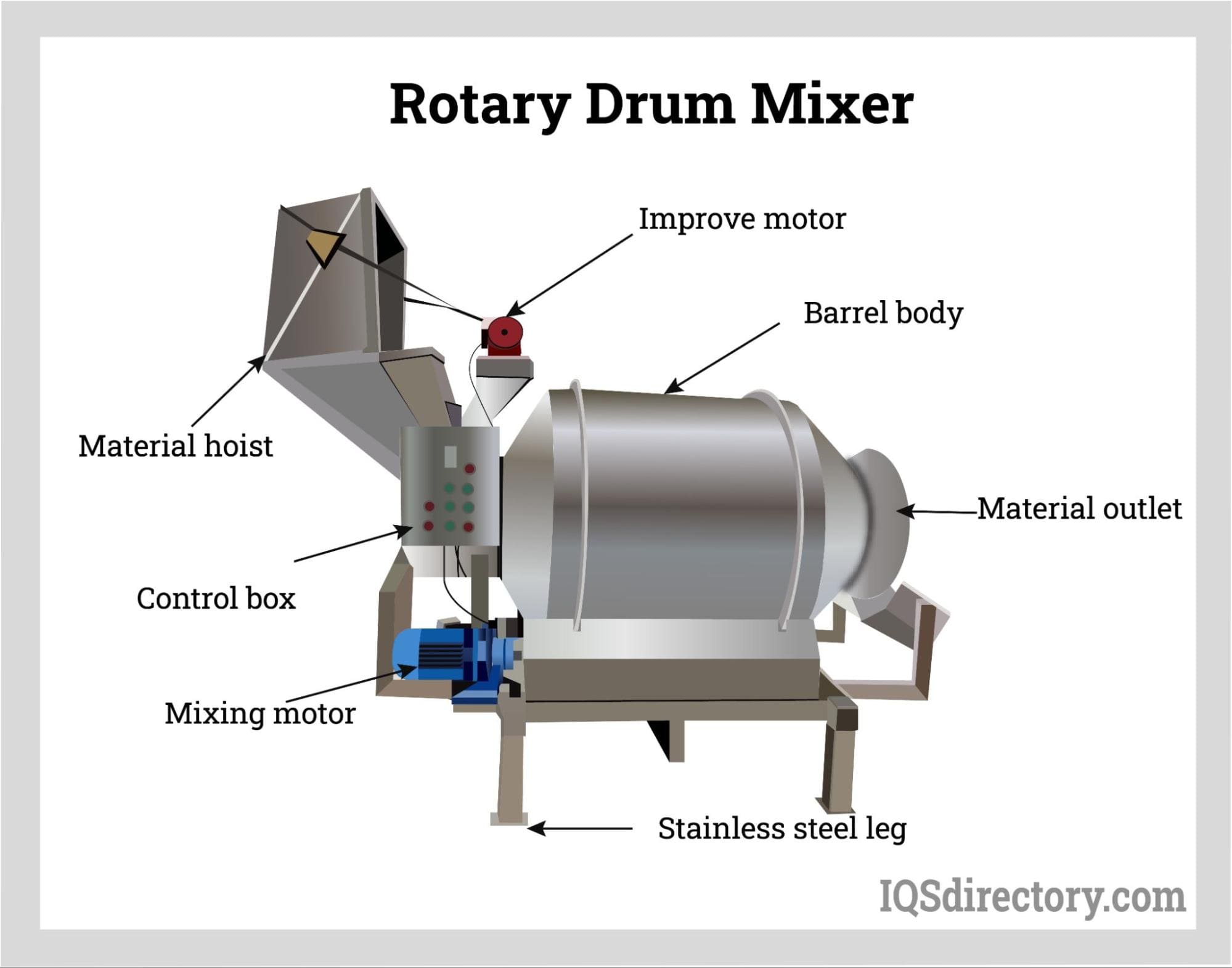

Drum Mixers

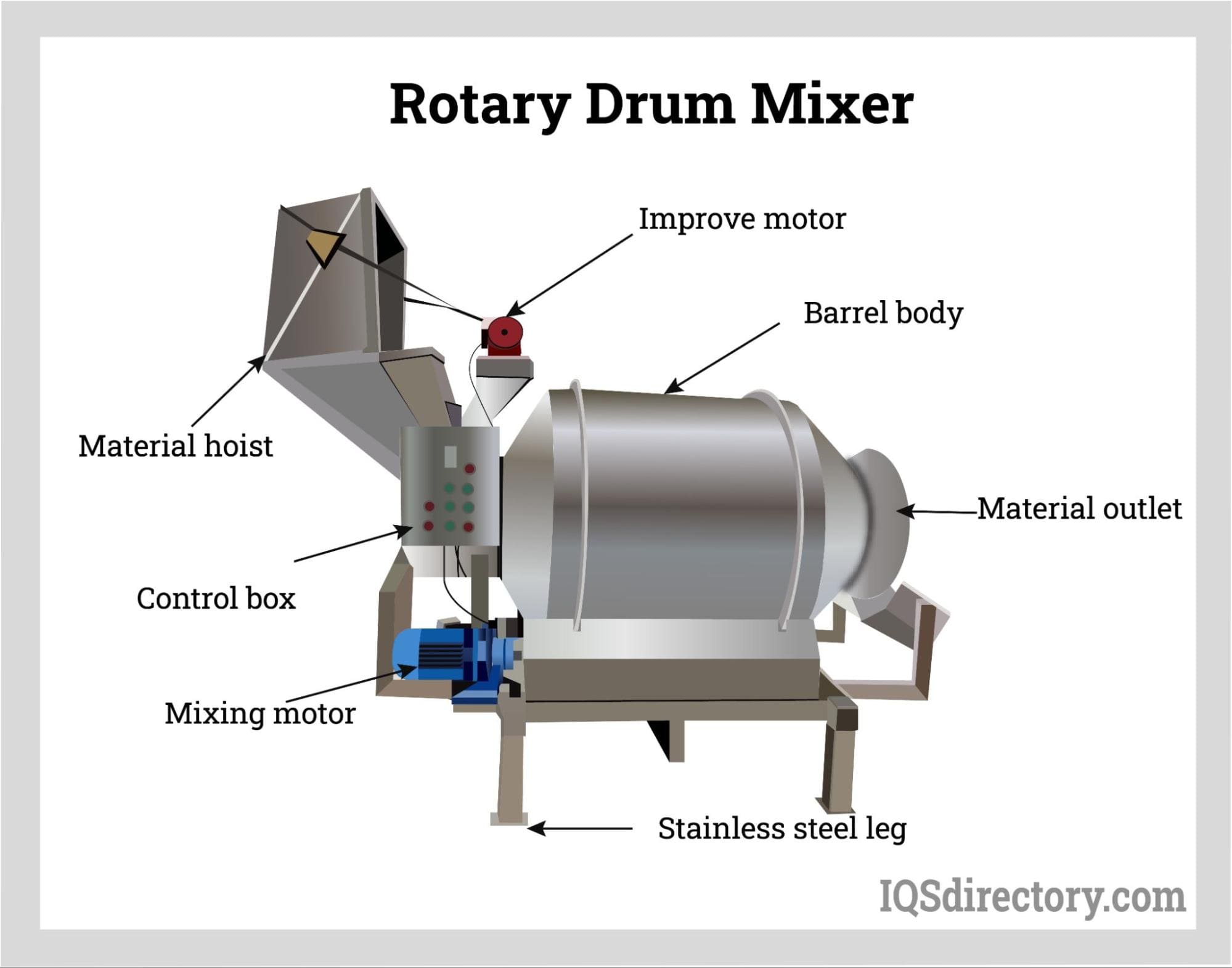

Drum mixers are mixers that are used for mixing free flowing materials by rotating them forward and reverse with welded chutes or flights that fluidize the mixture. The design of drum mixers gives them...

Please fill out the following form to submit a Request for Quote to any of the following companies listed on

This article takes an in-depth look at agitators.

Read further and learn more about topics such as:

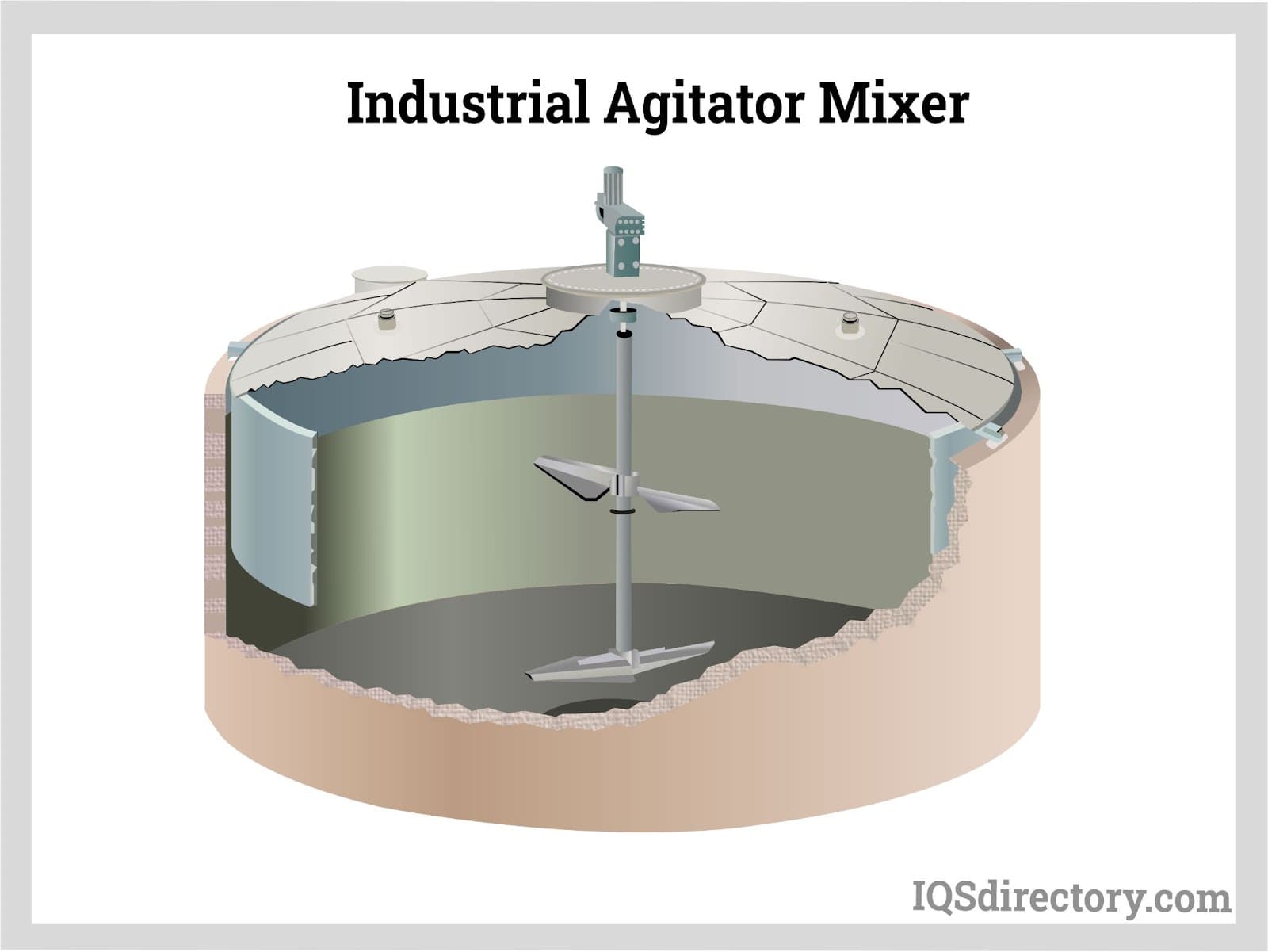

Agitators are devices designed to blend media uniformly within a tank. They function by spinning submerged impellers at specific speeds, measured in revolutions per minute (RPM). The movement generated by the impellers creates flow and turbulence in the tank, aiding in the uniformity of media with single or multiple components. This process ensures consistent flow and pattern within the tank.

In industrial settings, agitators play several crucial roles, such as:

Agitators are versatile, handling a range of media types, including liquids, gases, and solids like granules and powders. They are also adept at managing slurries, suspensions, and viscous liquids. However, selecting the appropriate agitator type, size, and design is essential, tailored to the media’s specific traits. Considerations such as viscosity and shear sensitivity are vital when choosing an agitator. These devices are widely used in various sectors, such as food and beverage, pharmaceuticals, agriculture, biotechnology, paint production, and water treatment.

Although commonly used interchangeably, “agitators” and “mixers” have distinct purposes. Mixers aim to swiftly combine two or more components, regardless of whether they are similar or different phases (solid-liquid, liquid-liquid, gas-liquid). Typically, components enter a mixer in a “pure” state and exit as a combined mixture. Conversely, agitators focus on preserving uniformity and stability within an existing mixture, preventing concentration and temperature variation to ensure the mixture stays consistent.

