Agitators

Agitators are equipment used in homogenizing media inside a tank. It works by rotating the impeller at its immersed end at a controlled speed or revolutions per minute (rpm). The work exerted by...

Please fill out the following form to submit a Request for Quote to any of the following companies listed on

This article takes an in-depth look at homogenizers.

Read further to learn more about topics such as:

A homogenizer is a specialized mixing device designed to create a uniform and consistent blend by forcing substances through a restricted passage. Various forces such as turbulence and cavitation, along with high pressure, are applied to homogenize the solution contents evenly. Homogenizers are equipped with a positive displacement pump and a homogenizing valve configuration. The pump propels the material under pressure through a small gap situated between the valve seat and valve itself. This pressure-induced flow and subsequent turbulence ensure thorough mixing. Many industries depend on homogenizers for producing stable, uniform, and reliable products, beyond just mixing. Homogenizers are also used for emulsifying, suspending, grinding, dispersing, and dissolving materials. Industries like pharmaceuticals, beverages, and chemicals capitalize on homogenizers for enhancing product quality and consistency.

Homogenizers are frequently paired with high shear mixers, batch mixers, and paddle mixers, and are installed downstream to achieve finer mixtures. Some homogenizers, however, have limitations when it comes to processing materials with highly coarse particles, as this can lead to increased energy use, reduced flow rate, heat buildup, and accelerated wear on materials. Upstream mixers help condition and prepare materials through premixing before the homogenization process begins.

The invention and evolution of homogenizers started in the early 20th century with Auguste Gaulin’s groundbreaking design for milk homogenization. His apparatus included a three-piston positive displacement pump and capillary tubes at the outlet, which acted as throttling devices, converting fluid pressure into velocity. Consequently, milk droplets were driven against a concave valve located downstream from the capillary tubes.

Subsequent refinements in homogenizer technology replaced multiple capillary tubes with a singular, narrow tube. The key innovation was the narrow gap inside this tube, where the primary homogenization process took place. This advancement led to various gap geometries, further expanding and improving the equipment's range of applications and effectiveness.

Over the years, several theories have emerged to explain the science of the homogenization process, especially in the context of high pressure homogenizers. Homogenization is a critical engineering process in a wide variety of industries—including food and beverage production, pharmaceuticals, cosmetics, biotechnology, and chemical processing—driven by the need to achieve consistently fine particle or droplet size distribution in fluid mixtures. The two most widely accepted theories describing how homogenizers operate are globule disruption by turbulence and cavitation. These foundational principles reveal how homogenizers use mechanical forces to achieve stable emulsions and suspensions.

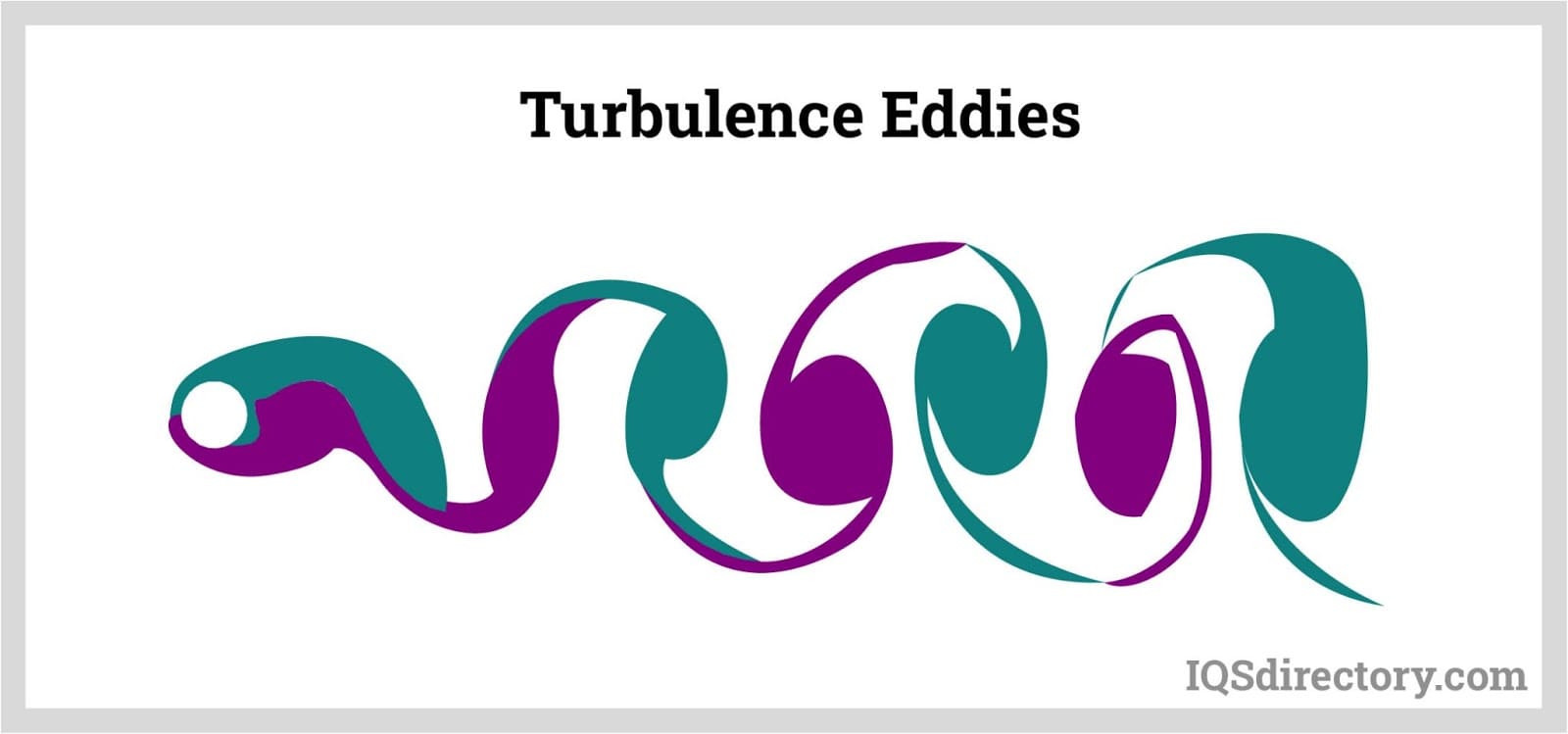

The globule disruption by turbulence theory suggests that as a liquid jet exits through a narrow gap or valve, intense turbulence generates myriad small eddies or micro whirls. Under increased pressure, the velocity of these jets rises, increasing the energy and size of the eddies. When droplets within these turbulent flows collide, they deform, elongate, and break into smaller, more uniform particles. The extent of reduction in droplet or particle size, often measured as particle size distribution, typically correlates directly with the pressure applied during the homogenization process—making pressure optimization essential for achieving desired product uniformity.

