The term "material handling" refers to the industry that focuses on solutions regarding the protection, control, movement and storage of of materials. The ultimate goal of material handling equipment is to foster maximum productivity within a safe work environment. Material handling is especially important in plants and warehouses and it touches many different industries.

There are four distinct types of material handling equipment: storage and handling equipment, engineered systems, industrial trucks and bulk material handling.

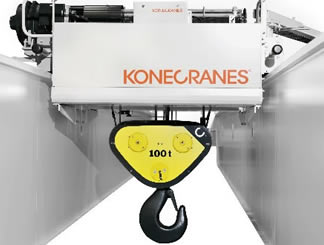

Examples of equipment from these respective categories include: storage racks, conveyors, forklifts and cranes. Storage racks are shelf-like structures that manufacturers and homeowners alike can use to store, display or organize items of all kinds. Conveyors are used within industrial and commercial facilities to move, or convey, materials from one place to another. They can provide simple transportation or they made be just one component of a larger assembly. Forklifts and cranes are both used to pick and up and move heavy and/or bulk materials. Forklifts are smaller than cranes and more mobile. They mostly lift, load and move heavy pallets. Cranes, on the other hand, are more often used to hoist and move loads of various sizes. Generally, they can hoist loads up to 1,000 tons. Another difference between forklifts and cranes is how they pick things up. Forklifts have a driver-controlled lift mechanism that slides underneath loads like a dolly. Cranes pick up materials with a hook or a hoist that is attached to a chain or wire rope.

Other examples of material handling equipment include hydraulic lifts, balers, palletizers, pallets, hose reels and automated guided vehicles (AGVs). Hydraulic lifts use liquid mechanics to lift, lower and support materials that are too heavy to be moved by hand. They‘re especially important in bulk material handling. Balers are used to bind and compress materials. They are most often used in agriculture, waste management and recycling. Palletizers are machines designed to load and unload pallets before and after shipment. They are available in manual, automatic and robotic forms. Pallets are simply stackable platforms upon which products can be placed for both storage and transportation. Hose reels are secondary items of sort. In essence, they are giant spools that house hosing. They are important tools for keeping industrial hosing dry, kink-free and organized. They‘re available in both manual and automatic models. Finally, AGVs are self-guided vehicles that move around a plant transporting materials from one place to another or performing tasks like parts assembly.

Frequently, manufacturers supplement their material handling equipment with analytical systems that help them track and process their inventories.

Material handling equipment is essential to the assembly and manufacturing processes of many industries. If you‘d like to learn more about the individual equipment and machines used in material handling, browse the sections below. With each, you will find a list of manufacturers that make or supply those pieces of machinery. Visit their websites or give one or more of them a call to find out what they can do for you.