Deburring

Deburring is a secondary operation of a machining process that enhances the final quality of the product by removing raised edges and unwanted pieces of material, known as burrs, left by the initial...

Please fill out the following form to submit a Request for Quote to any of the following companies listed on

This article will take an in-depth look at tumbling machines.

The article will bring more detail on topics such as:

This segment delves into tumbling machines, outlining their components, operation, and the complete process they encompass.

A tumbling machine is a durable piece of equipment designed for deburring and polishing metals, making it perfect for finishing either large components or many smaller ones. Known also as a barreling or mass-finishing machine, it functions by rotating parts inside a multi-faceted, urethane-coated barrel filled with processing media and a liquid compound, efficiently deburring parts through its tumbling motion.

The operation occurs as the media's top layer continually slides down the incline formed by the spinning barrel. Tumbling machines are extensively used in the jewelry industry for processes such as stone tumbling, jewelry polishing, and deburring metal parts. The rotary barrel tumbling machine and the vibratory tumbling machine are the most prevalent types used.

A tumbling machine consists of several essential components, including:

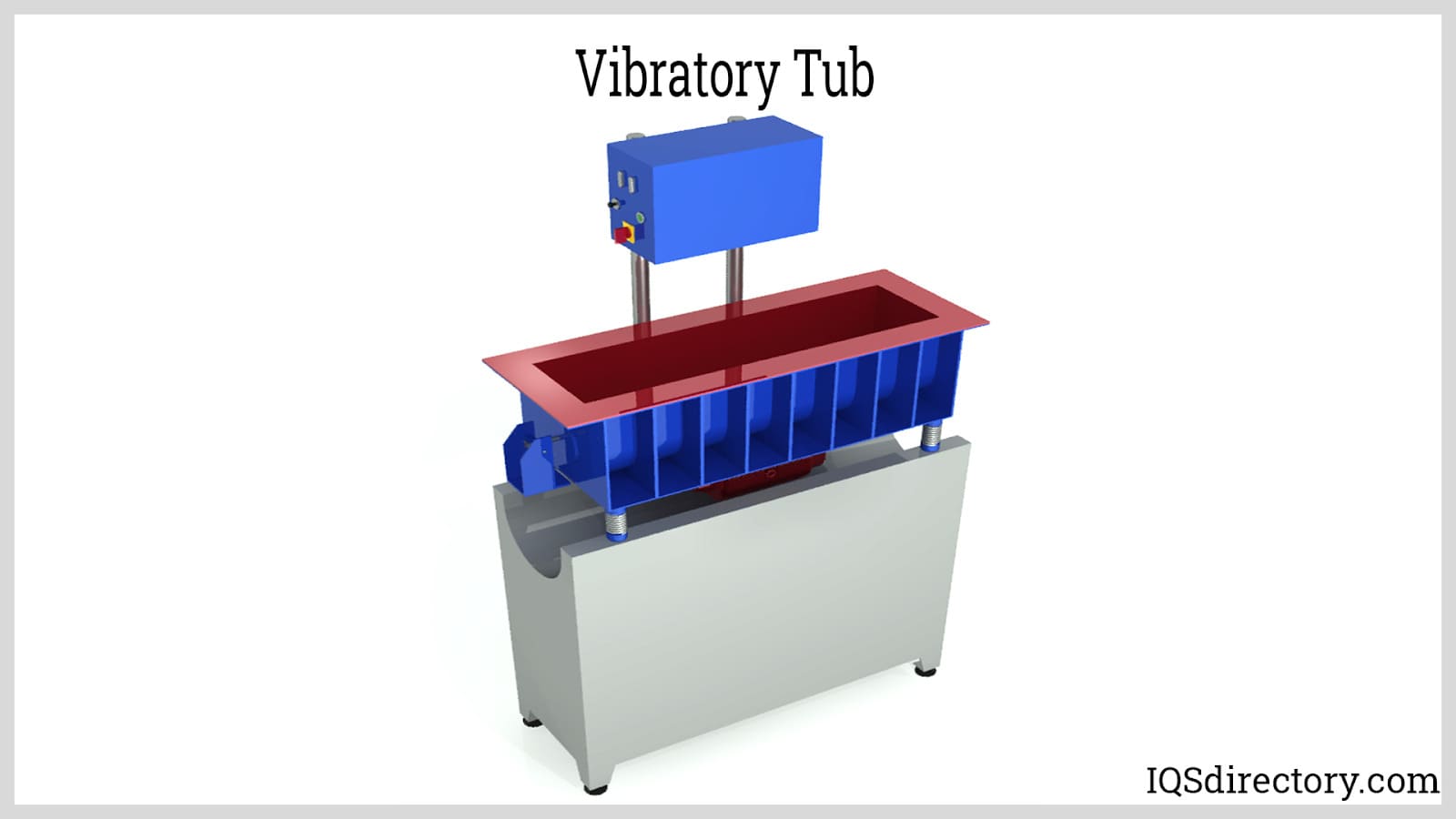

This includes components like the vibratory tub, motor, bearings, shaft, eccentric weights, electric control panel, and a spring system. These parts work together to create the vibratory motion essential for the finishing process.

Water & Chemistry plays a vital role in the wet deburring process, significantly reducing friction between parts and media (discussed below). It also helps in removing dirt and grease by washing away the scrap, resulting in clean parts. Main purpose is to keep a fresh abrasive surface on the media.

