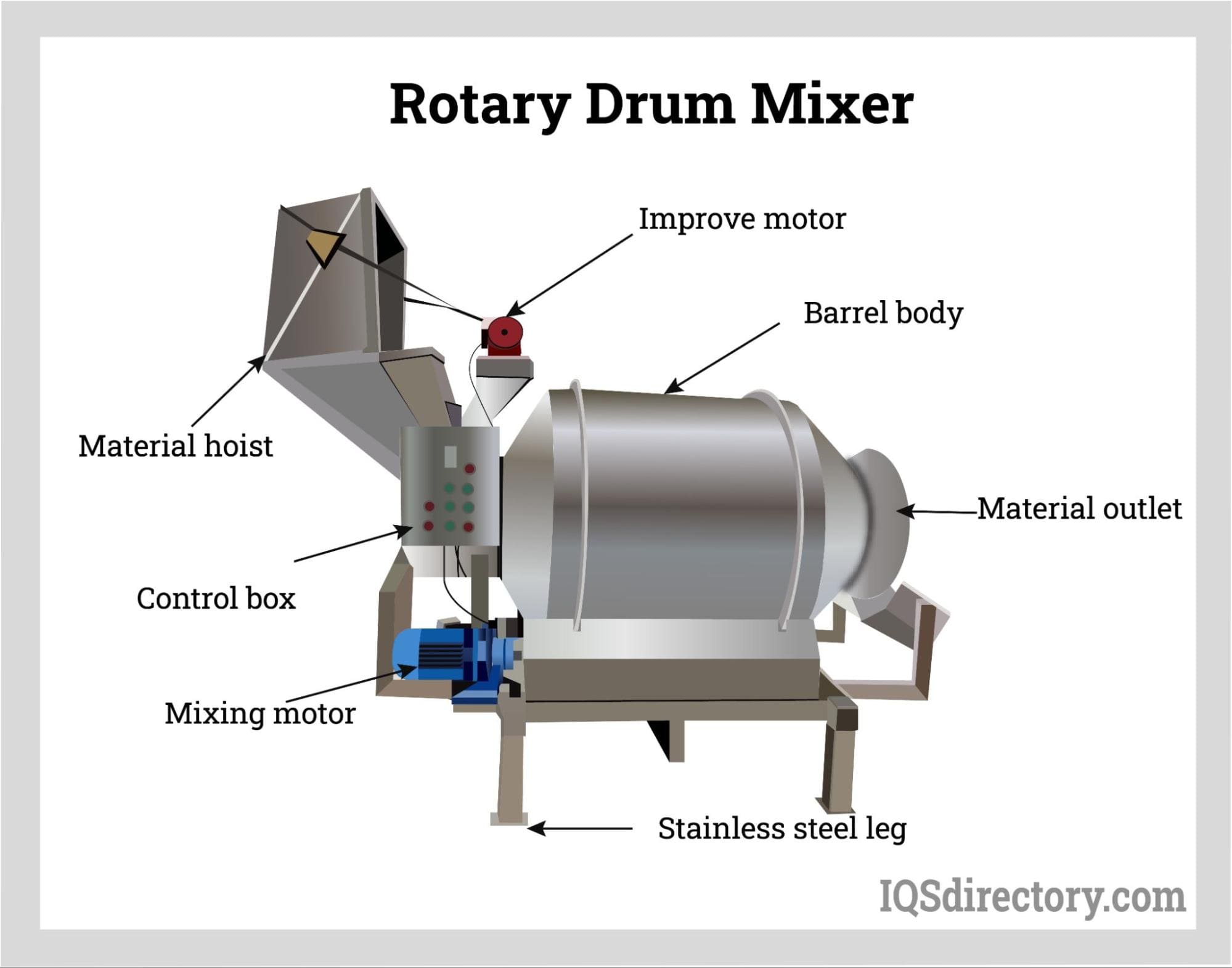

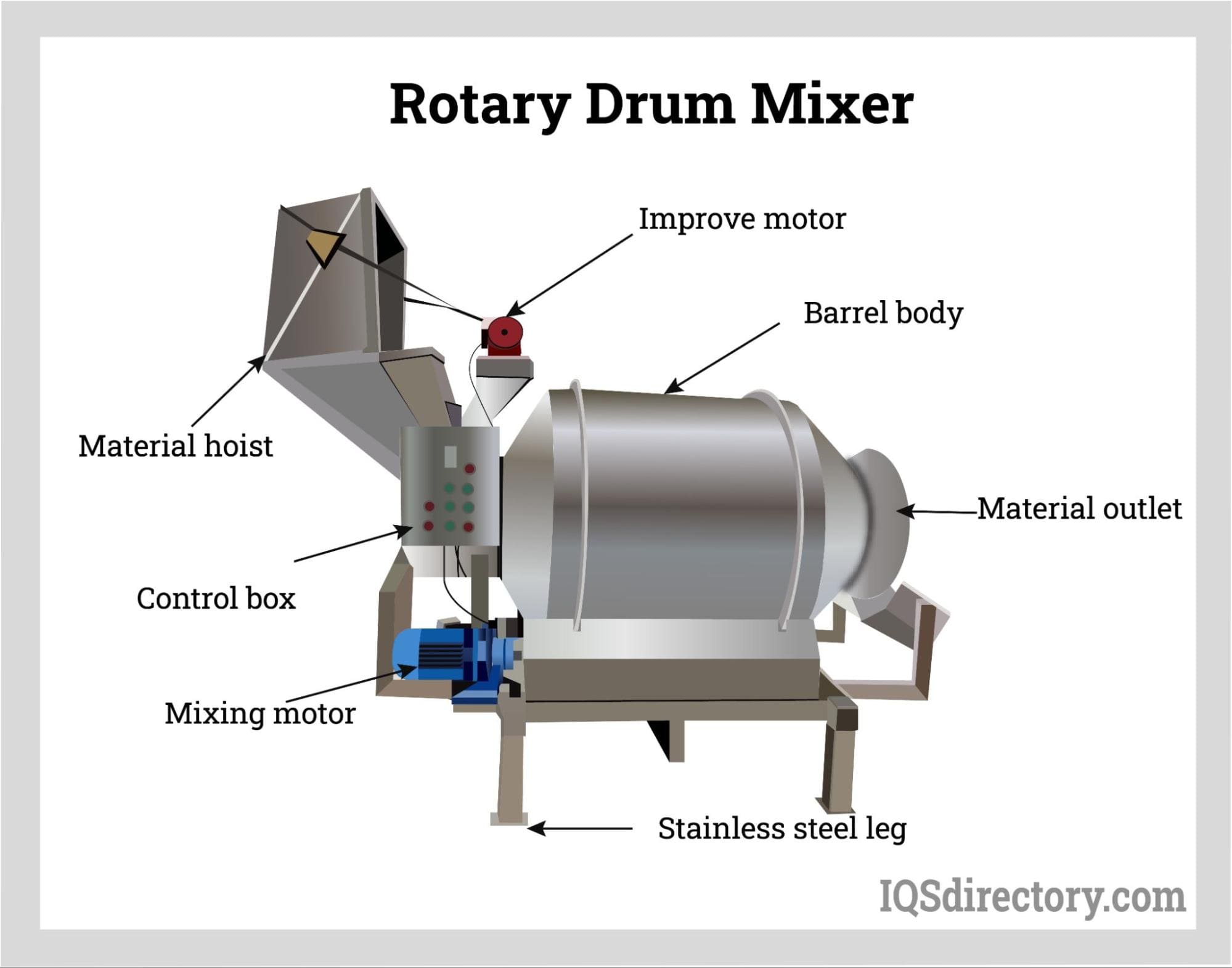

Drum Mixers

Drum mixers are mixers that are used for mixing free flowing materials by rotating them forward and reverse with welded chutes or flights that fluidize the mixture. The design of drum mixers gives them...

Please fill out the following form to submit a Request for Quote to any of the following companies listed on

Includes information about mixer blades, their importance, and mixer blade producers

You will learn:

A mixer mixing blade is a component of a mixer that blends or agitates substances to transform them into homogeneous materials. Mixing blades are designed to blend, mix, and stir liquids, high and low viscous pastes, and various types of granular materials. The term mixing blade covers several types of components that are essential parts of industrial mixers. The many names for mixing blades include impellers, propellers, blades, foils, and on and on. The term that is the most popular is impeller, which is described as a piece of metal on the end of a shaft that spins to mix ingredients.

Regardless of the type of mixing blade, all types move substances and materials up and down or from side to side. The kinds of materials determine the type of mixing blade, with some materials requiring a gentle even rotational motion while others require greater shearing force to achieve required homogeneity. In addition, the strength, composition, and shafts of mixing blades widely vary between manufacturers and types of mixers.

