Quick Release Couplings

Quick release couplings are simple mechanical devices that permit easy and immediate connection or separation of fluid transmission lines with a minimum of stoppage time and spillage. They are connectors that allow fluids to easily stop and start traveling through tubing at any given time. In simplest terms, they are a device that creates a joining bond between two or more parts.

To make a complete coupling set, two parts must be used which are the male and the female connectors. Here the male connector fits perfectly into the female connector for a tight seal. Quick connectors or quick disconnects can also refer to couplings or fittings. Quick connect fittings replace threaded or flanged connections which require tools such as wrenches.

Quick release couplings are known by many other names including:

Quick links to Quick Release Couplings Information

Benefits of Quick Release Couplings

The advantage to quick release couplings is the ease to connect and disconnect at any time. With any other hose hook up commonly found, it is a threaded hook up where one must twist on to one another. Sometimes the hose can twist with the threaded motion causing the hose to get kinks and have other issues. Having the quick release couplings save a lot of time and hassle compared to hooking up regular hose connections.

Speed is crucial to effective emergency first response. This makes quick release couplings, which are characterized by their ease of use and their ability to be attached and disconnected quickly, a perfect fit for emergency response applications.

Designs for Quick Release Couplings

- Coupling Materials

- The majority of quick release couplings are composed of metal materials such as brass, nickel-plated brass, aluminum, copper, bronze, carbon steel or stainless steel. However, plastic couplings have increased in popularity due to their corrosion-resistant properties and lower cost. Common working fluids include air, hydraulic fluids, steam, water, oil, fuel, chemicals, gas or solid transfer. Sizes range from 1/8 inches to ten inches in diameter, and they can usually handle high pressures and temperatures. Materials chosen would be best based on the type of project and the types of liquid that would be running through the coupling.

- Connectors of Couplings

- A release coupling is a device that joins two or more parts together to prevent leaking or a drop in pressure. In a coupling, the male tip can be referred to as the connector. Quick couplings are operated by connecting the female end onto the male end, the connector, of a hose or tool. At least one of the ends has a valve, and when the valve opens, the quick coupling is connected, allowing fluid to flow through in either direction. When it is disconnected, a spring closes the valve, preventing fluid loss and the entrance of air. This happens quickly, shutting the system down almost immediately.

- Ways Couplings Disconnect

- The quick disconnect coupling can be connected or removed by turning an interlock mechanism, such as a nut. A quick disconnect is always operated by hand rather than by machine because something unexpected could happen to which a machine could not respond. Some installations require the quick disconnect coupling to be safe-tied with wire. Quick disconnect fittings are often designed to be operated with one hand without the aid of tools, though some models still require the use of a wrench.

