High Pressure Boilers

Heat transfer is a process where the internal energy from one substance, material, or fluid is transferred to a similar or different substance. The study and physics of heat transfer is part of the science of thermodynamics, which studies the relationship between heat and temperature. The process of heat transfer and its aspects is an essential part of understanding the workings of engines and pumps.

Energy is generated by the motion of atoms and molecules, which is transferred as heat from one body or system to another such body or system. There are several ways that heat can be transferred. They include conduction, convection, and radiation, where conduction happens by physical contact and conviction through a surface. Radiation, on the other hand, does not require any contact or material.

The conduction process of heat transfer is best performed when the two surfaces of the medium are smooth and in close contact. If there is a gap between the materials, the performance and heat transfer will be poor. The connection between the two surfaces is referred to as thermal contact. Insulation is designed to prevent thermal contact and the transfer of heat.

Convective heat transfer comes from the interaction of two processes, which are conduction and advection. The process of convection is the transfer of heat to another substance such as a liquid. In most cases, this process takes place between a heated surface and a fluid that moves over the surface. When a fluid comes in contact with a surface, it experiences an increase in velocity and temperature.

In the case of radiation, heat transfer takes place in the form of electromagnetic waves that are found in the infrared range. A substance emits radiation when there is thermal activity in its molecules. In industrial heating, radiation is used in ultraviolet, infrared, microware, and short radio wavelengths. Unlike the other two methods of heat transfer, radiation transfers heat without the need of matter, a substance, or contact.

The primary types of heat transfer equipment are condensers and evaporators, which have two opposite purposes. The function of a condenser is to cool refrigerant vapors back to a liquid state. Evaporators perform the opposite function by heating a liquid until it becomes a vapor.

Heat transfer systems circulate thermal fluid through processing equipment in order to maintain an even temperature throughout the system. A system of pipes, tanks, pumps, and heating and cooling methods circulate water, steam, and oils as a central part of the system. Heat for the system is produced by various fuels such as gas, propane, or oil. Alternate methods of heating include solar power and electricity.

The most common type of heat transfer system is a series of small tubes with fluid flowing through them. A second liquid flows over the tubes encased in a shell. This type of heat transfer is found in oil refineries and chemical processing.

Heat transfer equipment can be found in every part of our lives from stoves that cook our food to the fan that cools a computer processor. The energy that we use is in the form of thermal energy, which is the reason that heat transfer equipment is so important and essential.

Boilers are closed vessels in which water or some other fluid is heated.

In the United States, when the purpose of the boiler is not to boil water, it is more commonly called a furnace, or domestically, a water heater. These utilities are used in industrial, commercial and domestic settings in order to offer heated air and hot water, as well as steam in steam-operated machinery.

Learn more about boilers.

Boilers are closed vessels in which water or some other fluid is heated.

In the United States, when the purpose of the boiler is not to boil water, it is more commonly called a furnace, or domestically, a water heater. These utilities are used in industrial, commercial and domestic settings in order to offer heated air and hot water, as well as steam in steam-operated machinery.

Learn more about boilers.

Liquid chillers quickly cool large amounts of liquid refrigerant in order to remove heat from the air or other liquids. They then pump cooled liquid or air out as needed.

Learn more about chillers.

Liquid chillers quickly cool large amounts of liquid refrigerant in order to remove heat from the air or other liquids. They then pump cooled liquid or air out as needed.

Learn more about chillers.

A cooling tower is an enclosed structure that removes heat from water (or other fluids) used in industrial plants and processes.

There are different designs, types, shapes, and sizes of cooling towers. The basic working process is the same, however, and is based on evaporative cooling. Heat from water is transferred to the air through the process of evaporation, which lowers the temperature of the water. (A cooling tower is sometimes called an evaporative condenser or a fluid cooler.)

A cooling tower is an enclosed structure that removes heat from water (or other fluids) used in industrial plants and processes.

There are different designs, types, shapes, and sizes of cooling towers. The basic working process is the same, however, and is based on evaporative cooling. Heat from water is transferred to the air through the process of evaporation, which lowers the temperature of the water. (A cooling tower is sometimes called an evaporative condenser or a fluid cooler.)

Evaporative cooling depends on wet bulb temperature, which is the lowest temperature to which the water can be cooled in the plant, process, or system. The rate of heat transfer needed for the evaporation of water into the air tells how well the cooling tower is performing. The wet bulb temperature of the air entering the tower is a primary measure of the effectiveness of a cooling tower. The American Society of Mechanical Engineers (ASME) and the Cooling Technology Institute (CTI), an industry association that provides technical and educational services for its members, recommend that towers be sized and tested based on entering wet-bulb temperatures. (Wet-bulb temperatures are taken with a psychrometer). Learn more about cooling towers.

Industrial furnaces are enclosed structures that contain high heat chambers. Compared to industrial ovens, they provide much higher temperatures and therefore are mostly used on materials with high melting points. They are found in glass fabrication, steel service centers, foundries, forgeries, metal recycling plants and any metallurgy application involving the use of heat to alter, improve, fabricate or form metals like steel, titanium and aluminum, alloys, glass, composite materials and some plastics.