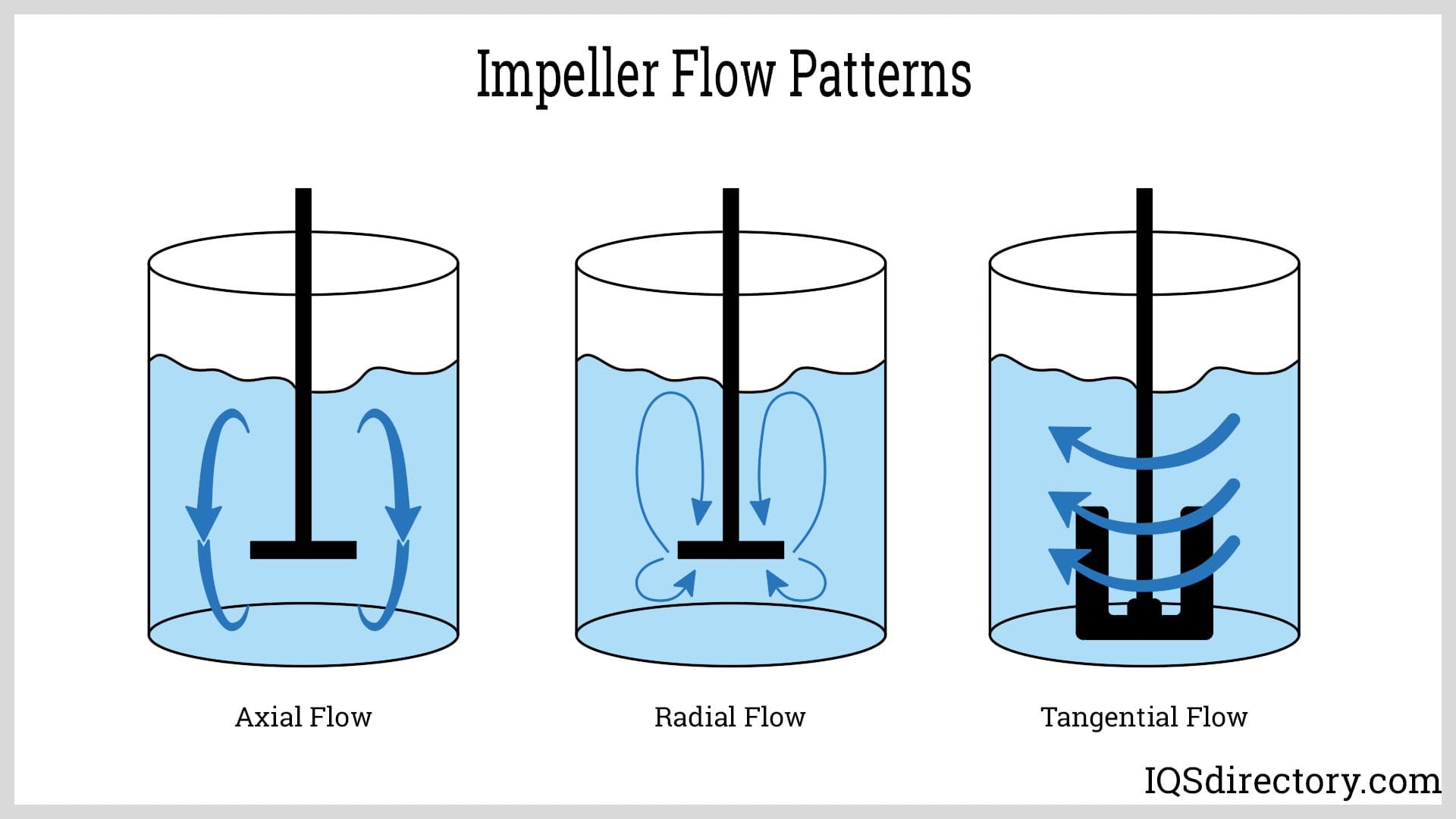

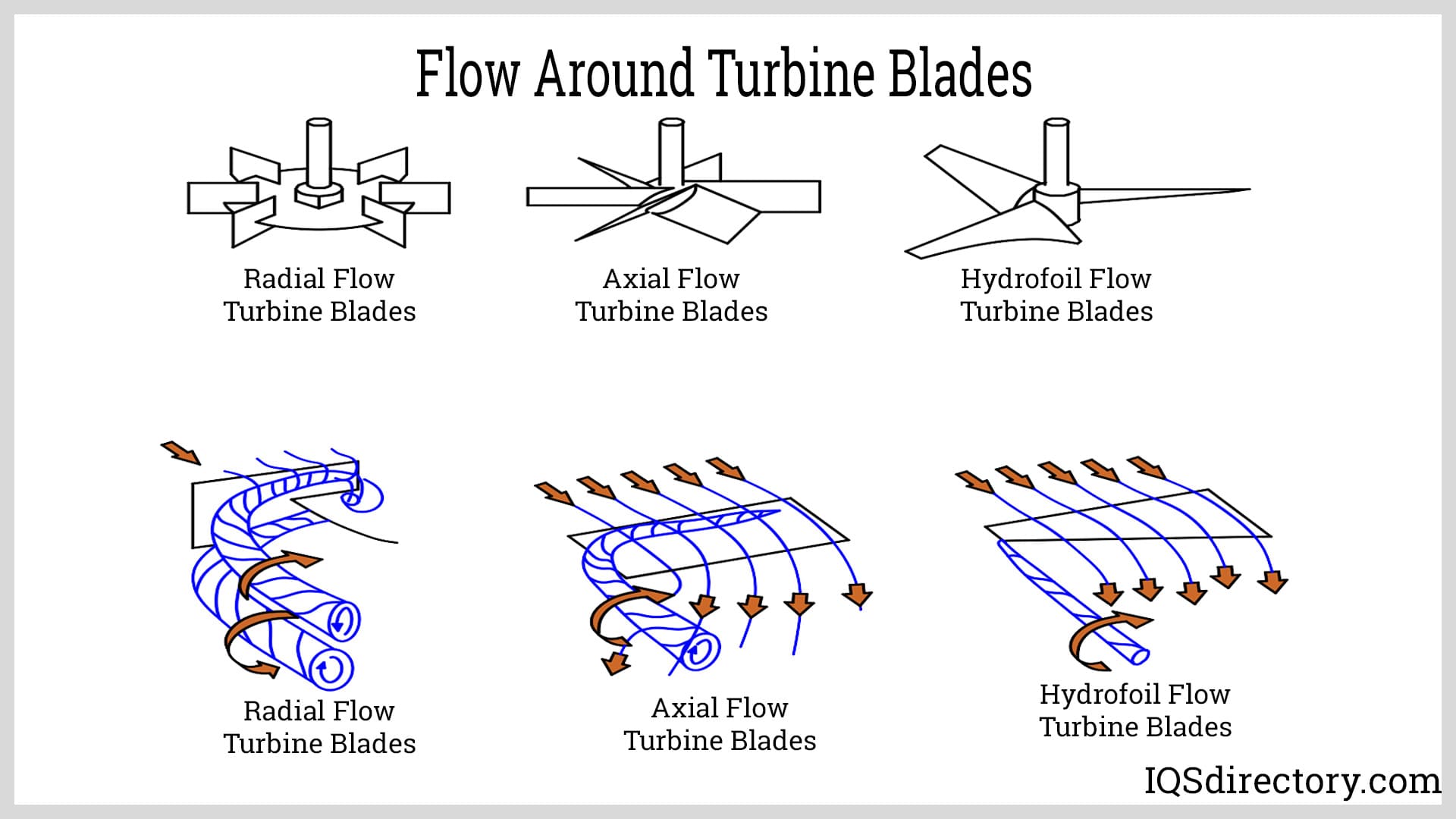

The critical component of any industrial mixer is their impeller mixing blades. Each type of impeller creates a different flow pattern, which is the primary consideration when designing an industrial mixer. The various flow patterns are critical to achieving a desired homogeneous mixture. The most common types of flow patterns created by impeller mixing blades are axial or up and down and radial or from side to side. The designations for flow patterns are generic descriptors for classifying impellers.

A third category for flow patterns is tangential flow where fluids move horizontally around the mixing container. A tangential flow pattern has low shearing force with very little vertical flow. It is best suited for the mixing of high viscosity materials.

Since impellers are geometric shapes, their performance is determined by key factors in regard to adherence to geometric parameters. Angles, curves, diameters, and blade shapes are the essential and primary factors used in the design of impellers, which are carefully examined to ensure the stability and reliability of an impeller.

Each of the various impeller mixing blade types have different motions that are designed to accomplish different mixing jobs. They are chosen in accordance with the application for which they were designed. While axial impeller mixing blades are ideal for stratification or solid suspension, radial impeller mixing blades provide high shearing force with a lower flow rate. During mixer design, impeller mixing blades are carefully selected to fit an application’s requirements.

| Impeller Design Parameters | ||

|---|---|---|

| Type of Impeller | Flow | Application |

| Straight | Radial | Recommended for applications requiring high speed |

| Ideal for mixing tasks with low viscosity | ||

| Propeller | Axial | Recommended for applications requiring average or high speed |

| Ideal for mixing tasks with medium or high viscosity | ||

| Excellent mixing properties for homogenization and suspensions | ||

| Turbine | Radial | Recommended for applications requiring average speeds |

| Best for mixing tasks with low or medium viscosity | ||

| Often used for gassing and dispersion of liquids | ||

| Anchor | Tangential | Recommended for applications requiring low speed |

| Suitable for mixing tasks with medium viscosity | ||

| Centrifugal | Axial | Recommended for applications requiring medium to high speed |

| Good for vessels with narrow necks | ||

| Dissolving | Radial | Recommended for applications requiring average to high speed |

| Ideal for mixing tasks with medium or high viscosity | ||

| Excellent mixing properties for homogenization and suspensions | ||

The common use for an axial flow pattern is for mixing bulk materials. The blades of an industrial mixer for an axial flow pattern are angled downward. As the blades spin, the material to be mixed is forced downward toward the bottom of the mixing tank. At the bottom, the mixture bounces off and moves to the sides of the tank. The continuous movement of the mixing blades moves the mixture up the sides from which it repeats the cycle.

The wide use of axial flow mixing is due to its ability to mix under multiple conditions. It is ideal for suspending solids in liquids, which prevents them from settling on the bottom of the mixing tank. The axial flow pattern produces sufficient flow to overcome the settling velocity of particles in liquids.

Unlike the axial flow pattern that forces mixtures downward, the radial flow pattern forces mixtures towards the side of the mixing tank. As the mixture hits the sides of the tank, it divides into two parts with one part moving upward while the other part moves downward. The radial flow pattern produces high shearing force due the angle of attack. Radial flow impeller mixing blades are used for low level mixing in elongated tanks. The radial flow pattern is sensitive to viscosity, which makes them ideal for mixing pastes and caulking compounds.

The tangential flow pattern moves mixtures in a rotational or circular pattern, which is not ideal for mixing low viscosity liquids. With rotational or circular flow, mixtures move around the shaft of the mixing blade orbiting it without moving out, up, or down. The motion does not mix substances, which is the reason that the tangential flow pattern is used for very high viscosity materials. During the mixing of viscous materials, the tangential flow pattern moves substances along the walls of the mixing tank breaking down the material’s boundaries. A common occurrence with the tangential flow pattern is the formation of a surface vortex.

