Solenoid Valves

Solenoid valves are electromechanical valves that are used to control the flow of fluid or gas. Because they focus on control of gas and fluid flow, they can also be called control valves.

Solenoid valve pressure is measured in pounds per square inch (psi), bars, or both. In the United States, solenoid valve manufacturers and solenoid valve users usually use psi.

Quick links to Solenoid Valves Information

The History of Solenoid Valves

The solenoid control valve was first manufactured and sold in 1910, by a company called ASCO Numatics.

In the 1950s, companies began manufacturing versions of the solenoid valve with plastic molded bodies. This made the solenoid valve more chemical resistant, corrosion resistant, and generally more reliable and efficient.

Over the years, solenoid valves have evolved to become better and better. For example, beginning in the 1970s, customers started using automatic shut-off valves, which are safer and easier to control than manual control shut-off valves.

Solenoid valve standardization came about in the 1990s. With this change came the possibility of greater international trade, easier repairs, and easier collaborations between companies.

Finally, the most recent development in the evolution of solenoid valves has been sustainable design. Newer standards, such as those put out by RoHS, have restricted the use of hazardous substances in valve manufacturing. This change is helping push engineers to innovate and find materials that are better for the environment and better for human health.

Advantages of Solenoid Valves

There are many beneficial characteristics of solenoid valves that give them advantages over other valve types. For example, since solenoid valves are powered by natural pressure and electromagnetic force, they generally have fewer moving parts than other valves. This is widely considered to be a good design, since moving parts require maintenance.

In addition, solenoid valves can be easily operated by remote devices that activate the solenoid coil, making solenoid valves extremely useful for hazardous applications. Also, solenoid valves can use either hydraulic or pneumatic power because both can be activated or piloted by solenoids. However, pneumatic power is more commonly used because it is considered cleaner and lower maintenance than hydraulic power, due to the absence of degrading fluids which produce waste and must be maintained.

Finally, solenoid valves offer rapid and safe switching, compact design, high reliability and typically long service life.

Design of Solenoid Valves

- Production Process

- Solenoid valve components are fabricated through processes such as coil winding, CNC machining, injection molding and laser welding. Once the components are made, manufacturers assemble them.

- The primary components to come out of these various processes (and others) are the solenoid coil and the valve. Other components include: a spring, an inlet port, an outlet port, an orifice (the connection between the inlet port and outlet port) and an actuator (a plunger, also known as a ferromagnetic core).

- In addition, solenoid valves come with a range of coil housing types. American National Standards Institute (ANSI) and National Electrical Manufacturers Association (NEMA) designates standards for suitability of a valve. The general rule is, the higher the ANSI/NEMA type number, the greater the exposure to the elements that can be permitted.

- A NEMA Type 1 is well suited for indoor applications, whereas NEMA Type 4 is suitable for outdoors. Gradually the number goes upwards, and a NEMA Type 7 or Type 9 is required for locations where there are explosive vapors or dust.

- Valve Materials

- Manufacturing processes vary based on a number of factors, including the materials with which manufacturers are working, which may be quite a few; solenoid valves can be constructed from a range of materials, including several plastics and metals. Plastic solenoid valves can be constructed PTFE, PVC, natural polypropylene, CPVC and PVD. Metal solenoid valves can be constructed from materials such as stainless steel, bronze, aluminum and brass. Some solenoid valves include seals. These are typically made from some sort of rubber; the most common type of valve seal is the viton seal.

- Design Aspects of Solenoid Valves

- Manufacturers make design choices, including material, size, configuration, type, and number of ports, based on application.

- A brass solenoid valve, for example, is good for work with substances like light oil, water and inert gas. A brass valve would not, however, be appropriate for use with a highly corrosive substance, because brass is not strong enough. A PTFE solenoid valve, on the other hand, can handle corrosive fluid and harsher gas. Meanwhile, a stainless-steel solenoid valve is ideal for chemical processing applications; this is because stainless steel has qualities of high corrosion and abrasion resistance, which allow for excellent control of acids, gas, analytical reagents, and bases. In addition, a miniature solenoid valve is a good choice for use with medical applications such as gas analyzers, biotechnology equipment, and portable medical devices. Finally, a high-pressure solenoid valve allows gas and fluid flow control in areas in which other valves could not operate, such as potentially dangerous machinery or inaccessible lines.