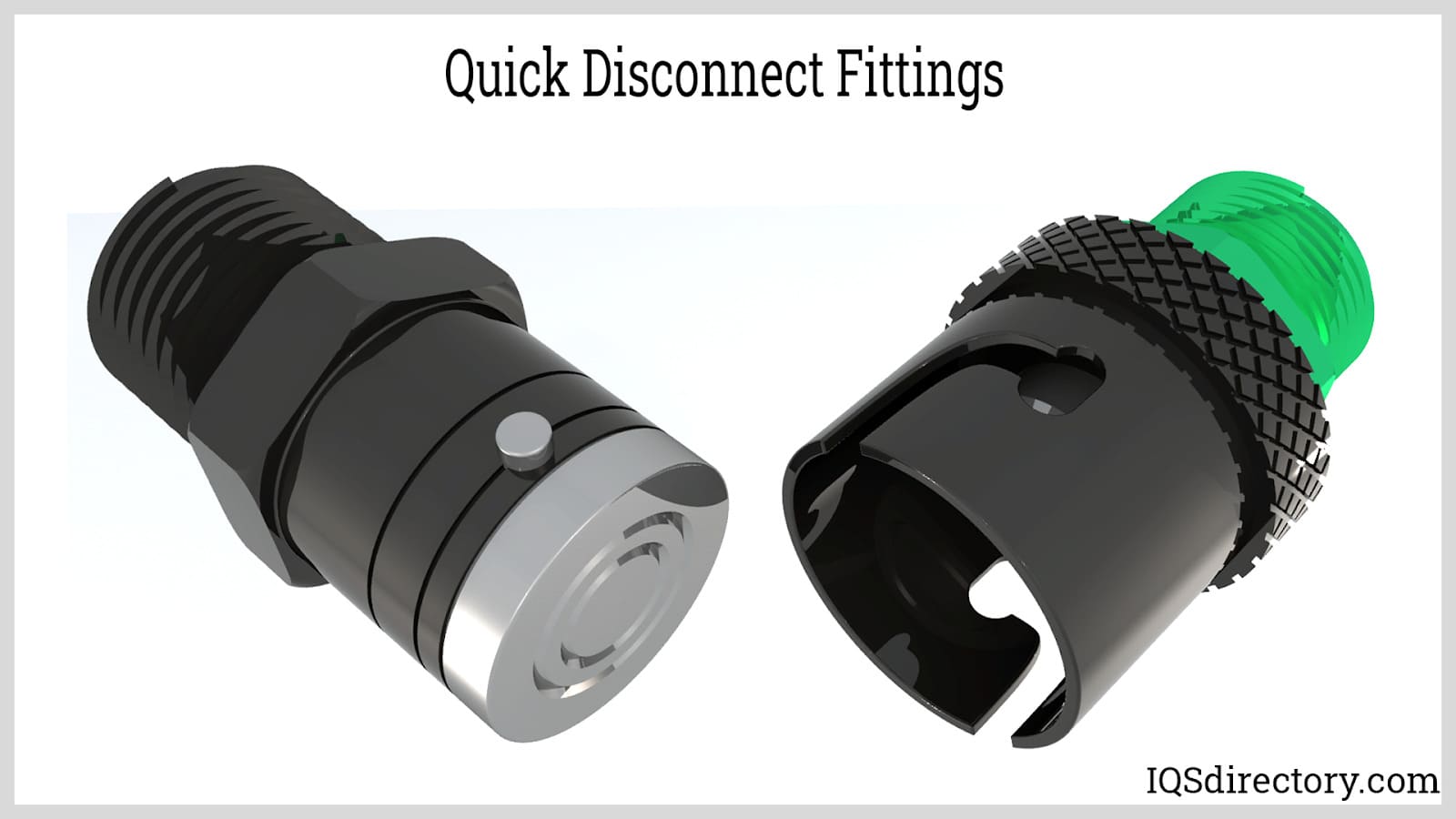

- A quick release fitting, or quick disconnect fitting, is a general term given to a part that simply connects two pipes or hoses together without valves or seals. One main difference is that couplings can rotate while connected, but fittings cannot.

Quick Release Coupling Images, Diagrams and Visual Concepts

Quick disconnect couplings are fittings used to provide air and fluid lines an easy connection and fast disconnection.

Quick disconnect couplings are fittings used to provide air and fluid lines an easy connection and fast disconnection.

