Alloys

Alloys are a combination of two or more metals or a metal and a non-metal

that possess unique and enhanced properties compared to their individual

components. The creation of alloys dates back to the Bronze Age, where

people discovered that combining copper with other metals, such as tin,

lead, or zinc, can produce a metal with superior strength and durability.

Creating Alloys

There are several methods of creating alloys, including melting, powder

metallurgy, and solid-state reactions. Melting is the most common method,

where two or more metals are melted together at high temperatures to form a

homogeneous mixture. In powder metallurgy, metal powders are mixed and

compacted under high pressure before being heated to form a solid alloy.

Solid-state reactions involve heating two or more metals in a vacuum or

inert gas to induce diffusion and bonding between the atoms.

The purity of the constituent metals is crucial in the alloy-making process.

Any impurities can significantly affect the properties of the alloy, such as

its strength, ductility, and corrosion resistance. Therefore, manufacturers

use advanced techniques to ensure the purity of the constituent metals.

Popular Alloys

There are many alloys used in various industries, but some of the most

popular include:

Steel

A combination of iron and carbon with small amounts of other elements, such

as manganese, silicon, and chromium. Steel is known for its high strength,

durability, and corrosion resistance.

Brass

A mixture of copper and zinc that is malleable, ductile, and

corrosion-resistant. Brass is commonly used in plumbing fixtures, musical

instruments, and decorative items.

Bronze

An alloy of copper and tin that is hard, strong, and corrosion-resistant.

Bronze is used in statues, coins, and other decorative items.

Stainless Steel

A combination of iron, chromium, and nickel that is highly resistant to

corrosion and staining. Stainless steel is used in kitchen appliances,

medical equipment, and other applications where hygiene is critical.

Aluminum Alloys

Combinations of aluminum with other metals, such as copper, magnesium, and

zinc. Aluminum alloys are lightweight, strong, and corrosion-resistant,

making them suitable for aerospace and automotive applications.

Limitations of Alloys

While alloys offer many benefits, there are also some limitations and

negative impacts associated with their use. For instance, the production of

alloys can be expensive and energy-intensive, leading to a significant

carbon footprint. Some alloys may also lack ductility, making them brittle

and prone to cracking under stress.

Benefits of Alloys

Despite their limitations, alloys provide significant benefits in various

applications. For instance, alloys can be customized to have specific

properties, such as strength, ductility, and corrosion resistance, depending

on the intended use. This makes alloys suitable for a wide range of

applications, from construction to medicine. Additionally, alloys are highly

resistant to wear and corrosion, making them long-lasting and durable, even

in harsh environments.

Applications of Alloys

Alloys can be customized to suit specific requirements by adjusting the

proportions of the constituent metals, making them a versatile material for

a wide range of applications. As a result, alloys find use in numerous

industries, such as:

Aerospace Industry

Alloys are widely used in the aerospace industry due to their high

strength-to-weight ratio and resistance to corrosion. Titanium alloys,

nickel alloys, and aluminum alloys are commonly used in the manufacture of

aircraft and spacecraft.

Automotive Industry

Alloys are used extensively in the automotive industry to make parts that

are strong, lightweight, and corrosion-resistant. Common alloys used in this

industry include aluminum alloys, steel alloys, and magnesium alloys.

Construction Industry

Alloys are used in the construction industry to make building materials that

are strong, durable, and corrosion-resistant. Examples of alloys used in

construction include steel alloys, aluminum alloys, and copper alloys.

Electronics Industry

Alloys are used in the electronics industry to make components that have

desirable electrical properties. For example, alloys of copper and nickel

are used to make resistance wires for heating elements, while aluminum

alloys are used to make electrical conductors.