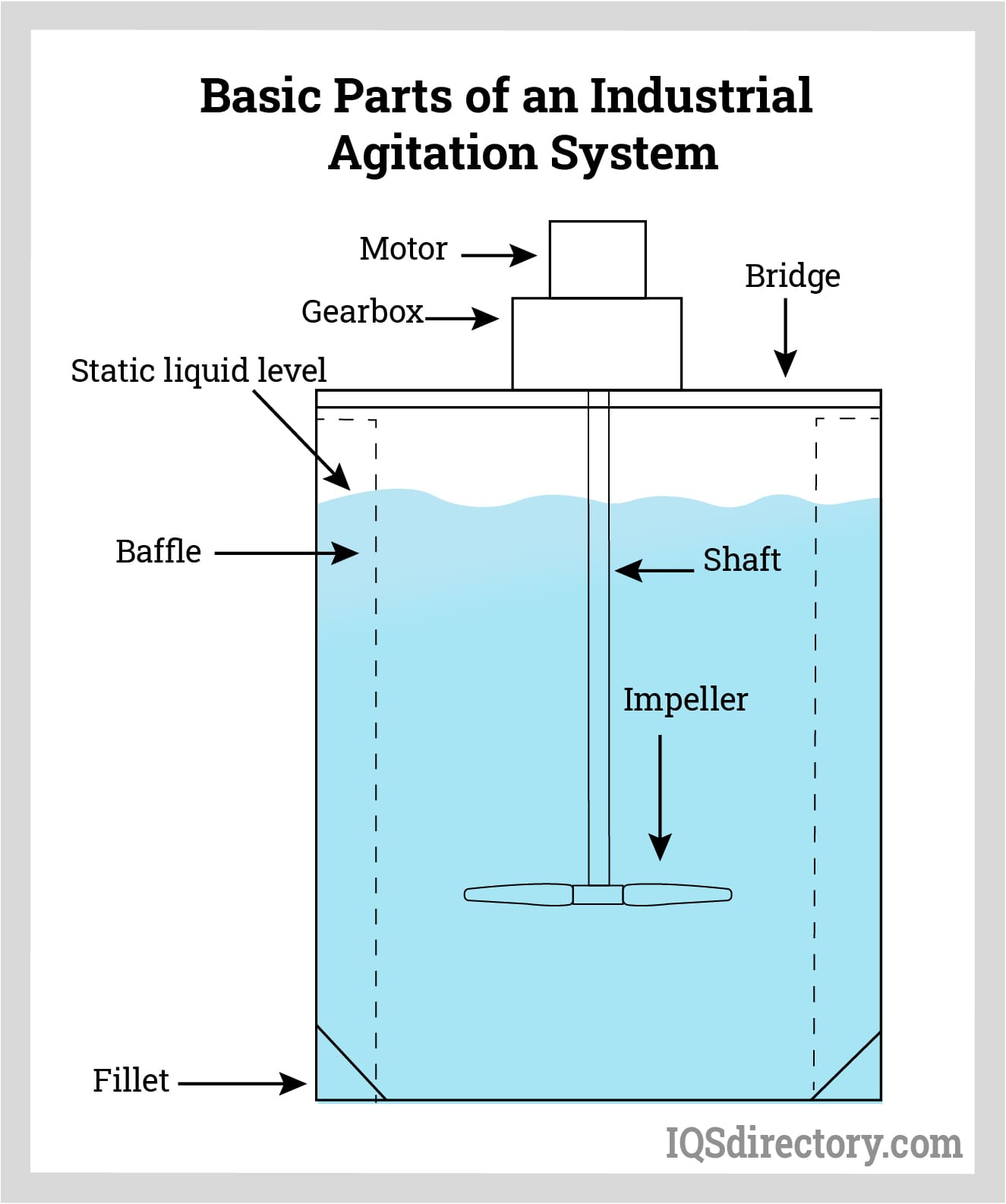

Industrial agitators are essential mechanical devices used extensively across various industries, including chemical processing, pharmaceuticals, wastewater treatment, food and beverage, and paints and coatings. Understanding the main parts of an agitator helps optimize mixing performance, maintenance, and process efficiency. Agitators typically consist of three main components: the motor, shaft, and impeller.

The motor is the driving force behind the agitator system, converting electrical energy into mechanical movement. This component delivers the torque required to rotate the shaft and impeller, generating the desired mixing action. The power requirements of an industrial agitator motor depend on several process variables, such as:

Selecting the correct agitator motor size and type is essential for achieving desired blend uniformity, reducing power consumption, and ensuring long-term mixer reliability. Common industry options include electric motors, pneumatic motors, and variable speed drives, each tailored to specific process requirements and hazardous environments.

The shaft connects the motor’s driveshaft to the impeller, transmitting rotational torque. Shaft assemblies in industrial mixers often use couplings, end caps, bushings, and other devices to enhance mechanical stability and alignment. Proper shaft design is crucial to prevent excessive vibration, shaft deflection, and mechanical failure, especially in high-viscosity mixing or large-volume applications. To prevent leakage, contamination, or material build-up at the vessel entry, various mechanical seals and gland packing systems are implemented.

The impeller is the most critical part of the agitator, as its geometry determines flow pattern, mixing efficiency, shear rate, and dispersion capabilities. By rotating within the fluid or slurry, the impeller directly influences blend time, particle suspension, gas dispersion, and overall process uniformity.

Impellers typically consist of a hub and blades. The hub attaches to the shaft via a shaft key and grub screw, providing a secure connection. Agitator blades are affixed to the hub either by welding or screwing. A welded connection is often preferred in sanitary applications, such as food and pharmaceutical mixing, since it minimizes product build-up and simplifies cleaning-in-place (CIP) procedures. Multiple impellers may be installed along a single shaft to improve axial flow or mixing in tall tanks. The optimal number and spacing of impellers depends on vessel dimensions, liquid height, media properties, and desired agitation results.

There are two main types of impellers used in mixing technology:

Proper impeller selection ensures the agitator meets critical industry standards for homogenization, emulsification, heat transfer, and solid suspension. Other advanced impeller designs include hydrofoil, anchor, turbine, and propeller types—each engineered for specific agitation demands.

When selecting the appropriate agitator components, it is vital to consider the characteristics of the mixing application, such as tank geometry, process objectives (blending, solids suspension, heat exchange), product viscosity, and chemical compatibility. Consulting with leading agitator manufacturers and mixer suppliers can significantly enhance process efficiency and ensure the installation of optimized components. Routine inspection and maintenance of agitator motors, shafts, and impellers help reduce production downtime while extending equipment longevity.

Understanding the flow patterns generated by agitator impellers is crucial for optimizing industrial mixing, blending, and agitation processes. Impellers are classified based on the dominant fluid flow they produce within a mixing tank—each type delivering unique hydraulic effects suited to different applications and goals. Choosing the correct impeller type and flow pattern is vital for achieving proper mixing, solid suspension, gas dispersion, and homogeneity. Below, we examine the typical flow patterns, operational features, and suitable use cases for each impeller category to help engineers and plant operators select the most effective agitation equipment for their process requirements.

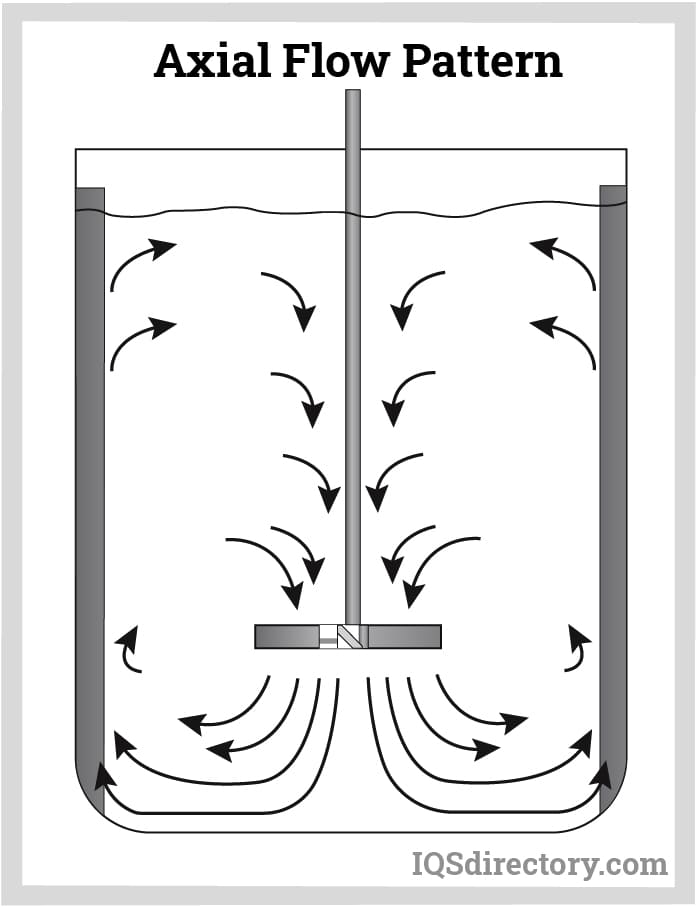

Axial flow impellers cause the media to flow parallel to the impeller’s axis of rotation. These impellers have blades angled at less than 90 degrees to the plane of rotation, facilitating a "top-to-bottom cyclic" flow pattern within the tank. Fluid near the top is pushed downward by the impeller until it reaches the bottom, where it spreads across the tank floor and then flows upward along the wall before being drawn back into the impeller. This movement effectively mixes the fluid throughout the tank, preventing solids and solutes from settling at the bottom.

Axial flow impellers are suitable for solid suspensions and low to medium viscosity fluids. They exhibit low shear characteristics, making them ideal for shear-sensitive media like non-Newtonian fluids or those affected by stress-induced viscosity changes. They are also utilized in heat transfer applications and are typically installed in tanks with high liquid levels to induce substantial vertical currents.

Typical applications for axial flow impellers include blending, solids suspension, and scenarios where uniform temperature distribution and rapid mixing times are critical. Popular designs in this category are marine propellers, hydrofoil impellers, and pitched blade turbines, each suited for industrial processes such as fermentation, wastewater treatment, and chemical processing. The gentle yet efficient flow created helps improve yield and process efficiency in batch and continuous mixing systems.

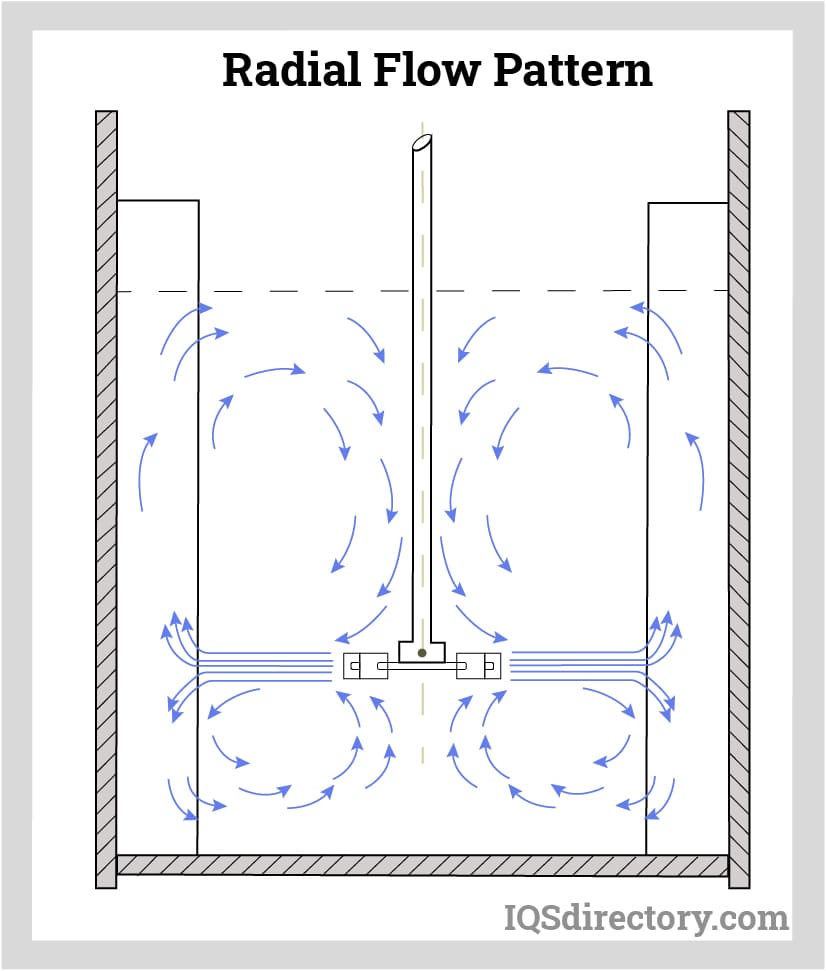

Radial flow impellers cause the media to flow perpendicular to the impeller’s axis of rotation, generating a "side-to-side flow pattern" within the tank. Fluid ejected from the impeller moves towards the tank walls, then either upward or downward before returning to the impeller's center. This continuous motion thoroughly mixes the tank contents. Unlike axial flow impellers, radial flow impellers lack angled blades directing fluid downward, necessitating baffles to minimize vortex formation and swirling.

Radial flow impellers induce high shear and less overall flow due to their sideways fluid movement. They are effective for blending viscous liquids and for gas-liquid and liquid-liquid dispersions. These impellers are commonly used in elongated tanks for low-level mixing applications.

Common radial flow impeller types include the Rushton turbine and flat-blade disc turbine, which are widely used in gas-liquid contacting processes (like oxygen transfer in bioreactors), emulsion formation, and where efficient surface renewal is essential. They promote turbulence and enable efficient mass and heat transfer, which is critical when dispersing gases or immiscible liquid phases. Choosing a radial flow impeller can enhance product uniformity, yield, and mixing rate for these demanding applications.

