Ceramic Manufacturing

In the simplest terms, ceramic manufacturing is the technique of creating ceramic materials that can support a wide range of high-tech engineering products and machinery. As their name implies, these items are made from ceramics, usually clay and other non-metallic materials. The material components are mixed with highly pure chemical solutions to meet the strength of the machine they support.

Quick links to Ceramic Manufacturing Information

Applications of Industrial Ceramics

Typically, people associate ceramics with artistic and decorative pottery made from clay and other composite materials. Industrial ceramics serve different purposes, though they are made using the same materials. Industrial ceramics are used to provide support to machines or machine parts and enhance the yield of manufacturing processes. The ceramic industry has customers all across the board.

Industries that rely on ceramic parts and products include aerospace, automotive, military and defense, medicine and healthcare, power generation, refractory, industrial, food processing, chemical, and construction.

Ceramic Manufacturing Products

Ceramic products can be broken up into four main categories: structural ceramics, refractories, whitewares, and technical ceramics (also known as engineering ceramics or advanced ceramics).

Structural ceramic products include things like brick shapes and ceramic tiles. Refractory ceramic products include kiln linings and crucibles. Whiteware products include bone china for dining and other decorative pottery. Finally, technical ceramic parts include high-performance ceramic parts used in aerospace, nuclear power, bio-medical, military, defense, and automotive applications that require exceptional heat resistance or insulation, wear, and corrosion resistance.

A lesser-used ceramic product category is electrical ceramics, which includes items like ceramic insulators, capacitors, magnets, and superconductors.

Other products made via ceramic manufacturing include electric motor parts, ceramic magnet parts, ceramic balls, ceramic rods, ceramic blades and rotary bearings used with wind turbines and jet engines, ceramic insulators, ceramic spacers, shuttle tiles, floor tiles, ceramic tubes, prosthetic limbs, bone and teeth replacements, body armor, chemical and environment ceramics (fibers, membranes, and catalysts), and ceramic coatings for surface protection and temperature regulation.

History of Ceramic Manufacturing

The concept of using ceramics to meet numerous needs in our daily lives and industrial production is not new. We have been using clay-based pottery for thousands of years. However, modern industrial ceramics can be traced back to the 1700s.

In 1709, Abraham Darby used coke combined with clay to improve the efficiency of the smelting process at his production facility. It was the first known and noted evidence of ceramic engineering in recent human history. Fifty years later, in Stoke-On-Trent, England, a man named Josiah Wedgwood opened the first ceramics manufacturing factory.

In 1880, brothers Pierre and Jacques Curie discovered piezoelectricity, which is a key property of electroceramics, sometimes known as piezoelectric ceramic manufacturing. Ceramics then got a big boost in 1888, when Austrian chemist Carl Josef Bayer developed a process for separating aluminum from bauxite ore. This process, which is still used today, made it easier and less expensive to create diverse ceramics. In 1893, E.G. Acheson invented a process for creating synthetic silicon carbide, another popular ceramic material.

During the first half of the 20th century, chemists discovered new and refined existing ceramic materials, while engineers and manufacturers fine-tuned and expanded the processes used to make ceramic products. Thanks to these improvements, ceramics were widely used in the production of arms and safety equipment during World War II.

Today, the ceramic industry is reaching for new horizons, as chemists create more capable ceramic material compounds. For example, they have managed to synthesize hydroxyapatite, which is the natural mineral component of bone. By using this process to form ceramic material, manufacturers have been able to branch out into the field of bio-ceramics and create products like synthetic bones and dental implants. Also, trains in Japan now use the Meissner effect with ceramic magnets to create levitation. It is clear that ceramics will continue to be used for a variety of applications in the future.

Process of Industrial Ceramic Manufacturing

The traditional manufacture process of industrial ceramic products follows multiple stages that include milling, batching, forming, drying, and sintering.

- Milling

- In this stage, raw material is given a desired small shape. Milling of raw material has different sub-stages, which include destructing, compressing, and impacting.

- Batching

- This stage of the process involves exercises like amassing the materials, according to the pre-defined ceramic preparation method. It also includes additive manufacture.

- Mixing

- In this step, the ceramic ingredients are mixed through various procedures and machines. Often, they are turned into slurries through the addition of water or another liquid additive.

- Forming

- After the base has been prepared, the actual formation of the ceramic components begins. There are several forming processes that manufacturers use to create ceramic parts. These include processes such as slip casting, pressing, extrusion, and injection molding.