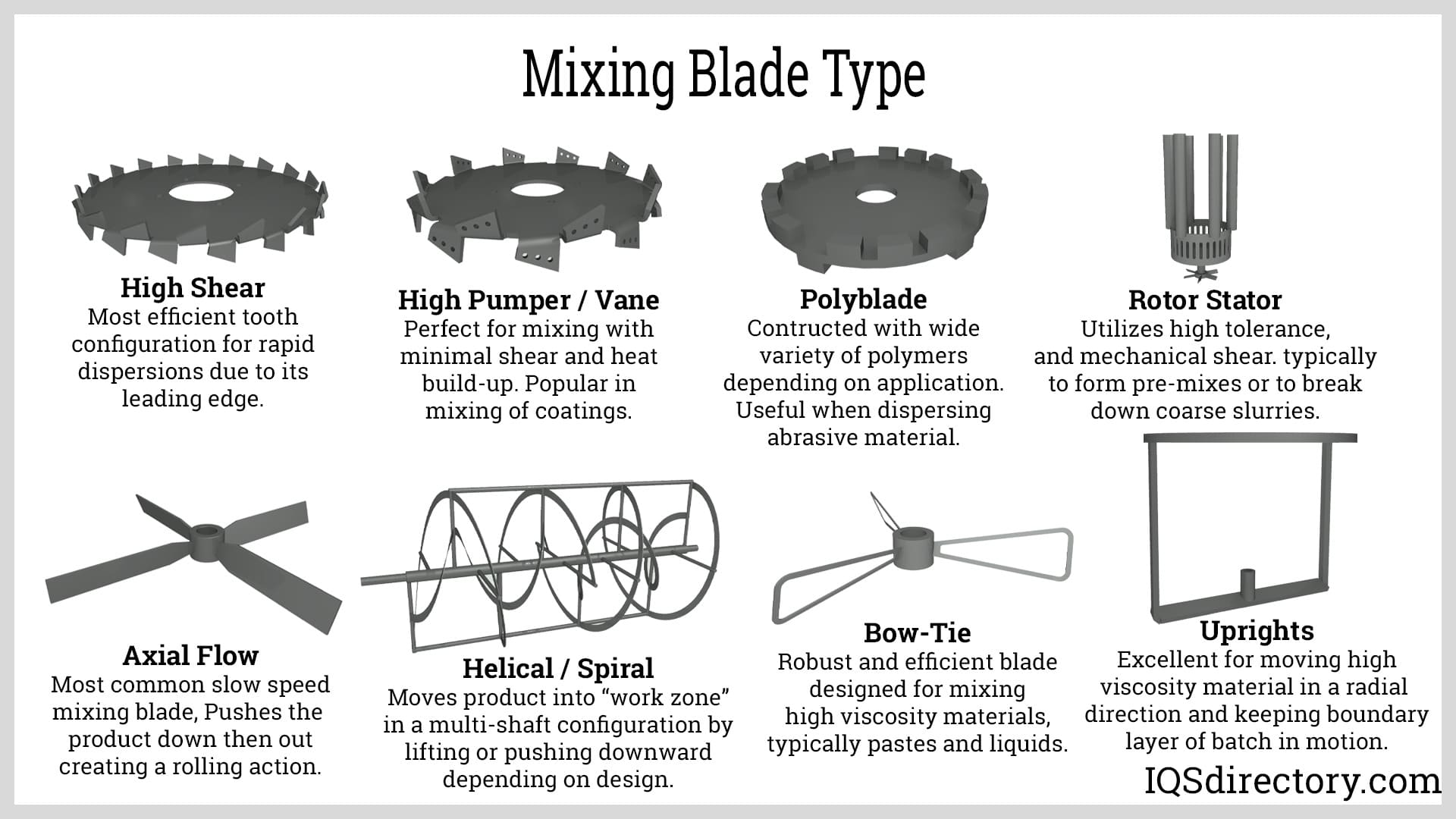

There are many different types of impeller mixing blades. They are designed to change the pressure and flow of fluids and are categorized according to the direction a fluid flows through the blades. The term impeller, as with the term mixing blade, is a generic term used to describe the portion of an industrial mixer that spins and blends materials.

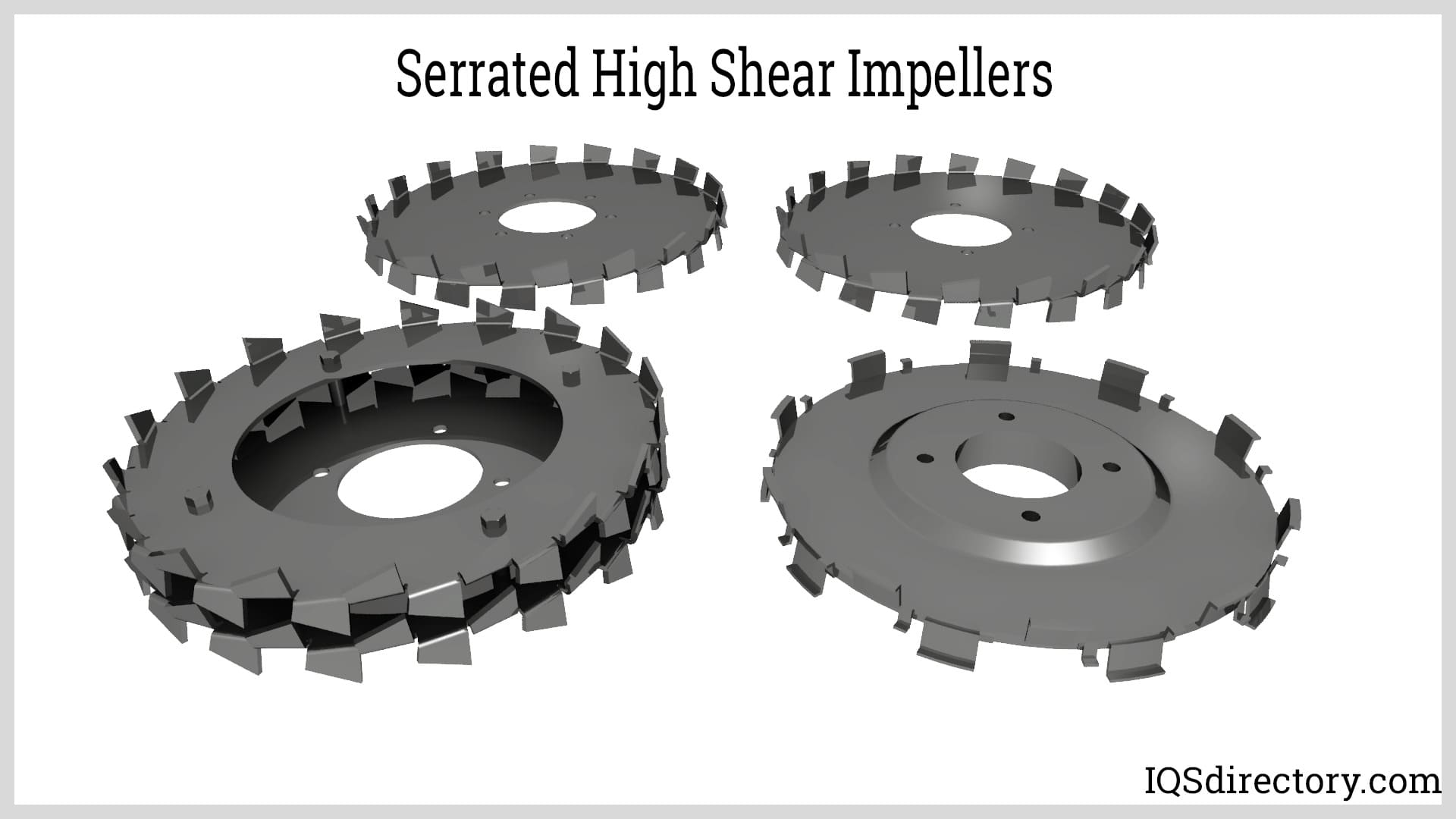

High shear impeller mixing blades are designed for breaking up solids and are a common form of disperser mixing blade. They have a series of blades that are used with high powered industrial mixers. High shear impeller mixing blades are designed for the most rigorous mixing conditions. In many instances, they are matched with an axial flow impeller mixing blade to provide more homogeneous mixing. The high shearing of high shear impeller mixing blades increases the rate of dispersion and homogenization.

The metals used to produce high shear impeller mixing blades include Grades 304 and 306 stainless steel, grades SAF2205 and SAF2507 duplex stainless steel, and carbon steel grades GR250, GR350, and 4140. High shear impeller mixing blades come in several shapes with the commonality between the shapes being their multiple teeth and high durability.

The high speed of a high shear impeller mixing blades creates centrifugal displacement that creates a vortex. Materials to be mixed are drawn down into the vortex where they are subjected to intense shearing forces at the tip of the high shear impeller mixing blades, the result of which is rapid dispersion.

Ribbon impellers, or helical ribbon impellers, are unlike high shear impeller mixing blades in that they are low speed impellers that combine the features of a helical ribbon with a screw impeller. They are used for mixing and heat transfer of middle to medium high viscosity materials. The action of a ribbon impeller forces materials inward, outward, forward, and backward, which is ideal for blending slurries, dry powders, and granular materials.

The structure of a ribbon impeller includes a shaft with spokes that hold the helical ribbon. Dual ribbon impellers have an external ribbon and internal ribbon that work together to move mixtures inward and outward. The combination of the two ribbons creates a folding and convective mixing motion.

