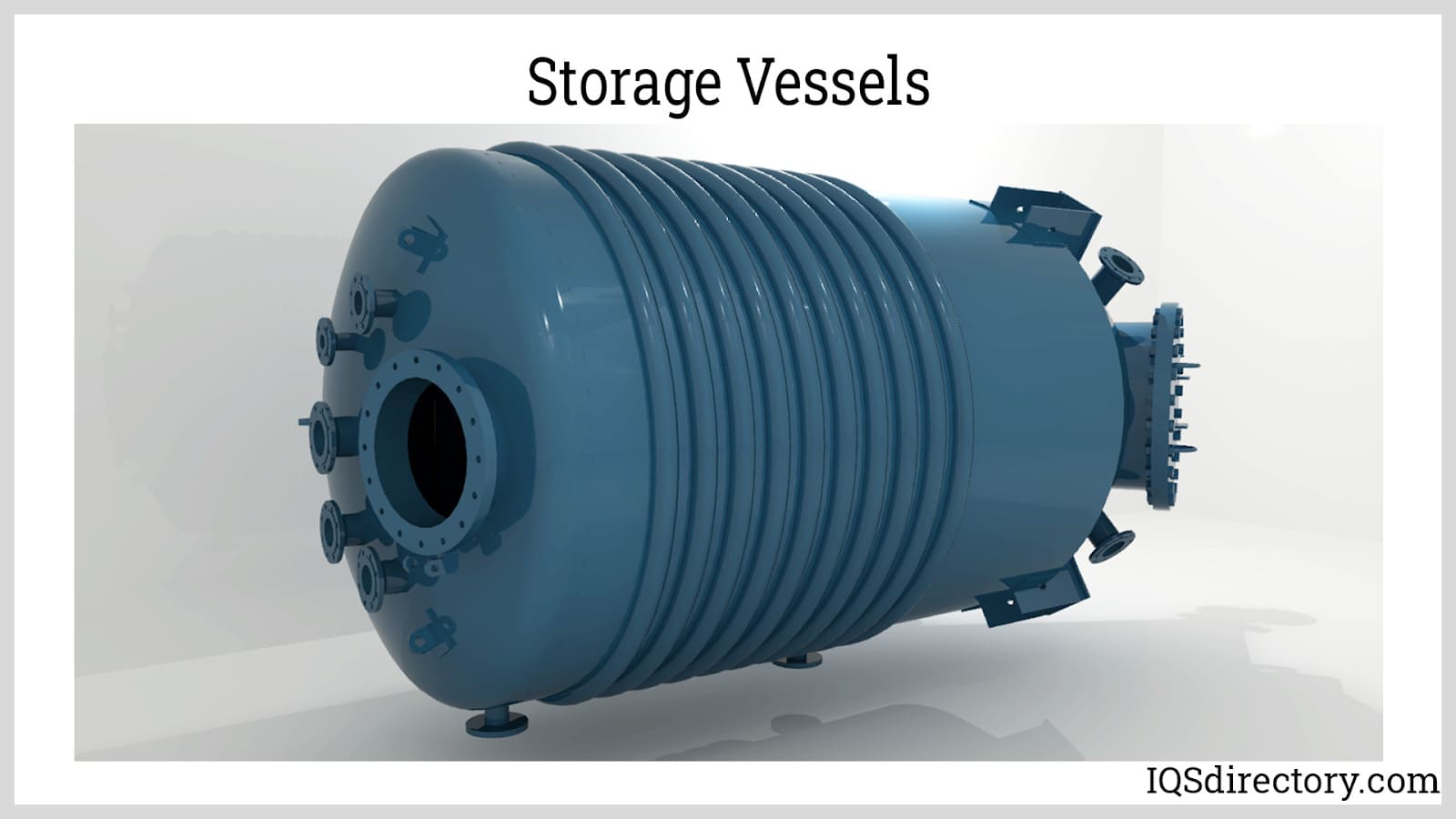

Storage Vessels: Storage vessels are pressure vessels designed for the temporary or long-term holding of liquids, vapors, and gases under pressure. These tanks are widely used across petrochemical plants, refineries, and industrial gas operations to store fluids for subsequent processing or containing finished products such as compressed natural gas (CNG), liquefied petroleum gas (LPG), and liquid nitrogen. Storage pressure vessels are engineered considering factors like maximum allowable working pressure (MAWP), temperature, and material compatibility to ensure safety and integrity.

