Air Pollution Control

Air pollution control equipment removes and eliminates a wide variety of pollutants, known as volatile organic compounds (VOCs) and hazardous air pollutants (HAPs) including sulfuric fumes, gases, odors and vapors from the atmosphere. VOCs and HAPs cause serious environmental and biological damage resulting in smog, acid rain, carbon emissions and global warming, but they are reduced or eliminated by air pollution control equipment.

Quick links to Air Pollution Control Information

The History of Air Pollution

During the industrial revolution, large factories created assembly lines, spewing plumes of smoke into the air. Automobiles, boats and airplanes spewed exhaust gas into the air. Some believe that air pollution is the price of progress.

Air pollution can reach toxic levels. In 1948, 20 people died and 7,000 people were injured in Donora, Pennsylvania. This remains the worst air pollution disaster in American history. The worst air pollution disaster in world history might have occurred in Bhopal, India in 1984. A Union Carbide factory killed at least 3,787 people and injured between 150,000 and 600,000 citizens. In 1952, London, England had a severe smog that might have led to 4,000 to 12,000 deaths.

In America, the 1970 Clean Air Act established a new priority for environmental health. Hereafter, the EPA would require businesses to keep their emissions below a safe threshold for a targeted list of hazardous chemicals. Now, a manufacturer can be held liable decades after causing poor air quality.

In 1824, one of the most important technologies for air pollution control equipment - Electrostatic Precipitator (ESP) - was invented in Germany by Hohlfeld. Although this technology was amazing, it had no real world industrial application until the 1970 Clean Air Act was passed.

In 1907, Professor Frederick Gardner Cottrell received a patent for the first commercially viable electrostatic precipitator. This is primarily used to collect, treat and remove sulphuric acid from an emission. Professor Gardner placed his patent in a foundation, which could not financially benefit until after 1970.

What is Air Pollution?

Ambient air consists of gases, liquids and even solids. Government regulators have created standards for acceptable levels of different chemicals in the ambient air. The goal of manufacturing companies is to keep every emission below the government threshold for airborne pollutants.

As civilization has advanced, it has also unleashed more dangerous chemicals into the environment. The industrial revolution has caused high levels of hazardous chemicals, such as carbon monoxide, sulfur dioxide and nitrogen oxide to accumulate in the atmosphere.

Scientists have been able to estimate the levels of toxic emissions in the air throughout history by comparing various soil samples. For example, while the modern industrial society has carbon dioxide in the ratio of around 405 parts per million (ppm), pre-industrial society has carbon dioxide in the atmosphere at a lower ratio of only 280 ppm.

The atmosphere can only handle a certain amount of pollutants. The ambient air can become toxic and dangerous when there is too much sulfur dioxide or carbon monoxide in it.

What is Air Pollution Control Equipment?

To remain in compliance with federal emissions regulations, facilities must install emission control systems to keep air pollution output below levels specific to facility size and pollutant type. Oxidizers perform a process in which air pollutants such as hydrogen sulfide are broken up and reformed into safe, non-toxic carbon; this process, called oxidation, is performed by burning air pollutants and is at the heart of most of these systems. Depending on the type of air pollution being controlled, facilities may also use wet scrubbers or dry air scrubbers, mist collectors, electrostatic precipitators, odor control systems or simply air filtration systems. Automotive, agricultural, petrochemical processing, mining, pharmaceutical and most industrial manufacturing facilities require air pollution control systems to regulate air purity inside the facility and without. To recuperate some of the cost of running this equipment, many manufacturers use heat recovery systems as well.

Oxidizers may be thermal or catalytic, using either high heat or elemental additives to catalyze oxidation, or burning of VOCs (which is one common method of VOC abatement). Catalytic oxidizers typically wash polluted air in platinum or palladium, causing oxygen to separate from VOCs and create non-toxic bi-products such as nitrogen and oxygen, as opposed to nitric oxide. Both catalytic and thermal oxidizers may be regenerative or recuperative. Recuperative oxidizers use ceramic heat transfer beds to recover as much energy as possible from the oxidation process -- often as much as 90% to 95%. These heat transfer beds act as heat exchangers, coupled to a retention chamber where the organics are oxidized. Regenerative thermal oxidizers recover up to 90-95% of the heat energy released from oxidation processes with ceramic heat transfer beds. Recuperative oxidizers use a plate, shell, tube or other conventional type of heat exchanger to preheat VOC-contaminated process gas in an energy recovery chamber. A catalyst - either heat or elemental additives - oxidizes the VOCs, which then release enough energy to allow self-sustained operation.

