Electric Heaters

Electric heaters are utilities used for heat generation. The use of electric heaters throughout industry, commerce, and consumer products contexts is widespread and varied; the number of different heater configurations and applications grows almost daily. Some heater varieties resemble each other very closely. Band heaters and strip heaters, for example, are distinguished from each other only by the fact that band heaters are usually slightly smaller and more flexible than strip heaters.

The variety of electric heaters on the market is astounding, sometimes with cross over styles. Cartridge heaters sometimes qualify as immersion heaters, but not always. Sometimes, a heater’s name is descriptive of its use, as is the case with drum heaters. In other cases, a heater’s name is descriptive of its configuration, as is the case with tubular heaters. Some heater terms can be used interchangeably; air heaters and duct heaters are both used in HVAC filter systems to heat air, though a free-standing space heater could also be considered an air heater but not a duct heater. Both could be described as circulation heaters, though some circulation heaters are used to heat liquids in a containment system. All of these heaters can be considered process heaters, depending on their use, and they are all likely to feature wire or coil heating elements with ceramic, mineral, or other insulation material. Despite the seeming interchangeability of terms and the confusion it can cause, each variety contributes to an important industrial process or commercial utility as well as some purposes in the context of consumer products.

An electric heater is any electric-powered device used to create heat. They are used in a great variety of contexts. In manufacturing and industrial processing, electric heaters can provide localized heat to an area within a machine to help shape or melt materials, heat liquid tanks, radiate heat through the air, or preserve the molten state of a substance. Strip and band heaters as well as cartridge and air heaters are all frequently used for these purposes. In metal, plastic, and rubber extrusion, for example, the friction generated as a natural expression of the extrusion process does not always generate sufficient heat to plasticize the materials intended for extrusion. Heaters can be used as a supplement to generate and sustain material plasticization, which contributes to a more efficient process and helps yield a higher-quality extruded product. Heat is an essential part of many other manufacturing processes as well. In packaging, foam fabricating, metal fabricating, and food processing industries, cartridge heaters are most often inserted through a custom-sized hole into equipment parts that require localized or high temperature heat. Radiating heaters like immersion heaters and tubular heaters are used to heat liquid or air in water treatment facilities, residential applications, commercial buildings, and many other applications.

Every electric heater consists of a few parts that are essential for electrical heat generation. Electric heating is the process by which electricity is converted into thermal energy. An electric charge is usually conveyed by electrons flowing through a medium. When such a medium is connected to an electrically resistant material, the electrons collide with the atomic particles of the resistor, causing them to vibrate. The noticeable expression of that vibration is heat. In the case of electric heating, the resistor is called the heating element. Heating element composition and configuration is variable. Coil heaters can be a simple metal resistor coiled into a spiral shape. Others can feature elaborate configurations and advanced ceramic insulators to maximize heat generation, direct heat distribution, and otherwise control the qualities of the heat more effectively. Electric heaters only need heating elements to generate heat, but most of them feature some kind of insulation, and almost all of them feature a sheath of stainless steel, aluminum, nickel, or another material to improve performance and extend operating life. Insulation is necessary in many types of electric heaters to retain and absorb electrical energy, so it can be released as heat energy by surrounding coils or materials.

Ceramics are the most common type of insulation, although electric heaters can be fitted with mineral, mica, or fiberglass insulation as well, depending on the heater's application requirements. Radiating types of electric heaters transfer heat from ceramic cores or complete heating elements by moving heat through the air with fans, as is the case with space heaters, or through hot air ductwork systems, as is the case with duct heaters. Each application for electric heaters will require a standard for material make-up, temperature capacity, and power. Non-electric heating systems can involve coal, wood, gas, or water, although most of these alternatives are far less energy-efficient than electric heat generation. Electric water heaters, for example, are more environmentally sustainable and economical than other heating methods. Safety is another crucial concern when purchasing a heater. Different heaters respond in different ways to different environments and applications. Successful industry professionals carefully choose electric heaters based on a foundation of clear knowledge about the operating conditions in which an electric heater will be employed and on what tasks a heater will be applied to.

Quick links to Electric Heater Information

How Heaters Work

Heaters are fitted with a high resistance wire that converts electricity to heat energy. It works the same way resistors in home and industry applications do—by obstructing or opposing the flow of current. The first heaters were in the form of a bulb; current was passed through a thin wire, a filament, which produced a white glow accompanied by heat.

Most of the high power incandescent bulbs are rated 100 Watts, but their heat barely reaches the user. To this end, making heaters will require a high resistance wire such as Chromel to form a heating element.

Typical heat production-elements are designed in the form of coils—ribbons of strips of wire that give off heat just like a lamp filament. They are used in many applications in homes and in industries. These elements are either iron based or nickel based. Nickel based elements are usually nichrome, or chromel, an alloy of nickel and chromium. In nichrome, nickel forms about 80 percent of the alloy.

Nichrome is preferred as at its melting point, ranging between 1400 and 2550 degrees Fahrenheit, it does not oxidize; it only shows slight expansion when heated and has an optimal resistance. Granted, most applications use nichrome.

There are other forms of heat production elements used in industries and homes.

- Bare Nickel-Chromium Wire (NiCr) or Ribbon

- Can be used straight or coiled, is normally used in toasters and hair dryers.

