Linear Actuators

Many modern linear actuators don't look substantially different in form or function from their earliest antecedents, though the precision with which they're produced and the power sources generating the motion have changed significantly since the production of the first linear actuator.

It's difficult to pin down an exact date for the creation of the first linear actuators, but tools resembling those used in modern machine shops likely arose during the Industrial Revolution. By the 1800s, English and American machinists, manufacturers, and industrialists were working with a number of tools reliant upon linear actuators.

Several basic types of linear actuators were invented or standardized through the 1800s along with the further evolution of machining, hydraulics, and pneumatics actuators.

Moving to the latter half of the 20th century, Bent Johnson invented the first electric linear actuator to improve a friend's wheelchair in 1979. Within a few years, the electric actuator had spread to agriculture and other industries, where it then revolutionized automation in many fields.

Today, developments in engineering, materials, and physics have allowed the invention of several forms of the linear actuator, and the continued refinement of various technologies used in the production of actuators. Even the simplest micro linear actuator from 2017 utilizes centuries of advancements in machining, standards, and materials manufacturing in its design.

Quick links to Linear Actuators Information

Designing and Engineering Linear Actuators

When determining a design for your linear actuator or actuators, there are plenty of factors to take into consideration. One of the first determinations you’ll need to make is the viability of standard linear actuator designs for your project. If standard cannot be made to work efficiently, it's time to start looking at custom options.

Important requirements to consider when ordering a linear actuator:

- Size

- Input Voltage

- Load Speed

- Load Capacity in Lbs

- Environment

- IP Rate

- Production

- Material

Linear Actuators Images, Diagrams and Visual Concepts

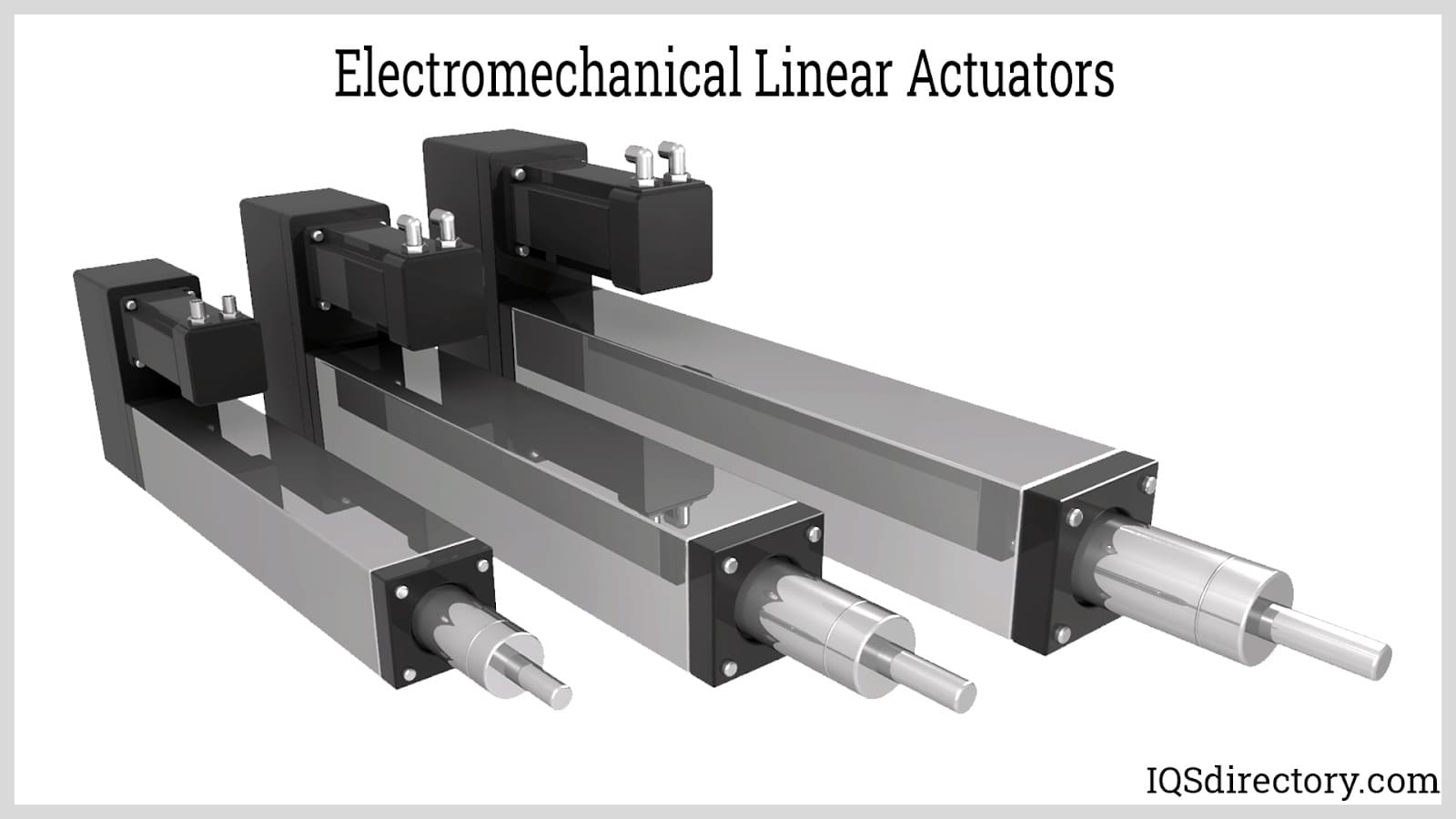

An example of a linear actuator that uses a motor and a series of gears for motion.

An example of a linear actuator that uses a motor and a series of gears for motion.