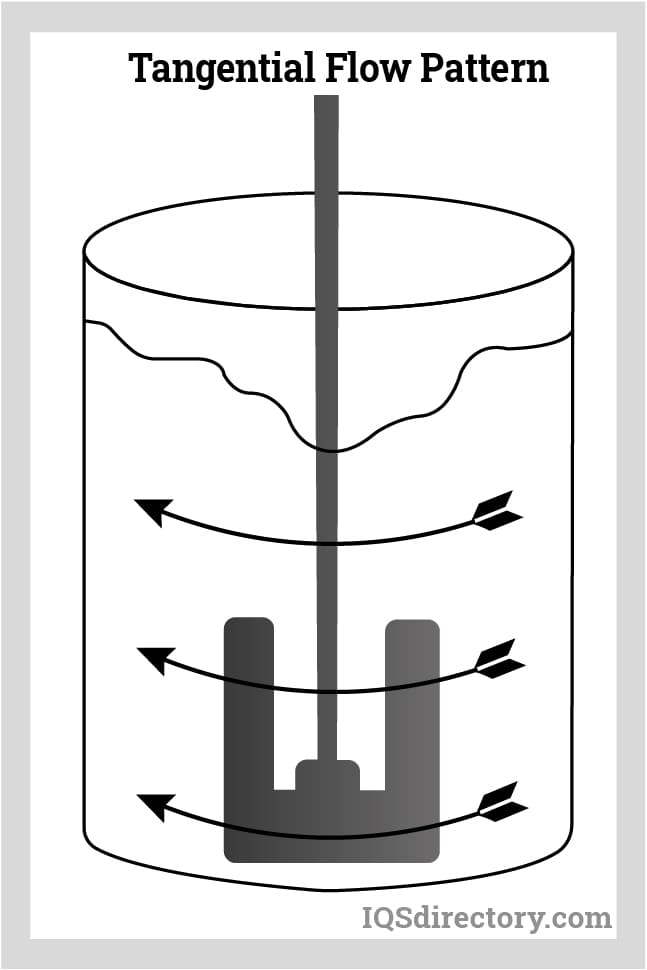

Tangential flow impellers direct the media to flow in a circular path around the shaft, causing the fluid to rotate around the vessel along with the impeller blades. This rotational motion results in minimal vertical flow as the fluid impacts the tank wall. Tangential flow impellers are characterized by low shear forces.

These impellers are typically employed for blending highly viscous media and promoting stratification within the tank.

Popular tangential flow impeller designs include disc and paddle impellers, often used for gentle blending, heat-sensitive products, or processes where minimal product aeration is desirable. Because these impellers promote rotational but limited axial or radial movement, they are ideal for homogenizing high-viscosity compounds in food, cosmetic, pharmaceutical, and paints industries. Tangential flow impellers are also advantageous when maintaining laminar flow or controlled mixing without foaming is important.

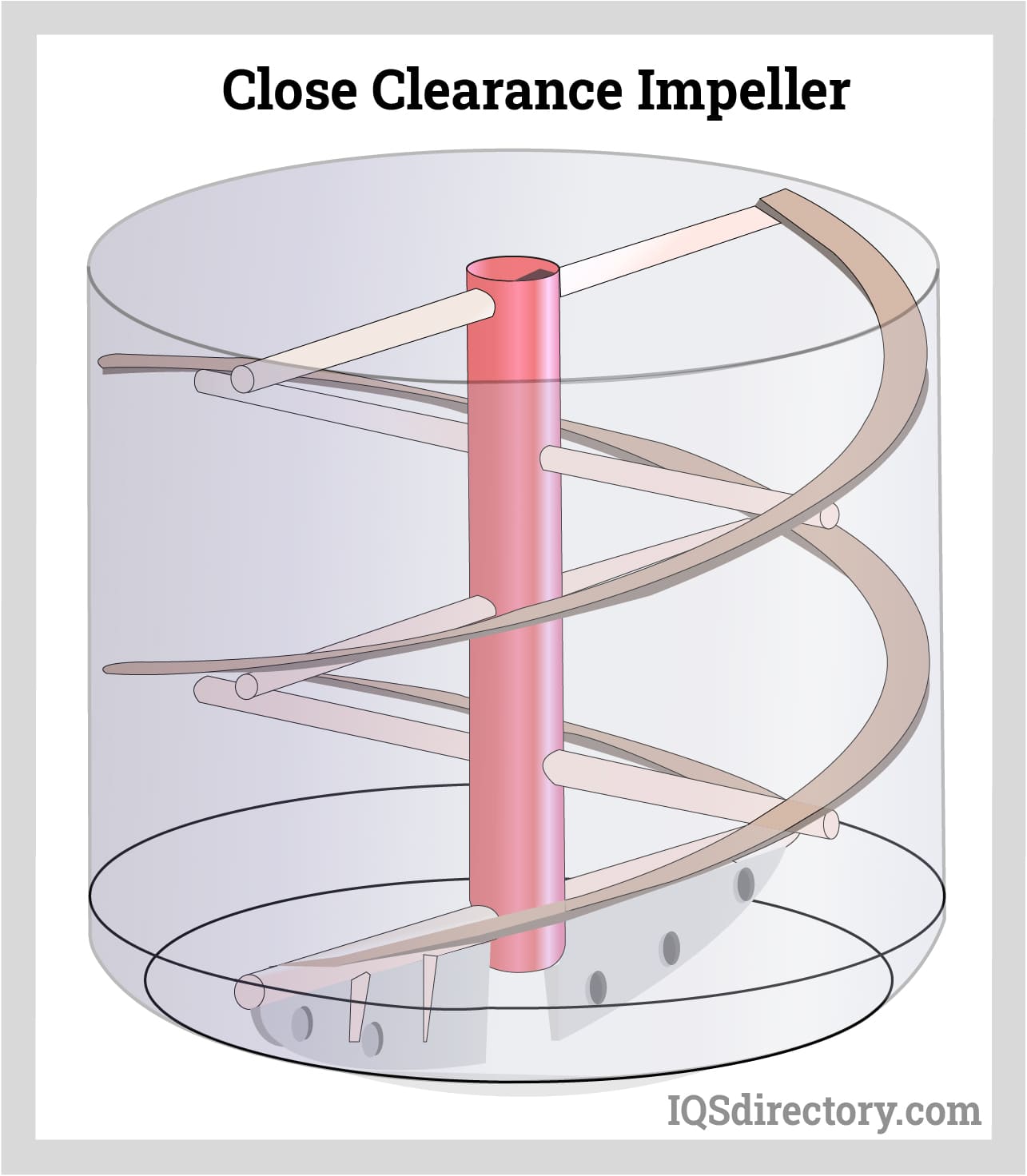

A close clearance impeller belongs to a category of impeller types characterized by a high diameter ratio, typically around 80% of the tank diameter. These impellers maintain a small clearance between their outer edges and the tank wall. This design allows them to gently scrape sticky products that may accumulate on the tank walls, thereby improving product homogeneity and preventing fouling, which can reduce heat transfer efficiency.

Close clearance impellers are specifically used for low-speed laminar blending of highly viscous liquids, typically those with viscosities greater than 50,000 cP. They are commonly employed in industries handling paints, inks, adhesives, grease, polymer solutions, and other viscous products.

Examples of close clearance impellers include anchor, paddle, gate, and helical ribbon impellers. These impellers typically have diameters that are about 80% of the tank diameter. In contrast, other types of impellers like turbine impellers and propellers generally have diameters approximately one-third of the tank diameter.

When evaluating agitator impeller types for processing viscous fluids or mixing challenging materials, close clearance impellers deliver superior wall cleaning and ensure consistent blending by preventing build-up and fouling. They are often selected for large reactors, process vessels, and specialty batch mixers where maintaining product quality and preventing contamination is a primary concern. Optimization of clearance, impeller speed, and design features can significantly improve process efficiency, reduce maintenance intervals, and support compliance with food-grade or pharmaceutical industry regulations.

Selecting the appropriate agitator impeller and understanding its flow pattern is essential for maximizing mixing efficiency, ensuring homogeneity, and achieving the desired product properties. Consider factors such as fluid viscosity, tank geometry, specific mixing goals (e.g., suspension, dispersion, homogenization), and the need for heat or mass transfer when evaluating impeller designs. Properly matched flow patterns and impeller types result in reduced mixing times, enhanced product quality, and energy savings. To consult with experienced mixer manufacturers or learn about custom impeller solutions for your application, consider requesting a process analysis or pilot testing with your intended fluid system. Learn more about industrial agitators and impeller selection.

Agitators are designed to uniformly blend media within a tank by generating flow and turbulence, ensuring consistent texture, preventing concentration differences, and aiding in temperature and chemical reaction control.

Mixers rapidly combine different components into a new mixture, while agitators are used to maintain uniformity and stability within an existing mixture, preventing settling or separation.

Key parts include the motor, which drives the system; the shaft, which transfers torque; and the impeller, which determines flow patterns and mixing efficiency by moving the media within the tank.

Axial flow impellers suit low-to-medium viscosity fluids, radial flow impellers are best for gas-liquid dispersions, tangential flow impellers handle highly viscous media, and close clearance impellers blend thick, sticky products.

Agitators are widely used in food and beverage, pharmaceuticals, agriculture, biotechnology, paint manufacturing, and water treatment for diverse mixing and blending applications.

Selection depends on tank geometry, process goals, product viscosity, chemical compatibility, and industry standards. Assessment of mixing requirements ensures optimal agitator type, size, and component selection.

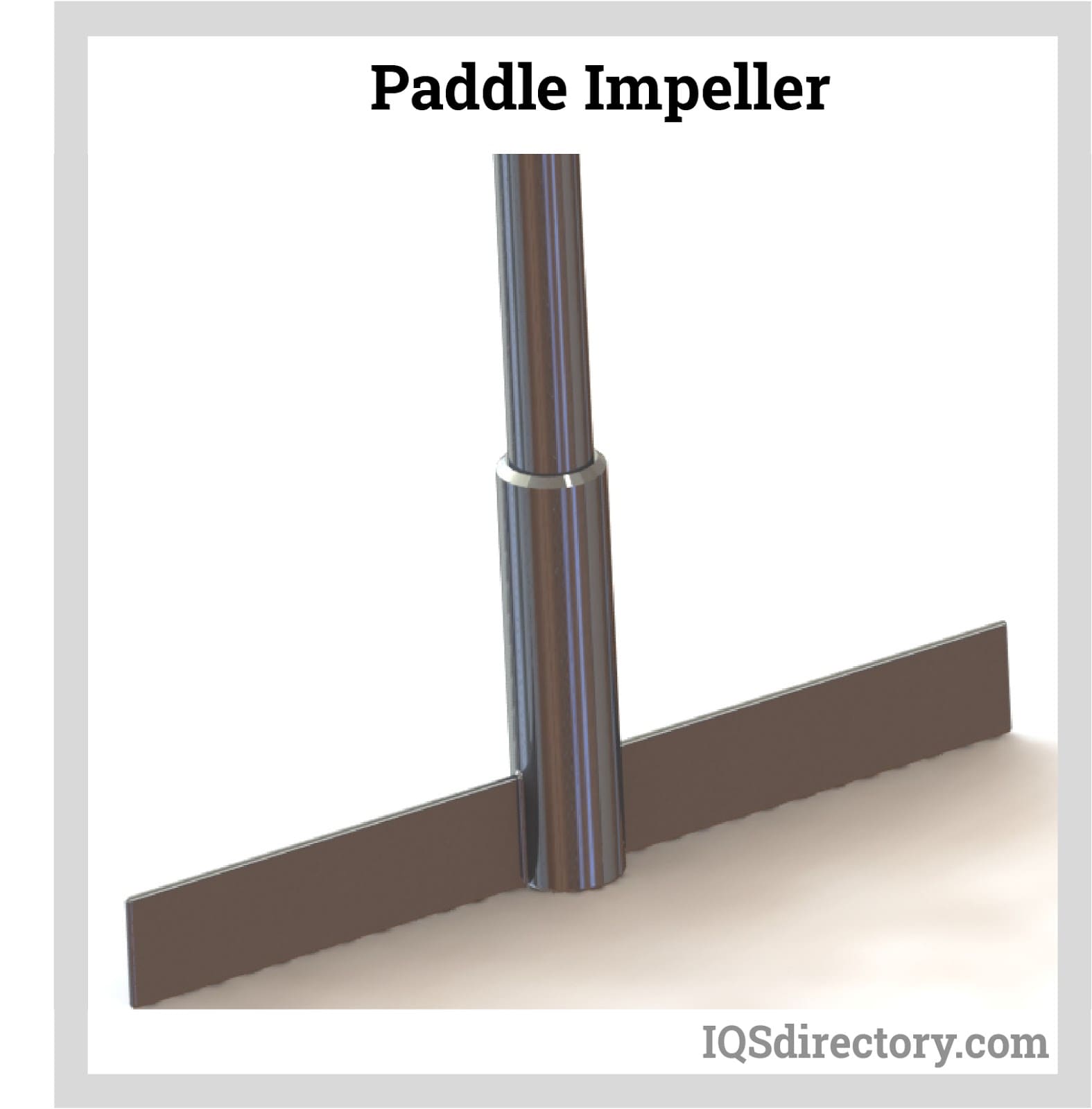

Paddle agitators consist of two flat paddle-shaped impeller blades extending to reach the tank walls. They are used if no extensive axial and radial flow is required. These impellers can produce a laminar low shear flow and are used for low viscosity liquid mixing, crystallization, dissolution, and heat transfer. They are typically operated at low speeds and predominantly give a tangential flow pattern. Secondary blades can be installed on the paddle blades to enhance the mixing of more viscous materials.

The impeller blades are inclined relative to the plane of rotation, creating an axial flow pattern. This design is commonly used for homogenizing suspensions and is a variation of the paddle agitator.