- Screen Printed Metal or Ceramic Tracks Deposited in Metal Plates Insulated with Ceramic

- Common in kettles and other domestic appliances.

- Clarod Sealed Elements

- Nickel-chromium wires with a ceramic binder and are sealed inside a metal shell. They can be straight or curved rods and are normally used in coffeemakers, ovens, and electric stoves.

- Heat Lamps

- High powered incandescent lamps radiating infrared instead of white light. They are used in space heaters and food warmers.

- PTC Ceramic

- Short for Positive Thermal Coefficient Ceramic, is a type of ceramic that becomes highly resistive above a given composition dependent temperature threshold. This property allows the material to act as its own thermostat.

In industries that require high amounts of heat, such as those melting metal and plastic, metal alloys, Silicon Carbide, and Molybdenum Disilicide are used.

Ceramics are the most common types of insulation, although electric heaters can be fitted with mineral, mica, or fiberglass insulation as well, depending on the heater's application requirements. Radiating types of electric heaters transfer heat from ceramic cores or complete heating elements by moving heat through the air with fans, as is the case with space heaters, or through hot air ductwork systems, as is the case with duct heaters.

The History of Electric Heaters

Early forms of electric heaters used bulbs. Credit is given to Thomas Edison who invented the light bulb in 1880. However, heaters needed to be durable and produce more heat for different applications; a high resistance wire needed to be used. Albert Leroy Marsh developed chromel, the first alloy to be used in these heaters. Chromel, also referred to as nichrome, was up to 300 times stronger than other alloys developed at that time.

The alloy can heat up to more than 1400 degrees Celsius, and it is corrosion resistant. This revolutionized electrical engineering.

In the early 1890’s, General Electric, an American company, started producing the first heaters. These heaters used an elongated glass bulb and were produced in two companies, one of which was headed by Thomas Edison.

- The UK and Heater Technology

- In the UK, Herbert John Dowsing was designing an all-electric cooking method based on the long cylindrical bulb model in 1891. Though the design was rudimentary, it was the closest to modern heaters. The unit had copper backing to ease radiation of heat into the room. He is credited for domestic heating in the UK.

- In 1912, portable heating technology started gaining traction. Charles Reginald Belling set up his own business to manufacture heaters. The early heater models were in the form of table lamps.

- Electric-Heaters in the 1900’s

- Radiant heating became popular after World War II. During this era, the bar heater, also known as electric fire, was invented. Radiant heater units were using bars of coiled wire that would give an orange glow when current passed through them.

- Most units produced were portable electric heater units. However, the units were not completely safe as they would be knocked off and start fires or inquisitive fingers would get burned. Today, bar heaters are still produced but with better safety standards.

- In the 1960’s, the demand for power led to the development of storage heaters that allowed those in different industries and those in homes to get heat production while using less power.

- Modern heat production focuses on the use of smart technologies to control radiant heat production. Applications in different industries use remotes and digital programming. This has enhanced energy efficiency, made the units more portable, and allowed them to be used in industries that require high amounts of heat.

Ways to Enhance the Efficiency of Electric Heaters

Heating appliances are essential for any industrial process. Even before the Industrial Revolution, various types of heating systems were used for the production of goods and in several other processes. However, if we look back at the major transformations in the structuring and capacities of industrial heating applications, we find that most of the changes occurred after the 1970s and 80s. Electric heaters have replaced their traditional coal-powered counterparts, lowering our overall dependency on wood and coal. This shift has no doubt slowed down the spread of pollution caused by industrial processes.

- Induction Systems

- Industries are rapidly employing induction-heating systems in their processes thanks to a host of benefits offered by these advanced systems. We will be discussing the advantages delivered by these appliances in later sections, but before that, let us understand the features of modern-day induction systems.

- Induction heating made its entry into industries in the 1980s. However, it was within the last decade that induction heating rose to fame. Its rise in popularity was due to its intelligent control system and promise to help industries save thousands of dollars every month.

- Most of today’s induction heaters employ Eddy Current and electricity conducting metal to generate the energy required to power industrial processes. With the help of a metal piece and automatic control panel, the devices provide even heating and help save big on energy consumption.

- By introducing an induction-based electric heater in your manufacturing process, you can increase operational efficiency while decreasing your surplus energy consumption. Check out some of the biggest benefits of induction based heaters in the following paragraphs.

- Flame & Pollutant Reduction

- When you use traditional fuels such as coal, wood or petroleum, pollution is the usual outcome of your industrial processes. Smog, vapor, smoke, chemicals, harmful gases, etc. are some of the most common releases from industrial processes. By using induction-based electric heaters, you can significantly bring down the rate of flames and other pollutants from your facility. In fact, induction systems release no flame causing them to become a widely popular heating appliance among industries.

- Easy Heat Adjustment

- Electric heating systems use electro-magnetism to generate energy according to the industrial procedure at hand. Any temperature can be achieved by adjusting the controls of the system. You can easily adjust the output temperature of the heating application.

- Process Versatility

- You can implement induction-based electric heaters in almost any process. You have options to make adjustments in the coils to fit into an application of any shape or size. Additionally, a single device can be used as the heating source for various applications. However, you will need to check the capacity of the device before making such adjustments.