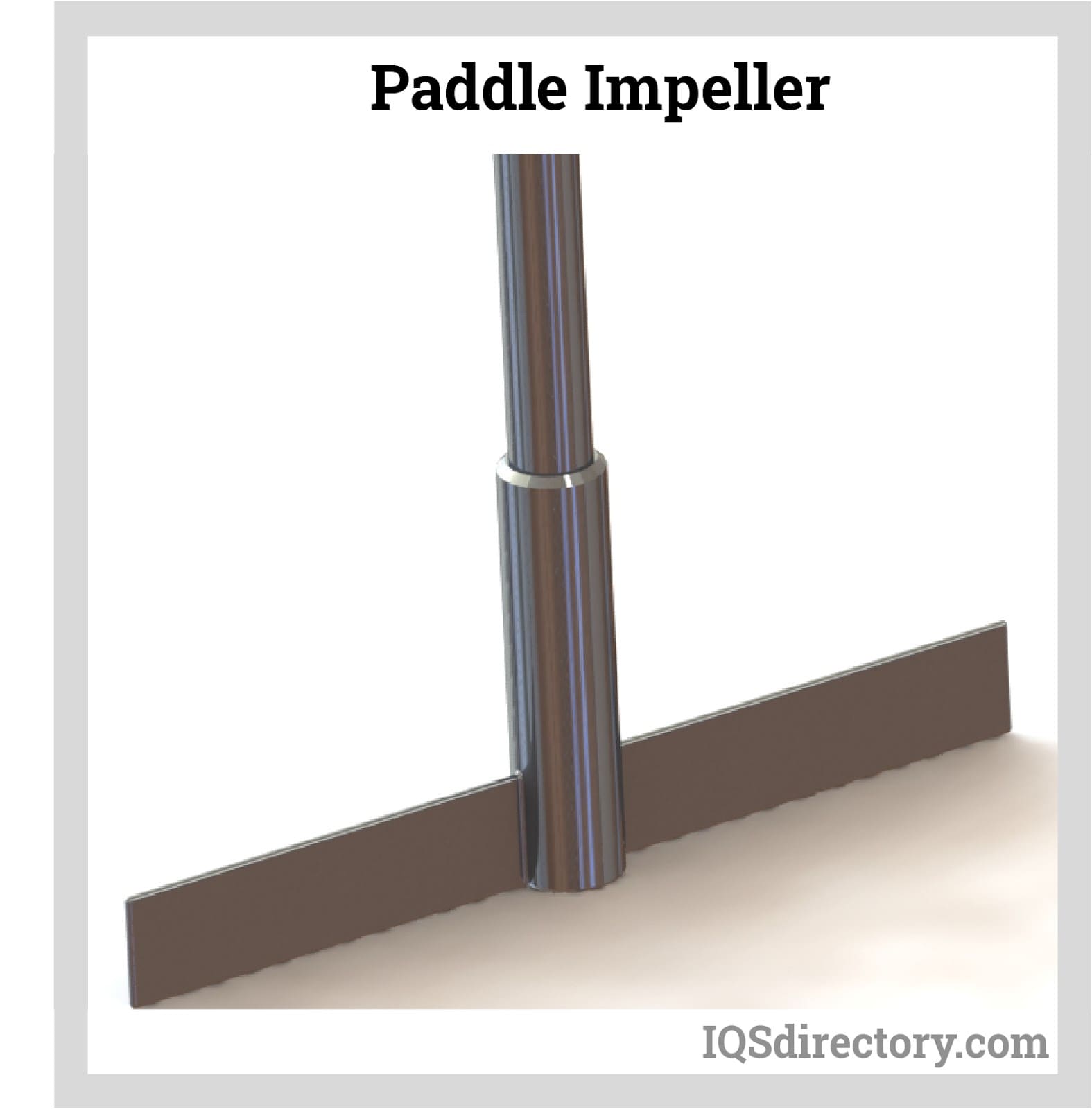

Paddle impeller mixing blades have flat paddle shaped blades mounted on a central shaft for creating a radial flow pattern. The flat blades stretch across the diameter of the tank and reach the mixer’s walls. They generate a high degree of shearing force to disperse solid particles and break up agglomerates. The radial flow pattern helps with heat and mass transfer as a mixture circulates. Paddle impeller mixing blades operate at lower speed, which results in lower energy consumption and reduced shear on a mixture.

The efficient shearing force of paddle impeller mixing blades creates little resistance, which makes paddle impeller mixing blades ideal for mixing heavy resistance solids, wet dry mixtures, slurry mixing, and high viscosity applications. The types of paddle impeller mixing blades includes two shaft, ribbon, and high speed, each of which is used for a specific application.

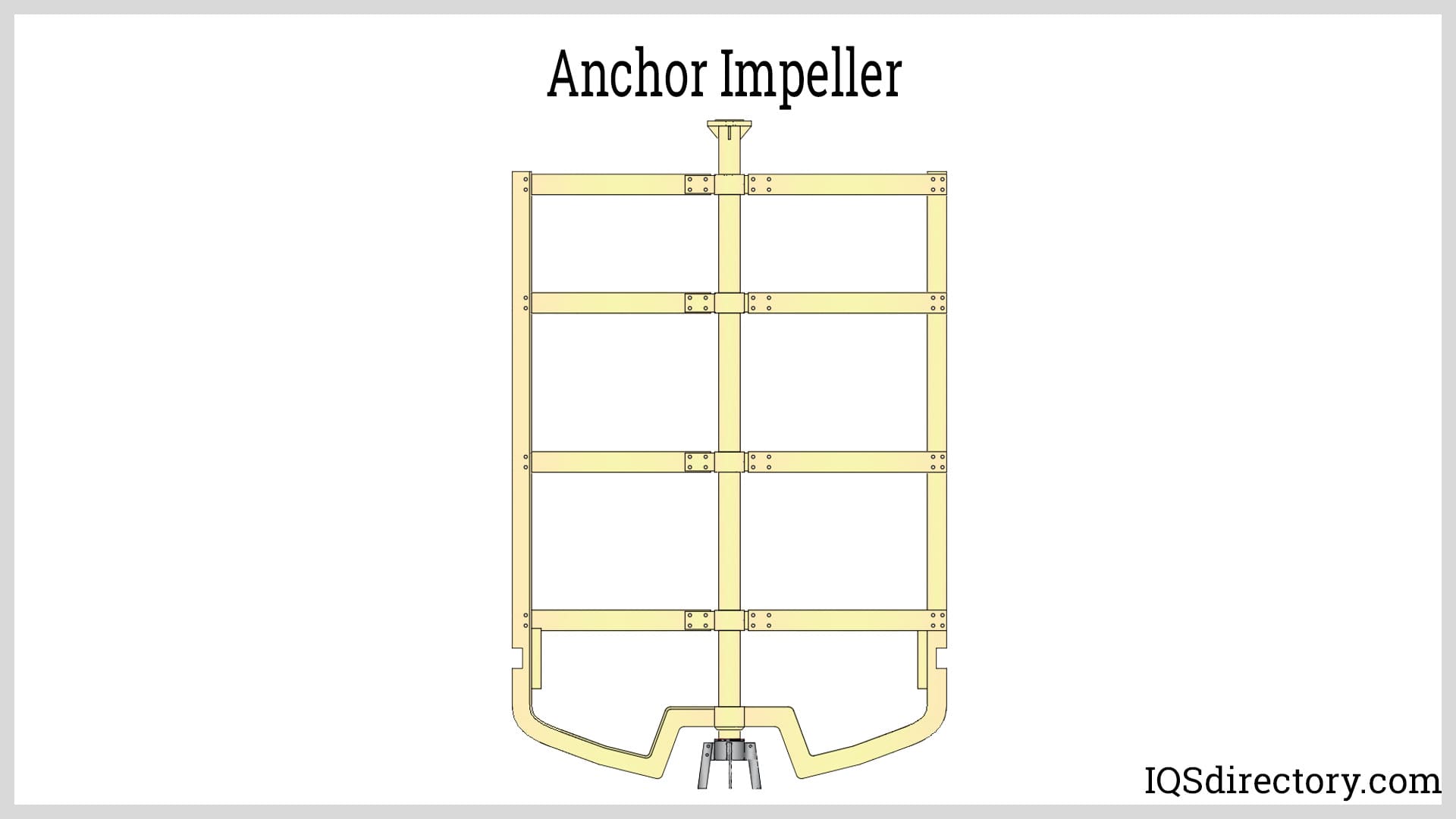

Anchor impeller mixing blades are used for high viscosity mixing of fluids that have a centipoise range of 5000 cP up to 50,000 cP. Centipoise refers to the viscosity of liquids and is used to describe the resistance of a liquid to flow. A higher centipoise (cP) value indicates how thick a liquid is and what its viscosity is. The curved design of an anchor impeller’s mixing blades allows them to be closer to the walls of a mixing vessel such that they can scrape the walls. This motion prevents sedimentation and helps in heat transfer.

The tangential flow pattern of anchor impeller mixing blades is ideal for heat transfer and preventing the build up of viscous materials. An anchor impeller includes two or more angled blades attached to the central shaft. The angles of the blades vary in accordance with the requirements of a process with 45o and 90o being standard. The blade configuration creates maximum energy dissipation and efficient mixing, which is the reason they are ideal for high viscosity mixing.

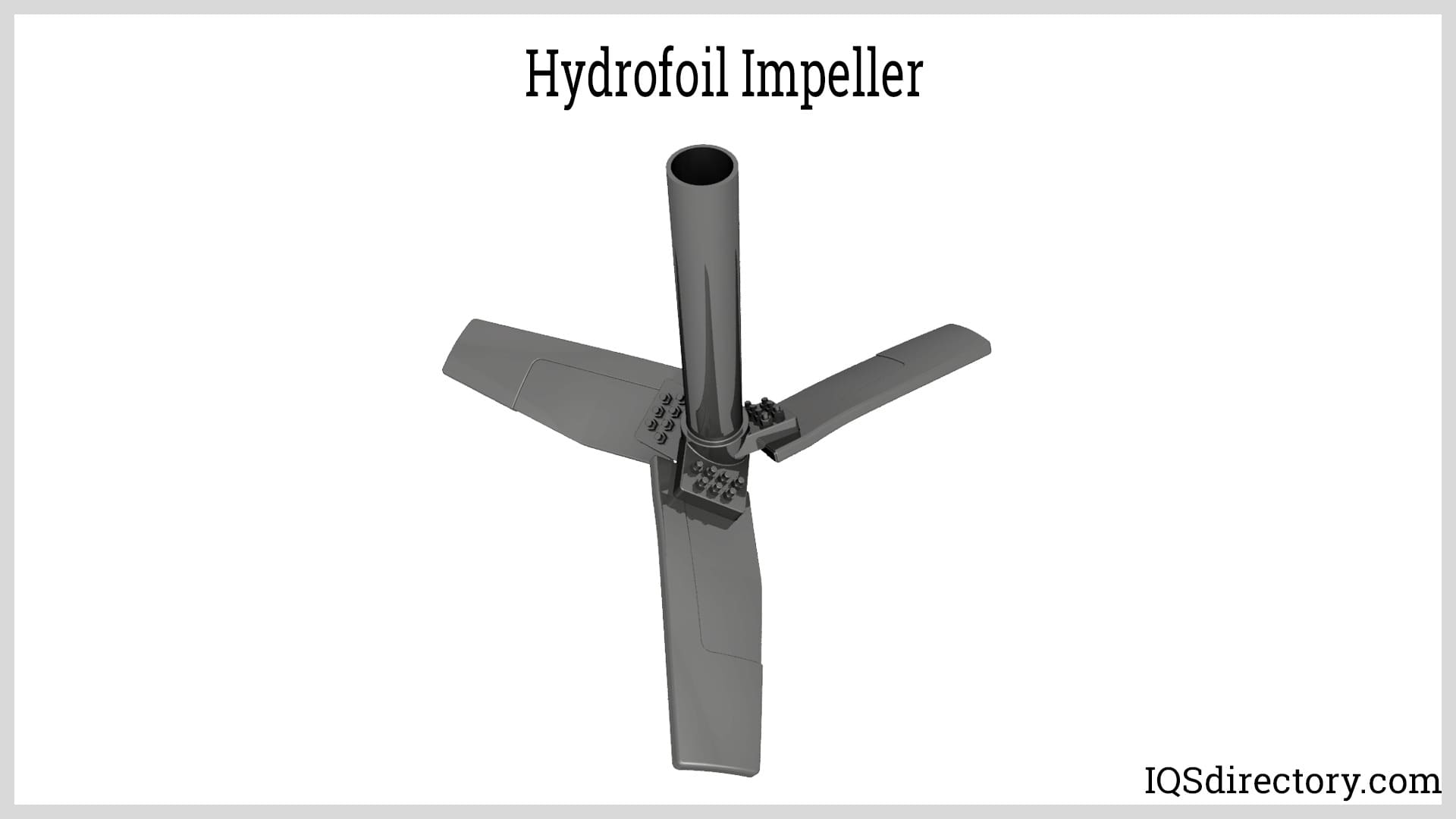

Hydrofoil impeller mixing blades are based on the Bernoulli principle that states that when the speed of a fluid in motion increases, the pressure of the fluid decreases, and its energy is converted into motion rather than shearing force. The flow rate of hydrofoil impeller mixing blades is high with low turbulence, which makes them ideal for shear sensitive materials. Hydrofoil impeller mixing blades are known for producing high flow rates with very little shearing.