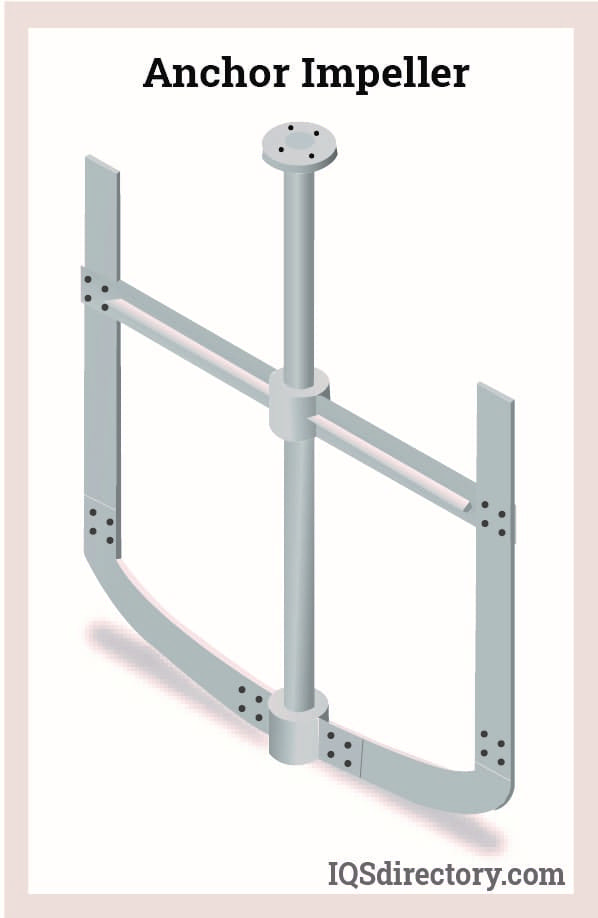

Anchor agitators feature impellers shaped like anchors, typically with a U-shape that matches the tank's contour. They predominantly generate a tangential flow pattern but can incorporate angled blades on their horizontal supports to produce an axial flow.

These agitators are used for blending and heat transfer of highly viscous liquids. Their impellers create a laminar, low-shear flow, making them ideal for mixing shear-sensitive media. Anchor agitators are among the most economical options for laminar flow agitation and are suitable for tanks with rounded or conical bottoms. The impeller design allows for low clearance with the tank wall.

Helical ribbon agitators feature a helical impeller blade mounted on a shaft by rods. These impellers serve as an alternative to anchor impellers and are designed to generate an axial flow pattern. They provide a higher fluid contact area, making them effective for mixing fluids with higher viscosities.

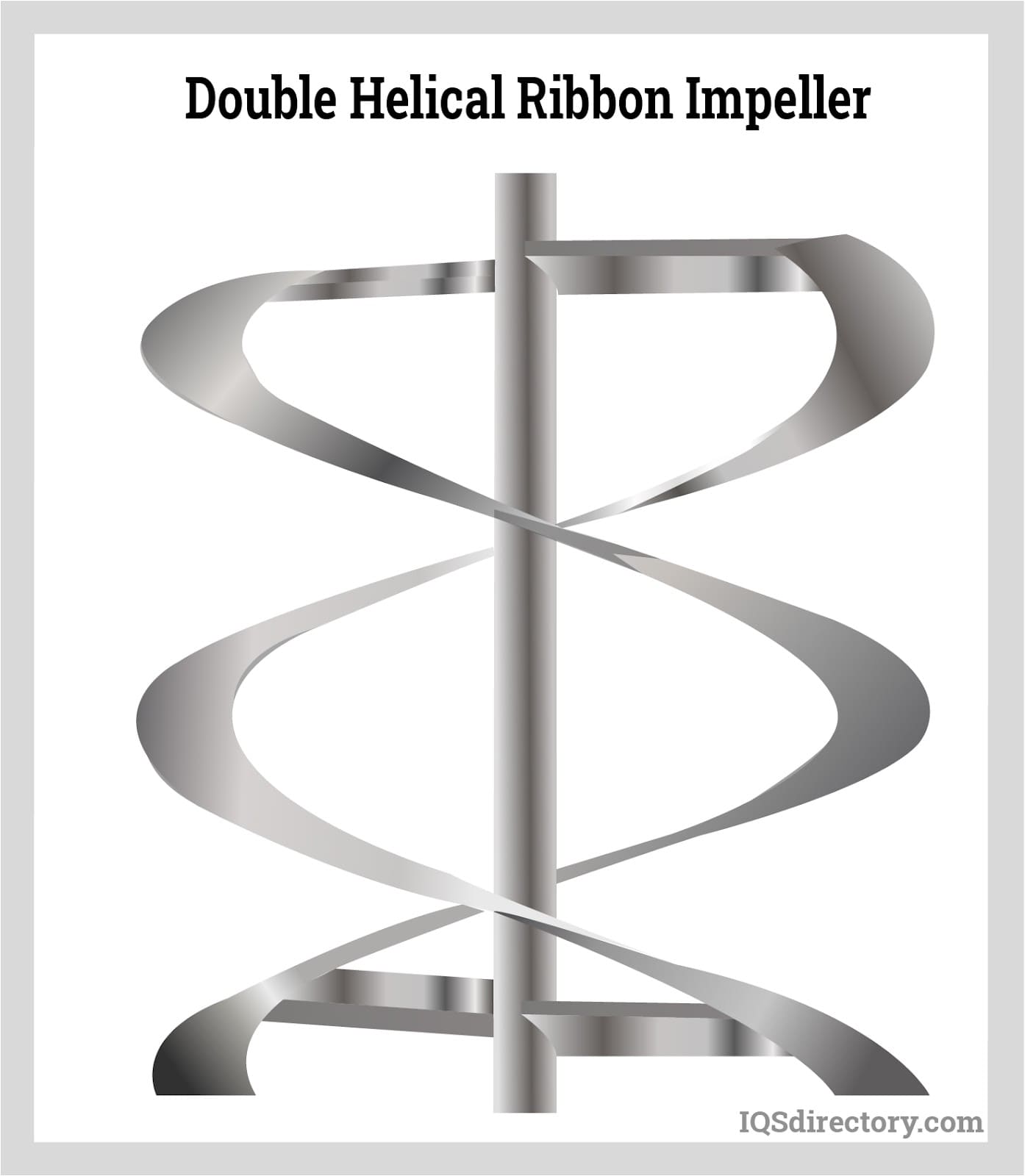

Double helical ribbon agitators feature two helical blade flights running through the shaft in opposite directions. This design improves the mixing of more viscous fluids. They are also used in heat transfer applications and are regarded as the best impeller for high-viscosity laminar flow. The impeller can be designed with low clearance to the tank wall.

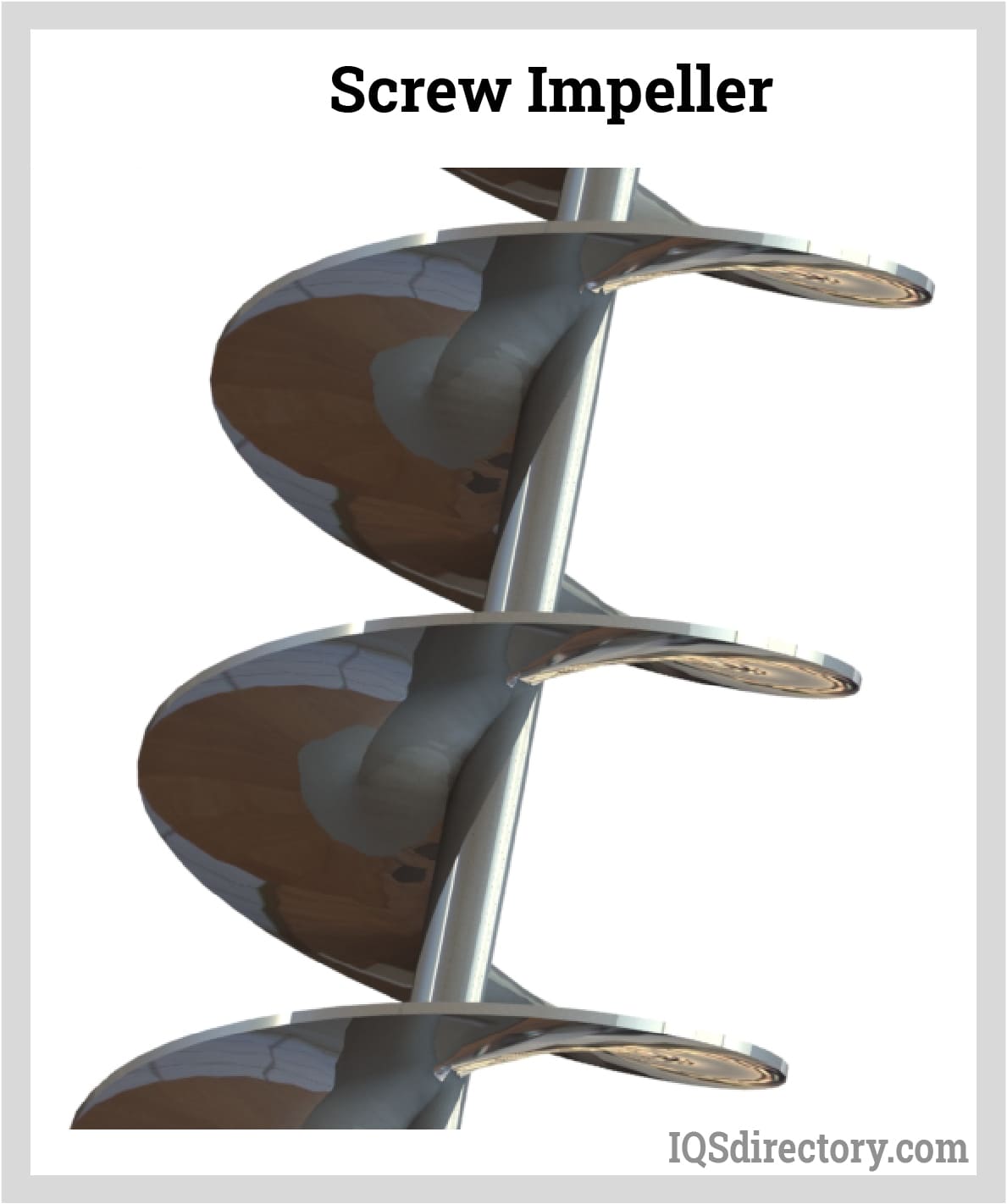

Screw impellers are close-clearance devices with a helical flight attached directly to the impeller shaft. They provide excellent top-to-bottom turnover and are used for blending high-viscosity and shear-sensitive media.

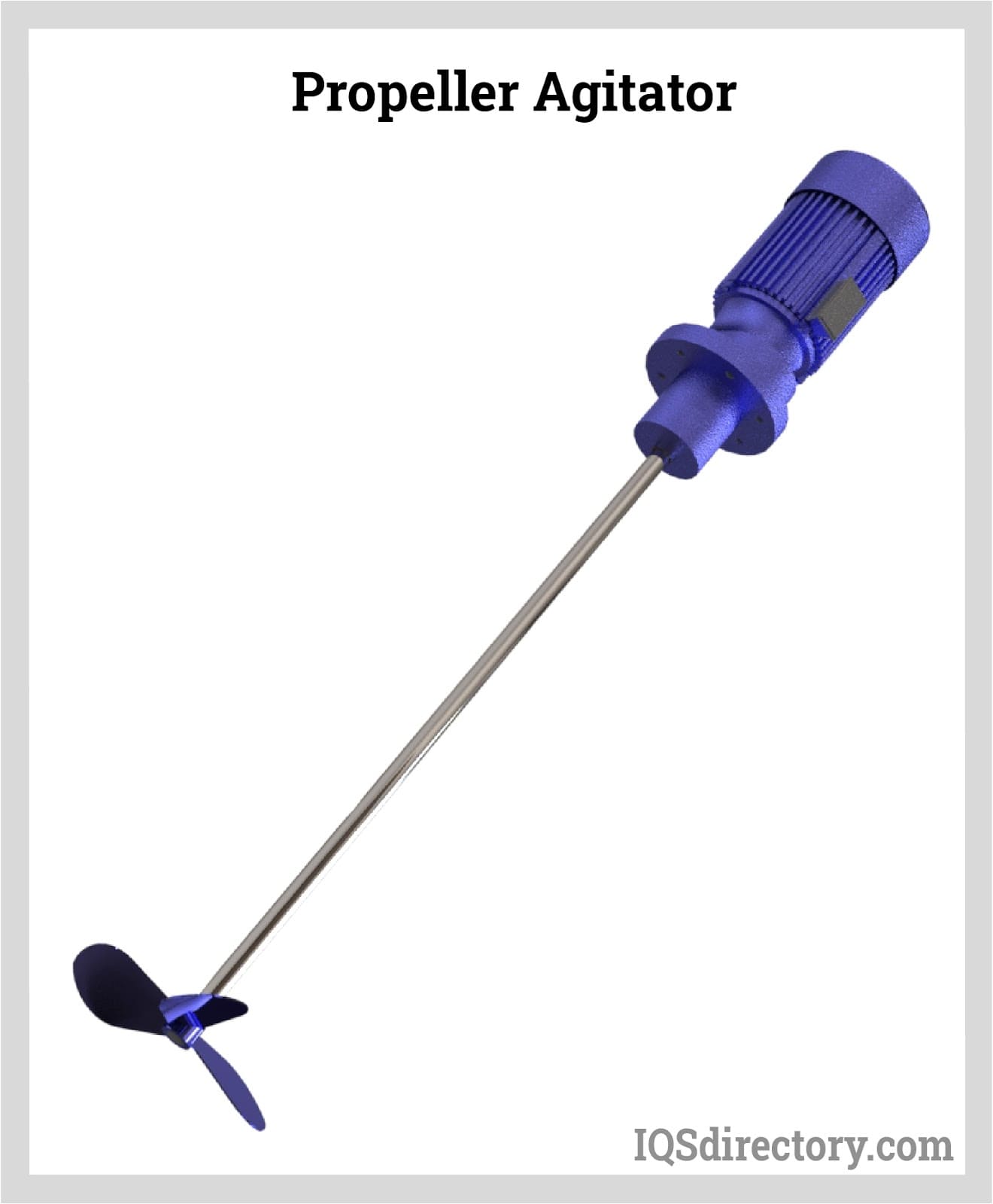

Propeller agitators primarily produce an axial flow pattern, though they can also create a tangential flow. The fluid is displaced and accelerated along the length of the tank as the impeller blades draw it in. The inclination of the impeller blades affects how the fluid is deflected. These blades are tapered towards the shaft to minimize centrifugal force and maximize axial flow.