- Apart from these features, electric heating devices can be designed and ordered according to your needs. They are handy and mobile, and they will not show any limitations because of their size. You can get your induction heater designed in small sizes without compromising strength and heating output.

Important Tips to Consider for Electric Heater Maintenance

To ensure that your industrial heating appliances are working efficiently and cost-effectively, two things are mandatory: proper installation and proper maintenance. Regular maintenance ensures that your heater is performing efficiently but also lowers the risk of frequent repairs and replacements that affect your overall expenses.

The Department of Energy suggests that electric heaters should be cleaned twice every year. A number of manufacturers also say cleaning of heating appliances every six months is imperative if you are expecting a long and uninterrupted performance. However, this suggestion is unrealistic for heating devices that run extensively day and night. An ongoing maintenance routine should be selected based on the frequency of machine utilization.

Cleaning improves the performance of your process machines and enhances the quality of your plant and facility equipment. This is especially true for the processes that require a constant temperature level. Maintenance ensures that a heater is providing the necessary heat to a manufacturing process.

Whether you install an electric heater or another other type, such as a band heater, strip heater, or pipe heater, the following tips will help you perform effective maintenance on your machine. These tips may also be followed for the maintenance of home heaters.

- Cut Off the Power Supply

- You cannot clean your electric heater while it is turned on. Switching the heater off is the first step in the maintenance process. Use a voltmeter to make sure there is no electricity flowing to the device and the heater has been switched off completely.

- Remove the Thermostat Carefully

- If there is a thermostat in your heater, it should be removed first after disconnecting the power supply. Be careful while removing the grill. Find the knob or screw that mounts the thermostat to the heater. Many users remove the thermostat inaccurately and end up damaging the unit.

- Vacuum Clean the Heater

- Use a vacuum cleaner to blow out the debris from the heating appliance. If you do not have a vacuuming device, you can use a hair dryer to remove dirt from the corners and sides of the heater. Experts say you should never use canned air to remove debris, reasoning that this process could increase the production of potentially inflammable elements. Another safety tip from energy.gov: make sure the fans of the heater do not move while you blow out debris from the heater.

- Gently Clean the Grill

- Use lukewarm, soapy water to remove all dust and dirt from the grill. Soak the grill in this solution for 10 minutes to soften the debris before final cleaning.

- Carefully Replace the Grill

- After you have cleaned the grill, allow it to dry out completely. Reinstalling the grill while it is wet can severely damage the heater and electric circuits. Carefully place the thermostat on the heater, put in the screw, and tighten it.

- Now, turn on the power supply, and allow the thermostat to run for a few minutes before turning it on. Observe if there are any changes in the noise or heating. If you notice a change, you should speak to an electric heater repair service.

Electric Heaters and Costs

In the design of electric-heaters, whether tankless water heaters or garage heaters, manufacturing companies consider that intermittent or partial day use will be more energy efficient. When used in industries, these units are relatively cost effective.

Granted, most of the units, when fitted into applications, are designed with auto shut-off with the exception of air heater features to reduce energy consumption. The programmable nature of the units and their use of infrared sensors allow modern heaters to save more energy.

Different Types of Industrial Heaters

Electric heaters are important industrial and domestic devices that use electric current to produce heat. These appliances use an electrical resistor that supports the theory of Joule Heating. According to this theory, a current converts into heat energy while navigating through an electrical resistor. In most present-day electric heaters, the element wire is made of nichrome. There are various types of electric heaters, used by industries and households. A description of various types of industrial heaters follows.

Immersion heaters have uses a cross a number of different industries, including plastic, food processing, etc. These heating applications are used to heat liquids stored in large containers, reservoirs, or tanks. Working on the principles of direct heat transfer, these heaters can be used for processes that require quick and high temperature adjustments.

Moreover, if you have fluids of dissimilar characteristics, then electric heaters provide an obvious choice. Immersion heaters work well with liquids that have different properties. The aspect that makes immersion heaters the favorite of many industries is that they do not need frequent repairs and maintenance. Immersion heaters can be subdivided into Flanged, Screw-plug, Circulation, and Side Heater varieties. A large number of today’s immersion heaters work on electricity, while the ones of earlier generations used petroleum as fuel.

Pipe heaters are designed and shaped to be incorporated in pipes of two and three inches in diameter. These tiny devices perform well while staying mounted inside a pipe. Ideally used for applications that need slow and low heating, pipe heaters are widely used for processing wax and tar. They are also used for supplying heat for the treatment of highly corrosive materials. An interesting fact about these devices is they do not actually touch the liquid they’re supposed to heat. Therefore, these heaters do not follow the principles of direct heat transfer; they work on indirect heat transfer. An element inside the pipe carries heat to the liquid. As the heater is not put into the liquid, pipe heaters do not require frequent maintenance.

Cartridge heaters are designed to warm up solids—typically, metal-based solids. These appliances work on extremely high temperatures because the melting or heating point of metals is usually very high. Cartridge heaters are affixed into a mold and perform thermo coupling to control their temperature. Providing accurate heating and temperature control, these heaters are used for motor or hydraulic oil applications, gearboxes, and water-based applications. Cartridge heaters are also used in food production and laboratories. Cartridge heating devices use conductive wires for the transfer of heat.

