Dust Collectors

A dust collector is a piece of air filtration equipment. It improves commercial or industrial air quality by capturing particulate matter (like dust particles) and then releasing clean air into the atmosphere on the other side.

Dust collectors also filter a number of pollutants and solid particles that the government has banned in response to continued air pollution.

Quick links to Dust Collectors Information

The History of Dust Collectors

The need for dust collectors began in the 19th century during the Industrial Revolution, when companies began producing high volumes of industrial waste like fine dust, wood dust and other particles. In 1852, an American man named S.T. Jones applied for one of the first dust collector-type device patents, the single bag filter.

Then, in 1921, a man named Wilhelm Beth, who was from the German city of Lübeck, patented three filter designs. One involved cloth filtering, another agitation/shaking devices for cleaning filters, and another tubular filter devices. He also constructed hose filters. He focused on filtering both air and gas.

At the beginning of 1950s, the air filter industry was transformed by the invention of the reverse air jet system. At the end of the 1950s, engineers introduced the pulse jet filtration system. This system brought down the number of mechanical parts involved in air cleaning.

Since the 1970’s and 1980’s, when air quality requirements and pollution restrictions became more stringent, dust collectors have become very popular, and manufacturers continue to innovate their design. Today, as the dust collecting industry advances, smaller, cleaner and more efficient separating and filtering equipment is being developed.

Benefits of Dust Collectors

- There are Four Major Advantages of Dust Collectors

- The Reduced Risk of Fire

- The Prevention of Dust Explosion

- The Enhancement of Visibility on the Work Site

- The Reduction of Industrial Odors

In addition, dust collectors have low operating costs and they’re highly efficient.

Why Use a Dust Collector

The purpose of dust collectors is to capture the particles emitted during the manufacturing processes. The particles released during manufacturing processes are hazardous to both worker and equipment health, quickly leading to a number of problems if particles are not captured by dust collection equipment and filtered from facility air. A dust collection system addresses this problem by drawing contaminated air through a filter or separator, trapping harmful particles and releasing cleaner air into the atmosphere or back onto the work floor.

As we’ve said, dust collectors improve both indoor and outdoor environments by capturing a high percentage of the particles emitted by industrial processes. However, they also play a major role in helping companies meet the requirements of various standards. For example, industry-specific OSHA regulations hold facilities to strict standards for indoor air quality. Also, the EPA and other regulatory bodies put limits on emissions of dust, smoke and fumes into the atmosphere.

Dust collection is a vital process for coal handling, cement fabrication, metal fabrication, mining, chemical processing, woodworking, pharmaceutical, recycling and agricultural industries, among many others. Within their facilities and outside, companies can incorporate several different dust collector types into one system, or they may use smaller, self-contained or portable units to get the job done.

Dust Collector Design

Industrial dust collectors come in various types and sizes. Plus, they’re made up of many different parts. So, the design and manufacturing process varies from one type of dust collector to another.

However, all are made using some combination of machining and assembly. For example, most (if not all) dust collectors come equipped with a blower. To make this blower alone, manufacturers must design and create an engine, fan blades, a wheel or rotor mounted on a shaft and a housing. Those dust collectors that feature a fabric filter or compact filters like the cartridge filter, require the manufacturing of several other parts, including: a blow pipe, housing and hopper, clean plenum, dusty plenum, tube plate, compressed air header, bag, cage and more.

Once you’re done manufacturing and assembling the parts of your dust collector, you can strengthen them with secondary processes. For example, to make sure a fabric filter will work well and for a long time to come, manufacturers often choose to coat the filter with something called a pre-coat or filter enhancer. The most common type of pre-coat is chemically inert limestone.

Typically, the outside or frame of a dust collector is constructed using a strong metal material like mild steel or stainless steel. Fabric filters can be made from materials like: felted cotton, woven cotton, synthetic material or glass fiber material.