The blades for hydrofoil impeller mixing blades are curved with a foil shape to minimize drag and enhance flow efficiency. They are energy efficient and are available in several different designs. The high efficiency rating of hydrofoil impeller mixing blades is due to their maximization of flow rate with minimum shear rating.

Although a majority of mixing applications take place in industrial mixers, there are applications where materials are mixed in drums or totes that have limited access for fixed blade impellers. For those conditions, impeller mixing blade manufacturers invented a folding impeller mixing blade that has blades that fold under the shaft and expand when activated in an enclosed space. Some designs of folding impeller mixing blades can include more than two blades, but the majority of them have just two blades.

To place folding impeller mixing blades in a drum or tote, the blades are folded against the shaft and inserted through a bung hole. When the mixer motor activates, the impeller mixing blades spread outward from the shaft. In some designs, impeller mixing blades are capable of sliding up the shaft to provide radial and axial flow with high shear levels for exceptional mixing. In order to match the dimensions of the bung hole, the diameter of folding impeller mixing blades is 4.25 in (10.79 cm).

The few impeller mixing blades described above are a sampling of the many impeller mixing blades available for a variety of applications. In addition, mixing blade industrial manufacturers work with their clients to custom design impeller mixing blades that meet the needs of unusual and unique applications. Those types of impeller mixing blades are the product of the collaboration between manufacturers and their clients.

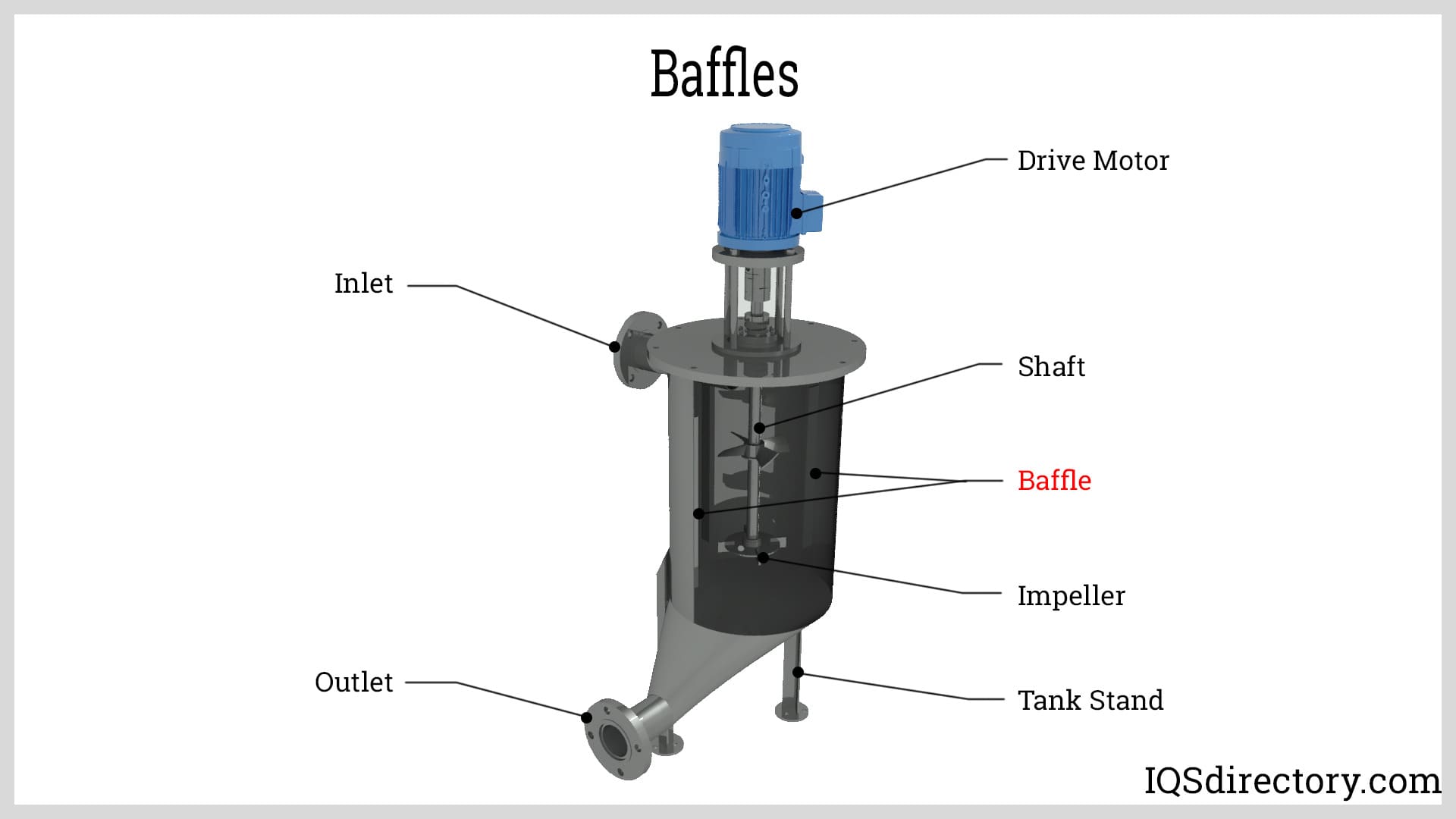

Baffles are used in cylindrical tanks that mix solid suspensions. Offset mounts generate unbalanced loads that put pressure on the mixer shaft. One solution to the problem is to install a heavy-duty agitator gearbox and bearings, a factor that makes an industrial mixer more expensive. Baffles, long, flat plates, do not generate an unbalanced load but disrupt the flow pattern creating a top to bottom flow.

When mixing solid suspensions in large cylindrical tanks, a swirling flow pattern is created due to solids tending to collect at the bottom of the tank. The installation of baffles along the sides of a tank prevents that from happening. They are necessary for larger tanks of more than ten feet in diameter. Baffles can also be installed in smaller tanks for the disruption of mixing vortices.

The blades of an impeller are critical aspects of an industrial mixer. They generate fluid flow and are responsible for producing homogeneous mixtures. The manufacture of impellers and their blades take several forms, which are chosen in accordance with the material of the impeller, accuracy, design complexity, and the production volume of an application.

The methods used to manufacture mixer blades are ones that are commonly used for most metal products. Although there are several methods commonly used, the top five are casting, metal machining, welding, powder metallurgy, and 3-D Printing or additive manufacturing. Casting, welding, and machining are traditional techniques that have been used for many years while powder metallurgy and 3-D printing are newer methods.

Casting is a centuries old manufacturing method that takes several forms and includes the use of molten metals, such as stainless steel, cast iron, or bronze. The popularity of casting is due to its accuracy, ability to produce complex geometries, and high production volume. The critical aspect of casting is the machining of the mold, which takes time and skill. With the advent of computers, the precision of casting has been substantially enhanced since CAD designs can be tested for their accuracy and tolerances prior to being formed and machined. Impeller mixing blades are normally cast using computer numerical control (CNC).

Of the various methods used to produce impeller mixer blades, machining is the most labor intensive and requires the most skill. Machining is a metal removal process that involves shaping, cutting, and forming an impeller from a solid piece of metal. The process is used to produce medium sized impellers and is preferred for its dimensional accuracy and exceptional tolerances. Machining is ideal for producing impeller mixing blades with superior surface finishes. As with casting, the process can be completed using CNC programming.

Welding is used to form impeller mixer blades with simple shapes for arduous and demanding conditions. The success of welding an impeller blade requires careful preparation using the proper welding method. The focus of the process is to avoid distorting the blades. In addition, as an extra precaution, a low heat welding process is used to prevent cracking and warping. It is essential that the blades of an impeller be perfectly proportionally formed to ensure their proper rotation and mixing. Multiple passes are required with a cooling period between passes, which ensures a tight and even connection between the welded surfaces. As with all forms of impeller mixing blades, surfaces of welded impeller blades are treated and smoothed.

The process of powder metallurgy has existed for many years. It is only recently that it has gained popular use. At the beginning of the 21st century, production using powder metallurgy radically increased. The process of powder metallurgy involves heating compacted metal powder to just below its melting point. The essence of powder metallurgy involves several different technologies with pressing and sintering heated metal powder being the most common.

For the manufacturer of impeller mixer blades, powder metallurgy is used to produce impellers from materials that are difficult to cast or machine. Complex shapes and impellers with high strength and dimensional accuracy are produced using powder metallurgy. In many cases, custom impellers are produced using materials that have high wear or corrosion resistance.

Additive manufacturing is an emerging manufacturing technology that is rapidly gaining popularity. It is a very flexible process that is capable of producing intricate and complex geometries with exceptional accuracy. Additive manufacturing is an ideal method for producing high quality impeller mixing blades. The manufacture of impeller mixer blades using additive manufacturing involves adding materials to a base or foundation to form a part. The key to the process is a computer rendering that is downloaded into a 3-D printing machine that slowly, layer by layer, builds the final mixing blade.

The selection of the manufacturing method for the production of mixer impeller blades involves the choice of materials, the type of impeller, and its size, complexity, accuracy, quantity, and cost. As with all manufacturing, each of the various methods have limitations and strengths. The correct choice ensures that an impeller meets application specifications with exceptional performance.

A mixer blade blends, agitates, and stirs substances to achieve a homogeneous material. It moves liquids, pastes, and granular materials using varied motions based on application requirements.

Elements such as diameter, blade angle, number, shape, width, materials, and surface finish determine mixer blade efficiency, flow rate, energy usage, and suitability for different substances.

Mixing blades generate axial (up-down), radial (side-to-side), or tangential (circular) flow patterns, each optimized for specific viscosity and mixing applications.

Common methods include casting, machining, welding, powder metallurgy, and additive manufacturing, each chosen for accuracy, complexity, materials, and production volume needs.

Anchor and ribbon impellers efficiently handle high viscosity fluids. Anchor blades scrape vessel walls to prevent sediment, while ribbon impellers fold and convectively blend thick mixtures.

Yes, manufacturers often collaborate with clients to custom design impeller mixing blades, ensuring precise fit and performance for specialty mixing needs.

Impellers and propellers are mechanical mixing devices designed to move fluids and substances in a mixing tank. The designs of impellers include axial, radial, and tangential, which are selected in accordance with the flow pattern of a fluid. Propellers convert rotational power into linear thrust and are used for high flow mixing. They are a low shear high flow mixing device.

