Brushes

Brushes are tools made with bristles, wires, or other filaments for cleaning, painting, and surface treatment tools. It is one of the most diverse, versatile, and simple tools. From the simplest brooms to the heaviest-duty power brushes and sweepers, brushes have been and continue to be an important part of a wide range of industrial and commercial operations.

Quick links to Brushes Information

The History of Brushes

The first recorded use of the word “brush” in the English language was in 1377; the first mention of a “bottle brush” took place in 1713. Because brushes have been a part of the world for such a long time, it’s hard to track their exact origins. We believe, however, that brushes have been used for applying pigment since the Paleolithic Period, which began around 2,500,000 years ago. The evidence for this comes from cave painting, like the one found in Spain in the Cave of Altamira, or the one found in France in the Périgord. The ancient Egyptians also used them for tomb paintings, and the ancient Chinese used the tips of long-haired brushes to write.

Believe it or not, toothbrushes have been around since between 3500 and 3000 B.C., when the Babylonians and Egyptians created brushes by fraying the end of a stick. The first natural bristle toothbrush is believed to have been invented by the Chinese in the fifteenth century.

In 1777, a British man named William Kent founded the first hair brush manufacturing company, Kent Brushes. In 1854, a man named Hugh Rock submitted the first U.S. patent for a hairbrush design. The first hairbrush designed with synthetic bristles was invented and patented in 1898 by a woman named Lyda Newman. Newman, quite the innovator, also invented brushes with detachable handles and air chambers for ventilation.

The earliest brushes of all kinds, including brooms, were made with what was on hand. The brushes of ancient Egypt, for example, were made from split palm leaves. Over the centuries, the most popular type of brush filament has been bristles, which come from hogs, pigs, and boars. As time has gone, depending on technology and depending on the resources of the region, brush filament materials diversified. Today, for example, they can be made from bristles, synthetic fibers, natural fibre, wire, and more.

Modern brushes can be found in use in almost every industry in some form or another, used for applications from applying watercolor to scrubbing dirt and oil off metal wheels or cleaning rust off on metal. Each type of brush is distinguished from each other based on their construction, composition, and application or use. With so many applications, types and sizes, we will continue to see new brushes being made and used in new ways now more than ever before.

Advantages of Brushes

The greatest advantage of brushes is the fact that they offer their users a high level of control over their application. In addition to that, they’re highly versatile; there’s a brush for application under the sun. They range widely in style, filament type, and size.

Brush Design

The shape, size, and materials that brushes are made out of are endless and new designs and uses are being implemented every day. Mostly, though, brushes are made with bristles, or filaments, and some type of handle with which man or machine can facilitate movement.

Metal wire brush bristles can be made of steel, stainless steel, brass, bronze, copper, nickel silver, or titanium filaments. Each brush wire is chosen based on its qualities of abrasiveness, conductivity, and corrosion resistance. Other types of cleanroom, strip, cylinder, and maintenance brushes are made from a wide variety of natural and synthetic fibers such as horsehair, straw, polypropylene, and nylon. Twisted-in-wire tube and bottle cleaning brush filaments are usually either nylon or metal. Abrasive nylon embedded with mineral grit, like silicon carbide, is sometimes substituted for wire filament in power brushes.

Handles are often made of wood, aluminum, copper, nickel, plastic, rubber, or other related materials.

To enhance their effectiveness, manufacturers may manipulate brush filaments. For example, wheel, cup, and end power brushes' filaments are usually crimped to maintain cutting action as the brush wears. In addition, power brushes' cutting action is often amplified by knot-twisting sections of wire in wheel, cup or end brushes or by encasing them in a semi-hard polymer.

When designing a standard or custom brush, manufacturers consider many things. For instance, each bristle material is chosen based on its qualities of abrasiveness, conductivity, and corrosion resistance. Likewise, when choosing from metal filaments, manufacturers think about their bending plans, since some metals bend better than others. Filament density, material type and coarseness determine a brush's performance. As the nature of the demand for brushes in industrial processes changes, brush materials will change to meet those needs. If you’re interested in a custom filament type, like a more obscure fiber, talk to your manufacturer.

The way an individual works depends on its construction. Typically, brooms can be pushed, pulled, or used in a sweeping motion. Other brush types are either handheld or machine operated.

Applications of a Brush

Brushes are produced for many different reasons. Some applications include cleaning, scrubbing, painting, and product application. Others include cosmetic or functional maintenance. In truth, the possible applications of brushes are too many to list here.