Non-oxidizing air pollution control equipment uses a variety of filtering methods to separate volatile organic and inorganic compounds from processed air. Air scrubbers may be dry scrubbers or wet scrubbers; dry scrubbers remove acid gases such as sulfuric oxide and hydrogen chloride using dry sorbent alkaline materials, while wet scrubbers clean flue gas of larger pollutants and dust using water or other liquid reagents. Electrostatic precipitators clean pollutants and dust particles from polluted air using electrical ionizing fields and tightly woven fabric filters to remove particulates from boiler flue gas and other process air. Electrostatic precipitators often filter process smoke, mist or other large liquid or solid particle contaminants in a process called mist collection. Mist collectors and oxidizers are often used as odor control systems for high methane producing facilities such as pulp and paper or livestock processing. Nitrogen oxide controls include the processes of selective catalytic reduction, which controls emissions of nitrogen oxides from stationary sources, and selective non-catalytic reduction, which changes oxides of nitrogen (NOx) into molecular nitrogen (N2). If VOCs have recovery value, carbon adsorption, scrubbing and condensation are typical techniques that may recuperate materials. Thermal and catalytic oxidation and biofiltration are common VOC controls utilized when the VOC stream has no recovery value.

How Air Pollution is Created

- Man Made Airborne Contaminants

- It can be a challenge to properly control all of the man-made airborne contaminants. Carbon monoxide, nitrogen oxide and sulfur dioxide might be generated by cars, ships, airplanes, manufacturing factories, power plants, oil refineries or other industrial processes. Superior air quality keeps these gases below acceptable levels.

- The "greenhouse effect" has morphed into climate change, leading to the banning of chlorofluorocarbons (CFCs). These punched holes in the ozone layer, leading to higher levels of ultraviolet radiation.

- Carbon monoxide (CO) is a toxic, colorless, odorless gas that is primarily found in car exhaust, but it is also due to incomplete combustion from a wood stove or coal-fired power plant emission. If a garage, warehouse or factory does not have proper ventilation, then carbon monoxide levels can become very dangerous and lethal.

- Nitrogen oxide (NOx) is an emission from high temperature combustion. Therefore, you can expect it in the emission of a power plant, manufacturing factory or oil refinery. Nitrous oxide is also found in lightning.

- Sulfur dioxide (SO2) is found in a coal or oil refinery emission.

- Air Pollution by Smog

- You might not worry about poor air quality, until you see a pea soup colored smog. Smog warnings have become common for California residents. There is a difference between traditional smog and photochemical smog.

- Traditional smog is likely to be caused by a coal-fired power plant or other type of fossil fuel process. These coal burning particles might include carbon, smoke, carbon monoxide or and sulfur dioxide.

- Photochemical smog starts with a toxic haze in the atmosphere, which reacts with ultraviolet rays.

- Some business owners might not know their emission levels. They might need to hire scientists to monitor the gas emission from smoke stacks, especially carbon, sulfur dioxide and nitrogen oxide. The air pollution control board regulates industries and can help them understand the dangers of air particulate.

- An air pollution control system should be installed early on and can use a variety of technologies, including fans, filters and scrubbers.

- Carbon emission is a key target for environmentalists. These can be dangerous to people and even agricultural crops. The reduction of this carbon emission is also a goal of government regulations. Improving the air quality can help maintain a sustainable ecosystem. Reducing an air pollutant is a group effort.

Air Pollution and Human Health

The studies are piling up showing that air pollution can have a negative impact on human health. The range of symptoms due to air pollution are quite extensive, including mild discomfort, sluggishness, fatigue, depression, throat irritation, coughing, wheezing, shortness of breath, dizziness, asthma, bronchitis, emphysema, pneumonia, respiratory infections, heart disease, COPD, allergies, sleep disorders, insomnia, mood changes, strokes, lung cancer or death.

A Danish study found increased levels of nitrogen oxide concentrations could lead to higher rates of cervical and brain cancer. Pregnant mothers and babies who are exposed to fine particulate matter are at high risk.

Pregnant mothers, who use wood or coal burning stoves might have higher CO levels. This could lead to lower birth weights, according to a Chinese study.

Fine particulate matter might increase the blood pressure in children, according to some scientists. Baby lung development might also suffer due to air pollutants.

- Increased Lung Problems

- Lung problems could include clogged nasal passages, lung disease, phlegm, dyspnea, reduced lung function, increased sputum production and purulence. Natural gas leaks might make people feel dizzy. Thankfully, most urban gas has had potent odors added to help people identify the danger.

- Indoor Air Quality

- Buildings get their air from the outside; therefore, Indoor Air Quality (IAQ) might also suffer due to high levels of outside air pollutants. The advent of more “green” buildings has increased IAQ, reducing hazardous chemicals that might be found in man-made cleaning solutions, building material and equipment emission. Government regulations seek to improve indoor and outdoor air quality.