- For mass production, slip casting works quite well. It’s especially well-suited for complex shapes, thin walls, and sanitary ware. Pressing methods like hot pressing and hot isostatic pressing work best with advanced ceramics. Molding processes like extrusion and injection molding work best in the creation of more simple ceramic mold parts, like pipes and tubes.

- Drying

- After the ceramic has been formed, it is allowed to dry out completely. This process solidifies the shape of the ceramic.

- Sintering

- To complete the forming process, manufacturers put the ceramic piece, known as greenware, in an extremely hot oven or chimney. Sintering strengthens a ceramic part by causing its oxides to bond and desificate. During this chemical change, both ionic and covalent bonds are formed and create the ceramic’s crystal structure. This process involves cations. The ionic structure is determined when you calculate the difference of electronegativity between cations and anions.

After forming is finished, manufacturers can put ceramic parts through secondary processes like glazing, polishing, grinding, cutting, or machining.

Ceramic Manufacturing Design and Engineering

During the ceramic manufacture process, the key concern of product designers is to create something that fits well with the design and engineering of the application. To do so, they carefully consider factors like the materials, which all offer different qualities. Oxides (e.g., silica and zirconia) and non-oxides (e.g., silicon nitride and silicon carbide), for instance, hold different properties of translucency, hardness, corrosion resistance, heat resistance, wear, weight, microwave absorption, and heat insulation. Aluminum oxide and boron carbide, for example, are both exceptionally hard and, therefore, useful in armoring applications.

To manufacture ceramics, suppliers rely on the assistance of machines like ovens for sintering, silicone or metal molds, rubber extrusion machines, injection molding machines, and computer programs for creating blueprints.

Any ceramic manufacturing system can be customized to fit the application(s) on which it is working. Customizations are typically based on factors like required production volume and speed, quality requirements, shape complexity, and secondary processes.

Benefits of Using Industrial Ceramics

The long-term benefits of ceramics include reliable part performance, which often triples that of other materials. This makes ceramic materials a more cost-effective choice in many applications.

In addition, ceramic-made parts offer a high melting point, oxidation resistance, high hardness, and light weight. They are also a bit chameleon-like: many of the desirable properties of various metals, polymers, and rubbers can be displayed in ceramic materials. For example, ceramics are often as corrosion-resistant as stainless steel. Some varieties can be harder than titanium. Some can be injection-molded or cast like polymers and rubbers and many are lightweight like aluminum or polymers.

Advanced ceramics are able to outperform metals in many situations, especially in harsh environments, and are also sometimes able to conduct electricity better than copper. There are a wide variety of products that are made possible solely by ceramics, such as space shuttles and missile cones, which would crack without heat-insulating ceramic casings.

Another advantage of ceramics is that they can be used in environmental applications to absorb toxic materials and decrease pollution or help with water purification.

Choosing the Right Ceramic Manufacturer

Ceramic products are varied and complex and it takes a good industry guide and manufacturer to get high quality solutions upon which you can rely. More than a good contract manufacturer, though, you want the right manufacturer, one who can match all your specifications, work within your timeframe and budget, and who will work hard for you. The best way to find this manufacturer is by browsing the list of suppliers we have listed near the top of this page. Check out their websites, then reach out to one or more of them for a quote.

Ceramic Properties

General Characteristics of Structural Materials:

| Characteristic |

Ceramics |

Metals |

Polymers |

| Density |

Low to High |

Low to High |

Low |

| Hardness |

High |

Medium |

Low |

| Tensile Strength |

Low to Medium |

High |

Low |

| Compressive Strength |

High |

Medium to High |

Low to Medium |

| Young’s Modulus |

Medium to High |

Low to High |

Low |

| Melting Point |

High |

Low to High |

Low |

| Dimensional Stability |

High |

Low to Medium |

Low |

| Thermal Expansion |

Low to Medium |

Medium to High |

High |

| Thermal Conductivity |

Medium |

Medium to High |

Low |

| Thermal Shock |

Low |

Medium to High |

High |

| Electrical Resistance |

High |

Low |

High |

| Chemical Resistance |

High |

Low to Medium |

Medium |

| Oxidation Resistance |

Medium to High |

Low |

Low |

| Machinability |

Medium |

Low |

Medium |

Ceramic Manufacturing Images, Diagrams and Visual Concepts

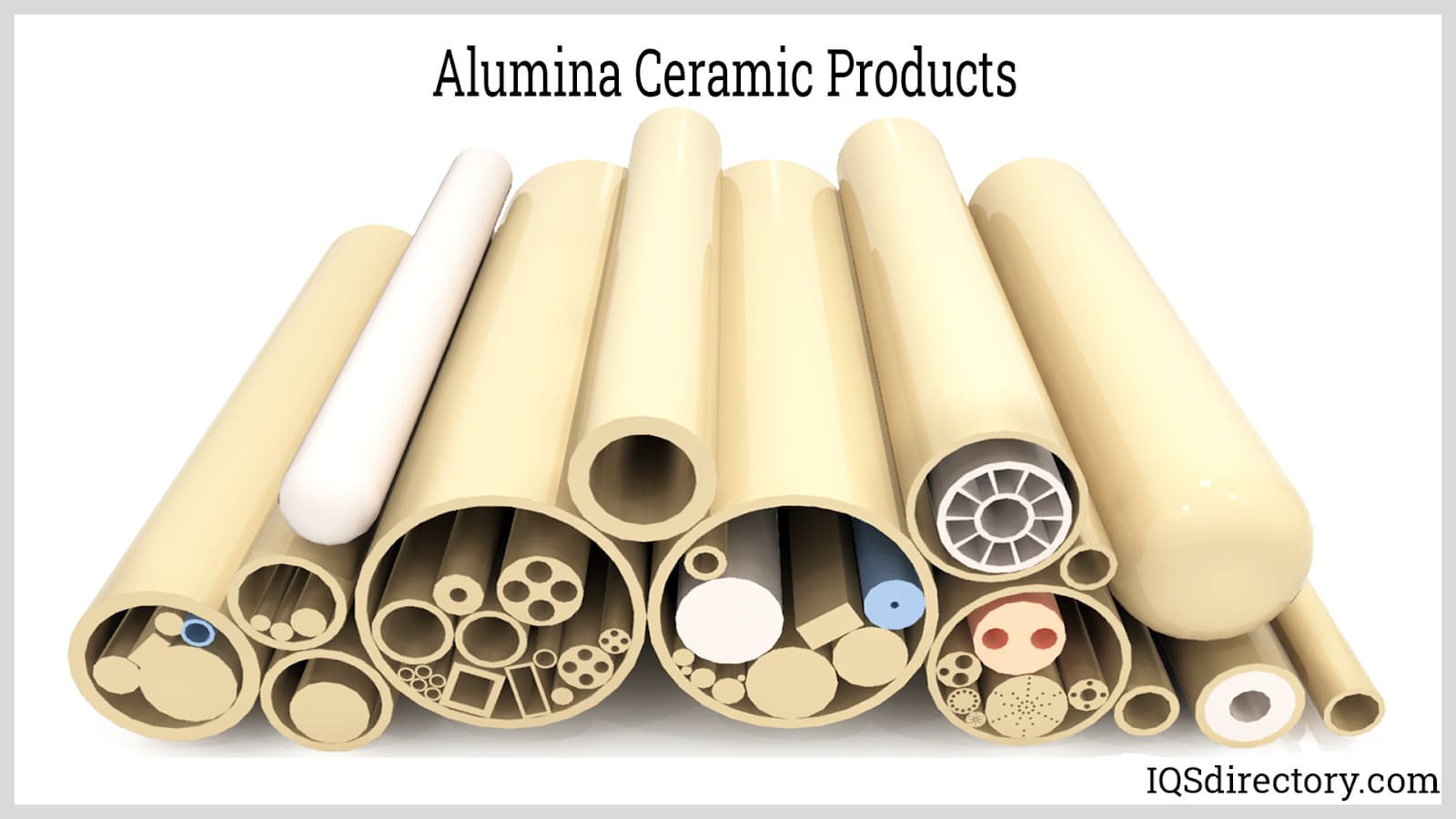

Alumina ceramic is an industrial oxide ceramic that is wear and corrosion resistance.

Alumina ceramic is an industrial oxide ceramic that is wear and corrosion resistance.

