Flow Meters

A flow meter, also spelled “flowmeter,” is an instrument used to measure the flow of a liquid or gas in a supply pipe. The device is fitted into a pipe to gauge the quantity of gas or liquid passing through it.

Many flow meters measure the volume of the material flow, some flow meters measure the speed, and other flow meters measure material mass. For the most part, flow meters are used to infer mass flow through calculations that flow meters and flow monitor instruments make after taking various measurements, such as absolute pressure, differential pressure, viscosity, and temperature.

Quick links to Flow Meter Information

Flow Meter Applications

Flow meters are used for efficiency purposes and to help companies determine profit gain or loss. More specifically, they are produced so that users of all kinds can be sure of the accuracy of their machines and processes. Manufacturers rely on them for this purpose and, as a byproduct, to help them keep up with their production demands and meet consumer or user expectations. Industries that benefit from the use of flow meters include the automotive, petroleum, gas, utility services, HVAC filters, food and beverage processing, chemical, and raw material industries.

Every flow meter type works differently. For example, some flow meters are designed to measure for a specific material, while other flow meters can detect a variety of materials. Also, flow meters will commonly utilize two different measuring styles: mass flow or volumetric flow. Devices that calculate for mass flow determine the characteristic of a material in terms of pounds or kilograms, while systems that measure for volumetric flow will produce results in liters or cubic inches.

Basically, flow meters work by taking measurements and reporting the results.

History of Flow Meters

Reinhard Woltman invented the earliest manufactured flow meter (the turbine flow meter) in 1790. It was used to calculate energy loss in open canals. It was not widely used until the mid-20th century. Around 200 years ago, Michael Faraday also attempted to create an electromagnetic flow meter for measuring the Thames, though he did not succeed. While scientists and engineers like Faraday expressed the formulas for flow meters centuries ago, none were produced commercially until the 1900s. For example, though Gustave Coriolis defined the concept of inertial force in 1835, the related Coriolis flow meter wasn’t released as a commercial unit until 1977. Likewise, electromagnetic flow meters weren’t sold on the mass market until 1952, and ultrasonic flowmeters weren’t produced commercially until 1963.

Once flow meters received attention from potential customers in commercial and industrial markets, the flowmeter industry grew exponentially. Today, that growth rate has not slowed down. In more recent years, flow meters have developed with modern technology, sporting digital readouts, high-tech sensors, and more. We believe that they will become easier to use remotely, using wireless internet, perhaps acting as smart meters. All flow meters will also likely have no moving parts at some point in the future. Wherever the flow meter industry goes in the future, we know it will pull other industries ahead with it.

Design of Flow Meters

Most flow meters are made of the primary device, a transducer, and a transmitter. These three flow meter parts are usually combined so that the meter is one complete instrument. Some variations, like positive flow meters, feature a precise output signal for real-time and accurate gas or liquid flow volume measurement. This output signal is directly connected to the force that the passing gas or fluid applies on the sensor of the device. Apart from mass or force, it is also correlated to the velocity of the flow. Output signal accuracy is usually connected to flow meter systems like turbine or rotater wheel, plate, channel, nozzle, laminar, and pilot table systems.

Certain flow meters are manufactured using specific materials to maximize results. However, in general, they are made from materials such as stainless steel plate, which is corrosion resistant, or brass, aluminum, PVC, PVDF, and nylon.

When designing a flow meter, manufacturers think about a variety of factors. These include substance viscosity, flow cleanliness, process pressure, process temperature, and the size of the pipe. Using such considerations, along with individual specifications and restrictions, they can manufacture custom flow meter systems for virtually any application.

Types of Fluid-Based Flow Meters

Flow meters are divided into two categories: gas-based and fluid or liquid-based flow meters.

If we focus on fluid-based flow meters, then we can organize them into five subcategories: differential pressure flow meters, velocity flow meters, positive displacement flow meters, mass flow meters, and open channel flow meters.

Differential Pressure Flow Meters

Differential pressure flow meters were devised on the Bernoulli Equation, which itself was based on the flow of fluids. They work simply; they take both a primary and a secondary measurement and report the difference. Note: the first measurement causes a change in kinetic energy by directing the air through a hole in the flow meter, which is measured by the second element.

These meters can be put into various sub-types, such as orifice plates, flow nozzles, venturi flow meters, and rotameters.

- Orifice Plate Flow Meter System

- Using these systems, you can measure the change in the flow’s pressure, going from upstream to downstream. However, for such measurement, it is important to have the flow in a partly blocked pipe.

- Flow Nozzle

- Can be used for measuring both air and gas flow rates. They are simple in design and the cost is minor.