- Reduced Worker Productivity

- The wise business owner wants to create a work environment where his employees can be the most productive. Air pollution can lead to discomfort, irritation or sickness. Increased sick days can lower your overall workplace productivity. Brain activity is better in oxygen rich environments.

How Air Cleaning Devices Work

There are three of the primary ways that air pollutant devices work:

- Destroy Contaminants

- Modify Chemicals

- Remove Hazards From the Air

The ideal air pollution control device will completely destroy a hazardous chemical. The problem with many of these chemicals is that they have very high boiling points. They cannot be burned up easily - that is why they are used for high heat industrial processes.

Therefore, destruction of these hazardous gas chemicals is very difficult. The flue gas desulphurization electrostatic precipitator is used to transform hazardous chemicals into inert chemicals.

The baggers and collectors work like your vacuum cleaner - collect all of the gas in a bag, then dispose of it by transforming it into a wastewater slurry or sludge.

Air Pollution Control Equipment

The majority of the scientific community agrees that climate change is happening and that it is a human-caused phenomenon. Studies have estimated that the average temperature of the Earth has risen by about 0.8 degree Celsius since the Industrial Revolution. To an untrained mind, it may seem like a miniscule change; however, this increase in temperature is attributed to serious catastrophic events, such as recurrent droughts, devastating hurricanes like Katrina, and escalated melting rate of glaciers.

Citing these studies, the federal and state governments have passed several standards aimed at regulating emissions from a range of sources, such as coal-based electricity producers, vehicles; large or small, and industries.

Equipment for air pollution control removes and eliminates a wide variety of pollutants, known as volatile organic compounds (VOCs) and hazardous air pollutants (HAPs), including sulfuric fumes, gases, odors and vapors from the atmosphere. VOCs and HAPs cause serious environmental and biological damage, resulting in smog, acid rain, carbon emissions and global warming, but they can be reduced or eliminated by using air-pollution control equipment. Among all government mandated emission control systems, the two main types of equipment that are used most frequently are: carbon absorbers and oxidizers.