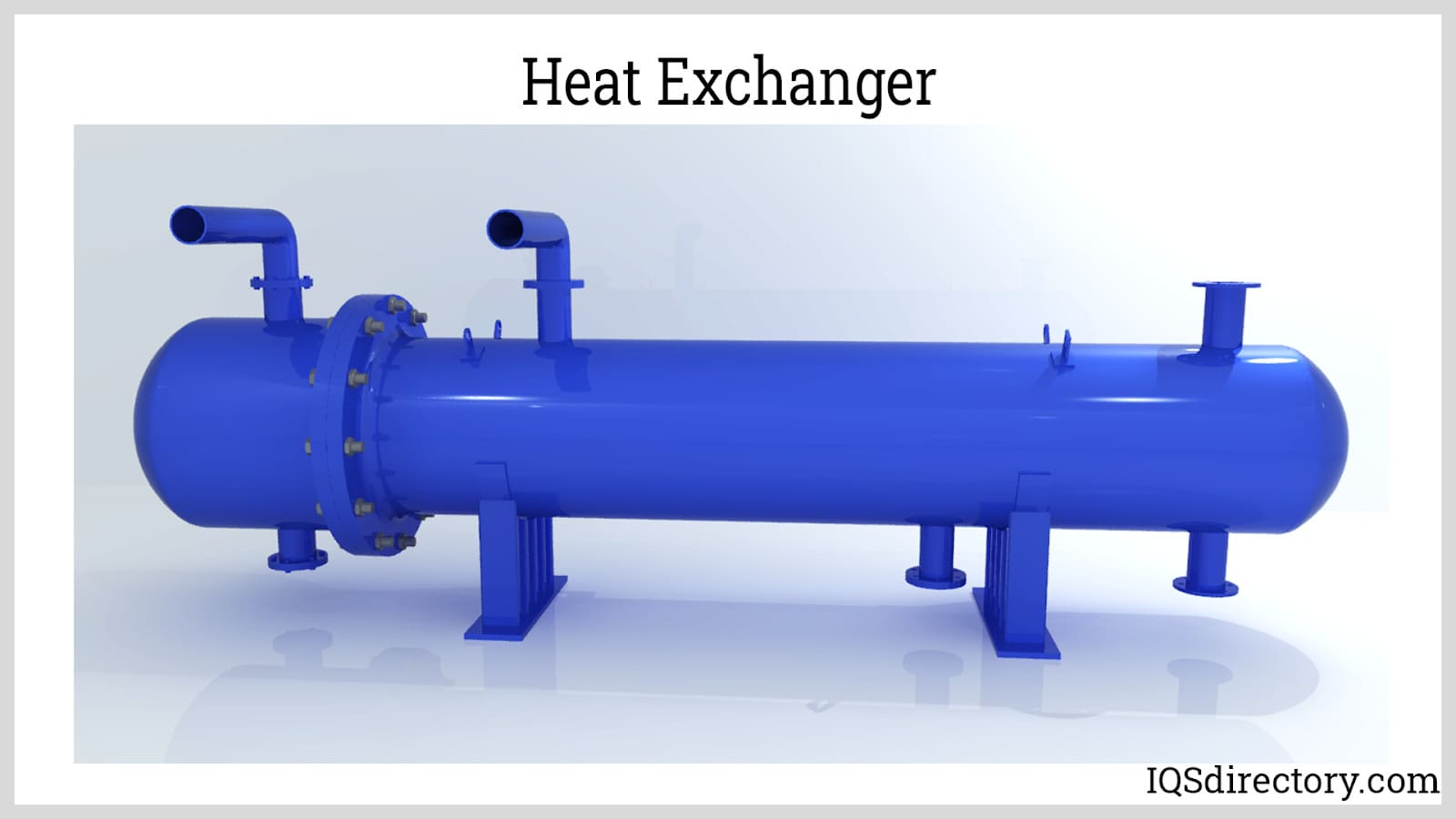

Heat Exchangers: Pressure vessel heat exchangers are used to efficiently transfer thermal energy between two or more process fluids, all while maintaining mechanical integrity under internal pressure. These units are integral in sectors such as food processing, pharmaceuticals, power plants, and bioprocessing, enabling temperature regulation and energy conservation. Industrial heat exchangers experience combined stresses from temperature gradients, thermal cycling, and internal pressurization. Compliance with standards like ASME Section VIII and rigorous material selection ensure safe operation and longevity in corrosive or high-temperature environments.

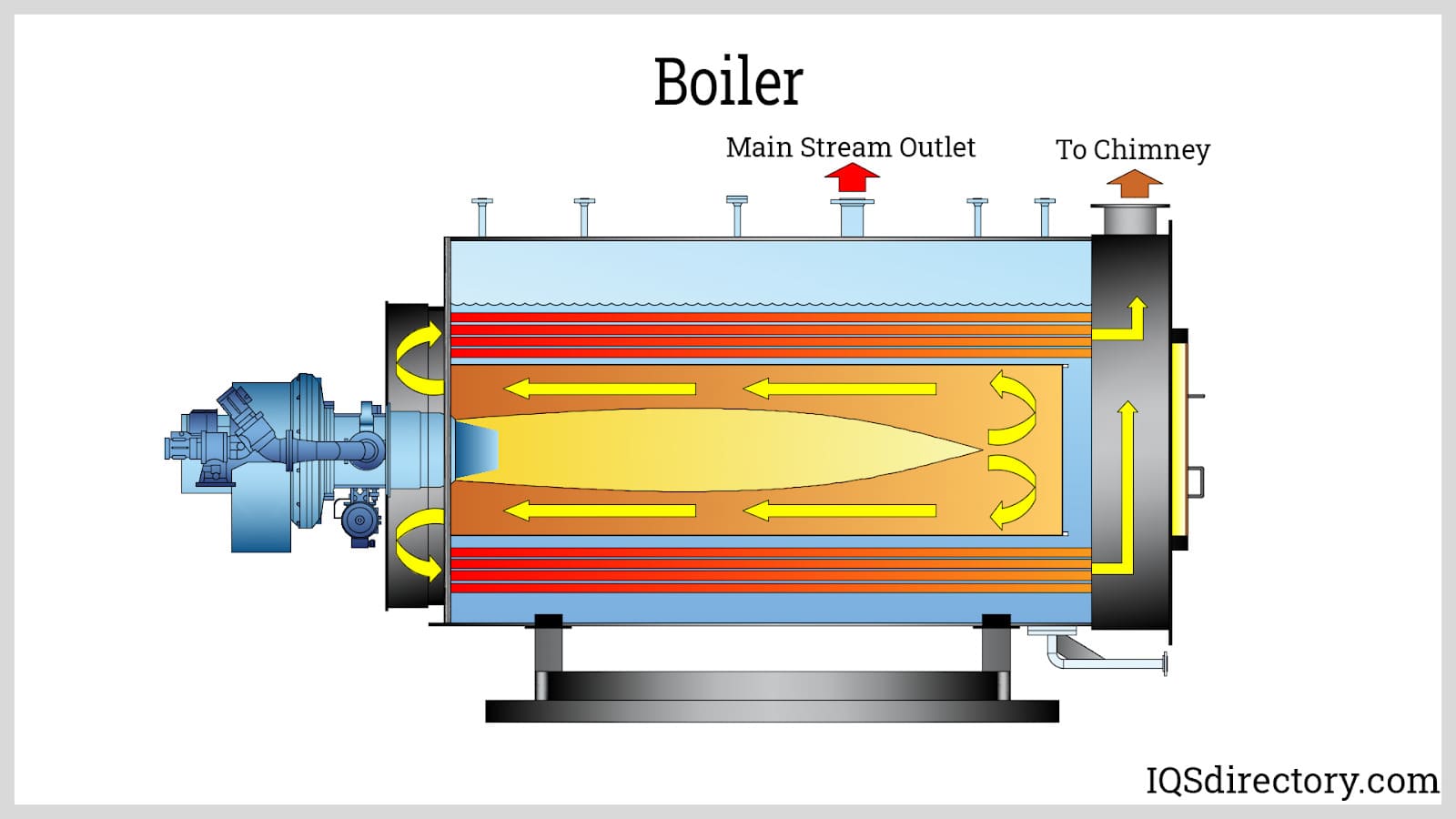

Boilers: Boilers are pressurized vessels that use fuel, nuclear, or electrical energy to generate heat. The core function of an industrial boiler is to heat water or other fluids, often inducing phase changes from liquid to vapor (steam generation). High-pressure steam produced by boilers is critical for power generation, thermal heating, and process operations. Boiler design incorporates high-strength alloy steels to withstand intense thermal and pressure stresses, and strict adherence to codes like ASME Boiler and Pressure Vessel Code ensures operational safety and efficiency. Water-tube boilers, fire-tube boilers, and electric boilers are common types adapted to specific process needs.

Process Vessels: Process vessels are a broad classification of industrial pressure vessels designed for specialized chemical or physical transformations. These include equipment for mixing, agitation, decantation, distillation, extraction, and chemical reactions. The internal operating pressure often fluctuates based on reaction dynamics, process requirements, and changes in physical state. Various subtypes of process vessels enable precise control over industrial manufacturing and material handling:

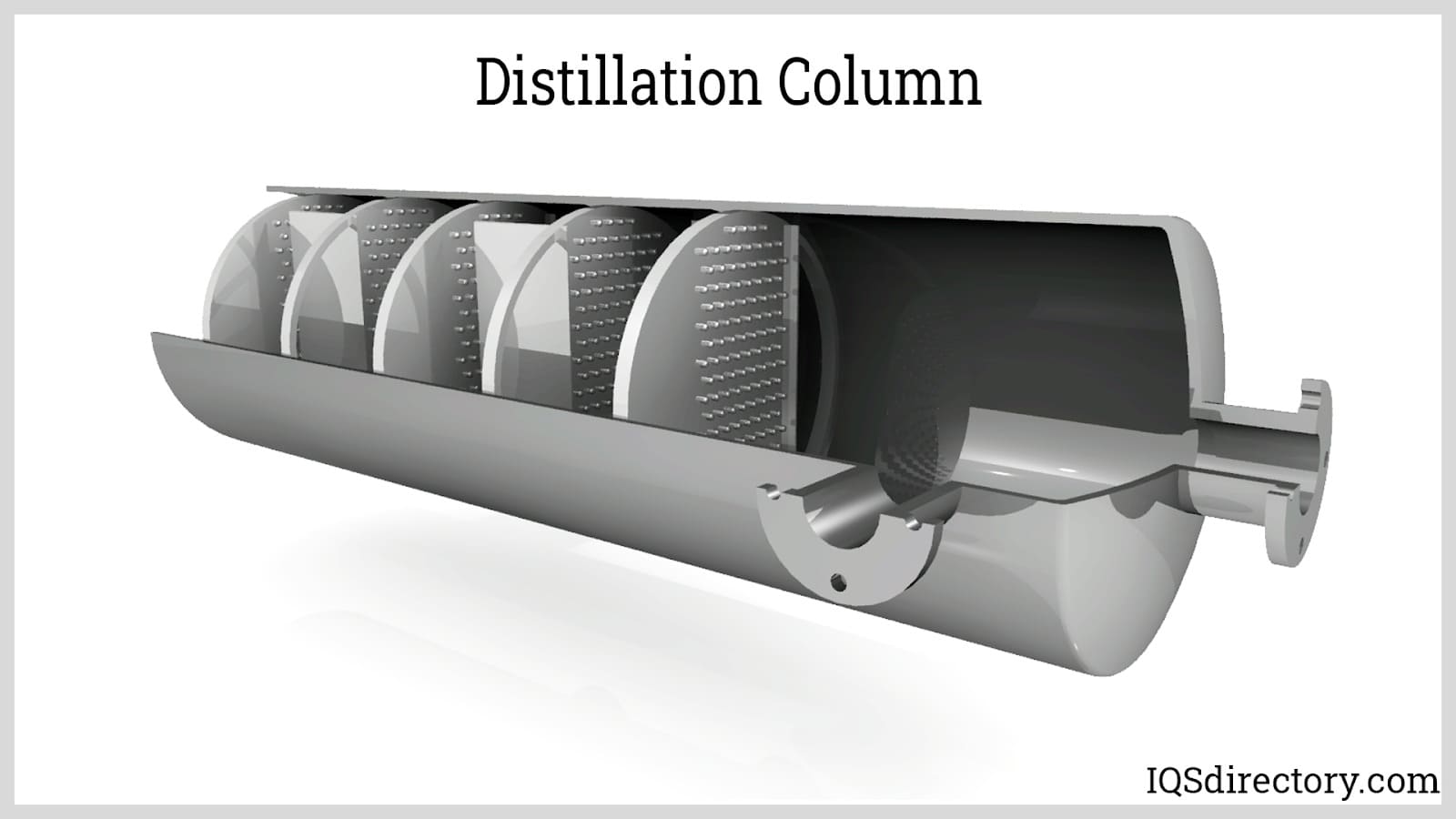

Distillation columns enable the efficient separation of mixtures based on differences in volatility. They are essential in refining, petrochemical, and pharmaceutical industries. Two major types:

Industrial mixers are specialized pressure vessels equipped with motorized blades and agitation systems. Used to homogenize, blend, or emulsify a range of liquid or semi-solid substances, mixing vessels are engineered for batch or continuous processes that may require elevated temperature and pressure. Optimized mixing enhances product consistency, quality, and process throughput.

As chemical reactions progress, internal vessel pressure may increase due to vapor or gas production, particularly at higher temperatures. Safe design and pressure relief systems are paramount to preventing over-pressurization.

The following are common chemical reactor types requiring pressure-resistance:

Jacketed reactors feature an integrated jacket for regulated heating or cooling. Circulating utilities like chilled water or steam through the jacket maintain optimal reaction temperatures, supporting both exothermic and endothermic reactions. Reactor temperature control increases product yield, prevents thermal runaway, and improves plant safety.