- Venturi Tube Gauge

- These flow gauges help in measuring the liquid flow rate. The device checks the change in pressure, which occurs because of a cross-sectional flow area in the flow path.

- Rotameter

- Also known as variable area flow meters, use a rotating float that moves vertically through a tapered tube. This type of flow indicator measures the pressure applied on the fluid by the Earth's gravity. The rotameter is most commonly used for measuring gases and liquids. Advantages include linear output, simplicity, low cost, low-pressure drop, and wide rangeability.

Velocity Flow Meter

Velocity flow meters calculate the flow of fluid by sensing the speed at more than one point in the piping system. To produce a reading, they use a depth measurement and the average air velocity of the flow. Process engineers can then maintain the required flow throughout the stream. Note: Velocity flow meters have a greater range than differential pressure devices.

Some types of velocity flow meters include pitot tube flow meters, calorimetric flow meters, turbine flow meters, and electromagnetic flow meters.

- Pitot Tube Flow Meter

- Check the velocity of flow by translating its kinetic energy into potential energy. These devices are installed in most ventilation and HVAC systems today and are the most popular, most used, and cheapest fluid flow meters.

- Calorimetric Flow Meter

- Have two temperature sensors that are fixed closely and serve as a touching base for the liquid. Because of their intelligent design, these flow meters can provide highly accurate air flow readings.

- Hydraulic Flow Meter

- Measure the flow rate or volume of liquid inside a hydraulic system. Their general applications are testing, troubleshooting, and maintaining hydraulic systems. Using hydraulic flow meters, operators of hydraulic systems can measure how efficiently and effectively their systems are running and properly address any problems as they arise.

- Turbine Flow Meter

- Work using flow, which moves or rotates it (the turbine). When this happens, the meter measures the speed of the turbine. Primarily used with clean and viscous liquids, turbine flow meters are incredibly accurate. In fact, they have an accuracy of 0.5% of the reading. The meter has a multi-bladed rotor that is mounted at right angles to the flow. The outputs are a sine wave or square wave frequency. Note: If you need signal conditioners, the meter can also be mounted, but only on explosion-proof classifications.

- Electromagnetic Flow Meter

- Or magnetic flow meter, is a type of volumetric flow meter that functions based on Faraday's law of electromagnetic induction.

- Vortex Flow Meter

- Measure flow rate by placing an obstruction directly in a flow path and forcing liquids or gases to move around it. When the flow moves around this obstruction, or bluff body, two symmetrical vortices are created on the opposite side, changing the pressure of the flow. A flow sensor, placed between these vortices, measures these pressure changes and transmits the data to an electronic signal conditioner outside the meter.

