Hose Reels

When it comes to useful gadgets and tools to keep around a workshop, the hose reel seems to be one of the most underrated items. However, among other benefits, its ability to transform a work space in terms of functionality and organization alone make this piece of equipment a must have. The purpose of this article is to focus on the industrial information regarding hose and cord reels, and provide an in-depth overview of its design and uses.

On its most basic level, a hose reel is a cylindrical piece of equipment that holds the purpose of store hoses and other lengthy materials. Due to its design, it quickens the process of winding and unwinding hoses with great ease by ensuring a tangle and kink free means of storage. Reels come in a variety of materials with the most common ones being plastic, fiberglass, or metal. They range in size to fit a wide demographic of needs as well, and can be used to hold anything from a simple garden water hose to a heavy duty industrial sized fire hose. In some cases, a hose or cable reel can be used to hold large amounts of rope and cable, and provide a connection to an electric current as well.

A hose or cord reel can be found in many environments, but are most notably in commercial and professional work spaces such as those that deal with manufacturing and construction. However, reels can be found in unsuspecting places as well. Many hospitals and emergency vehicles use them as a way to extend equipment and tools to meet their needs and allow the freedom of movement. Car mechanics often require vehicle exhaust hoses, and reels are ideal for storing these as well. Farmers and agriculturists use large industrial hose reels in their fields and facilities to aid with watering and irrigating crops. Additionally, many food packaging businesses benefit from having a reel as an easy way to clean large areas of floor and furniture pieces, and to sanitize trash collecting areas.

Hose reels are manufactured to meet the specific requirements of a variety of applications. For instance, for residential applications, there are smaller versions of hose reels available that are able to house small diameter and lighter hosing such as the average garden hose. For larger diameter hoses, such as fire department and construction hoses, the hose reels will need to be built much larger and out of much more rigid materials in order to support the extra length and weight of the tubing. Another type of large diameter hose would be used in industrial manufacturing applications, in which industrial reels are used to wind the hosing as well as cords and cables used for arc and gas welding, air and hydraulic tools, industrial lighting and more. In addition, there are hose reels that are solely utilized for the transportation, while other types of hose reels can be used for both storage and transportation applications. Still, there are types of hose reels that allow the use of the hose while it is still wound up and others, known as retractable hose reels, which allow for self-contained, automatic retrieval of the unwound hosing. One of the main benefits shared by all of these different types of hose reels is that they provide easy access and storing efficiency, which is what draws the consumers towards them.

Quick links to Hose Reels Information

The History of Hose Reels

The first concepts of a hose reel came about back in 17th-century Holland. As inventors during this time worked on perfecting the fire hose, they finally landed on a design that was functional and effective. However, the materials used caused the hoses to become very heavy. To solve this problem, special drums were used to transport the hoses. Time progressed along with the drum designs, and reels eventually came about as an easier built-in method for fire trucks to use. As ideas and technology were shared, it didn’t take long for the hose reel to make its way to a universally used piece of equipment.

As the industrial revolution came about in the 18th century, new materials and machinery were available. The fire hose had evolved to become somewhat lighter, so had the design of a fire hose reel. The currently and commonly known shape of a spool allowed for greater storage while still supporting the weight of hoses. Soon the design for the hose and cable reel became accessible to everyone, and it’s many other uses became apparent. Technology began making leaps and bounds in terms of advancements, and the reel started being mass produced. While the size, materials, and design may have varied based upon need, the overall general concept and use remained the same.

Benefits and Advantages of Hose Reels

Rather than having a messy workplace, hose reels are quite beneficial to have around and keep things organized. By reducing the risk of work related accidents and tripping, they work to keep cables and hoses tightly wound and off the floor making any work environment safer to operate in. Additionally they are designed to wrap their contents in a way that will evenly distribute weight, avoid tangling, and prevent kinks. This also helps prevent wear and tear that would come from storing hoses and cables on the floor or in a messy bundle.

