Magnets

Magnets are metallic composites, usually ferrous metal composites, which produce a magnetic field. The magnetic field causes other magnetic objects to be attracted to the magnet while other magnets are either attracted or repelled. There are many different types of magnets, all with different magnetic strengths, heat resistance, corrosion tolerance, and permanence.

Magnets can largely be broken up into two categories: non-permanent and permanent. Non-permanent magnets are electromagnets that require an external source of power and are triggered electrically to be magnetic. Electromagnets have many industrial applications and are used in such equipment or processes as solenoid valves, AC and DC motors, biomagnetic separation, and transformers. Permanent magnets include ceramic magnets (also known as ferrite magnets), alnico magnets, and rare earth magnets. For instance, magnetic ceramic products have lower magnetic power and are more brittle and easily breakable than some other magnets, but they are much more cost-effective and are used in non-structural applications in motors, magnetic chucks, and magnetic tools. Rare earth magnets, on the other hand, are less cost-effective to manufacture but are far more powerful and retain their magnetism better than ferrite magnets. They are used as industrial magnets for holding and lifting, motors, speakers, sensors, testing, and MRIs.

Magnetic assemblies are tools or systems that use electromagnets, ceramic magnets, alnico magnets, rare earth magnets, or a combination of these to do specific kinds of lifting, holding, or separating metallic materials. Combinations of different magnets in assemblies can increase the overall magnetic force of the tool. Most magnetic assemblies used in industrial and metal manufacturing use permanent industrial magnets to do various kinds of physical work, including metal parts and sheet metal lifting, mounting and holding, as well as separating and water treatment. Permanent and nonpermanent (electromagnetic) magnet assemblies are used in automotive, aerospace, electronics, and biomedical fields in beam control, film and software disk programming and erasing, Magnetic Resonance Imaging (MRI), sound speakers, sensors, TV monitors, welding equipment, power meters, ignition timing systems, linear actuators, blood testing and separating, and electric motor activation. Many types of magnets are used in specific industries and applications. For example, sheet magnets are a flexible ferrite-plastic composite that is extruded into magnetic sheets and used in automotive and consumer industries and can be cut into magnetic strips of rubber material. Bar magnets are the most common type of magnet used today and are made from a ferrite metal material.

The most important properties magnet manufacturers consider during fabrication are porosity, ease of fabrication, magnetic retention under heat and corrosion, magnetic strength, and overall cost. There is not one magical type of magnet that will have all of these characteristics. Different types of permanent magnets are made from various composites, which means they have different properties and applications. Ceramic magnets are sintered powder composites of ceramic powder, iron oxide, and either strontium or barium. Ceramic magnets can be compressed, extruded, or sintered into a variety of shapes. The finished material is a cost-efficient, brittle, porous, charcoal gray ceramic, which is often sintered into arcs for motors, discs, and blocks for lifting and holding. In addition, because ceramic magnets are porous, they are highly susceptible to corrosion and lose their magnetism under high temperatures. Slightly more expensive alnico magnets are composites of aluminum, nickel, cobalt, and iron and are similar to ferrite ceramic magnets but less brittle, more easily fabricated into shapes, and have higher magnetic resistance. You can find a list of manufacturers who make these types of magnets here on IQS Directory.

Rare earth magnets include neodymium magnets and samarium cobalt magnets and are far more powerful than ferrite ceramics or alnico magnets. Rare earth lanthanide elements, neodymium and samarium, have partially filled outer f-electron shells, which are the source of their exceptionally powerful magnetic fields. Neodymium magnets are neodymium, iron, and boron composites with more powerful magnetic pull than any other type of magnet. Although they have high magnetic force, neodymium magnets have low heat and corrosion resistance and lose magnetism under 200 degrees Celsius or more. Find magnets of this type here. Samarium cobalt magnets are composed of samarium and cobalt and are much more resistant to demagnetization and corrosion than neodymium magnets. They also possess thermal stability of up to 550 degrees Celsius. Samarium cobalt is therefore used most in high heat applications such as motors and medical tools. Neodymium magnets are harder than ceramic magnets but are still brittle and are most often nickel-coated for protection. Due to the scarcity of rare earth materials and the long process of rare earth extraction from lanthanide ores, rare earth magnets are much more costly than non-rare earth magnets.

Quick links to Magnets Information

Notable Applications of Industrial Magnets

- Sorting

- A simple application of basic magnetic properties allows one to sort ferrous materials from non-ferrous materials and magnetic materials from non-magnetic materials.

- Magnetic Sweepers

- Another rudimentary application that uses magnets to attract loose ferrous components for safety and loss prevention.

- Imaging Devices

- An advanced application for medicine and other fields, producing images of otherwise unviewable places and things.

- Lifts

- Industrial application using magnets in magnetic pick-up to lift, hold, and move ferrous materials with fewer moving components.

- Data Storage

- Credit cards, hard drives, and other data storage mediums depend on magnetism to function.