Customize your dust collector by adding custom panels, giving it a paint job (with industrial grade paint), adding accessories like tailpipe adaptors, or by retrofitting it.

Dust Collector Images, Diagrams and Visual Concepts

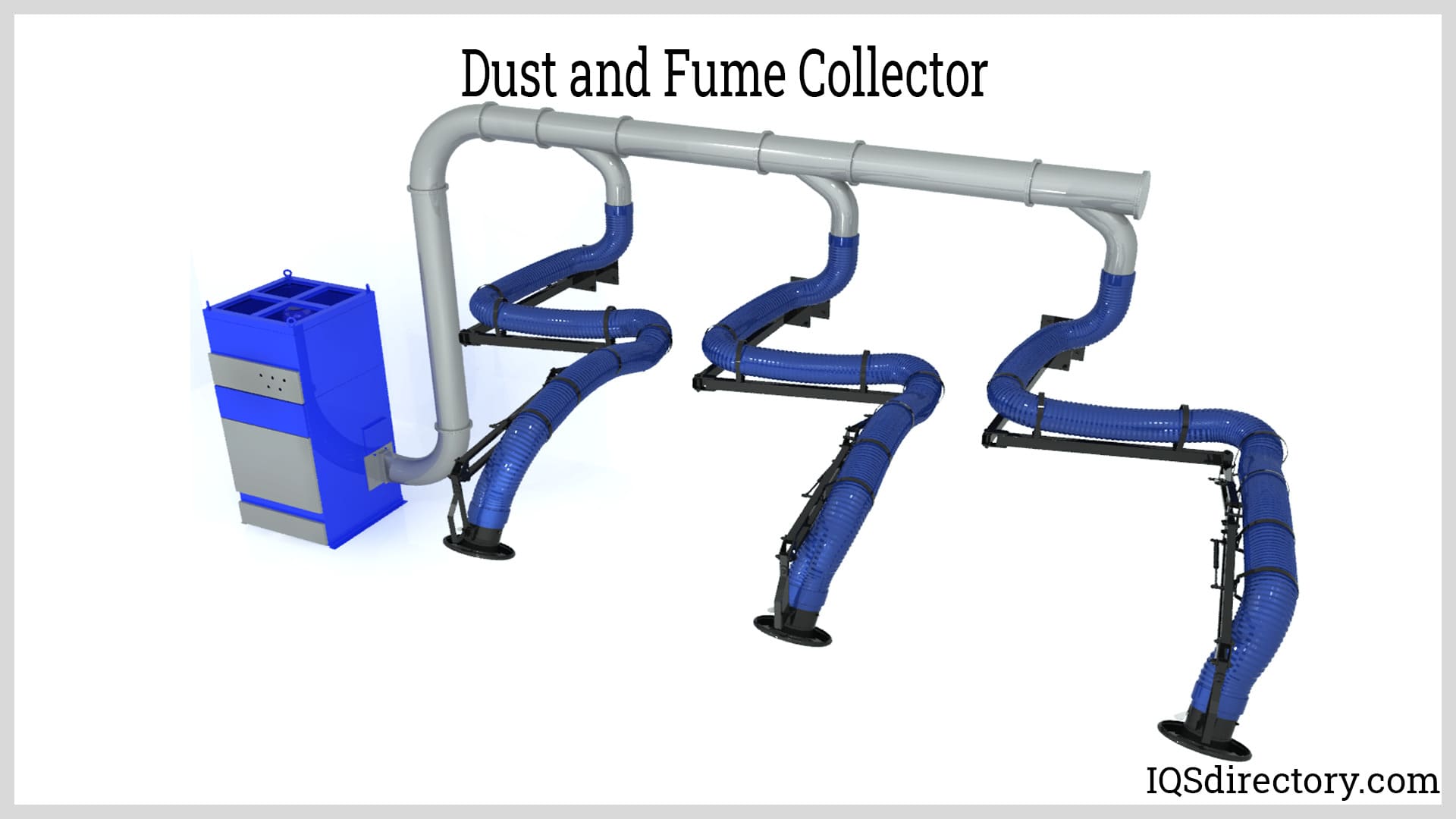

A dust collection system, a system that removes particulate contaminants from the air in production facilities, workshops, and industrial complexes.