Their transportation abilities are bountiful, as they can easily be placed on a reel cart for quick mobility, or securely mounted on a wall when working in smaller areas. Their design is sleek and can easily blend into workshops while taking up minimal space. The uses of reels are endless, and they have the ability to be tailored to fit specific needs, and hold specific items. Consumers can pick between automatic and spring based reels, making it a great piece of customizable equipment that will fit any need.

Theft is less of an issue with hose reels as well. Rather than having a hose or cables lying around, attaching them to the reel makes it harder for them to be stolen. Overall, workplace efficiency is increased by having a hose reel on hand. Instead of having to run around and gather all the mechanisms needed to hook up a hose or cable, they are all confidently in one place and ready to grab and go. This saves on time and frustration.

Design of Reels

Designing Hose Reels

As stated before, the early concepts of a hose reel started as large metal drums or rods that were consistent in width throughout. However, as hoses and cables became lighter, and consumers started needing more materials, the design of the reel had to evolve to keep up. The initial bulky setup was slimmed down and transformed into the large spool shape around today.

In its essence, a hose or cord reel is meant to have its contents wrapped around its sturdy core just as thread is wrapped around a regular spool. This design of having a slimmer center with two large barriers on either end helps keep the contents secure, tidy, compact, and readily available. The finite details of a reel will vary based on consumer need. For example, a hose or cord reel can possess a spring driven mechanism that works in a self retracting way. Other designs involve retracting contents by means of a manual hand crank or a motor.

There are many different design options for hose reels. One of the major variations in design that a hose reel can have is different retraction options. Different retraction options for hose reels include manual, electric, hydraulic, spring and pneumatic. For a manual hose reel, there is no automatic retraction mechanism, in its place there is a hand-turned crank. For electric, hydraulic and pneumatically-powered hose reels there is a motor that is used to power the automatic retraction mechanism. Spring-powered hose reels, however, work through different means and instead have an internal spring that is utilized in order to retract the hosing. When it comes to spring hose reels, the spring motor is often hermetically sealed in order to completely isolate it from both dirt and moisture. No matter the type of retraction option, the majority of these hose reel types come with a latching mechanism that is used to assure positive extension stop and ease of retraction at any length. Another design option for hose reels is the type of material used to construct the reel itself.

Hose Reel Materials

The materials of a hose reel are another important factor to consider. For simple uses like a garden hose, air hose, or extension cord, a simple plastic body would be perfectly sufficient and affordable. As the hose length gets longer, manufacturers need to find a way to support the weight of the industrial hose or cord reel contents and keep it durable given the environment it will be located in. If a reel will be exposed to harsh outside elements on a regular basis, then weather resistant materials and specific anti-corrosion metals are used. Fiberglass and stainless steel are other great options that are available. They have the ability to withstand accidental physical abuse such as drops and scratches, as well as sudden temperature changes and moisture.

Some applications require the use of a specific type of material, such as medical cord reels require the use of a sanitary grade materials such as 304L stainless steel, whereas other types of hose reels, such as industrial reels, simply require the use of a heavy-duty and corrosion-resistant type of metal, which could include various grades of steel, stainless steel and even aluminum.

Customizing Hose Reels

When it comes to customizing a hose or cable reel, this is usually an option best used for those who want one for their home work space. If choosing to make one entirely by hand, the material options are endless as long as they can withstand the weight and regular use being put on the reel. Customization can be done by swapping out handles or cranks, engraving the surface of the reel, and even by painting the body.