- Valve Customization

- There are a number of ways in which manufacturers can customize a solenoid valve. For example, while manufacturers typically create 2-way solenoid valves, meaning that they have two connection areas and one orifice, they can also make 3-way solenoid valves. In addition, while a solenoid valve typically operates using a 12-volt DC power source, manufacturers can also customize it to work with 3v, 6v or 24-volt power sources. Manufacturers can also customize a solenoid valve via: size, spring return, pressure levels, etc. If you’re interested, don’t hesitate to ask about different brass alloys or stainless-steel grades.

Solenoid Valve Images, Diagrams and Visual Concepts

Solenoid valve used to regulate flow of liquid or gas.

Solenoid valve used to regulate flow of liquid or gas.

The parts of a solenoid valve are separated into two major components the solenoid and the valve body.

The parts of a solenoid valve are separated into two major components the solenoid and the valve body.

A special type of solenoid valve that provides a continuous variation in flow or pressure in response to electrical input.

A special type of solenoid valve that provides a continuous variation in flow or pressure in response to electrical input.

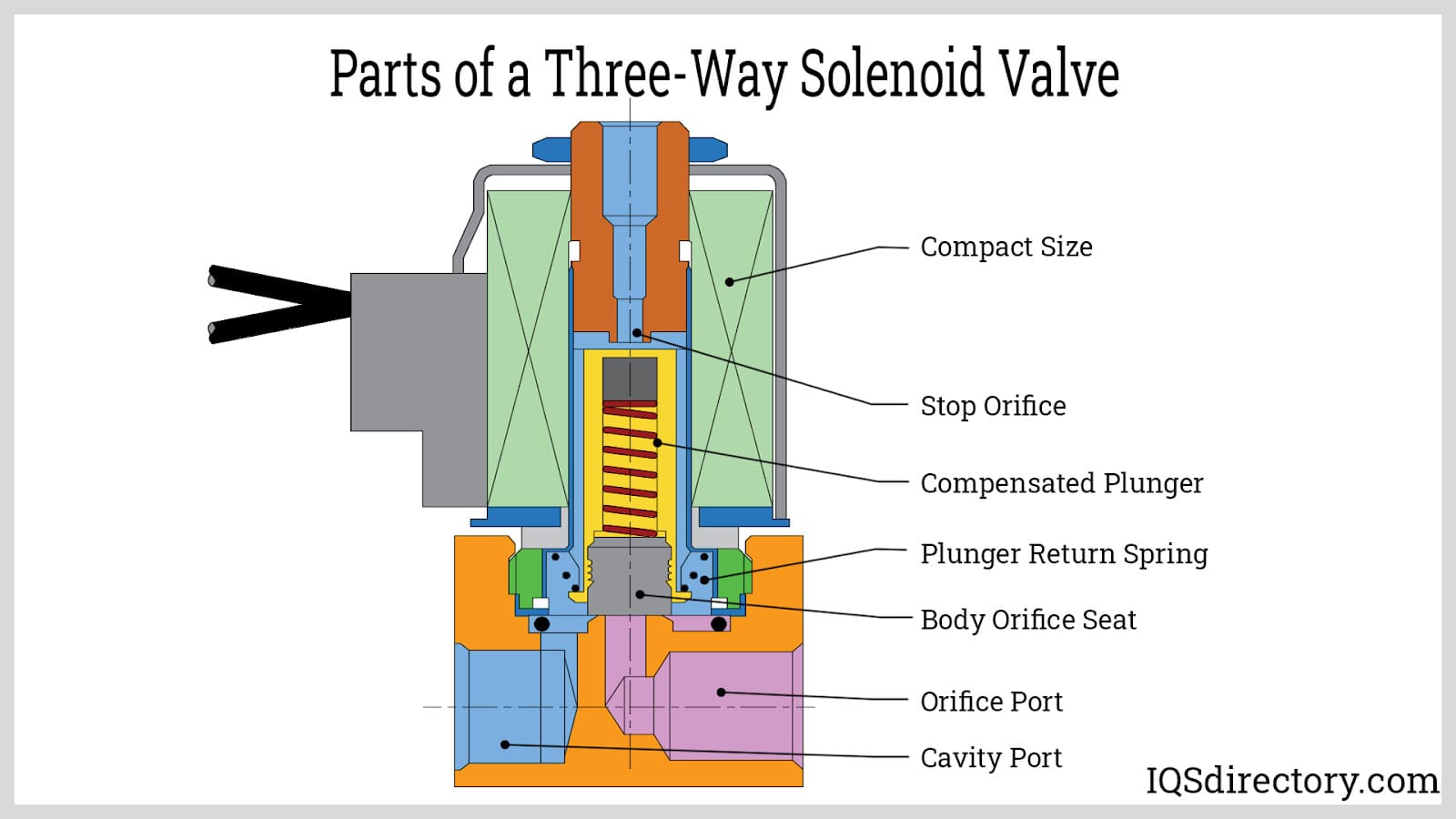

A three-way solenoid valve which allows for three connections the body orifice, a cavity, and a stop port.

A three-way solenoid valve which allows for three connections the body orifice, a cavity, and a stop port.

FM Approvals are an international leader in third-party testing and certified to test property loss prevention products and services for quality, technical integrity and performance.

FM Approvals are an international leader in third-party testing and certified to test property loss prevention products and services for quality, technical integrity and performance.

Solenoid Valve Types

- 3-Way Solenoid Valves

- For hydraulic and pneumatic applications. 3-Way solenoid valves have three ports, one being the pressure port, one the tank and the last, the service port.

- 12 Volt Solenoid Valves

- The standard amount of voltages supplied by the direct current (DC) power source.

- Air Valves

- Regulate the release of air.

- Gas Solenoid Valves

- One of the most common flow control valves that handle and control the flow of gaseous media.

- Hydraulic Solenoid Valves