Operating at medium to high speeds, propeller agitators often use marine propellers.

They are commonly used for homogenizing, dispersing, and suspending low-viscosity products. In solid-liquid suspension systems and chemical reactors, propeller agitators help prevent solids from settling at the tank bottom. They can be installed in unbaffled tanks, either vertically inclined from the centerline or positioned off-center.

Turbine agitators serve as an intermediary between propeller and paddle agitators. They typically have larger diameters compared to propeller agitators and combine centrifugal and rotational motion. Turbine agitators are used in emulsification and dispersion processes where high-speed flow of the media is required. They provide a good balance between flow and shear, and are usually operated at high speeds. These agitators can handle a wide range of material viscosities while maintaining high mixing efficiency.

The types of turbine agitator impellers are as follows:

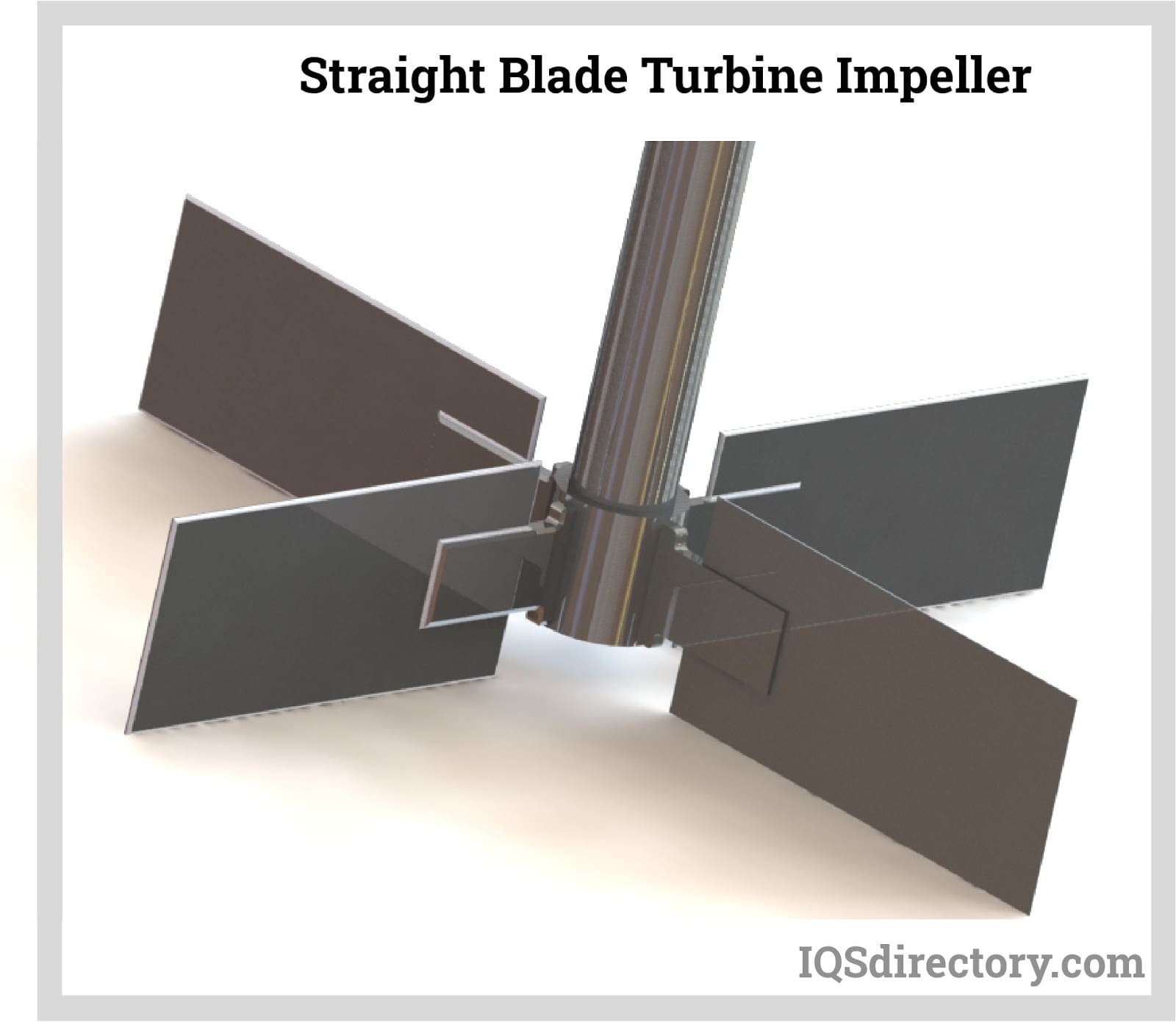

Straight blade turbine impellers consist of two to eight flat vertical blades. These turbine impellers generate a radial flow pattern and high shear. They are used in solid suspension systems, heat transfer applications, and moving solutes from the bottom of the tank.

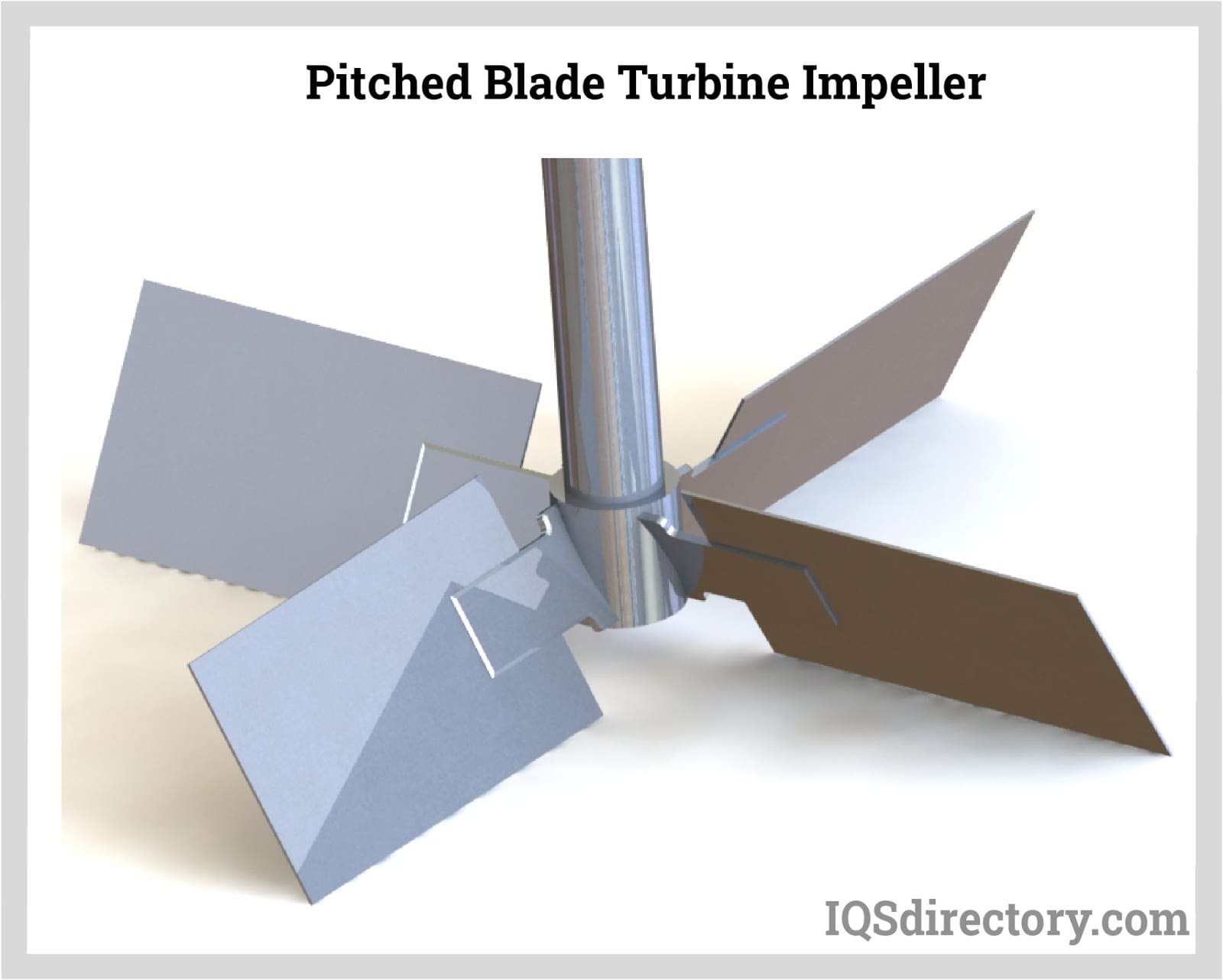

Pitched blade turbine impellers have flat angled blades. The most common type is a four-blade turbine that makes a 450 angle with the vertical. They provide a combination of axial and radial flow; the axial flow is more dominant than the latter. They generate high shear and have good mixing efficiency. They are used in gas dispersions and solid suspensions.

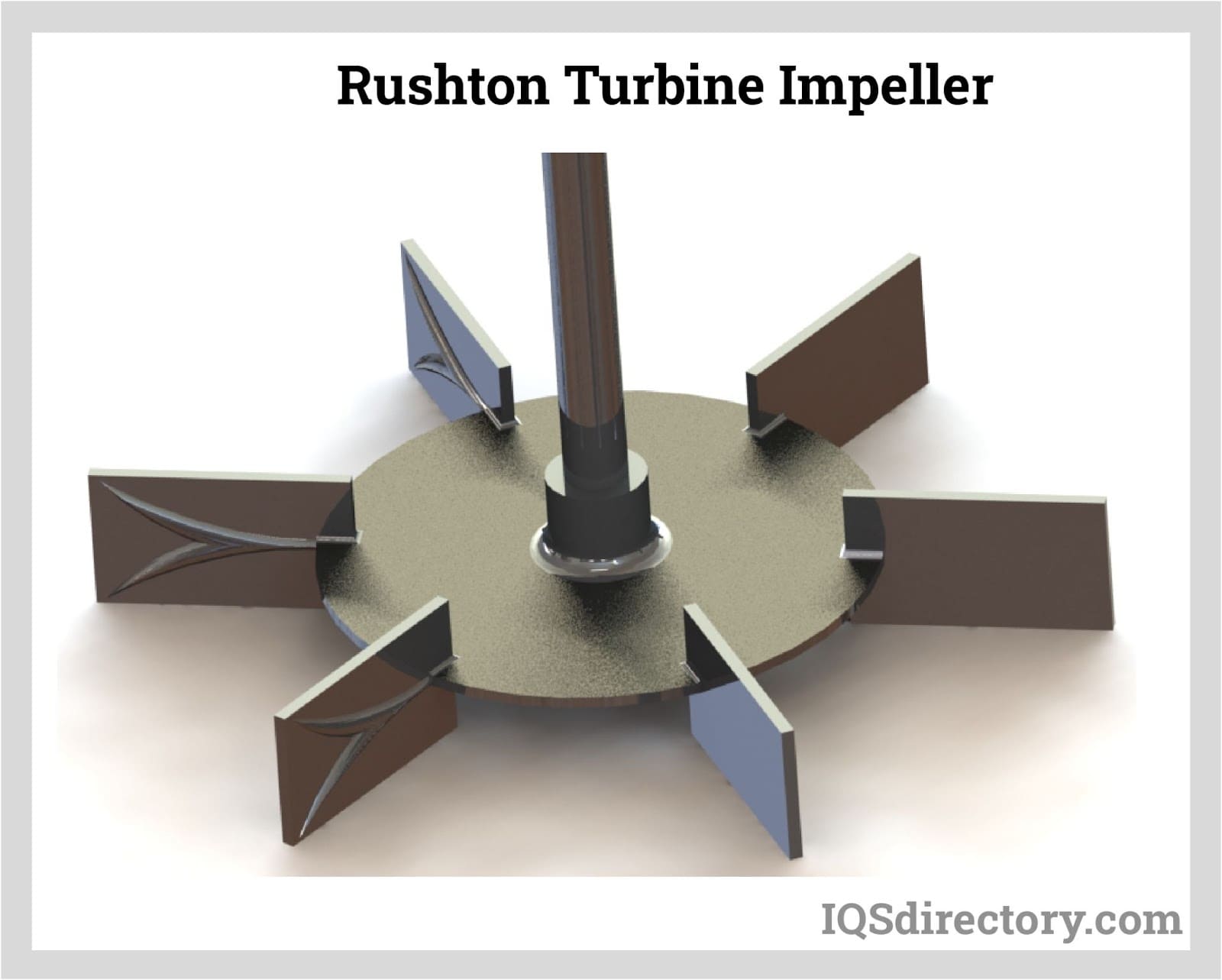

Rushton turbine impellers consist of flat vertical impeller blades arranged symmetrically around the circumference of a horizontal disc. These impellers generate a radial flow pattern. Rushton turbine impellers are effective for gas dispersion applications. The gas is sparged and captured below the rotating disc and then diverted in high turbulent regions near the blades. They can also be used in gas-liquid contacting and mixing.