Duct Heaters are commonly used in airflow ventilation systems, comfort heating systems, and several process heating applications at commercial and industrial facilities. Residential ovens are also based on this technology. Duct heater motors can be classified in three categories: tubular, open coil, and finned tubular duct heaters.

The Design of Heating Elements

Heat production elements are designed for the smallest of heat production applications, such as kettles, and the largest applications, such as metal melting units. Engineers consider up to 30 different factors when designing these units. When electrical energy is passed through a heat production unit to warm air or heat water, its performance will be affected by current in amps and voltage in W for domestic applications and kW for applications in industries.

The performance is also affected by length and diameter of the element used, the material of the element, and operating temperature. For each type of element, there are specific factors to be considered including length, stretch, and pitch among others. For a ribbon element, thickness, width, weight, and surface area are of key importance during the design of heat production elements.

Heat production elements will not work in isolation but will need to be integrated into different appliances. How the element is used or abused will also determine the end performance. This includes how the element will relate with the insulators it is fitted in. The size and the thickness of the elements will be determined by the appliance to be made. For instance, the element to be used in a convection heater is different from the one used in a soldering iron.

The expansion of the element material will determine how it reacts when supported between insulators. Some elements might sag and cause problems.

The above and many more factors have to be balanced for the heater to work optimally without causing any safety issues.

Producing Heat in Industries

Electric heat production has been adopted in different industries because it does not lead to the production of fumes. Electric heat is easily applied at the precise point it is needed. In industries, there is normally a high concentration of power in per unit volume and per unit area. These units can be designed in any size and, therefore, can be used anywhere within a processing plant. Given the high speed of response, these heaters lead to rapid cycling mass production of equipment.

Transferring electricity to the exact point of use is relatively costly. Designing a system for industry use starts with identifying the temperature and amount of heat required, and the most feasible methods of transferring heat within a plant.

The most common heat transfer methods include:

- Conduction

- Convection

- Radiation

- Electric Fields

- Magnetic Fields

Industries apply different forms of heaters based on their needs. Some of the most common methods include:

- Resistance Heat Production

- Electric Arc Heat Production

- Induction Heat Production

- Dielectric Heat Production

In some applications, the heat from the heater is directly applied to the workpiece, such as in arc welding. In other applications, heat is produced from the heater and transferred by any of the methods listed above. Industries require low temperature (about 400 degrees Celsius), medium temperature (about 1150 degrees Celsius), or high temperature (above 1150 degrees Celsius). High temperatures are needed in smelting, welding, cutting, and brazing among other applications.

Points to Consider When Selecting an Electric Heater for Industrial Use

Industrial heaters are powerful and well-controlled devices with features well beyond heaters used within residences. This heavy energy expenditure adds to the final cost of production when industrial heaters are in use at a manufacturing facility.

Moreover, some processes and productions are entirely dependent on the performance of an electric heater when used in conjunction with other plant and facility equipment. Choosing the wrong heating appliance may have a significant impact on the quality of production.

Consider the following criteria when selecting an industrial heating system.

- Types of Electric Heaters

- Basically, there are four types of industrial heaters: electric, radiant, infrared, and petroleum. Out of these types, petroleum-based appliances produce the greatest level of pollutants and smoke, and the electric versions produce the lowest.

- Electric Heaters

- These are the easiest to operate and easiest to install machines and the most popularly used industrial heaters. Electric heaters can be used for home, commercial and industrial purposes. These machines are powered by electric energy, which is converted into heat following Joule's theory of energy conversion. The structure of electric heaters also involves a fan that circulates heat over the area or application it is being used for.

- Radiant Heaters

- If an industrial application needs simple and even heating, radiant heaters are the most suitable pick. These machines work on the principles of radiant heat to radiate energy to anything that lies in its range. The nearer you are, the more heat you will feel.

- Infrared Heaters

- Similar to radiant heaters. However, they provide heating only to the area that has been fixed as its target. No fan is used in infrared heaters, so you can be sure that no unnecessary noise pollution is being spread via your industrial processes.

- Petroleum-Based Heaters

- Employ gas, diesel, and kerosene as fuel, and they release a large amount of chemicals, smoke, smog, and various pollutants into the environment.

- Power Consumption

- Since we are talking about the selection criteria of industrial heaters, it would be wise to consider the power consumption or wattage of the appliance you are investing in. You need to discuss the capacity requirements of your process equipment with your engineers and suppliers. Make sure that you invest in a machine that has been rated as very energy efficient.

- Safety Considerations

- In addition, keeping the safety of your workers and facilities in mind is an important concern. When selecting an electric heater, ideal features include an automatic tip-over switch, overheat protection sensor, cool-touch exterior housing, adjustable louvers, carrying handle and wheels, and many other design-related conveniences that promote the safety of users.

Choosing the Right Manufacturer

There are many heater manufacturers creating heaters for common applications and custom heaters as requested by clients. Companies that offer custom heaters are preferred.

When requesting a heating system, clients will specify the power and voltage, material of the heat production-element, size, including length, width and diameter, styles, whether coiled or straight, and much more. Hot water heaters will need lower power than industry heaters. The overall cost of the unit will be dependent on the factors specified by the client.

A good company should incorporate the needs of the client by designing the unit with the client.

Electric Heaters Images, Diagrams and Visual Concepts

Electric heaters are made up of a heating core radiator that when an electric current enters the device the core increase in temperature.