- Household Goods

- Refrigerator magnets, basic holds for cabinets and doors, and similar household applications.

- Maglev Trains

- Use of repelling magnets to allow for low-friction movement of trains over magnetic rails at high speeds.

- Seals

- Used to securely close refrigerators and other containers.

- Generators and Electric Motor

- A key component in any electric motor or motor assembly (though the type of magnet may vary).

- Electronics

- Many electronic devices use magnets for various proprietary purposes, such as the deflection of electrons in a cathode ray tube television.

History of Magnets

Natural magnets have been in use for much of recorded history, dating back to ancient Chinese mariners who utilized the properties of natural magnetite for compasses. The earliest attempt to scientifically research the general scientific concept of magnetism came more recently, however, with the experiments of William Gilbert in 1600. Gilbert discovered the earliest ways to produce magnets and the influence of temperature on magnetism.

Heavy industrial use of magnets came later, after additional breakthroughs in electronics and magnetism made by famous physicists like J.J. Thomson. While rudimentary electromagnetic generators and other magnet-dependent technologies existed at the turn of the 19th century, only in the 20th century did our understanding of magnetism and its properties advance enough for many of our modern applications.

Rare earth magnets, some of the most potent industrial magnets, weren't developed until the 1970s and 1980s, while superconducting magnets were theorized in 1911 but only successfully produced in 1955. Smaller advances have accelerated the use of magnets in recent years alongside the general development of superconductors and electronics.

Basic Categories of Industrial Magnets

- Permanent Magnet

- The most commonly used magnets and maintain permanent magnetism.

- Temporary

- Materials that operate as magnets in the presence of strong magnetic fields, usually simple ferrous materials. Used in various electronic devices.

- Electromagnets

- These magnets work through the magnetic fields produced by an electric current. They work with a continuous supply of electricity through a tightly wound custom coil of wire and can be turned off or on at will. Used in many electronic devices.

- Superconductors

- Similar to electromagnets but must be cooled below a certain temperature and feature no metal core. These are the strongest magnets. They are used for heavy industrial magnetic separator machines, MRI machines, and other magnetically intense processes.

Benefits of Using Industrial Magnets

Many industrial magnets see use in highly specific products, so it is difficult to state the advantages of such magnets. The same is true for many products where magnets serve as key components due to their wholly unique properties.

General industrial use, however, offers several consistent benefits to the companies using magnets.

- Reduce Maintenance Costs

- There are a variety of ways magnets can reduce maintenance costs. For example, collecting ferrous materials can prevent punctured tires, damage to mechanical components, and even injury of personnel. Clever use of magnets in various industrial machines can also reduce mechanical wear and tear by lowering the need for moving parts in holding and lifting mechanisms.

- Prevent Contamination

- Many manufacturers use general-purpose magnets to attract ferrous and magnetic materials on production lines and in storage scenarios. This can be particularly important in food, medicine, and chemical production industries.

- Quick Sorting and Separation

- The simplest application of magnets lay in the ease with which they can sort ferrous from non-ferrous and magnetic from non-magnetic. If you have any sorting application involving this type of material, using industrial magnets could save hours of work.

Industrial Magnet Accessories

Most industrial magnets serve as components in larger devices or assemblies, so there isn’t much need for accessories for the individual magnets. Smaller magnets used raw, though, can benefit from a few added pieces of technology, such as:

- Covers

- Various covers serve to protect magnets from physical damage, insulate nearby electronics from them while out of use, or prevent demagnetization.

- Ferrous Components

- Small ferrous components, such as steel-and-nickel discs, can be used in combination with magnets for any number of purposes.

- Connectors and Adhesives

- Connecting magnets to other materials sometimes involves the use of special connectors and adhesives.

Design Factors to Consider for Industrial Magnets

There are a few general components of magnet design you'll want to have in mind when talking to a supplier.

First, you'll want to know either the specific type of magnet you'll need or the details of strength, durability, and permanence so your supplier can make a recommendation.

You will also need to know what shape your magnet should be for your application. If the shape doesn't matter, you can save money by accepting whatever is easiest to produce, as complex designs will cost more.

Coating for magnets requiring additional protection against wear and tear or chemical corrosion should also be considered, as some magnets may not be suitable for certain coatings.

Environment will also play an important role, as many magnets function differently under different temperatures. Other magnets may have component metals, like iron rust, in moist environments if they are not given additional treatments or coatings.

Magnet Safety Considerations

- Goggles

- There are several reasons to wear goggles when handling heavy duty magnets. Heavy duty magnets can shatter or break other materials. When used in machining or other industrial tasks, they can burn or spark dangerously.

- Gloves

- Heavy duty magnets can cause abrasions, sprains, and broken bones if handled improperly. Magnets can also shatter and cut the skin. Heavy duty gloves are advised when using these magnets.