- Use fluid pressure and are ported through the return line to the reservoir.

- Miniature Solenoid Valves

- Fit easily into small areas and also measure or dispense small amounts of material. Mini solenoid valves are particularly useful in medical applications.

- Direct Operated

- The orifice of this solenoid valve type is closed by a plunger with a flow-choking rubber gasket on its bottom. The mediums that flow through here have relatively small flow rates; direct operated solenoid valves are used from 0 bar port pressure (0 psi), up to the maximum permissible pressure. They can be 2 or 4 way, and they can be Normally Closed or Normally Open.

- Indirect Operated

- This type of valve, which is normally closed, regulates opening and closing by the differential pressure of the medium. They need a minimum differential pressure to operate, which is around 0.5 bar (7.25 psi). They have applications only in devices that need one-way flow, such as in showers, irrigation systems, and car wash systems.

- Semi-Direct Operated Solenoid Valve

- Combine the attributes of direct and indirect valves, so that they can work from 0 bar (0 psi), and handle a high-flow rate. They are normally used as high-pressure solenoid valves.

- Purge Valve

- Typically made from a strong metal like stainless steel, purge valves are a special kind of valve used in vehicles. They are part of the EVAP system, which is installed in order to prevent fuel vapors from the engine from escaping into the atmosphere. The system traps vapors from the fuel tank and temporarily stores them in a charcoal canister. When the engine is running under certain conditions, the fuel vapors are purged from the canister and burned inside the engine. The purge valve, which is normally closed, carefully controls the flow of fuel vapor that is purged.

- Actuated Ball Valve

- Mostly used to shut flow off or turn flow on, not necessarily for flow control. It is normally closed. A ball valve contains a ball with a small hole in the middle that helps to control the flow of materials through the pipe, and an actuator that rotates the ball to start or stop flow. While there are many applications in which solenoid valves should be used instead of ball valves, such as low flow and high-speed cycles, there are also applications in which a ball valve should be used instead of a solenoid valve, such as high flow and applications requiring a manual override option.