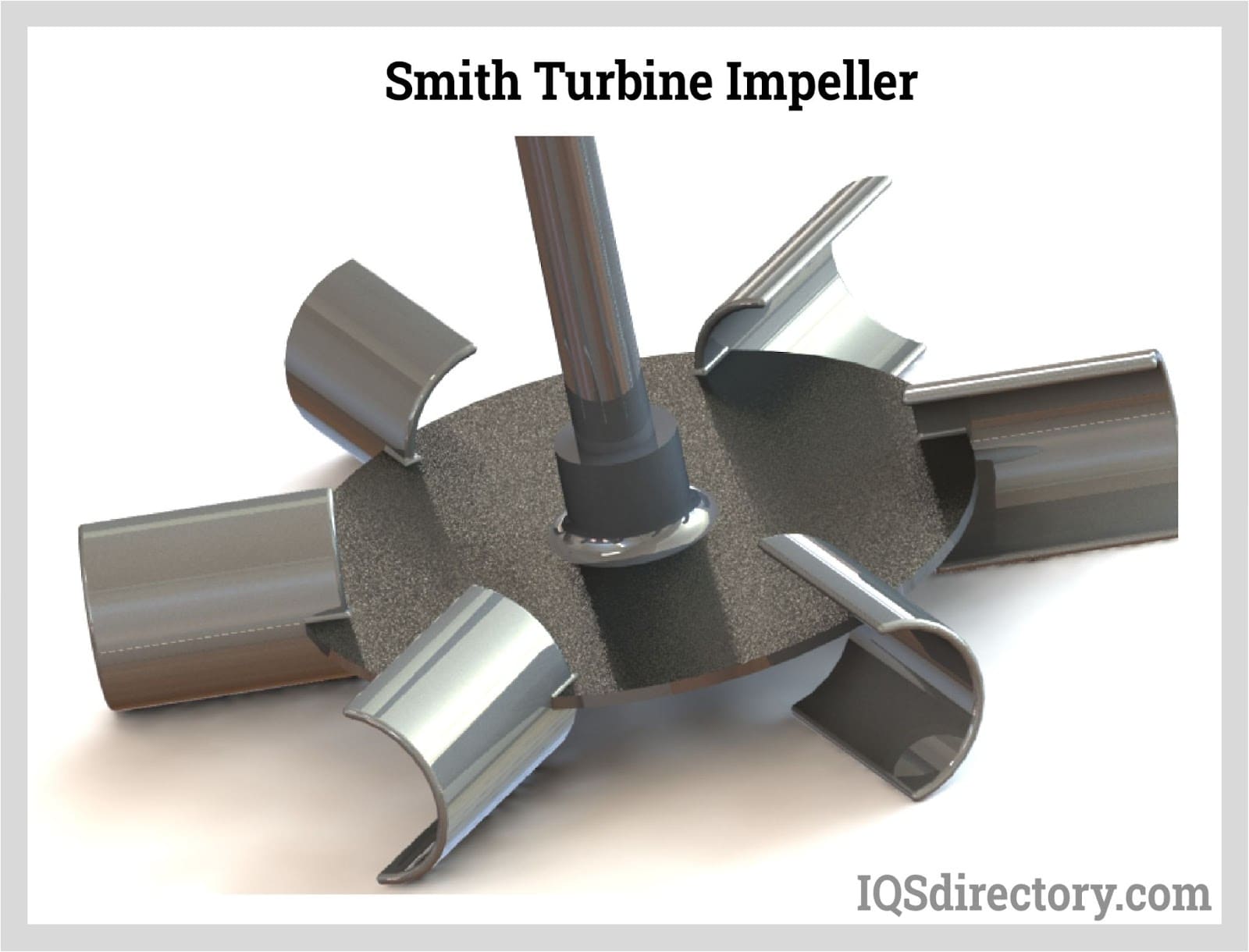

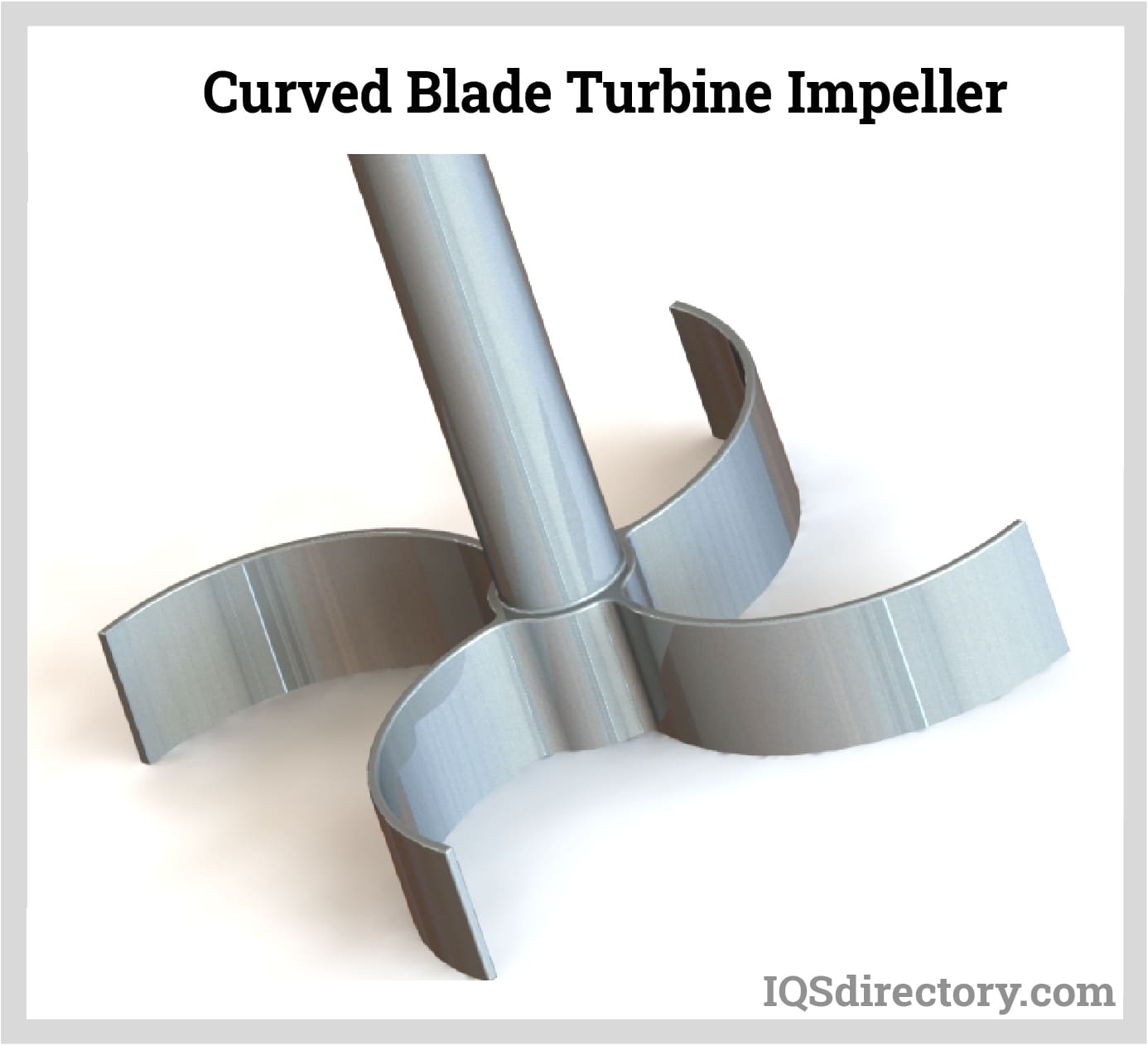

Smith turbine impeller is a variation of a Rushton turbine impeller, in which semi-circular or curved blades are attached instead of flat blades. This impeller is designed for gas-gas and gas-liquid dispersions and emulsions. It has a lower power requirement and larger gassing duty before flooding than Rushton turbine impellers.

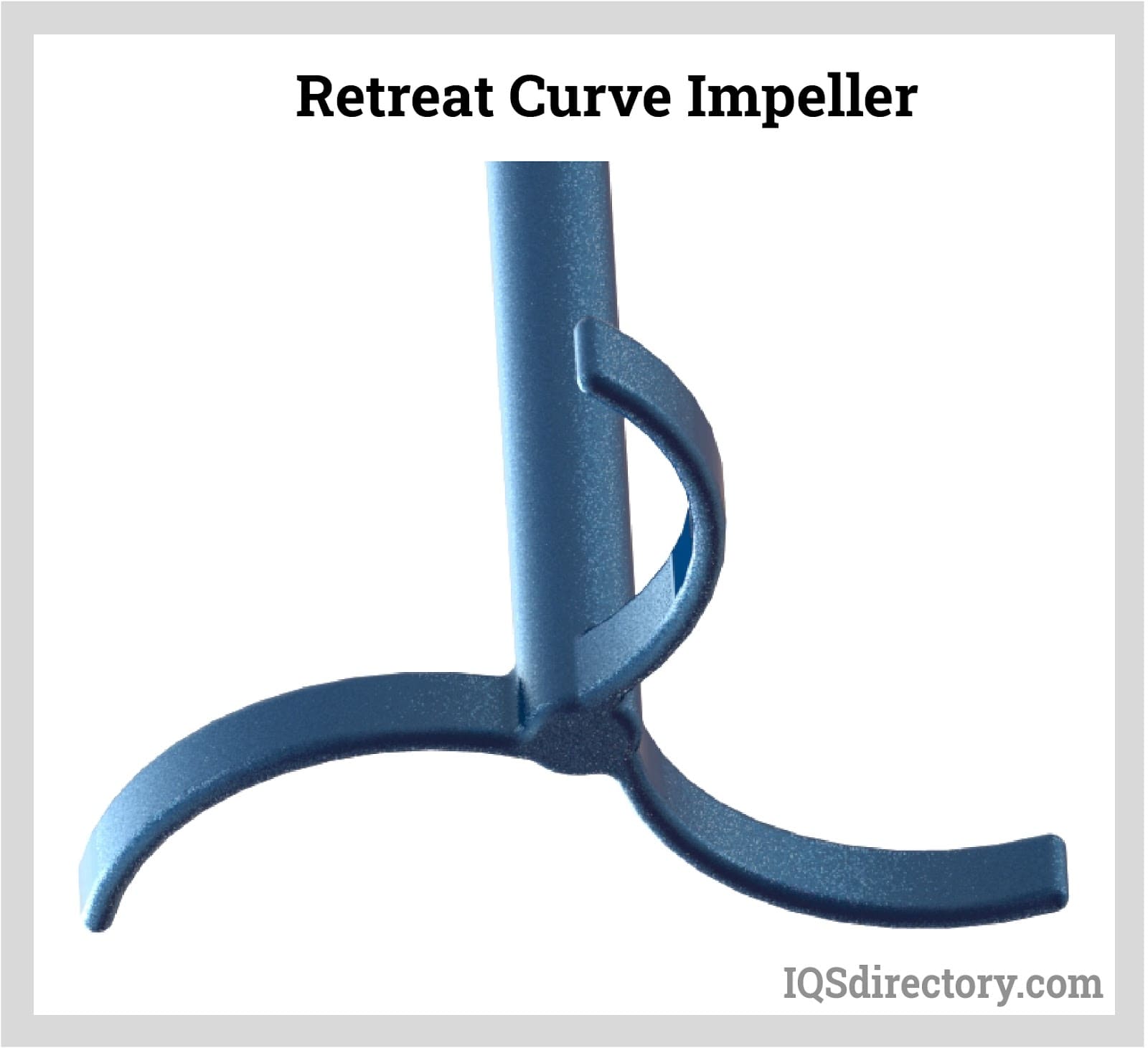

Retreat curve impellers are designed with three curved blades that have rounded edges and corners, making them suitable for coating with glass. This coating helps to prevent corrosion and contamination, which is crucial in industries such as food, beverage, and pharmaceuticals. These impellers mainly produce radial flow, while the axial flow is affected by the ratio of the impeller diameter to the clearance from the tank bottom.

They are particularly effective for achieving uniform dispersion in solid-liquid and slurry mixtures. The rounded corners help reduce turbulence and ensure low shear, which is ideal for shear-sensitive materials. Typically, retreat curve impellers are used at lower speeds.