- Electronics

- Be careful with any industrial magnet near electronic devices or data storage, as the magnetic fields can interfere with the function of such devices and damage or destroy them.

- Pacemakers

- As a form of electronic device, pacemakers are susceptible to interference from industrial magnets. This can prove lethal, so anyone with a pacemaker or other medical device susceptible to magnets should avoid work with industrial magnets if they do not have doctor approval.

- Allergies

- Many individuals suffer from allergies to the component metals of common industrial magnets, so it's important to be aware of the potential dangers of direct contact with, as well as the inhalation of dust from, magnets and their components.

- Navigation

- Certain strong magnets can interfere with navigational tools such as GPS, so special precautions must be taken when traveling with industrial magnets.

- Transport

- When shipping powerful magnets alone or as components, it's important to be sure they will not interfere with transportation or adhere to surfaces within the shipping container.

Care of Industrial Magnets

Inspection rules for magnets will depend on the application at hand. While all magnets function best when cleaned and decontaminated regularly, the degree of degradation and the necessary frequency of cleaning will need to be determined with use.

Regular testing of any magnet that often holds loads should also be performed to avoid unexpected failures of magnetism and the dropping of heavy ferrous materials. If you're not sure whether a magnet is working properly or not, you can contact your manufacturer for testing or replacement.

Industrial Magnet Compliance and Standards

Compliance and standards are application-specific with industrial magnets, given the wide variety of applications. Carefully researching the standards for magnets being used in your application will make the manufacturing process for custom magnets much easier. If you're unsure of standards or compliance requirements for your application, your manufacturer may be able to help you.

Of course, general safety concerns apply to all uses of magnets, especially powerful rare earth magnets, superconductors, and electromagnets.

Choosing a Manufacturer for Industrial Magnets

Because of the many differences in industrial magnet applications, it can be difficult to identify a single “best” manufacturer in your area. Instead, you should look for a manufacturer most suited to your needs and expectations as a customer. Look for these traits:

- Familiarity with Your Specific Need

- First and foremost, you want an industrial magnet supplier familiar with the type of magnet you're using and the application you’ll be using it for. A supplier familiar with your needs and expectations can offer superior service, lower expenses, and fewer mistakes. Seek out references from similar businesses to yours or ones that have used magnets for similar applications.

- Versatility

- You want a manufacturer that can customize to your exact needs. That doesn't mean you should look for a manufacturer with a one-size-fits-all solution somewhat close to what you need. The best custom magnet fabricators will go the extra step to meet your specific needs and adjust as necessary when it comes to any unusual requests.

- Transparency

- You want to fully understand what you're getting for what you pay in every interaction with a vendor, supplier, or contractor. This holds as true with magnets as it does with anything else.

- Schedule

- Make sure you're working with magnet manufacturers or suppliers who can meet your scheduling needs. You don't want to end up halfway through a project only to find out you won't have the magnets necessary to proceed for weeks or months to come.

If you need help, you can refer to the convenient list of manufacturers listed at the top of this page.

Magnet Images, Diagrams and Visual Concepts

Magnets are materials that exert a noticeable force on different materials.

Magnets are materials that exert a noticeable force on different materials.