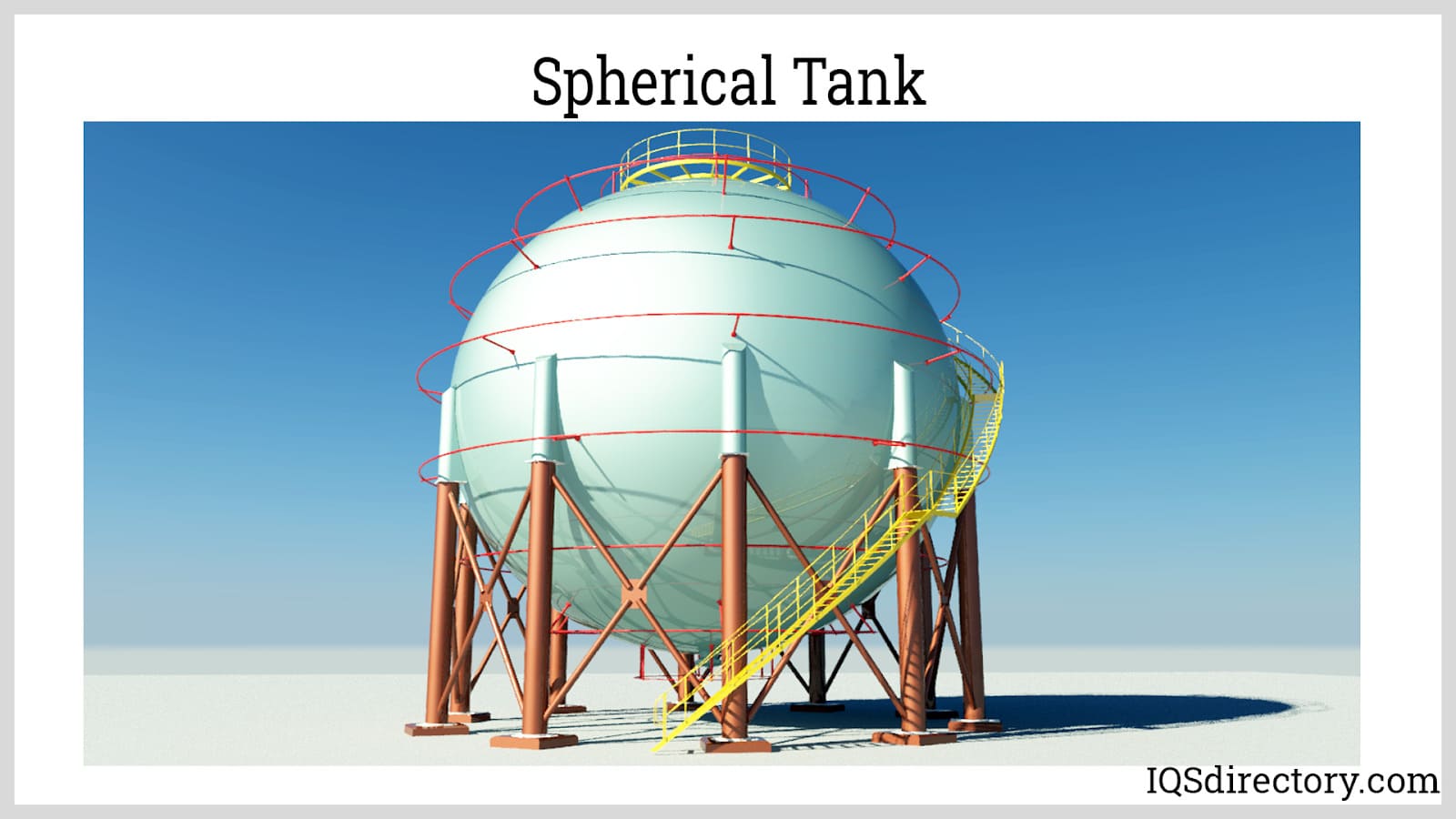

Spherical Pressure Vessels: Spherical pressure vessels, often known as \"spherical tanks\" or \"Horton spheres,\" are preferred for storing large volumes of highly pressurized gases such as LPG, LNG, and ammonia due to their uniform stress distribution and structural efficiency. Their geometry minimizes the use of construction material for a given volume and optimizes pressure resistance, leading to enhanced safety and durability. These vessels are common in gas storage terminals, chemical plants, and refineries, although fabrication is more complex than for other shapes.

Cylindrical Pressure Vessels: Cylindrical pressure vessel tanks consist of a tubular shell capped with end heads. The cylindrical configuration is the most widely used vessel shape in industrial applications due to its versatility, ease of fabrication, and cost-effectiveness. Applications include air receivers, process tanks, autoclaves, and reactor shells. However, their structure is subject to higher localized stress compared to spheres, requiring thicker walls or reinforced construction for high-pressure service.

Choices for vessel heads—critical in pressure vessel design and strength—include:

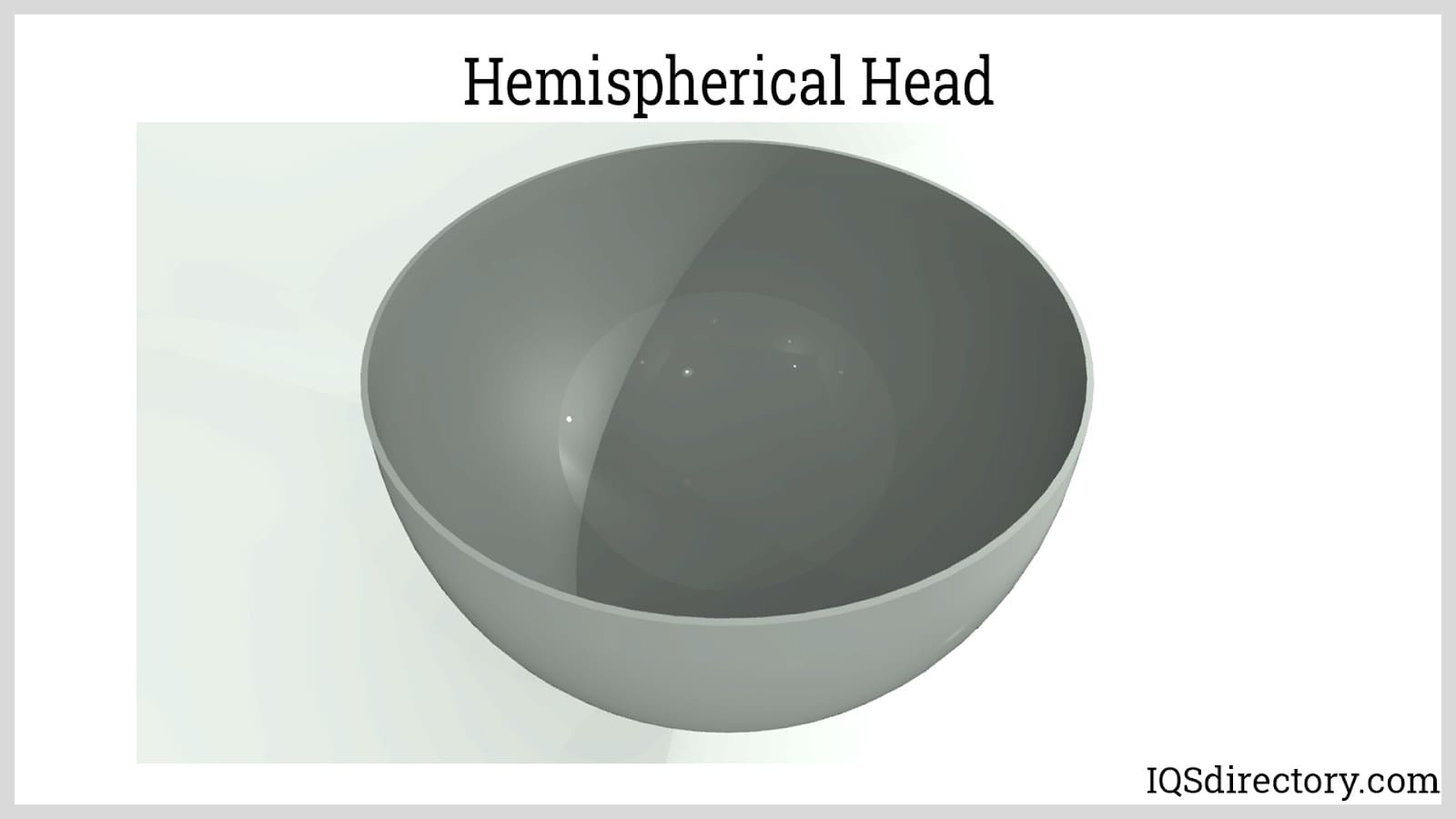

Hemispherical heads are well-suited for high-pressure applications and large-diameter pressure vessels due to their optimal geometry for uniform stress distribution. These heads allow for lower wall thickness and material cost while offering maximum volumetric efficiency.