Electric heaters are made up of a heating core radiator that when an electric current enters the device the core increase in temperature.

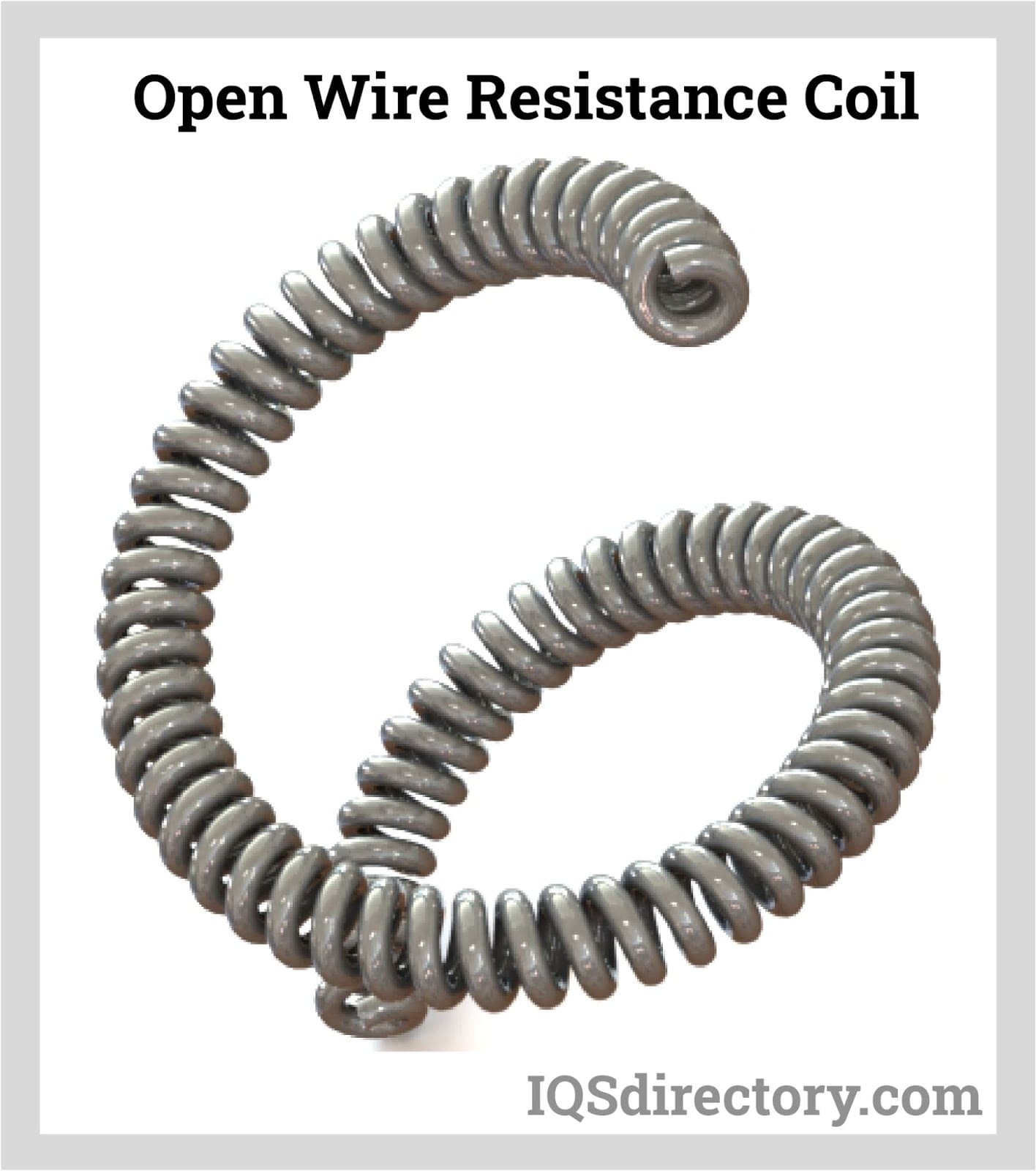

Open wire is a nickel chromium resistance wire that is placed on ceramic or mica insulation.

Open wire is a nickel chromium resistance wire that is placed on ceramic or mica insulation.