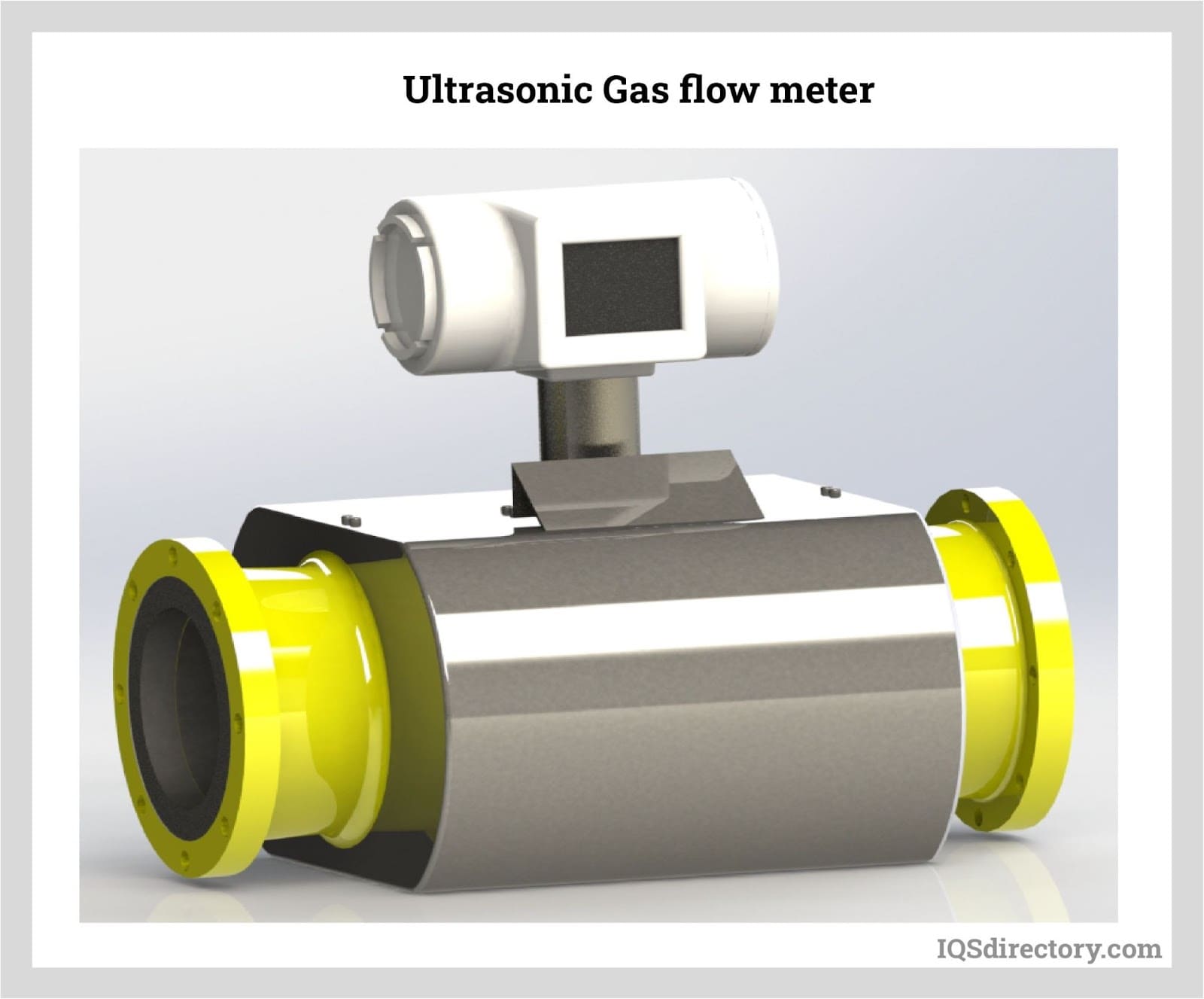

- Ultrasonic Flow Meter

- Measure fluid velocity using ultrasound technology, which lets them calculate flow volume. There are two main types of ultrasonic flow meters: in-line flow meter varieties and clamp-on flow meter varieties.

Positive Displacement Flow Meter

Positive displacement flow meters, or PD flow meters, measure viscous liquid flow using their rotors as sensor or flow measuring elements. The volumes of the air flow are displaced in these devices by mechanisms such as vanes, gears, pistons, or diaphragms. The rotation of the rotors is related to the volume of the flow being blown toward it.

They are used in measurement when straight pipe is not available, or as a replacement for turbine meters and paddlewheel sensors when too much turbulence is in the flow.

Mass Flow Meter

Mass flow meters, or true mass flow meters, are used for the direct measurement of mass flow.

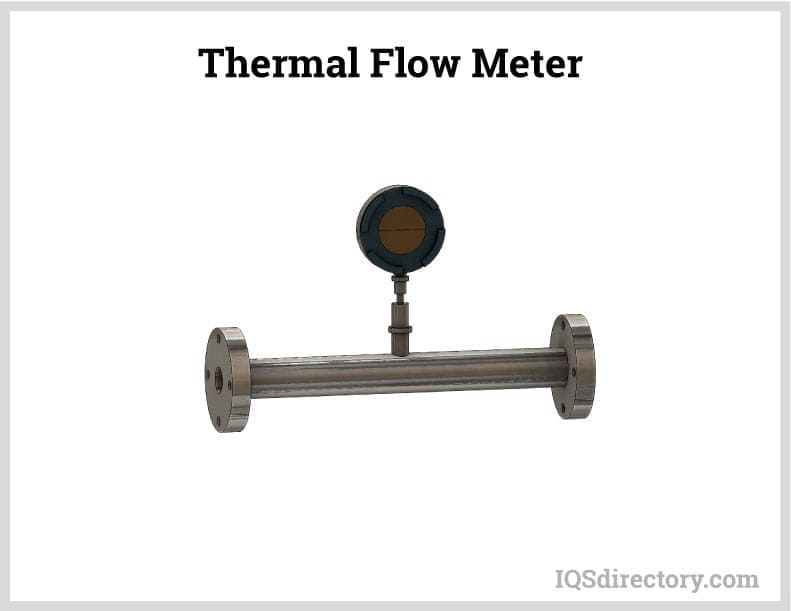

- Thermal Mass Flow Meter

- Measure with two sensors that work together. These sensors (a temperature sensor reference and active heat sensors) take measurements by calculating how much heat loss occurs in the flowing liquid and determine the flow rate based on this amount.