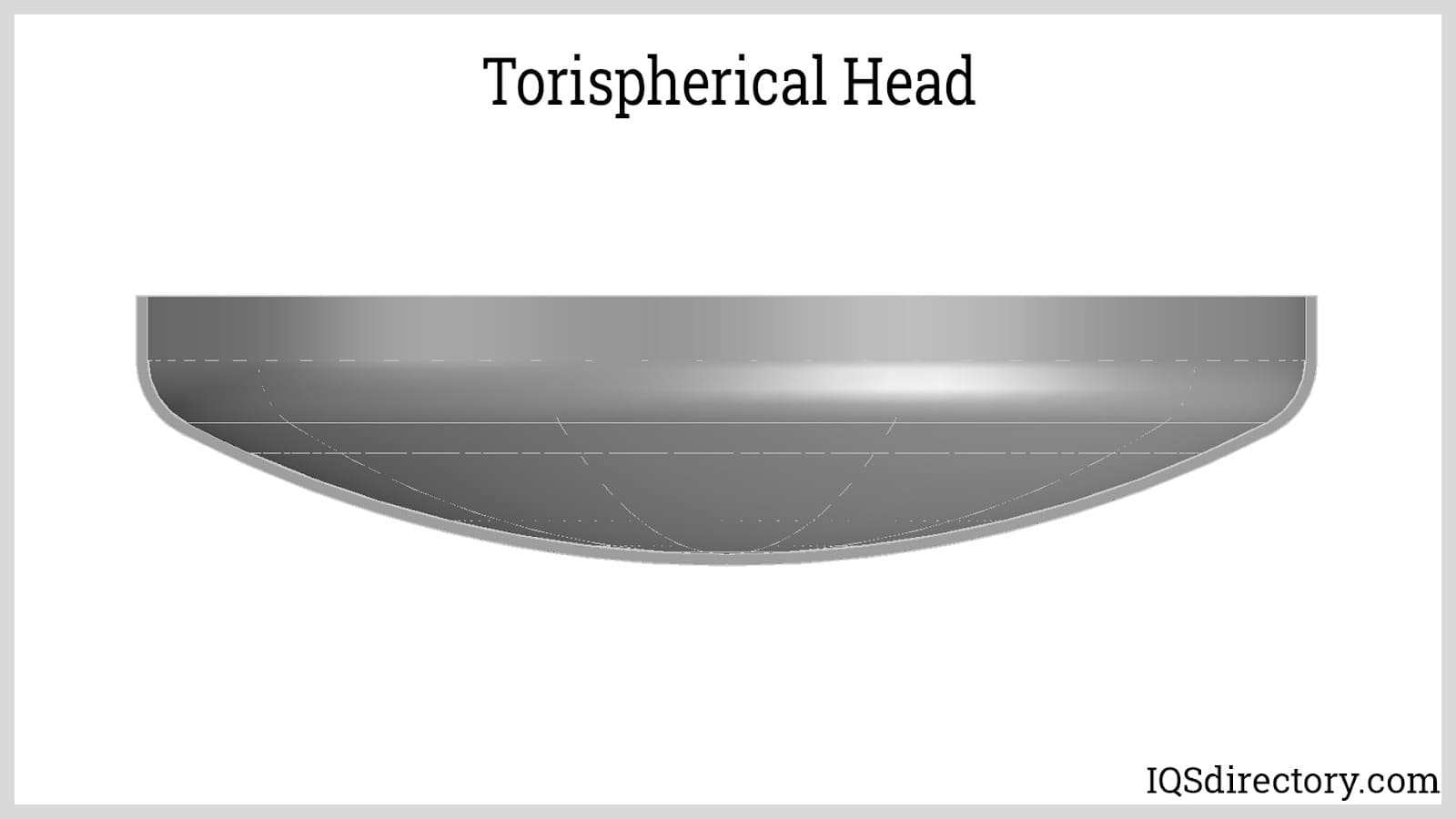

Torispherical heads provide a practical, cost-effective option for moderate-pressure applications (typically under 15 bars). With their flatter profile, they are favored in compact systems and equipment with height restrictions. Their design incorporates both crown and knuckle radii, balancing strength and manufacturability.

Ellipsoidal heads (also known as 2:1 elliptical heads) are excellent for containing high-pressure gases, as their geometry provides elevated strength and reduces required wall thickness. These heads are a standard choice for ASME-coded pressure vessels where efficiency and cost savings are important.

Cylindrical pressure vessels are installed in vertical or horizontal orientations, with the choice driven by application requirements, space limitations, and process needs. The vessel’s position impacts maintenance, mixing efficiency, drainage, and overall accessibility.

When selecting a pressure vessel, consider aspects such as operating pressure, temperature, vessel material (carbon steel, stainless steel, alloys), corrosion resistance, inspection standards (such as ASME, PED, or API), maintenance accessibility, and the intended process application. Working with leading pressure vessel manufacturers ensures compliance, custom solutions, and reliable service for your specific industry.

Selecting the optimum material for pressure vessel construction is critical for ensuring safety, performance, and cost-effective operation across industries such as oil and gas, chemical processing, pharmaceuticals, and power generation. The right choice enhances the vessel’s longevity, operational efficiency, and regulatory compliance while minimizing long-term risks and expenses. When choosing the right material for constructing pressure vessels, engineers and decision-makers should evaluate the following essential criteria:

Common pressure vessel materials—each offering unique advantages for specific operating environments—include:

Carbon Steel: Carbon steel is a widely used and cost-effective material containing up to 2.5% carbon, making it suitable for high-pressure applications requiring robust tensile strength. Carbon steel vessels deliver high performance at a relatively low cost and are commonly utilized in refineries, water treatment, and compressed air systems. However, carbon steel lacks comprehensive corrosion resistance, making it more susceptible to oxidation and rust, especially in wet or chemically aggressive environments. To enhance longevity, carbon steel tanks often require protective coatings or internal linings.

Stainless Steel: Stainless steel features a chromium content of 10.5–30% and trace amounts of nickel, granting it superior chemical and corrosion resistance. The formation of a chromium oxide passive layer shields the vessel from rust, pitting, and chemical attack, making stainless steel ideal for processing corrosive fluids, food and beverage storage, and pharmaceutical manufacturing. It offers excellent weldability, ductility, and a favorable strength-to-weight ratio with minimal wall thickness. Although typically more expensive than carbon steel, its reduced maintenance and longer service life often yield a better value over time.

Nickel Alloys: Nickel-based alloys, such as Inconel and Monel, offer robust resistance to corrosion, oxidation, and extreme temperatures, making them suited for critical applications such as cryogenic tanks, chemical processing, and offshore oil and gas storage. These alloys maintain their strength and ductility across a broad range of temperatures, minimizing risks of embrittlement or deformation. While fabrication can be challenging and costly, the investment is justified for environments requiring exceptional corrosion, thermal, and fatigue resistance for a long operational lifespan. Purity and precise alloy composition are essential to guarantee performance and safety.

Aluminum: Aluminum alloys provide a favorable strength-to-weight ratio, facilitating lightweight pressure vessel designs. They are valued for their natural corrosion resistance and ease of fabrication, reducing manufacturing complexity and costs in applications such as laboratory vessels, beverage storage, and portable compressed gas cylinders. However, limitations in strength and lower density restrict their use in very high-pressure situations. Aluminum is also less effective under extremely high temperatures compared to steel-based alternatives.

Summary: In conclusion, material selection for pressure vessels combines evaluating mechanical properties, corrosion resistance, cost-effectiveness, manufacturability, and compliance with industry standards. Consulting relevant codes and working with experienced pressure vessel manufacturers helps ensure your final choice maximizes safety, service life, and long-term value. Aligning your selection with the specific operational environment—pressure, temperature, chemical exposure, and inspection requirements—will yield the best results, minimizing risk and maximizing operational efficiency. To learn more about best practices for pressure vessel design, fabrication, and inspection, be sure to consult industry resources and reputable manufacturers.

A pressure vessel is an enclosed structure designed to hold liquids, gases, or vapors at pressures different from ambient pressure. They are widely used in petrochemical, oil and gas, chemical processing, food manufacturing, and power generation industries.

The ASME Boiler and Pressure Vessel Code (BPVC) provides comprehensive requirements for design, construction, inspection, and certification. API 510 covers in-service inspection, rating, repair, and alteration to ensure safe operation and longevity.

Pressure vessels are classified by function—storage vessels, heat exchangers, boilers, process vessels—and by geometry, such as spherical and cylindrical shapes. Each type addresses specific operational, safety, and process requirements.

Material selection depends on strength, pressure ratings, corrosion resistance, cost, weldability, regulatory compliance, temperature limits, and availability. Applied standards and process requirements also play crucial roles in final material choice.