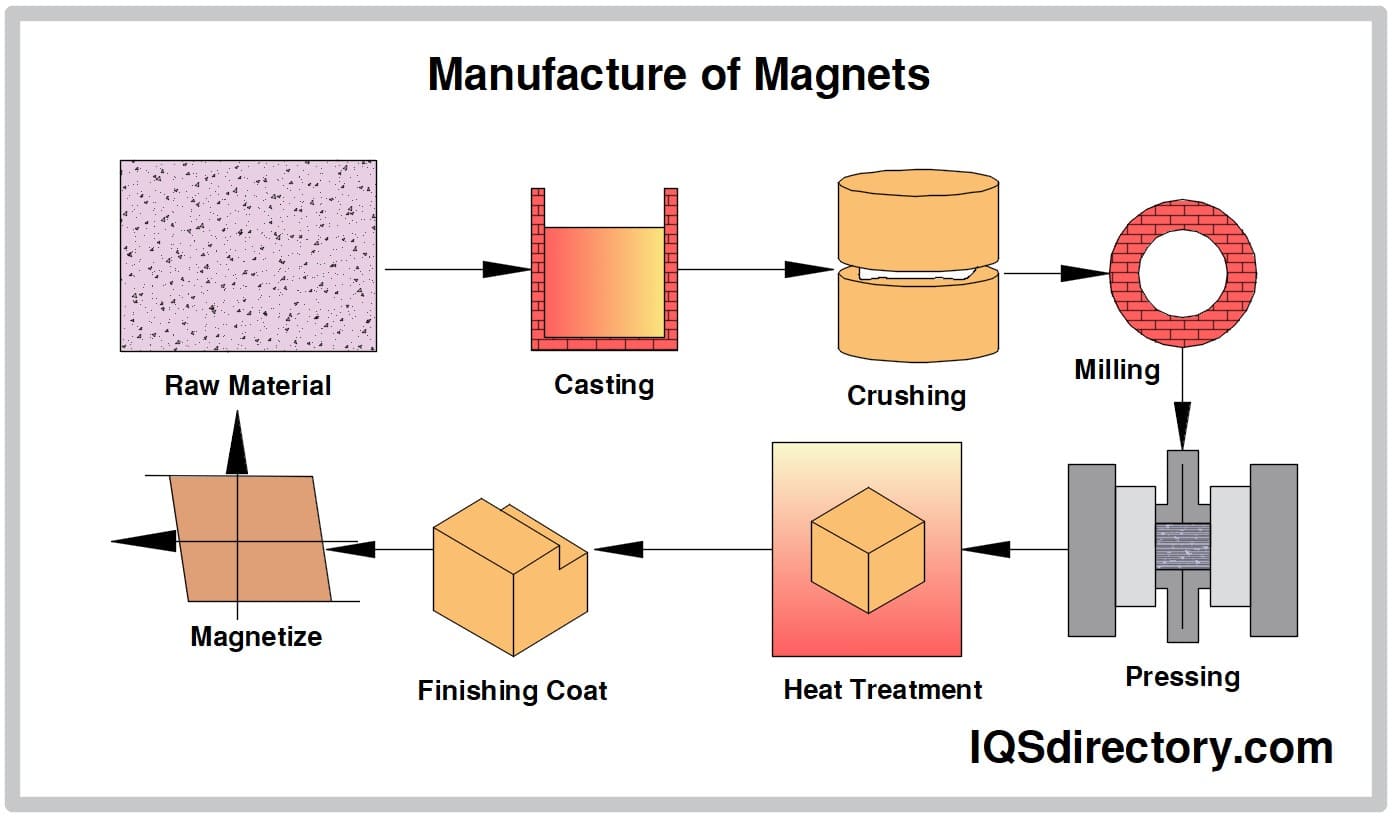

Since magnets are comprise different materials so the processes of manufacturing are different and unique.

Since magnets are comprise different materials so the processes of manufacturing are different and unique.

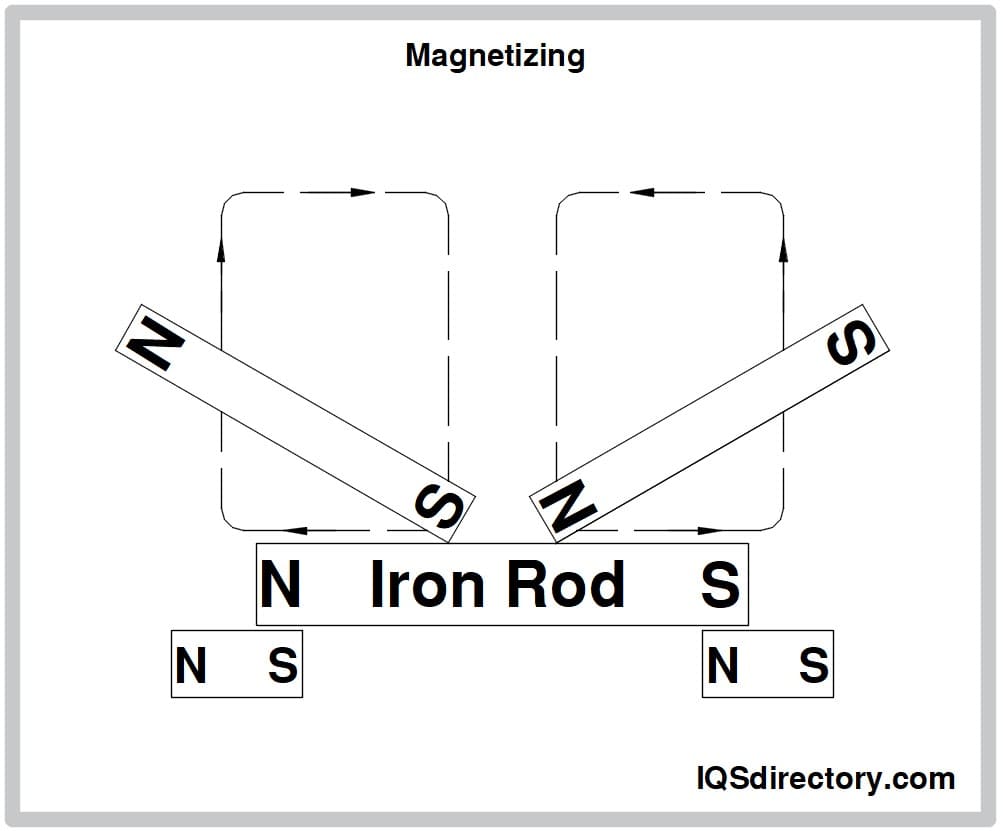

Following the finishing process and the manufacturing process, the magnet needs to be charged in order to produce an external magnetic field.