Brushes are used in many industries, including industrial manufacturing, art, cosmetics, cleaning and sanitation, food service, painting, healthcare, automotive manufacturing and maintenance, and more.

Brushes Images, Diagrams and Visual Concepts

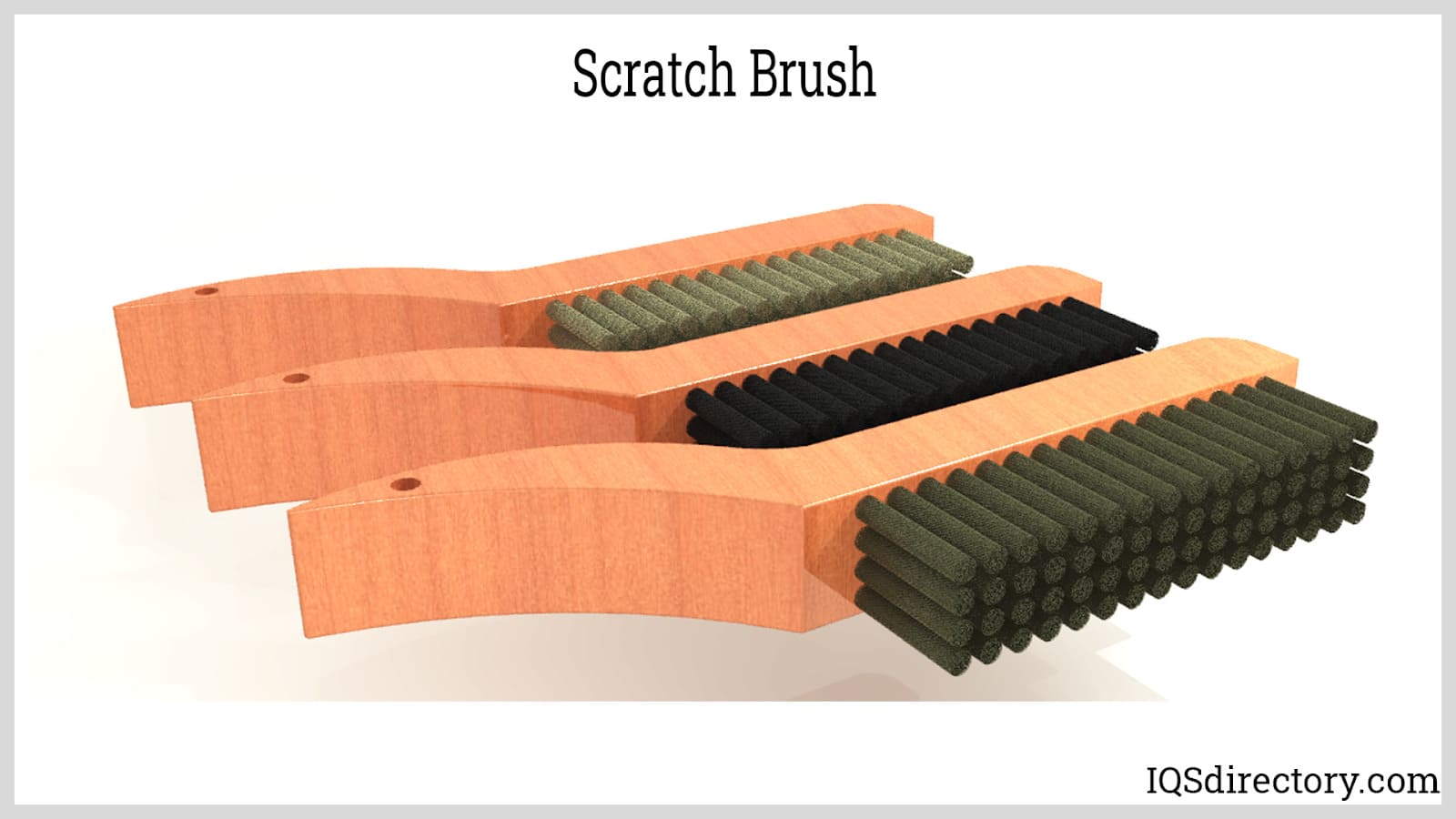

A general purpose brush for removing paint, rust, and dirt.

A general purpose brush for removing paint, rust, and dirt.

A brush with nylon polymer filaments that are exceptionally tough, strong, flexible, and elastic.

A brush with nylon polymer filaments that are exceptionally tough, strong, flexible, and elastic.