Spherical tanks provide uniform stress distribution and optimal pressure resistance, making them ideal for storing large volumes of highly pressurized gases such as LNG and ammonia in industrial terminals.

Vertical vessels save floor space and enhance mixing or separation, while horizontal vessels are used where accessibility, cleaning, and reduced fluid velocity are needed. Orientation is selected based on process needs and space constraints.

In designing a pressure vessel, the following parameters are essential for determining the wall thickness of the shell and heads:

Design Pressure: The design pressure is a value in which the vessel specifications are calculated. It is derived from the maximum operating pressure, which is the anticipated surge in pressure during upset conditions such as start-ups, emergency shutdown, and process abnormalities. It is always higher than the maximum operating pressure. The pressure relief system of a vessel is also based on this parameter to minimize the risk of explosions. According to Towler, the design pressure should be overdesigned by 5-10% from the maximum operating pressure.

For vessels that potentially can experience vacuum pressure, the design pressure must be set to resist one full vacuum (-14.7 psig).

Maximum Allowable Working Pressure (MAWP): The MAWP is the highest permissible pressure measured at the top of the equipment at which the vessel must operate based on its design temperature. It is the highest pressure that the weakest part of the vessel can handle at its design temperature. MAWP value is designated by the American Society of Mechanical Engineers (ASME) and is used by industries to ensure that the vessel will not operate beyond this value to establish safety protocols and prevent explosions.

MAWP is different from the design pressure. MAWP is an extensive property that is based on the physical limitations of the material. Corrosion and wear lower the MAWP of the material. The design pressure, on the other hand, is based on the operating condition of the process, and it may be lower than or equal to the MAWP.

Design Temperature: The maximum allowable stress is highly dependent on the temperature, as strength decreases with increasing temperature and becomes brittle at very low temperatures. The pressure vessel should not operate at a higher temperature where the maximum allowable pressure is evaluated. The design temperature is always greater than the maximum operating temperature and lesser than the minimum temperature.

There are several rules of thumb in evaluating the design temperature. Towler suggests that the design temperature must be 50°F from the maximum operating temperature and -25°F from the minimum operating temperature. For Turton, a maximum allowance of 25°C must be given for vessels that will be operating between -30 to 345°C. The disturbances that have a drastic influence on the temperature of the pressure vessel must be considered by the designer.

| Category A | Longitudinal or spiral welds in the main shell, necks or nozzles, or circumferential welds connecting hemispherical heads to the main shell, necks or nozzles. |

| Category B | Circumferential welds in the main shell, necks or nozzles or connecting a formed head other than hemispherical. |

| Category C | Welds connecting flanges, tubesheets or flat heads to the main shell, a formed head, neck or nozzle. |

| Category D | Welds connecting the communicating chambers or nozzles to the main shell, to heads or to necks. |

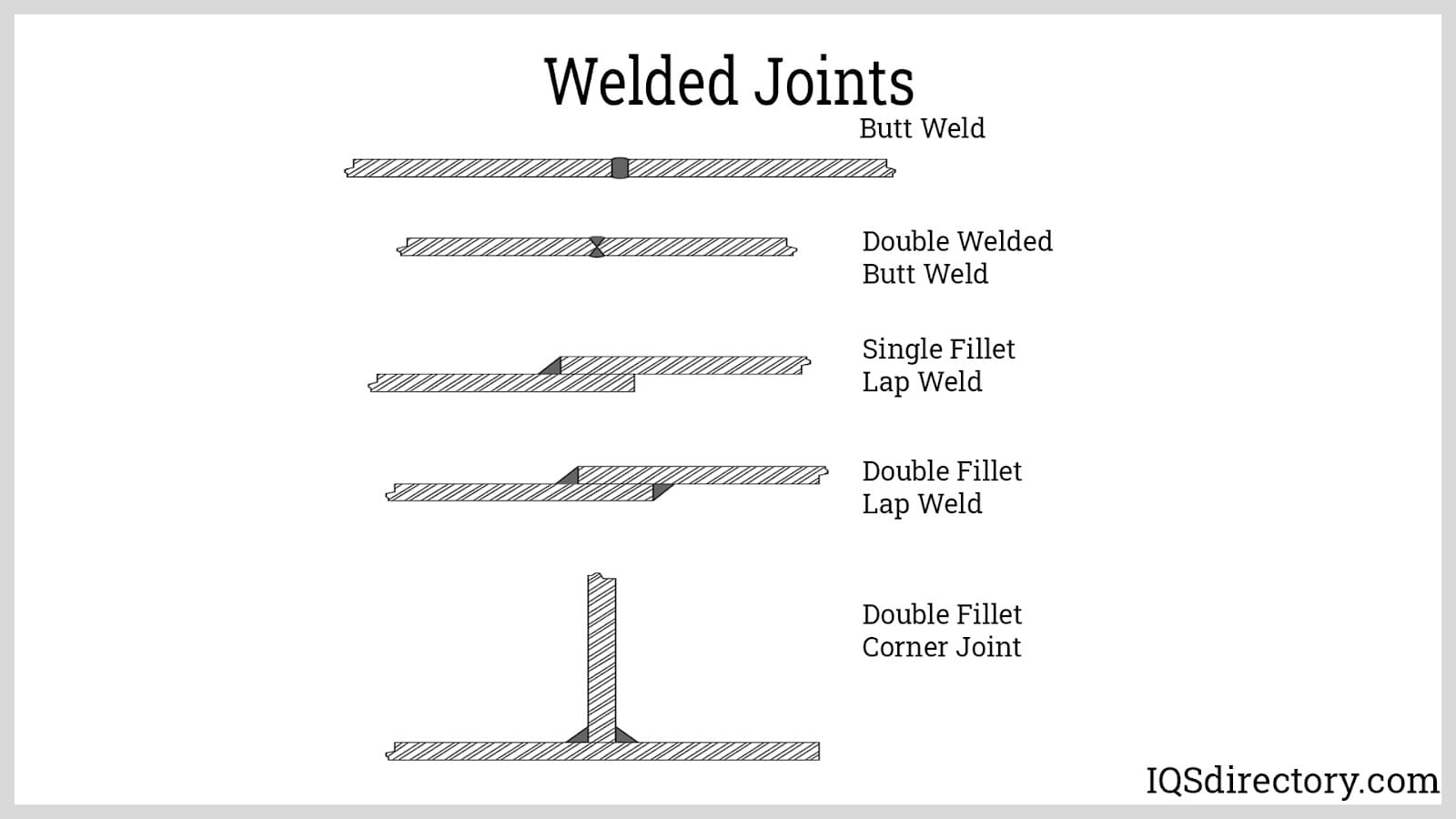

The joint efficiency is the ratio of the strength of the welded plate to the strength of the unwelded virgin plate. Generally, the strength is lower at the welded joint. Welded joints without further inspection and radiographic testing are assumed to be weaker due to defects such as porosity are potentially present. Joint efficiencies allowed under ASME BPV Code Sec. VIII D.1 is summarized in the table below:

| Joint Description | Joint Category | Joint Efficiency (Based on degree of radiographic examination) | ||

|---|---|---|---|---|

| Full | Spot | None | ||

| Double-welded butt joint or equivalent | A, B, C, D | 1.0 | 0.85 | 0.70 |

| Single-welded butt joint with backing strip | A, B, C, D | 0.9 | 0.8 | 0.65 |

| Single-welded butt joint without backing strip | A, B, C | NA | NA | 0.60 |

| Double full fillet lap joint | A, B, C | NA | NA | 0.55 |

| Single full fillet lap joint with plug welds | B, C | NA | NA | 0.50 |

| Single full fillet lap joint without plug welds | A, B | NA | NA | 0.45 |

The vessel's shell and heads are fabricated by forging, rolling, and welding metal sheets. The wall thickness of these components is determined through detailed calculations, taking into account the previously mentioned factors. To ensure the pressure vessel functions effectively, various auxiliary equipment, devices, and accessories are also installed:

Post-weld heat treatment is performed to alleviate stresses induced during the welding and forming processes.