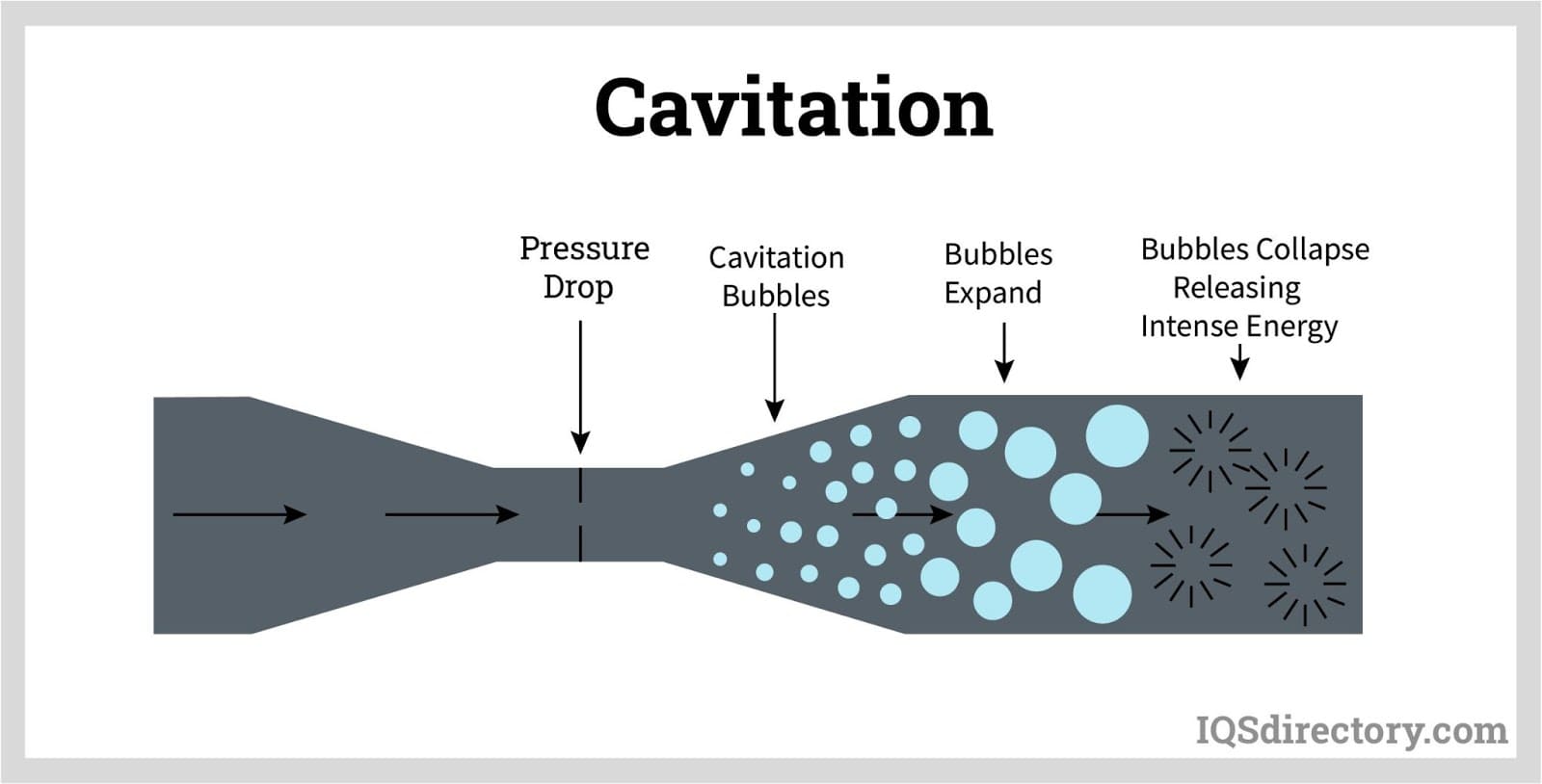

In contrast, cavitation theory explains how sudden pressure changes during homogenization form vapor bubbles or cavities in the liquid. When these bubbles collapse, or cavitate, they release intense localized energy—creating high-speed micro-jets that powerfully impact and break apart suspended droplets, fat globules, or solid particles. This energy disperses particles, resulting in a finer, more homogenous mixture. The synergy between turbulence and cavitation is essential for efficient mechanical disruption in both high-pressure and ultrasonic homogenizers.

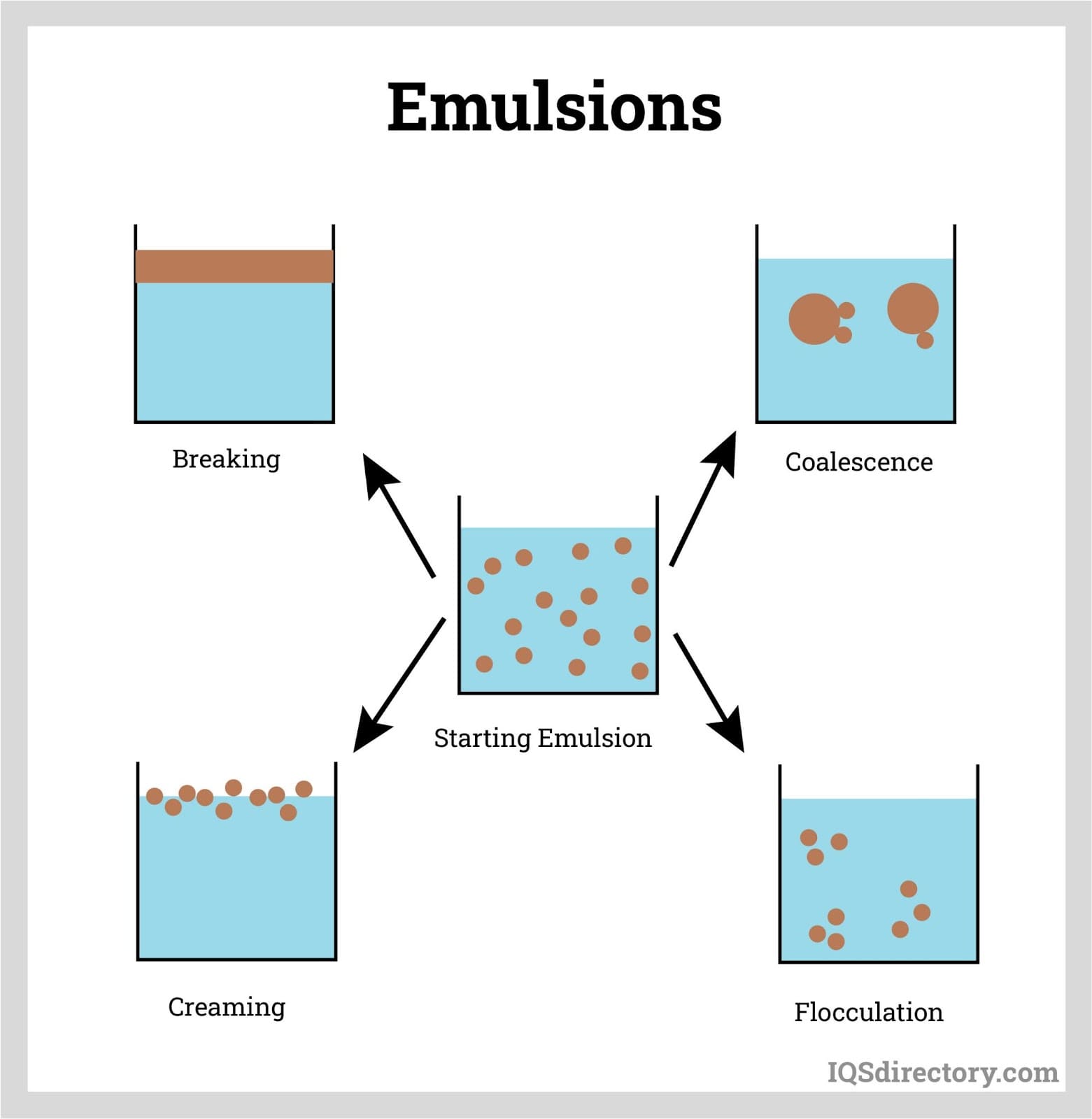

Homogenizers are commonly used to mix and stabilize emulsions and suspensions. An emulsion is a heterogeneous mixture comprising two or more immiscible liquids—such as oil and water—that resist mixing due to factors like interfacial surface tension, molecular polarity, and viscosity. Homogenization enables the even dispersion and reduction of droplet size, transforming typical emulsions into colloidal solutions with improved stability, texture, and shelf-life. Common examples include milk, mayonnaise, paints, and pharmaceutical creams. This process is fundamental to the food and dairy industries, where micro- and nano-emulsions are required to meet quality and safety standards.