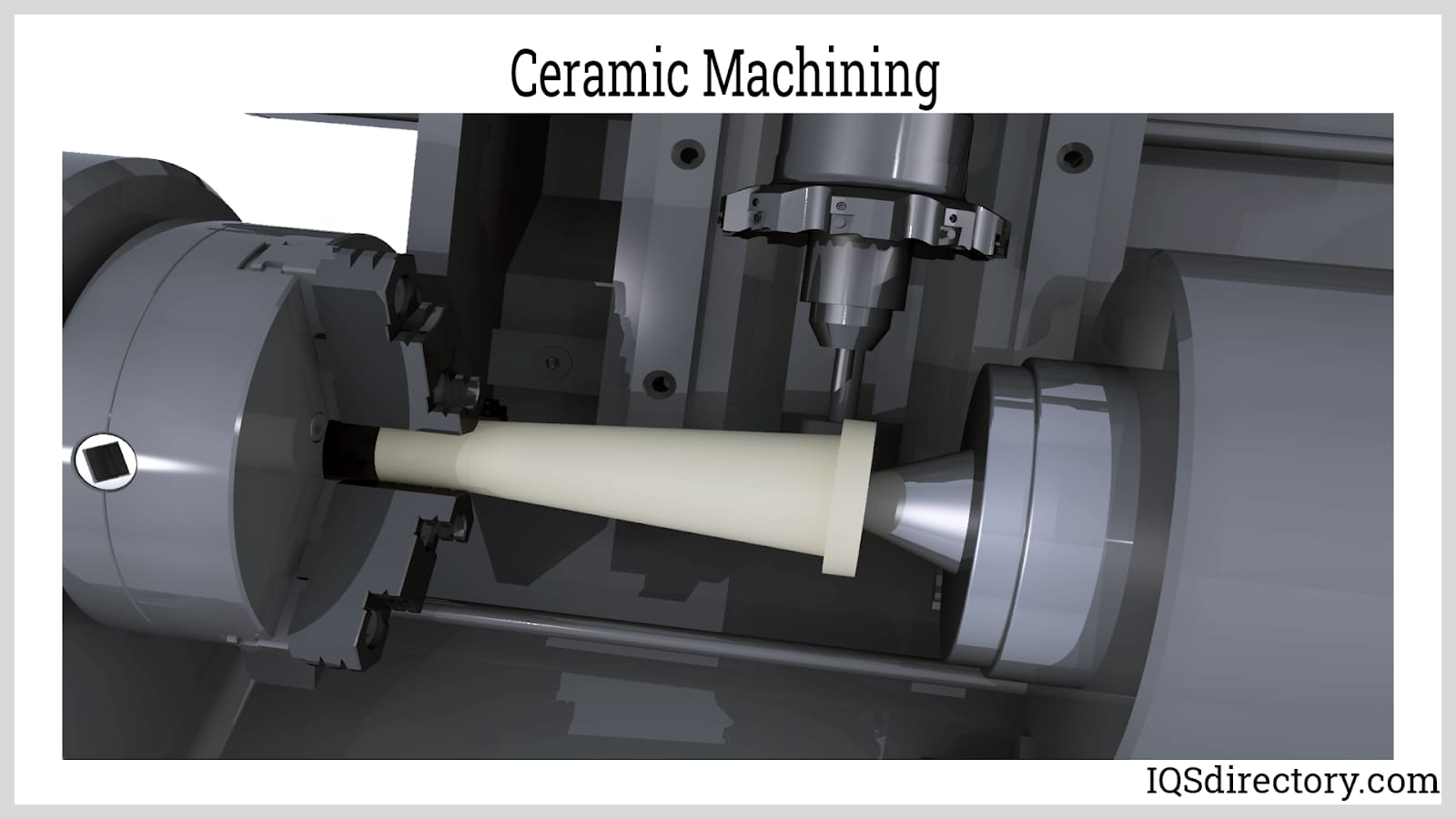

Ceramic machining refers to the manufacture of ceramic materials into finished products.

Ceramic machining refers to the manufacture of ceramic materials into finished products.