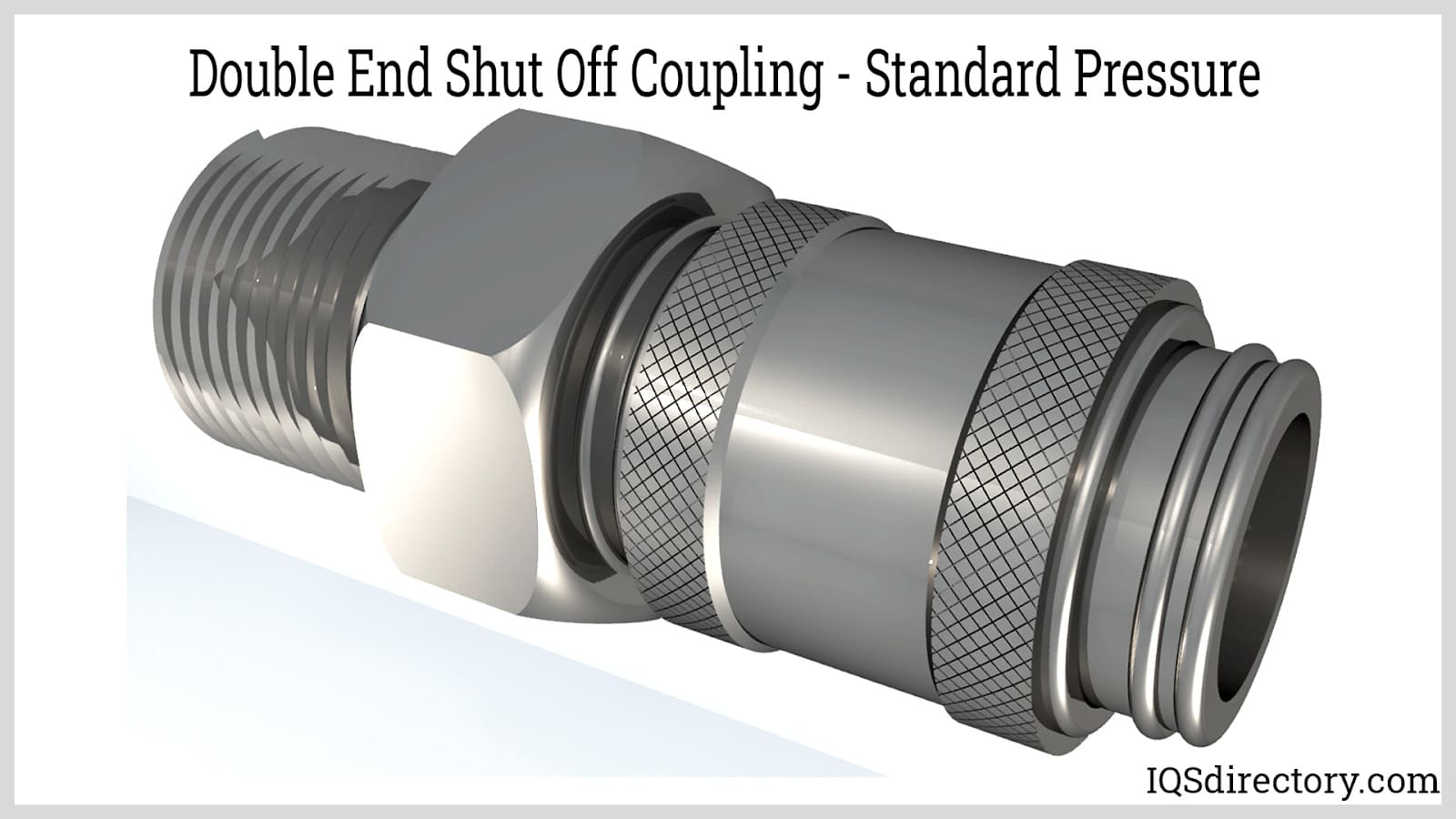

A double end shut off coupling can shut off the plug and the socket instantaneously upon disconnection.

A double end shut off coupling can shut off the plug and the socket instantaneously upon disconnection.

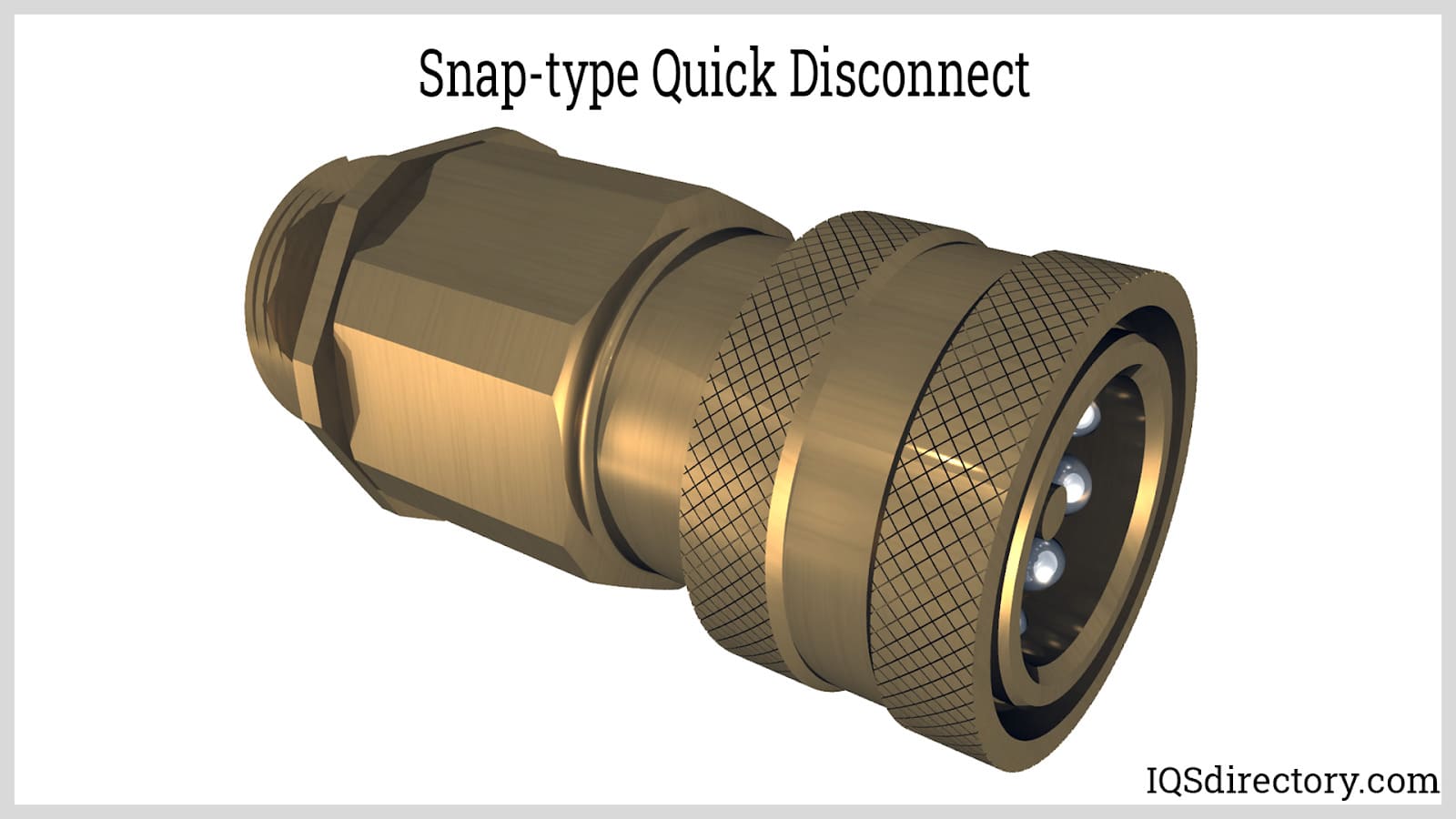

Snap-type quick disconnect automatically locks the two halves when pushed together.

Snap-type quick disconnect automatically locks the two halves when pushed together.