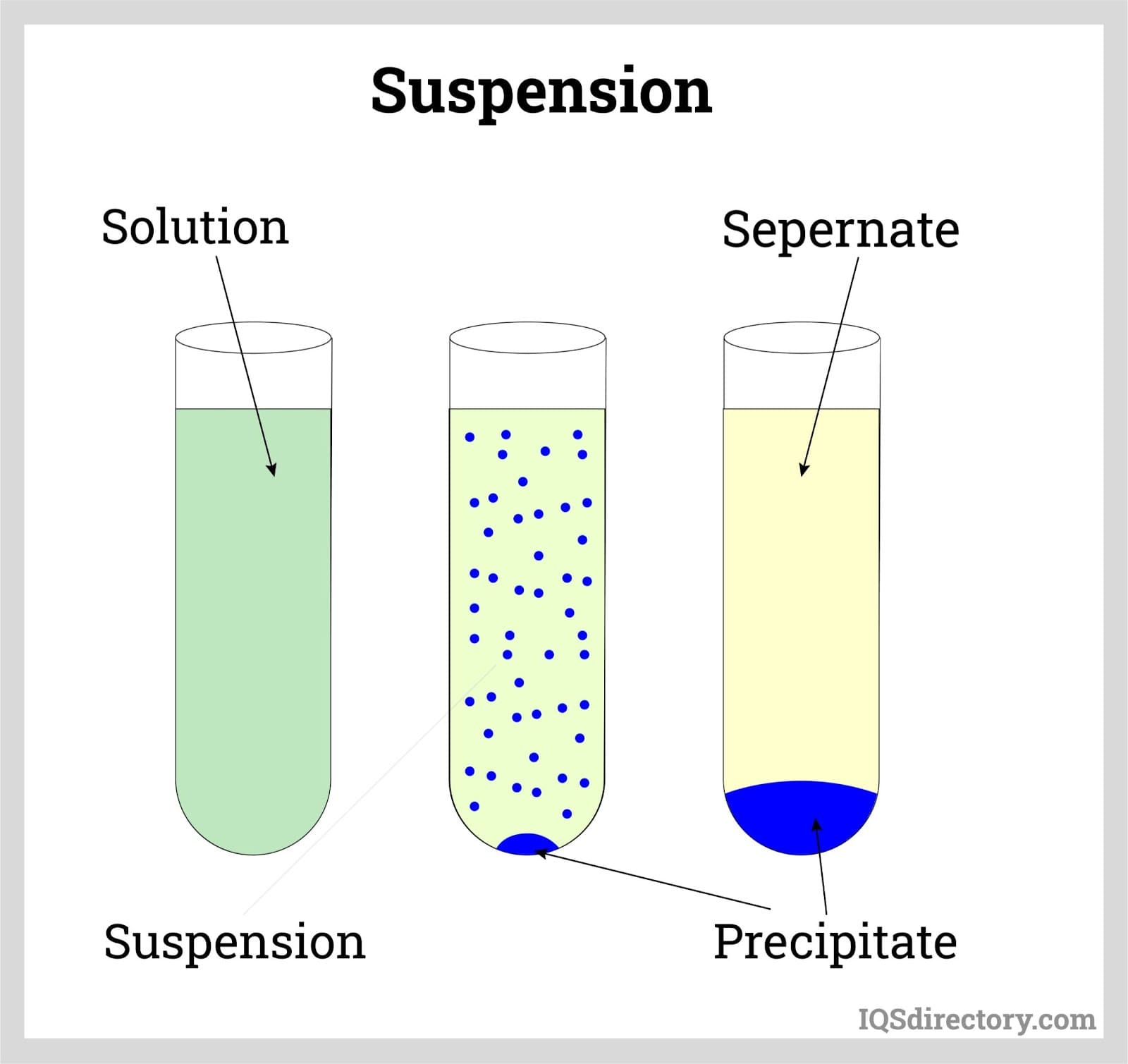

A suspension is a mixture containing dispersed solid particles that do not dissolve and typically settle over time, resulting in phase separation. In suspensions, particle sizes range from visible aggregates to fine particulates—often hundreds to thousands of times larger than in true solutions. These non-homogeneous systems, such as pharmaceutical suspensions, pigment dispersions, and wastewater treatments, require industrial homogenizers to reduce particle size and enhance product uniformity by preventing sedimentation, separation, and agglomeration.

Particles in suspensions can vary widely in size, with some large enough to be seen clearly. Through mechanical shear, impact, and high pressurization, a homogenizer can effectively disperse even coarse particles, ensuring optimal integration of solids with liquids. This results in improved product consistency, bioavailability, and process yield—benefits particularly valued in chemical, biotech, and laboratory sample preparation settings.

Understanding the behavior of different heterogeneous mixtures—such as emulsions, suspensions, and colloids—processed by a homogenizer clarifies its operational value across diverse applications. Homogenization technology works by breaking down and subdividing dispersed phase particles, often via micronization or even nano-milling, into extremely small sizes, while rapidly and evenly distributing them throughout the continuous phase. The homogenizer continuously prevents particle agglomeration and precipitation, resulting in enhanced product stability and improved physical properties, such as increased viscosity and uniform texture.

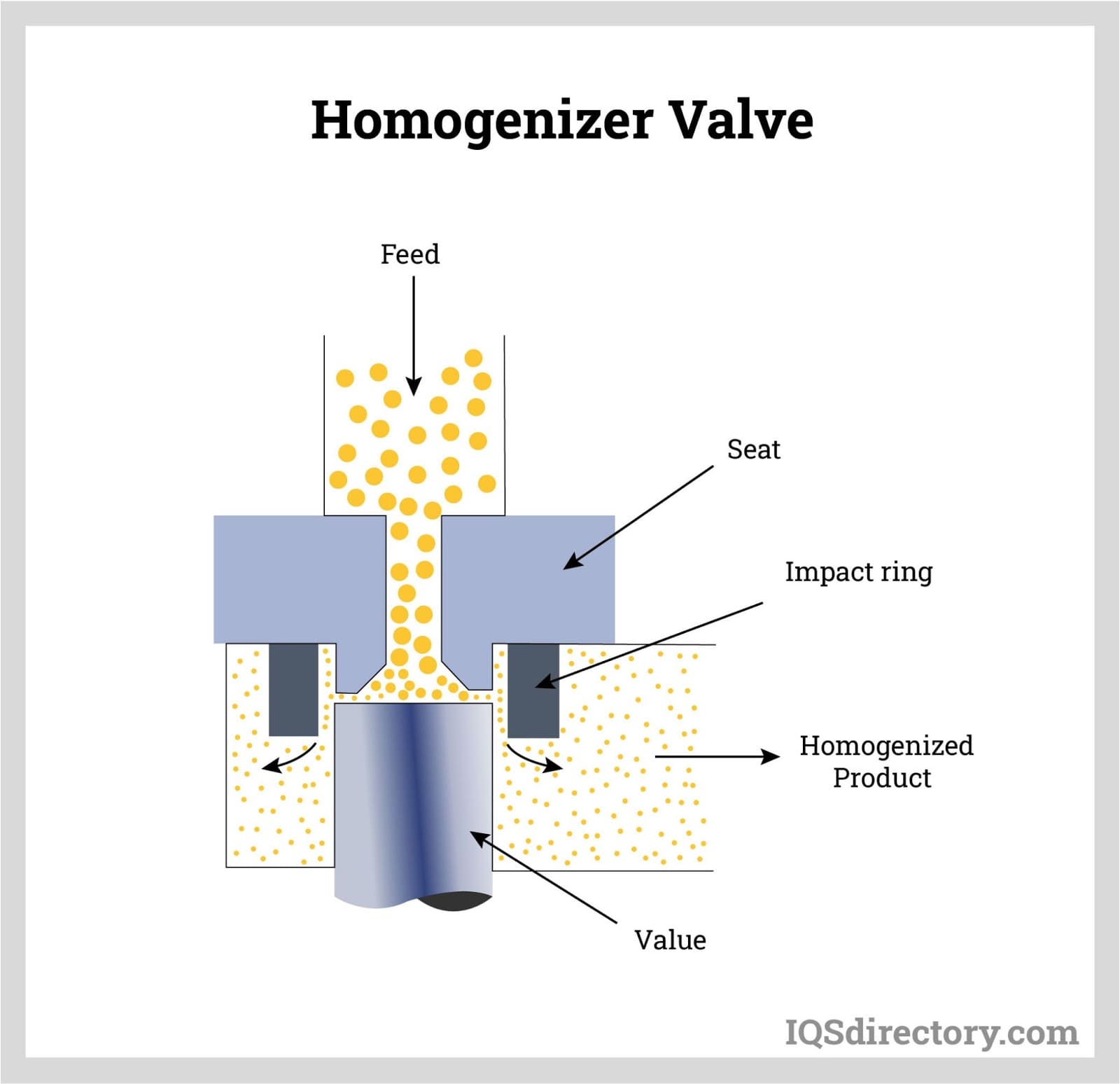

Homogenization primarily occurs within the homogenizer valve, a critical component that determines efficiency and product quality. Early homogenizer valves utilized a capillary tube and a concave valve seat, constricting fluid flow to convert pressure into high-velocity kinetic energy and providing an impact surface for disintegration. Modern high-pressure homogenizers utilize advanced valve designs, such as flat, conical, or multi-orifice seats, to precisely control the gap and optimize flow conditions for a wide range of product viscosities and required particle size reduction. These technological advances allow for customizable homogenizing conditions, energy efficiency, and improved cleaning protocols.