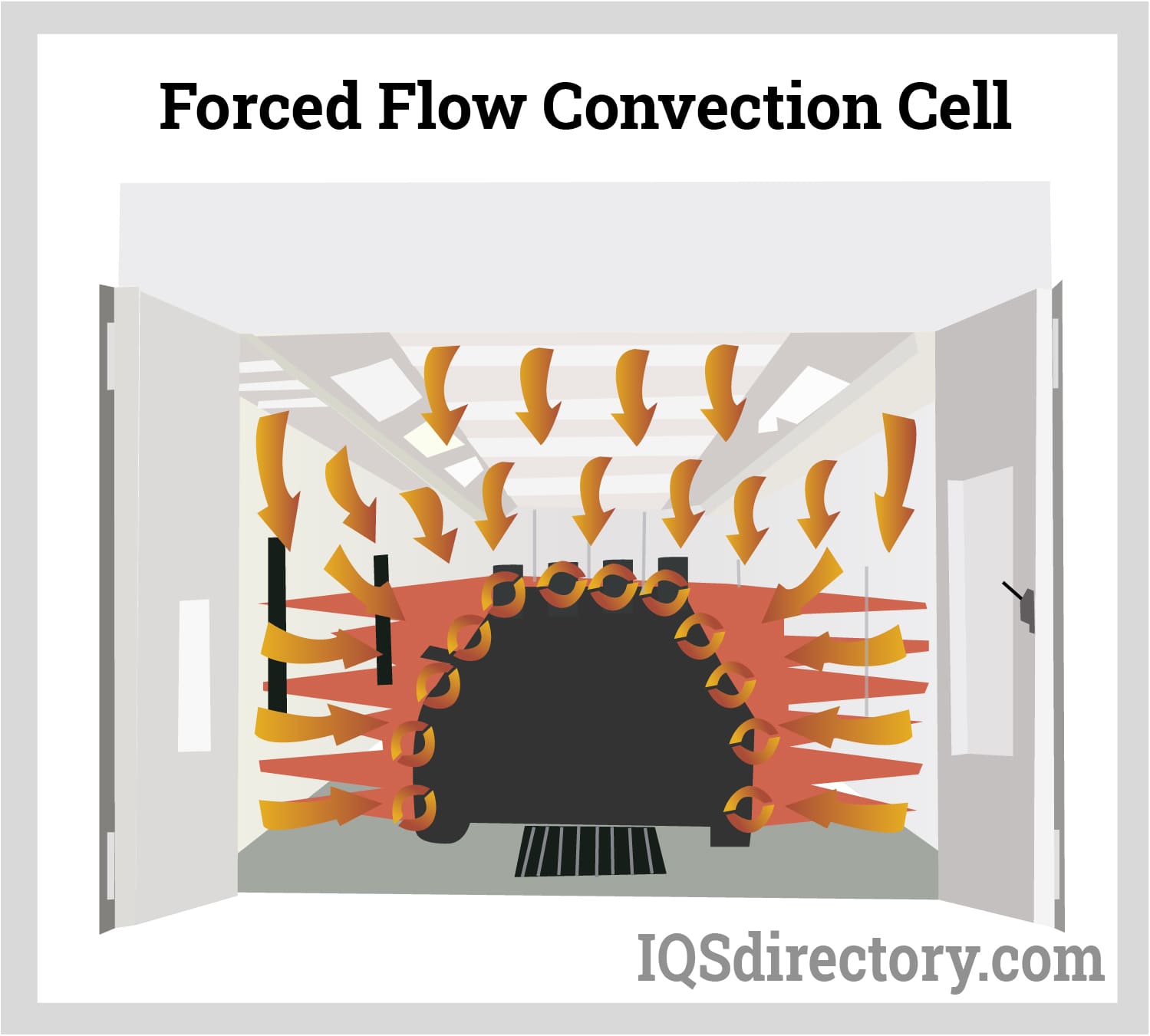

The process of heat transfer in an air heater is by convection and a method in which heat is transferred through a fluid or a medium.

The process of heat transfer in an air heater is by convection and a method in which heat is transferred through a fluid or a medium.