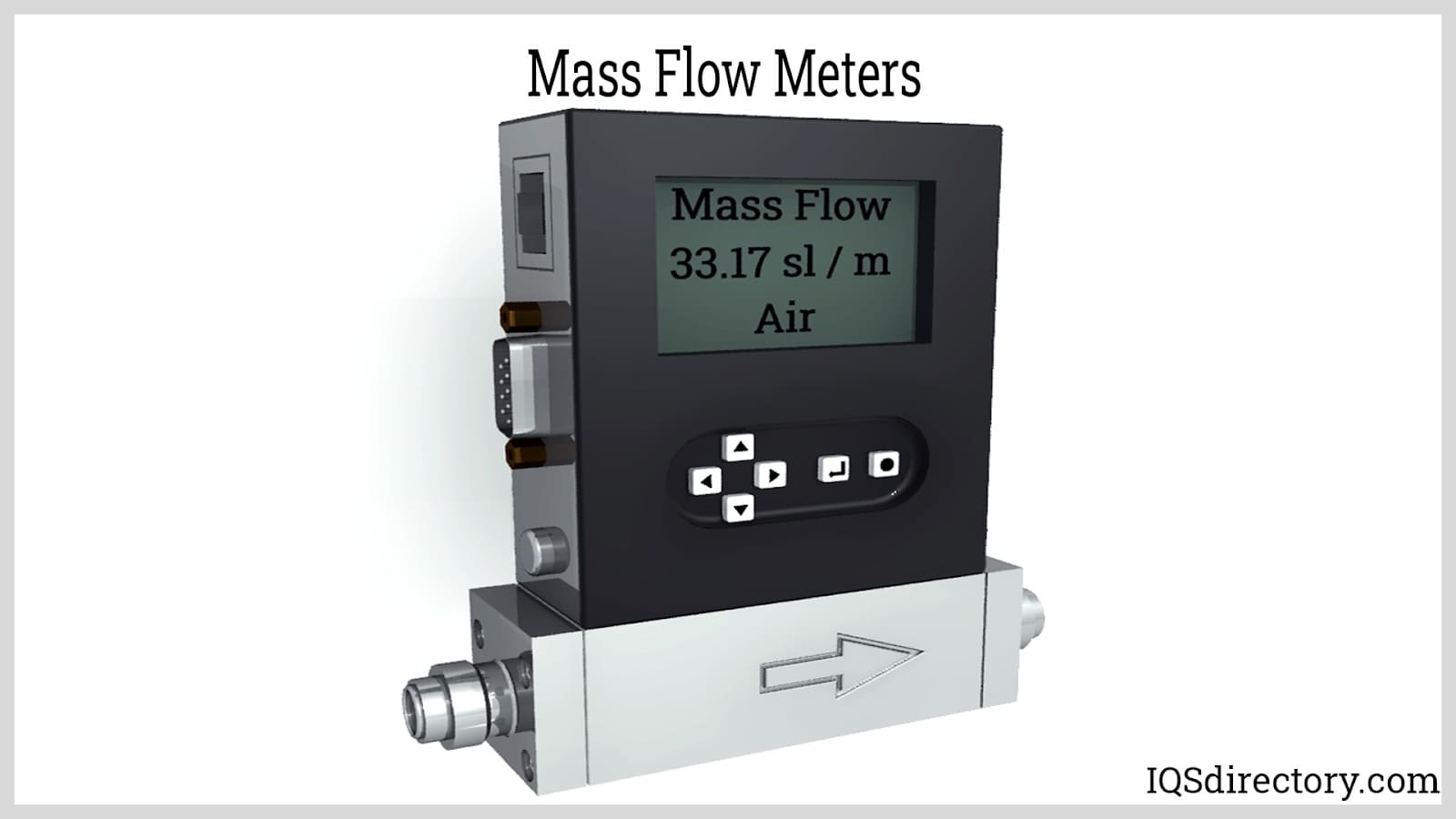

- Mass Gas Flow Meter

- Also known as Coriolis flow meters, these flow meters work based on the Coriolis Effect. Mass gas flow meters base measurements on pressure, density, and fluid viscosity using a temperature sensor and a differential pressure transducer or a heated sensing element. They also have built-in digital displays and analog outputs and are popular for leak testing and low-flow measurements.

Open Channel Flow Meter

Open channel flow meters allow the engineers to determine the flow by checking the height of the liquid. They are only used with flows that are exposed to the air on the top.

Other flow meter types include the air flow meter, spring and piston flow meter, water flow meter, fuel flow meter, flow switch, peak flow meter, and digital flow meter.