Pressure vessels can be fabricated either on-site or in a shop. Field-erected pressure vessels are too large to be assembled in a workshop and transported as a whole, so their parts are individually fabricated in a shop and then transported to the installation site. Assembly, welding, finishing, and accessory installation occur on-site. In contrast, shop-erected pressure vessels are smaller and can be fully assembled within a manufacturing facility. Once assembled, these vessels are transported to the site where only the installation of piping and minor adjustments are needed. The major phases of fabrication are completed in the shop before the vessel is delivered.

To verify the reliability of a pressure vessel, the following testing methods are utilized:

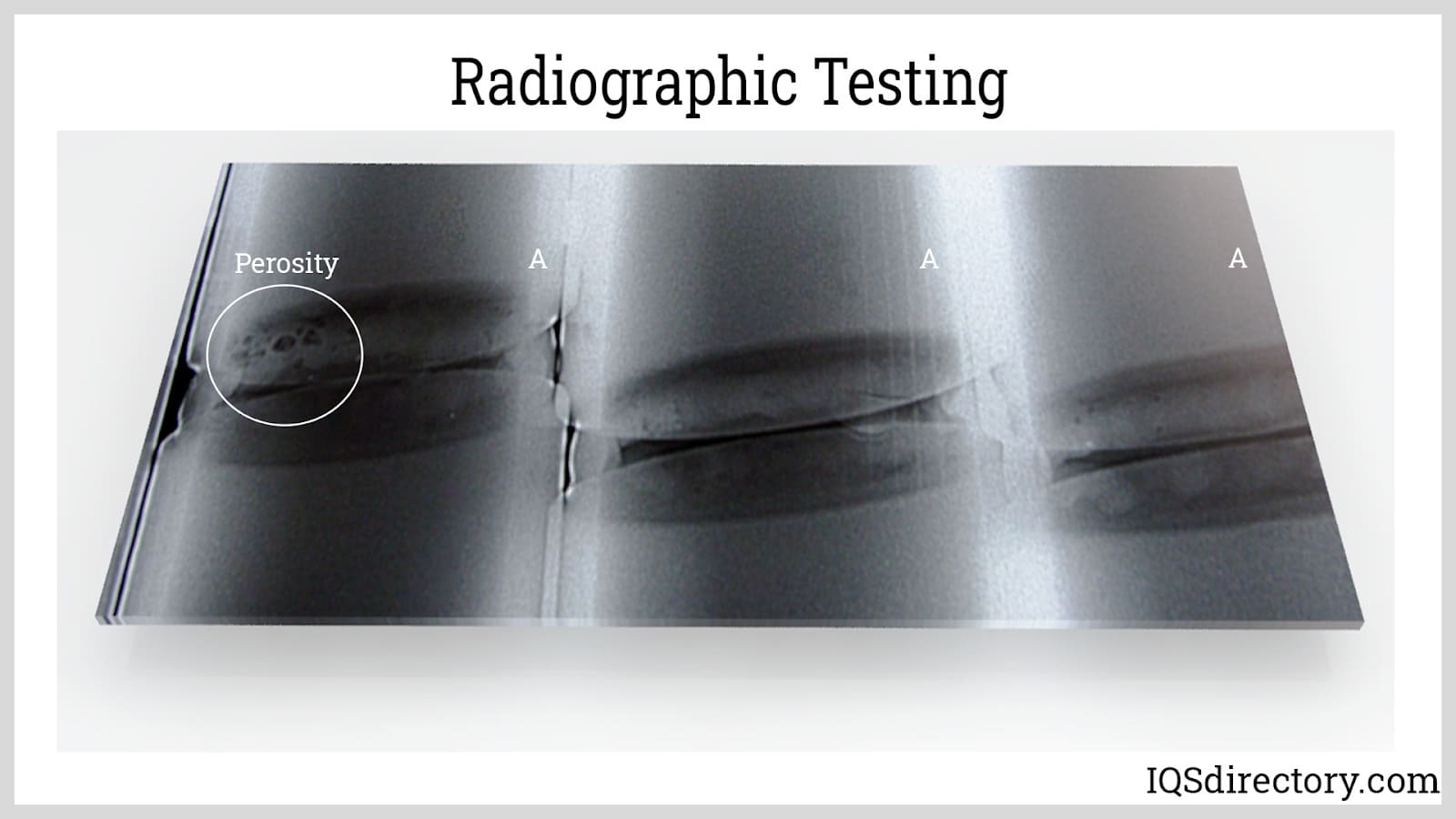

Radiographic Testing utilizes x-rays or gamma rays to produce an image of a pressure vessel‘s surface and subsurface. The reflected rays will be distorted once it passes any discontinuities, holes, and difference in density and will be exposed in the film. Radiographic testing is highly reproducible and requires minimal surface preparation. However, it is more expensive and requires a highly skilled operator to handle ionizing radiation.