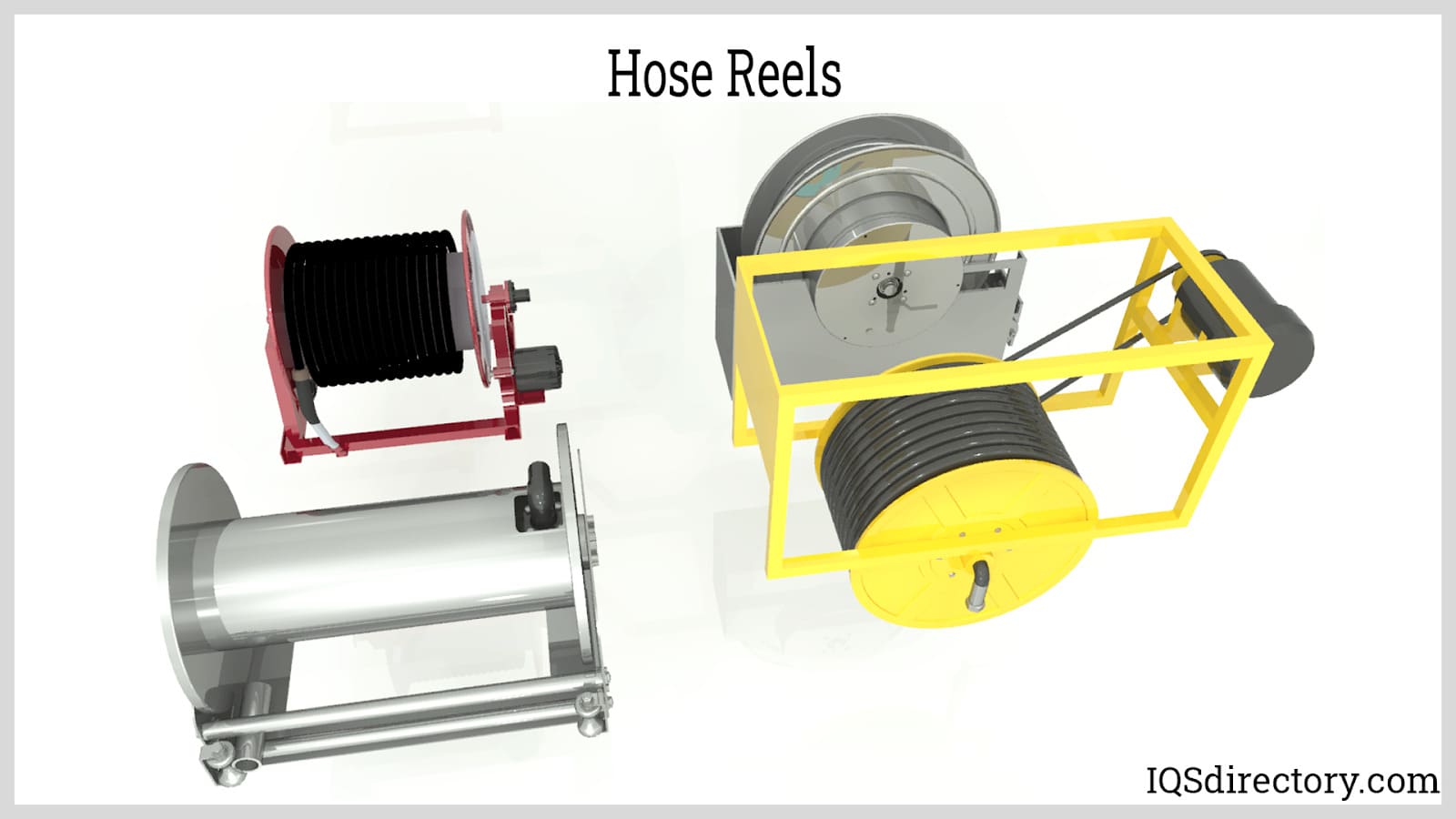

Hose Reel Images, Diagrams and Visual Concepts

Hose reels mechanisms for the storing and use of a hose on a barrel designed to make hoses, cords, flexible tubing, or wire available for usage.

Air hose reel are connected to an air compressor with the hose wound around the reel and to prevent extra wear on the hose they are hung from the ceiling.