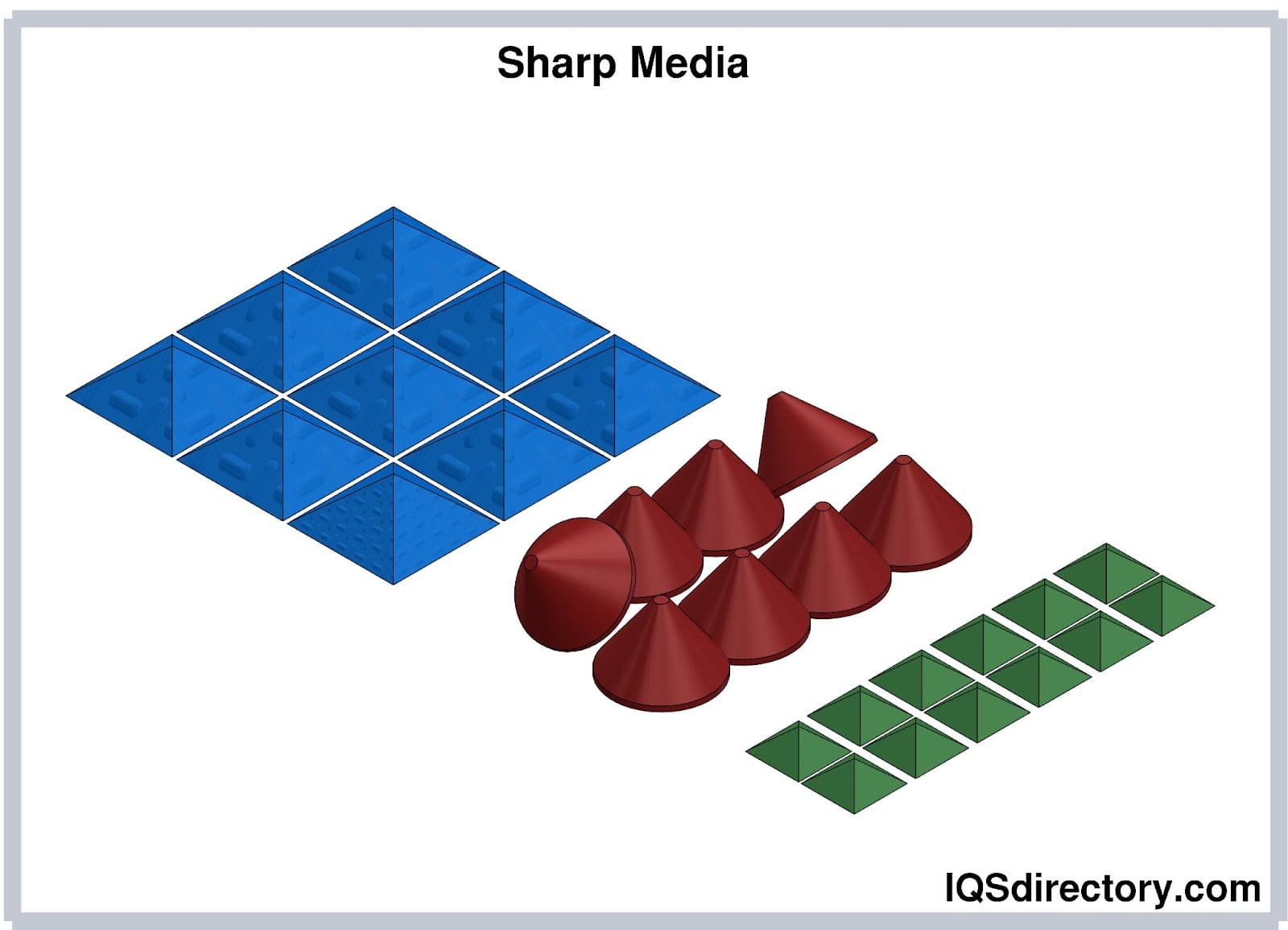

Media, made of various abrasive materials, are added to the bowl along with the parts to optimize the polishing or deburring process. The effectiveness of deburring is determined by the abrasive content in the media.

Chemistry or Compounds are mixed with media to enhance polishing or other specific functions. Usually in liquid form, sometimes as a paste, certain compounds can also act as a degreaser, descaler, burnisher, or corrosion inhibitors.

Tumbling machines have barrels filled with media, abrasives, and the items to be processed. The machine induces a consistent rotation in the barrel, filled with these elements. The friction from this movement grinds, smooths, and polishes the surfaces of the items handled.

Each material requires a different cycle based on its properties. Hard materials need specialized media and abrasive compounds, distinct from those used for softer materials. The surface treatment is mechanical; the tumbler creates friction depending on the type and amount of deburring media, whether it uses vibration or rotation.