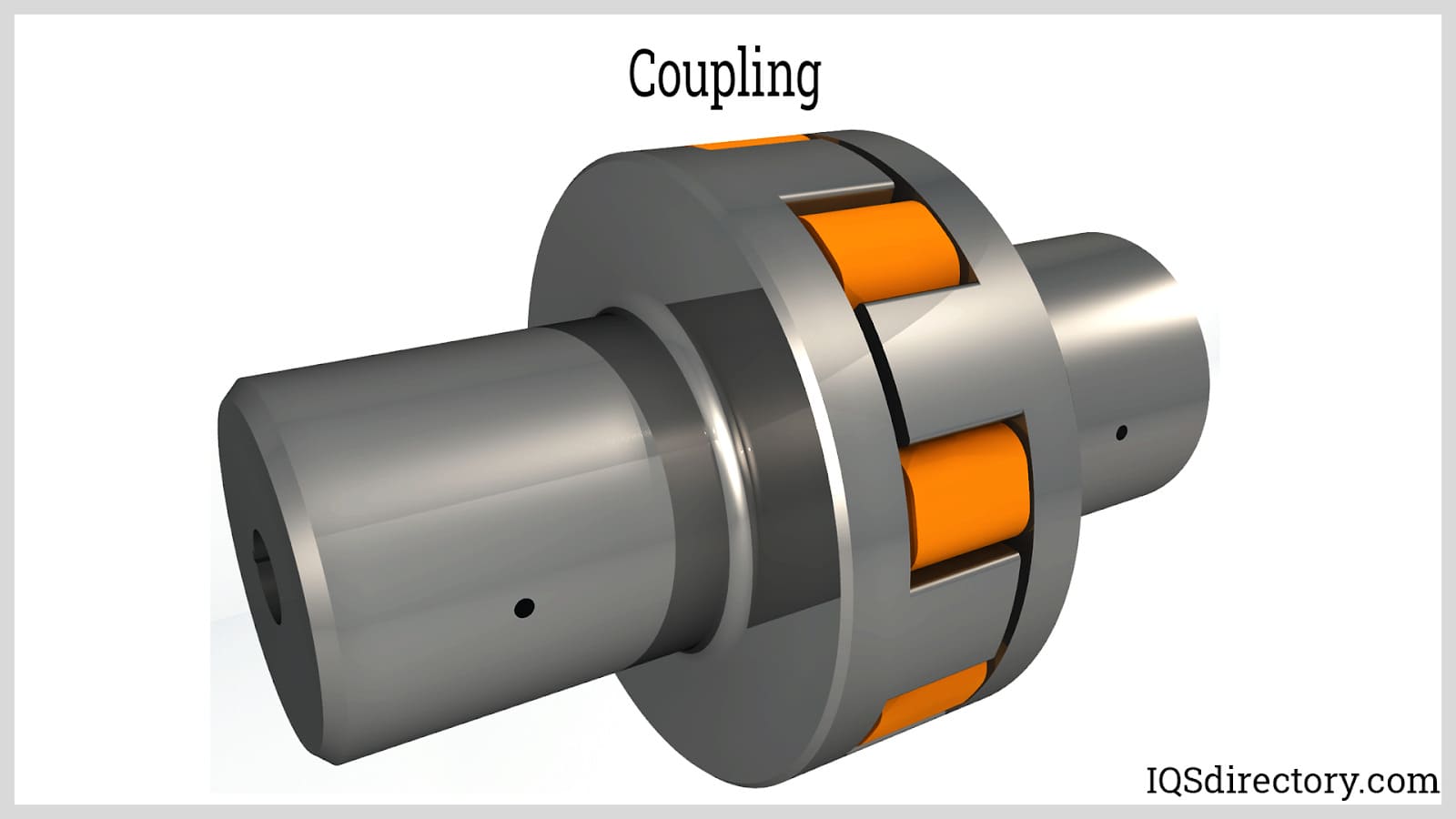

Couplings join two pieces of rotating equipment together, while permitting some degree of end movement in both.

Couplings join two pieces of rotating equipment together, while permitting some degree of end movement in both.