Controlling Through Oxidizer Use

- Thermal Oxidizers

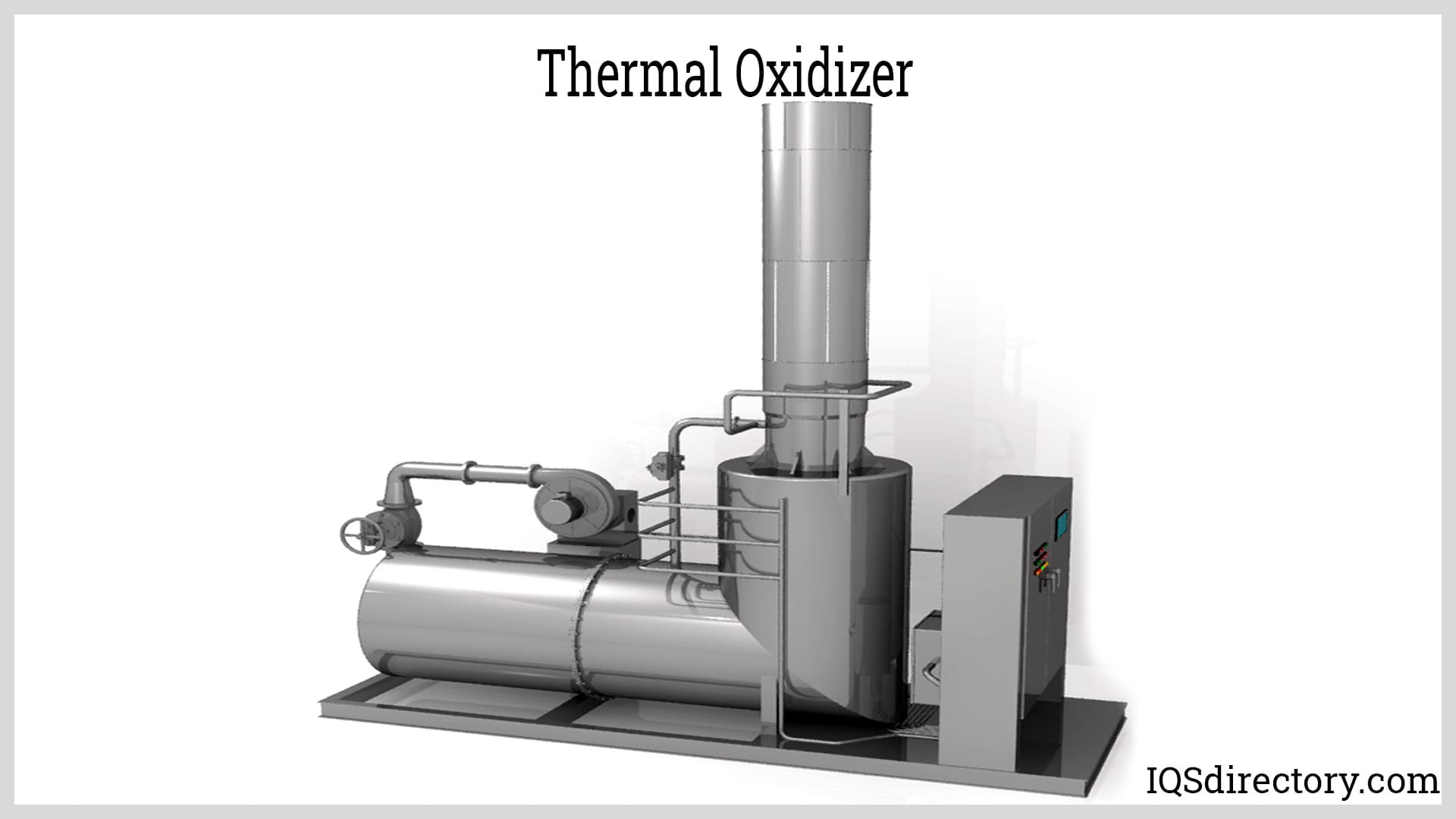

- Thermal oxidizers use heat to convert contaminated air into clean air. The same functioning principle is applied in thermal recuperative oxidizers, afterburners, rotor concentrator systems, regenerative catalytic oxidizers, and regenerative thermal oxidizers, with varying degree of modifications for better results. Emissions are pulled into the machine, where high heat induces a chemical reaction between the pollutants and a metal catalyst bed resulting in the removal of chemicals and contaminants.

- Catalytic Oxidizers

- It typically washes polluted air in platinum or palladium, causing oxygen to separate from VOCs and create non-toxic bi-products, such as nitrogen and oxygen, as opposed to nitric oxide.

- Both catalytic and thermal oxidizers may be regenerative or recuperative. Recuperative oxidizers use ceramic heat transfer beds to recover as much energy as possible from the oxidation process -- often as much as 90% to 95%. These heat transfer beds act as heat exchangers, coupled to a retention chamber where the organics are oxidized. Regenerative thermal oxidizers recover up to 90-95% of the heat energy released from oxidation processes with ceramic heat transfer beds.

Controlling Air Pollution Through Carbon Absorbers

In a carbon absorber, also known as air pollution scrubbers, contaminated process steam flows over an activated carbon bed, which removes the volatile organic compounds from the steam, and absorbs them, and then releases the contaminant free air. The absorbers make use of various chemicals and technologies, including:

- Amines

- For example, monoethanolamine.

- Minerals and Zeolites

- Such as serpentinite, a magnesium silicate hydroxide, and olivine.

- Sodium Hydroxide

- Using Zeman and Lackner Method.

- Lithium Hydroxide

Since carbon absorbers are expensive in terms of installation and operation, the technology has only been lightly implemented; however, soon they will all be mandatory under new regulations.

Most Common Types of Pollution Control Equipment

The pollution control equipment is primarily employed for regulating industrial emissions, so that the good ambient air quality can be achieved. The present day air-pollution control equipment primarily filters out many contaminants, including fine particulate matter, sulfur dioxide, carbon monoxide and dioxide, lead and oxides of nitrogen. Moreover, many measures and devices selectively filter out volatile organic compounds.