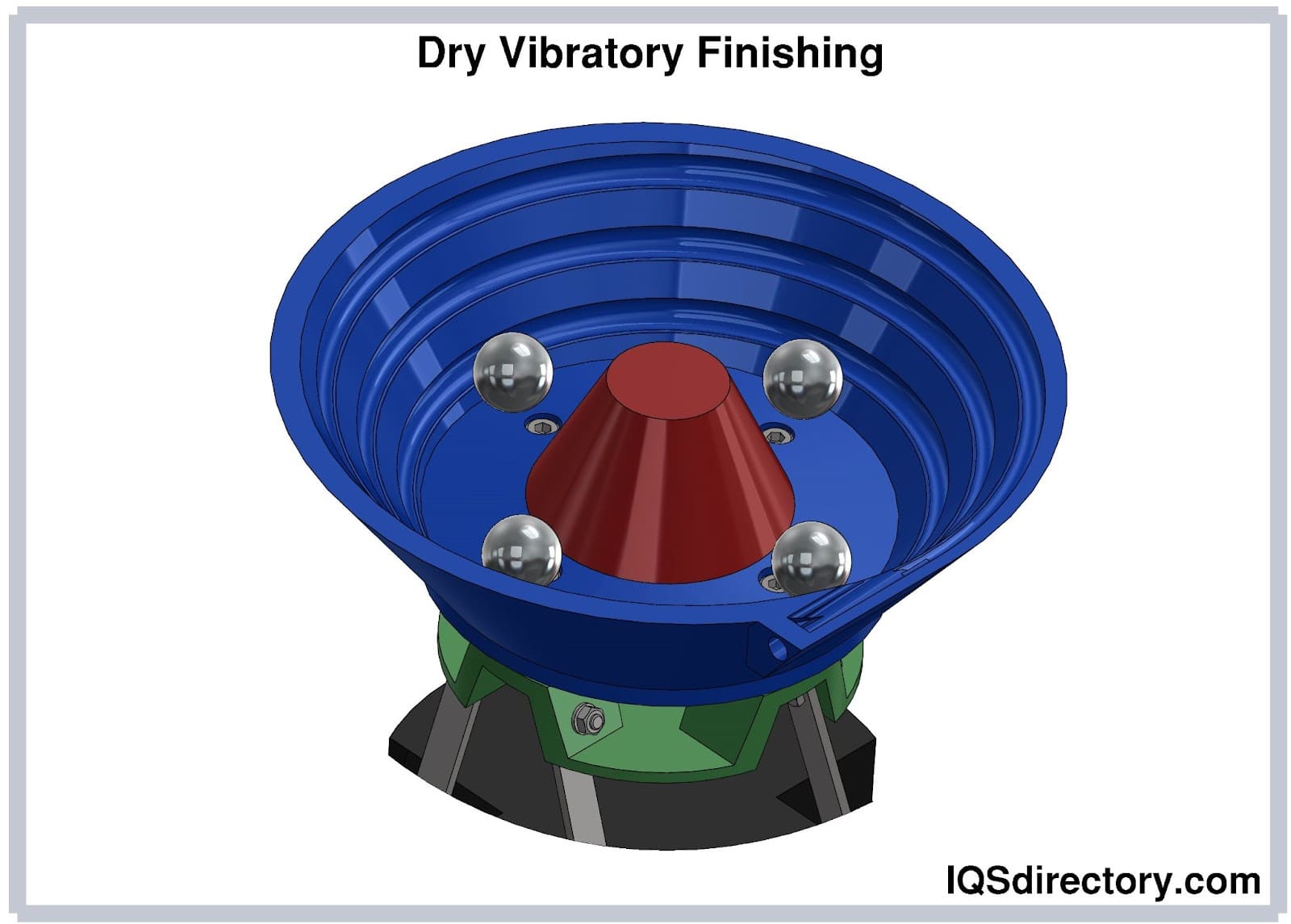

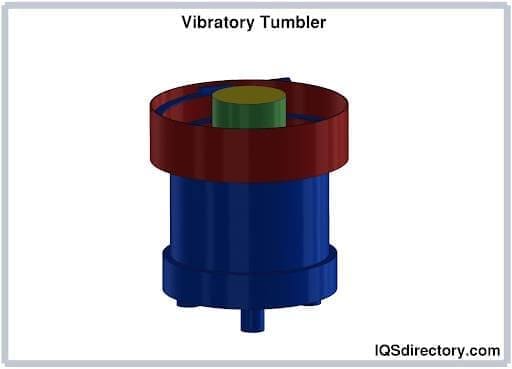

A vibratory deburring machine features a circular tumbler lined with polyurethane (PU) to accommodate the parts and media mixture. A motor powers the machine, and springs provide stability. Activating the machine makes the bowl vibrate, initiating the parts' finishing process.

Within the bowl, the media rubs against the parts, aiding in their finishing. The vibratory motion helps deburr the parts, while the toroidal movement ensures comprehensive cleaning, deburring, and polishing.

Tumbling is a crucial surface finishing process employed on an industrial scale to eliminate surface imperfections, burrs, and sharp edges resulting from prior machining or manufacturing processes. Additionally, tumbling is widely utilized to polish the surfaces of various components, enhancing their final appearance, increasing surface smoothness, and improving the performance and longevity of finished parts.

Industrial tumbling and vibratory finishing processes are employed for deburring, edge rounding, cleaning, descaling, and polishing of metal alloys, plastics, natural materials, and precious metals. These mass finishing systems are essential across numerous industries—including aerospace, automotive, medical device manufacturing, jewelry, and electronics—for their ability to improve product quality, enhance corrosion resistance, and boost overall manufacturing efficiency.

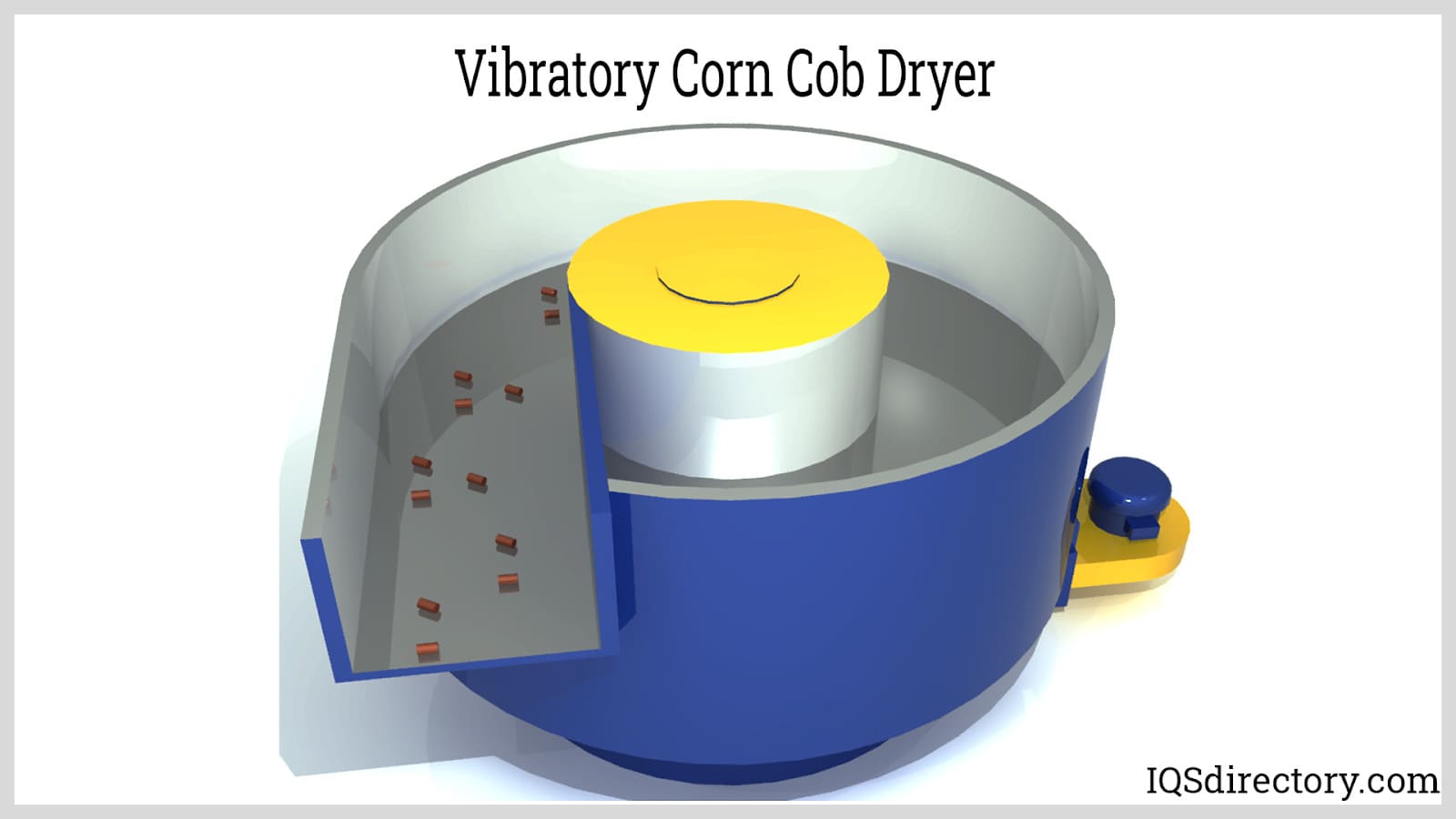

The vibratory tumbling process is one of the most common and versatile methods in surface finishing technology. Tumbling machines using vibratory action effectively create smooth, clean, and polished surfaces on plastic and metal parts. In this process, water and abrasive media—such as ceramic, plastic, or stainless-steel media—are combined in a specialized machine called a vibratory tumbler.

Vibratory tumbling machines work by generating high-frequency, low-amplitude vibrations that cause the abrasive media and workpieces to move against one another. This motion produces rapid and consistent surface abrasion, facilitating strong collisions that efficiently deburr, descale, or polish the parts. The vibratory finishing process is gentle enough to finish delicate plastic parts while robust enough for heavy-duty metal deburring. Vibratory tumbling systems are available in various sizes—from bench-top machines for small batches to large industrial vibratory bowls or troughs—delivering high throughput and process repeatability. This method is ideal for manufacturers seeking automated, continuous processes that increase production speed and reduce manual labor costs.

