Clean Rooms

Clean rooms are enclosures designed to facilitate sensitive research, fabrication, and other operations that must take place in the absence of dust, moisture, and other airborne contaminants.

The measure of clean room cleanliness is the number of air pollutants that can be found in an air sample. Many clean rooms are not intended to be completely sterile environments. Instead, professionals concern themselves with the amount of dust floating in the air or dust that can be kicked up from the floor when stepped on. This dust is microscopic and can sometimes only be measured by specialized machinery. Typically, particles are measured in microns—a unit of measurement that equals one millionth of a meter.

There are some cases in which sterility is a requirement for clean room equipment suppliers; many medical research operations and testing procedures must be conducted in a sterile environment. Pharmacological studies, infectious disease testing, and other highly sensitive medical research-related procedures often require the complete evacuation of any microbes that may be present in their surrounding environments. Clean room cleanliness is determined by the presence of contaminants over 0.5 micrometers in size.

Quick links to Clean Rooms Information

Clean Room Applications

Clean room ceiling manufacturers provide designs intended to create a workspace in which factors like airborne dust, variable air temperature and pressures, moisture, and other atmospheric conditions can be carefully controlled.

All of the different possible clean room constructions allow professionals a range of workspace possibilities. They range from strict Class 100 clean rooms to less rigidly controlled portable clean rooms and modular clean rooms. As more and more operations came to rely on clean rooms, regulatory authorities and standard-setting organizations classified clean rooms according to their capacity for removing contaminants.

Class 1,000 clean rooms, for example, employ clean room supplies that are unlikely to release fibrous contaminants. The standards for clean room equipment used in Class 10,000 clean rooms are less strict; they can often feature soft walls and are used for less sensitive applications.

IQS Directory provides a list of clean room suppliers for aerospace, semiconductor, pharmaceutical product manufacturing, scientific and clean lab research, medical device manufacturing, military contract manufacturing, biology and microbiology, optics, consumer products, nanotechnology, and more.

Examples of clean room applications include pharmaceutical packaging rooms, powder coating enclosures, plant cultivation rooms, oil mist enclosures, powder coating and painting enclosures, and IV prep rooms.

The History of Clean Rooms

The first modern clean room was designed in 1960 by an American physicist named Willis Whitfield. He did so at the behest of the company for which he worked, Sandia National Laboratories. They were responding to the needs of the aerospace and microtechnology industries. In the early 1960s, as these and other high tech disciplines like bio-technology and medical research developed, and as products and research subjects became smaller, airborne contamination became increasingly disruptive. The clean room-esque spaces they had been using before Whitman’s invention had trouble with particles and unpredictable airflow. Once the modern clean room environment was invented, they were able to rigidly control environments and flush out impurities using constant, highly filtered air flows.

Clean Room Design

Clean rooms used by major manufacturers of microelectronics, pharmaceutical products, or circuitry can be as large as warehouses. In fact, they can be so large that they contain entire manufacturing facilities with multiple factory floors. Spaces with this clean room design are sometimes referred to as "ballrooms."

Other clean rooms can be as small as household ovens; these are used in small scale medical testing procedures as well as specialized, limited, or exclusive-run manufacturing operations. They can also be used for repairs and for small experiments.

Permanent clean rooms are usually built into the structures of the buildings that house them, as are the machines that regulate their conditions. However, some permanent clean rooms can be enclosed by glass or clear plastic walls.

Soft walls, which are most commonly used in clean rooms with lower decontamination standards, are often available from flexible acrylic fabrication suppliers and plastic manufacturing.

All of the materials used in clean room construction must be carefully chosen for their non-fibrous, non-static electricity-generating, and non-corrosive qualities. Any material that could contribute to air contamination must be avoided during the construction of clean rooms. Even stainless steel can corrode when exposed to bleach, which is sometimes used as a disinfectant.