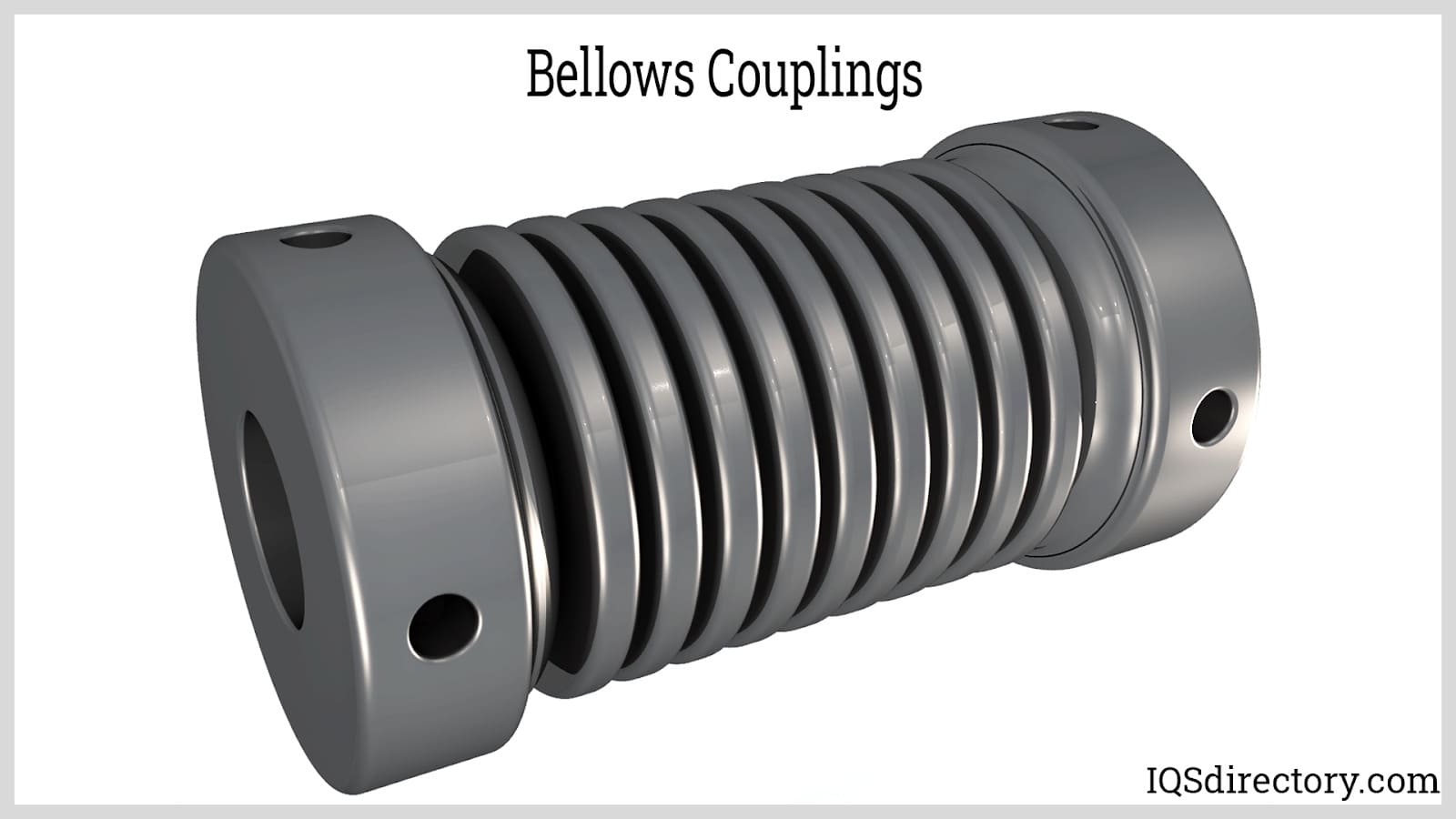

Bellows couplings have twin couplings which can accurate transmit velocity, torque, and angular position.

Bellows couplings have twin couplings which can accurate transmit velocity, torque, and angular position.