The high-energy tumbling process, also known as centrifugal barrel finishing (CBF) or high-energy barrel finishing, is a rapid surface finishing solution designed to achieve exceptionally smooth and burr-free surfaces in a fraction of the time required by conventional methods. Like vibratory tumbling, this process utilizes water and abrasive media to refine part surfaces, but with significantly increased rotational forces.

During high-energy tumbling, sealed barrels are loaded with parts, water, and media before being mounted onto a carousel. This carousel spins in one direction while the barrels are rotated in the opposite direction, generating intense centrifugal forces. The result is accelerated material removal, surface refinement, and edge radiusing. High-energy tumbling machines are ideal for precision deburring, rapid finishing of small and complex parts, and applications where cycle time is critical. These machines come in various sizes, accommodating both large production runs and small prototype lots, making them suitable for diverse industrial sectors such as medical devices, aerospace, and metalworking.

When evaluating vibratory tumbling versus high-energy tumbling, several key factors should be assessed to align with your specific finishing requirements. Cycle time is typically shorter with high-energy tumbling systems due to their powerful forces, making them ideal when fast turnaround is necessary. However, these machines may require more manual loading and offer less automation compared to vibratory tumblers, which are renowned for their fully automated, hands-free operation and ability to process larger part volumes continuously.

The sophistication and investment required for each technology varies. Vibratory finishing equipment can feature more complex controls and integrated process monitoring, potentially increasing costs but yielding consistent and repeatable results. In contrast, high-energy tumbling often involves simpler setups but excels at handling small, intricate, or high-value components with extreme precision and a high level of surface refinement. Both processes help manufacturers reduce post-processing rejects, extend part lifespan, and ensure compliance with strict industry surface finish standards. Vibe = set it & forget it & time vs. Centrifugal barrel = initial cost & operator handling.

The tumbling-vibro finishing process comprises three essential stages: grinding, smoothing, & polishing. Each step plays a pivotal role in achieving a flawless, mirror-like, and smooth surface finish on a variety of materials

By following these sequential steps, tumbling and vibro finishing ensure that parts meet both aesthetic and functional requirements for critical industries, delivering improved wear resistance and reducing the risk of component failure.

Tumbling machines and associated finishing equipment are adaptable to a vast range of materials commonly encountered in manufacturing and fabrication. Popular tumbling media and techniques are selected according to specific substrate requirements and desired final finish. Typical materials suitable for tumbling include:

Choosing the correct combination of machine type, abrasive media size and shape, and processing parameters ensures optimal results for each material type. Manufacturers often experiment with tumbling media, speeds, and chemical additives to achieve the perfect finish for unique parts and applications. For more guidance on selecting media and customizing surface finishing processes, consult an experienced tumbling equipment supplier or partner with an industrial finishing specialist.

Tumbling machines, essential tools in surface finishing, deburring, and polishing processes across many manufacturing industries, come in several types designed for different parts finishing requirements and production scales. Selecting the right tumbling machine and compatible media is critical to optimizing batch quality, cycle times, and process efficiency. This guide details the main tumbling equipment and finishing media types to support buyers and engineers evaluating mass finishing solutions.

The centrifugal barrel tumbler operates similarly to a Ferris wheel, with smaller baskets mounted on the edges of a large wheel. This high-energy finishing tumbler features four barrels, each akin to a seat on the Ferris wheel, and a large flywheel. As the flywheel rotates, each barrel completes a full turn, generating extremely high centrifugal forces due to the flywheel's rapid spinning speed.

These forces can be 15 to 20 times greater than gravitational force, causing the contents to slide against each other under high pressure. This intense pressure enables rapid processing of metal parts and produces smooth, consistent finishes. The operator can adjust the tumbling speed, allowing for fine finishing and polishing at lower speeds or more aggressive deburring and edge smoothing at higher speeds.

Centrifugal tumbling machines are highly effective at removing significant burrs, blending machining lines, and eliminating tool marks left by milling or stamping. They excel in polishing and burnishing applications as well. When used with various ceramic or organic media, these machines can achieve a broad spectrum of surface finishes—ranging from aggressive metal burr removal to super-fine, high-gloss polishing.

These industrial finishing machines are esteemed for their versatility and efficiency, processing a variety of metals such as aluminum, brass, chrome, steel, titanium, and stainless steel with consistent, repeatable results. However, they are not suitable for deburring plastic parts, as plastic is too pliable for this high-pressure process.

Typical configurations of centrifugal barrel tumbling machines include:

A barrel divider enables the operator to split each barrel into smaller compartments, allowing simultaneous finishing of multiple part types or protecting delicate workpieces from part-on-part contact and surface damage during processing. These dividers improve the efficiency and flexibility of your barrel finishing setup.

This option is commonly used in larger mass finishing systems to separate tumbling media from metal parts after processing. Without a separator, operators must manually pick out parts from the media, which can be very time-consuming for smaller components or intricate geometries. The separator uses a vibratory screen to separate parts from media, with interchangeable screens available to handle different sizes of media and parts, increasing throughput in large-scale finishing operations.

This option is commonly used in smaller systems to trap sediment and spent abrasive from the tumbling process. A cascading feature removes sludge—fine particles of metal and media—from the processing table and traps it, while a sump pump expels the water from the tank. The sludge accumulates over time and needs to be cleaned out regularly to maintain optimal finishing performance and machine longevity.