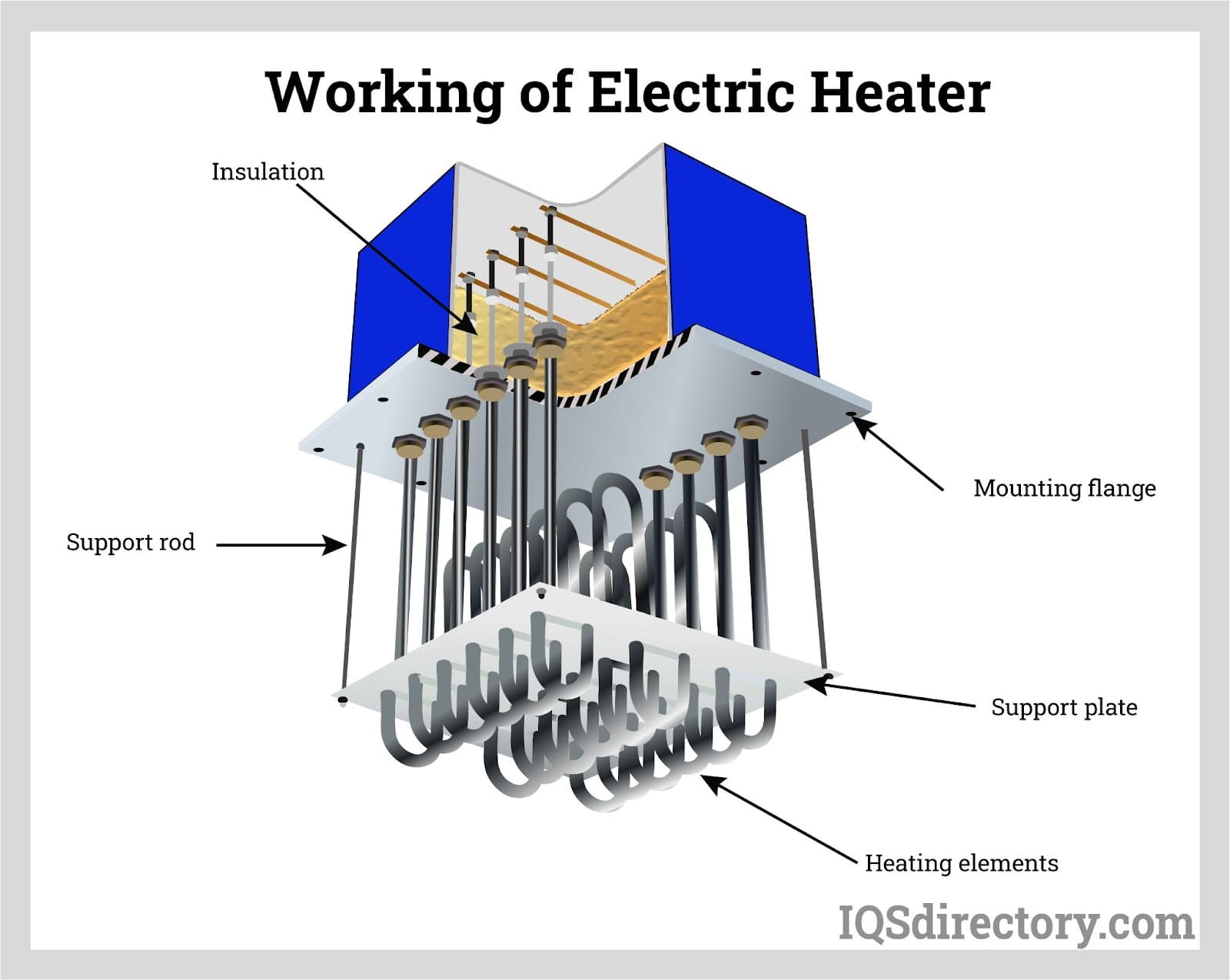

The electric heater works when an electric current passes through the resistors in the heater and give off their energy in the form of heat.

The electric heater works when an electric current passes through the resistors in the heater and give off their energy in the form of heat.

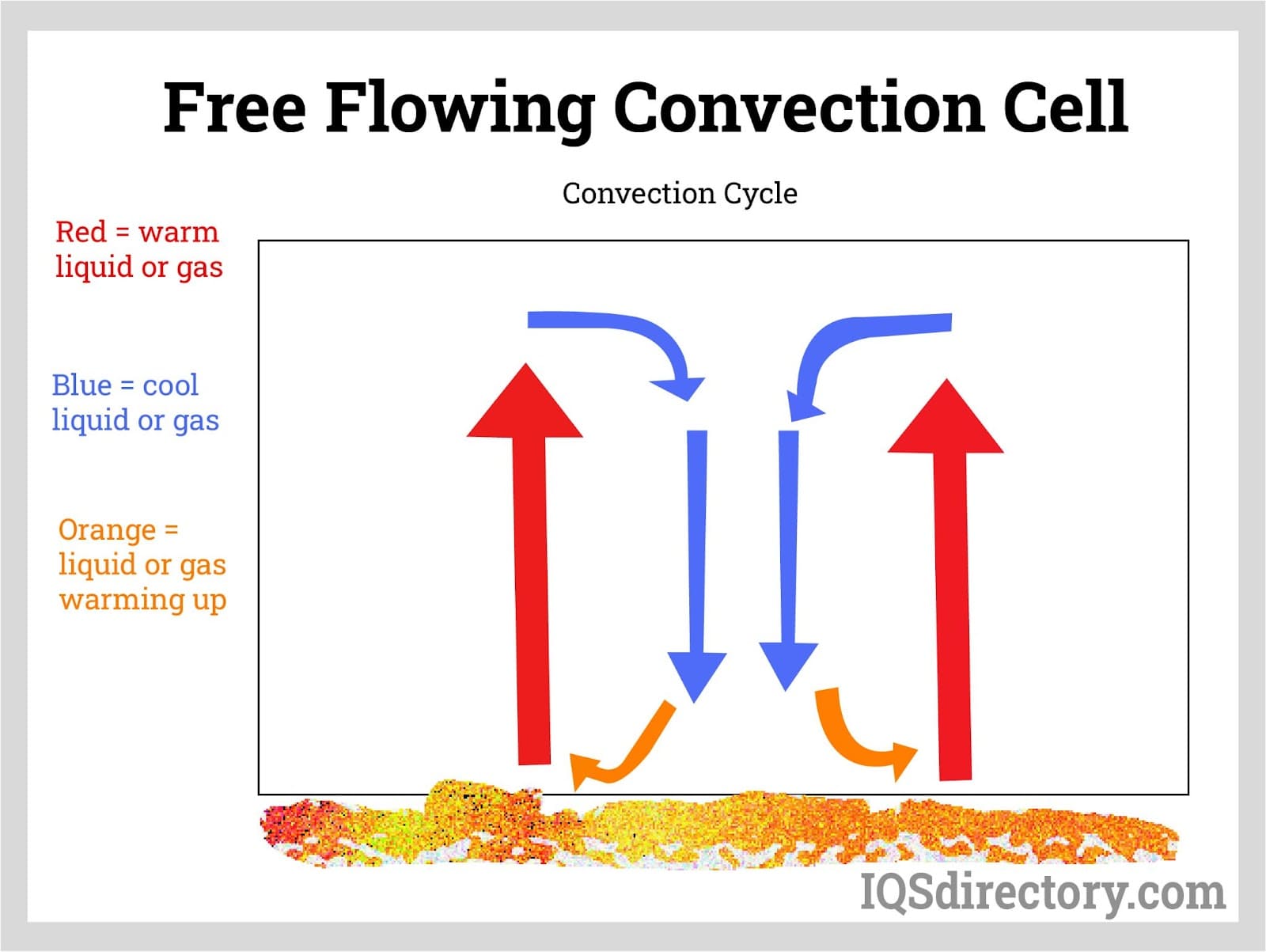

The convection cycle shows that warm air and gas rises, well cool air and gas sinks.