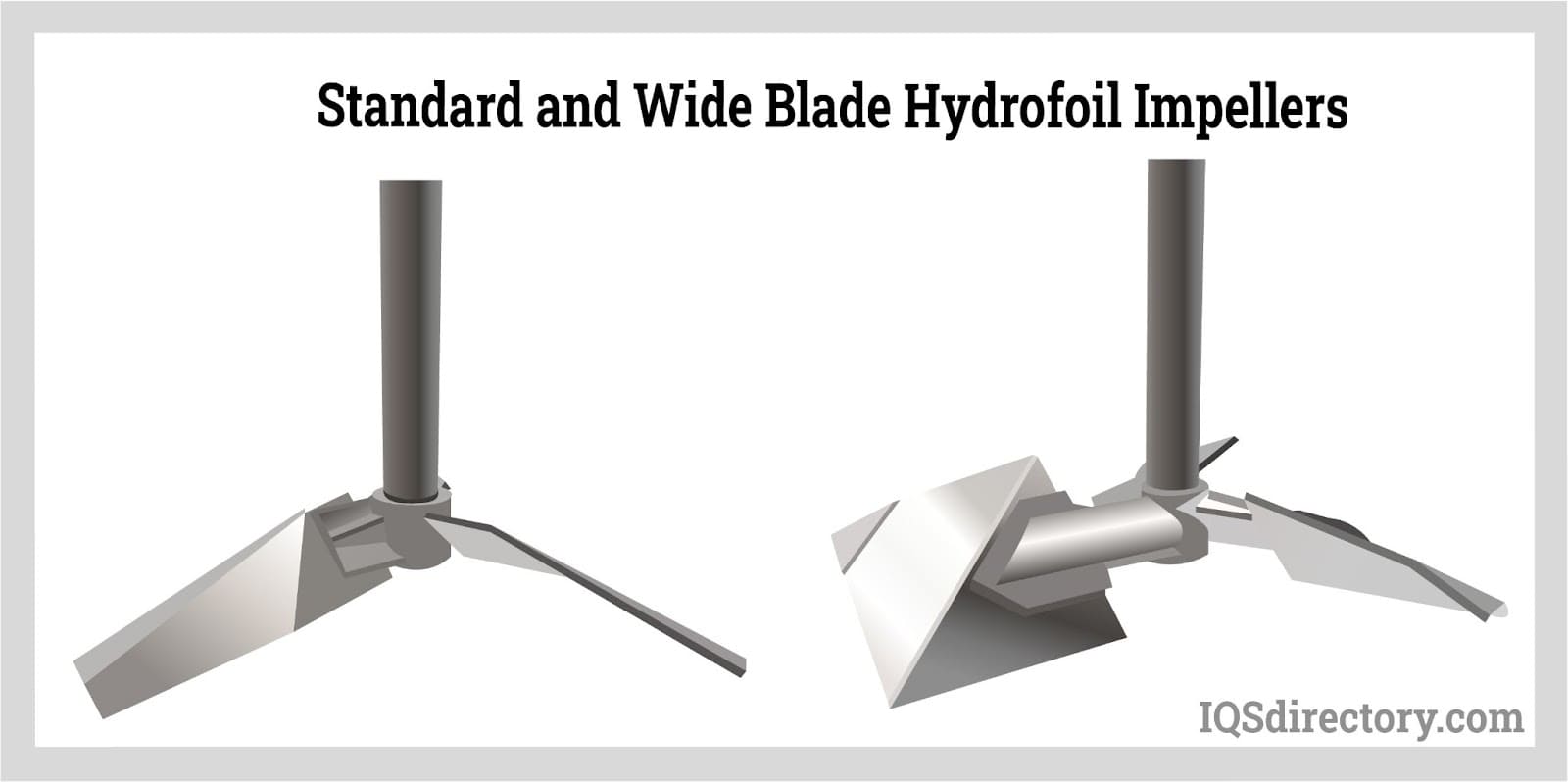

Hydrofoil impellers feature two to four narrow, tapered, and cambered blades, with the three-blade configuration being the most common in industrial applications. The blade angle increases from the tip to the hub, creating an axial flow pattern. These impellers are designed to maximize fluid flow while generating low shear and consuming minimal energy, making them more efficient than pitched blade impellers. Hydrofoil impellers are also more economical than propellers for large diameter tanks.

Standard hydrofoil impellers are ideal for mixing, suspension, and flocculation in low viscosity fluids. They are also effective for shear-sensitive media, such as high-biomass slurries.

Wide blade hydrofoil impellers have a higher solidity ratio compared to standard hydrofoils, which is the ratio of the total blade area to the area of the circle encompassing the impeller. Due to their larger contacting area, these impellers are well-suited for gas-liquid dispersions. Although they require more power than standard hydrofoil impellers, their power requirement is still lower than that of pitched blade impellers.

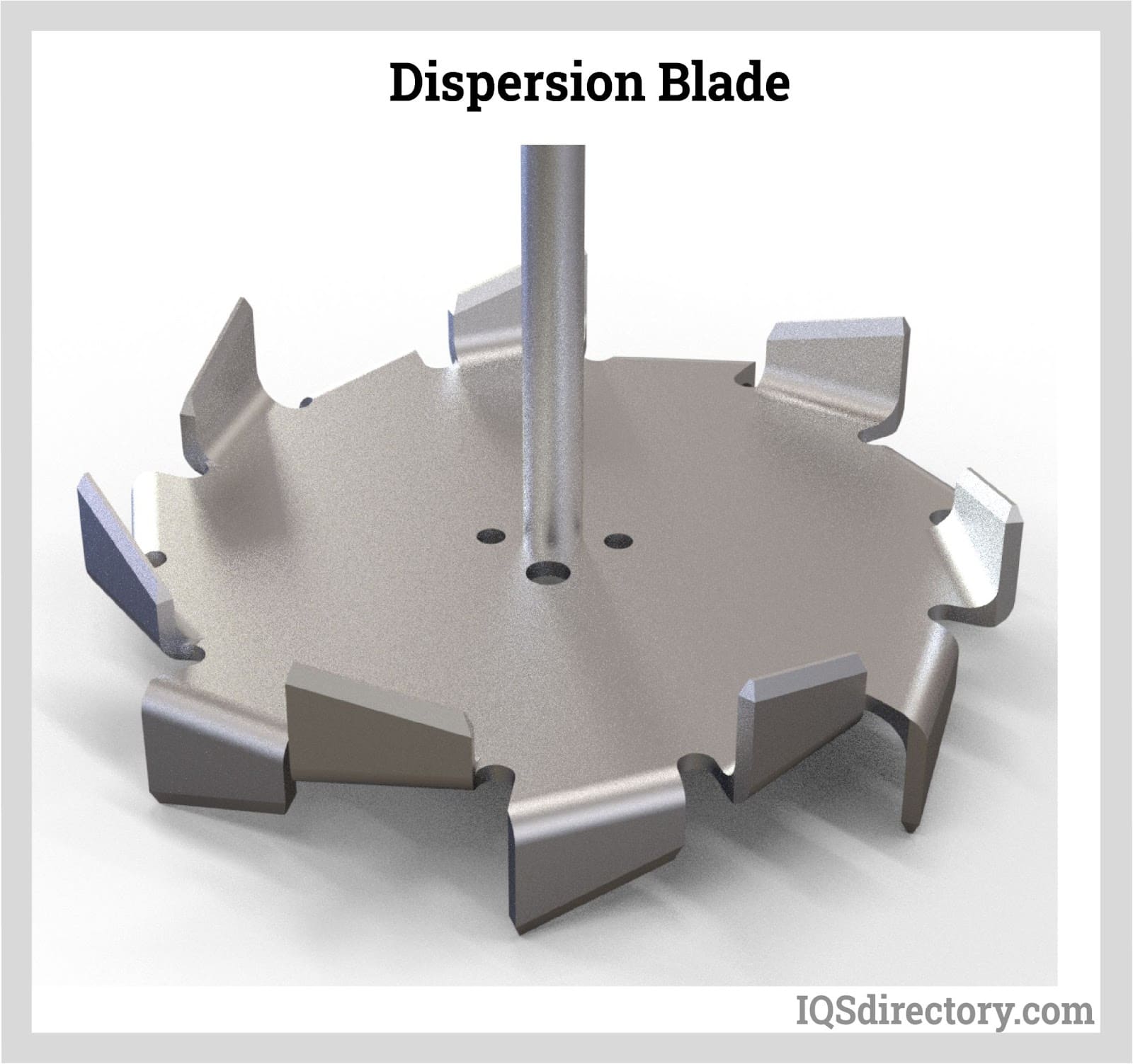

Dispersion blade impellers feature a disc with sharp outer blades or teeth designed to break down agglomerations of solids and viscous liquids into fine particles. The sawtooth design is commonly used in various industries. Over time, the outer blades become sharper due to abrasion with the media. These impellers operate at high speeds to generate high shear and turbulent flow. Typically, dispersion blade impellers are made from durable materials like carbide and stainless steel.

Dispersion blade impellers are commonly used in solid-liquid or liquid-liquid dispersion. They are used in dispersing pigments in a viscous paint mixture. They are also used in emulsification and grinding applications.

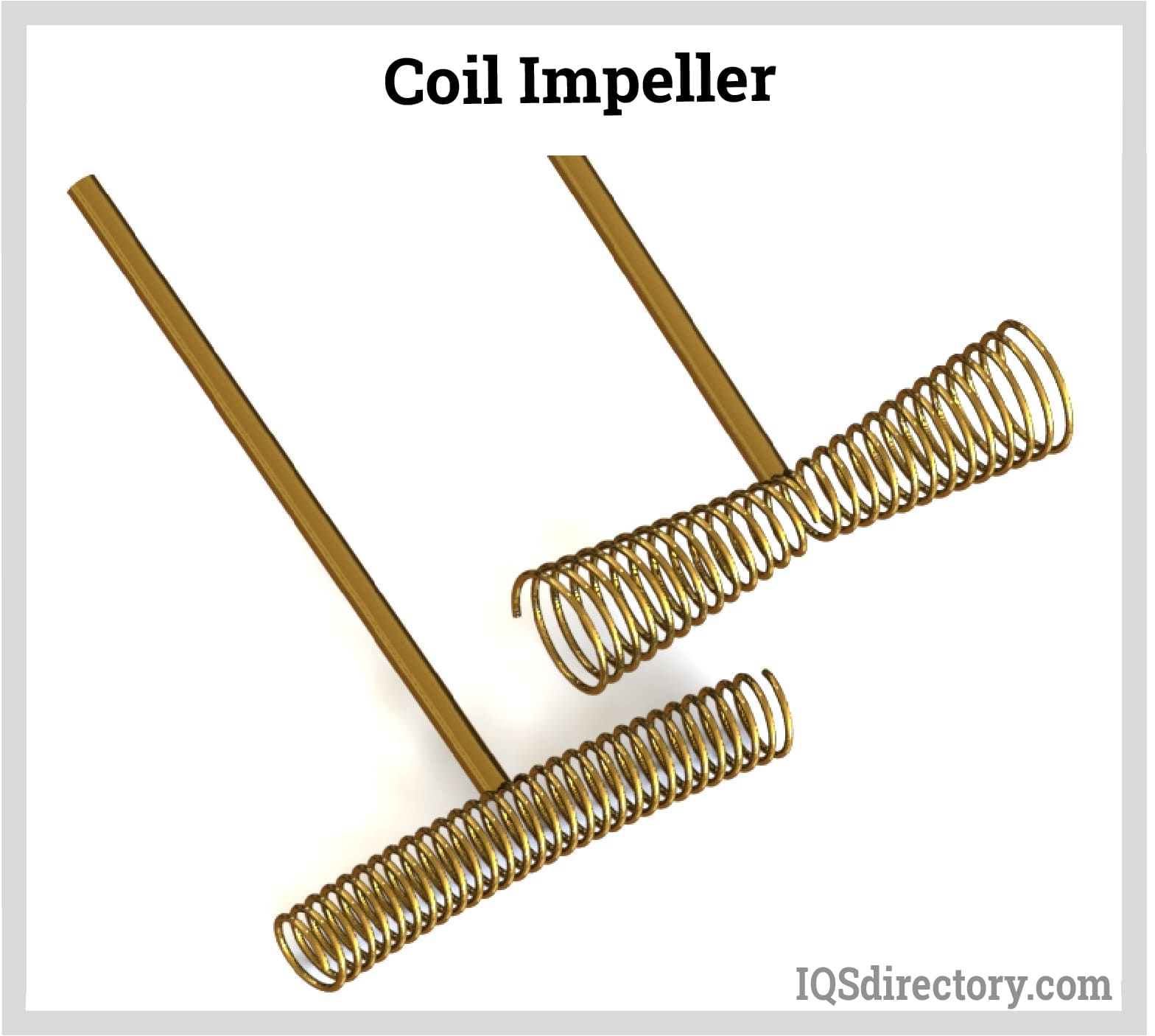

Coil impellers utilize springs as their impeller blades, generating a primarily radial flow pattern. The springs are designed with high mechanical rigidity to overcome the resistance from solids at the bottom of a suspension during mixing. Additionally, coil impellers help prevent solids from settling at the bottom of the tank.

The types of agitators, based on their configuration when installed in a mixing tank, are as follows:

Top entry agitators are installed above the liquid level, typically at the centerline of a baffled vessel. They are well-suited for wide tanks with small aspect ratios (i.e., the ratio of liquid level to tank diameter) of about 1:1. These agitators can be positioned at an angle from the vertical to effectively suspend solids within the solution. They are suitable for sealed tanks and can be mounted using either a plate mount or flange mount. Their design and location facilitate easy dismantling and cleaning.

The top entry configuration is the most common type used in industrial mixing applications.