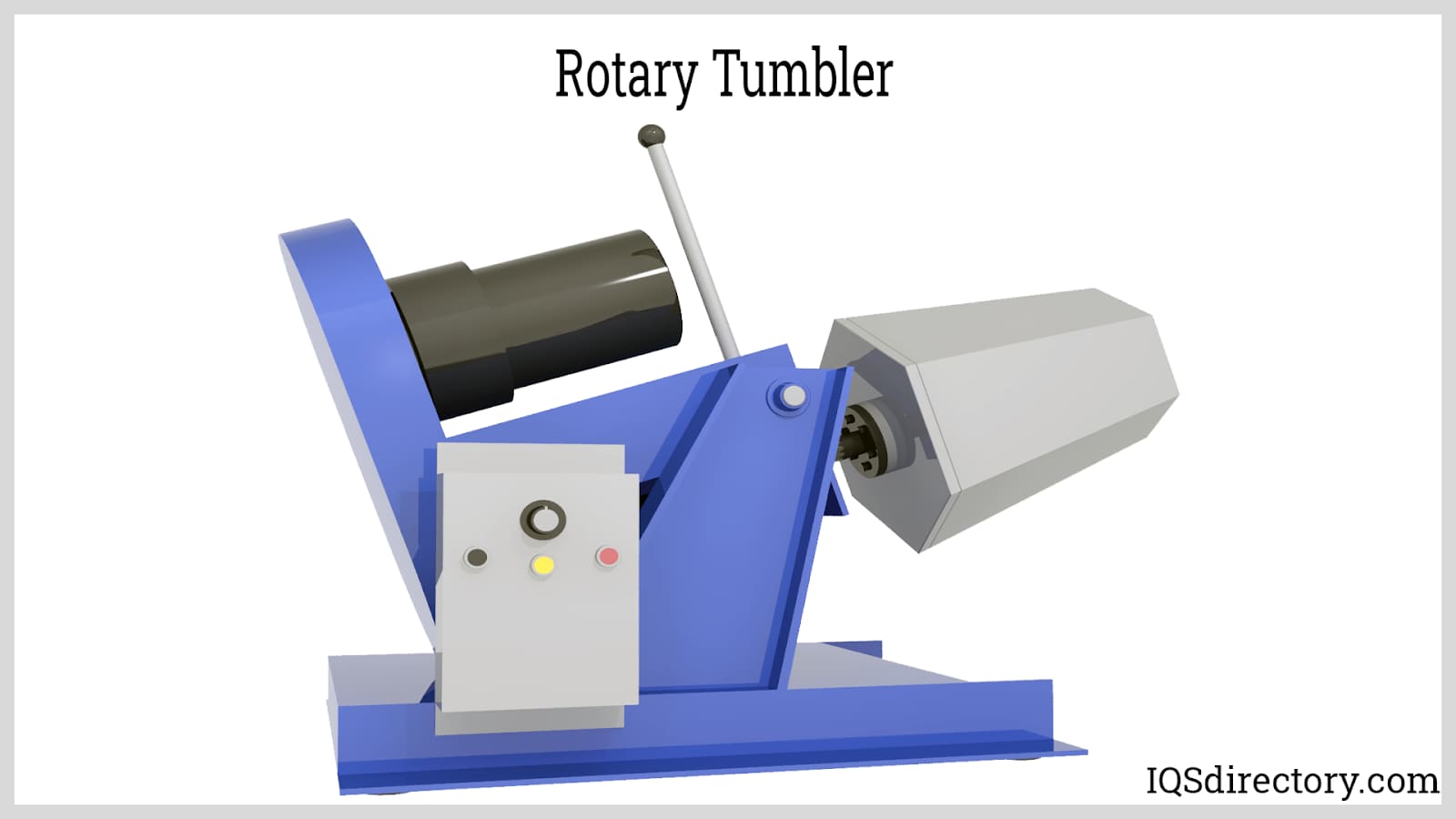

An industrial parts tumbler, also known as a rotary barrel tumbler, executes finishing processes in three key stages: deburring, blending, and polishing. The initial step removes sharp edges, flashing, or burrs left on metal surfaces after machining or stamping operations, improving part safety and assembly fit. A common example is rounding off sharp corners on a machined or punched metal piece.

The second process, blending, smooths and homogenizes the surface by eliminating tooling marks, machining lines, or scratches, resulting in a uniform finish and improved paint or coating adhesion. The third stage, polishing (also referred to as burnishing), enhances surface luster for cosmetic appeal or functional requirements such as reducing friction or improving corrosion resistance. This step can deliver a bright, mirror-like finish on both ferrous and non-ferrous components.

Rotary barrel tumblers accommodate a variety of tumbling media—including ceramic, steel, plastic, and organic options—to tailor the aggressiveness and finish quality to your part design.