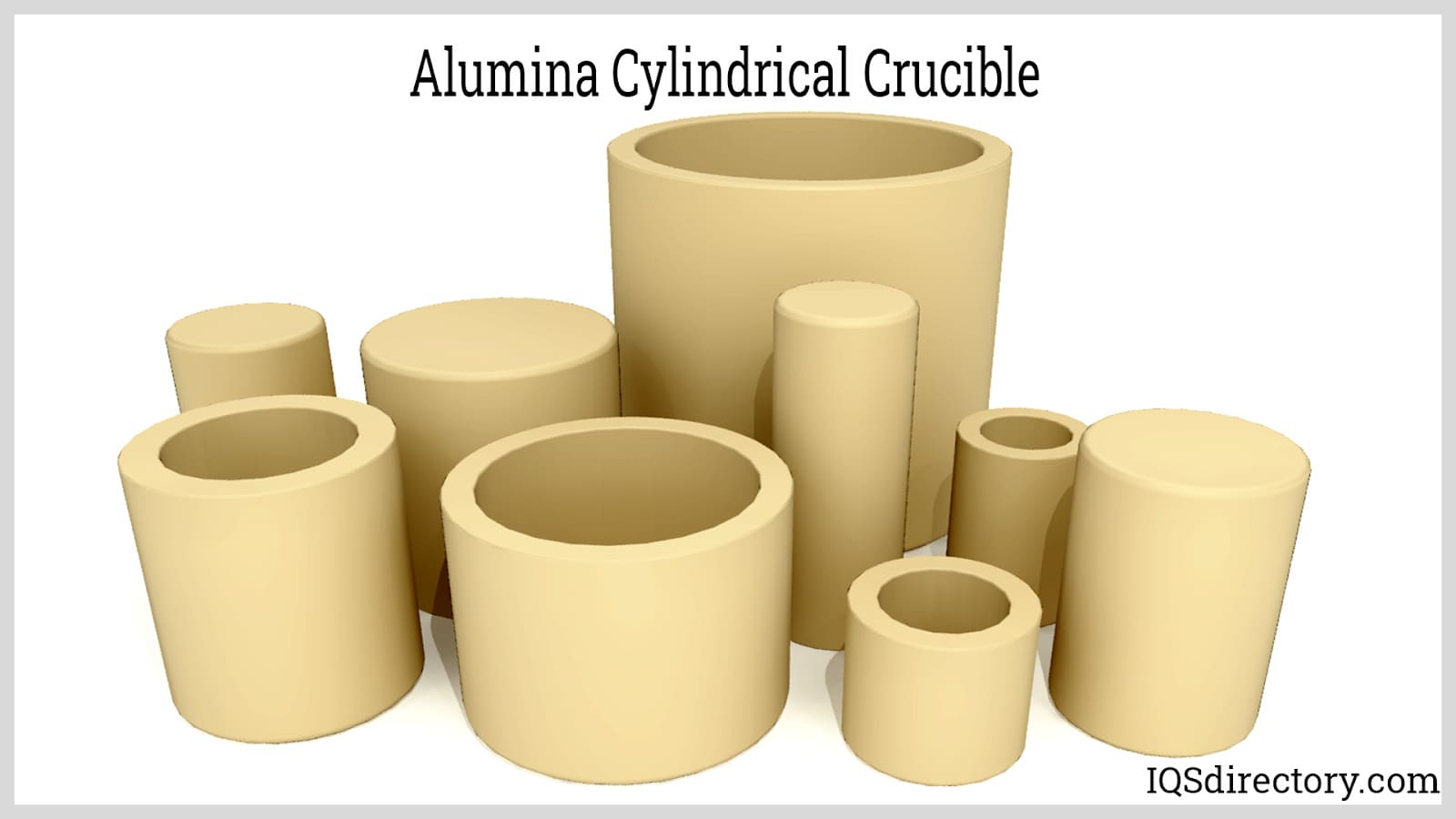

Alumina ceramic can with stand high tempertures and has high durability.

Alumina ceramic can with stand high tempertures and has high durability.

