Electric Heaters

Electrical components are parts that are capable of controlling and/or altering currents or voltages. They can do so without non-electrical means, including mechanical means. Electrical components are formed from different conductive materials, such as aluminum, copper and silver. Electrical components can come as switches, assemblies (such as cable assemblies or patch cords), connectors (like sockets, pin headers or screw terminals), terminals (like screw terminals), protection devices (such as circuits breakers or fuses), mechanical accessories (like heat sinks or fans) and more. They may operate as a single device or as part of a larger system.

Electrical, or electronic, components can be divided into two main categories: active components and passive components. Primarily, the difference between the two is the fact that active electrical components require electricity to enable their operation, while passive components do not. In other words, active components rely on an energy source, like a DC circuit, to function. Also, they can usually inject power into a circuit. In contrast, while passive components can use the power source to which they are connected, they cannot introduce new energy into a circuit. Nor can they amplify signals.

Two examples of active electrical components are transistors and diodes. Both of these are types of semiconductors, and there are many electrical components that fall under their respective umbrellas. Transistors are used to amplify and switch electronic signals and electrical power. Components that fall under their umbrella include: field-effective transistors (FET), photo transistors, thyristors and composite transistors. Diodes, in general, conduct electricity in one direction. Some types of diodes include: light-emitting diodes (LED), tunnel diodes, photodiodes, constant current diodes and solar panels.

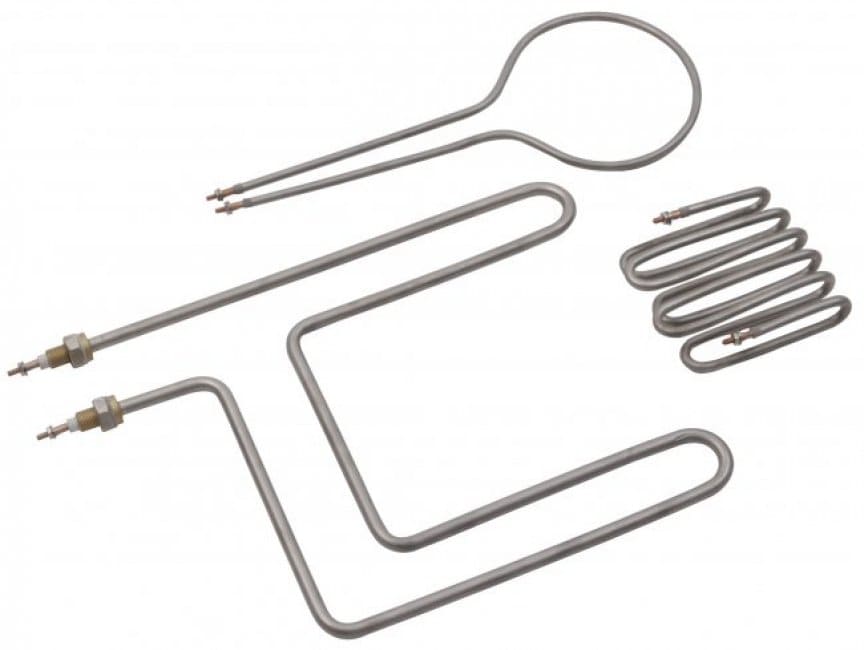

Two examples of passive electrical components are capacitors and resistors. Like transistors and diodes, there are many different electrical components that count as these. Capacitors are used to store and release electrical charges. You can find them filtering circuit lines, blocking DC voltages (while allowing AC voltages to pass through) and tuning resonant circuits. Examples of different capacitors include: integrated capacitors, fixed capacitors and variable capacitors. Meanwhile, resistors work to oppose currents and/or pass currents in proportion to voltages. Examples of resistors include: power resistors, fixed value resistors, photoresistors, Nichrome wire, resistance wires and heaters.

Electrical components of all kinds are important to many different industries. Four great examples of these industries are industrial manufacturing, healthcare, automotive engineering and aviation. In industrial manufacturing, electrical components are used in countless ways. They are found in electrical switches, power supplies and in electric transformers used in machinery and more. In the medical industry, healthcare providers utilize devices composed of electrical components such as low current amplifiers and implantable sensors. In both automotive engineering and aviation, professionals install wire, cable, electrical connectors and countless other electrical parts and supplies.