A dust collection system, a system that removes particulate contaminants from the air in production facilities, workshops, and industrial complexes.

When the air is cleaned, the particulate contaminants are expelled outside or recirculated, after the achievement of the proper emission‘s standards.

When the air is cleaned, the particulate contaminants are expelled outside or recirculated, after the achievement of the proper emission‘s standards.

The baghouse is the most common and the most efficent form of dust collection systems.

The baghouse is the most common and the most efficent form of dust collection systems.

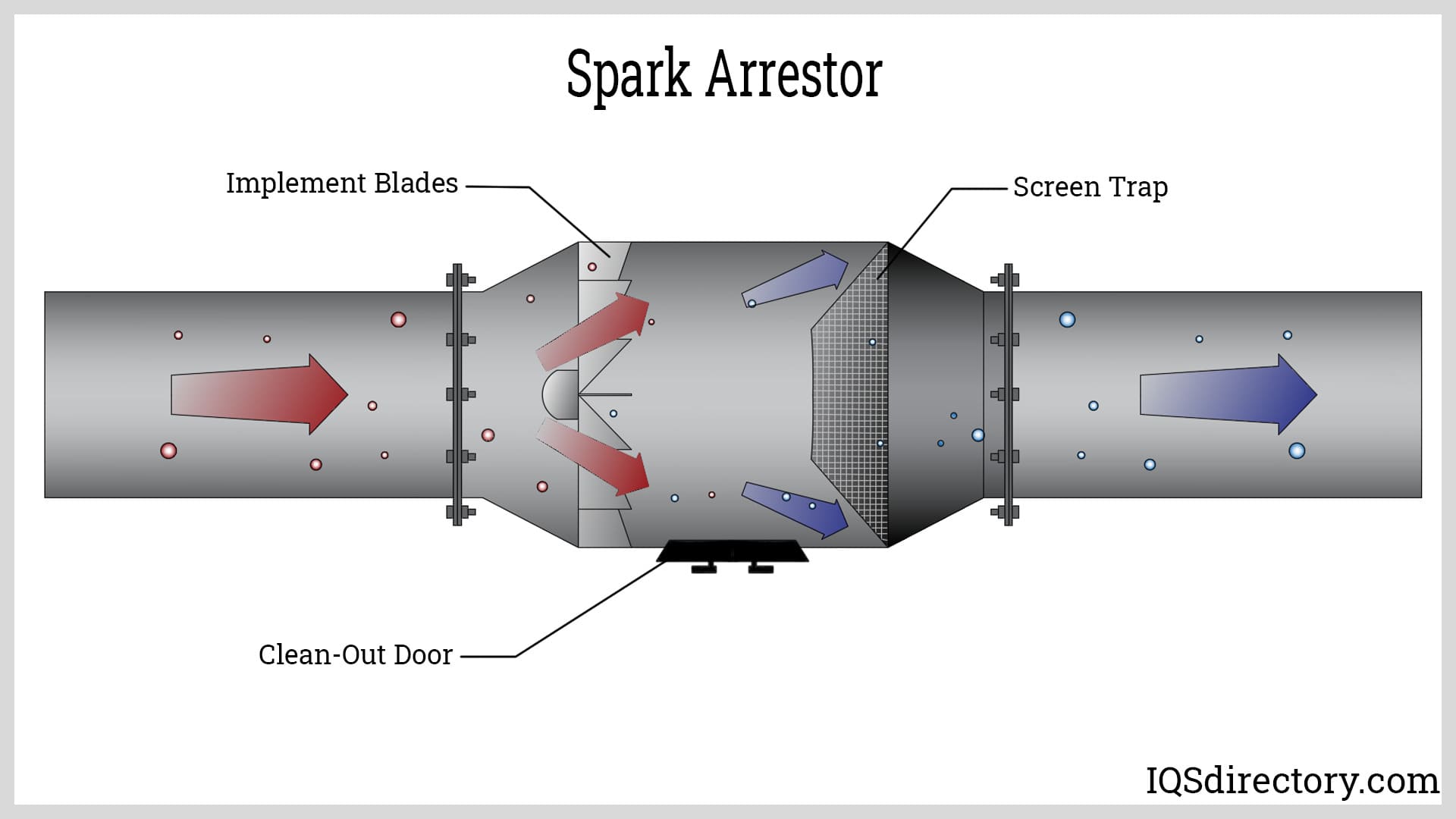