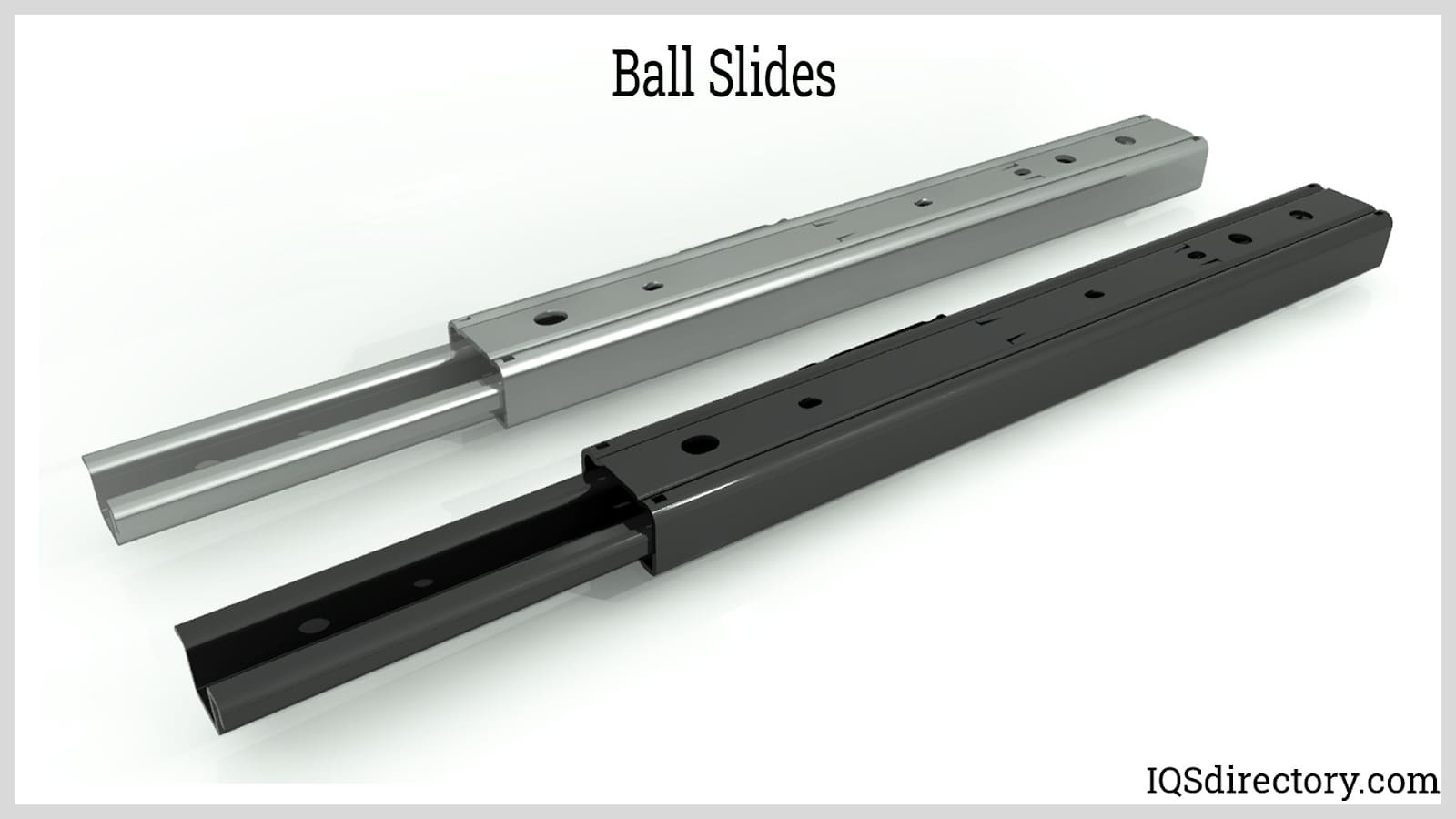

Ball-guided positioning linear slides that have precision accuracy and sturdy.

Ball-guided positioning linear slides that have precision accuracy and sturdy.

The motion of a linear actuator when supplied with enough force or energy.

The motion of a linear actuator when supplied with enough force or energy.

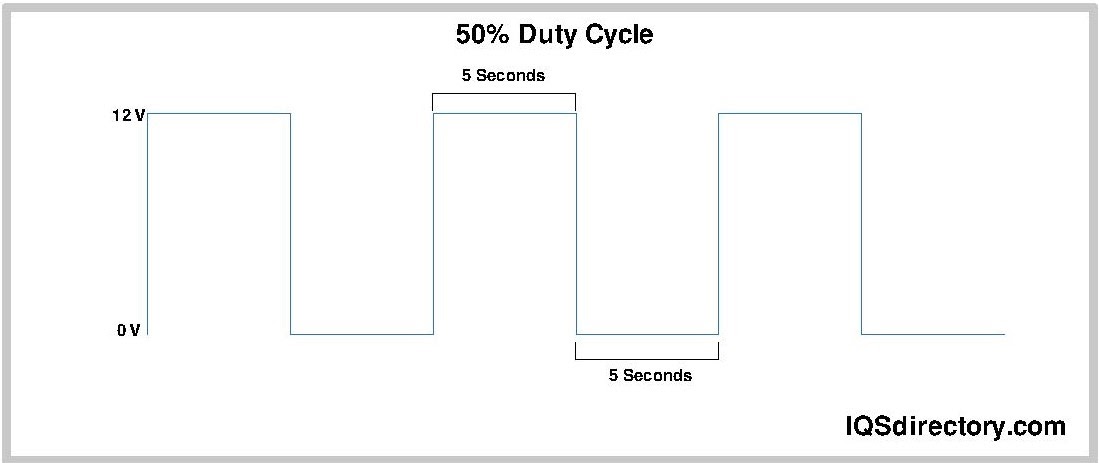

The duty life cycle of a linear actuator when the cycle is set at 50 percent.

The duty life cycle of a linear actuator when the cycle is set at 50 percent.

Notable Types of Linear Actuators

- Mechanical

- Simple linear actuator models, which typically convert rotary motion to linear motion. Normal ball screw actuators, leadscrews, rack and pinion, belt drive, and cam actuators all fall into this category.

- Hydraulic

- Also called hydraulic cylinders, these linear actuators involve a hollow cylinder with a piston inserted into it. The incompressible nature of liquids allows unbalanced pressure on the piston to create linear displacement. This category of actuator includes hydraulic car jacks and similar devices, but more commonly refers to devices leveraging a hydraulic pump for force.

- Piezoelectric

- Linear actuators which leverage the property of certain materials to expand with the application of voltage (known as the piezoelectric effect). You'll see these discussed as ultrasonic actuators and used in the manipulation of fluid films. The relative weakness of the effect makes piezoelectric linear actuators a choice for applications requiring highly precise positioning with short ranges of motion repeatability with piezoelectric actuators can be a concern.

