Plastic Tubing

Plastic tubing refers to any number of tubes and pipes produced using plastic.

The versatility of plastic tubing makes it a presence in countless industries, such as the medical, aerospace, and beverage industries.

Quick links to Plastic Tubing Information

Applications of Plastic Tubing

The applications of plastic tubing are endless, but for the most part come down to the general idea of transferring fluids, gases, or certain solids from one point to another.

Plastic tubing is used more often than tubes made of steel and other competing materials for a few reasons. First, plastic tubing can be designed to be flexible in a way other tubes and pipes cannot. Second, plastic offers an extremely wide range of material options, such that a manufacturer can produce tubes as at-home in extreme industrial applications at extreme temperatures and pressures as they are in mundane day-to-day applications. Plastic tubes are also generally cost effective compared to similar alternatives.

Nearly every industry on the planet uses plastic tubing in one form or another. Any industry which needs to convey flowing materials from one location to another will probably use some form of plastic tubing to achieve it at some point in the process. Just a few notable industries that use plastic tubing in major roles include:

- Medicine and pharmaceuticals - Used for intravenous delivery of drugs, blood transfusions, and countless other applications.

- Aerospace engineering - Used for fuel tubes, hydraulics, and transference of other fluids. Similar applications in automobiles and other mechanical devices.

- Water management - Used in plumbing, water treatment, irrigation, and drainage systems.

- Agriculture - Used to transfer fluids, bulk solids, and other substances on a wide variety of farms.

- Fuel - Used in piping systems for liquid and gaseous fuels such as gasoline, natural gas, and butane.

History of Plastic Tubing

The history of plastic tubing largely follows the history of plastic in general.

It's difficult to determine who created the first plastic tubes, but we can point to the invention of parkesine in 1856 for the creation of the first man-made plastic. Over the course of the next century, several forms and applications of plastics were invented, with the chemical discoveries of World War I leading to an explosion in usage and inventions by the 1940s and 1950s. Plastic tubes began replacing predecessors in various industries as new technologies developed. For example, the earliest use of a plastic catheter for intravenous delivery in medicine dates to 1945.

Today, plastic tubing is a ubiquitous component in every industry and field around the world.

Plastic Tubing Production Methods

There are two major forms of plastic tube manufacturing, each offering its own set of pros and cons. They are simply explained as plastic pultrusion, a process which pulls material through a die, and plastic extrusions a process which pushes material through a die.

Pultrusion is a form of plastic tubing production in which fibers are pulled through a shaped die while resin is simultaneously injected. This creates products with all fibers oriented along the length of the tube, which in turn results in exceptionally high performance in applications involving bending and pulling forces. Conversely, this uniformity of fiber orientation leads to pultruded plastic tubing being unsuitable for applications involving loads such as torque or crushing force.

Extrusion, on the other hand, produces end products with a much wider variety of traits and can be produced at a very high speed with high volumes while maintaining lower costs. To extrude plastic is a relatively simpler process, in which raw plastic is melted and forced through a shaped die to produce a consistent cross-section or profile.

Materials Used to Produce Plastic Tubing

Tubing can be constructed from a variety of plastic materials. Below are materials tubing is commonly constructed from.

- Acrylic

- Tubing made with acrylic materials is characterized most frequently by its exceptional optical clarity. It is sometimes referred to as clear acrylic tube and can be made from an acrylic sheet. Because it is usually clear, it’s great for any situation where consumers will need to see what is inside of the tubes they are using. Some of its applications include lighting, fish tanks, storage, and industrial uses. Acrylic tubing is usually created using a casting process. It is a durable and useful type of tubing.

- Cast Acrylic

- An exceptional thermoplastic tubing with glassy properties, stability under a wide array of environments, resistance to wear and corrosion, low weight, good durability, and shatter resistance.

- PVC

- Corrosion-resistant, flexible, flame retardant, and immune to heat shrinking, PVC tubing offers exceptional performance with great physical and electrical properties.

- Latex

- A tubing material notable for returning to its original shape after being stretched, maintaining flexibility in extremely low temperatures, and its high holding strength.

- CPVC

- Chlorinated polyvinyl chloride tubing is similar to PVC tubing but with an increased resistance to corrosion at higher temperatures

- Fiberglass

- Tubing made from fiberglass, used frequently in high-temperature applications and in areas where abrasion resistance would be valued. The manufacturing process is impacted by what the final product will be used for. Since fiberglass is naturally RF transparent, it can easily be used for many different radome and communication purposes. Unlike carbon fiber, fiberglass is nonconductive. For this reason, fiberglass tubes are frequently used in situations where electrical conductivity could pose a danger. Fiberglass is an extremely efficient material and is a favorite tubing type within many different industries.