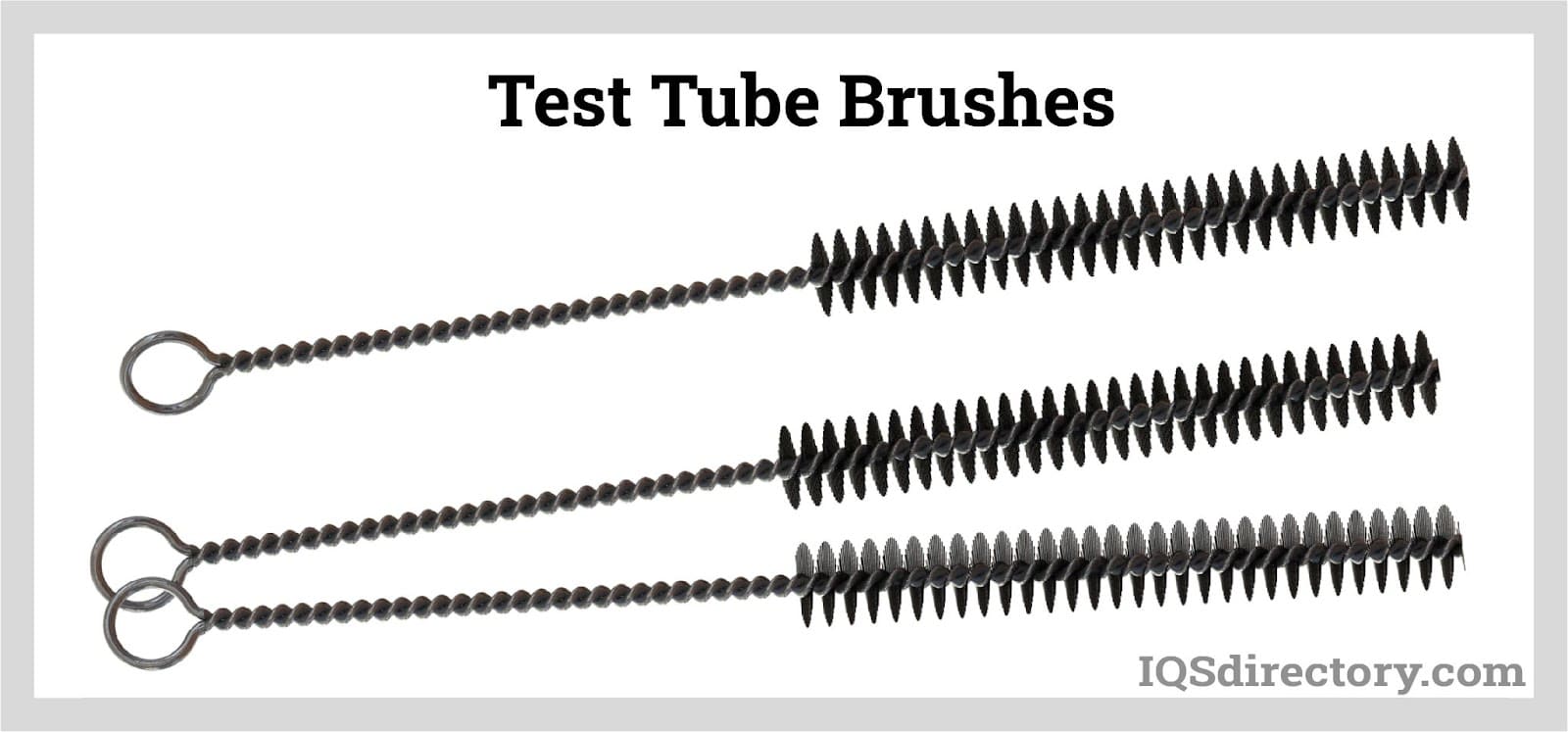

Small sized brush which allows to dislodge accumulated material inside test tube.

Small sized brush which allows to dislodge accumulated material inside test tube.

A high quality brush with the ability to form a sharp tip which allows for precision.

A high quality brush with the ability to form a sharp tip which allows for precision.

Cylinder brushes have bristles that are flexible around a metal mandrel.

Cylinder brushes have bristles that are flexible around a metal mandrel.

Types of Brushes

Brushes can be broadly broken down into the categories of applicator brushes, material removal brushes, combing brushes, and specialized brushes. Let’s look at these in more detail.