- Pollution Control Through Electrostatic Precipitators

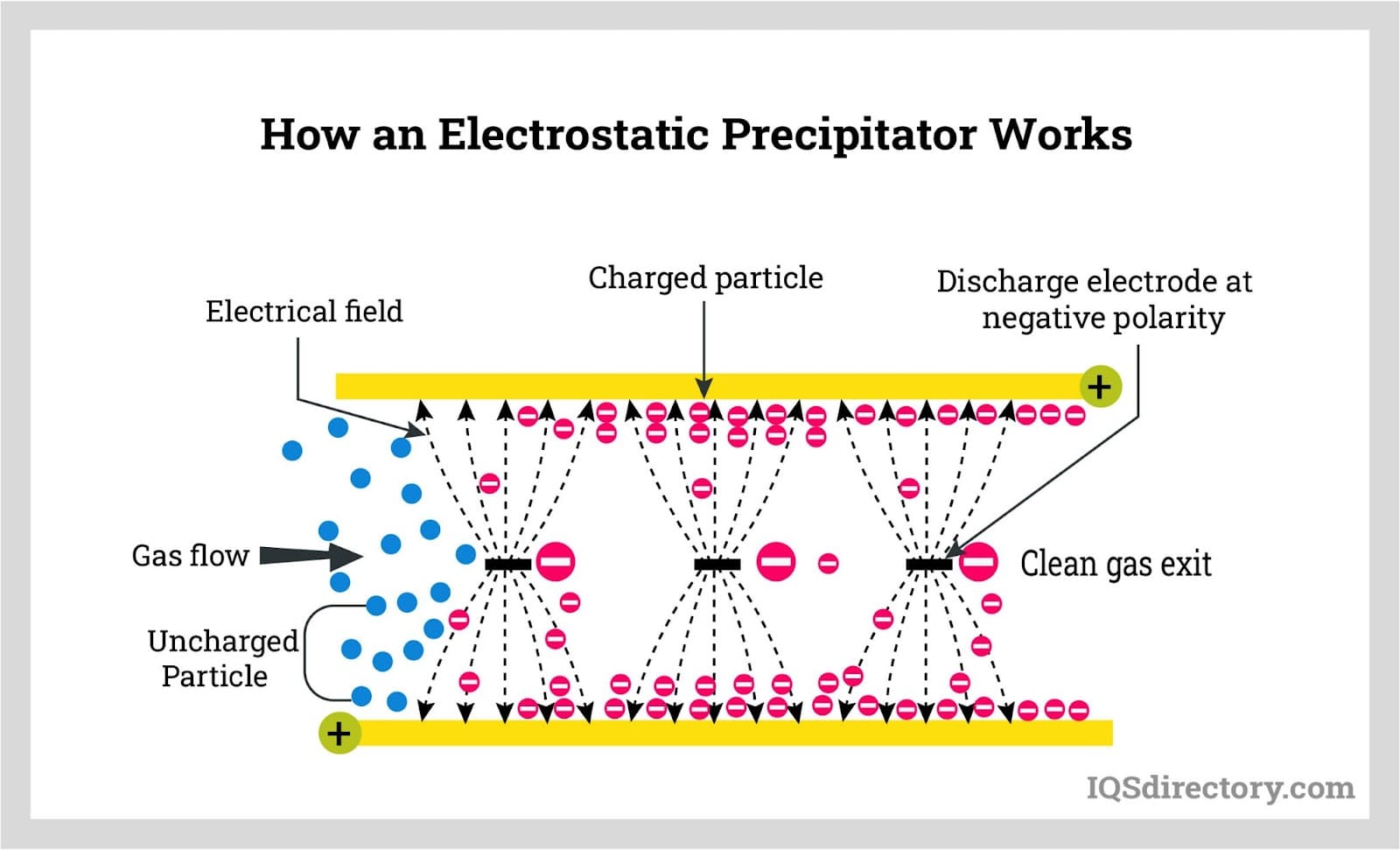

- Precipitators specifically are used to remove particulate matter from exhaust airstreams. When an airstream is exposed to an electrostatic precipitator, it endows electric charge to the particles presented in the airstream, and then removes them by the electric field. Precipitation unit has many parts, which range from discharge and collection electrodes, to baffles to distribute airflow, to collection hoppers and a dust clean-out system. They have high efficiency that can exceed 99 percent, and can remove small particles up to 1 micrometer. They are typically used for controlling fly ash at fossil-fuel furnaces.

- Cyclones as Pollution Control

- To remove particulates, cyclones use spiral paths to create cyclonic motion in the airstream in the chamber. As the gas swirls, within the chamber, the larger particles move outward against the chamber wall, under inertia. Once they get in contact with the wall, they slow down and slide down, along the wall in a dust hopper. Then the clean air leaves through an outlet, which is situated at the top. The hopper that collects the particles is then cleaned. They have an efficiency of 90 percent, and can catch particles of size about 20 micrometers. However, the present environmental regulations are stricter, and cyclones quite cannot meet those standards. Therefore, they are only used as pre-cleaners.

- Air Pollution Scrubbers

- Catch suspended particles by absorption, as an incoming airstream is exposed to a spray of water, or other solvents, which vary based on the application. Several types of scrubbers are available, including spray-tower, orifice scrubber and venturi. All, more or less, use the same phenomenon to clean the exhaust air stream, only difference is the path of air stream, when it enters the chamber, and how it is manipulated to achieve better efficiency. Venturi scrubbers are the most effective design, which can attain efficiency up to 98 percent. Cleaning these devices can be difficult, so you might want to take this into consideration when choosing the best design. Cleansing this equipment can be a difficult chore. Determine how long you want the equipment to last before replacement.

- Bag-house Filter Control Systems

- The most efficient devices, when it comes to removal of particulates. It consists of fabric-filter bags, which have a multitude of narrow and long bags suspended in a large enclosure. As the air with dust ascends to the bottom of the enclosure, assisted by fans, the particulates in the air get trapped in the air filters, and the clean leaves the system at the top. They have unparalleled efficiency going up to 100 percent, when particulates are large as 1 µm, however, as the size of the particulates goes down, the efficiency comes down a bit. They are expensive to use, as maintenance and the operation cost are high. They are used with cooling coils that bring down the temperature of the air stream.