A spark arrestor is used for combustion preventative and is an add-on for systems that have potential for combustion, which traps exhaust and lower the temperature before the particles enter the dust collecting device.

A spark arrestor is used for combustion preventative and is an add-on for systems that have potential for combustion, which traps exhaust and lower the temperature before the particles enter the dust collecting device.

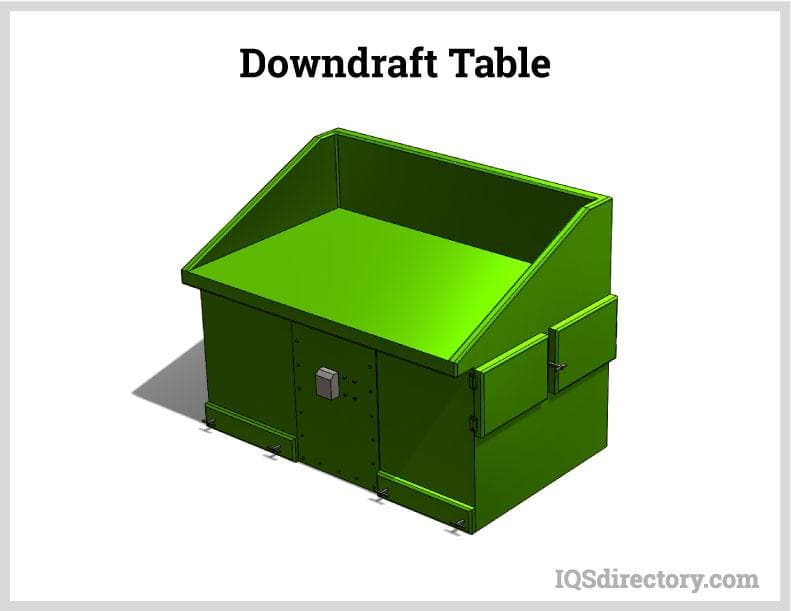

Downdraft tables are self-contained dust collection systems that remove particulate matter from the surface into a filtration system.

Downdraft tables are self-contained dust collection systems that remove particulate matter from the surface into a filtration system.