- Applicator Brushes

- Any brush used to apply a material to another surface can be considered an applicator brush. Examples include paint brushes, artist brushes, wallpapering brushes, makeup brushes, mascara brushes, nail polish brushes and pastry brushes.

- Artist Brush

- Handheld brushes used for artistic endeavors. They are made with a variety of different bristle types, bristle shapes, and bristle densities, depending on what type of art for which they are made. For example, used for painting tiny details on canvas, some are as soft and fine as a baby's hair.

- Miniature Brushes

- In industrial or commercial settings where fine detail work is required on small or intricate parts and components, miniature brushes are used to clean, paint and polish surfaces. These brushes can be used by hand, but some have attachments so that they can be used with a drill or some other power tool.

- Polishing Brushes

- Come in a variety of sizes and are used to clean everything from jewelry to cars to shoes to stainless steel dishware. A polishing brush is usually much less abrasive than a wire brush because it is used on the surface after it has already been cleaned. The goal of polishing is to make the object shine and give it a brand new, finished appearance.

- Material Removal Brushes

- Brushes that fall under this umbrella include domestic and industrial cleaning, polishing, and surface treatment brushes. Some of the most common cleaning brush types include brooms, bottle brush, spiral brush, chimney brush, toothbrush, car wash brush, chip brush, dishwashing brush, vacuum cleaner brush, abrasive brush, power brush, and wire and lavatory brush varieties.

- Anti-Static Brushes

- Tools that provide manufacturers of electronics and static charge-sensitive products with electrostatic discharge.

- Broom

- The most widely used brush variety in the world. Its variations can be found in more homes and places of business than not. Even in the cleanest offices, dust accumulation warrants the use of brooms to maintain the appearance and healthiness of workspaces. In homes, where cleanliness and safety are also very important, brooms serve the same purpose. Successful professionals in the industry make the connection between workplace safety and productivity; brooms of all shapes and sizes are employed in warehouse and factory floors as well as in break rooms and all other spaces in and around an industrial operation.

- Industrial operations, commercial enterprises, and individuals all over the world make use of some variety of brush for some purpose. The manufacture and fabrication of plastic, wooden, and metal parts, in particular, creates a high volume of debris, and using push brooms and sweepers in concert with ventilation systems and vacuums can improve the safety of a workspace. Brooms are the most basic of all brush designs, though they share the same basic principle that all brush varieties have in common; all brushes are collections of bristles mounted to a surface.

- Bottle Brush

- Can be used for cleaning bottles, machinery and other objects that may be difficult to clean with large brushes.

- Spiral Brush

- Small brushes used for cleaning, bottles, pipes, and tubes. They can be attached to equipment for custom high-speed spin cleaning.

- Pipe Brush

- Used in plumbing and equipment maintenance applications to clean pipes or other hard to reach areas. The brush is usually attached to a long, thin piece of metal than can be inserted deep into a pipe.

- Power Brush

- Also known as machine brushes, power brushes are defined as any power-driven, wheel-shaped brushes powered by a machine at variable speeds. Power brush applications include metal deburring, removing rust, paint or coatings, gear and thread cleaning, surface preparation for welding or painting and surface finishing on a variety of materials.

- Vacuum Brush

- Brushes usually made with soft, natural material such as camel hair, goat hair or sable hair, but may also be made with nylon and other synthetic materials. Vacuum brushes vary in size and shape depending on the work surface from which removal of excess materials is required.

- Wire Brush (Industrial Wire Brush)

- Brushes made with metal bristles. Metal manufacturers and fabricators rely on metal wire brushes for deburring, surface brushing, and parts cleaning. Metal wire brushes, like the steel wire brush, can be hand-held or machine-operated; hand-held metal wire brushes tend to be used for heavy-duty scrubbing, and machine-operated metal wire brushes are used to machine or treat a surface. Brass brushes, made from brass, which is a softer wire than stainless steel. Brass brushes are perfect for use in applications that require burnishing, polishing, non-sparking static spark removal and some deburring and material removal.

- Wheel Cleaning Brush

- Most are designed to be used with handheld power tools, although some heavy duty industrial ones are made to be installed on larger pieces of equipment. A wheel cleaning brush can have a circular hole at the center so that it can fit as an attachment on an angle grinder, or it can have a stem for use with a power drill. The rapid rotation caused by the power tool enables the brush to clean and polish quickly and effectively on a variety of surfaces.

- Wire Wheel Brush

- Wire brushes designed in a circular shape. They consist of a base or core and wire bristles, which are affixed into holes drilled into the core. They’re most commonly used in industrial settings where continuous brushing action is required. If desired, users can attach them to machinery that spins the brush around at high speeds, making them exceptional surface treatment tools.