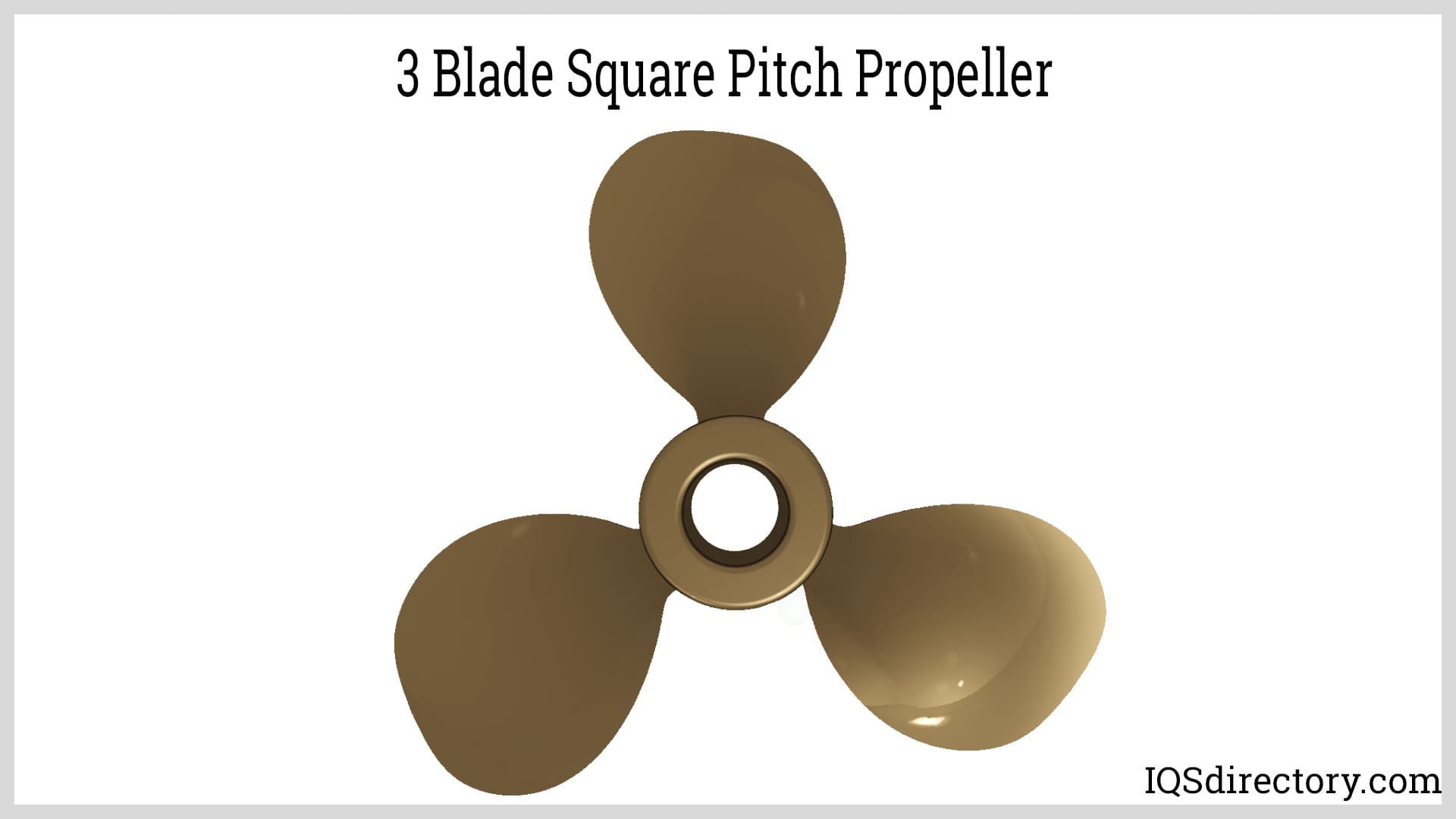

Propellers are types of impellers that are low shear and high mixing components. They provide axial flow and are ideal for gentle agitation and solid suspension in low viscosity fluids. The flow of propellers can be left or right-handed. Steep pitch propeller blades provide increased flow rates using slightly more power.

Typically, the terms propeller and impeller are used interchangeably as generic terms. Propellers gained their name from their similarity to marine propellers. They are used for high-speed mixing that blends low viscosity miscible liquids or liquids with solids. The two types of mixing propellers are three blade propellers and steep pitch propellers.

Left hand (LH) propellers are the most common form of propeller impeller. It has a clockwise rotation that creates downward flow for optimal tank turnover. Propellers are all purpose impellers that are used for blending, mixing, agitating, and liquid movement.

Three blade propellers are multi-purpose propellers with a semi-elliptical design. They are available with full mixer blade tips for liquids. Certain styles of propellers are used for wastewater treatment and have a non-fouling design to avoid equipment failure. The marine style of three blade propellers is used in tanks to provide excellent homogenization. Three blade mixer blades provide axial flow.

As with most mixing blades, propellers come in a variety of diameters and bore sizes with custom sizes available for unique processes. They mix in a downward direction, depending on their material, and provide a high level of chemical and abrasion resistance. The top to bottom circulation of materials provides exceptional agitation. The addition of baffles eliminates any swirling.

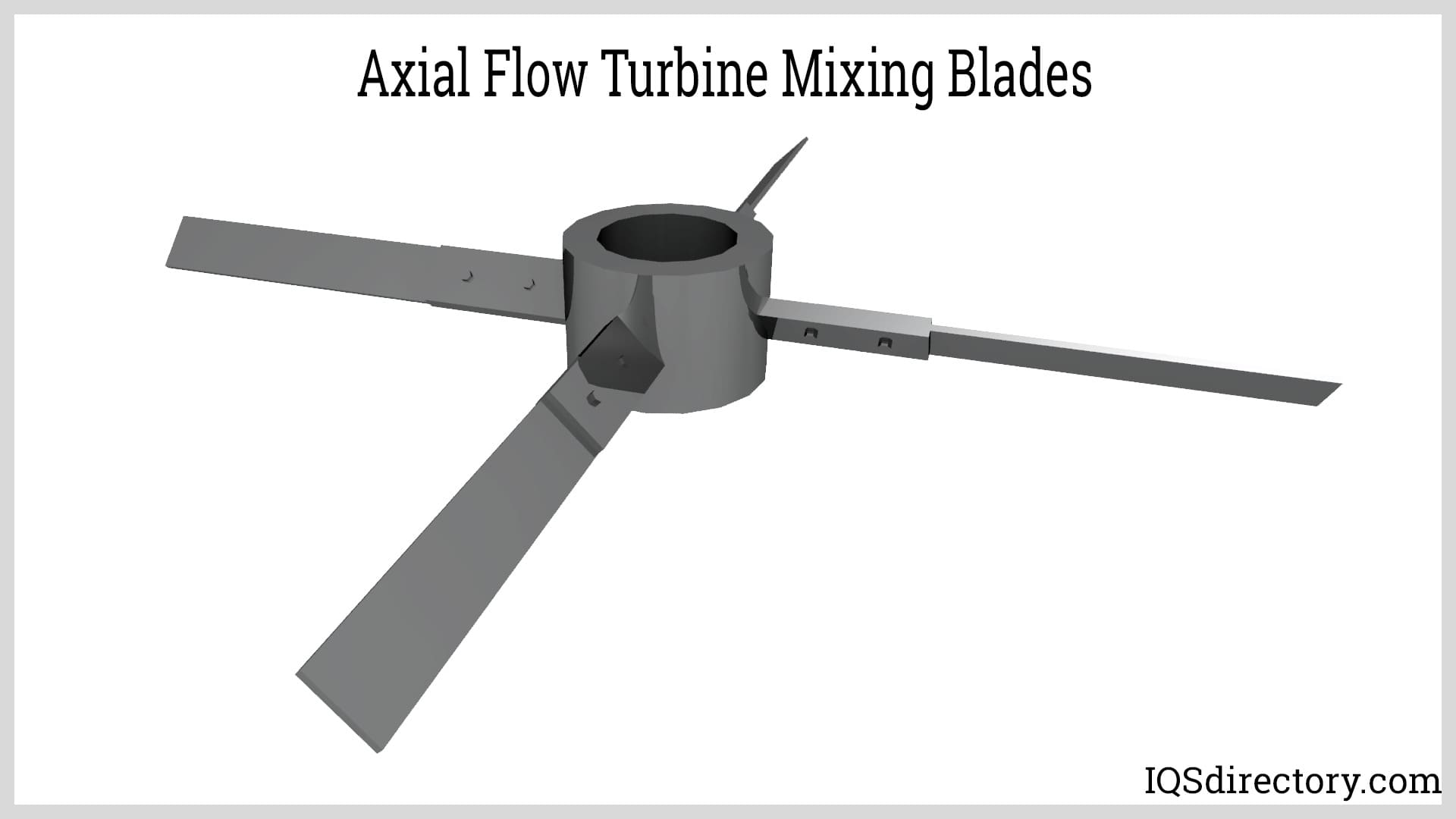

The term turbine refers to a wide range of impellers that include radial and axial designs. They have two or more blades with a constant blade angle and can have blades being vertical or set at an angle that is less than 90o. In addition, blades can be flat or curved. Turbine mixing blades are designed to perform rapid mixing that increases the flow rate and the dissolution of liquids. They create turbulence in a liquid that generates rapid mixing and high shear forces that break down particles.

Axial flow turbines are used with medium viscosity fluids that have a cP range of 0.5 cP up to 1000 cP. Included in this viscosity range is olive oil, motor oil, liquid soap, corn oil, and shampoo. Axial flow turbine impellers have three or four rectangular mixing blades welded to a hub at a 45o angle. The broad surface of the mixing blades maximizes liquid movement. Under normal conditions, an axial flow turbine impeller has a diameter that is 70% to 80% of the diameter of a mixing tank. Gear reducers are necessary to supply sufficient torque.

A recent development with axial flow turbine mixing blades has been hydrofoil mixing blades with weaker tip vortices that dissipate energy uniformly. These narrow mixing blades are used for improved heat transfer, solid suspension, and dissolution.