- Poppet Valve

- Also known as a mushroom valve, is a stainless steel or brass valve used for controlling timing and quantity of air and gas flow inside an engine. It can be a closed or open type. It consists of a round or oval hole, and a typically disk-shaped tapered plug. The plug is located on the end of a shaft that is also called a valve stem.

- Plastic Solenoid Valves

- Primarily used in applications that involve corrosion or chemicals.

- Pneumatic Solenoid Valves

- Similar to the hydraulic version in that they both use pressure. However, the return port of a pneumatic valve, which uses air, is exhausted to the atmosphere. One of the most common types, pneumatic solenoid valves are used to regulate the flow of air and other gas types through the use of a diaphragm and gas pressure. While some pneumatic valves regulate air or gas flow at relatively normal pressure levels, such as in-home heating and cooling applications, other pneumatic valves are designed to output gas at extremely high-pressure levels, as they do with power tools. This type of solenoid valve can also be referred to as a pneumatic valve, a gas solenoid valve, a diaphragm solenoid valve, a solenoid air valve, or simply as an air valve.

- High Pressure Solenoid Valves

- Solenoid valves that control the flow of fluids or gases in high pressure applications.

- Proportional Solenoid Valves

- Have direct-acting control valves with linear characteristics.Proportional solenoid valves control accuracy, hysteresis and repeatability within close tolerances. Proportional solenoid valves function by utilizing the same elements as regular pneumatic or hydraulic solenoid valves, but with more advanced flow control capabilities. These capabilities allow them variable flow that is proportional to the electrical control signal.

- Rotary Solenoids Valves

- Have three bearing balls that ride on an inclined plane and turn linear motion into rotary motion. The magnetic arrangement permits direct rotational motion.

- Solenoid Air Valve Controls

- Electrical valves that regulate the flow of air.

- Solenoid Water Valves

- Electrical devices that control water flow. Also known as a hydraulic solenoid valve, the solenoid water valve is less common than the pneumatic solenoid valve, but still vital to many applications. Solenoid water valves are typically Normally Closed, as well as pilot-operated, as opposed to direct-acting. Brass is usually acceptable for their construction, though some clients may opt for carbon steel or stainless steel.

- Stainless Steel Solenoid Valves

- Electromechanical valves that are used to control the flow of liquids or gases; they are ideal for chemical processing applications due to the high corrosion and abrasion resistant properties of stainless steel that allow for excellent control of acids, analytical reagents and bases.

Solenoid Valve Applications

Solenoid valves are fabricated in order to serve flow control applications of all kinds. These include: shutting off, dose, releasing, mixing or distributing fluid or gas.

Solenoid valves are used in a wide range of industries; particularly, they’re popular for use in HVAC filters and air conditioning, refrigeration, automotive engineering, hydraulics, pneumatics, and household appliances.

Below are some great examples of purposes they serve in these various industries.

- Refrigeration

- In air conditioning systems, electric solenoid valves are used to control the flow of the refrigerant to heat exchangers. The efficiency of an air conditioning unit or refrigeration unit can be affected greatly, if a defective solenoid is used.

- Pneumatic and Hydraulic Systems

- Pneumatic conveyor systems require specially designed pneumatic solenoid valves, or air valves; similarly, hydraulic systems have their own valves. They are used to regulate the flow to hydraulic and pneumatic motors, buffers and cylinders.

- Car Wash

- Solenoid valves used in car wash systems are Normally Closed (NC) and made from stainless steel. They regulate the flow of detergent mixed water and release it at high pressure. For other applications in car washes, low-pressure valves are used; for example, foam brushes use Normally Open (NO) valves.