- Nylon

- Strong abrasion-resistant tubing used in high-pressure and high-temperature applications. Some varieties of nylon tubing will not corrode or degrade in chemical solutions. Nylon tubing is also very versatile and can be put to many useful applications. Some of these applications include hydraulic hoses, robotics, different types of vacuum lines, fuel lines, vapor lines, air lines, brake lines, oil processing lines, tool lubricating systems, and chemical processing lines. Nylon tubing also has UV stabilization which can be handy in warmer areas where the tubing will be exposed to direct sunlight. Nylon tubing is extremely flexible and can fit into multiple complex designs. Nylon tubing also has a good resistance to substances like solvents, alkalies, oils, grease, petroleum, and most varieties of mold and fungus. Some varieties of nylon tubing are high pressure, super soft, coiled, and D.O.T. tubing.

- Polycarbonate

- Tubing with good physical properties frequently used in harsh environments. This type of tubing provides consumers with a strong and lightweight option. It can be custom made to be whatever thickness a client may specify. Polycarbonate is flame and impact resistant. This kind of tubing strikes the perfect balance between transparency and durability. This thermoplastic compound has been trusted for years as a great solution for industrial hard plastic tubing uses. Polycarbonate tubing usually has a diameter that ranges from 1/8" to 8" with wall thickness from .010" and up. This tubing can be used for things like bird feeders, novelty items, mailing tubes, and also has many uses in the medical industry.

- Polyethylene

- Also called poly tubing. Tubes made of this material have a waxy, tough texture and are used due their resistance to erosion by water and various chemicals.

- Polystyrene

- Polystyrene tubing is both lightweight and flexible. It is also extremely durable. This type of tubing can fill a wide range of consumer needs. It is frequently involved in the transferring of different fluids and gases. It can safely transfer many types of chemical compounds as well. It has a fantastic vapor and moisture resistance. It is available in various burst-prevention rates and heat resistance standards.

- Silicone

- Rubber-like tubing used in medicine and related fields due to cleanliness, non-toxicity, versatile temperature resistance, and inertness.

- Vinyl

- Extremely versatile tubing used in many mundane applications due to its chemical resistance, low weight, high strength, non-toxicity, and transparency.

- Polypropylene

- Similar to polyethylene, but can be produced optically clear and features a higher melting point.

- HDPE or High Density Polyethylene

- High-density polyethylene pipe, popular in any number of industrial and infrastructure piping applications due to its high strength/density ratio and the reduced risk of shattering, corrosion, and other dangerous malfunctions or failures when compared to steel or PVC pipes.

- PTFE

- Also known as polytetrafluoroethylene or Teflon tubing. PFTE tubes are by far the most flexible of all fluoropolymer tubing. These types of tubes also have a broad temperature range at around -390°F to 500°F. Another key feature they boast is their high resistance to dangerous corrosive liquids and gases. PFTE tubes can even resist liquid corrosion and will not crack when subjected to high temperatures. They have a smooth finish and low friction rate. They are frequently used in laboratories, chemical processes, high-temperature situations, brushing, bearing applications, and in the electrical and automotive industry. These tubes are usually made using a pultrusion process.

- XLPE High-Density Cross-Linked Polyethylene

- Tubing used in certain chemical applications where HDPE plastic isn't adequate.

Plastic Tubing Design Factors

There are many design factors one might need to consider to acquire their optimal tubing. In no particular order, a given application may require careful consideration of:

- Strength

- Diameters

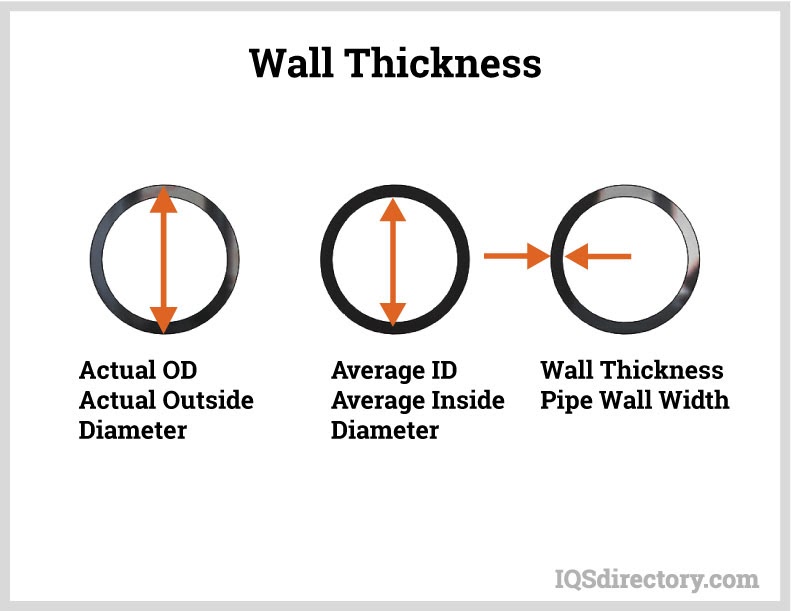

- Wall thickness

- Flexibility

- Cost

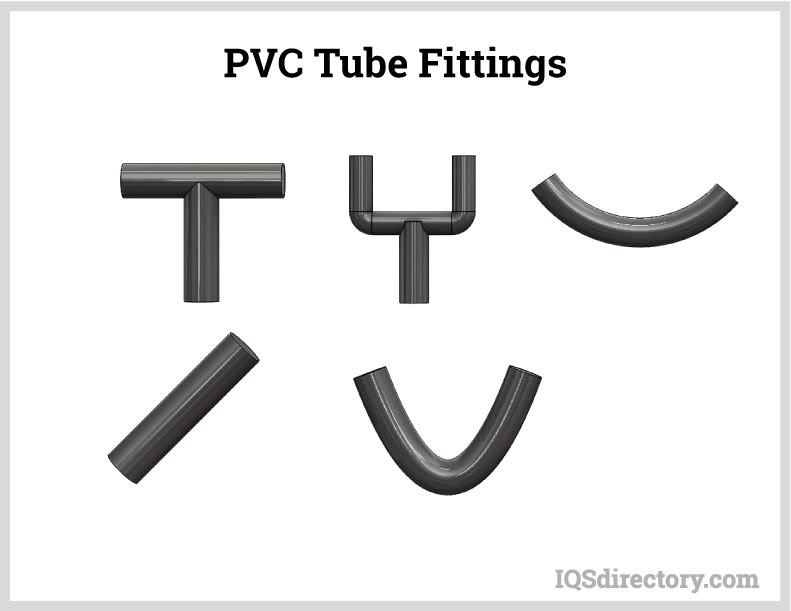

- Fittings

- Load

- Color

- Length

- Performance

- Stretch

- Corrosion

- Coatings

- Microbial properties

- Toxicity

- Maintenance

Characteristics of Plastic Tubing

Plastic tubing is a simple product with many application scenarios. In most cases, the use of plastic tubing depends more upon the fittings and devices connected to the tube than anything inherent to the tube.

Of course, some tubes installed for drainage and similar applications work simply by offering a path of least resistance to fluids. For example, a corrugated tube laid down in the right place in a yard might prevent puddles, erosion, or basement flooding without any need for additional materials.

Characteristics also vary significantly between different materials and production methods.

Advantages of Plastic Tubing

Like most plastic products, it's the versatility of plastics that makes plastic tubing useful in so many industries. Plastic can be designed as rugged and inflexible as metal tubes or as flexible plastic tubing, but it can be made to withstand the greatest extremes of temperature, pressure, and corrosion imaginable. All of these features can be shared with plastic tubing produced from appropriate materials using the right methods. In other words, the advantages of plastic tubing depend on how good the tubing manufacturer you select is. In the right hands, plastic tubing can meet nearly any application goal effectively and cost-efficiently.

Plastic Tubing Accessories

Plastic tubing rarely works well without fixtures and connectors to maintain strong, effective seals. When looking at plastic tubing as a solution for a given application, make sure you also take into account any necessary fittings for your task and how they will work with your tubes.

Some accessories you may need to consider are:

- Fittings

- Valves

- Connectors

- Couplings

- Inserts

- Joints

Proper Care of Plastic Tubing

When caring for plastic tubing, you'll want to keep the traits of the materials used in mind throughout. Check for corrosion, cracks, tears, and leaks as necessary for your application. While many forms of plastic tubing are designed to fail safe, others may have a risk of shattering or explosive failure. For these, be particularly alert to any problems and complete repairs in a timely manner.