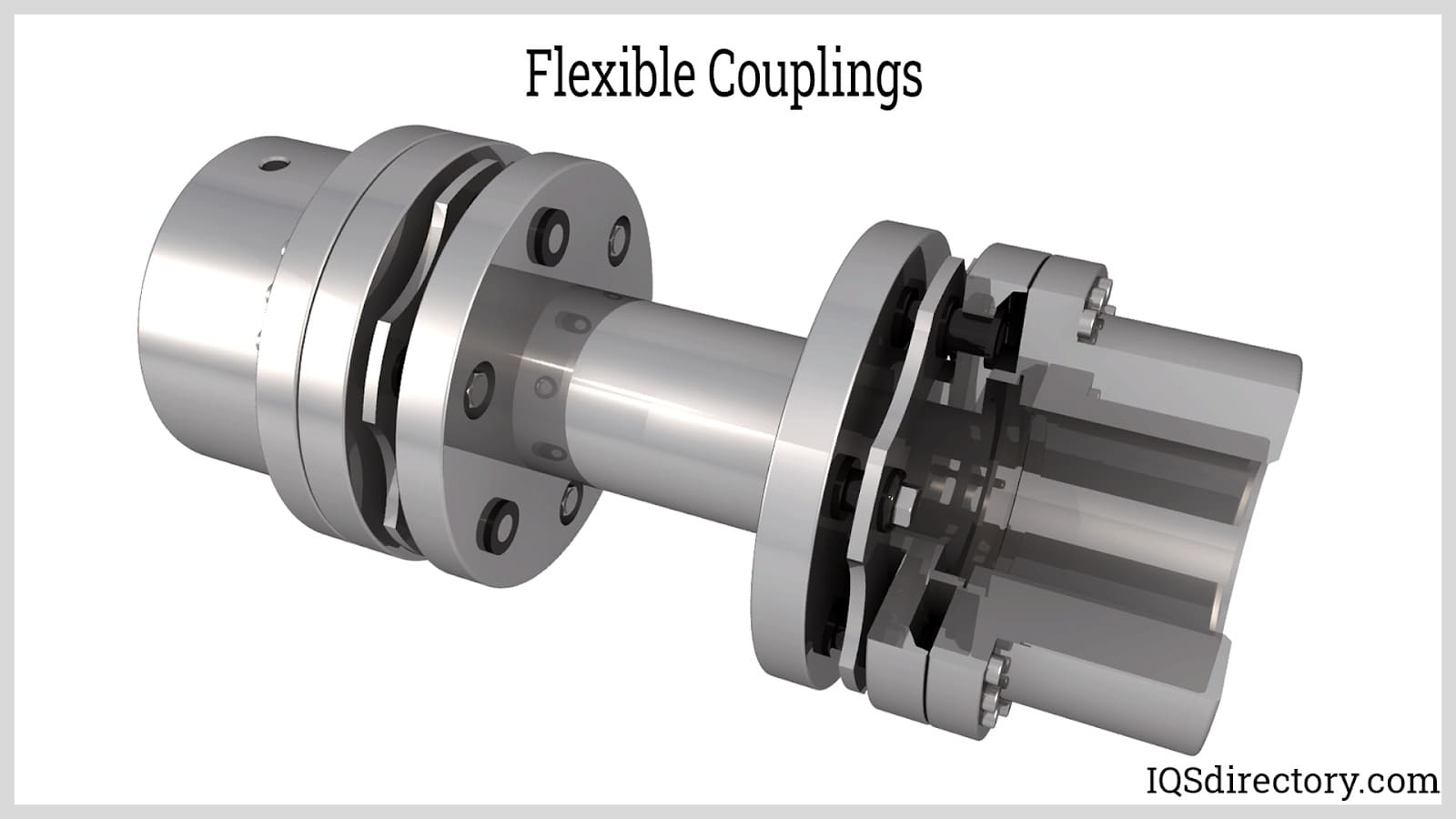

Flexible couplings compensating for the changes in temperature in the joined components and couplings which permits movement of the shafts without interference.

Flexible couplings compensating for the changes in temperature in the joined components and couplings which permits movement of the shafts without interference.

Quick disconnect fittings provides an easy and fast connection and disconnection.

Quick disconnect fittings provides an easy and fast connection and disconnection.

Quick Release Coupling Types

- Air Conditioner Couplings

- Used in refrigeration and cooling system applications. Air conditioner couplings are designed to withstand vibrations without disconnecting and to minimize any refrigerant leakage once disconnected.

- Ball Connectors

- Have a number of balls on one or both of the male/female bodies that are drawn in when a button is pressed. Once the balls are drawn in, the two halves are connected and the button is released, projecting the balls and locking them in place.

- Connect-Under-Pressure Couplings

- Use a valve to relieve back pressure. This design makes it simpler to insert the hose into a receiver when hydraulic lines must be connected or disconnected.

- Double Shut-Off Quick-Release Couplings

- Have shut-off valves in both the male and female halves.

- Dry Break Couplings

- Sliding, sleeve-style, quick disconnect couplings for hydraulic systems. Capable of connecting with little air inclusion and can be disconnected with minimal or no spillage.

- High Flow Couplings

- Used in applications in which larger volume flow is required. High flow couplings can be made of polypropylene (PP), polysulfone, brass and stainless steel, among other materials.

- Hydraulic Quick Disconnects

- Any type of quick disconnect that is used in a liquid system.

- Hydraulic Couplings

- Commonly contain shut off valves to prevent spillage and reduce air inclusion when connecting/disconnecting.

- Non Spill Couplings

- Resistant to a wide range of media. Standard non spill couplings come with non-spill shut-off valves, color-coding that delineates a variety of media lines, olefinic overmolding, which makes the connection more durable and improves the grip for users and seals and springs formed from materials that are determined by the amount of chemical resistance required.

- Non-Valved Quick-Action Couplings

- Do not have shut off valves in either the male or female halves.

- Pneumatic Couplings

- Also called “single shut off (SSO) couplings,” are generally used to connect tools, equipment and hoses that utilize compressed air. Pneumatic couplings may also be used in applications in which other gases and low pressure liquids are in use.

- Poppet Couplings

- A type of valve used in hydraulic quick disconnects that disables fluid flow when the two mating halves are separated. The poppet-style quick disconnect coupling is one of the most popular hydraulic couplings.

- Plain Connectors

- The simplest and least expensive, join the male and female with a ball-bearing sleeve lock.

- Push-and-Pull Quick Disconnect Couplings

- Typically have a sleeve on the female half that is pulled back and into which a male tip is inserted, locking it into place when the sleeve is released. To disconnect, the sleeve is once again pulled back, and the male half is withdrawn.

- Quick Action Couplings

- Often used to separate or join hydraulic lines. The quick action coupling eliminates the need for tools or special devices.

- Quick Connect Couplings

- Composed of two mating halves used to join two pipes together. Within a quick connect coupling, there is a male plug and a female coupling. In order to connect the two, the male plug is inserted into the opening in the female half. Quick connect couplings are designed to prevent leakage from the line and often are fitted with shut-off valves for this purpose.

- Quick Connectors

- Devices that are used to join two or more pipes, hoses or tubes together in order to prevent leaking or a drop in pressure.

- Quick Coupling

- Used to join two pipes or hoses or a combination of the two together. They are composed of two mating halves: a male plug and a female coupling. In order to connect the two, the male plug is inserted into the opening in the female half.