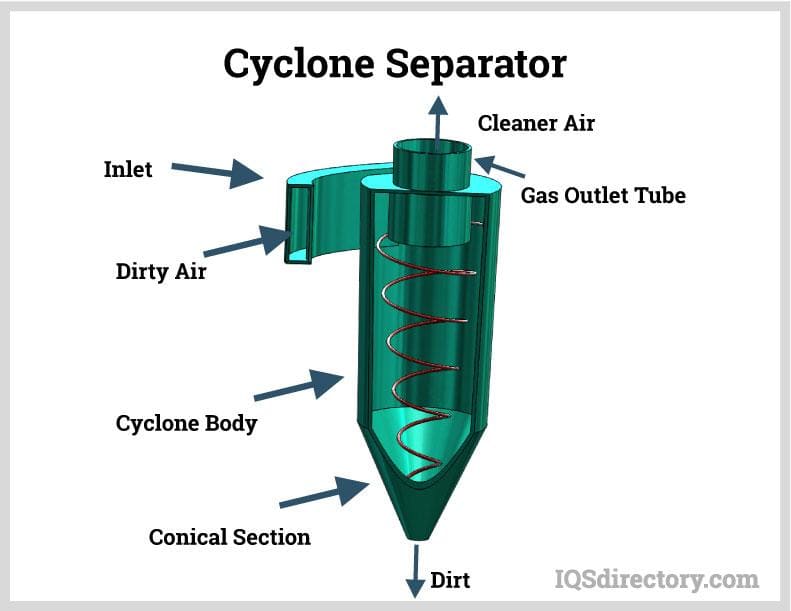

Cyclone dust collection systems are a form of inertial separator that uses centrifugal force to separate particulates, which that the cyclone in the self-contained chamber where the air is purified.

Cyclone dust collection systems are a form of inertial separator that uses centrifugal force to separate particulates, which that the cyclone in the self-contained chamber where the air is purified.

The most common material removed by a dust collection systems.

The most common material removed by a dust collection systems.

Dust Collector Types

- Baffle Chambers

- Cause dusty air to change direction suddenly so that gravity and inertia carry the heavier dust particles downward, out of the air stream and into a collection area.

- Baghouse Type

- Dust collection filters typically constructed from glass fibers or fabric.

- Cartridge Collectors

- Compact filters that have a much greater surface area than bags, which increases the airflow, lowers resistance and reduces frequency of cleaning.

- Cyclone Dust Collectors

- Rely on centrifugal force to remove dust from air.

- Cyclone Separators

- Filter dust particles by spinning the air around in its tank. The particles, being heavier than air molecules, are thrown against the outer wall of the hopper and fall to the bottom, where they are collected. Multi-cyclone dust collectors have a single main inlet on one side and a single outlet on the other side, but incorporate many cyclone cylinders inside the chamber that run concurrently; single-cyclone dust collectors have only one cyclone.

- Downdraft Booths

- Systems that vent from the top and pull fumes and dust up past the worker's face.

- Downdraft Tables

- Or workstations have perforated tabletops and back walls and draw dust and fumes away from the worker's breathing zone.

- Dust Collecting Systems

- Filter air and remove dust before releasing clean air back into the environment.

- Electrostatic Precipitators

- Collect dust through ionization. As dust-filled gases move through the system's positively-charged, grounded electrodes called collection plates, discharge electrodes give the dust particles a negative charge, which causes the ionized dust particles to be attracted to and caught by the collection plates.

- Fabric Collectors

- Often known as baghouses, fabric filters are very efficient as well as cost effective. Dusty gases pass through fabric bags of various materials such as felted or woven cotton and glass-fiber material. Fabric filters are relied on heavily as they have collection efficiency of over 99% for very fine particles.

- Baghouses have the most common and cost-effective dust collector design. To work, they draw contaminated air in through ducts and to a hopper-shaped baghouse containing fabric filters made of cotton, synthetics or glass-fiber. The air is pulled through the fabric bags by a vacuum-creating fan that captures dust, smoke and particles. Finally, clean air exits through the fan at the outlet. Those dust particles left behind either cling to the filter or settle into an airlock at the bottom of the hopper, which is routinely emptied.

- Industrial Dust Collectors

- Minimize the presence of various pollutants in order to maintain a high standard of clean air in workshops, plants and manufacturing facilities.

- Inertial Separators

- Separate dust particles from gas by changing the direction of gas streams as the streams flow through the collector.

- Jet Dust Collectors

- Use a jet-based cleaning cycle.

- Portable Dust Collectors

- Can be moved from place to place.

- Pulse Jets

- Use compressed air to force a burst of air down through the fabric bag and expand it violently. When the bag reaches its limit, the dust separates from the bag, and the escaping air carries the dust away from the fabric surface.