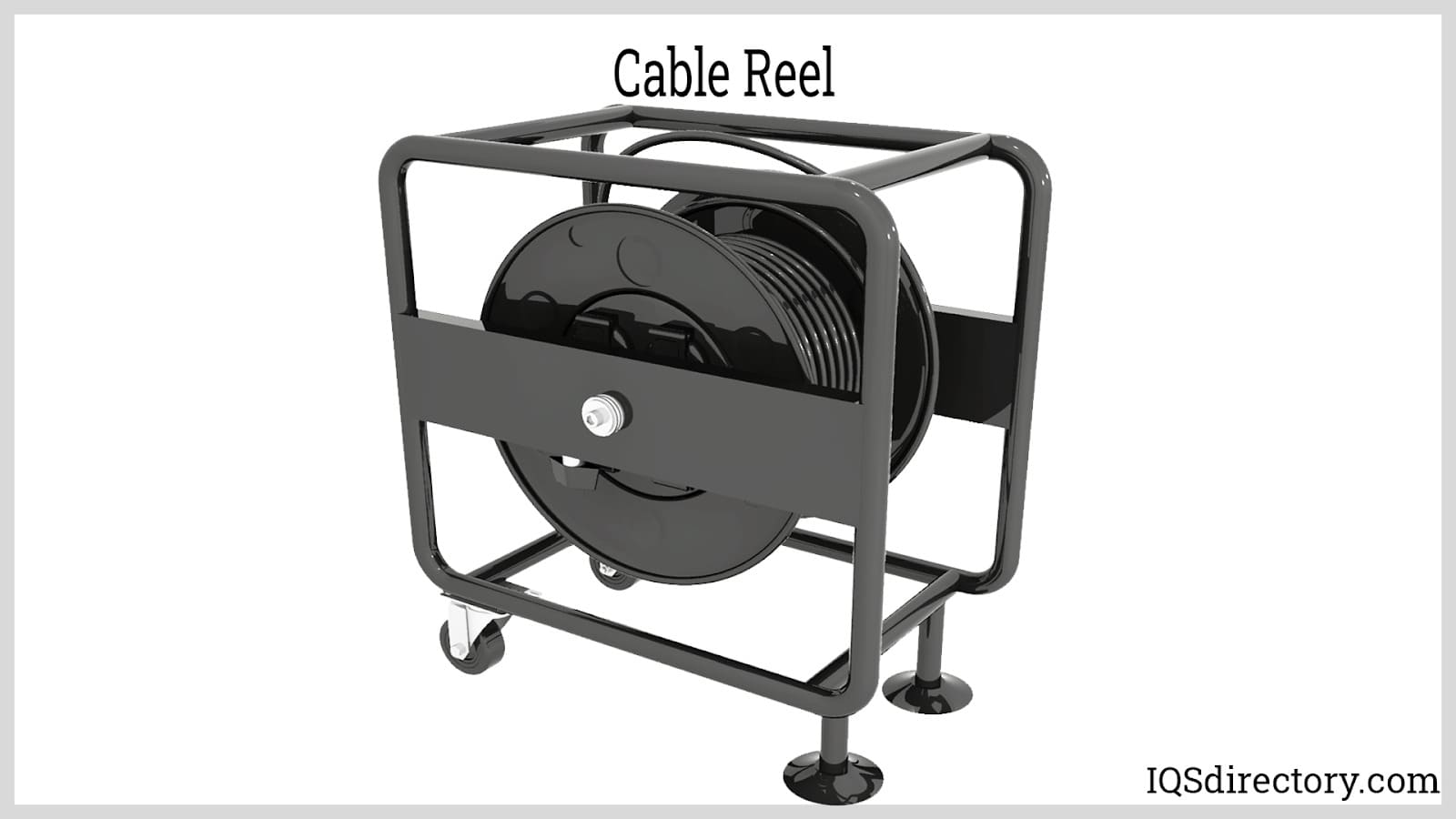

Cable reels hold conductive cable or lifting cable, either for storage, unwinding, and winding.

Cord reels hold extension cords used for supply power to electrical equipment or devices.

High pressure hose reels prevent the hoses from kinking, tangling, or being damaged, which could lower the pressure of the hose line.