- Quick Disconnect Couplers

- Mechanical devices that allow immediate connection and separation of air and fluid lines. They are designed to prevent spillage and are equipped with seals and valves for this purpose.

- Quick Disconnect Couplings

- Used to join together two hoses, pipes, or a combination of the two. They are designed to make connections without allowing leakage or a loss in pressure. They are used in the transport of many different materials, including water, gas, air, hydraulic fluid, and various chemicals.

- Quick Disconnect Fittings

- Non-mechanical parts that connect pipes and hoses together without valves or seals.

- Quick Disconnect

- Used to connect pipes and hoses quickly without leaking or losing pressure. They are simple mechanical devices that can usually be connected with only one hand.

- Single Shut Off Quick-Action Couplings

- Have a shut off valve in either the female or male half only.

- Single-Poppet Connectors

- Have one seal to close off the supply of liquid and are frequently used for applications when a minor spillage is acceptable.

- Double-Poppet Couplings

- Have two seals that close off both sides. This traps only a small volume of fluid between the valves. Though more mechanically complicated than other options, the double-poppet eliminates the need to collect spilled product or drain the lines before disconnecting the coupling.

- Sleeve and Poppet Coupling

- Experiences zero fluid loss and does not allow air to enter the system.

- Sliding Seal Couplers

- Have seals flush to the exposed ends of the male and female halves, which allows little space for dirt and bacteria. They are used for hazardous chemicals for minimum spillage.

- Other Quick Release Couplings

- Types include double rotating ball, sliding seal and stapler couplers.

- Threaded Couplings

- Best suited for high pressure and high flow applications. To form a connection, the male half of a threaded coupling is screwed into the female acceptor, both of which are threaded, and turned clockwise; the male half is turned counterclockwise to disconnect the coupling.

Applications for Quick Release Couplings

Most often quick release couplings are used to connect pipes, tubes, or hoses together for the transfer of various liquid forms. They can be found to be in use around many industrial manufacturing buildings in conjunction with the equipment and machines they use. Another popular place for them to be seen is on boat and camper plumbing systems. This allows for a very simple clean out system throughout a boat or camper toilet and shower hook ups from the draining to the waste system.

Quick release fittings are used in many industries where the efficient flow of fluids with quick and easy disconnection is necessary, such as in gas transfer, fire fighting hoses, agricultural sprayers, automotive systems, chemical and food processes, and in the construction industry.

Quick couplings also help ensure safety. For example, aircraft fuel tanks are filled by hoses equipped with dry disconnect couplings because the fuel is extremely combustible, and couplings reduce spillage, preventing accidental fires and inhalation of fumes by the operator.

Quick release couplings are important parts of a wide variety of industrial, commercial, and consumer utilities including:

- Hydraulic Quick Release Couplings

- Used in hydraulic systems to quickly connect and disconnect fluid lines without losing fluid pressure or introducing air. A hydraulic system is a set of equipment in which pressurized fluid is involved in the transmission of power, often in heavy machinery for the purposes of moving heavy parts. They are utilized because of their enhanced durability and strength, which minimizes the loss of fluid and pressure. In order for a hydraulic system to function, it must be equipped with hydraulic fluid transmission lines that can withstand the high levels of pressurization to which the fluids are subject. Some kinds of equipment involving hydraulic systems must be equipped with quick disconnect components to allow for easy connection and disconnection of hydraulic fluid transmission lines. This can be for safety purposes or for other reasons relating to the system’s operation. Such components involve special couplings that can be connected and disconnected, usually by hand, without disrupting the pressurization level of the transmission line or other equipment. Hydraulic quick coupling can be essential to the safe and effective operation of hydraulic systems.

- Air Coupling Applications

- Used when working with air. Air quick couplers are used to make connections between air compressors and pneumatic tools. Because "spilling" air is not typically dangerous, the seals used in these couplings are not as quick and tight as they are in other systems. Air quick couplers are used in air compression systems to connect hoses quickly without leaking air or losing pressure.

- Hazardous Material Uses

- Breakaway Couplers minimize product loss and safety hazards by remaining open during normal use and closing rapidly under excessive force. They are typically used during the transfer of hazardous materials. Breakaway couplings are designed to permit a steady flow of material until excessive force is exerted on the coupling; it then pulls apart to avoid damage to the system and can be reassembled quickly by one person without tools or spare parts.

- Dry Disconnect Couplings are used in sanitary conditions or where hazardous materials are handled. They provide a drip-free connection and have a variation of a mechanical internal lock to prevent accidental releases and openings. Before the coupler can be separated from the hose or pipe, the valves are closed and sealed off by identical discs in the male and female halves to prevent excess spillage and to decrease the hazards typically found when handling/processing corrosive, toxic, caustic or other harmful products.

- No Leak Performance Couplings

- Flat Face Couplings specifically designed for applications needing no-leak performance. With mating faces that are easily cleaned before connecting, flat face couplers are the ideal solution for limiting contamination in a hydraulic circuit.