All in all, electrical components are an essential part of modern life. They can be found serving the smallest application to the largest. To find out how they may help you and your application, reach out to a knowledgeable electrical engineering company today.

Electronic coils are a type of electrical conductor. Also known as magnetic coils or electromagnetic coils, they get their name from the shape in which they are wound. This shape is a coil, also known as a spiral or a helix. Electric coils are mainly designed to transmit electricity, heat or sound. Also, they are generally used to produce movement, regulate flow and/or transform electric currents in applications related to telecommunications, computers and appliances. Typically, they're made from metal wire.

Electronic coils are a type of electrical conductor. Also known as magnetic coils or electromagnetic coils, they get their name from the shape in which they are wound. This shape is a coil, also known as a spiral or a helix. Electric coils are mainly designed to transmit electricity, heat or sound. Also, they are generally used to produce movement, regulate flow and/or transform electric currents in applications related to telecommunications, computers and appliances. Typically, they're made from metal wire.

Electric coils can work in a few different ways. Some work when an electric current passes through them and creates a magnetic field. Others work when they're fed by a voltage-generating time-varying magnetic field. In this scenario, the field is found outside of the coil, but the voltage passes through it.

Electric coils are found in a wide variety of industries, including electronics, automotive engineering, healthcare and energy. Within these industries, they manifest in a variety of iterations, including solenoid coils, molded or encapsulated coils, induction coils, transformer coils and choke coils. Of these, solenoid coils are the most widely used. They allow for remote machinery activation and remote switching as they carry currents through the coils and become magnetized. Learn more about electric coils.

Electric switches are electrical components designed to safely open or close an electrical circuit. Note that an open electrical circuit is not connected, while a closed circuit is connected. So, though it seems counterintuitive, if a circuit is open, current cannot pass through it and it is not working. Likewise, if a circuit is closed, current can pass through it and it is working.

Electric switches are electrical components designed to safely open or close an electrical circuit. Note that an open electrical circuit is not connected, while a closed circuit is connected. So, though it seems counterintuitive, if a circuit is open, current cannot pass through it and it is not working. Likewise, if a circuit is closed, current can pass through it and it is working.

Some electric switches work only in the open and closed positions. They are known as binary devices, since they have only two states. There are many other switches, though, that permit varying voltages to pass through them. These switches, instead of just having an open position and a closed position, have several different closed positions, which allow them emit varying amounts of output. To understand this better, think of dimmer lights.

Electric switches were originally invented so that people could safely and simply control of the flow of electricity. Today, they do just that. They are typically small and discrete, but they literally bring light to our world, among other things. We use them constantly, whether we're at home reading by lamplight, at a factory operating industrial machinery or using cleaning tools in a dental office. Learn more about electric switches.

Electric transformers electrical devices that transfer electrical energy between two or more circuits. They can also increase, decrease, isolate, pattern and translate electrical currents of all power levels. The purposes of such actions are to make sure that they match the voltage and the voltage safety requirements of any given piece of equipment.

Electric transformers electrical devices that transfer electrical energy between two or more circuits. They can also increase, decrease, isolate, pattern and translate electrical currents of all power levels. The purposes of such actions are to make sure that they match the voltage and the voltage safety requirements of any given piece of equipment.

Electronic transformers serve every piece of equipment that is powered by electricity. This is because the transformers provide electrical equipment with the current to voltage conversions that they require. Transformers are also important in the storage and transportation of energy in power lines and power grids.

To meet the needs of their innumerable applications, electronic transformers are configured using countless designs. They vary in many ways, including by: frequency range, voltage class, basic magnetic form and general winding configuration. Examples of transformer types include: step up and step down, polyphase, toroidal and zig zag transformers. Generally speaking, though, electric transformers consist of the following components: a core and windings. Among other materials, the core may be made of laminated steel, powdered iron or non-conductive magnetic ceramics (ferrites). Windings serve to minimize the leakage of inductance. In addition, very large transformers are equipped with high voltage insulated bushings. Learn more about electric transformers.

Electronic connectors are devices that connect two or more electrical terminations in order to create electrical circuits. Composed simply of plugs and jacks, they do so by conducting electricity between said terminations. In this context, the circuits may come in the form of cables alone, or they can manifest as one cable and one electrical terminal.