Furnaces meant for small runs are usually of single chamber design and are manually loaded and unloaded with various tools to lift crucibles full of molten metal or heat treated products. Larger volume furnaces have automated conveyor systems that allow many parts or products to be treated at a time. Their controlled atmospheres can be oxidizing, inert, salt bath or vacuum. Their most common use is for heat treating glass and metal, which alters or improves the material's properties by exposing it to high temperatures, then rapid cooling. Furnaces are also capable of aging, annealing, sterilizing and sintering materials, as well as melting raw substances for molding or casting purposes. Furnace specifications include temperature requirements, pressure, internal width, length and height, as well as heat source.

There are many different furnace heat sources available today. They include radiant, natural gas, induction, conduction, electrical and dielectric. Each method has specialized benefits, limitations and applications. Radiant heat furnaces are similar to wood stoves and portable heaters. They use a flame to heat an object, commonly a ceramic plate. This object gives off heat that transfers throughout the area. Natural gas furnaces are very common. Compared to electric furnaces, they are an economical method of creating a high heat environment. They burn natural gas or propane in order to generate heat, and are used for their high temperature abilities. Induction furnaces use a combination of electrical resistance and hysteresis losses to heat metal parts. They are exposed to a magnetic field around a coil-carrying alternating current. Induction furnaces are the first choice in metal melting applications and are often used by iron foundries. Electric furnaces are also popular for melting metal. The most common type is an electrical arc furnace, which uses high amounts of electrical current, which travels through a metal arc and is conducted onto large amounts of scrap metal. The current heats the scrap metal to a high enough degree to melt it completely. These furnaces are mostly used for recycling metal parts to be formed into new products. Learn more about furnaces.

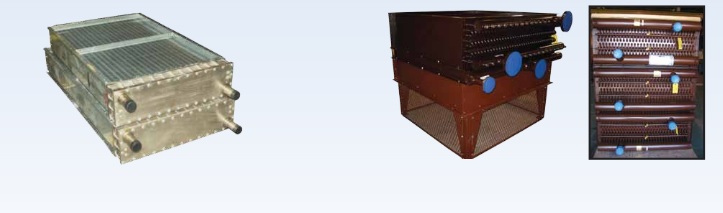

Heat exchangers are devices that are constructed with thermally conductive materials and are used in heat transfer between fluids. Depending on the model type of the exchanger, the fluids could be in direct contact or separated. Heat exchangers, therefore, facilitate heat transfer for purposes such as cooling or heating of substances that are then utilized in other processes.

Heat exchangers are essential in industrial processes pertaining to the design, operation and maintenance of heating systems, power generation, air-conditioning systems, chemical processing, engineering and waste heat recovery systems. The basic concept of heat exchangers is used in the design of boilers meant to heat large spaces by diffusing heat outward from a centralized source. Learn more about heat exchangers.

Heat transfer equipment are devices that are utilized for transfer heat from one medium to another medium. There are several types of heat transfer equipment each with their own distinct advantages and disadvantages. When selecting the proper type of heat transfer equipment for an application there are several factors that should be considered. Temperature range, thermal performance, fluid flow capacity, high/low pressure limits are all important variables to take into account. Another aspect to analyze is to determine possible need for future expansion of additional heat transfer equipment. Different types of heat transfer systems require particular types of maintenance to efficiently operate and the layout configuration as well as the materials determine what type of maintenance will be required. Heat transfer equipment are used in a number of different industrial settings for many industrial applications. These industries include waste water treatment, refrigeration, petroleum refining and many more. These products can be designed for air-to-air (https://www.iqsdirectory.com/air-to-air-heat-exchangers), water-to-air, water-to-water, oil cooling (listed here on IQS Directory), flat plate heat transfer (find them here), waste heat recovery and number of other styles.

Learn more about heat transfer equipments.

Heat transfer equipment are devices that are utilized for transfer heat from one medium to another medium. There are several types of heat transfer equipment each with their own distinct advantages and disadvantages. When selecting the proper type of heat transfer equipment for an application there are several factors that should be considered. Temperature range, thermal performance, fluid flow capacity, high/low pressure limits are all important variables to take into account. Another aspect to analyze is to determine possible need for future expansion of additional heat transfer equipment. Different types of heat transfer systems require particular types of maintenance to efficiently operate and the layout configuration as well as the materials determine what type of maintenance will be required. Heat transfer equipment are used in a number of different industrial settings for many industrial applications. These industries include waste water treatment, refrigeration, petroleum refining and many more. These products can be designed for air-to-air (https://www.iqsdirectory.com/air-to-air-heat-exchangers), water-to-air, water-to-water, oil cooling (listed here on IQS Directory), flat plate heat transfer (find them here), waste heat recovery and number of other styles.

Learn more about heat transfer equipments.