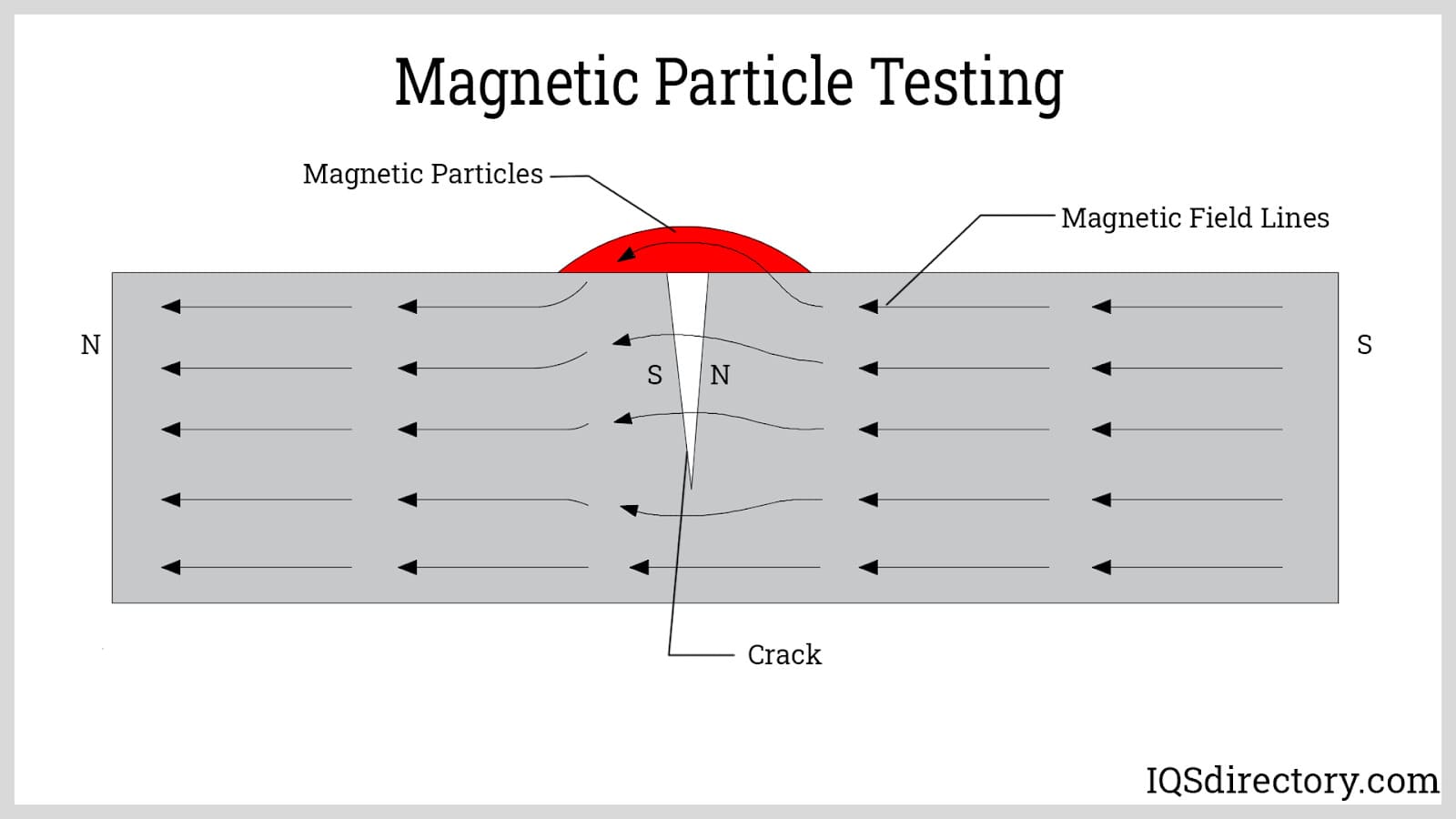

Magnetic Particle Testing uses magnetic current to detect discontinuities on the surface in ferromagnetic materials. The inspector runs a magnetic current through the pressure vessel between two probes. If the material is defect-free, the magnetic flux flows through the material without any interruption. However, if cracks or any other imperfections are present, the magnetic flux leaks out of the material. The imperfection will be more visible once ferromagnetic particles, either in a liquid suspension or powdered form, are applied to the vessel.

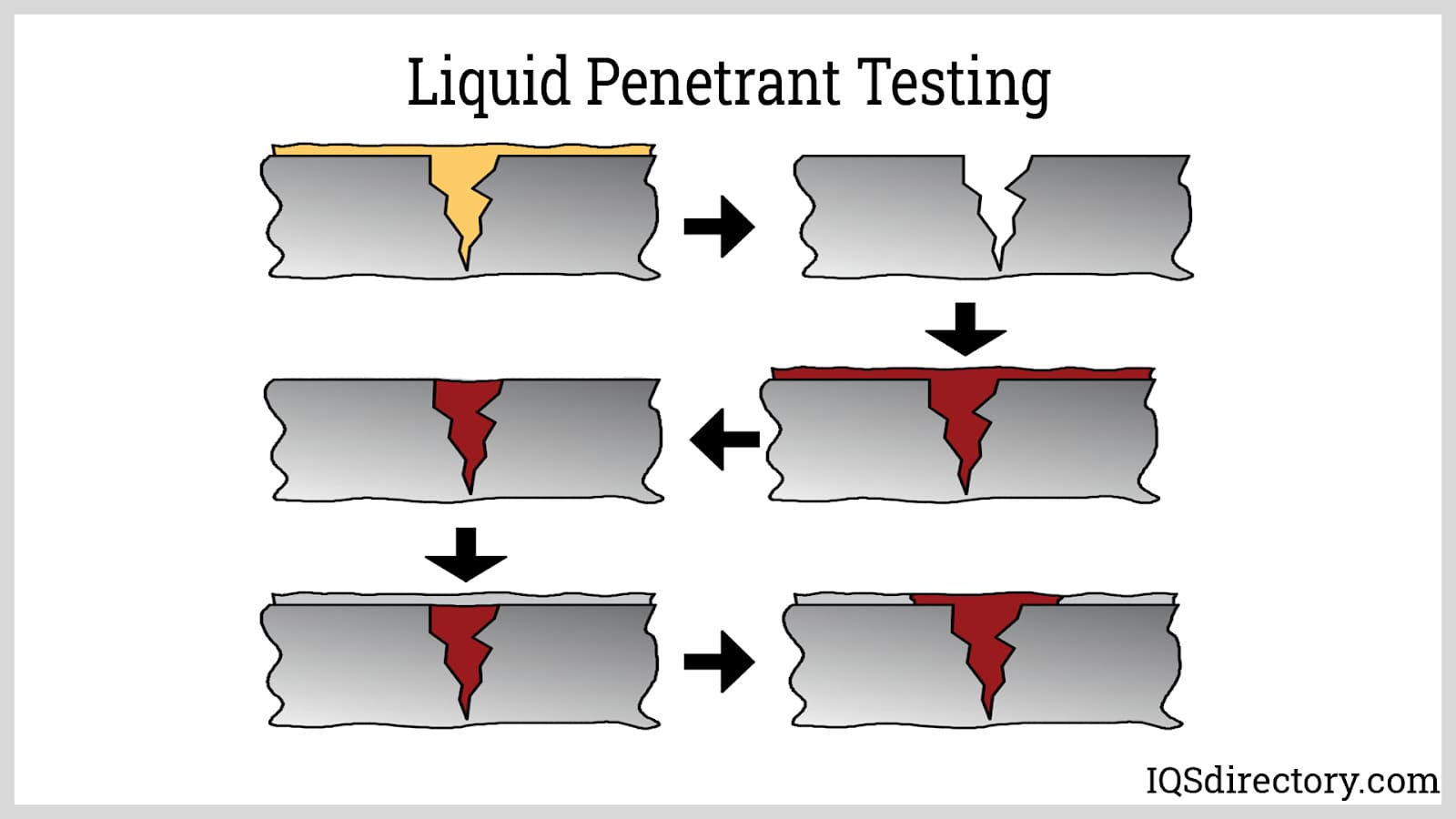

Liquid Penetrant Testing is commonly used on welded seams and plates. The inspector applies a small amount of liquid, called the penetrant, to an area with a possible flaw. The penetrant is allowed to settle after spraying and then wiped to clean the excess penetrant on the surface. The developer is then applied to reveal the penetrant that has seeped into the cracks.

Pressure tanks are vessels that are used to store, hold, and/or convey gasses, vapors and fluids at pressures greater than atmospheric pressure, also known as high pressures...

Stainless steel tanks are widely used in food, beverage, dairy, medicine, cosmetics, and other manufacturing processes where cleanliness and purity are important. These are also used in industrial plants for storing chemicals and gases where strong resistance from chemical degradation is required...