- Emergency First Response Couplings

- There are many examples in the context of emergency first response where the use of quick release couplings may be observed. A moderately uncommon but extremely important example is in the use of emergency decontamination shelters by first responders in disaster areas or in areas stricken by an outbreak of infectious disease. These shelters are designed to be highly portable and easily deployed; they usually feature soft fabric walls supported by aluminum frames and are equipped with waterjets. These waterjets are connected to their water sources by quick release couplings because they can be quickly and easily connected when first responders need to set up quickly.

- In the context of supplying oxygen to patients in emergencies, quick release couplings are also very valuable utilities. When a patient is injured or suffering a traumatic health event, time makes all the difference when it comes to the success of the first response. Quick release couplings can be used to quickly connect oxygen lines to oxygen supplies in such situations, shaving tens of seconds off of the time it can take to prepare equipment for patient use.

- Other Quick Release Coupling Applications

- There are variations of couplings that are advantageous to use in certain situations and come in a variety of generic and proprietary types with the market dominated by three standards:

-

- Industrial-Type Based on Military Specification

- ARO-Type Mainly for Fluid Applications

- Automotive-Type Including Inflation and Pneumatic Tools

- When chosen carefully and applied correctly, quick release couplings can be invaluable assets to their users. Quick release couplings are available with a variety of connection designs.

Things to Consider When Purchasing Quick Release Couplers

IQS Directory implements a thorough list of quick release coupling manufacturers and suppliers. Utilize our listing to examine and sort top quick release coupling manufacturers with previews of ads and detailed descriptions of each product. Any quick release coupling company can design, engineer, and manufacture quick release couplings to meet your company’s specific qualifications.

An easy connection to reach quick release coupling companies through our fast request for quote form is provided on our website. The company information includes website links, company profile, locations, phone, product videos and product information. Customer reviews are available and product specific news articles. This source is right for you whether it's for a manufacturer of hydraulic quick release, quick hose couplings, and quick connect couplings.

Proper Care of Quick Release Couplings

To prevent contamination during disuse, use caps and plugs on the couplings. A fail-safe mode should also be designed in case problems do occur so hoses or the couplings do not endanger anyone. It is also important to note that couplings from different manufacturers may not be completely compatible. However, in the event the couplings are, the lowest pressure rating out of the two couplings should not be exceeded.

If the couplings are properly implemented there should be no problems. First thing is to consult the safety guide provided by quick release coupling manufacturers. Both the person responsible for selecting the proper couplings and the person to use the coupling should have a copy of the correlating safety guide. It is important to know if the coupling is suitable to seal various fluids that may be toxic or flammable.

Quick Release Coupling Terms

- Air Inclusion

- Ambient air that is forced into a system during the connection of quick disconnect coupling mates.

- Brinelling

- Grooves or dimples that are worn into the shoulder of a male half. These deformations are engendered by the locking balls of a female body.

- Breakaway Clamp

- A device that clamps to hold the sleeve of the quick disconnect coupling, which permits movement of the body. The movement is either forward within a single or double-acting sleeve upon disconnection, or backward within a double-acting sleeve upon connection.

- Connector

- Any device that is used to join two or more parts together. In quick disconnect couplings, the male tip is often referred to as the connector.

- Connect-Under-Pressure Rating

- The designation given to a coupling that refers to its ability to be connected with applied pressure from one or both sides of the hosing.

- Coupler

- A part used to connect multiple pieces together. Female acceptors are referred to as couplers in quick disconnect couplings.

- Double-Acting Sleeve

- A sleeve that allows for pull-to-disconnect and push-to-connect.

- Dust Cap

- A removable device that protects the male tip from everything but contamination when it is disconnected from the female body.

- Dust Plug

- A removable device that protects the female body from everything but contamination when it is disconnected from the male nipple.

- Female Body

- The accepting half of the coupling. The female body consists of an opening that contains locking balls to keep the male end in place.

- Flow Checking

- Also called “ball checking,” “lock-up” or “check-off,” it is the closure of the male tip half valve during high flow conditions, such as the rapid lowering of a heavy loader.

- Inside Diameter (ID)

- The distance measured from an inner surface of a quick disconnect coupling to the innermost point directly opposite the original mark. Equal inside diameters between connectors and hosing ensure equivalent flow rates throughout the system.

- Interchange

- The variations in locking design between internal coupler mechanisms and external nose configurations.

- Locking Balls

- A series of small, circular-shaped objects that project and retract from a female body. Locking balls allow for the insertion and withdrawal of the male nipple.

- Male Tip

- The nipple-shaped coupling half. The male tip is inserted into a female body and kept in place by locking balls.

- National Taper Pipe Thread (NPT)

- A standardized groove design for threaded parts for the United States.

- Pivot Joint

- A connector assembly that is able to turn in multiple directions.

- Poppet Valve

- A machined, self-aligning valve that typically offers higher flow than ball valves. Elastomers are incorporated into poppet valves to provide a positive seal upon disconnect and to prevent low pressure leakage.

- Pounds Per Square Inch (PSI)

- A unit of measure of pressure. The maximum rated PSI for quick disconnect couplings must meet or surpass that of the other system components to ensure reliable performance.

- Spillage

- Fluid or air loss in a system due to the disconnection of a coupling device.