- Compressed Air Systems

- In compressed air systems, solenoid valves are used to control air supply, actuators, or as an unloader valve. Almost all compressed air systems have a high Kv value, which minimizes the pressure drop. Usually, direct valves are generally used since there is always a pressure difference. In some cases of low pressure, such as after a reducer, a semi-direct or direct type of valve performs better.

- Central Heating

- One home appliance that relies on a control valve and pressure switches is a central heating system. The control valve works in conjunction with the thermostat, controlling the flow of hot water to the radiators.

- Clothes and Dish Washing

- All washing machines and dishwashers make use of solenoid valves that control and provide the correct amount of water.

- Agricultural Irrigation

- Solenoid valves are used for high flow rate irrigation supply.

Features of Solenoid Valves

In short, solenoid valves work like this: as electric current passes through the coil, it creates a magnetic field, which in turn, exerts force on the plunger; the plunger moves under the action of magnetic field towards the center of the coil, and in the process, opens the orifice. A spring returns both the plunger and the valve back to their un-activated state when the current flow is no longer present.

There are two main ways that solenoid valves function; this is based on whether they are “normally closed” or “normally open.”

- Normally Closed (NC)

- In a normally closed (NC) valve, a plunging pin or rod within the valve is held in place by a solenoid coil to block flow. In order for gas or fluid to flow through, an electromagnetic charge is run through the solenoid valve coil, which becomes active and lifts the plunger out of the passage to allow flow.

- Normally Open (NO)

- Normally open (NO) valves are the opposite; they remain open, with gas flowing, until the solenoid is activated and pushes down the plunger, blocking flow and creating pressure to keep the valve closed. Another variation in how they function is based on whether they are direct-acting or pilot-operated.

- Direct-Acting Solenoid Valve

- Direct-acting solenoid valves have a plunger that is in direct contact with the in-flow opening in the valve body, or orifice. This plunger is used to open and close the orifice, which permits or hinders flow of gas.

- Pilot-Operated Solenoid Valve

- The pilot-operated valve, or solenoid pilot valve, which is actually a combination of a pneumatic or hydraulic valve and a smaller solenoid valve, works with a diaphragm rather than a plunger, using differential pressure to control the flow of gas or fluid. Solenoid valves, no matter the type, stand out among other valves because they control gas and fluid flow.

Installing Solenoid Valves

Solenoid valves are installed at critical points, giving any system the ability to work optimally for several years. It’s important that they’re installed in a dry and well-ventilated environment, because they can get quite hot during operation. When you do install it, check for an arrow on the valve body, which indicates flow direction, and install it in that direction. If you’re not confident in putting it together yourself, that’s okay! Turn to a professional, such as your supplier or someone recommended by your supplier, to install it for you.

Standards and Specifications for Solenoid Valves

Depending on your application, there are many standards to which you and your manufacturer must adhere when operating and manufacturing solenoid valves, respectively.

For example, the U.S. state drinking water and plumbing codes require RO equipment to meet NSF 61-G, a leachate and lead-free regulation. A buyer or manufacturer should check if Original Equipment Manufacturers (OEMs) are complying with the regulations. A special caution is advised while specifying composite valves for the RO systems. In North American locations, like Vermont or California, all RO systems must have a NSF certification.

Also, to reduce lead amounts in drinking water, all pipes, plumbing fittings, fixtures and flow control related products, including electric solenoid valves, should be lead free, one should look for valves that pass and possess all the certifications. For international use, the valves should get certification from NSF International and accredited by ANSI and the Standards Council of Canada.

Things to Consider When Purchasing Solenoid Valves

To select a high quality and appropriate valve, there are a number of questions you must ask, other than usual right size, pressure level, and wattage; these are related to: availability, certifications, ease of assembly, and support.

These factors have a significant impact on equipment life, availability, and time-to-market.

- Availability

- Lean manufacturing methodologies demand that OEM provide composite valves readily. Non-availability of parts results in uncertain scheduling and longer lead times, which ultimately threatens assembly line and target dates.

- When evaluating a valve maker, determine whether the supplier has quick-shipment programs and what the standard lead times and delivery schedules are.