Following the finishing process and the manufacturing process, the magnet needs to be charged in order to produce an external magnetic field.

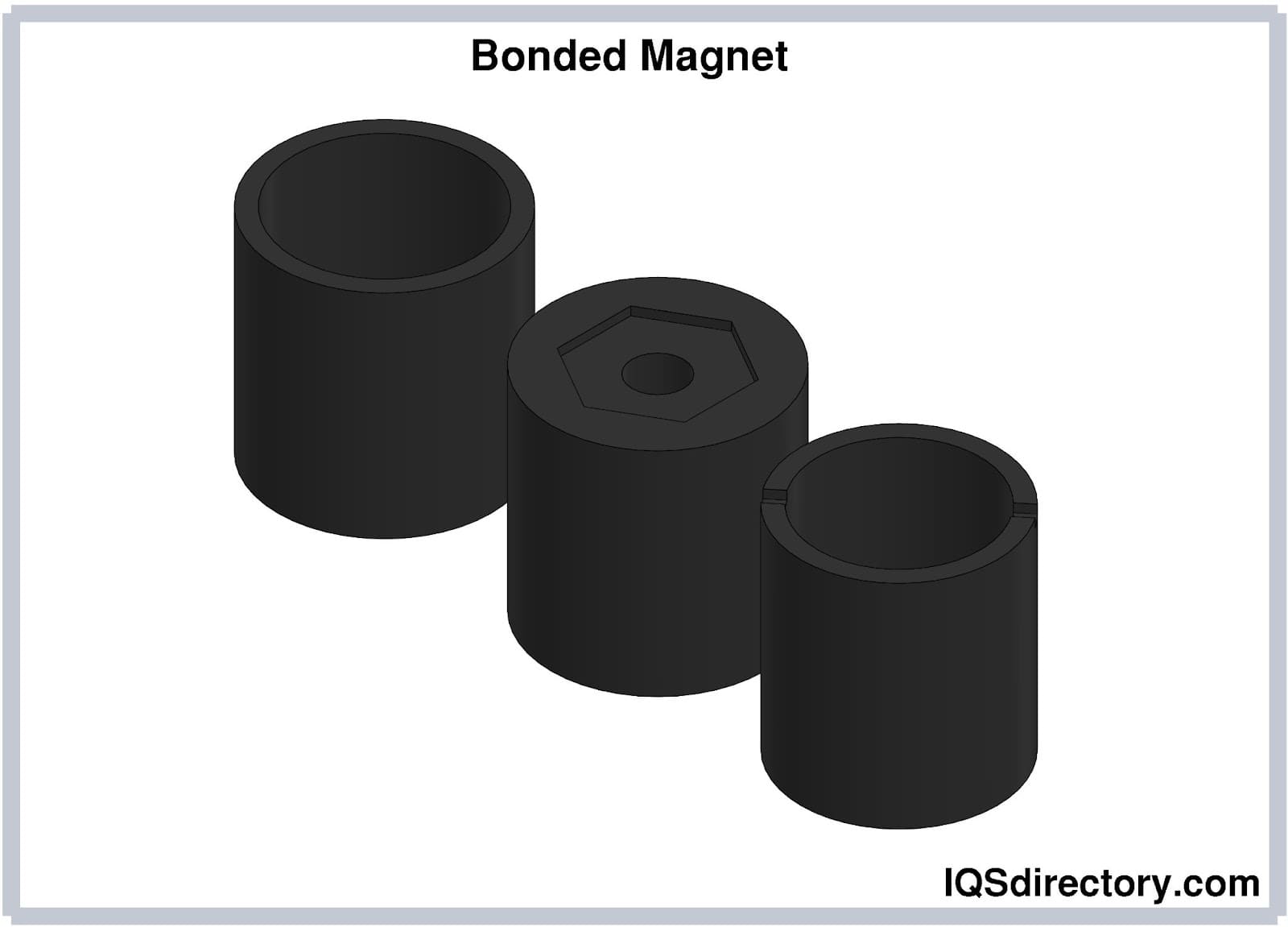

Bonded magnets have two main components a non-magnetic polymer and a hard magnetic powder which aims to be magnetically bonded no matter the materials.

Bonded magnets have two main components a non-magnetic polymer and a hard magnetic powder which aims to be magnetically bonded no matter the materials.