Things to Consider When Purchasing an Air Pollution Control System

Pure and clean air is essential for sound health and proper wellbeing. However, pollution of the air has increased to such an alarming level in most towns and cities that it requires coordinated and comprehensive efforts from the government, industries, private institutions, and the public to reduce the current level and improve air quality.

With a plethora of air pollution control equipment available in the market, what simply requires is the will and commitment to adopt them to check the air pollution. When it comes to investing in air pollution control equipment, you need to consider some of the essential factors to make the most of your purchase.

- Select Premium Quality Control Equipment

- Installation of high quality air pollution control equipment is essential in order to reduce air pollution and improve air quality. Based on the nature of your business and the amount of pollutants you are releasing into the air, you can select the most suitable equipment and purchase it from a leading supplier. Finding the best equipment depends on the hazardous gas that you want to reduce. You might emphasize affordability or efficiency.

- Flue gas desulphurization might utilize a variety of air pollution control technologies. The problem with baggers is that you still must remove the pollutants.

- Selecting a Professional Supplier

- Selecting a professional supplier of air filters, dust collectors, or other pollution control equipment is crucial to getting excellent equipment at a competitive price. You can check online directories to find out a leading supplier of such equipment.

- Before finalizing the supplier, you must check the site, their products list as well as clients’ testimonials to get a fair idea of the competence and professionalism of the company.

- Check the Quality and Service

- Whether you have to purchase a wet scrubber or mist collector, you must check the features of the equipment to ensure that it suits your requirement and your pocket. Besides this, you can also check the quality of installation, repair, and maintenance services as provided by the supplier. This will ensure that you get quality after-sales services.

- Consider the Price of Pollution Control Equipment

- You can check the price quote of the desired pollution control equipment on different sites to get the best value for money. However, you should not compromise with the quality of the equipment, as an inferior quality product would not serve your purpose and would lead to wastage of your time and money. Additionally, low quality products tend to be inefficient and non-durable, which will defeat the purpose of installing them in the first place.

- Installation and Maintenance of Air Pollution Control Equipment

- Besides purchasing quality equipment, it is important to get it installed properly by experts and get comprehensive maintenance to ensure long lasting service. A reputed supplier will, more likely than not, ensure that expert technicians install the equipment. However, do not forget to negotiate a maintenance contract for your equipment.

- Given the current precarious state of the environment, it is high time everybody do something in his or her unique way to reduce pollution. If you are a manufacturer or a factory owner, you can contribute by using techs that help curb industrial emissions.

Air Pollution Equipment Images, Diagrams and Visual Concepts

Thermal oxidizers break down organic or hydrocarbon-based HAPs and VOCs into carbon dioxide and water.

Thermal oxidizers break down organic or hydrocarbon-based HAPs and VOCs into carbon dioxide and water.

Electrostatic precipitator is a dry scrubber that uses static electricity to remove soot and ash.

Electrostatic precipitator is a dry scrubber that uses static electricity to remove soot and ash.

An air scrubber is an air purification system that removes particulate matter from the air.

An air scrubber is an air purification system that removes particulate matter from the air.

An air scrubber is to make air breathable after it has been contaminated by toxic fumes, chemicals, gases, and pollutants.

An air scrubber is to make air breathable after it has been contaminated by toxic fumes, chemicals, gases, and pollutants.

Utilizing Emission Control Systems

The U.S. Energy Information Administration (EIA) published a report that showed carbon dioxide (CO2) emission, generated by electricity, has gone down by 21 percent in 2015 from the 2005 level.

Steps taken to regulate the emission of greenhouse gases by the federal government are coming to fruition. According to the EIA, the decrease has been drastic because of the adoption of cleaner fuel sources. When you examine the country’s electricity generation mix you can see a clear shift to renewable and natural gas-fired electricity generation.

The same shift is also seen in the air pollution control equipment landscape, the new generation emission control systems are effectively removing sulfur dioxide (SO2) and oxides of nitrogen (NOx) emissions, and particulates emitted by incineration, power, and chemical plants.

- Demand Increase for Emission Control Systems

- The need to comply with the EPA's Mercury and Air Toxics Standards (MATS) rule has driven the demand of new emission control systems; there is a growth of 6.47 percent in the demand of new equipment. Many coal-based electricity generation facilities are embracing these systems; the latest addition to the list is the Lon D. Wright Power Plant in Fremont, Nebraska. The plant has upgraded its air quality control system (AQCS), adding pulse jet fabric filters as well as an activated carbon injection system and a spray dryer absorber.