If you're not quite sure how to care for a particular type of plastic tubing, asking your engineers and your manufacturer for input should be a high priority. This can help you avoid costly or unsafe mistakes down the line.

Plastic Tubing Compliance and Standards

Many industries have strong recommendations or firm regulations in place regarding the specifications and materials allowed for plastic tubing used for certain tasks. Surgical tubing and drinking straws, for example, must meet standards of safety and non-toxicity. Tubing for fuel piping systems must be reliable and safe, while industrial tubing must be resistant to the unique environmental forces present in that industry.

There is no single, fixed standard to adhere to due to the sheer versatility of plastic tubing. Instead, make sure to investigate standards and compliance issues specific to your application in advance, or work with a plastic tubing manufacturer that can handle compliance and standards on your behalf.

Choosing the Right Plastic Tubing Manufacturer

Because of the sheer number of options and applications out there for plastic tubing, it's more important that your manufacturer match your needs than that they meet some hypothetical perfect standard.

Ideally, a manufacturer should have experience producing plastic tubing for your industry or application, or something very similar. If you're working on an especially exotic or hyper-specific application and can't find a manufacturer with matching experience, a manufacturer with a history of working with custom plastic tubing would be your next best bet.

If you're working in a field with extremely stringent compliance considerations, it's even more important that you select tubing manufacturers carefully. A good contract manufacturer can help you maintain compliance even if you're unfamiliar with the nuances of regulations regarding tubes for your application.

Outside of specific experience, look for manufacturers with generally positive customer feedback, plenty of references, good communication skills, and transparency of pricing and expenses.

Plastic Tubing Images, Diagrams and Visual Concepts

Plastic tubing can be made into many different forms and can serve a variety of proposes.

Plastic tubing can be made into many different forms and can serve a variety of proposes.

The flexibility of the plastic tube are determined by the material used in manufacturing, which different material are more flexible.

The flexibility of the plastic tube are determined by the material used in manufacturing, which different material are more flexible.

Determining the wall thickness of the plastic tube influences what the tube can be used for.

Determining the wall thickness of the plastic tube influences what the tube can be used for.

There are a variety of fittings include compression, push to connect, quick turn, threaded, barbed, socket, and flanged. The type of fitting is determined by the usage of the tube.

There are a variety of fittings include compression, push to connect, quick turn, threaded, barbed, socket, and flanged. The type of fitting is determined by the usage of the tube.

Plastic tubing does not have the same durability of steel, however plastic is able withstand daily wear.

Plastic tubing does not have the same durability of steel, however plastic is able withstand daily wear.

Produced with the same clarity as glass without being fragile with greater strength and endurance.

Produced with the same clarity as glass without being fragile with greater strength and endurance.

Plastic Tubing Types

The versatility of plastic tubing has resulted in countless types and categories being described. Many of these types overlap in basic design or function, while others may be wholly unique and quite different from any other form of plastic tube. Here are just a few of the most common types of plastic tubing you may see described or referred to elsewhere:

- Corrugated Tubes

- Designed with tight ridges and valleys perpendicular to the length, resulting in increased sturdiness at the cost of reduced flow. It can be made of a variety of different materials. Some of these materials include nylon, types of polyurethane, polyethylene polyvinyl chloride and other low-density linear plastic materials. This tubing can be made to fit just about any length or size though the standard size is 10mm. Corrugated varieties of tubing can be either disposable or reusable. This tubing is commonly designed to be used for anesthesia & respiratory ventilators, as well as many other medical purposes.

- Clear Plastic Tubing

- Any tubes made from clear plastic materials.

- Heat Shrinkable Tubes

- Plastic tubing designed to shrink when heated, creating a tightly conforming insulated protective cover.

- Medical Tubing

- Any plastic tubing used for catheters, IVs, and other medical and surgical applications.

- Plastic Pipes

- Typically refer to rigid plastic tubes and usually measured by inner diameter.

- Pultruded

- Any tube produced using pultrusion manufacturing.

- Square Plastic Tubing

- Any plastic tube designed with a square cross-section instead of a circle.

- Surgical Tubes

- Used for various medical purposes; see medical and silicone tubing for more information.