- Certification

- Make sure that the solenoid valve manufacturer you select can and will build your valves to the standards you require; ask them for certification. A trustworthy manufacturer will have no problem with this.

- Installation

- Most of the time, integration of components into systems proves time-consuming and difficult. This mainly happens when vendors present pressure switches in closed versions, which may result in purchasing diverter valves. Therefore, it is important to find a vendor that provides valves with both open and normally closed versions.

- Support System

- Other than hardware characteristics, you need to have a proper support system from the vendors. Some suppliers put resources and energy into maintaining a high-quality support system and some do not. In addition, some vendors end up providing bad service without intending to because of a geographical disadvantage. That is why, for North American customers, Asian and European products are not deemed appropriate.

- Find a vendor that can answer your queries related to 2-way solenoid valves, 4-way solenoid valves or 12-volt solenoid valves, pressure levels, etc. Make sure they can give technical fixes and provide onsite training. Most important of all, find a vendor that takes into consideration all of your requirements, respects your timeline and budget, and puts you at ease. Start your search for the right supplier by browsing the list of top-notch companies that we have listed near the top of this page.

Proper Care for Solenoid Valves

It’s important that you clean your solenoid valves from time to time. Fortunately, if you have proper tools, like those provided in a maintenance kit, you most likely won’t have to completely dismantle your valve assembly in order to clean it. In addition to your routine cleaning regimen, you should clean your valve if and when notice: excessive noise, sluggish operation, or leakage.

To help your valve system run even better: never use mismatched fluids that could cause untimely wear; do not allow substances inside your valves to freeze, and make sure you always keep it at appropriate pressures and temperatures.

Accessories for Solenoid Valves

The most common solenoid valve accessories are connectors, which help you set up more sophisticated assemblies. Others include lights, gaskets, screws, and manifolds. To see if any of these accessories will benefit your application, talk to your manufacturer.

Solenoid Valve Terms

- Analog Position Sensor

- Position sensor whose voltage output differs through various values.

- Bubble-Tight Sealing

- A circumstance in which there is no leakage of air from between the internal sealed ports of the valve, whether in the energized position or not, in a five second time period. Soap bubbles are used to detect leakage.

- Closed State

- A situation in which the tubing is pinched in the valve.

- Coil Voltage

- The maximum voltage to which the coil must be energized for the valve to achieve its highest specific capacity.

- Continuous Duty

- Energizing a solenoid valve at a constant level of power for its entire on-time.

- Current Drain

- The quantity of current in amperes flowing through a solenoid valve coil when it is energized.

- Cycle

- The normal opening and closing of a valve.

- Cycle Rate

- The measure of how many times a valve is able to open and close within a set period of time.

- Duty Cycle

- Proportion of time that the solenoid receives power.

- Flow Control

- A feature that allows for the manual reducing or controlling of flow.

- Flux Plate

- Magnetic steel plate that helps transmit magnetic flux in the magnetic circuit of a solenoid valve from the enclosure to the sleeve construction. A flux plate is necessary on valves with a body construction consisting of a non-metallic body.

- Frequency Response

- Changes with the output variable in steady-state conditions, caused by a sinusoidal input variable.

- Gain

- Association of input to output or the sensitivity of a device.

- Hysteresis

- The variation between up-scale and down-scale outcomes in equipment response, when exposed to the same input from the opposite direction.

- Normally Closed

- A term that refers to a valve that is closed when unenergized.

- Normally Open

- A term that refers to a valve that is open when unenergized.

- Open Loop

- A system in which direct feedback is not supplied to gauge the response.

- Position Sensing

- Employing electronic sensors to watch the position of the valve and provide electronic feedback.

- Pulse and Hold

- Increases function of solenoid valves by reducing power consumption and heat generation. The valve is opened and held open at decreased power.

- Pulse Width Modulation (PWM)

- A technique that utilizes a modulated wave function to control analog devices.

- Repeatability

- The ability of the equipment to generate consistent results on successive tests.

- Stroke

- The space the plunger covers during a state change.