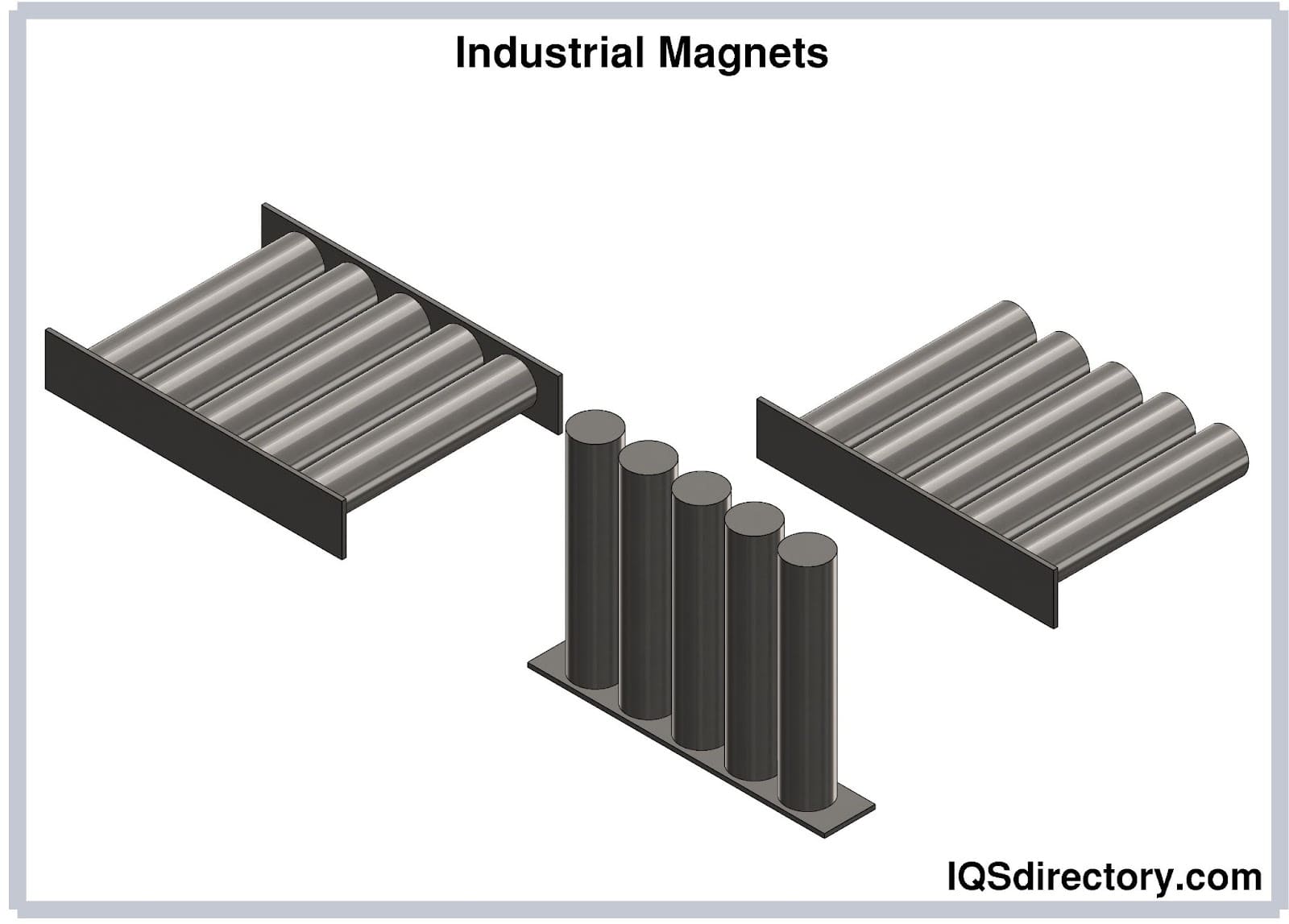

A very powerful magnet made of a ferromagnetic substance which is magnetized by an outward magnetic field which are capable of being magnetized over a long period of time.

A very powerful magnet made of a ferromagnetic substance which is magnetized by an outward magnetic field which are capable of being magnetized over a long period of time.