- Electro-Mechanical

- The same basic mechanism seen in various mechanical actuators drives the linear motion of an electro-mechanical actuator but uses an electric servo motor instead to generate rotary motion rather than with a knob or handle. There are a large number of variants on the basic electro-mechanical linear actuator, including but not limited to:

- Simplified Design

- Standard Design

- Compact Designs

- Linear Motors

- A type of motor similar to a rotary electric motor, but which utilizes repeated magnetic field structures across the length of the actuator to produce motion. Doesn't require a lead screw for conversion due to the motion of the motor, but offers a fairly low load capacity due to the limitations of the materials used. Viable in many environments which would otherwise be hostile to motors and linear actuators and long-lasting by nature.

- Telescoping Linear Actuator

- Comprises various types of specialized actuators used where space is limited. These include but are not limited to:

- Telescopic Cylinder Actuator

- Rigid Belt Actuator

- Segmented Spindle

- Rigid Chain Actuator

- Helical Band Actuator

Linear Actuator Accessories

The specific application and type of linear actuator you're using may require or suggest the use of various additional components, tools, and accessories.

For example, with electro-mechanical linear actuators, you may need to use speed controllers, digital timers, fuses, monitoring tools, and various other electrical accessories to optimize the use and management of your actuator.

Some makers may also offer customized accessories for adjusting standardized actuators to specific tasks or for simple convenience and ease of use. Be sure to ask your manufacturer about any recommended or available accessories for use with your actuators.

Linear Actuator Maintenance and Storage

The wide variety of applications and the many fine details of using linear actuators make it difficult to offer universal instructions for their implementation. Follow manufacturer instructions and the advice of your mechanics and engineers for optimal efficiency, efficacy, and safety.

- Installation of Linear Actuators

- While all linear actuator installations will be different, these are a few key suggestions you'll want to keep in mind regardless of any specifics:

- Know your goals and what to expect in advance.

- Familiarize yourself with instructions before putting anything together.

- Follow all manufacturer instructions for all involved parts and systems.

- Check components individually if possible before starting the system.

- If something looks, feels, or sounds wrong, stop and confirm with the manufacturer.

- Linear Actuator Maintenance

- A linear actuator should be attended to frequently by someone familiar with the component and its function. As a general rule, if something looks wrong, sounds wrong, or feels wrong in operation, it deserves attention, even if it hasn't become a problem yet.

- When a linear actuator goes bad, it can go very bad, with implications for the rest of your system. Take the time to identify and resolve problems with your actuators early and they'll cost you far less time and money in the future.

- If your linear actuator appears to have a problem, your best bet for identifying and resolving it will be to check back with the manufacturer. The detailed specifications of linear actuators can lead to some unique issues that a typical mechanic or engineer may not be able to easily spot and resolve.

- Actuator Lubrication Increases Efficiency

- Different linear actuators in different applications and environments have distinct requirements for lubrication. Check with your manufacturer and engineers to determine the ideal lubrication type and schedule so your actuators remain operating at peak efficiency. This becomes critically important the more precise and finely tuned your system is.

- For example, if you’re using ball screws, you've invested a lot to achieve an efficiency level of 90% or higher. Poor lubrication practices can drop that by as much as 85%, leaving you worse off than you'd have been with a naturally less efficient linear actuator.

- Linear Actuator Storage

- Linear actuators should be stored in their factory packaging until they are ready to be used or installed. This prevents the build-up of dust and other debris on the surface of the unit. The type of linear actuator you're using will determine how long it's safe to store your linear actuator, as well as the adjustments or shifting you should perform to keep it in functional condition. Adjustments every few months to encourage the even distribution of oil are recommended in most cases.

- Compliance Issues

- Compliance concerns for linear actuators will be on a case-by-case basis, with the specific requirements and expectations varying between industries, applications, environments, labor laws, and various other federal, local, and industrial regulations. There are, however, “common sense” considerations you'll want to keep in mind to minimize risk and liability.

- Because so many linear actuators end up requiring a fair degree of customization to their specific role, there are few hard standards to go by in the industry.

- Other Considerations

- Outside of the topics we've already discussed, there are a handful of factors to keep in mind when shopping for linear actuators, especially if you will need to make additional purchases in the future for maintenance, expansion, or ongoing manufacture.

- Compatibility

- Repeatability

- Sourcing

- Repairs

Choosing a Linear Actuator Manufacturer

There are two ways to measure the quality of a linear actuator manufacturer: their quality as a manufacturer in general and their quality as a manufacturer for your individual needs. Combining the two will get you the best possible outcome for the foreseeable future.