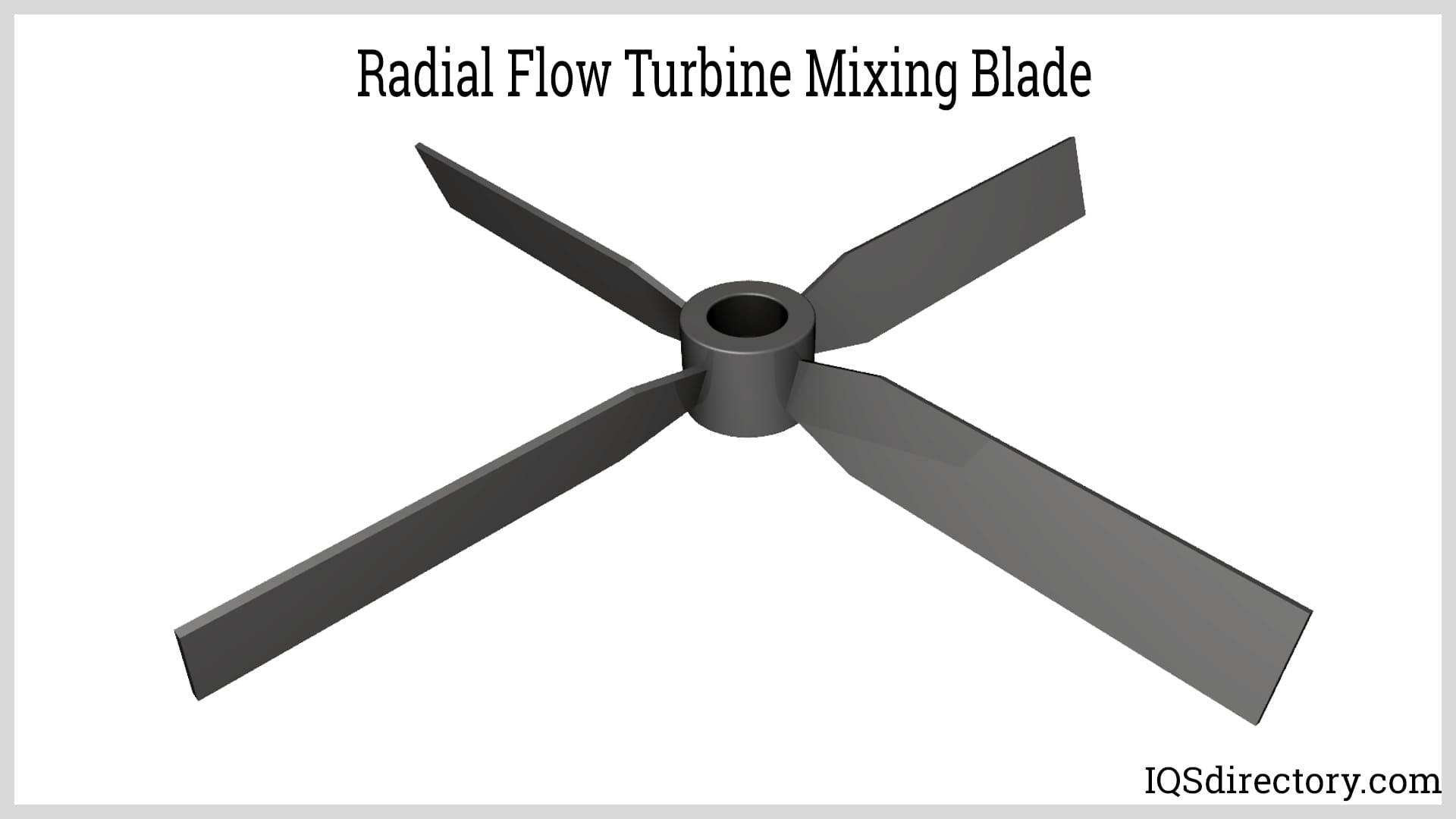

As with axial flow turbine mixing blades, radial flow turbine mixing blades are welded to their hub but have blade surfaces that are parallel to the shaft. The flow pattern created by radial flow turbines mixing blades moves mixed materials away from the impeller toward the sides of the mixing tank. The movement of the flow impacts the sides of the mixing tank and separates the flow into upward or downward motion. Radial flow turbine mixing blades are used in combination with gas sparging systems that have gas pumped into a liquid through a hollow sparge, a pipe or tube that injects a fluid, below the radial flow of the turbine mixing blades. As with axial turbine mixing blades, radial flow turbine mixing blades require significant torque and horsepower.

Although both axial and radial flow turbine mixing blades are commonly used, axial flow turbine mixing blades are used more than radial flow turbine mixing blades. Axial flow turbine mixing blades are designed to break up agglomerations. The 45° angle of the mixing blades has an edge for fluids to move over, creating a shear area. The applications that use radial flow turbine mixing blades the most are ones that require gas dispersion.

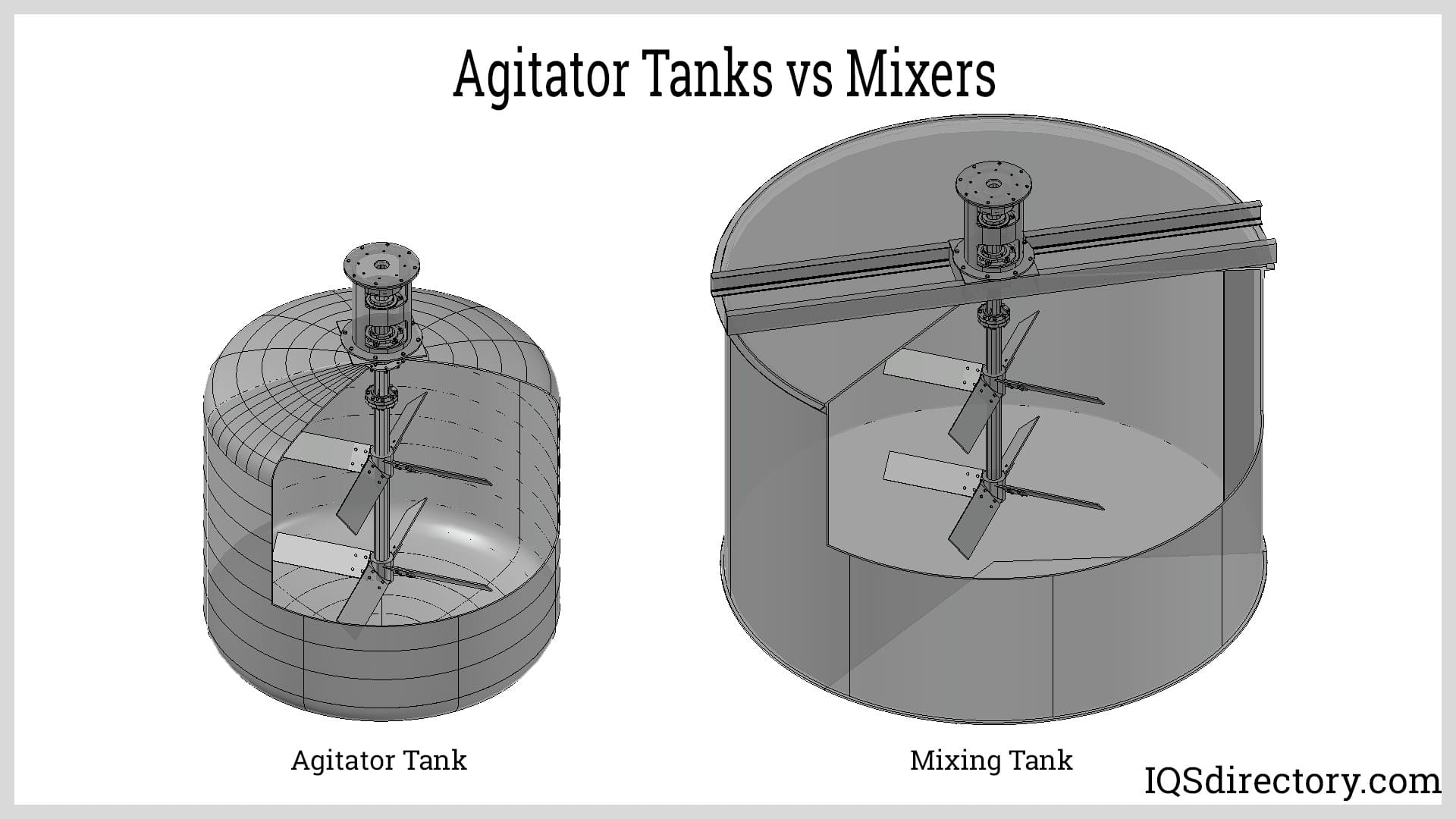

Agitation and mixing are fundamental industrial processes that are crucial for the homogenization and integration of ingredients and fluids. Their use is critical to the quality of final products in terms of consistency and stability. Agitation and mixing are necessary for the uniform distribution of ingredients and fluids to guarantee the efficacy of a product.

Some of the confusion regarding the difference between agitation and mixing is due to agitation being a part of the mixing process, which is not always the case. The difference between the procedures lies in their objectives and techniques. In all cases, the proper use of agitation and mixing improves efficiency, reduces energy consumption, and has minimum waste.

The movement in liquids created by agitation are circular, linear, or turbulent, which occur in accordance with equipment design and the objectives of a process. Agitation is used when it is necessary to maintain homogeneity, prevent sedimentation, and improve heat transfer. The overall goal is to ensure ingredients remain evenly distributed. Agitation focuses on maintaining movement in a fluid to achieve homogenization or heat transfer.

Frequently, agitation is described as the induced motion of particulate matter. During agitation, particles move in a specified way, which is usually a circular pattern. Unlike mixing, agitation can involve a single substance, like stirring a cup of coffee or tea. In a cement truck transporting cement, the purpose is not to mix the contents but to rotate the contents to prevent separation and solidification.

Mixing is a more robust process that refers to the combining of substances to form a homogeneous mixture. It involves a wide assortment of substances that includes gases, liquids, solids, and the combining of such materials. The ultimate goal of mixing is the even and uniform distribution of materials, ensuring that the final product has the same physical and chemical properties. The focus of mixing is combining materials to form a uniform homogeneous mixture by the random distribution of particles.

The difference between agitators and mixers is based on their sizes. Agitation is carried out in small agitation tanks using different patterns according to their weight while mixing requires the use of a mixing tank that uses fluid mechanics. The two processes have different torque ratings, surface areas, and spin rates. The movement of liquids by an agitator is done in accordance with a fluid's desired motion. With mixing, to achieve a constant solution from a set of ingredients, different shearing forces are provided by the mixing blades.

Each of the various types of mixing blades and impellers are found in agitators and mixers. With agitation, the purpose of mixing blades is to achieve axial flow while the flow in mixing varies between radial, axial, and tangential depending on the ingredients to be mixed.

The vast number of mixing blades on the market make it difficult to determine which making blade is the right one for an application. Mixing blade manufacturers work closely with their clients to determine the right mixing blade for a process. Although the expertise and skill of manufacturers is beneficial when choosing a mixing blade, it is advantageous to have rudimentary knowledge of mixing blades in order to speak authoritatively about them.