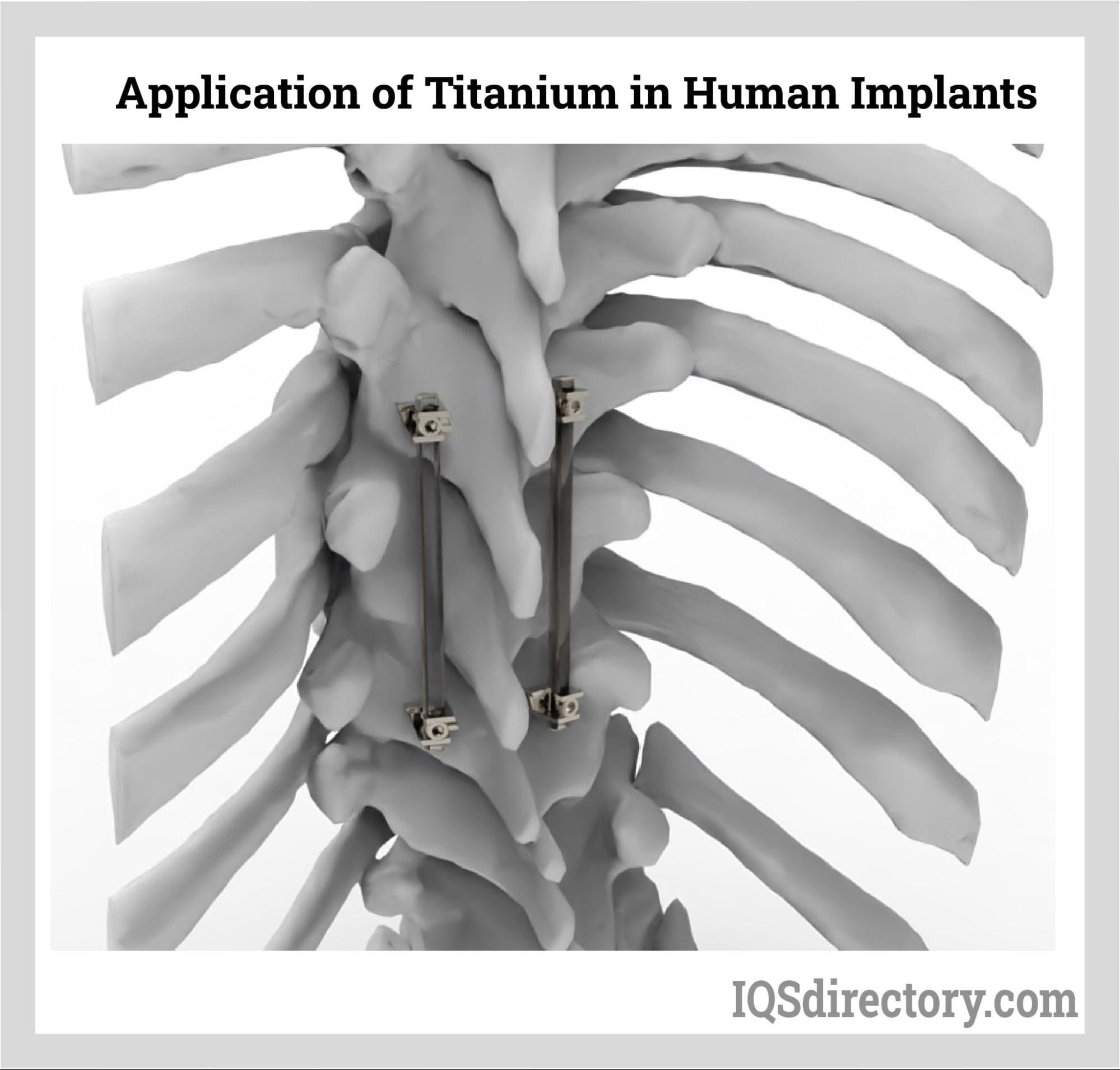

Medical Industry

Alloys are used in the medical industry to make surgical instruments,

implants, and other medical devices. Titanium alloys, stainless steel

alloys, and cobalt-chromium alloys are commonly used in medical applications

due to their biocompatibility, strength, and corrosion resistance.

Jewelry Industry

Alloys are commonly used in the jewelry industry to make precious metals

more durable and less expensive. For example, 14-karat gold is an alloy made

by combining pure gold with other metals such as copper, silver, or nickel.

Food Industry

Alloys are used in the food industry to make cooking equipment that is

resistant to corrosion and oxidation. Stainless steel alloys are commonly

used in this industry to make pots, pans, and other cooking utensils.

Choosing the Right Alloy Manufacturer

To ensure you have the most beneficial outcome when purchasing alloys from

an alloy manufacturer, it is important to compare several companies using

our directory of alloy manufacturers. Each alloy manufacturer has a business

profile page highlighting their areas of experience and capabilities, along

with a contact form to communicate with the manufacturer for more

information or request a quote. Review each alloy business website using our

proprietary website previewer to quickly learn what each company specializes

in. Then, use our simple RFQ form to contact multiple alloy companies with

the same form.