Clean Room Features

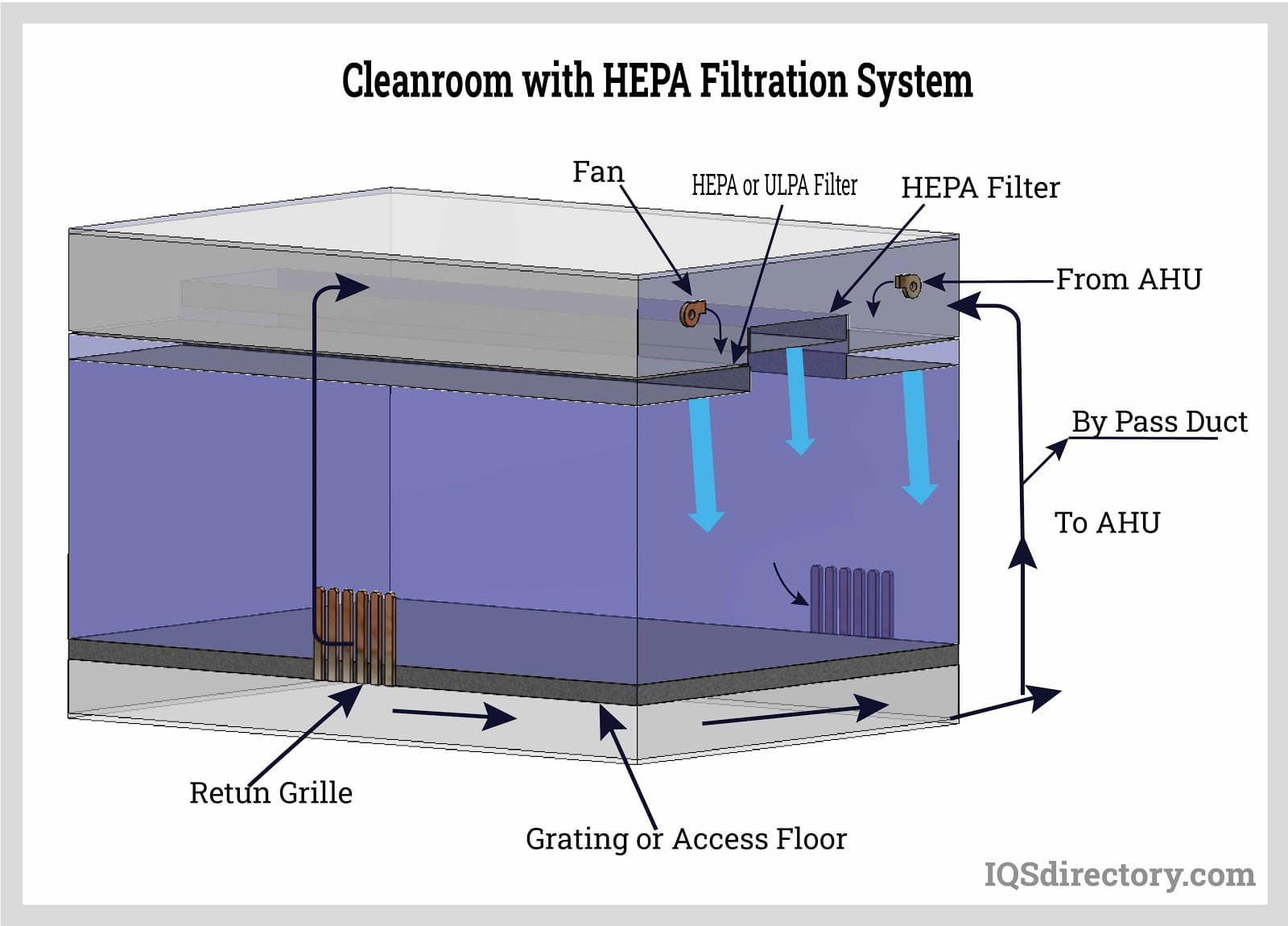

Clean rooms work first by filtering the air that enters them, making sure it is free of contamination from particles like dust. They do so with air filters and fans. They ensure the air inside stays clean by constantly recirculating it either through a HEPA Air Filter or a ULPA filter.

A clean room facility has a number of preventative devices and lots of clean room equipment and materials to create a controlled environment that is free from dust and microorganisms. The equipment can be for personal protection or it can be used to have germ or dust-free air in the facility. For example, to ensure that no contamination breaches the clean room, workers enter and exit through airlocks. Additionally, these airlocks sometimes feature an air shower stage. Please note that, while the cost of personal gear and supplementary devices, such as highly efficient particulate air filters, air showers, and anti-static devices, is quite high, they are very important to the integrity of the clean room.

You can customize your clean rooms with a number of different features that make them work better for their chosen application. Some, for example, may stay at a constant point of positive pressure, ensuring that, if the chamber springs a leak, air will exit, not enter. This feature is ideal for clean rooms at risk of leaks and/or that are used for highly sensitive applications.

You may also customize your clean room in terms of minimum and maximum temperature, room division and panels, lighting fixtures, furniture, and more.

Advantages of Clean Rooms

Clean rooms offer many advantages to their users.

First, they allow users to use and/or study highly sensitive technology and materials without compromising them. Without impurities like dust, systems have the opportunity to work with much more efficiency and accuracy. They’re also less likely to break down or malfunction.

Using a clean room also means that a researcher or worker can create a mini or micro environment around their product. For example, they can control electrostatic discharge by engineering a condition of low humidity. Or, they can contain leaks by creating an environment of constant positive pressure.

In addition, because of all of the aforementioned benefits, clean rooms earn their users an incalculable increase in revenue.