- Utilizing the Regenerative Thermal Oxidizer (RTO) System

- The RTO is the most efficient and cost saving system these days. As RTO reuses around 97% of the thermal energy and has a Hot Gas Bypass, it is widely used in the industry in challenging conditions, like emission spikes. It also can handle higher concentrations of exhaust gases unlike conventional oxidizers. Moreover, it does not have a catalyst in the design, which saves significant capital in maintenance and replacement parts.

- Rotary Concentrator System

- Rotary Concentrator System is a hybrid air pollution control system, designed especially to efficiently destroy and remove pollutants from exhaust air streams. However, its application is limited to exhaust air streams. It removes air pollutants with the use of a hydrophobic zeolite rotating wheel.

- Secondary Recovery Units

- There are a number of secondary recovery units available that can be fitted in the existing oxidizer system or in a newer system, giving a greater degree of efficiency. Secondary recovery units can be used effectively to capture the 250 degrees to 1,500 degrees Fahrenheit of heat energy, which otherwise would have been vented out to the atmosphere. They can be designed optimally for minimal pressure drop without affecting the operation.

- Similarly, more efficient air filtration systems and air pollution scrubbers are available on the market that provide good return on investment while saving substantial capital for industries.

Best Products for Your Purpose

Think about capture, control and compliance when considering different air pollution control devices. Carefully monitor the hazardous chemicals in your emission. Then, compare your levels to what is accepted by the EPA. Determine if you can remove all of the pollutants in one step or if multiple steps are required.

Find the best air pollution control devices to accomplish your goals. Certain equipment is better for certain chemicals. You also might want a variety of devices as part of your overall air quality control system.

Air Pollution Control Equipment Types

- Air Filtration Systems

- Remove impurities from the air with a number of different filtration and purification schemes.

- Air Scrubbers

- Consist of a fan containing several filters that separate contaminants from clean air and recirculate the air into the atmosphere.

- Catalytic Oxidizers

- Utilize a metal catalyst, such as platinum, within the unit to speed the breakdown of hazardous compounds. The use of a catalyst allows the substance breakdown to occur at a lower temperature than that of a thermal oxidizer.

- Dust Collectors

- Use an online process to either retrieve usable granular solid or powder from process streams or to eliminate granular solid pollutants from exhaust gases before they are vented into the atmosphere.

- Electrostatic Precipitators

- Utilize grounded electrodes called collection plates to ionize and capture dust and particulate matter in contaminated air. These systems are often used prior to other pollution control equipment.

- Emission Control Systems

- Devices that monitor and diminish harmful byproducts of combustion and other processes.

- Gas Scrubbers

- Use a high-energy liquid spray to remove gaseous pollutants, such as sulfur, from an air stream, either by absorption or chemical reaction.

- Heat Recovery Systems

- Includes any method that recaptures heat generated as the byproduct of one process and reuses it for another process.

- Ionizing Wet Scrubbers

- Remove acid gases and fine particulate that can include a variety of heavy metals such as antimony, lead and zinc from the air stream.

- Mist Collectors

- Consist of a filter containing mesh and steel wire, capture mists of water and oil created during industrial applications.

- Odor Control Systems

- Neutralize unpleasant smelling gases.

- Oxidizers

- Chemicals that readily yield oxygen and can be used to start or to feed fires.

- Particulate Control Systems

- Utilize systems, such as electrostatic precipitators (ESPs), baghouses, wet particulate scrubbers, mechanical/inertial collectors (cyclones/mutilcyclones) and high temperature/high pressure (HTHP) particulate control systems, to control ash that is emitted into the atmosphere through combustion, industrial processes, fugitive emissions and natural sources.

- Pollution Control Equipment

- Any device that removes and eliminates a wide variety of impurities from the air.

- Rotary Concentrators

- Compress air and gas streams containing small amounts of VOCs into concentrating streams containing greater volumes of VOCs, which makes it easier for oxidizers to break down.

- Thermal Oxidizers

- Heat contaminated air in order to break down hazardous compounds into carbon dioxide and water vapor, a process called oxidation. In order to conserve energy, many thermal oxidizers contain a heat exchanger that recovers and reuses the heat from incoming polluted air.

- Venturi Scrubbers

- Wet scrubbers that collect extremely tiny (less than a micron) dust particles from the gas stream in a slurry system using an orifice to spray water into the vortex in the cyclone section.

- VOC Abatement Process

- A process in which VOCs are rendered inert by removing them from the point of generation, subjecting them to high temperature and long residence time and then discharging the resulting treated gas into the atmosphere.

- VOC Destruction Process

- The oxidation process in which VOCs are heated by incineration or subjected to microorganisms (biodegradation) to produce carbon dioxide and water.

- Wet Scrubbers

- Devices in which exhaust air is forced into a spray chamber wherein the water particles cause the dust to drop from the air stream.