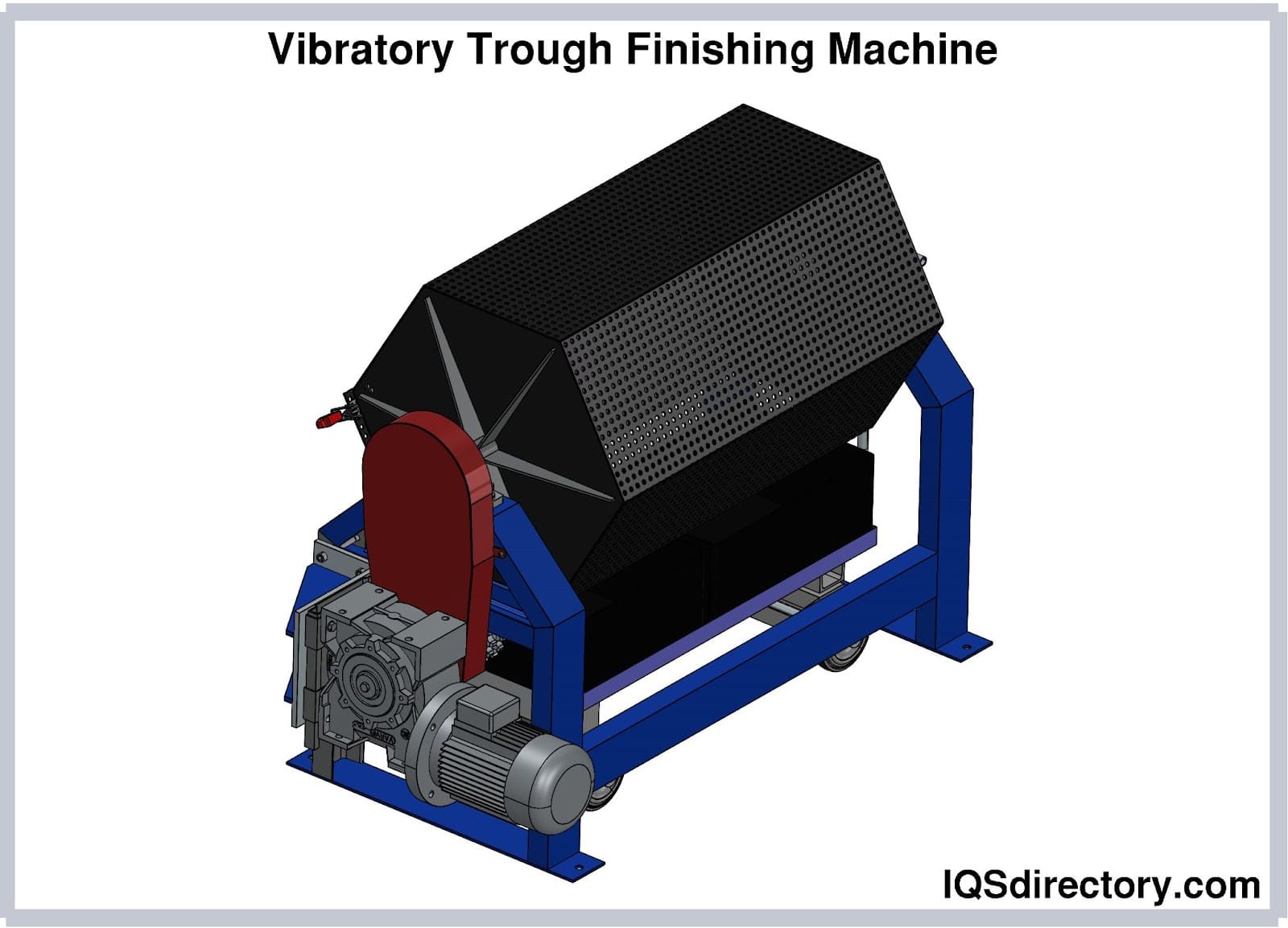

A vibratory tumbler is a widely used mass finishing machine shaped like a large, donut-shaped trough or bowl. It consists of parts and finishing media that vibrate in a mechanical, circular motion, generating friction and scrubbing action that efficiently removes burrs, descales, or polishes the batch of parts placed inside. Vibratory finishing is especially effective for delicate or oddly shaped items that require gentle handling or where precise surface finishes are desired. After processing, the tumblers empty into a conveyor belt and are routed through a drying and cleaning stage. These units often employ specialized solutions with rust inhibitor agents to prevent oxidation and extend the shelf life of plain-finished parts.

Factors that affect the shelf life and integrity of finished parts include environmental exposure, improper handling, and inadequate storage. To minimize damage or corrosion, avoid dropping parts from significant heights and always handle them with gloves to prevent transfer of oils or contaminants onto freshly finished surfaces. These practices are especially important in industries such as automotive, aerospace, and precision tooling, where strict surface finish standards are enforced.

A drum tumbling machine is engineered with internal rubber-lined strips and adjustable drum tilt features, enabling users to precisely control the frequency and intensity of part-to-part collisions and impact finishing action. Its operation depends on the tumbling and cascading movement of similarly hard workpieces inside the drum, leading to effective removal of burrs, scale, and flash. Drum diameter and length are selected based on required production volume and batch size, making this type ideal for high-capacity parts finishing.

Drum tumbling machines may come equipped with automated workpiece loading and finished part transfer systems. Such automation streamlines operations—allowing direct palletization or packaging, crucial for large-scale manufacturing. Integrated dust removal mechanisms help prevent particulate buildup, which can degrade machine performance, contaminate parts, or accelerate equipment wear. For optimal operation and finished product quality, regular inspection and cleaning of these dust control systems are highly recommended.

Linear tumbling machines, also called linear vibratory finishers, operate differently from rotary drums. Instead of rotating a barrel, linear tumblers use crank-driven or chain-driven beaters to strike or vibrate part surfaces, producing a distinct finishing effect without the rolling or sliding action inherent to rotary systems. This linear impact is best suited for processing flat components or single-surface finishing applications common in stone, facade tile finishing, or architectural panels.

A disadvantage is the frequent replacement of beater components due to wear. However, linear tumblers minimize edge and corner rounding since only one side of the workpiece is exposed at a time. This selective surface finishing makes them ideal for preserving critical dimensions and features not intended to be altered during mass finishing.

Barrel tumblers (rotary and centrifugal designs) rely on rolling motion with abrasive finishing media, creating sliding friction against workpieces to facilitate polishing, deburring, and edge radiusing. Centrifugal barrel tumblers intensify this action with enhanced g-forces, yielding faster cycle times and more aggressive material removal for batch-loaded jobs. In contrast, vibratory tumbling machines generate a shearing action through circular side-to-side movement in a trough or bowl. This high-frequency scrubbing action is effective for gentle deburring of complex shapes, internal features, and delicate components. Both methods are foundational in parts finishing—choice depends on target finish, material, throughput, and sensitivity to part-on-part contact.