Clean Room Accessories

Depending on the types of materials manufactured in a clean room, customers may choose to accessorize their clean rooms with an array of accessories. For example, in a computer parts manufacturing unit, all the workers in a clean room need to wear anti-static garments and bracelets or anklets to prevent static current.

Customers may also choose to use items like tables, pass through cabinets, ceiling grids, benches and fume hoods (like the laminar flow hood). Another popular accessory is the clean room fogger, which is a machine that generates fog. It is used in smoke studies, where it helps researchers visualize air flow, air flow patterns, and turbulence.

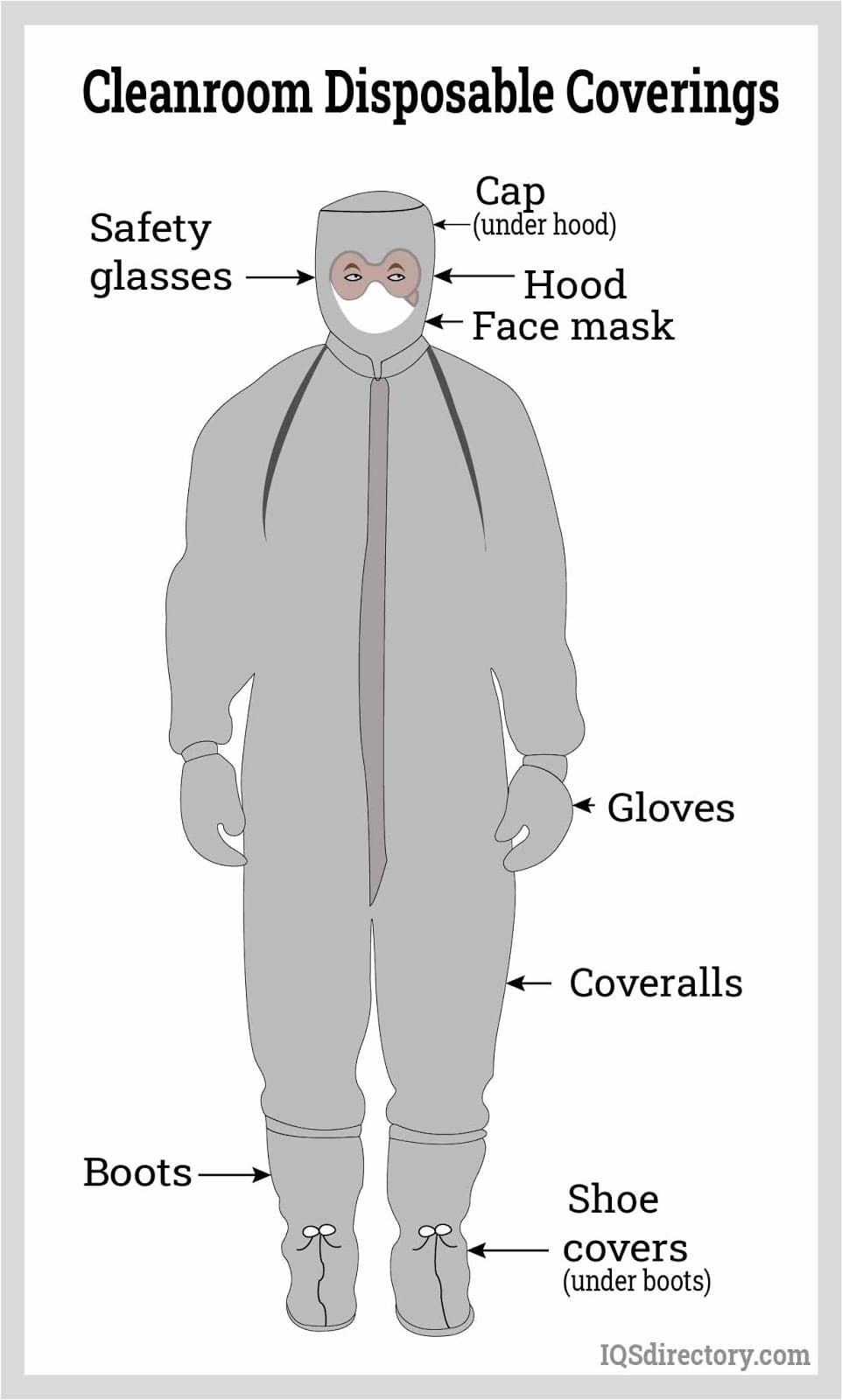

Another important accessory is the clean room suit. This suit, which features items like hoods, face masks, boots, and coveralls, keeps the skin and hair of workers unexposed. This is important because workers must not contaminate the clean room environment, and a human hair is usually around 100 micrometers wide, and humans shed dead skin cells at a rapid rate of 100,000 particles per minute while standing still. Remember: clean room cleanliness is determined based on the presence of contaminants over 0.5 micrometers in size.