- Twisted-in-Wire Brush

- Smaller brushes that are basically pieces of doubled-over wire with bristle material inserted between the fold of the wire stem. These hand-held or machine-powered brushes are smaller than the wheel brushes, so they are useful to reach smaller areas that need to be deburred or finished.

- Tube Brush

- A brush used specifically for cleaning tubes, like test tubes. They are usually quite small but can be made larger, per application requirements.

- Rotary Brush

- Used with a machine that spins it on a cylinder or on a ring with the bristles pointing downwards. These brushes can be found on automatic shoes polishers, street cleaners, conveyor belts and more. In any industry where heavy duty cleaning equipment is needed, there is usually a piece of equipment that is fitted with a series of durable rotary brushes to get the job done.

- Strip Brush

- Brushes arranged in a long strip, can be used as seals in the space between doors and door frames, and they can also be used as cleaning tools. Like many other brush varieties, their bristles are often composed of nylon, which is favored for its characteristics of abrasion resistance and strength.Stave brushes are long, rectangular wooden or plastic blocks with one or more rows of tufts.

- Detail Brush

- Made with nylon bristles, are able to remove wax and dirt build-up from crevices. Brass bristles are useful for removing corrosion from hard-to-reach places, and stainless steel bristles can be used to remove rust from metal or chrome surfaces.

- Cup Brush

- Useful in the removal of scale, rust, and paint, as well as for deburring and polishing applications. Depending on their construction, cup brushes can be used for light or heavy-duty manufacturing processes. They’re especially useful for reaching dirt and debris in cracks and crevices.

- Combing Brushes

- Used to straighten and detangle filaments. The most common type of comb brush is the hairbrush. Others include dog grooming brushes, cat grooming brushes, and horse grooming brushes.

- Hair Brush

- Handheld stick brushes, used to detangle, smooth, and style human hair. The filaments can be made of bristles, but more commonly, they’re made from synthetic plastic or nylon materials. Brush handles often have cushioned grips for comfort.

- Specialized Brushes

- Specialized processes call for custom brushes with special qualities. For example, manufacturers manufacture conductive brushes or ESD cleanroom nylon static dissipative brushes for use during the fabrication of sensitive electronics. They help by cleaning parts and eliminating static.

- Tin acid brushes have extra stiff black horsehair bristles with a tin handle and are utilized in soldering applications that include mucilage and with acid.In addition, they manufacture cup, strip, and cylinder brushes with nylon bristles specifically for fruit and vegetable cleaning. Other types of brushes include electric brushes, magnetic brushes, and medical sampling brushes.

Standards and Specification of Brushes

Because brushes are so diverse, from hairbrushes to custom industrial brushes, there isn’t really a set of standards to which they all should be made. Generally speaking, brushes used in the food industry should be made to FDA standards, brushes used in the medical industry should be made to medical standards, and brushes used in industrial settings should be up to OSHA and ISO code.

To learn more about the standards you should seek for your specific application, talk to your supplier.

Things to Consider When Purchasing a Brush

The brush industry is vast and can be confusing. To help you navigate it, we recommend you connect with a knowledgeable industrial brush manufacturer, such as those listed on this page. Start by checking out their individual websites. Decide which ones you are interested in, and send them an email, a request for a quote, or call them. When you’re talking to them, note how they communicate with you. Are they engaged? Do they take an appropriate interest in your application and specifications? In addition, do they indicate that they’re willing to work within your timeline and budget? It’s super important that you find a manufacturer with whom you can have a healthy and comfortable working relationship. When you partner with the right manufacturer, you can achieve great things, no matter your application. IQS takes pride in working with only the best and brightest stars of the industrial brush industry.

Proper Care for Brushes

To keep your brush in proper working condition for as long as possible, we recommend that, when appropriate, you use the lightest necessary touch. If you’re using your brush as an applicator, make sure to clean it every time you use it. If you, for example, allow paint to dry on your brush, it will be hard to clean off and may ruin your brush by making it stiff and changing its texture.

Brush Accessories

Examples of various brush accessories include brush holders, hose attachments, mounting hardware, extension rods, wire wheel metal brush adaptors, brush arbors, brush bridles, and more.

Brush Terms

- Abrasive Nylon

- Long-wearing material available in several filament diameters and grit sizes. Abrasive nylon is excellent for surface finishing applications.