Electronic connectors are devices that connect two or more electrical terminations in order to create electrical circuits. Composed simply of plugs and jacks, they do so by conducting electricity between said terminations. In this context, the circuits may come in the form of cables alone, or they can manifest as one cable and one electrical terminal.

Regardless, there are three main types of electronic connectors: temporary connectors, permanent connectors and assembly required connectors. The first type of connector is mostly used in portable equipment, where it can expect its lifespan to be relatively short. Permanent connectors, on the other hand, are placed in equipment or applications where they are expected to function successfully for a long time. Finally, assembly required connectors are just as they sound. They require assembly. Typically, they are best used in applications that, while trusting in longevity, plan for the option of removal or replacement down the road. In addition, some electronic connectors are made to fit specific applications. Examples of electronic connector applications include: DIN connectors for loudspeakers, PCB connectors for printed circuit boards and connectors for military equipment. To make connectors appropriate for the military, manufacturers use specific materials and sizes that meet military specifications. Learn more about electronic connectors.

Electronic enclosures, also known as electronic cabinets, are structures used to house electrical systems and wiring. Often manufactured as boxes, electronic enclosures are made to protect their contents from physical damage from impact, moisture, contaminants and the like. They also protect their contents from electromagnetic interference. In turn, electronic enclosures can protect people from electrical surges and other dangers like that. In essence, electronic enclosures are shields, jackets or tents.

Electronic enclosures, also known as electronic cabinets, are structures used to house electrical systems and wiring. Often manufactured as boxes, electronic enclosures are made to protect their contents from physical damage from impact, moisture, contaminants and the like. They also protect their contents from electromagnetic interference. In turn, electronic enclosures can protect people from electrical surges and other dangers like that. In essence, electronic enclosures are shields, jackets or tents.

Electronic components typically found housed within electronic enclosures include audio equipment, switches, computer servers, conduits and general connections. Because electrical equipment is so sensitive, electronic enclosures are important components of electrical equipment used in many industries. These industries include industrial manufacturing, healthcare, agriculture, automotive engineering, transportation and more. Basically, though, they're found anywhere there is electronic equipment, including in the home, in commercial buildings, in libraries and in stop lights.

Some of the most commonly produced electronic enclosures include: access points, labels, lids, keypads, removable panels and vents. Typically, they are made from materials including rigid plastics and metals like stainless steel, carbon steel and aluminum. To increase their corrosion resistance, enclosures can be galvanized. Likewise, to alter their appearance, they can be painted. In general, electrical enclosures are highly customizable. Learn more about electronic enclosures.

The EMI in EMI shielding is short for electromagnetic interference. Electromagnetic interference is a type of electromagnetic radiation that can interfere with, lessen or damage the various functions of electronic equipment and devices. It is able to do this when it travels along wires, electrical circuits and conductors. Simply put, EMI shielding blocks EMI. It also blocks radio frequency interference (RFI), which creates the same problems. RFI radiates electromagnetic noise and travels through the air as radio waves. When it used to block RFI, EMI shielding may alternatively be referred to as RF or RFI shielding.

The EMI in EMI shielding is short for electromagnetic interference. Electromagnetic interference is a type of electromagnetic radiation that can interfere with, lessen or damage the various functions of electronic equipment and devices. It is able to do this when it travels along wires, electrical circuits and conductors. Simply put, EMI shielding blocks EMI. It also blocks radio frequency interference (RFI), which creates the same problems. RFI radiates electromagnetic noise and travels through the air as radio waves. When it used to block RFI, EMI shielding may alternatively be referred to as RF or RFI shielding.

EMI shielding works by creating a barrier that EMI, RFI and other magnetic and/or conductive materials cannot cross. Usually, EMI shieldings are produced in the form of an enclosure, coating or transmitted signal. No matter their exact configurations, though, EMI shieldings isolate their paired device from everything on the outside. External fields cannot get in and potentially damaging internal fields cannot get out. EMI shielding products are super important to the proper functioning of most any electronic device, most particularly communication devices. Most often, these products are made from metal foam, metal screen or sheet metal. Alternatively, they may be coated with metallic ink. Learn more about emi shielding.