Inside the clean room, workers must only use specialized clean room equipment and clean room supplies, including buckets and mops. Clean room equipment and furniture are specially designed to produce the smallest possible number of particles and comply with clean standards. They are also easy to clean, so those few particles they do produce are not a problem.

Clean Room Installation

Before installing your clean room, always double check the dimensions you have drafted will fit your space exactly. This advice holds true whether you are retrofitting a used space or you are building in a brand-new one.

The easiest way to install a clean room is by pre-fabricating it. By this, we mean having the manufacturer assemble as many parts as possible at their facility before they bring it to you. This will make the process quicker, and it will reduce the amount of construction and construction dust you have to deal with at your site.

If you do not choose to pre-fabricate your clean room, installation will take longer. However, it will still be done with precision. Your prefabricated manufacturers will send builders out to your site to assemble your clean room then and there, from disassembled components.

Proper Care for Clean Rooms

The best way to clean a clean room is with a combination of cleaning solutions and an efficient air filtering system, such as a HEPA filter.

When you select your cleaning solution, make sure that it is not so caustic that it will cause corrosion or any other counterproductive damage. In addition, there are a myriad of clean room supplies available to help you. Those which you will use depend upon your application and the nature of your clean room.

To put together a cleaning system that works, you must consider:

- What is to be cleaned?

- How is cleanliness measured?

- What cleaning materials or supplies should be used?

- When to clean?

- How frequently does one need to clean?

Remember, there are set standards for cleaning everything. Visit the ISO website to get the guidelines.

ISO Clean Room Standards

There are four styles for measuring and classifying ISO clean room standard cleanliness: US FED STD 209E, ISO 14644-1, BS 5295, and EMP EU. However, US FED STD 209E and ISO are the two main clean room standard systems against which the cleanliness of a clean room is measured.

US FED STD 209E outlines the federal standard of the United States government; clean room models are assigned a class number based on the number of 0.5 micrometer-sized particles found in every cubic foot of atmosphere within the clean room. The class numbers correspond with the particle per cubic foot number. Class 1 clean rooms can be expected to contain one 0.5 micrometer-sized particle per square foot, Class 100 can be expected to contain 100 particles, and so on. If regular, unfiltered air were assigned a classification, it would be Class 1,000,000.

The International Organization for Standardization also assigns standards to clean rooms. ISO grading is based on the number of particles, 0.1 micrometers or larger, permitted per cubic meter of air. There is a table standardized by ISO that defines various grading; for instance, an ISO 3 clean room has a maximum of 103 particles per meter cubed, or 1,000 particles. They are commonly known as Class 10000 Clean Rooms and Class 100 Clean Rooms.

There are nine ISO classes, each with different permitted contaminants in the air, the lowest being ISO Class 1, and the highest ISO Class 9.

ISO has written standards for the following:

- Clean Room Testing for Compliance

- How Cleanliness is Measured

- Methods for Evaluating & Measuring Clean Rooms & Associated Controlled Environments

- Clean Room Design & Construction

- Clean Room Operations

- Terms, Definitions, & Units

- Enhanced Clean Devices

- Molecular Contamination

- Bio Contamination: Control General Principles

The British Standard system is also recognized by some industries; their system measures contaminants in cubic meters instead of feet. To ensure their clean rooms are not only in compliance but also effective, manufacturers should always follow these guidelines.

Things to Consider When It Comes to Clean Rooms

When you’re in the market for a new or refurbished clean room, you must consider a number of factors. These include the length of your project, how sterile the environment must be, the sensitivity of the items inside the clean room, the dimensions of your space and the nature of your space (indoors, outdoors, new, existing, etc.).

When deciding on a contamination control program, also consider the following:

- Design and Airflow

- Architecture of clean rooms is designed while keeping in mind the needs of a facility. The principal aim is to achieve and maintain an airflow that has uniform velocity that follows a parallel flow line throughout the enclosed space—a uniform laminar flow.

- The rule of thumb: the more restriction to air flow, the more turbulence it causes. Turbulence has been attributed to many contamination problems. According to ISO clean room standards, all clean rooms should have a well-designed space where airflow is not restricted in any way.

- Filtration System Manufacturers

- Almost all standards specify High-Efficiency Particulate Air (HEPA) filters as required equipment in clean rooms. They filter very small particles with 99.97% efficiency.

- For low-grade clean rooms, like class 100 clean rooms, an HVAC unit can be used as an alternative.

- There are many filtration mechanisms other than HEPA filters available; weigh the price, advantages, and installation cost before choosing an alternative to a standard filtration system.