The physical processes that drive homogenization include three core principles:

Shearing in liquids stems from friction between adjacent molecules, governed by the fluid’s viscosity. Under flow, particularly between fixed surfaces and moving fluid layers (as in rotor-stator homogenizers), velocity differences create intense shear forces. Large droplets or aggregates trapped between fluid layers moving at different speeds are stretched and broken into smaller particles by mechanical and hydraulic shear. The result is improved dispersion and smaller particle sizes, essential for stable emulsions and suspensions required in pharmaceutical drug formulations, nanoemulsions, and cosmetic creams.

Cavitation arises from a significant drop in fluid pressure as liquid passes through the homogenizer valve at high velocity. A powerful industrial pump introduces the fluid under pressure; as it moves through the narrow gap, pressure converts to kinetic energy, potentially dropping below the fluid’s vapor pressure to create transient vapor cavities. The implosion of these vapor bubbles produces high-energy shockwaves that forcibly break apart suspended particles and droplets, accelerating homogenization. Efficient cavitation amplifies the effectiveness of cell lysis, lump-free blending, and size reduction processes fundamental to biotechnology and nanotechnology applications.

The final principle is turbulence. At elevated flow velocities and through restrictive valve designs, fluid motion becomes highly chaotic and irregular, filled with random eddies and vortices (turbulent flow). These swirling currents dissipate kinetic energy through collisions and fluctuations, exerting physical forces that break up droplets and particles further. The degree of turbulence, regulated by the homogenizer settings, largely determines the final particle size, emulsion stability, and product consistency—vital parameters in quality control for food processing, chemical engineering, and pharmaceutical manufacturing.

The relative influence of shearing, cavitation, and turbulence on the homogenization process depends on several key factors: homogenizer valve design, process pressure, fluid viscosity, temperature control, and feed composition. Most research concludes that turbulence typically serves as the dominant mechanism, especially in high-pressure homogenizers, but advanced ultrasonic and microfluidizer systems may prioritize different principles for specialized results.

It’s important to note that while these physical effects are commonly produced by traditional piston-type or high-pressure homogenizers, several alternative homogenizing technologies—including ultrasonic homogenizers, bead mills, and high-shear mixers—may employ different mechanical actions yet accomplish similar outcomes in terms of particle size reduction, cell disruption, and emulsion formation. Choosing the right homogenizer and operating parameters ensures optimized product quality, processing efficiency, and cost-effectiveness tailored to each industry’s requirements.

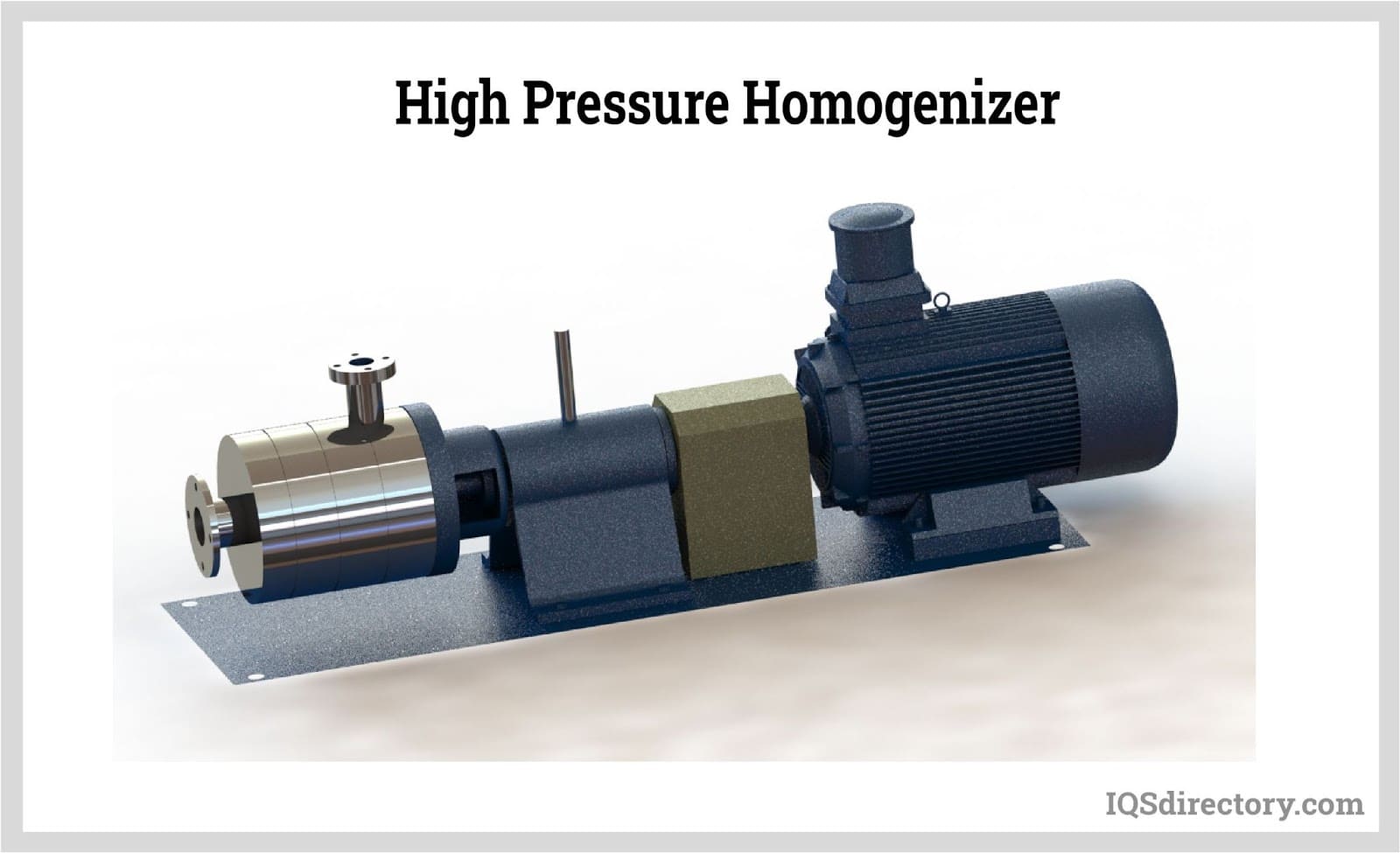

The high-pressure homogenizer (HPH) is one of the earliest and most widely used industrial homogenizers. Renowned for its efficiency, power, and versatility, the HPH has become a top choice in various industrial, pharmaceutical, and food manufacturing processes worldwide, where achieving superior dispersion, particle size reduction, and emulsification is critical for product quality and uniformity.

High-pressure homogenizers, often referred to as piston or high-shear homogenizers, feature a robust high-pressure pump paired with a precision-engineered homogenization valve. The positive displacement reciprocating pump used in these machines is ideal for processing viscous liquids, suspensions, and emulsions, maintaining process consistency and mechanical efficiency even when flow and pressure fluctuate. Most industrial-grade HPH systems are equipped with three or more pistons or plungers, which work together to stabilize fluid delivery, minimize pulsations, reduce vibration, and extend equipment longevity.

Operating pressures for high-pressure homogenizers typically range from 8,000 psi to 40,000 psi (550 bars to 2,750 bars), allowing manufacturers to achieve ultra-fine particle and droplet sizes. In the food industry, this is crucial for producing smooth dairy products, sauces, and beverages, while the pharmaceutical industry relies on these machines for cell lysis, nanoemulsion formation, and API (active pharmaceutical ingredient) dispersion.