The first step in selecting a mixing blade is identifying the goal of the mixing process. Each of the functions of a mixing blade, blending, emulsification, and suspension, requires the use of a different mixing blade. The factors that determine the best results, such as vortex, high or low shear, heat distribution, or aeration, have to be examined as to which mixing blade will provide such factors to achieve the desired results.

Anyone associated with the mixing industry is well aware of the type of flow that each mixing blade provides. The primary flow patterns, axial, radial, and tangential, determine the flow pattern and movement of materials as they mix to form a homogeneous mixture. Axial flow is used for liquid-to-liquid mixtures, heat transfer, and stirring. Radial flow has a high shear and turbulent mixing process used for gas to liquid dispersion and emulsion mixing. Materials with a high viscosity over 20,000 cP require the use of mixer blades that produce a tangential flow.

Mixing blades are attached to a shaft to form an impeller. The size of an impeller is determined by its diameter and the diameter of the tank or vessel in which it will be used. The rule for axial and radial flow patterns is an impeller diameter that is one third of a tank’s diameter. With axial impellers, diameters should be less than 70% of a tank’s diameter to avoid obstructing the recirculation. The largest diameters of impellers are anchor impellers, which are 90% of the diameter of a mixing tank.

As with flow patterns, viscosity is continually on the minds of mixing experts since it determines the type, strength, materials, and shape of mixing blades. Viscosity is measured in centipoise (cP), a factor that defines the thickness of a material or its resistance to flow. As the centipoise value increases, the thicker, more viscous a liquid is. The measurements of centipoise is the internal resistance of flow provided by a liquid, which is the amount of friction there is between layers of a moving liquid. Water has the least resistance and has a centipoise of 1 cP. Mixing blade manufacturers closely study centipoise due to it being a crucial factor in the effectiveness of a mixing blade.

Propeller impellers are used for low viscosity substances, while pitched blade turbine impeller mixing blades and vertical mixing blade turbines are used for high viscosity substances. The highest viscosity materials require the use of anchor paddles and square mixing blades.

| Viscosities by Centipoise | |

|---|---|

| Item | Approximate Viscosity in Centipoise (cps) |

| Water at 70 | 1 to 5 cps |

| Blood | 10 to 20 cps |

| Antifreeze | 20 cps |

| Corn Oil or Motor Oil SAE 10 | 50 to 100 cps |

| Maple Syrup or Motor Oil SAE 30 | 150 to 200 cps |

| Castor Oil or Motor Oil SAE 40 | 250 to 500 cps |

| Glycerin or Moto Oil SAE 60 | 1,000 to 2,000 cps |

| Honey or Corn Syrup | 2,000 to 3,000 cps |

| Blackstrap Molasses | 5,000 to 10,000 cps |

| Chocolate Syrup | 10,000 to 25,000 cps |

| Ketchup or Mustard | 50,000 to 70,000 cps |

| Tomato Paste or Peanut Butter | 500,000 cps |

| Shortening or Lard | 1,000,000 to 2,000,000 cps |

| Caulking Compound | 5,000,000 to 10,000,000 cps |

| Window Putty | 100,000,000 cps |

Another factor that is crucial to the success of a mixing blade is whether its shaft fits into the chuck of a mixer. Impeller mixing blades are designed to fit on a shaft that connects to a mixer using set screws. Large impellers that require higher torque from a mixer’s motor have to be exceptionally secure to avoid accidents.

Custom impeller blades, such as collapsible blades, are required for unusual or unique mixing applications. Mixing blade manufacturers work with their clients to provide custom designs that meet the parameters of a specific type of material or application. Manufacturers are able to provide sizes, shapes, and dimensions that custom fit any circumstances.

The proper placement of impeller mixing blades is critical to the achievement of uniform mixing and the prevention of vortex formation and dead zones. Impeller mixing blades are designed to produce a circulation pattern with proper energy distribution. Placement is meticulously calculated based on tank size and application requirements. Typical placement is one third the height of the liquid level with adjustments being made based on the specifics of the mixing process. This aspect of mixing blade use requires the expertise of the technicians and experts at mixing blade manufacturers.

When an impeller mixing blade is placed properly, it provides maximum mixing with minimal energy consumption. The wide variety of impeller mixing blade designs makes it possible to offer ones that are exceptionally efficient and energy saving. As with all aspects of manufacturing, energy costs are a primary concern and can be avoided for impeller mixing blades by matching the right mixing blades with their designed application.

Drum mixers are mixers that are used for mixing free flowing materials by rotating them forward and reverse with welded chutes or flights that fluidize the mixture. The design of drum mixers gives them...

An emulsifier is an emulsion device used for colloidal dispersion of liquid droplets of immiscible liquids in the presence of an emulsifying agent. It enables the combining of non-soluble solutions or liquids...

High shear mixers, also known as high shear reactors (HSRs), rotor-stator mixers, and high shear homogenizers, are used to emulsify, homogenize, disperse, grind and/or dissolve immiscible mixtures with components of the same or different phases...

A homogenizer is a type of mixing equipment used to create a uniform and consistent mixture. It works by breaking the components and evenly distributing them throughout the solution. The components are either immiscible, have varying sizes, or are in different phases from each other...

An industrial blender is a machine for large-scale production that consists of a large tank capable of mixing and blending batches of manufacturing materials to create a reaction between the materials. The many uses for industrial blenders are due to their capacity and...

A mill is a mechanical device that is often a structure, appliance, or machine that is used to break down solid materials into smaller pieces by cutting, grinding, or crushing them. Many industrial processes involve...

A tank mixer is a mixing device that blends several different ingredients in a single tank to make a single solution. It is a mixing process capable of mixing wettable powders, liquids, emulsifiable concentrates, and surfactants. They mix and blend...

A mixer is a complex and precise tool that is used in combining and mixing of substances and chemicals for manufacturing, production, and industrial use. There are many types of industrial mixers including...

A plastic tank is a large capacity liquid or granular storage unit that can be vertical, horizontal, below or above ground, as well as movable. They are designed to hold several gallons of a variety of substances for long periods without experiencing wear, weathering, or deterioration...

A plastic water tank is a large capacity container designed to store water for household, agricultural, irrigation, and industrial manufacturing use. There are various types of water tanks produced to meet the needs of specific applications, with...

A poly tank is a plastic storage tank used to store, transport, and collect water, other liquids, and granular or powder materials. They are made of polyethylene or polypropylene and are a cost effective, lightweight, and easy to handle...

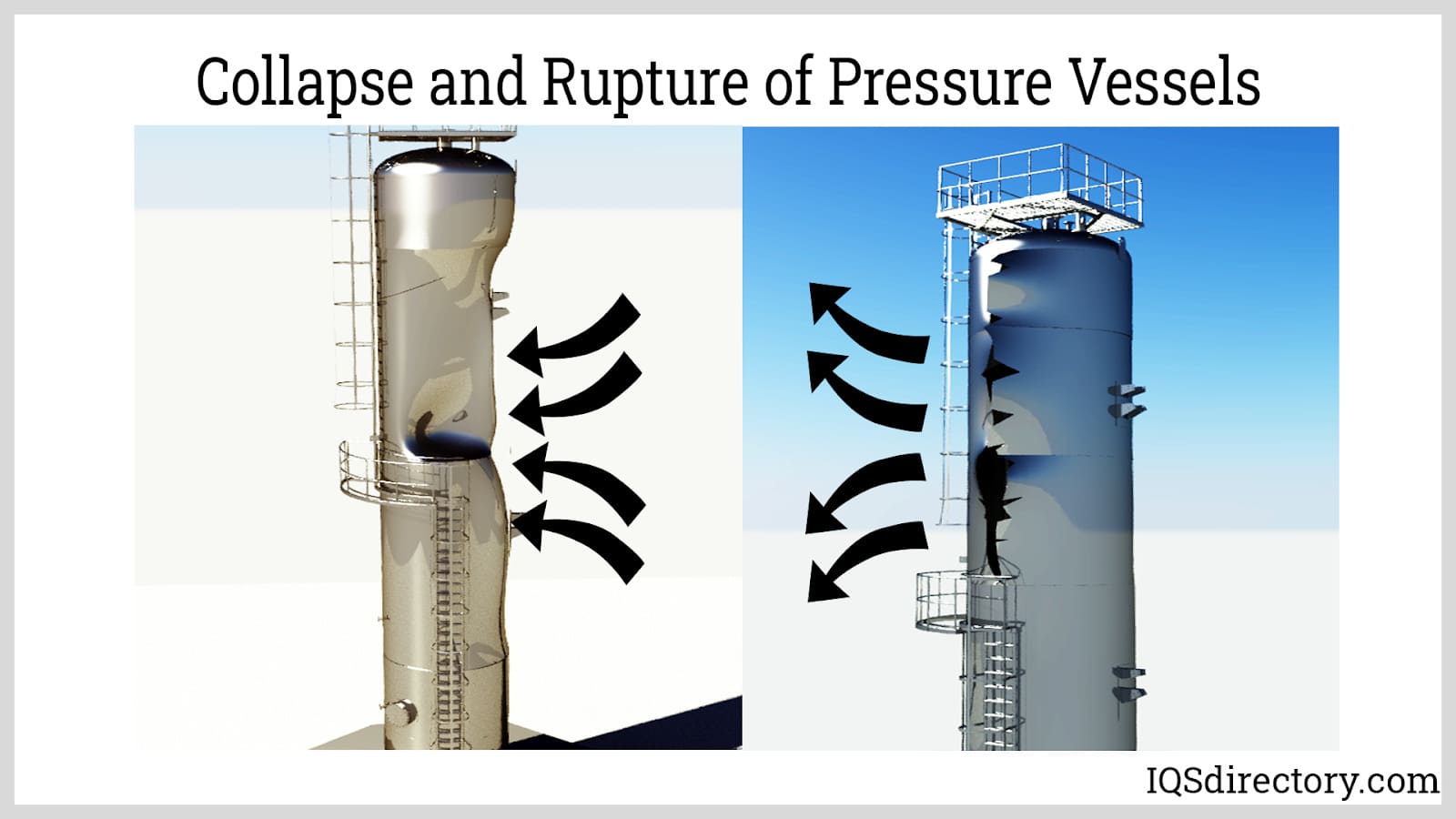

Pressure tanks are vessels that are used to store, hold, and/or convey gasses, vapors and fluids at pressures greater than atmospheric pressure, also known as high pressures...

Pressure vessels are enclosed containers used to hold liquids, vapors, and gases at a pressure significantly higher or lower than the ambient pressure. They are widely used in various industries such as...

Stainless steel tanks are widely used in food, beverage, dairy, medicine, cosmetics, and other manufacturing processes where cleanliness and purity are important. These are also used in industrial plants for storing chemicals and gases where strong resistance from chemical degradation is required...