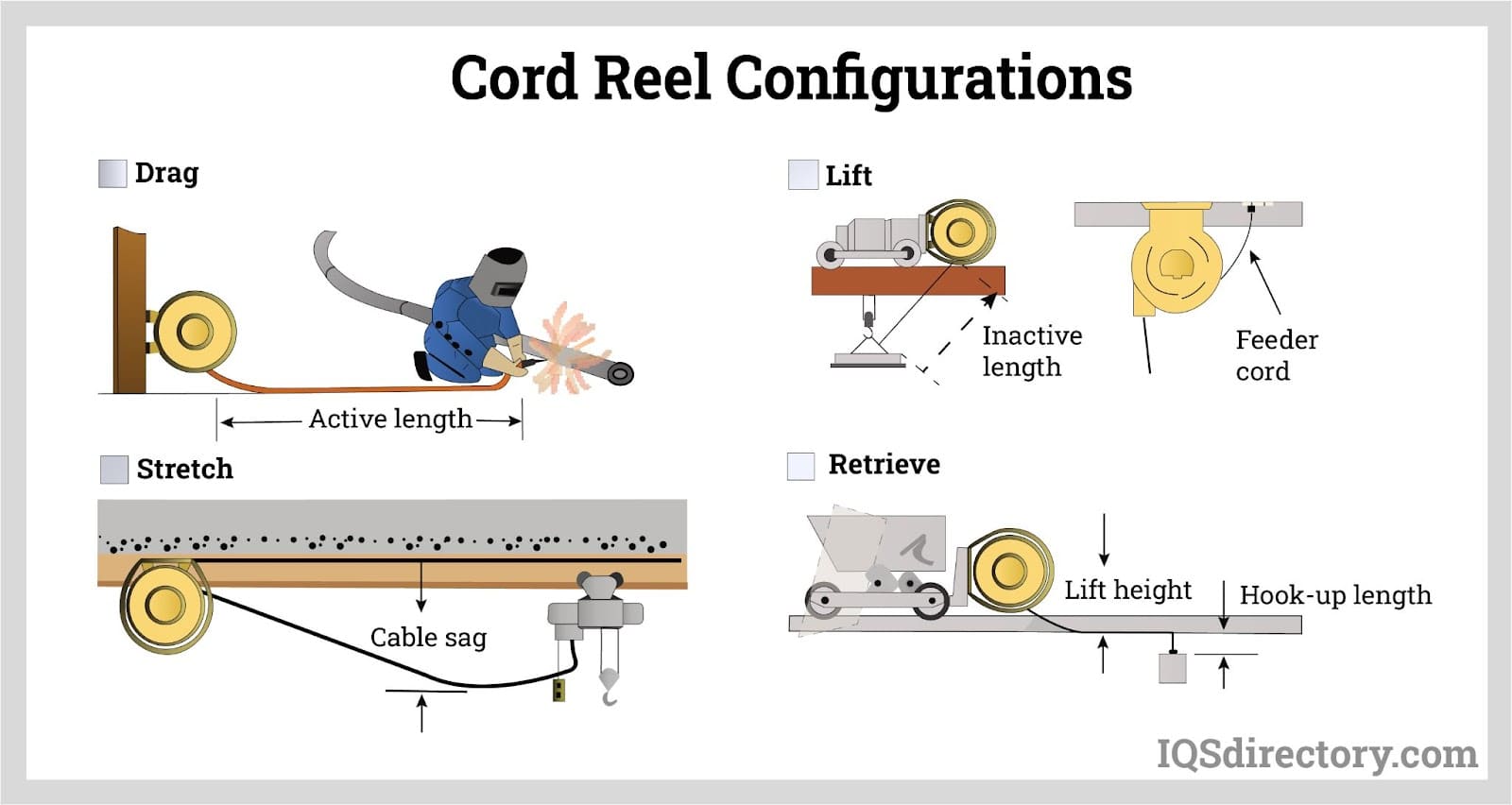

Installation arrangements of cord reels depending on their usage based on there lift, drag, stretch, retrieve, and vertical pick up.