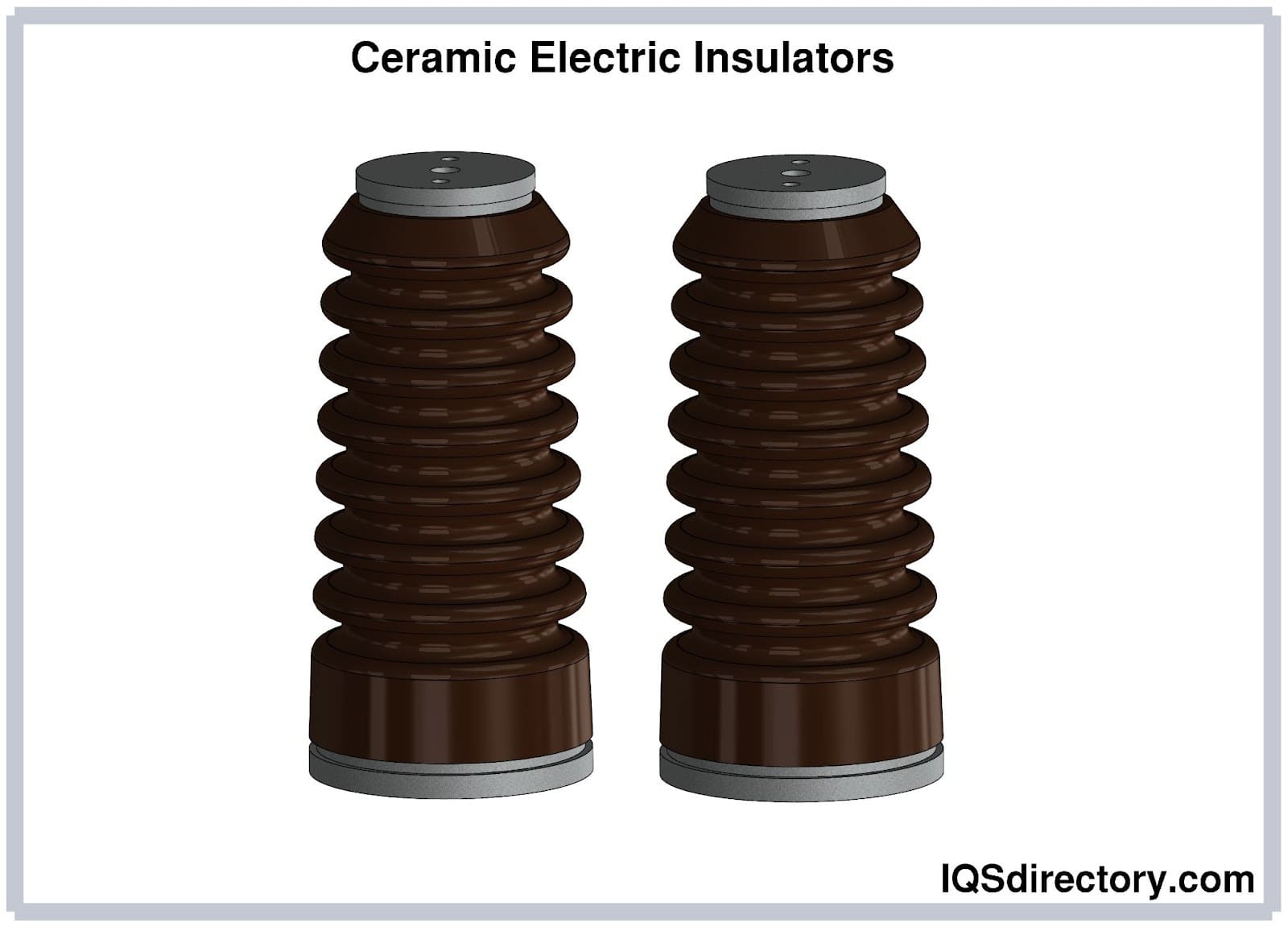

Ceramic insulator, a non-conductive insulator made from porous clay which provides a bridge between electronic components and has high dielectric strength.

Ceramic insulator, a non-conductive insulator made from porous clay which provides a bridge between electronic components and has high dielectric strength.

Silicon carbide ceramics are durable and are used in cutting tools to power systems.

Silicon carbide ceramics are durable and are used in cutting tools to power systems.

Zirconia ceramics are technical ceramic materials with excellent durability and corrosion resistance without being brittle.

Zirconia ceramics are technical ceramic materials with excellent durability and corrosion resistance without being brittle.