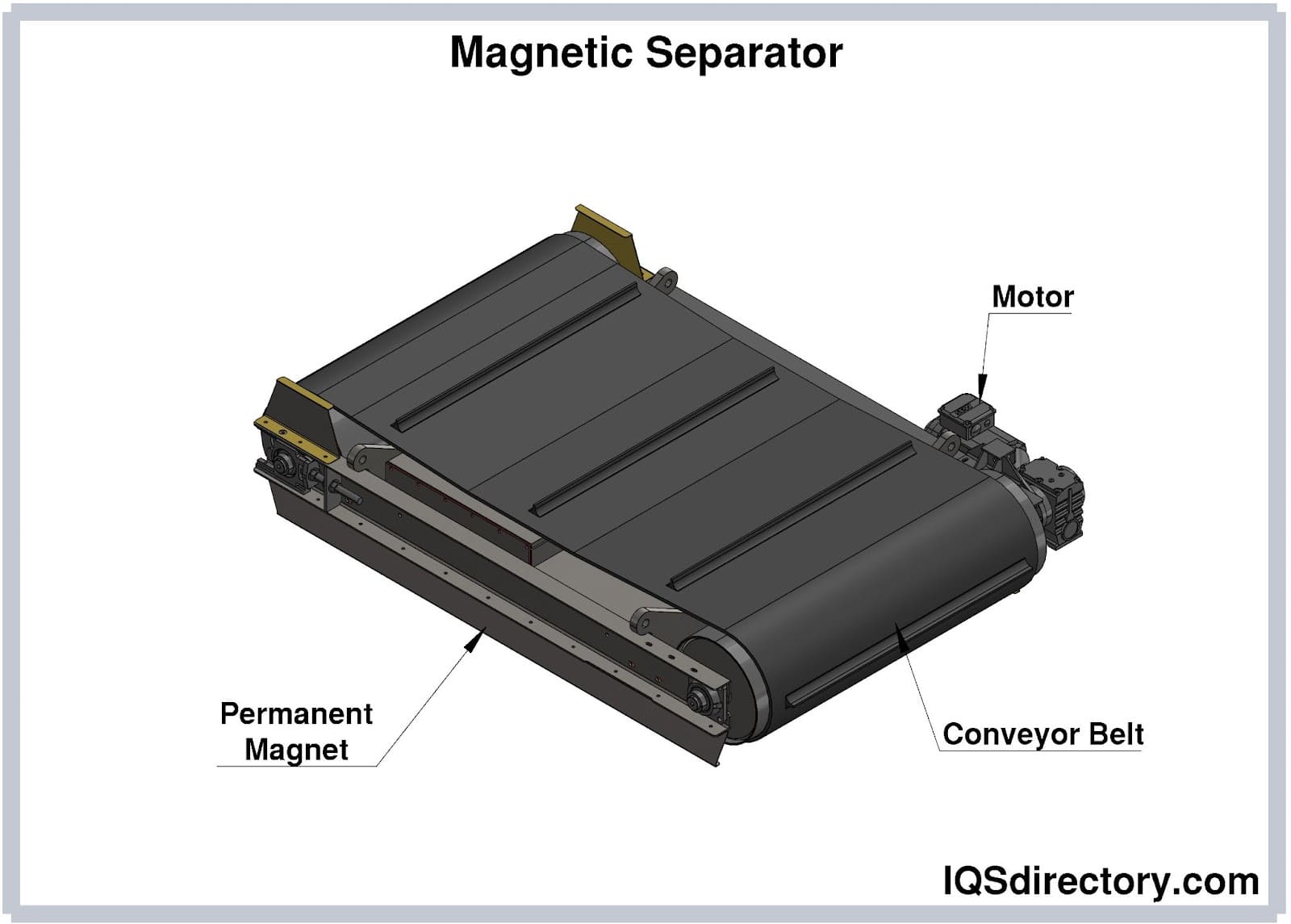

Magnetic separation involves separating a mixture of different components using a magnet to attract the magnetic materials.

Magnetic separation involves separating a mixture of different components using a magnet to attract the magnetic materials.

Magnet Types

- Alnico Magnets

- Sintered from a compound of aluminum, nickel, and cobalt and have higher magnetic permanence and strength than all other non-rare earth magnets. Alnico magnets are only exceeded by rare earth magnets.

- Bar Magnets

- Narrow, rectangular pieces of ferromagnetic material or composite that generate a magnetic field.

- Bipolar Assemblies

- Advantageous during part transference, welding alignments, and part holding applications. Bipolar magnetic assemblies maintain high heat resistance and wide magnetic reach.

- Bonded Magnets

- Combine thermoplastic and thermoelastomer resins with magnetic powders to create injection-molded, flexible magnets. These magnets are great for custom applications in which a traditional, solid magnet would not offer the same type of value.

- Ceramic Assemblies

- Maintain resistance to demagnetization, can withstand exposure to electrical fields and vibration, and are economical. Their demagnetization resistance is beneficial in the welding and construction industries, as well as other environments subject to vibration and electricity. However, they do have low heat resistance.

- Ceramic Magnets

- Made of strontium carbonate and iron oxide or other ceramic materials.

- Custom Magnets

- Sheet, alnico, neodymium, rare earth, or ceramic magnets fabricated to specialized sizes, magnetic strengths, or densities to fit certain applications.

- Electromagnets

- Require an electric current for the production of a magnetic field.

- Ferrite Magnets

- Common lost-cost magnets. Ferrite magnets are usually brittle but otherwise resilient. Also called ceramic magnets.

- Industrial Magnets

- Heavy duty magnets used for industrial applications.

- Magnetic Assemblies

- Tools and systems that use large amounts of magnets to lift, separate, and hold metallic materials.

- Magnetic Strips

- Thin pieces of flexible magnetic rubber material that usually have an adhesive on one side and can conform to irregular or uneven surfaces.

- Neodymium Magnets

- Composed of a combination of neodymium, iron, and boron. Also known as neodymium iron boron magnets and NdFeB magnets.

- Permanent Magnets

- Retain magnetism without a magnetic field. Permanent magnets do not generate electricity or heat.