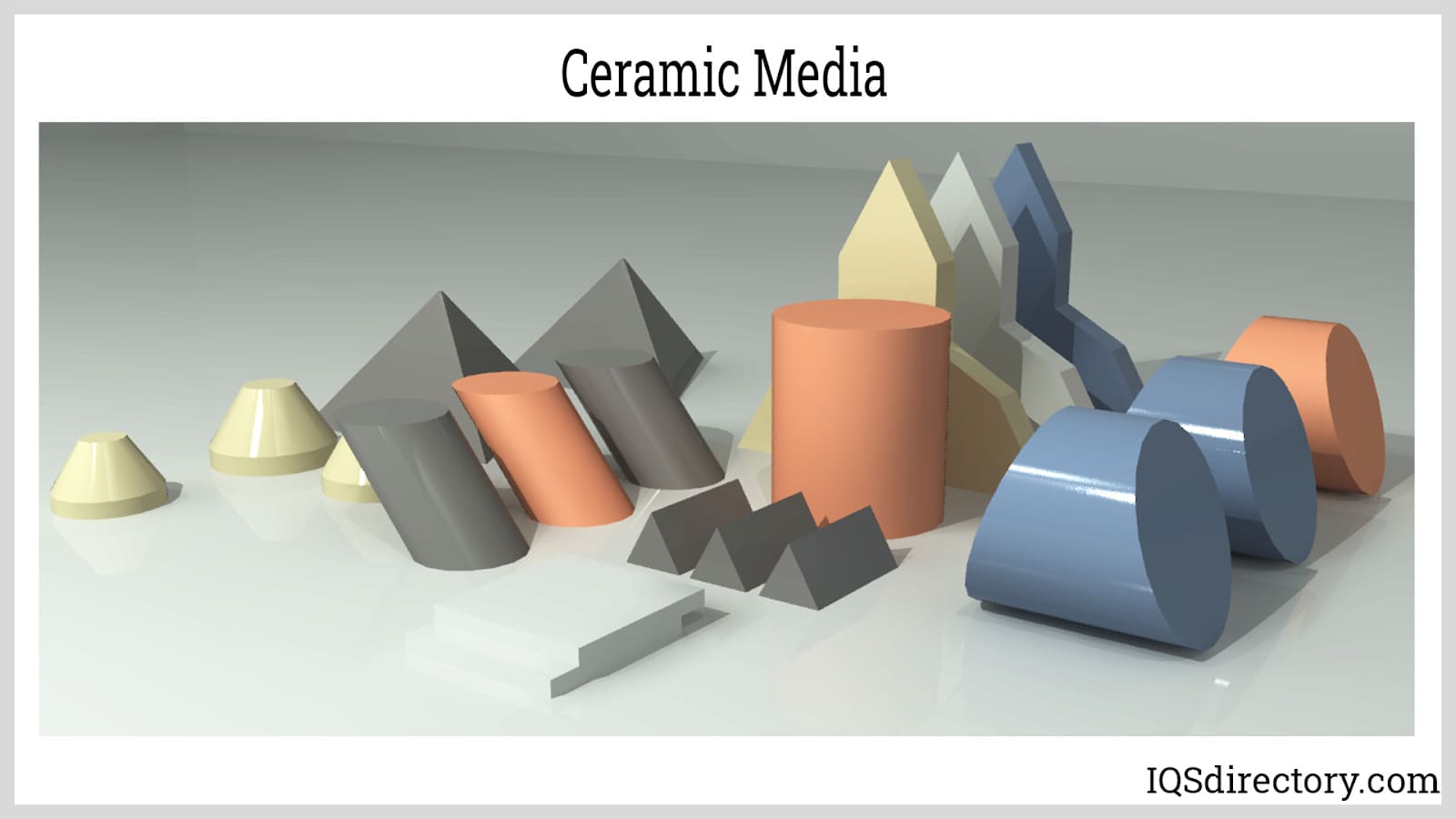

For general-purpose polishing, light to heavy deburring, and rapid metal removal, ceramic tumbling media is highly recommended, particularly in industrial finishing and manufacturing environments. It excels when processing harder metals such as steel and stainless steel, but it can also be used on softer metals like aluminum and bronze. Ideal for large or heavy metal parts due to its high mass and cutting efficiency, ceramic media is cost-effective, long-lasting, and universally popular for mass finishing operations in automotive, aerospace, and metal fabrication sectors. This media is crafted from a blend of ceramic material, silica, abrasives, and binders and fired into tough shapes—making it an effective grinding and finishing agent suitable for a spectrum of components and complex geometries.

This industrial-grade formulation creates a hard, cement-like product extruded into stars, triangles, cylinders, and ellipses, which are then cut to custom sizes. Density and abrasiveness depend on the type and amount of abrasive included before firing; higher-bond abrasives increase material removal rate and enable rapid surface refinement but may wear faster. The right selection of shape and density improves tumbling media flow, contact pattern, and finishing uniformity for your specific application.

Carbon steel tumbling media is primarily used for burnishing, ball burnishing, and polishing non-ferrous and ferrous metals. Its high bulk density generates strong compressive force, quickly delivering a bright, reflective finish or smoothing out minor surface defects. This media is essential in processes requiring a hard, metallic burnished finish, such as in jewelry, firearm components, and high-strength fasteners. Additionally, carbon steel media aids in surface work-hardening—improving wear resistance and fatigue life of treated components. Offered in a range of shapes and sizes (balls, pins, diagonal cut cylinders), this finishing media ensures efficient material flow and rapid batch processing with short cycle times.

High-density ceramic tumbling media offers greater durability and cutting performance than standard ceramic types, suited for heavy-duty applications and demanding mass finishing tasks. Preferred for rapid cycle times and producing minimal residue or sludge, this type is fracture-resistant and offers a fast, aggressive cutting action. High-density ceramic media is popular in aerospace, automotive, and toolmaking industries for deburring, radiusing, and fine finishing of hard metals.

Premium ceramic tumbling media is engineered for superior, precision finishing. Its fine granularity and uniform shape are ideal for intricate parts or detailed component deburring, achieving ultra-smooth surfaces and tight dimensional control. Available in fast-cutting or polishing grades, premium ceramic media is frequently specified for finishing medical devices, aerospace parts, electronics, and other components where consistency and control are paramount.

Hardwood tumbling media is carefully cut for use in dry tumbling and finishing. It works very well with polishing pastes or burnishing creams for gentle surface refinement, final polishing, or delicate deburring, especially on plastics or softer alloys. Hardwood media achieves near-mirror finishes reliably, reduces the risk of overcutting, and, being reusable and exceptionally long-lasting, is a cost-effective choice in light-abrasion applications such as jewelry, electronics housings, or detailed assemblies.

Plastic tumbling media offers gentle but effective surface finishing for a range of processes—including metal deburring, precision deburring, edge radiusing, light burnishing, and surface smoothing. Especially well-suited for non-ferrous or softer metals like brass, aluminum, zinc, and for threaded or intricately machined parts, plastic media prevents part distortion while maintaining surface integrity. Additionally, it is often paired with compound solutions to enhance results or reduce cycle times for certain applications.

Choosing the Correct Tumbling Machine and Media for Your Application: When selecting a tumbling machine and media, consider factors such as part material (metal, plastic, etc.), desired surface finish (polishing, deburring, descaling, or burnishing), batch size, tolerance, geometry complexity, and downstream finishing requirements (like plating or coating). Consulting with a mass finishing equipment supplier can help you determine the optimal solution based on your manufacturing process, cycle time targets, and quality standards. For further insights, review supplier guides or compare tumbling machines and media in this comprehensive buying guide.

A tumbling machine is mass-finishing equipment that polishes and deburrs metals or other materials. Parts are placed in a barrel or bowl with abrasive media and a compound, then moved by vibration or rotation to produce the desired surface finish.

Key types include centrifugal barrel tumblers, industrial parts tumblers (rotary barrel), vibratory tumbling machines, drum tumblers, and linear tumblers. Each is suited for specific materials, batch sizes, and finishing goals.

Vibratory tumbling provides continuous, gentle finishing ideal for larger part volumes and automation, whereas high-energy tumbling achieves faster cycle times and precision on small or complex parts using intense centrifugal forces.

Ceramic media is preferred for hard metals; plastic media for non-ferrous or delicate parts; carbon steel media for burnishing; high-density ceramic for aggressive material removal; and hardwood for gentle, final polishing.

Tumbling machines execute grinding, smoothing, deburring, edge rounding, cleaning, descaling, and polishing. These operations improve surface quality, part performance, and comply with industry finish standards.

Yes, tumbling machines are widely used in the jewelry industry for stone tumbling, polishing, and deburring precious metals like gold, silver, and platinum components efficiently and safely.

This chapter will explore the various applications and advantages of tumbling machines.

Tumbling machines find application across diverse industries. They are commonly used in the production of buttons, eyewear, and jewelry. Additionally, these machines play a crucial role in treating the surfaces of small metal components and fashion accessories, including hair ornaments and costume jewelry.

In the medical device industry, customers demand consistent, high-quality finishes on metal components, particularly those with intricate geometries. Centrifugal barrel tumbling machines are renowned for their efficiency in polishing and deburring tasks. They excel in processing materials such as titanium, cobalt-chrome, and stainless steel, making them ideal for treating implants and surgical instruments. Additionally, these machines are used to polish dental implants and dental tools, ensuring a superior finish.

In the aerospace industry, achieving metal smoothness is critical for the high performance of components. Hand deburring of aerospace parts is often impractical and costly. As a result, manufacturers rely on centrifugal barrel tumbling machines to efficiently handle this task. This method is particularly advantageous for processing turbine blades and jet engine components, where precision and performance are essential.