Qualities of a Good Manufacturer

- Versatility

- A good manufacturer works to make the product you need—not shoehorn your requirements into one of their standard offerings regardless of how well it fits. While you can certainly save time and money by working with standardized equipment, it is not always efficient or effective to do so. Make sure you're working with a manufacturer who knows how to adjust to the needs of customers.

- Reliability

- Judging reliability may seem like a difficult thing without committing to a manufacturer, but you can tell quite a bit before you even request an estimate. Pay close attention to the way support staff communicates with you. Do you have to leave a message and wait for someone to get back to you on their schedule, or do you receive prompt and immediate responses to your inquiries? You should also look at references and look for any complaints against the manufacturer with appropriate groups.

- Experience

- Experience counts for a lot in manufacturing linear actuators and related equipment. Because of the wide variety of applications and order types coming through an actuator manufacturer's hands, you will want them to be able to quickly and effectively adjust to your project’s requirements. Seeking out a manufacturer with a good amount of actuator familiarity will keep you from being someone’s “learning experience.”

- Transparency

- You should always know what you're getting and what you're paying for when working with a manufacturer. This includes a lack of tacked-on fees after your initial estimate, a thorough understanding of shipping costs, and clear and concise terms on warranties, guarantees, and support agreements. If there's a delay or a problem, you should hear about it as soon as someone has time to call you—not days or weeks later once they realize it cannot be covered up.

- Support

- A good linear actuator manufacturer should be your first and final stop for information on maintaining and repairing your linear actuator. You can judge the overall quality of a manufacturer by observing the quality of the support staff managing customers, service requests, and other secondary and tertiary responsibilities. If the customer support isn't adequate, the manufacturing is likely to lag as well.

Qualities of a Suitable Manufacturer

- Specific Application

- A suitable manufacturer for your needs will have familiarity with your specific application or a similar one. They should have at least more than a passing familiarity with the particular type of linear actuator you need for your project. A manufacturer who understands your needs can help you avoid missteps, waste, and errors in production, installation, and operation. Look at the manufacturers whose needs and expectations most closely resemble your own when reviewing references.

- Logistics

- Logistical considerations play a major role in procuring components such as actuators. Make sure your expectations for shipping, handling, procurement, and other factors align well with a potential manufacturer.

- Scheduling

- Manufacturers don't often have infinite flexibility in their schedules. Make sure their general availability matches your current and future needs, lest you end up put on a back burner while higher priority customers and clients receive their orders.

- Volume

- If a manufacturer can't keep up with your volume requirements, they're not going to be a good fit. On the other hand, some manufacturers may require commitments to higher volumes than you're interested in. While there's some leeway here, as you could conceivably buy in bulk just to have replacements handy down the line, it's best to work with a manufacturer who operates at the same scale you need.

Linear Actuator Terms

- 12 Volt Linear Actuator

- Converts 12 volts of direct current (DC) electrical energy to provide linear mechanical motion. Though this linear motion is not at a very high speed, there are several benefits 12 volt linear actuators have to offer. These advantages include a high power level, durability, and reliability.

- Electric Cylinders

- Can also be referred to as electric linear actuators. These devices convert electrical energy into mechanical energy used for linear motion. Electric cylinders are more accurate and work efficient, are easier to install, and have a longer service life than pneumatic or hydraulic varieties.

- Miniature Linear Actuators

- A type of linear actuator manufactured on a smaller scale than the typical linear actuator size. Also referred to as micro linear actuators or mini linear actuators, miniature linear actuators produce mechanical linear motion through the conversion of various forms of energy into mechanical energy.

- Rotary Actuators

- Compact, simple, and efficient linear actuators that rotate an output shaft through a fixed arc to produce oscillating power. They require limited space and simple mountings and can produce high instant torque in either direction. Rotary actuators are used for lifting, lowering, opening, closing, indexing, and transferring movements.

- Servo Actuators

- Used to provide position control, utilizing linear motion to maintain the proper functioning of another mechanism or equipment part. At its most basic, a servo is a small device that operates based on responding to error-sensing feedback.

- Valve Actuators

- Mechanisms that provide linear movement to valves through the use of various screw assemblies. This movement is typically utilized to position the valve, as well as to open or close the valve, depending on the application.