- Settling Chambers

- Slow the movement of dusty air to allow for the heavier particles to settle out.

- Silo Vents

- Collect the product in filter bags as the silo is being filled with material. The bags are then shaken to return the valuable product to the silo.

- Small Dust Collectors

- Solve air pollution problems when limited space for filtration is available.

- Unit Collectors

- Small dust collecting systems that contain a fan and either a fabric collector or a cyclone. These are usually low in cost and portable and ideal for small operations or facilities with limited space.

- Shop Vacuum

- Another dust collector system is the shop vacuum. Shop vacs use centrifugal fans to pull in dry or liquid air; they hold it either in a fabric bag or via cyclone dust collection. Check out IQS Directory's page to find suppliers that offer the type of collector you're looking for.

- Ventilators as Dust Collectors

- Pull a continuous stream of air from the environment, removing airborne dust particles.

- Wet Dust Collectors

- Soak dust-filled gas streams with water and separate the wet dust particles through varying degrees of pressure drops. Wet scrubbers use liquid (usually water) for another method of efficient dust removal. Wet scrubbers capture gas streams containing dust when they come into contact with liquid streams. These liquid streams then carry the dust away, leaving purer gases. Wet scrubber types are categorized by energy usage.

Installation of a Dust Collector

Install your new or retrofitted dust collector with the help of your supplier, who will assist you to a greater or lesser degree, depending on the size and scope of your system. The largest dust collection systems require manufacturers' help with safety and support equipment like cranes and lifts, while smaller systems, like the shop vac, may simply require delivery. If you are doing the bulk of the installation yourself, make sure to consult with your manufacturer to confirm that you understand what you must do and you have all the right tools.

Standards and Specifications of Collectors

To make sure that your dust collectors are legal and your employees are safe, make sure to follow OSHA (the Occupational Safety and Health Administration) guidelines. Because dust collectors are so often used to help companies comply with government bans and regulations on emissions, it’s also wise to have your manufacturer follow EPA (Environmental Protection Agency) rules during design.

Things to Consider When Purchasing a Dust Collector

- To find the right dust collection design for you, there are a number of questions you must consider. These include:

- Is your application located indoors or outdoors?

- What is the density of the dust you want to collect?

- What is the size of your operation?

- What is the frequency with which your system will be used?

- What type of substance(s) (dust and fume, liquid and fume, etc) will your system be collecting?

- Once you figure out the system you need, you need to pick out the right manufacturer. Who is the right manufacturer? The right manufacturer is the one who is not only skilled and experienced, but also considerate and a great provider of customer service. To find that manufacturer, browse those listed near the top of this page.

Proper Care for Dust Collectors

One of the most important aspects of dust collector care is filter cleaning. For example, when the filter cake on baghouses becomes too thick, it begins to stress the system. While baghouses are sometimes equipped with vibrators that shake filters free of dust, you must occasionally clean the filters yourself to ensure sufficient airflow through baghouse filters.

It’s also important to sometimes clean other components of dust collectors, such as the dust collection hose and ducting. Maintaining ducting is also important because, if not, it can generate friction and excess static pressure.

Dust Collector Accessories

Depending on the type of dust collector, there are many value-adding accessories available to you.

These include: slide gates, HEPA air filters, dust drawers, explosion doors, ducting, an extra duct port, multiple suction hoods, flexible exhaust hoses, sprinkler systems, emission sensors, rotary valves, tailpipe adaptors, gas detectors and more.

To figure out what accessories might benefit your application, talk to your supplier.

Dust Collector Terms

- Air-to-Cloth Ratio

- The amount of process gas or air entering the fabric collector (baghouse) divided by the square feet of cloth in the fabric collector.

- Asbestosis

- Form of pneumoconiosis caused by the inhalation of asbestos minerals into the lung, resulting in lung scarring, breathing problems and various forms of cancer.