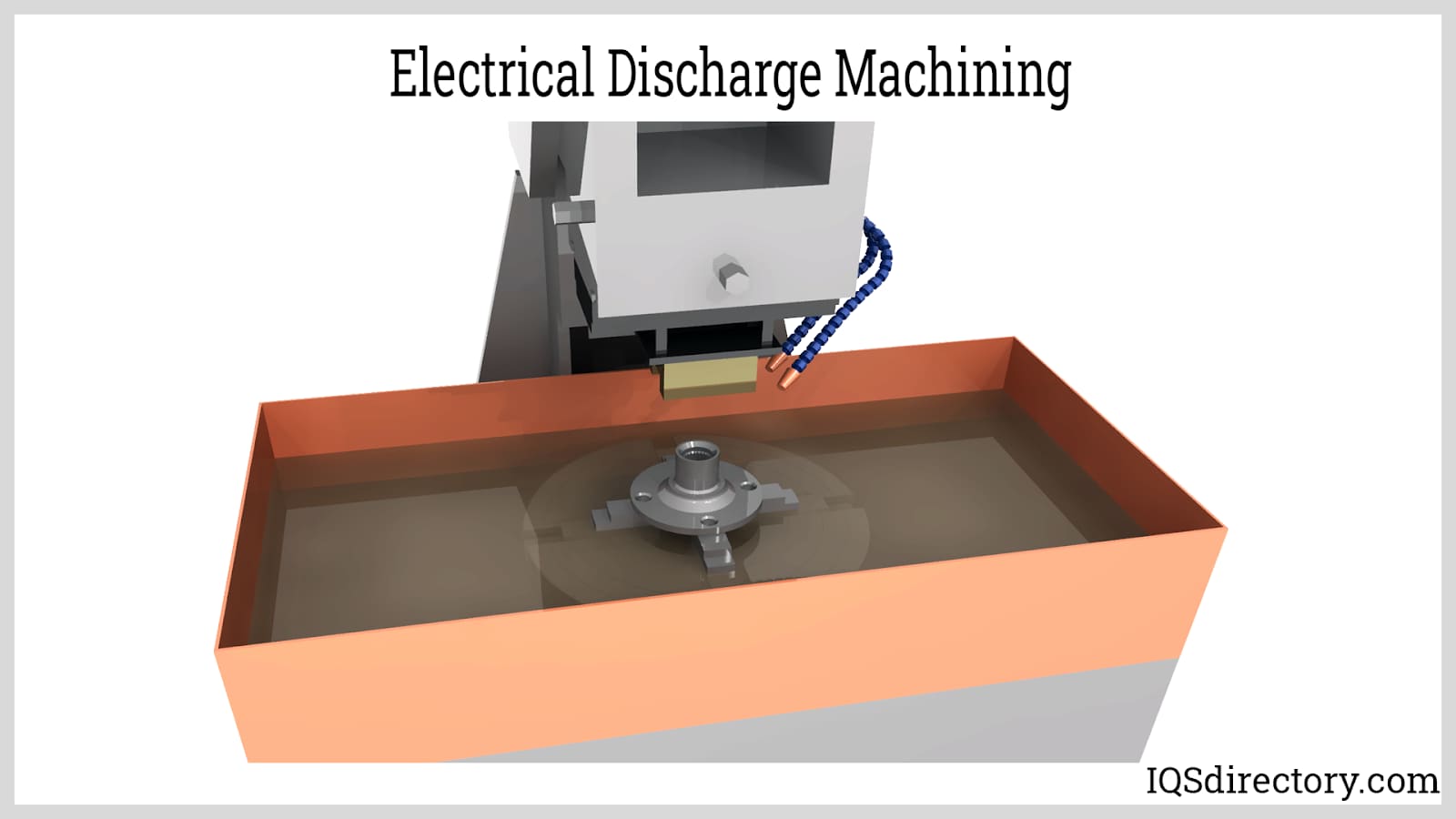

Electrical discharge machining requires workpieces to have a electrical resistivity less than 1000 ohm-centimeter.

Electrical discharge machining requires workpieces to have a electrical resistivity less than 1000 ohm-centimeter.

Ceramic Manufacturing Types

- Alumina Ceramic

- Or aluminum oxide, is an extremely durable and cost effective option used in many industrial and commercial applications.

- Alumina Crucibles

- A type of crucible made from alumina, also called aluminum oxide, which is the same material used to produce aluminum metal. The ceramic form of alumina is frequently employed for production of alumina crucibles because of its strength, low cost, and ability to withstand temperatures upwards of 3272°F.

- Ceramic Armor

- An extremely hard nonmetal body having good fracture toughness, extreme wear and corrosion resistance and a high capacity to absorb ballistic impacts.

- Ceramic Balls

- Rolling spherical elements made of inorganic, nonmetallic materials that are used in applications involving rotary or linear motion, in addition to a number of other functions.

- Ceramic Bearings

- Smooth, lightweight, and have high tolerance, leading to an increased maximum rotational speed.

- Ceramic Bushings

- Extremely reliable and hardy. They are often made from alumina ceramics or Steatite.

- Ceramic Coatings

- Although expensive, are able to give coated objects a life expectancy of up to 10 times longer than their average.

- Ceramic Composites

- Raw ceramics mixed with other materials to achieve desired properties. Ceramic composites can be significantly stronger and more resistant to damage.

- Ceramic Crucibles

- Crucibles made from ceramic material (like kiln-fired clay).

- Ceramic Grinding

- A design and manufacturing process whereby an abrasive is used for material removal, dimensioning, and finishing of ceramic components and products.