The automotive industry is another type of business that benefits from centrifugal barrel tumbling machines for smoothing metal parts surfaces. In particular, the automotive industry employs centrifugal barrel parts tumblers for polishing engine heads, fasteners, and gears.

At these shops, centrifugal barrel tumbling machines deliver fast, cost-effective performance for polishing as well as deburring metal parts.

Other benefits include:

The tumble finishing process can be completed in a remarkably short time, ranging from just a few minutes to several hours, depending on the size and type of the workpieces. This method is significantly faster than traditional technologies and ensures a consistent and repeatable finish.

Tumbling machines used for deburring offer a precise approach to removing sharp edges, cleaning drill holes, and enhancing the overall surface smoothness of parts.

Previously, smoothing and polishing metal and plastic materials required complex and costly equipment. Modern tumbling machines have revolutionized this process by making it both efficient and cost-effective. Vibratory deburring machines improve the reliability and longevity of parts, ultimately reducing costs for manufacturers.

Modern tumbling machines are designed to be low-maintenance, offering high reliability with minimal need for frequent repairs or cleanings. This leads to increased uptime, cost savings, and the capacity to handle more orders efficiently.

Many tumbling machines are capable of handling both large quantities and very small items simultaneously. This versatility helps to save both time and money, making the process more efficient.

Vibratory tumbling machines offer exceptional versatility, as they can polish a wide range of materials including ceramics, plastics, steel, stainless steel, aluminum, and copper. Additionally, these machines can be tailored to meet specific user requirements, enhancing their adaptability.

The vibratory finishing process relies on high friction to effectively clean and deburr parts. It is particularly suited for delicate materials that might break or lose their shape easily. Vibratory tumbling machines provide a smooth finish while preserving the integrity of the product.

In mass production, achieving uniformity is crucial. Metal parts often come off the production line with imperfections that can affect consistency. Barrel tumbling machines provide an effective solution for smoothing out these imperfections, ensuring a more consistent batch. Compared to hand polishing, mass metal finishing with these machines delivers far more consistent results.

Some of the factors to include when working with industrial tumbling machines include:

One must be aware that centrifugal barrel tumbling machines generate a significant amount of heat within each barrel. For example, at a speed of 150 rpm, a 120-liter (32 gallons) centrifugal barrel tumbling machine can boil water in 15-20 minutes. Operators must keep this level of heat in mind for safety reasons and also for how it impacts the surface-finishing process. Due to the heat generated, very long cycle times are usually categorized as 5-15 minutes for many parts. A cycle that goes beyond an hour is considered an extremely long one and is not recommended.

Placing too many parts in a tumbler’s barrels will result in part-on-part contact, which can damage the parts. For cosmetically-sensitive parts, barrel dividers can be employed as a solution. Other important factors to consider are the part-to-media ratio in each barrel, as well as utilizing an appropriate amount of water and cleaning compound.

A typical barrel centrifugal tumbling machine has four barrels. Filling only one barrel must be avoided, as this practice can be hard on the bearings; the same is true when loading three of the four barrels. It can cause the machine to be off-center. If an odd number of barrels must be used, the empty barrel(s) opposite the loaded one(s) must be counterbalanced. If nothing else, the opposite barrel(s) should be filled with water to help counterbalance the machine.

A tumbling machine is a machine that is utilized for the finishing processes of parts. There are different types of tumbling machines that are used including the vibratory tumbler, centrifugal barrel tumbler, parts tumbler, drum tumbler, linear tumbler, etc. These machines are utilized for smoothing and polishing products. The process utilized by these machines is called the tumbling process. There are also different types of tumbling media used by tumbling machines in the tumbling process. These media include ceramic media, hardwood media, stainless steel media, carbon steel media, plastic media, etc. Tumbling machines have different applications in a wide range of industries. For example, a tumbling machine is used in the aerospace industry for smoothing jet engines, as well as blades. In the automotive industry, tumbling machines are also utilized for polishing engine heads and gears. Tumbling machines also help produce a number of other items with great consistency. These machines are an efficient, durable, low- cost, low-maintenance solution for the deburring, polishing, and finishing of numerous parts.

Deburring is a secondary operation of a machining process that enhances the final quality of the product by removing raised edges and unwanted pieces of material, known as burrs, left by the initial...

Finishing machines are machines used for metal finishing, which is the last stage of the metal fabrication process; the stage encompasses the use of machines in finishing the metal surface...

Vibratory tumbler is the equipment used in a vibratory finishing process, one of the most common methods in mass finishing. But how does a vibratory tumbler work...

Industries worldwide utilize abrasive blasting for various purposes, including cleaning rust and oil, removing surface coatings like paint and pollutants, preparing surfaces for paint and coatings, reinforcing metal surfaces and...

An aqueous part washer is an automated or semi-automated machine manufactured to clean, remove tough grease, and dry large or small parts before distribution or surface treatment. The washing is necessary since...

Automated parts washers are mechanical devices designed to efficiently remove grit, oil, grime, dirt, paint and other contaminating substances from parts with minimum manual supervision. These substances are removed...

A parts cleaner is a cleaning device that uses various types of solvents, cleaning agents, and processes to remove grease, grime, and contaminating materials from manufactured parts prior to shipment or movement for further processing...

A parts washer is a mechanical device designed to remove grit, grime, oil, miscellaneous debris, dirt, paint, and other contaminating substances from parts in preparation for their use in assembly operations, packaging, or coating...

Sandblast cabinets include systems or machinery and components for projecting blast media against a part‘s surface to abrade, clean, or modify the surface. Sand, abrasive, metal shot, and other blast media are driven or propelled using pressurized water, compressed air, or a blast wheel...

Sandblasting equipment includes systems or machinery, and components for projecting blast media against a part‘s surface to abrade, clean, or modify the surface. Sand, abrasive, metal shot, and other blast media are driven or propelled using pressurized water, compressed air, or a blast wheel...

Shot peening equipment includes systems or machinery and components for projecting shot peening media against a part‘s surface to modify the surface or surface engineer the part...

An ultrasonic cleaner is a type of sonic cleaner or sonic cleaning machine that uses cavitation to remove unwanted material. The cleaning effect is created by the compression and refraction of a cleaning medium. Miniscule vibrations propagate throughout the...

Ultrasonic cleaning is a type of cleaning process which uses cavitation induced by alternating compression and rarefaction cycles at ultrasonic frequencies. Ultrasonic frequencies are sound waves vibrating at 20 kHz or higher...

A wastewater evaporator is a method of removing water from water-based waste by converting the water in the waste to a vapor and leaving contaminants. The function of a wastewater evaporator is to reduce the volume of waste materials...

Parts washers are designed for cleaning, degreasing of equipment, and drying of mass quantities of small or large parts in preparation for surface treatment, assembly, inspection, or shipment...