- Rare Earth Assemblies

- Maintain the highest holding ability of all magnetic assemblies in a compact design but generally possess low heat resistance. Rare earth magnets are comprised of neodymium magnets and samarium cobalt magnets. They are referred to as rare earth magnets because of their location in the periodic table.

- Rare Earth Magnets

- Composed of elements found in the "Rare Earth" part of the Periodic Table. These magnets are extremely powerful.

- Sheet Magnets

- Large, flat magnets that can cover a large area.

- SmCo Magnets

- Samarium cobalt magnets. They are a type of permanent magnet made up of the rare earth metals, samarium and cobalt.

Magnet Terms

- Alnico (Aluminum-Nickel-Cobalt)

- A shorthand reference to magnets made from an aluminum nickel cobalt compound. These types of magnets have medium to high magnetic strength and have excellent magnetic resistance to heat.

- Anisotropic

- A magnetic characteristic whereby magnetic orientation exists toward a specific direction as a result of the application of a magnetic field to a magnet during its production.

- Assemblies

- Systems and tools composed of magnets and other components. They are designed for the lifting, separation, or holding of magnetic or metal materials.

- Badge Magnet

- An encased magnet used to hold identification badges to clothing without causing damage.

- Bar

- Any of a number of ferromagnetic materials or composites made in the shape of a narrow rectangle.

- Bipolar Assemblies

- Special heat-resistant magnetic assemblies with a wide reach. They are useful for alignments, holding applications, and similar tasks.

- Bipole Electromagnet

- An electromagnet design in which the magnetic coil is located between two steel plates parallel to each other, which act as the north and south poles.

- Ceramic Magnet

- Magnet assemblies composed of strontium carbonate and iron oxide which are charcoal in color and typically appear in the forms of discs, rings, blocks, cylinders, and even arcs for motors.

- Curie Temperature

- The temperature at which the magnetic properties of a magnet begin to decrease upon exposure.

- Demagnetizer

- A device that can eliminate magnetism in magnetic assemblies by using an alternating electrical current.

- Demagnetizing Force

- Forces like temperature, shock, vibration, or electrical or magnetic currents that completely or partially demagnetize magnetic material.

- Ferrite Magnet

- A commonly used, low-cost magnet that is brittle though relatively hard and has good resistance to demagnetization, good temperature stability, and excellent corrosion resistance.

- Ferrous Material

- A material containing iron, which makes it inherently magnetically attracted.

- Flexible Magnet

- A magnet made by combining a mixture of ferrite powder and rubber polymer resin, forming it by extrusion or rollers, then magnetizing and laminating it with vinyl or adhesive. Flexible magnets are the most pliable permanent magnet and are the least expensive by volume.

- Flux

- The measure of the strength of the total size of a given magnetic field found in magnetic assemblies.

- Gauss

- A unit of measurement indicating magnetic induction.

- Industrial Magnet

- A magnet optimal for any big projects in which large metal products without brackets need to be lifted. Industrial magnets are adaptable enough to allow companies to customize them in order to make them better and more efficient for specific applications.

- Isotropic

- Magnetic characteristic whereby magnetic orientation toward a specific direction does not exist. Isotropic, or non-oriented, magnets can be magnetized in all directions.

- Lifting Magnet

- A magnet that is part of a lifting device used to move a variety of ferrous metals, ranging from small bundles of rod or scrap to large, heavy blocks.

- Magnetic Field

- An area characterized by the movement of an electric charge. Magnetic fields remain most intense at opposite ends of magnets, known as the North and South poles.

- Magnetic Flux

- The strength of the magnetic field of a magnet as shown by the rate of movement of magnetic energy.

- Magnetic Induction

- The initial magnetization of an object created by forces emanating from a magnetic field.

- Magnetic Orientation

- The direction toward which a magnet is predisposed as a result of exposure to a magnetic field during its production.

- Magnetic Pole

- The area of magnetic flux concentration in which magnetic fields are strongest. The North and South Poles are magnetic poles.

- Magnetic Separators

- Devices that remove ferrous metals from various materials while still protecting machinery.

- Maxwell

- A unit of measurement indicating magnetic flux.

- Neodymium Magnet

- A magnet made of a rare earth element that is smaller, stronger, and cheaper than most other magnets.

- Oersted (Oe)

- A unit of measurement indicating the strength of a magnetic field.

- Permanent Magnet

- A magnet that still retains its magnetism after having been removed from a magnetic field.

- Rotary Magnetic Sweeper

- A device that picks up all metal debris when rolled over spills. A release lever drops everything the rotary magnetic sweeper picks up, eliminating the need to handle potentially hazardous metal pieces.

- Sheet Magnets

- Describes a large, flat magnet used for covering large areas.

- Strips

- Thin pieces of magnetic material, usually magnetic rubbers with adhesives for attaching to irregular surfaces.