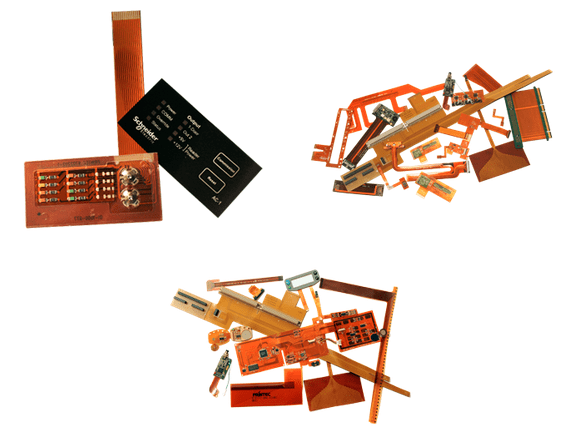

As defined by the ASTM, a membrane switch is a momentary switch device in which at least one contact is on, or made of, a flexible substrate. In essence, membrane switches are electrical switches used to turn circuits on and off that simply require a substrate and a circuit. Manufacturers print the circuit onto the substrate, which is usually PET or ITO, using conductive ink. This conductive ink is typically filled with something like copper, silver and/or graphite. Note that they are not the same thing as mechanical switches, which are made up of plastic parts and copper.

As defined by the ASTM, a membrane switch is a momentary switch device in which at least one contact is on, or made of, a flexible substrate. In essence, membrane switches are electrical switches used to turn circuits on and off that simply require a substrate and a circuit. Manufacturers print the circuit onto the substrate, which is usually PET or ITO, using conductive ink. This conductive ink is typically filled with something like copper, silver and/or graphite. Note that they are not the same thing as mechanical switches, which are made up of plastic parts and copper.

Membrane switch fabrication calls for fewer materials than most. Other types of interface equipment, such as mechanically operated keyboards, tend to be more complicated and resource-intensive. This comparative simplicity of design makes membrane switches both incredibly cost effective and incredibly popular. They are also well-liked because they are easy to clean. While they are a newer technology, they enjoy an ever-growing customer base. This base is particularly strong in industries such as: aerospace engineering, electronics, gaming and recreation, medical manufacturing and safety and security. A few common examples of membrane switch applications are: microwave oven panels, TV remote controls and air conditioning control panels. Learn more about membrane switches.

Power cords are electrical cables that transfer electrical power using either direct electrical currents (DC) or alternating currents (AC). Most often, they use AC. Either way, the purpose of power cords, also called cord sets or electric cords, is to provide electrical energy to any appliance or piece of electrical equipment. To make this happen, users simply connect the equipment or appliance in question to the main power supply.

Power cords are electrical cables that transfer electrical power using either direct electrical currents (DC) or alternating currents (AC). Most often, they use AC. Either way, the purpose of power cords, also called cord sets or electric cords, is to provide electrical energy to any appliance or piece of electrical equipment. To make this happen, users simply connect the equipment or appliance in question to the main power supply.

The metal plug component of a power cord varies by country, as different countries, like the US and the UK, have different electrical codes. Nevertheless, users tap into the main power source by plugging the power cord directly into a wall socket or indirectly into a wall socket, via an extension cord. Extension cords are extra long cords that sometimes come with power strips (full sets of extra power sockets). They can extend the reach of an electrical current literally hundreds of feet away from an outlet. Extension cords are particularly useful for use with power tools, stage lighting equipment, emergency medical defibrillators and any other equipment or device located away from a convenient power source. From the office to a construction site, power cords of all kinds are incredibly useful. Learn more about power cords.

Static eliminators, also known as antistatic devices, are products used to protect sensitive objects and materials from the hazardous effects of static electricity.

They are not to be confused with appliances like static mixers.

Static eliminators, also known as antistatic devices, are products used to protect sensitive objects and materials from the hazardous effects of static electricity.

They are not to be confused with appliances like static mixers.

Static electricity refers to electricity that is at rest, which is produced as a result of an unbalance in the molecular structure of insulating materials. Such materials include paper and plastics. When their molecular structure becomes unbalanced, they produce either excessive positive or negative charged particles called ions. Learn more about static eliminators.