Economic Cost of Air Pollution

Besides reduced worker productivity, some California wine growers are worried that air pollution is damaging their crops. Instead of tasting the wine, you might be tasting sulfur from the nearby factory. An ounce of pollution prevention is worth a pound of cure for environmental quality.

Everyone on earth might suffer due to the “greenhouse effect” causing higher temperatures. There might be more severe storms, such as Hurricane Harvey in Houston. Some wonder if this was due to the “greenhouse effect” or climate change.

Air Pollution Control Standards and Specifications

The Environmental Protection Agency has stipulated federal regulations regarding industrial facility air pollution emissions which limit the type and quantity of Volatile Organic Compounds and Hazardous Air Pollutants industrial manufacturing facilities may emit during processing. VOCs and HAPs pose threats not only to the safety of the environment and local ecosystems, but to human health as well. 188 HAPs have been regulated which are suspected or proven to cause cancer, birth defects and other serious health effects. Based on the federal regulations laid down in the Clean Air Act, the National Ambient Air Quality Standards (NAAQS) is a set of emissions standards based on scientific studies spanning several years designed to protect the health and safety of the environment and public. Most of these standards are recent, having been implemented only within the last ten to twenty years. Facilities may use data-providing Continuous Emissions Monitoring Systems (CEMS) to aid in the control, monitoring and reporting of pollutant emissions. VOC and HAP emissions have significantly decreased as a result of these strict regulations, but the emission of carbon, a non-volatile organic compound, is becoming of greater concern to environmentalists, lobbyists, state and federal legislators in recent years due to global climate change. Recent and proposed state and federal emissions regulations are beginning to concentrate on lowering carbon emissions further, a regulation which may require manufacturers to seek alternatives to oxidizers and incinerators.

Air Pollution Equipment Terms

- Adsorption

- The attachment of concentrated liquid or gaseous molecules to a solid or liquid surface. Unlike absorption, the substances, such as active carbon and silica gel, do not permeate one another.

- Baghouse (Fabric Collector)

- Dust collectors containing fabric bags, which trap dust while allowing gases to move through the collector.

- Certified Energy Manager (CEM)

- International professional designation available through training and testing by the Association of Energy Engineers (AEE).

- CFC (Chlorofluorocarbon)

- Family of chemicals used as refrigerants, being tightly regulated and phased out of production due to stratospheric ozone depletion potential. Examples: R-11, R-12, R-113, R-114, R-115.

- Cyclone Separator

- Device that extracts fine particles from air or gas by centrifugal means.

- Destruction Efficiency

- The effectiveness by which an oxidizer eliminates VOCs exhausted from by the oxidation process.

- Hazardous Air Pollutant (HAP)

- A specific category of 189 particularly harmful volatile organic compounds (VOCs) designated as such by the EPA's Clean Air Act.

- Heat Exchanger Bypass

- A system that will automatically modulate dampers in a thermal oxidizer to provide a safe route for the process exhaust in case there is a solvent overload.

- Hydrocarbon

- An organic compound composed of hydrogen and carbon. Many hydrocarbons are considered stable, as they only evaporate during heating and cooling processes, though some are considered volatile, because they evaporate under moderate conditions.

- HEPA (High Efficiency Particulate Air) Filter

- Air filter capable of trapping a minimum of 99.97% of particles at least .3 microns in size. HEPA filters are a common component of air scrubbers.

- Hopper

- In pollution control systems, the area in which the collected particulate is stored.

- Lower Explosive Limit (LEL)

- The lowest concentration of pollutants that would lead to combustion if ignited.

- Nitrogen Oxides (NOx)

- A group of air pollutants released during industrial combustion applications that contribute to smog and acid rain.

- Oxidation

- Process involving the transformation of harmful compounds into safer compounds through the application of oxygen and heat.

- Rapper

- Part of an electrostatic precipitator that transfers dust from the collection plates to the hopper.

- Rotor Concentrator

- An add-on available for oxidation technology that reduces air volume and increases concentration of VOCs by directing the process stream through a continuously rotating wheel impregnated with adsorbent. The VOCs are adsorbed, the clean air is exhausted into the atmosphere and the wheel is then regenerated by passing through a stream of warm, low volume desorption gas, producing a concentrated stream, which an oxidizer can more efficiently destroy.

- Tubular Precipitators

- High-voltage electrostatic precipitators consisting of cylindrical collection plates that rotate around the discharge electrodes.

- Turbulence

- A fixed condition that is built into the equipment design in order to make sure that there is the correct mix of VOCs and oxygen for combustion.

- Volatile Organic Compounds (VOCs)

- A group of pollutant compounds consisting primarily of carbon that, in combination with the sun's radiation and oxygen, form ozone. VOCs are those substances, such as gasoline, alcohol, ethers and esters, that form a gas or vapor under moderate temperature and pressure conditions.