- Spring and Piston Flow Meter

- To measure the flow, this type of flow gauge uses an annular orifice formed by a tapered cone and piston. Scales on piston flow meters are based on specific gravities of fluid; for oil meters, it is 0.84, and for water meters, it is 1.0. Their unique selling point is the simplicity of design. They have become an economical alternative to rotameters since they can be easily installed to transmit electrical signals.

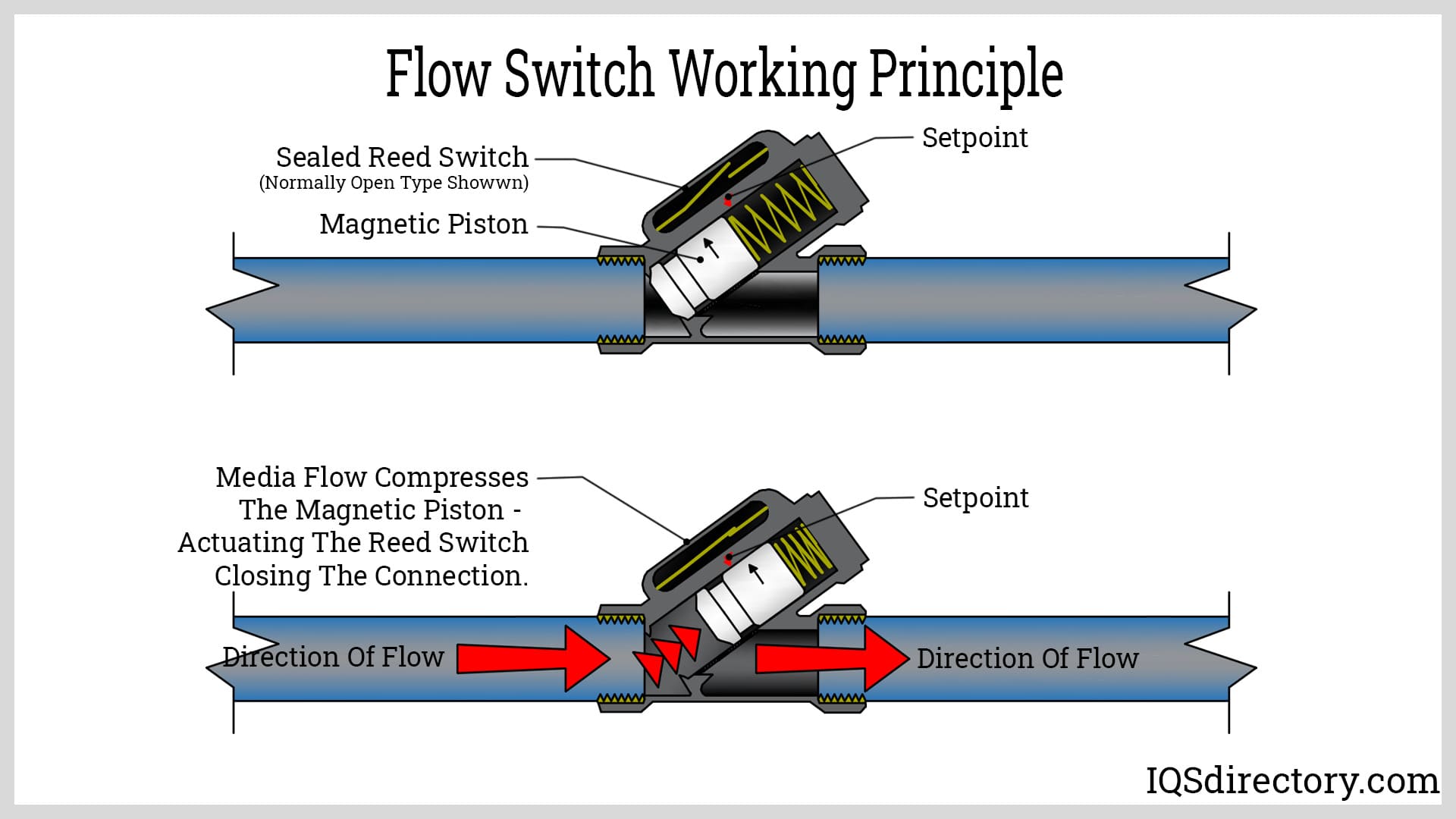

- Flow Switch

- Feature a flow meter regulator component that serves as a switching unit for controlling flow. They may also trigger a visual or audible alarm.

- Digital Flow Meter

- Defined as any flow measurement device with a digital display.