Hose Reel Types

Air Hose Reels

Designed to house air hosing, which is typically small in diameter. This smaller sized reel is suitable for storing air hoses.

Automatic Hose Reels

Retrieve the hose by themselves with the use of batteries, electricity or water or air pressure.

Cable Carriers

Composed of a series of flexible links that house and organize conduits such as cables, hoses and chains.

Cable Reels

Reels designed to hold cables for electrical or other industrial purposes. These reels, made up of several links, are used to store industrial type materials such as cables, rope, chains, and hoses.

Cord Reels

Store, pay out and automatically rewind electrical cable and are used to power mobile machinery from a stationary power source.

Electric Reels

Reels that utilize electric power to wind and unwind hosing, instead of requiring mechanical power. They are useful in situations where heavy hoses are continually used and relocated, such as in airplane refueling applications.

Extension Reels

A type of cylindrical device that electrical cords are mechanically or manually wound around to keep them organized, untangled and easy to use. Mainly used for supplying electricity to power tools, extension reels are ideal for environments where tools and equipment are constantly being relocated depending upon their use.

Fire Hose Reels

Designed to give easy access to a plentiful supply of water. They provide ample protection in high risk areas that require more than a nine liter fire extinguisher, such as large schools, hotels, warehouses, factories, concert halls and theaters.

High Pressure Hose Reels

Specifically designed to hold pressurized water and air hoses used for industrial processes and manufacturing operations. Used for industrial projects, this reel is designed specifically to hold hoses that are pressurized.

Industrial Reels

Utilized in applications necessitating high product flow and/or longer hose length.

Medical Cord Reels

Store, pay out and automatically rewind conductive cord or lifting cord that is used to power mobile medical machinery, such as crash carts, through contact with a stationary power source.

Phone Cord Reels

Self-retracting devices that reel the telephone cord into a small, portable storage container.

Retractable Hose Reels

Have cranks to retract and store the hose.

Spring Reels

Spring-driven retracting mechanisms suitable for industrial, farm, commercial and greenhouse applications.

Static Discharge Reels

Used to ground equipment that is operating in a hazardous atmosphere. When properly grounded, the reel gets rid of any static electrical buildup, which in turn decreases the chance of sparking and a potential explosion.

Truck Mounted Reels

Refer to cable and hose reels that are designed to attach to trucks or vans for different applications. These reels may be of different kinds, like air hose reels, static grounding reels, water hose reels, welding cable reels, cord reels, and can be used in any type of service truck or mechanics truck.

Water Hose Reels

Cylindrical cranks that a water hose can be manually or mechanically wound around.

Welding Reels

Allow for a very smooth operation when welding. These products can be engineered from different materials and even hard coated for increased durability.

Reel Features

The top and most notably useful feature of a hose reel is that of its mobility. While many hose reels can be placed securely on the wall, there are some instances where it is more practical to allow the reel to move around. Reels may be hung from the ceiling to allow better reaching from any angle. Additionally, industrial hose reels may be attached to carts or vehicles for easy transportation.

Installation and Product Care for Hose Reels

If using a mounted reel, it is important to follow the instructions given by the manufacturer to attach it securely to the wall. Typically, instruction manuals will list any specific nails or screws that need to be used. Never try to tape or glue the reel on even if it is light in weight. If it were to fall, injury or broken equipment is a very real consequence. If a hose reel is portable, be sure to check that it is always securely placed on its cart or wagon. Weight should be distributed evenly to avoid tipping over. If the material the reel is made out of is susceptible to rust or corrosion, be sure to store it inside in a dry, cool space.

Properly storing your reel will help it stay functional and in great shape. If using a hand crank, be sure to fully wind the hose back to its place. Leaving the hose lying on the ground defeats the purpose of having the reel and can become a hazard. If working with a spring reel, be sure to pull firmly when gathering cord and safely lock it into place when you have accumulated the desired amount of cord. However, do not swing the cord around while it is attached to the reel, and do not pull too forcefully as to rip it from its mounting or break the cord.