The convection cycle shows that warm air and gas rises, well cool air and gas sinks.

Electric Heaters Types

- Air Heaters

- Electric heaters used to heat air in an enclosed volume or in tandem with a fan system for distribution throughout a building.

- Band Heaters

- Small electric heaters that can be affixed to pipes, tubes, and nozzles for the application of heat in a small area.

- Cartridge Heaters

- Small electric heaters that can be inserted into machinery to provide heat in a small area; they are often used during extrusion and other thermoforming processes.

- Ceramic Heaters

- Electric heaters whose heat coils or other heating element materials are insulated with ceramic materials.

- Circulation Heaters

- Electric heaters used to heat a circulating volume of liquid or gas in an enclosed space.

- Coil Heaters

- Electric heaters characterized by the shape and composition of their heating elements, which are coiled metal ribbons or other similar materials.

- Drum Heaters

- Electric heaters used to heat drums. Large quantities of industrial chemicals, water, and even food products like chocolate (which are often stored or shipped in drums) can be heated with drum heaters.

- Duct Heaters

- Electric heaters used in tandem with other HVAC components in order to provide heat to a building.

- Foil Heaters

- Used in many industries and they can be found in products like car battery warmers, cabinets, defrost applications, heat exchangers, laboratory equipment, incubators, ceiling panels, and wall panels.

- Immersion Heaters

- Electric heaters that can be immersed in liquids and some solids and retain their functionality; these can be used for efficiently and safely heating large volumes of liquid.

- Kapton Heaters

- A type of electronic heater that use polyimide film to encapsulate heating circuits. This thin, ultra-flexible, and lightweight material makes Kapton heaters a great solution for compact applications.

- Process Heaters

- Electric heaters used to heat-treat or otherwise process raw materials with heat; process heaters can be used in surface treatment, raw materials shaping, and in many other industrial applications.

- Silicone Heaters

- Flexible heaters with an internal wire element and a body made of silicone rubber. These durable heaters can operate at temperatures of up to 450 degrees Fahrenheit. Silicone performs well in environments where there are rapid changes in temperature, and it is highly resistant to moisture and chemicals.

- Strip Heaters

- Small electric heaters used to conduct controlled amounts of heat in a small area; they can be affixed to equipment, which they heat on contact, or they can be used to heat small volumes of air.

- Tubular Heaters

- Electric heaters in a tubular shape.

Electric Heater Terms

- AC Current

- Short for "alternating current." An alternating current is characterized by the periodic reversal of the flow of electricity.

- Ceramics

- Non-metallic, inorganic, often crystalline materials used, in the context of electric heaters, as insulating materials.

- Conduction

- The transfer of heat. An object’s atomic particles vibrate when heated; there is a linear relationship between temperature and vibration intensity. When these vibrating particles come into contact with other particles, they transfer their energy. Energy can be transferred amongst every state of matter via conduction.

- Convective Heat Transfer

- The transfer of heat between fluids because of the movement of those fluids. Instead of direct transmission (conductive heat transfer), the heat in liquids and gasses is dispersed as the molecules move.

- DC Current

- Short for "direct current." A direct current is characterized by the unidirectional flow of electricity.

- Desalination

- Process by which salt is removed from saltwater.

- Ducts

- Channels used to direct filtered or temperature-treated air throughout an area.

- Electric Current

- The movement of an electrical charge through a conductive medium.

- Electro-Polish Finishing

- Used to remove unwanted material from a surface during surface finishing.

- Extrusion

- The shaping of a raw material into a useful product through the use of a die. Plastic, metal, elastomers, and other material can be formed into continuous profiles by extrusion.

- Heat

- The transfer of energy between objects; heat is the expression of atomic particles colliding with each other.

- HVAC

- Abbreviation for Heating, Ventilating, and Air Conditioning; HVAC equipment is any tool or component used in any HVAC process.

- Incoloy

- A proprietary superalloy characterized by its qualities of strength.

- Insulation

- Non-electrically-conductive material used to coat electrically conductive materials. In electric heaters, insulators are used to increase the efficiency of a heater and protect heating elements from damage.

- Molding

- The shaping of a raw material into a useful product through the use of a mold. Plastic, metal, elastomers, and other material can be formed into complex, non-continuous shapes through molding.

- NEMA Enclosures

- Enclosures built to varying standards set by the National Electrical Manufacturers Association; these enclosures house electrical equipment of varying sensitivity and delicateness. Corresponding NEMA numbers indicate the intended use of a given enclosure.

- Radiation

- The travel of energy particles and waves. Examples of radiation include visible light, radio waves, and heat generated by a heating coil.

- Thermostat

- A temperature-regulating device that employs the combination of a thermometer and mechanical parts to control heating and cooling equipment.

- Watt

- A unit by which the intensity of an electrical current is measured.