The heart of any high-pressure homogenizer is the homogenization valve assembly, made up of a seat, valve, and impact or wear ring. As fluids are forced through this narrow gap at high velocity, they experience extreme turbulence and intense shearing forces, which break down particulates, disrupt cell walls, and create highly stable emulsions and dispersions. Cavitation—the rapid formation and implosion of microbubbles—occurs when the fluid exits the high-pressure gap, generating shockwaves that further reduce particle size and homogenize the mixture. This homogenization process is critical for product stability, shelf-life extension, bioavailability enhancement in pharmaceuticals, and consistent texture in consumer goods.

Choosing the right homogenizer valve is crucial for optimizing process results and energy consumption. Each valve type offers unique advantages, performance characteristics, and suitability for specific raw materials or homogenization goals. Below, we explore the primary types of homogenizer valves that drive innovation in industrial mixing and high-shear processing.

The radial diffuser valve, commonly known as the standard valve for high-pressure homogenization, is widely deployed across the dairy, beverage, chemical, and cosmetic industries. This valve design includes a plug and seat, with many modern configurations featuring an adjustable seat to allow precise control over the critical gap—one of the main process parameters affecting particle size and emulsion stability.

During operation, the premix fluid flows axially before being redirected 90° by the plug, forcing the fluid to move radially through an engineered gap. The fluid stream then impacts an annular surface known as the impact or wear ring, where additional mechanical energy is imparted, contributing to fine particle breakdown and uniform droplet size.

This valve type's primary benefit lies in the ability to regulate homogenizing pressure by adjusting the gap, enabling constant flow operation while optimizing homogenization efficiency. It's especially valued in process environments demanding consistent, repeatable results and versatility in product formulations.

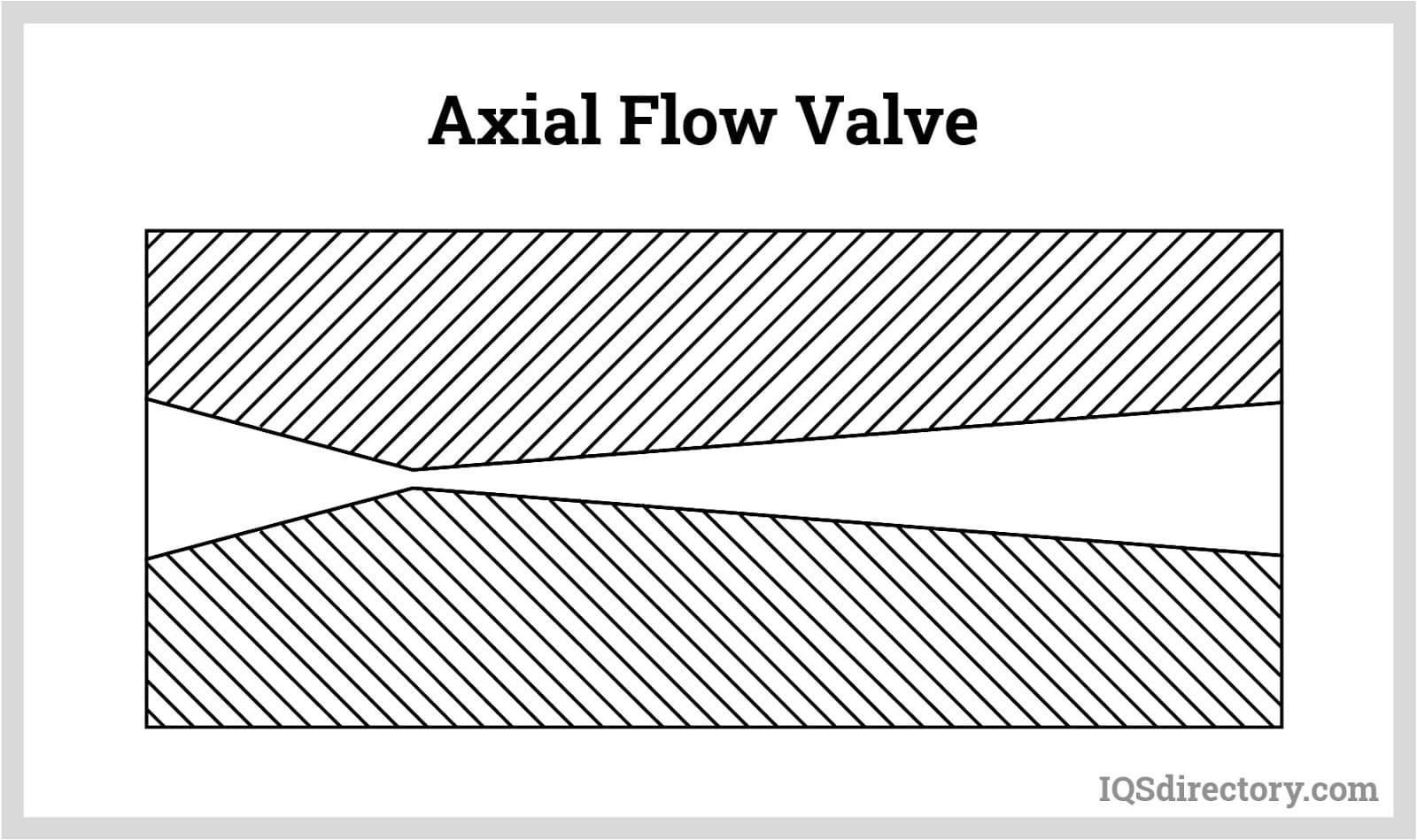

An axial flow valve is similar in principle to an orifice or venturi valve, employing a small, precisely manufactured gap—often formed by an orifice plate, venturi constriction, or short tube—to create controlled shearing conditions. Some models incorporate a movable needle, aligned axially with flow, providing real-time adjustment to accommodate variations in process pressure or viscosity. This flexible design allows for fine-tuning the homogenization intensity, benefiting industries such as biotechnology, nutraceutical production, and nanoemulsion formulation.

As the premix fluid flows axially through the orifice, intense shear, cavitation, and turbulence are generated within the narrowly confined space. Unlike radial diffuser valves, the axial flow configuration does not include an impact ring—resulting in a streamlined jet with predictable velocity profiles, ideal for continuous processing applications.

Axial flow valve design may vary between static and dynamic gap control. Static models adjust pressure through flow rate modulation, while those with a moving needle precisely vary the orifice width to maintain optimal process pressure and product consistency, particularly in sensitive bio-based or high-viscosity formulations.