- Bleedthrough

- Also called "leakthrough," it is the ability of particles of dust or fumes to migrate through the fabric bag.

- Cake

- Also referred to as "filter cake," it is the dust buildup occurring on the surface of the filter medium during filtration that often aids in the filtration process.

- Certified Energy Manager (CEM)

- International professional designation available through training and testing by the Association of Energy Engineers (AEE).

- CFC (Chlorofluorocarbon)

- Family of chemicals used as refrigerants, being tightly regulated and phased out of production due to stratospheric ozone depletion potential. Examples: R-11, R-12, R-113, R-114, R-115.

- Coating

- The act of dipping the filter medium into a solution in order to lubricate the fibers to reduce self-abrasion.

- Collection Plates or Tubes

- Electrodes in an electrostatic precipitator that attract and collect negatively charged particles of dust.

- Concentration

- The amount of dust that the gas or air contains. Concentration is expressed in grains per cubic foot or pounds per hour.

- Discharge Electrodes

- Electrodes in an electrostatic precipitator that negatively charge dust particles.

- Electrodes

- Conductors or parts of a semiconductor that create an electrical connection with nonmetals or control the movement of electrons.

- Fabric Bag

- Filter in a fabric collector consisting of woven or felt material such as cotton.

- Fibrogenic Dust

- Toxic particles that penetrate the lungs, causing lung dysfunction and scar tissue formation.

- Filter Media

- The porous barrier used in the filtration process to separate the particles from the fluid stream.

- Flange-to-Flange

- The fabric collector equipment from inlet flange to outlet flange.

- Flex Abrasion

- Cloth wear in a fabric bag caused by excessive bending.

- Hood

- A hood-shaped inlet designed to collect contaminated air and direct it into the exhaust dust system of a baghouse.

- Hopper

- In dust collecting systems, the area in which the collected dust is stored.

- Inert Dust

- Also called "nuisance dust," it consists of particles of which quartz and other silicates compose less than one percent.

- Inhalable Dust

- Medium- to large-sized dust particles that do not reach the lower respiratory tract but remain in the upper respiratory system, nose and throat.

- Mist Collector

- A device that sucks up fine particles from fluids like oils and even dry smoke using a three-phase motor. The inner drum rotates and draws the mist particles to the center of the drum where they are forced together and eventually pass through perforations in the drum and back into the machine's coolant tank, while clean air blows past the motor and back into the outside environment.

- Multi-Cyclone Separators

- Centrifugal separators containing several parallel cyclones that separate dust particles according to texture.

- Plate Precipitator

- Common high-voltage electrostatic precipitator consisting of flat collection plates along which discharge electrodes lie.

- Pneumoconiosis

- Respiratory ailment caused by excessive inhalation of metallic or mineral dust matter. Pneumoconiosis also includes diseases such as silicosis and asbestosis.

- Rapper

- Part of electrostatic precipitator that transfers dust from the collection plates to the hopper.

- Respirable Dust

- Small dust particles inhaled into the lower regions of the lungs that are responsible for different types of pneumoconiosis.

- Silicosis

- Incurable, potentially deadly type of pneumoconiosis caused by the inhalation of silica dust particles, resulting in lung diseases such as emphysema. Silicosis progresses even after contact with silicates has ceased.

- Surface Abrasion

- More or less consistent wear on the dirty side of the fabric bag cloth.

- Spark Arrestors

- An element that intercepts flammable debris from combustion sources in order to prevent fires. Early spark arrestors, commonly designed as spiral shaped cones, were employed in steam locomotives to separate embers from the exhaust through centrifugal force.

- Total Dust

- Consists of all dust particles, whether respirable or inhalable.

- Tubular Precipitator

- High-voltage electrostatic precipitators consisting of cylindrical collection plates that rotate around the discharge electrodes.

- Vibrator Systems

- Part of an electrostatic precipitator that transfers dust from the collection plates to the hopper.