Advantages of Flow Meters

Flow meters are a great investment because they can improve the efficiency of a facility by assisting in monitoring fluid consumption or other applications. While every flow meter type offers different pros and cons, in general, flow meters have many advantages. They are low maintenance, easy to use, versatile, and durable. Also, flow meters have few to no moving parts, which makes them less likely to break and less complicated to fix.

Installation of Flow Meters

To properly install a flow meter, you first need to know the area where the flow indicators will be located. You cannot install meters in the area where vibrations or a magnetic field is present, as either of these can interfere with the meter. Also, consider the direction of flow. In liquid applications, we advise you to avoid downward flow. In addition, some meters need to be installed in a straight pipe to work properly, though the required length of pipe can be compensated using straightening vanes.

For more tips and for detailed instructions on installing a flow meter, talk to your supplier.

Proper Care for Flow Meters

Each type of flow meter has specific guidelines that must be followed for proper use. For example, when using gas flow meters, the flow meters must remain full of gas. Liquid in gas flow meters can affect the flow meter's accuracy. Similarly, for liquid flow meters to work properly, they must remain full of liquid. Gas in liquid flow meters can affect the accuracy of flow meters' readings, as well as contaminants of any kind.

Industry Standards for Flow Meters

Always make sure your flow meters are ISO-certified. If workers will be around them, also make sure that they’re approved by OSHA. It’s also of great importance that you check to see what standard adherences your industry or region requires.

Points to Consider When Selecting a Flow Meter

If you are looking for a flow meter, use the following considerations to help you choose an appropriate flow gauge for your process.

- Gas or Liquid?

- One of the most important factors to have in your consideration is the medium in which you will mount the device. Remember that gas and liquid-friendly flow meters have different features (i.e. liquid-friendly flow meters are usually water-resistant).

- What’s Your Flow Rate?

- You need to know about the range of flow of the medium, either gas or fluid, in your system. The range of flow will help you eliminate some options that do not work properly in the range. Some meters work better with a low flow rate and some with a higher rate. You can check the capability of a meter in terms of the range of flow in the specifications that come with a product.

- How Accurate Does Your Output Signal Need to Be?

- It is important to determine the required flow measurement accuracy, since the performance of a flow gauge may not be acceptable over the full range of flow. You can get it determined in terms of percentage of calibrated span, actual reading, or full-scale units. Absolute accuracy is critical where a product is sold based on meter reading. In some other applications, repeatability can be a more important factor than absolute accuracy. Determining your needs will allow you to have an optimal experience.

- What’s Your Projected Flow Meter Environment?

- You need to keep in mind the maximum and minimum temperatures your system will probably reach. This will inform your decision regarding material choices.

- What are the Properties of Your Fluid?

- You need to know the characteristics of the fluid, such as its specific gravity, whether it’s Newtonian or non-Newtonian, its conductivity, and the vapor pressure at operating temperature. You also need information about the fluid's composition, toxicity, presence and size of particles in the fluid, and its light transmission qualities (whether it is opaque or translucent).

- What are Your System Measurement and Reading Requirements?

- A meter should be able to measure the instantaneous quantity (Qi), the rate at which water is pumped, and the total quantity of water flowed over time (Qa). The Qa is usually recorded in gallons. However, some meters can measure Qa in acre-feet. These types of meters are used in agriculture applications.

- Do you Have the Information You Need to Find the Right Flow Meter?

- To ensure that the right flow meter is installed for a particular system, get the checklists, questionnaires, and specification sheets from the manufacturer. These sheets are designed to give the critical information necessary to match the flow meter with the requirements.

Choosing the Right Manufacturer

Even if you’re equipped with all the answers to the questions above, you will still struggle to purchase the right flow meter and flow control-related products without a quality manufacturer to guide you. Here are some tips for knowing when a manufacturer is right for you:

- They treat you like you matter.

- They’ll want to find a creative solution for you

- They’ll show that they care about your success, not their bottom line.

Find this manufacturer by browsing the list of reputable and hardworking flow meter suppliers we have listed above.

Flow Meter Images, Diagrams and Visual Concepts

Flow meter, a measuring device used to determine the linear or nonlinear mass and volumetric flow of a liquid or a gas.

Flow meter, a measuring device used to determine the linear or nonlinear mass and volumetric flow of a liquid or a gas.

Mass flow meters measures the flow rate of a gas based on the convective transfer of heat and uses temperature sensors with electric heaters in the flow or outside the pipe.

Mass flow meters measures the flow rate of a gas based on the convective transfer of heat and uses temperature sensors with electric heaters in the flow or outside the pipe.

Ultrasonic flow meters measure the flow of liquids or gases by sending ultrasonic waves across the pipe.