- Ceramic Insulators

- Used for a wide variety of applications because of their good electrical conductivity.

- Ceramic Machining

- Involves the design and manufacture of ceramic precision components.

- Ceramic Manufacturers

- Companies that make ceramic materials.

- Ceramic Rods

- Solid, cylindrical ceramic products.

- Ceramic Spacers

- Provide equal and constant spacing between materials or objects.

- Ceramic Tubes

- Hollow, cylindrical ceramic products. They are often available with single or multiple bores.

- Ceramic Washers

- Used for their high abrasion, temperature, and corrosion resistance.

- Clay Ceramics

- Ceramic parts produced using clay materials include earthenware, stoneware, porcelain, and bone china. It is not typically used to make industrial ceramic parts.

- Industrial Ceramics

- Involve the use of non-metallic, inorganic, mineral compounds in the production of large, in size, or quantity, ceramics. They are used in a wide range of contexts due to their desirable high resistance and insulating qualities.

- Mullite Ceramics

- Since mullite is a rare material on earth, it is an expensive substitute for commonplace ceramic applications. However, mullite ceramics have no match when strength and high temperature resistance are required. The material can be used for applications that work within high thermal expansion and low-pressure conditions while needing low thermal conductivity.

- Silicon Carbide

- Or carborundum, is an extremely hard ceramic composed of carbon and silicon atoms bonded in a crystal lattice.

- Sapphire Machining

- The same basic process used to diamond ground any dense alumina oxide material. Sapphire is an anisotropic, rhombohedral crystal form of Aluminum Oxide. Some common properties of sapphire include thermal expansion and hardness.

- Steatite Ceramics

- Made from magnesium silicate, steatite ceramics offer a more advanced option to work as an electrical insulator. These ceramics offer strength, durability, and insulation. Because of their outstanding insulation properties, steatite is used in the designing and formation of thermostats. This material is a key ceramic component in an array of residential and commercial electrical parts.

- Zirconia Ceramics

- Zirconia is the key element in brilliantly designed automotive oxygen sensors and dental ceramics. Having a high resistance to corrosion and breakage, this material is a great choice for the ceramic manufacturing of highly sensitive and well-used components. Wear and abrasion are not concerns for manufacturers who use zirconia ceramics.

Ceramic Manufacturing Terms

- Adsorption

- The act of one material adhering to another. In the case of clay and water, water is held on the surface of clay by a loose bonding force.

- Amorphous

- A property meaning that something does not have a regular structure. Glass is an example of an amorphous material, as a result of its being cooled too rapidly to form a crystalline structure.

- Attribute

- A characteristic of an object.

- Bisque

- Unglazed, fired clay.

- Bloating

- A distortion caused by moving gases when the firing process occurs too rapidly.

- Blunging

- A term for the mechanical mixing of clay slurry.

- Ceramic Change

- The point at which, during firing, the clay becomes ceramic.

- Coefficient of Thermal Expansion

- The measurement of the length change of ceramic materials under temperature change. Ceramics expand while heating and contract while cooling.

- Deflocculation

- The process of changing a thick clay slurry into a thinner, pourable substance by adding small amounts of liquid or powder to the mixture.

- Devitrification

- The crystallizing of a ceramic melt during cooling, which results in a “matte” finish.

- Dunting

- The cracking that results from a fired object being cooled too quickly.

- Eutectic

- The lowest temperature at which two materials will melt together.

- Firing

- The act of maturing clay by heating inside a kiln.

- Flocculation

- A process that thickens liquid slurry into a gel in order to avoid drips and improve suspension.

- Flux

- A material added to a mix to lower the melting temperature of the whole.

- Glaze

- The liquid covering applied to bisque or greenware, which produces a hard, glassy surface.

- Greenware

- Clay objects that have not yet been fired.

- Kiln

- A high temperature furnace or oven, which is used to fire ceramics.

- Maturity

- The point at which ceramics have had the correct amount of firing.

- Mold

- A permanent form used to press clay into a shape in preparation for firing.

- Porosity

- A term for the amount of pores, or empty spaces, within a material.

- Refractory

- A material’s ability to endure heat without deforming.

- Sintering

- Heating clay to the point at which it will no longer break down when exposed to water.

- Thermal Shock

- The volume change in a material that results from a sudden shift in temperature.

- Vitrification

- The point during firing at which clay particles will turn into glassy melts, forming glass.