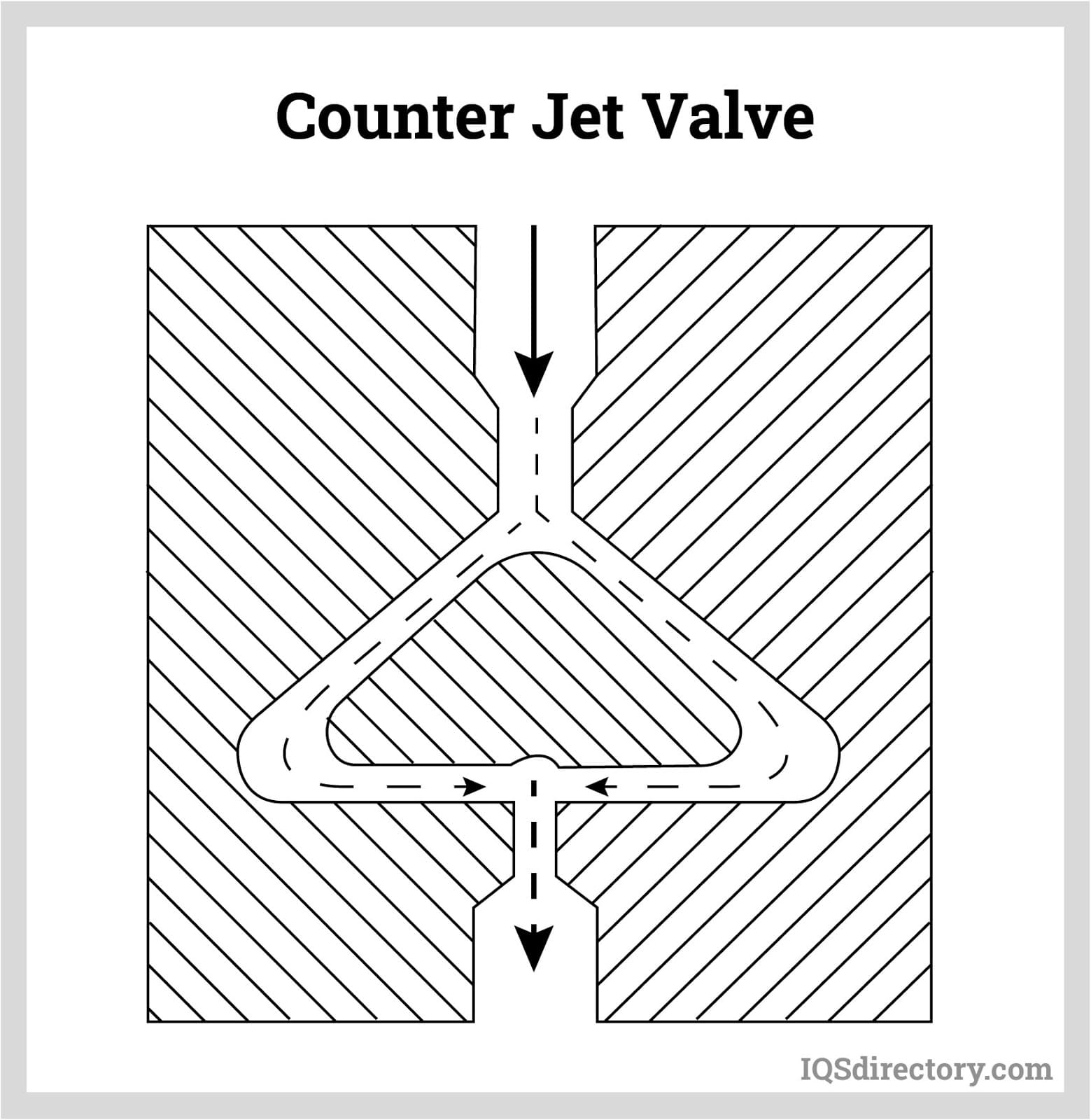

Counter jet valves utilize advanced microchannel technology to split the incoming premix fluid into two or more high-velocity streams, which collide head-on within a compact interaction chamber. This unique approach to high-shear mixing ensures dynamic energy transfer and highly efficient particle disruption without any moving parts—making counter jet valves an excellent choice for applications requiring robust reliability, such as continuous pharmaceutical manufacturing or specialty material processing.

The lack of moving components eliminates wear and minimizes maintenance requirements, improving overall equipment uptime. However, counter jet valves rely on a minimum flow rate to achieve effective energy transfer, which can limit maximum achievable homogenization pressure in systems handling low-volume or highly viscous products.

Because of their unique design, counter jet valves excel in applications demanding precise control over particle size distribution, uniformity, and rapid cell disruption, contributing to product scalability and high-throughput production capacity.

A microfluidizer is an advanced high-shear homogenization device that introduces product from an inlet reservoir into a proprietary pumping system, forcing it through engineered microchannels in an interaction chamber at pressures up to 30,000 psi. These extremely high shear rates and impact forces promote efficient cell disruption, nanoemulsion formation, nanomilling, and particle size reduction—making microfluidizers indispensable for pharmaceutical R&D, nanotechnology, cosmetics, and food science innovation.

Inside the microchannels, the product stream collides with both the chamber walls and itself, ensuring complete homogenization, narrow particle size distribution, and enhanced bioavailability for active ingredients. The result is a consistently smooth, stable, and reproducible product, meeting rigorous regulatory and quality control standards in demanding commercial environments.

When selecting between homogenizer valve technologies, consider key factors such as fluid characteristics, desired particle or droplet size, batch or continuous mode requirements, maintenance costs, and total lifecycle efficiency. Evaluating options in collaboration with experienced process engineers can optimize process outcomes and ensure production scalability in high-growth markets.

A homogenizer is a mixing device that creates a uniform blend by forcing substances through a restricted gap under high pressure, using turbulence and cavitation to evenly disperse particles, droplets, or solids and ensure product consistency.

Homogenization is governed by three core principles: shearing, cavitation, and turbulence. These physical effects disrupt, disperse, and reduce particle size, leading to stable emulsions and suspensions in various industrial applications.

Homogenizer valve types include radial diffuser, axial flow, counter jet, and microfluidizer designs. Differences center on flow direction, gap control, the use of impact surfaces, maintenance needs, and suitability for specific materials or homogeneity targets.

Homogenization breaks down droplets and particulates, creating finer particle size distribution that prevents phase separation, sedimentation, and agglomeration—yielding stable emulsions and suspensions with uniform texture and enhanced shelf-life.

High-pressure homogenizers achieve ultra-fine particle and droplet sizes essential for smooth textures, stable formulations, and bioavailability. This is critical in producing dairy, sauces, nanoemulsions, and dispersing active pharmaceutical ingredients.

Auguste Gaulin invented an early 20th-century milk homogenizer featuring a positive displacement pump and capillary tubes, establishing the foundational design used in modern high-pressure homogenizers for dairy and other industries.

Mechanical homogenizers utilize mechanical work to break down the components of the premix. They operate similarly to high shear mixers, allowing the introduction of the premixed fluid at atmospheric, low, or medium pressures—much lower than those used in high-pressure homogenizers. Instead of a valve, mechanical homogenizers use rotating elements such as cones, blades, and paddles. These rotors are paired with an appropriate stator to create optimal homogenization conditions. The process relies on mechanical tearing from the moving parts, though the core physical principles of particle disruption still apply.

Here are some of the most commonly used types of mechanical homogenizers.

A colloid mill is a type of homogenizer featuring a conical rotor and stator. The rotor and stator are positioned with a narrow gap through which the premix flows under the influence of shear and centrifugal forces. As the premix is fed into the rotor-stator unit from a hopper, it is propelled outward through the exit slots or holes. The rotor's high-speed rotation, ranging from approximately 3,000 to 15,000 rpm, generates significant shear forces that break down the premix components. Additionally, the rotor's acceleration of the fluid achieves high velocities, leading to the development of turbulence.

The level of shearing in a colloid mill can be controlled by adjusting the gap between the rotor and stator. However, reducing this gap can decrease the product's flow rate, which limits the fineness of the particle size compared to high-pressure or ultrasonic homogenizers.

Colloid mills are particularly effective for handling highly viscous materials or products with a significant amount of suspended solids.

These homogenizers have a construction that closely resembles high-shear mixers. The rotor-stator unit, often referred to as a mixing head, generator, or probe, is inserted into a container such as a batching tank or vessel where it performs the homogenization of the premix fluid.

Rotor-stator homogenizers operate by accelerating the fluid in a tangential direction. However, due to fluid inertia, the fluid does not completely synchronize with the rotor's motion. Instead, it is directed towards the shear gap, the space between the rotor's edge and the stator. This results in high-velocity differentials and turbulent flow within the shear gap, leading to high shear rates. The resulting particle size is influenced by the design of the rotor and stator, including their separation distance and any additional features like holes and slots.

The materials are drawn into the rotor-stator system in a spiral motion due to the high-speed rotation. The combined action of suction and high shearing forces in the shear gap processes the fluid. Rotor-stator homogenizers are not suitable for solid samples and can be labor-intensive when processing multiple samples.