Ultrasonic flow meters measure the flow of liquids or gases by sending ultrasonic waves across the pipe.

Magnetic flow meters uses electrodes connected to the liquid flow to measure the velocity of liquids.

Magnetic flow meters uses electrodes connected to the liquid flow to measure the velocity of liquids.

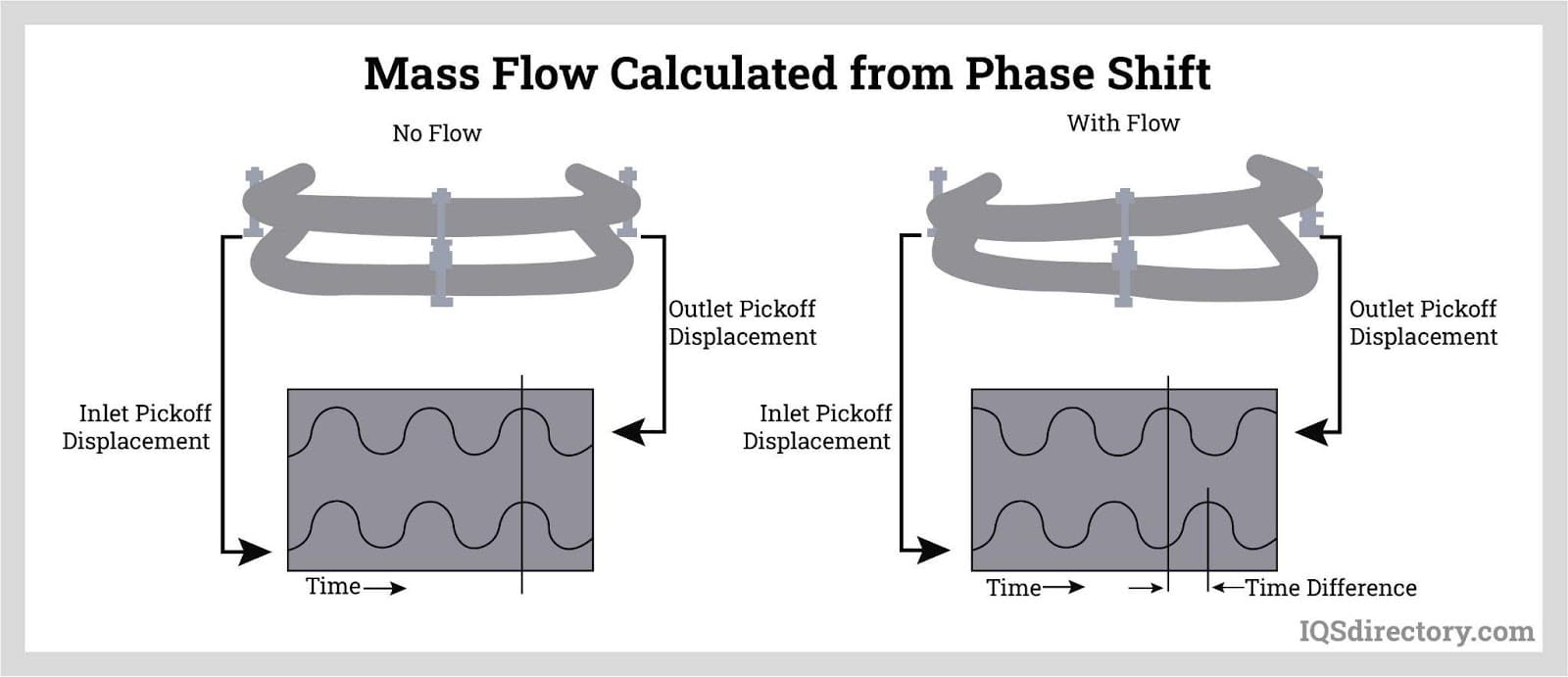

The readings of a coriolis flow meter will have different readings depending on the rate of flow and the displacement of the tubes.

The readings of a coriolis flow meter will have different readings depending on the rate of flow and the displacement of the tubes.

Flow switch, a device that measures the liquid flow rate and pressure in a system.

Flow switch, a device that measures the liquid flow rate and pressure in a system.

Rotameter, a device that measures the flow of fluid volume per unit of time in a closed tube.

Rotameter, a device that measures the flow of fluid volume per unit of time in a closed tube.

Flow Meter Types

- Air Flow Meters

- Used to measure the flow of air.

- Coriolis Flow Meters

- Used to measure the force of acceleration resulting from a moving object towards or away from the center of rotation.

- Differential Pressure Flow Meters

- Used to measure the flow of fluids and gases in a pipe by introducing constriction that causes the pressure to drop. The pipe must be clean to result in accurate measurements.