- Cleaning

- In most clean rooms, cleaning based on the requirements is a daily practice to maintain cleanliness . It is an important element of contamination control. Owners need to make decisions about maintenance, clean room supplies, and a cleaning schedule.

Also, you must make sure that every clean room product, every material, and every system you plan on installing is compatible with your application.

No matter what your application is or your specifications are, the best advice we can give you is to find the right manufacturer for you.

Who is the right manufacturer? Well, the right manufacturer is the one who looks out for you and your requirements. They’ll bend over backwards to make sure you’re satisfied. They’ll treat you with respect. Plus, they’ll know their stuff. To find the right manufacturer, check out those listed near the top of this page.

Clean Room Images and Illustrations

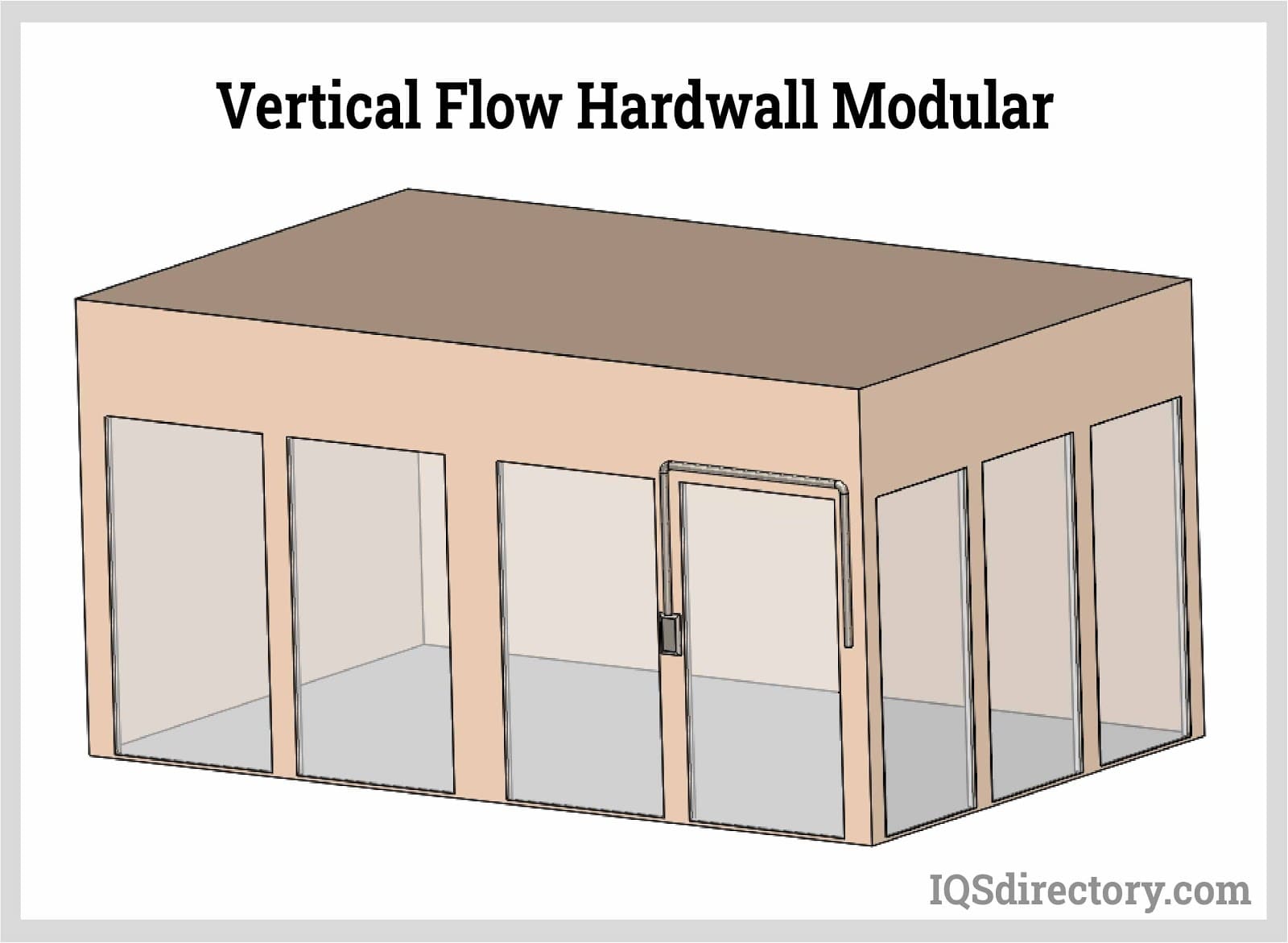

A prefabricated controlled environment that is constructed to limit the presence of sub-micron particulates.

A prefabricated controlled environment that is constructed to limit the presence of sub-micron particulates.