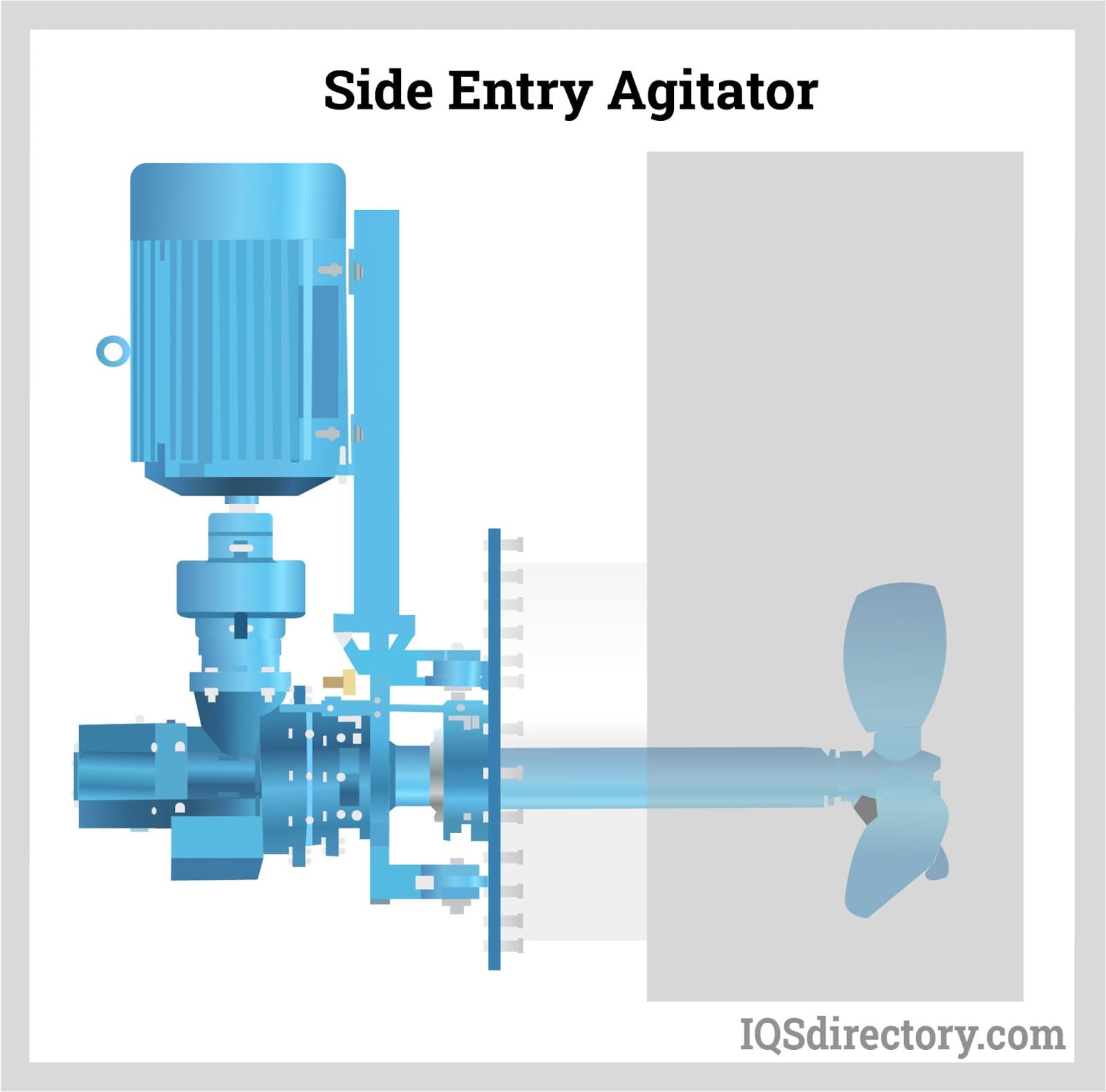

Side entry agitators are mounted on the sidewall of a tank and are ideal for situations where the tank's width is significantly greater than the liquid level. They are also used in tanks with low ceiling clearance, which prevents the installation of top-entry agitators. However, side entry agitators often result in less consistent mixing because the fluid is directed along the tank walls. During maintenance, the fluid must be removed. Additionally, side entry agitators generally have a higher power requirement compared to top-entry agitators.

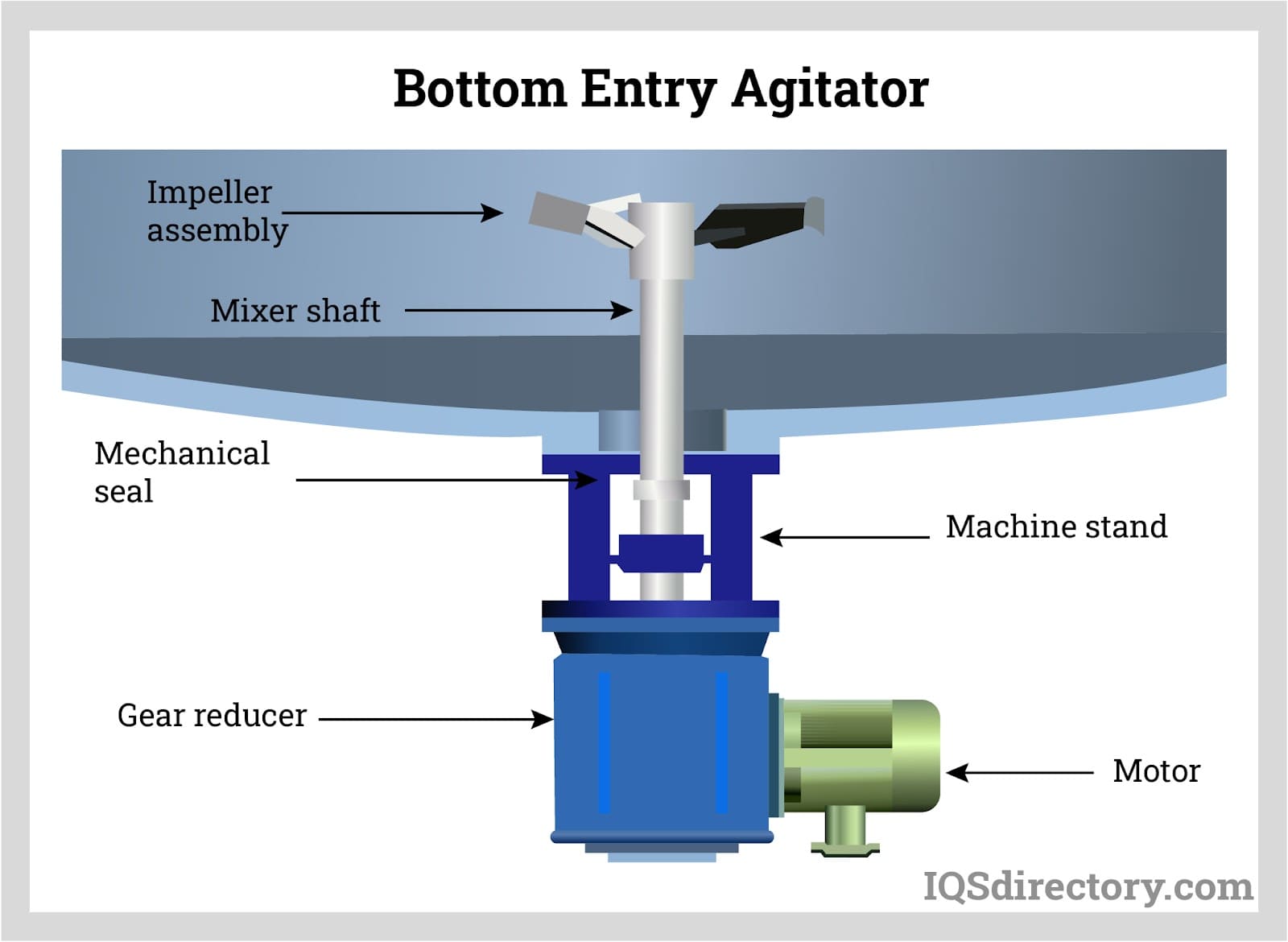

Bottom entry agitators are positioned at the bottom of the tank with a short shaft directly linked to the motor's driveshaft. They are highly effective for mixing materials that tend to settle at the tank's bottom. These agitators are commonly used in large tanks and are well-suited for homogenizing mixtures like oils, milk, juices, and similar substances.

Drum mixers are mixers that are used for mixing free flowing materials by rotating them forward and reverse with welded chutes or flights that fluidize the mixture. The design of drum mixers gives them...

An emulsifier is an emulsion device used for colloidal dispersion of liquid droplets of immiscible liquids in the presence of an emulsifying agent. It enables the combining of non-soluble solutions or liquids...

High shear mixers, also known as high shear reactors (HSRs), rotor-stator mixers, and high shear homogenizers, are used to emulsify, homogenize, disperse, grind and/or dissolve immiscible mixtures with components of the same or different phases...

A homogenizer is a type of mixing equipment used to create a uniform and consistent mixture. It works by breaking the components and evenly distributing them throughout the solution. The components are either immiscible, have varying sizes, or are in different phases from each other...

An industrial blender is a machine for large-scale production that consists of a large tank capable of mixing and blending batches of manufacturing materials to create a reaction between the materials. The many uses for industrial blenders are due to their capacity and...

A mill is a mechanical device that is often a structure, appliance, or machine that is used to break down solid materials into smaller pieces by cutting, grinding, or crushing them. Many industrial processes involve...

A tank mixer is a mixing device that blends several different ingredients in a single tank to make a single solution. It is a mixing process capable of mixing wettable powders, liquids, emulsifiable concentrates, and surfactants. They mix and blend...

A mixer is a complex and precise tool that is used in combining and mixing of substances and chemicals for manufacturing, production, and industrial use. There are many types of industrial mixers including...

A plastic tank is a large capacity liquid or granular storage unit that can be vertical, horizontal, below or above ground, as well as movable. They are designed to hold several gallons of a variety of substances for long periods without experiencing wear, weathering, or deterioration...

A plastic water tank is a large capacity container designed to store water for household, agricultural, irrigation, and industrial manufacturing use. There are various types of water tanks produced to meet the needs of specific applications, with...

A poly tank is a plastic storage tank used to store, transport, and collect water, other liquids, and granular or powder materials. They are made of polyethylene or polypropylene and are a cost effective, lightweight, and easy to handle...

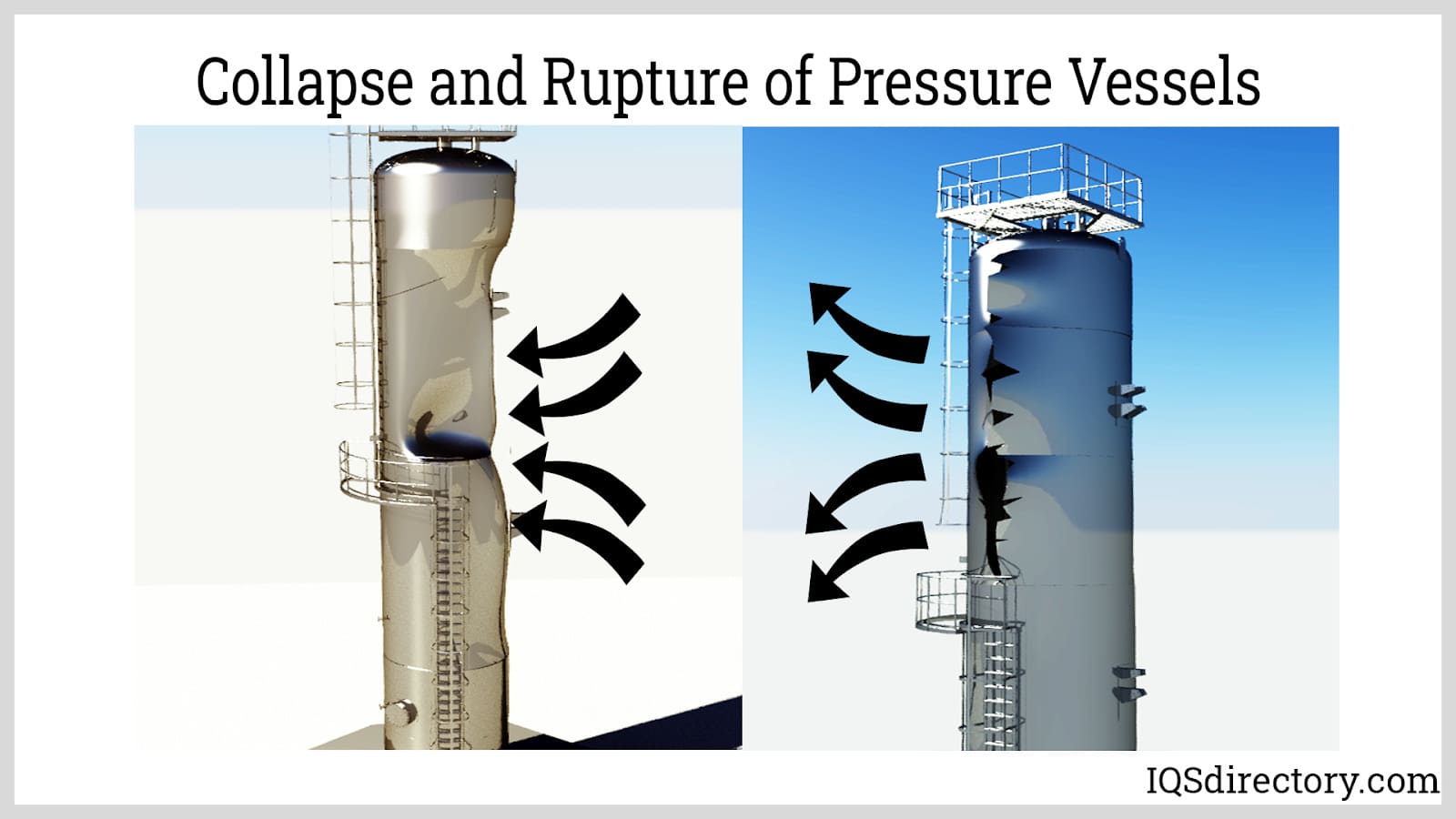

Pressure tanks are vessels that are used to store, hold, and/or convey gasses, vapors and fluids at pressures greater than atmospheric pressure, also known as high pressures...

Pressure vessels are enclosed containers used to hold liquids, vapors, and gases at a pressure significantly higher or lower than the ambient pressure. They are widely used in various industries such as...

Stainless steel tanks are widely used in food, beverage, dairy, medicine, cosmetics, and other manufacturing processes where cleanliness and purity are important. These are also used in industrial plants for storing chemicals and gases where strong resistance from chemical degradation is required...