- African Bass

- A light brownish, very coarse fiber that is typically used in street brooms.

- Arbor Hole

- The diameter of the brush-mounting hole.

- Bore

- Inside diameter of a core or hub for a roller brush.

- Brass Wire

- Rust-proof and spark resistant, brass provides gentle brushing action.

- Bristle

- The material that does the actual cleaning or cutting. Bristles can be made of natural, synthetic or metal material.

- Bronze Wire

- Stiffer than brass with the same non-sparking benefits as brass.

- Brush Part

- The length of the brush area on a core. Brush parts can be the same or shorter than the overall length.

- Conductive Nylon

- A non-marking synthetic brush fiber that can take the static charge created by the brushing action and send it to the ground.

- Core Diameter

- Diameter of a cylindrical brush core.

- Crimped

- Filament that has been composed with a wave pattern and is measured by amplitude and frequency.

- Cut End

- Part of a twisted-in wire brush where the wire has been flush cut at the brush part end.

- Cylinder

- A drive shaft that powers cylindrically shaped brushes. The brushes are part of an industrial or manufacturing process that requires a clean conveyor with a conveyor brush or product at a particular point in the process.

- End Tuft

- A twisted-in wire brush where the filament has been gathered to create a tuft parallel to the twist wire.

- Face Width

- Width of the brush face when the brush is in operation. Filament is usually stiffer and eliminates streakage.

- Ferrule

- A seamed or seamless steel tube that gathers and binds bristles in paint brushes.

- Filament

- The synthetic fibers that are used to create a brush tuft.

- Fill Material Size

- Thickness of a single filament or wire size in inches. Nylon ranges from .003 to .125 and wire from .003' - .020'.

- Flagged

- Filament whose ends have been splintered by a series of knives to produce a softer-tipped brush.

- Goat Hair

- Very fine and soft animal hair that is used for very short trim brushes.

- Hog Bristles

- Animal hair that has soft to slightly stiff texture. The natural flagging of hog bristles allows the brush to fit into cracks to remove fine dust.

- Horsehair

- A resilient and long lasting fiber that is excellent for sweeping polished surfaces.

- Level Fill Material

- The straight filament or wire of a brush.

- Nylon

- The toughest and longest wearing synthetic filament available. Nylon is excellent for industrial and food service applications.

- Oil Tempered Wire

- Also called "flat wire," it is a stiff, hard-working, resilient wire used in hand-scratch and power-driven brushes.

- Overall Diameter (OD)

- The diameter of a cylindrical brush measured at the filament ends.

- Overall Length (OAL)

- The length of a brush, usually measured as the length of the core.

- Palmyra

- A medium stiff to stiff textured vegetable fiber made from the leaf stalks of the Palmyra Palm of India. Palmyra can be mixed with Tampico to produce Union Fibre.

- Palpro

- A synthetic, long-wearing alternative to palmetto that resists acids, alkalis and organic solvents better than any natural bristle material.

- Patent

- A slightly stiffer, more durable selected grade of polished tampico.

- Pattern

- The distance between the tufts usually given by a row and column distance measurement for block brushes and by tufts per circumference and spacing for cylindrical brushes.

- Phosphorous Bronze

- A non-ferrous, non-corrosive material with more temper than brass.

- Pitch

- The distance between wraps on a coil brush.

- Poly Bass

- A synthetic brush material that is large in diameter and resistant to abrasion and most solvents and acids.

- Poly Core Roller

- A cylindrical brush that has a plastic core.

- Polyester

- Heat and moisture resistant synthetic filament. Polyester is also resistant to petroleum products, acetones, ketones, alcohols and weak acids.

- Polypropylene

- A material that has excellent wet stiffness and is resistant to most petroleum solvents, oils, greases, most acids and chemicals.

- Power Brushing

- Any process that uses a power-driven, rotating industrial brush to deburr, clean or finish a metal part.

- Stainless Steel Wire

- Rust-proof and very strong, stainless steel is used to prevent harmful ferrous deposits on brushed parts.

- Steel Low-Carbon Wire

- A soft, magnetic material used for light material removal and for surface finishing of soft materials. Steel low carbon wire will rust easily.

- Tampico

- A natural vegetable fiber that can be used wet or dry for scrubbing, washing and dusting applications and can be treated for applications of grease or abrasives.

- Trim

- Length of brush filament from the core.

- Ultrasonic Welding

- A process that utilizes high frequencies of sound to weld the base of a brush to the fill material.