- Electromagnetic Flow Meters

- Measure by creating a magnetic field that is channeled into the liquid and causes a voltage signal to be sensed proportional to the flow of the liquid.

- Flow Indicators

- Allow the operator to view the liquid as it is moving. Some models come equipped with lights to enhance fluid visibility.

- Insertion Flow Meters

- Measure flow at one position in a pipe, and then, based on the measurement, they estimate the flow rate for the entire pipe.

- Flow Switches

- Used to monitor fluid or gas flow while it is passing through its valve body, then to send an electrical control sign if the flow rate is too high or too low.

- Flow Meters

- Used to measure the flow of air, fluids, and gases.

- Fuel Flow Meters

- Ultrasonic, turbine, or positive displacement flow meters which measure fuel usage rate and remaining fuel quantities in transportation devices and stationary pumps.

- Mass Flow Meters

- Used to measure gas flow and are one of the more popular flow meters. This meter is relatively unaffected by changes in temperature or pressure in the tube or pipe.

- Open Channel Flow Meters

- Used to measure the flow of liquids when they are open to the atmosphere.

- Peak Flow Meters

- Used by patients with asthma or other lung disorders to measure the amount of air patients take into their lungs. These flow meters allow physicians to determine the severity of the illness.

- Positive Displacement Flow Meters

- Trap liquid to measure its flow by rotating parts that move between seals and the meter body.

- Rotometers

- Have a rotating float that moves vertically through a tapered tube.

- Target Flow Meters

- Measure the amount of force that is exerted on a target in a particular liquid or gas. This should not be used to measure high viscosity liquids because the target can be damaged.

- Thermal Flow Meters

- Meters that use the thermal properties of fluids to measure the flow. The meter is heated and, as the liquid flows by, it can tell the flow rate by the amount of heat lost.

- Turbine Flow Meters

- Consist of a rotor that measures the fluid when it passes through the blades. The blade speed is translated into the speed of the fluid.

- Ultrasonic Flow Meters

- Use sound to determine flow rate. Both Doppler Effect meters and time-of-flight meters are different variations of this type.

- Variable Area Flow Meters

- Measure by letting the flow stream change the opening in the meter with the movement of an internal part.

- Vortex Flow Meters

- Calculate flow rate by measuring the differential pressure of vortices created downstream from a partial obstruction, or "bluff body"; they are highly resistant to vibration and are often used in harsh environments.

- Water Flow Meters

- Flow meters designed for measuring flow rates of water in various channels, tubes, partially-filled pipes, streams, and rivers.

Flow Meter Terms

- Absolute Pressure

- Atmospheric pressure plus gauge pressure in flow meters.

- Accumulator

- Area where fluid is under pressure and stored as a source of power within flow meters.

- Bluff Body

- An obstruction, often wedge-shaped, placed in the middle of a gaseous or liquid flow. It is designed to create a downstream vortex in vortex flow meters to measure flow rate.

- Control Point

- The temperature flow meter instruments need to perform the designated functions of flow meters.

- Coriolis Force

- The force that occurs when a mass has a velocity moving outward in a rotating plane of flow meters.

- Counter Weight

- A mass that is added to a particular substance to create a more balanced and stable apparatus for flow meters.

- Current

- The flow rate of electricity within flow meters.

- Density

- A substance’s mass per unit of volume in flow meters.

- Flow

- The travel of materials in response to a force, such as pressure within flow meters.

- Flow Nozzle

- A constriction made of a contoured plate that forms a hole in flow meters for the flow stream so a measurement can be taken.

- Flow Rate

- The velocity of flow in flow meters.

- Head-Loss

- The loss of pressure in flow meters or a flow meter system that is measured with a length parameter (such as amount).

- Hot-Tap

- Allows for flow meters to be inserted or removed without causing a complete system shutdown.

- Integrator/Totalizer

- A flow meter device that measures the total flow of fluids.

- Manometer

- Measures fluid pressure. This is a U-shaped tube containing liquid that adjusts with the pressure in the flow meter tube.

- Mass Flow Rate

- The volumetric flow rate of a liquid or gas multiplied by its density. Expressed as pounds per hour or kilograms per minute in flow meters.

- Potential Energy

- The potential of energy when a liquid is in a position or height above a flow meter place to which it might flow.

- Transducer

- The part of flow meters that senses fluid as it passes through the device.

- Transmitter

- The part of flow meters that produces usable data from the transducer of flow meters.

- Weldolet

- A connection for a metal pipe that is used as a fitting for insertion-type sensors or flow meters.