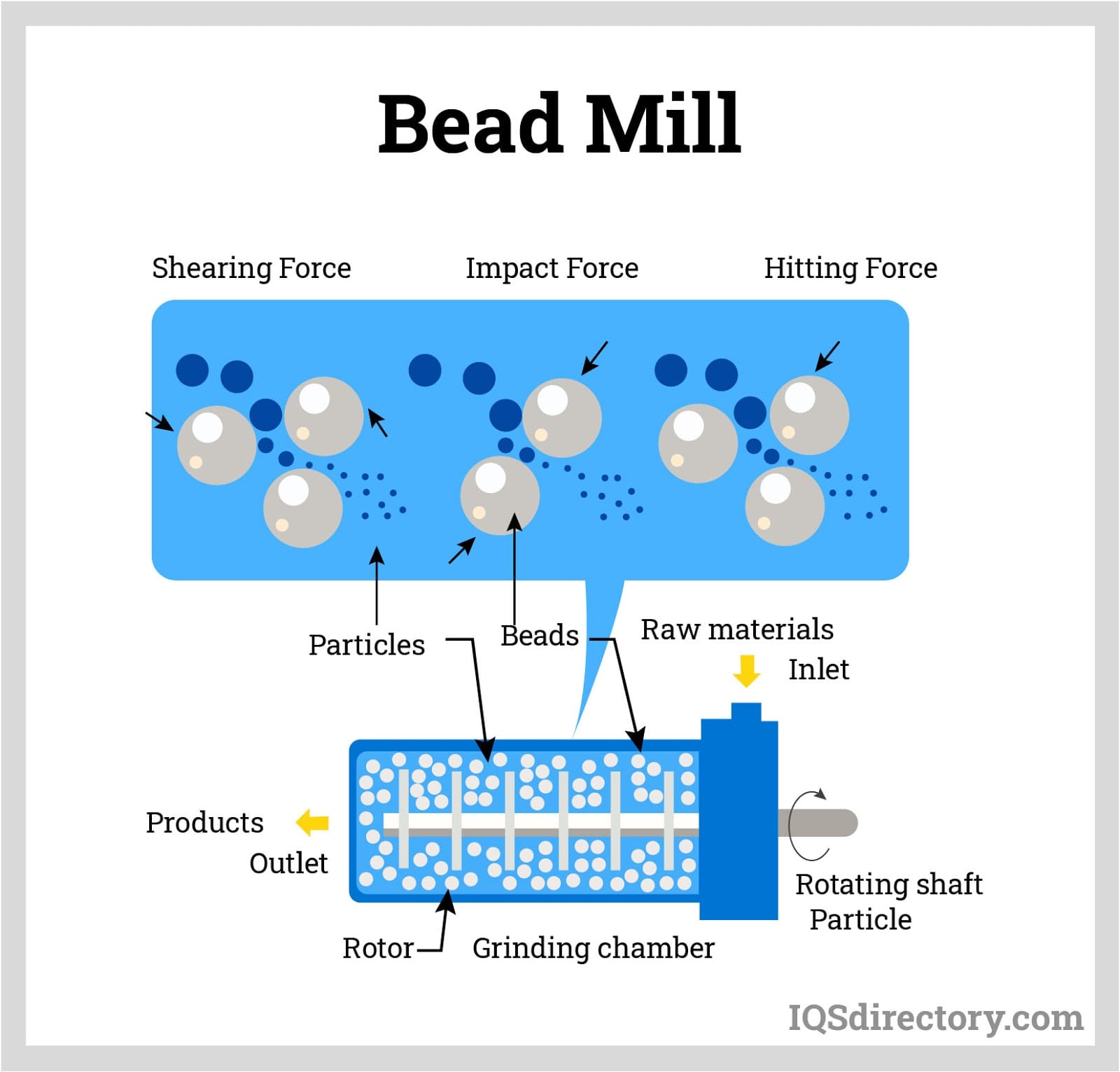

Bead mills, also known as ball mills, use beads as grinding media to mechanically crush and break down large particles suspended in the premix fluid. These beads create strong impact and shearing forces that reduce particle size effectively.

The beads are loaded inside the container and are in contact with the premix fluid. They are then agitated by internal, rotating components such as paddles and blades. Agitation can also be done by centrifugally spinning the container at extremely high speeds. Agitation using rotating components is typically seen in larger homogenizers in line with the production stream. Agitation through a centrifugal action is commonly used in laboratories for preparing homogenized product samples.

These homogenizers utilize blades as their rotors, and unlike colloid mills and rotor-stator homogenizers, they lack a shear gap formed with a stator. The shearing action is achieved solely through the high-speed rotation of the blades. Their design and functionality are similar to those of a blender.

Blade-type homogenizers generally offer lower efficiency compared to rotor-stator models. While they are effective at creating well-emulsified and dispersed mixtures, they do not achieve the fine particle sizes produced by other homogenizer types. To enhance their homogenizing performance, abrasive media like beads can be employed.

Ultrasonic homogenizers, also referred to as sonicators or sonic disruptors, utilize the principle of ultrasonic cavitation. These devices operate at ultrasonic frequencies, typically above 20 kHz, to generate sound waves. Cavitation occurs through the creation of alternating periods of rarefaction and compression, leading to the primary disruption of components via cavitation effects.

During the rarefaction phase of an ultrasonic wave, vapor cavities form, while the compression phase causes these cavities to collapse. Each cycle of the ultrasonic wave includes these alternating periods. Although these cavities are microscopic and invisible during operation, they represent high-energy, localized regions capable of reaching very high temperatures and pressures.

Ultrasonic homogenizers consist of three main components:

Ultrasonic homogenizers are similar to high-pressure homogenizers regarding particle size reduction and energy efficiency. They operate at atmospheric pressure, which is a key advantage. Additionally, the level of disruption can be adjusted by changing the generator’s electrical power and the temperature of the premix fluid, all without requiring moving parts.

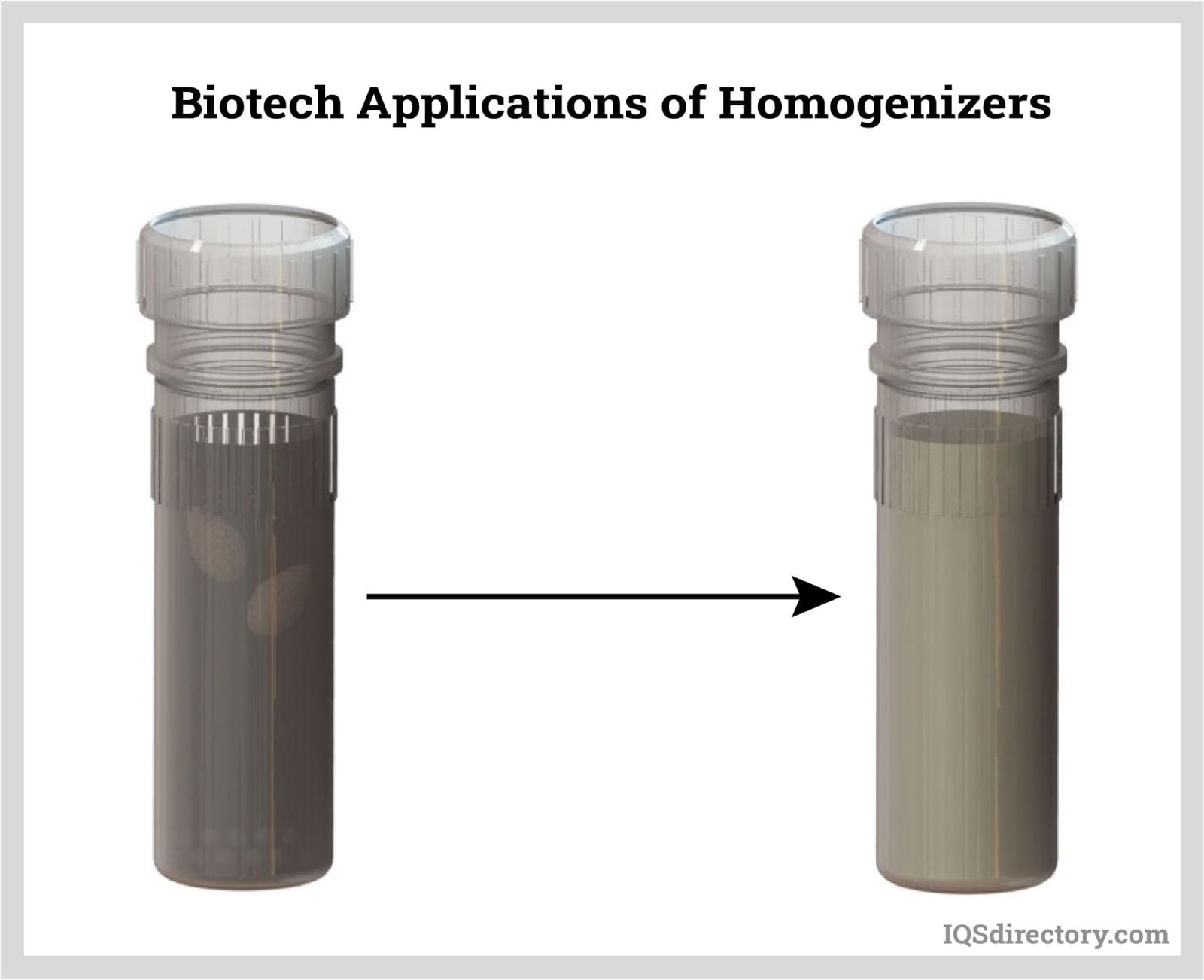

Aside from producing emulsions and suspensions through particle size reduction and mixing, homogenizers also perform other functions, particularly in the food and pharmaceutical industries. Their ability to mechanically disrupt microorganisms and natural compounds extends their viability as processing equipment. However, these roles are limited to high-pressure, ultrasonic, and bead mill homogenizers. These homogenizers can disrupt particles down to the nanoscale, ranging from 50 to 500 nm.