- Hard Plastic Tubes

- Any tubing designed to be relatively rigid and inflexible, but not as inflexible and rigid as true plastic pipes. This hard variety tubing is rigid and inflexible. Because of this rigid inflexibility, this tubing better resists things like kinks and abrasions. Hard tubing can be made out of many different materials. Hard tubing can be clear or opaque, depending on which plastic compounds it is constructed from. Some commonly used plastic compounds used for hard tubing are acrylic and polycarbonate. Hard tubing is much more flexible than PVC pipe or other types of plastic pipe. It is also stronger than many other types of thin tubing.

- Small Diameter Tubes

- Plastic tubing with a diameter less than 3 mm, sometimes smaller than 1 mm. Usually extremely flexible and relatively weak, used primarily in medical applications. Small diameter plastic tubing can be manufactured to have the exact diameter thickness that a company needs. In some instances, it is the only type of tubing that is capable of fitting certain designs. This thin wall plastic tubing is not as durable as other tubing types, but this is sometimes what is needed in order for the tubing to fulfill its purposes.

- Mini Tubes

- Used for various small plastic tubes used in electronics, medical products, swab sticks, and other products. Miniature plastic tubes come in a variety of materials and can be put to many uses. Some common materials that these tubes are made of include types of polycarbonate, compounds of polypropylene, polyethylene, polystyrene, and PVC. Manufacturers frequently make mini plastic tubes specifically for each individual client, though they can be bought in standard bulk forms as well.

- Rigid Plastic Tubing

- Type of tubing extruded from plastics that can be used in applications where tubing needs to be stiff and unbendable.

- Centrifuge Tubes

- Custom-made tubes produced using state-of-the-art processes from exceptional materials, for use in laboratory centrifuges. A laboratory centrifuge is a machine that spins liquid samples at high speeds. There are various different kinds and sizes of centrifuges so tubs are usually custom made. These tubes are usually made using a state-of-the-art process out of high purity resins or high-clarity polypropylene. It's important that centrifuge tubes are crafted with care, so companies should be sure that the manufacturer that they choose makes a quality product.

- Vinyl Tubing

- Hollow channels that are completely or primarily constructed of vinyl plastic. The word vinyl describes any material that belongs to the vinyl group of chemicals.

Plastic Tubing Terms

- Crazing

- Small cracks close to the surface of the plastic tubing.

- Brew Tube

- Brew tubes and brewery hose are a special type of tubing that manufacturers mainly make for use in beer brewing and coffee brewing.

- Ductility

- The amount of strain that plastic tubing can handle before breaking.

- Expansion

- The process in which the diameter of a plastic tube is enlarged while its wall thickness is reduced. This process is often used to create heat shrinkable tubing.

- Extrusion

- A process in which a solid plastic resin is melted and pushed by a screw through a heating chamber.

- Fish Eyes

- A small mass in a transparent material, such as plastic used in plastic tubing, created by incomplete blending.

- Flaring

- A process in which mechanical pressure works to increase the diameter of plastic tubes from the inside.

- Jacket

- The outer part of a heat shrinkable tube's dual wall.

- Latex

- A solution also referred to as rubber that usually consists of water and polymer.

- Liner

- The inner part of a heat shrinkable tube's dual wall.

- Polymerization

- A process typically carried out by a catalyst in which a large number of simple molecules combine to form a more complex, chain-like compound (polymer).

- Polystyrene

- A flammable, transparent plastic that is an excellent electrical and thermal insulator because of its high strength and impact resistance.

- Polyurethane

- A general term for a broad class of thermoplastic polymers that have good resistance to solvents and abrasion and can be either solid or foam (cellular).

- Pultrusion

- A process that produces reinforced plastic shapes with constant cross sections by pulling the reinforcing fibers, wetted by a thermoset resin mix, through a heated steel die.

- Plexiglass Tubes

- Transparent thermoplastic often classified as a glass. Because of their high optical clarity, high tensile strength, outstanding light transmission properties, and relative affordability, clear plexiglass tubes are often used in lieu of glass tubes or materials like polycarbonate (PC).

- Shore Hardness

- Scale used to measure the hardness of an object. Although there are different scales (plastic tubing uses the "A" scale), they are consistent in that the larger the number, the harder the object.

- Strain Relief

- A process in which plastic tubing is used as an outer cover for an object in order to reduce the stress being placed on the object by providing additional support and stiffness.

- Stress Cracks

- Small cracks, typically found in clusters, which occur in plastic tubing due to mechanical stress.

- Thermoset

- A material that remains hardened, even when reheated, due to its having undergone a chemical reaction.

- VW 1

- A rating given to highly-flame retardant plastic tubing by the Underwriter's Laboratories (UL).