Modular cleanrooms with aluminum posts and rigid wall construction for increased air pressure.

Modular cleanrooms with aluminum posts and rigid wall construction for increased air pressure.

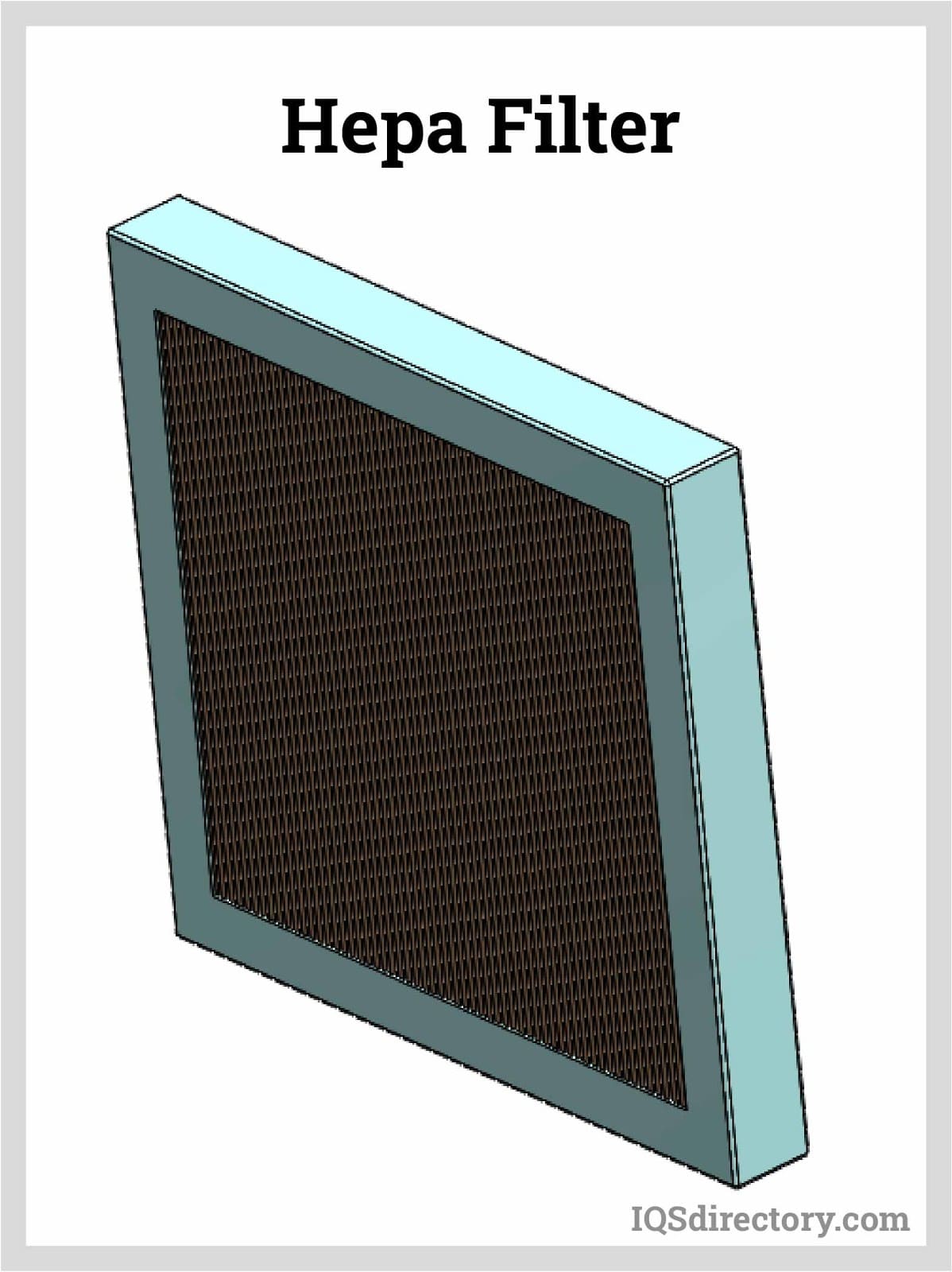

High efficiency air filters have tightly packed dense material to remove contaminants.

High efficiency air filters have tightly packed dense material to remove contaminants.

The multiple directions of the fibers of a HEPA filter are able to capture and trap microscopic particles.

The multiple directions of the fibers of a HEPA filter are able to capture and trap microscopic particles.

The required attire to enter a clean room.

The required attire to enter a clean room.