A homogenizer is a type of mixing equipment used to create a uniform and consistent mixture. It works by breaking the components and evenly distributing them throughout the solution.

Homogenizers were invented by Auguste Gaulin for homogenizing milk. The equipment was composed of a three-piston, positive displacement pump with capillary tubes fitted at the discharge.

The homogenization process happens within the homogenizer valve, which is the main component of the equipment.

Homogenizing action is created by the combined effect of three main physical principles: shearing, cavitation, and turbulence.

The three main classifications of homogenizers are high pressure (HPH), mechanical, and ultrasonic.

In addition to emulsification and dispersion, homogenizers perform other functions. Examples are microbial inactivation, cell fractionation, enzyme activation/inactivation, and compound extraction.

Agitators are equipment used in homogenizing media inside a tank. It works by rotating the impeller at its immersed end at a controlled speed or revolutions per minute (rpm). The work exerted by...

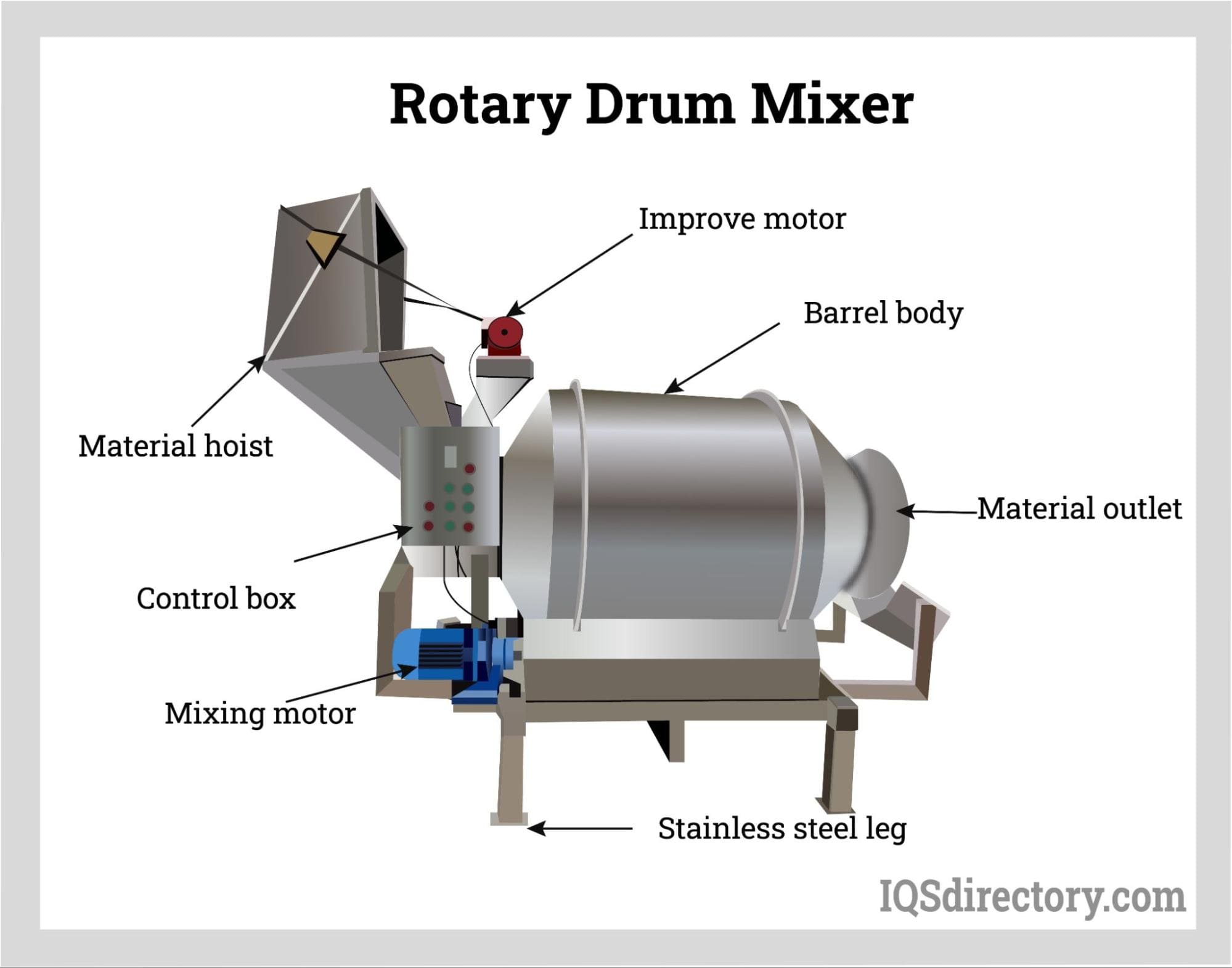

Drum mixers are mixers that are used for mixing free flowing materials by rotating them forward and reverse with welded chutes or flights that fluidize the mixture. The design of drum mixers gives them...

An emulsifier is an emulsion device used for colloidal dispersion of liquid droplets of immiscible liquids in the presence of an emulsifying agent. It enables the combining of non-soluble solutions or liquids...

High shear mixers, also known as high shear reactors (HSRs), rotor-stator mixers, and high shear homogenizers, are used to emulsify, homogenize, disperse, grind and/or dissolve immiscible mixtures with components of the same or different phases...

An industrial blender is a machine for large-scale production that consists of a large tank capable of mixing and blending batches of manufacturing materials to create a reaction between the materials. The many uses for industrial blenders are due to their capacity and...

A mill is a mechanical device that is often a structure, appliance, or machine that is used to break down solid materials into smaller pieces by cutting, grinding, or crushing them. Many industrial processes involve...

A tank mixer is a mixing device that blends several different ingredients in a single tank to make a single solution. It is a mixing process capable of mixing wettable powders, liquids, emulsifiable concentrates, and surfactants. They mix and blend...

A mixer is a complex and precise tool that is used in combining and mixing of substances and chemicals for manufacturing, production, and industrial use. There are many types of industrial mixers including...

A plastic tank is a large capacity liquid or granular storage unit that can be vertical, horizontal, below or above ground, as well as movable. They are designed to hold several gallons of a variety of substances for long periods without experiencing wear, weathering, or deterioration...

A plastic water tank is a large capacity container designed to store water for household, agricultural, irrigation, and industrial manufacturing use. There are various types of water tanks produced to meet the needs of specific applications, with...

A poly tank is a plastic storage tank used to store, transport, and collect water, other liquids, and granular or powder materials. They are made of polyethylene or polypropylene and are a cost effective, lightweight, and easy to handle...

Pressure tanks are vessels that are used to store, hold, and/or convey gasses, vapors and fluids at pressures greater than atmospheric pressure, also known as high pressures...

Pressure vessels are enclosed containers used to hold liquids, vapors, and gases at a pressure significantly higher or lower than the ambient pressure. They are widely used in various industries such as...

Stainless steel tanks are widely used in food, beverage, dairy, medicine, cosmetics, and other manufacturing processes where cleanliness and purity are important. These are also used in industrial plants for storing chemicals and gases where strong resistance from chemical degradation is required...