Automatic reels should never be left unsupervised. Lay the hose or cord out so it is untangled to aid in the process of the winding. If the reel has advanced settings, be sure to check their accuracy before turning on the machine. When a hose or cord reel is no longer in use, it should be stored in its designated area or it should be moved out of the way of workplace traffic flow.

What to Consider When Choosing a Hose Reel

There are many different aspects of the application to take into consideration before the purchase of a hose reel. For instance, what is the type of medium that the hosing housed by the reel is being used to convey. For air, such as required by pneumatic tools, it is important to figure out what pounds per square inch (psi) the hose must be able to handle. In addition to air, the hosing used to convey oil, grease and various lubricants also requires foreknowledge of the specific range of psi. For applications that may require more torque, it is important to take into consideration the inner diameter (ID) of the hosing, since applications requiring a lot of torque will require hosing with a large ID. For cord reels, factors such as type of cable, cable length, number of conductors and cable wire size should all be taken into consideration. In addition to choosing the incorrect hose reel for the application, there are a number of other reasons why hose reels may fail. For example, if a spring hose reel is not properly hermetically sealed and is thus exposed to the atmosphere, the internal spring will eventually rust and break. Also, incorrect material choice for parts may cause failure, such as latching mechanisms that are constructed from either thin sheet metal or cast aluminum.

Don’t be confused between a good manufacturer and the right manufacturer. A good manufacturer will be able to prove their quality with high ratings and good reviews on their manufacturing. While this is still a positive attribute, if the product doesn’t fit specific needs the point is moot. If possible, get a look at the equipment in person before buying to ensure it truly fits all specific needs.

Hose Reel Terms

Ball Stop

Also referred to as a "hose" or "bumper" stop, it is used to govern retraction length. When accessories such as drills and air guns are installed on hose reels, ball stops are frequently required.

Bracket

A simple L-shaped object, which has one arm fixed to a vertical surface, such as a wall. The other arm projects in a horizontal direction and is often used to support hose reels.

Bridge

A device placed over a section of hosing that allows traffic to pass over without damaging the hose.

Carcass

The fabric, cord and/or metal reinforcing section of a hose, which is different from the tube or cover.

Core Diameter

The diameter of the inside of the reel.

Coupling

A fitting that is attached to the end of a hose in order to connect two hose lines together or to connect the hose to an appliance, nozzle, discharge valve, fire hydrant, etc.

Cover

The outermost part of the hose that protects the hose reinforcement from physical and environmental abuse.

Fairlead

A square hose guide.

Guide Arm

A piece that usually projects from the side of the hose reel. Its purpose is to guide the hosing encased inside of it in a straight line, allowing for easier, less tangled hose retrieval.

Lift Height

The distance measured from where the hose is positioned to the centerline of the spool.

Pivot Base

A base that allows a hose reel to turn in different directions.

Pressure Rating

The maximum pressure capacity of hosing or cord. For air and water hoses, it is given in pounds per square inch (psi); for electrical cables and power cords, it is given in voltage (V).

Ratchet

A device used to hold hose reel spools in place at particular points of payout.

Reel Capacity

The maximum length of hosing, typically expressed in feet, that a reel is designed to efficiently house.

Reinforcement

The central part of the hose that gives it its strength. The hose working pressure depends on the type and amount of reinforcement used in the hose construction.

Safety Wrap

Hose that remains on the reel when the rest is completely unwound.

Slip Rings

A slip ring is a device that makes an electrical connection between a stationary structure and a rotating structure. Slip rings are utilized in systems that rely on the transmission of power/data while also maintaining rotation.

Spool Axial

The device upon which the hosing or wiring is wound. It rotates with the swivel, which in turn loads and unloads the hose.

Swivel

A supported pivot that allows the hose reel to rotate in a horizontal plane, enabling the winding and unwinding motions. The swivel also transfers gas/fluid from a fixed source to a rotating source.

Tie Rod

A part that keeps spool flanges connected rigidly to the drum.

More Hose Reels

Hose Reel Informational Video