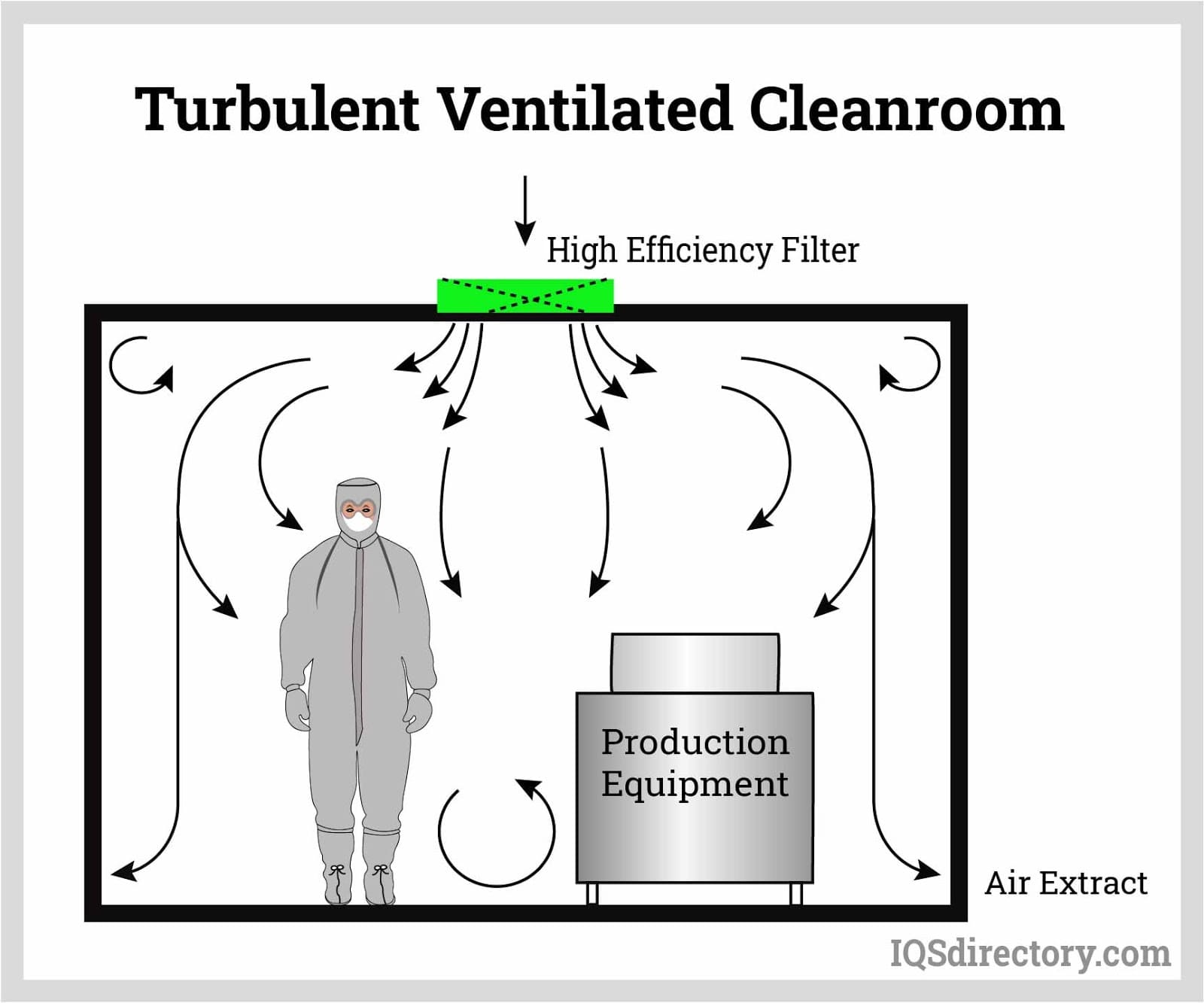

Turbulent ventilation are non-directional and unidirectional having air flow in one direction inside the clean room.

Turbulent ventilation are non-directional and unidirectional having air flow in one direction inside the clean room.

Clean Room Types

Clean room classification is often based on function or standard adherence. Examples of clean room types include modular clean rooms, portable clean rooms (mobile clean rooms), used clean rooms, ISO clean rooms, soft wall clean rooms, rigid wall clean rooms, and pharmaceutical clean rooms.

- Ballrooms

- Large-scale clean rooms.

- Class 100 Clean Rooms

- Federal Standard 209 regulated and never exceed 100 particles per foot.

- Class 1000 Clean Rooms

- Federal Standard 209 regulated and never exceed 1000 particles per foot.

- Class 10000 Clean Rooms

- Federal Standard 209 regulated and never exceed 10000 particles per foot.

- Clean Room Equipment

- Includes any tools, furniture, storage systems and work surfaces that are made specifically for use in clean rooms.

- Clean Room Systems

- Consist of all components that make up a functioning clean room.

- Clean Room Construction

- Companies manufacture custom or pre-designed clean rooms that fit all sorts of industry-specific standards.

- Clean Room Design

- The type of design, including conventional, portable, hard wall modular, and soft wall modular.

- Clean Room Supplies

- Include products that aid in maintaining a sterile clean room.

- Clean Rooms

- Areas where air content is strictly controlled.

- Conventional Clean Rooms

- Generally permanent clean rooms and are the most common type.

- Laminar Flow Clean Rooms

- Have filtration systems that control airflow and velocity to keep airborne particles from coming into contact with anything.

- Micro Environments

- Clean areas constructed for semiconductor fabrication and other similar, sensitive fabrication processes. In micro environments, small clean areas are constructed around the wafer (or other project piece) itself or around a part of the wafer to protect it from atmospheric exposure.

- Mini Environments

- Localized clean areas constructed around a specific tool or part to prevent atmospheric exposure.

- Modular Clean Rooms

- Clean rooms that are assembled on-site from pre-cut components (e.g. ceiling grid struts, walls, etc.).

- Portable Clean Rooms

- Transportable and self-contained.

- Softwall Clean Rooms

- Have walls constructed either of fabric stretched tightly over a frame or of free-hanging strips of fabric.

Clean Room Terms

- Air Lock

- A room located between a clean room and outside area that acts as a buffer during the transportation of materials into and out of the clean room.

- Air Shower

- A small room in which high-speed air jets rid personnel of contaminants prior to entering the clean room.

- Airborne Particulate Cleanliness Class Number

- Represents the number of particles 0.5 microns in size or larger per cubic foot of air in the clean room. The smaller the class number, the higher the air purity.

- Ceiling Grid System

- Structure that secures lights and filters into the ceiling.

- Clean Room Construction

- Custom or pre-designed clean rooms that fit industry-specific standards and come in many different forms.

- Clean Room Equipment

- Any movable furniture, machinery, tool, or storage systems made specifically for use in clean rooms.

- Clean Room Partitions

- Walls that create multiple clean areas to meet a variety of cleanliness requirements inside a single clean room.

- Clean Room Pass Thrus

- Air locks that provide a way for products and supplies to be delivered and picked up without personnel having to enter the room, minimizing the entry of contaminating agents.

- Clean Room Suits

- Also called “bunny suits,” they are worn over regular clothing and made from a special non-linting, anti-static fabric.

- Clean Room Tables

- Tables that come with either a perforated or solid top and meet clean room requirements.

- Contamination

- Harmful or unnecessary substances that decrease the purity of the environment in which they are found.

- Electrostatic Discharge (ESD)

- An uncontrolled dissipation of electricity, also called a “shock,” which can easily destroy semiconductor products.

- Equipment Layout

- A summary of the clean room and other functional areas that articulates the areas necessary for functioning and support.

- Federal Standard 209E

- Text that dictates air cleanliness standards in clean rooms.

- Filter Module

- Unit containing either a HEPA or ULPA filter located in clean room ceilings or walls.

- HEPA (High Efficiency Particulate Air) Filter

- Air filter capable of trapping a minimum of 99.97% of particles at least 0.3 microns in size.

- HVAC (Heating, Ventilation, and Air Conditioning) Systems

- The equipment responsible for providing and maintaining heating, cooling and air conditioning to a building or facility.

- Laminar Flow

- Airflow within a confined area traveling with constant speed and direction.

- Micron

- Measurement unit equivalent to one-millionth of a meter.

- Microbes

- Microscopic, living organisms. They can be released from human skin during skin cell shedding.

- Particle Size

- Represents the measurement or dimensions of a particle.

- Particle

- An object, either solid or liquid, ranging from 0.001 to 1,000 microns.

- Particulate

- A body of matter consisting of distinct particles.

- Prefilters

- Additional filter used in conjunction with the main filter to collect large particles and protect the main filter from excess contamination.

- Sealant

- Substance often consisting of plastic or silicone used to secure HEPA filters into ceiling grids.

- Sticky Mat

- Doormat located at clean room and shower entrances that utilizes adhesive film to clean the shoes of personnel.

- Testing/Certification Services

- Services responsible for the testing and maintenance of clean room components, including HEPA filters, HVAC systems, and other equipment. Tests on HEPA filters include particle count surveys, air condition measurement, vibration measurement, and airflow consistency.

- Turbulent Flow

- Airflow within an enclosure that does not travel in one direction.

- ULPA (Ultra Low Particulate Air) Filter

- Air filter capable of trapping 99.9999% of particles at least 0.12 microns in size.

- Utility Matrix

- Also called “process utility summary,” “tool matrix,” or “utility requirement spreadsheet,” it is the summary of the analysis of the services of each piece of equipment needed to plan the construction of a clean room.

- Wafer

- Also called a “slice,” it is a very thin piece of silicon that is the base material for microchips.