Wire Mesh

Wire mesh, or wire cloth, is an industrial product made from interlocking metal wires that have been weaved, welded or sintered together. Industrial wire cloth has evenly spaced and uniform openings.

Quick links to Wire Mesh Information

The History of Wire Mesh

The first noted use of wire cloth was recorded in ancient Egypt, when precious metals, such as gold and silver, were hand woven into cloth as jewelry for the wealthy.

For centuries, wire cloth was used for nothing other than jewelry in various forms. However, in the 5th century, people began using wire cloth for armor. The craftsmen of the century ingeniously fabricated metals, including iron, into chain mail, which acted as a protective shield for fighters and soldiers. The fluidity of chain mail gave soldiers flexibility, something metal body suits were lacking. Manufacturing and distribution was under the direct control of kingdoms, and many kingdoms regulated the sale and export, since in many battles chain mail was the difference between the victory and loss.

As chain mail was embraced all over the western world, the precursor of wire working and wire drawing industry was established. The industry evolved and artisans and metalworkers started to fabricate all sorts of wire form products, such as birdcages, mousetraps, windows, chains and hooks.

Large scale wire mesh product manufacturing did not begin until the advent of the Industrial Revolution. This time period saw the appearance of the first modern weaving looms, which were powered by steam. These looms automated wire weaving, allowing for quicker and higher volume product production. The industry was further buoyed by: the use of wire cloth reinforced sails in the maritime industry, flame-arresting wire cloth gauze and wire cloth gauge in mining, and fine wire mesh in the paper industry.

In the 20th century, wire mesh applications expanded again. At that time, manufacturers used an array of wire mesh products, like filters, for making military equipment like tanks, military vehicles and aircrafts. In WWI specifically, when chemical warfare was used extensively, wire cloth was used for making gas masks.

Today, wire mesh is used for even more, such as building and construction, food processing and decoration.

Benefits of Wire Mesh

What makes wire cloth important is its strength and accurate aperture size; these make it an appropriate material for the manufacturing of a wide range of fluid, gas, and particle cleaning equipment. Wire cloth is also versatile; it can be fabricated into a form as soft as silk or as stiff and robust as stainless steel. Wire mesh is also inexpensive and easy to customize.

Mesh Process Details

Manufacturers create wire mesh products using two basic processes: weaving and welding. They can also knit wire, which is a process that works just as it sounds, or sinter it. Sintered wire mesh, although more costly than welded or woven wire mesh, has high structural stability and is excellent for the transportation of bulk goods and powders.

- Weaving Wire

- Manufacturers using modern looms weave wire mesh using a right-angled pattern. Other than that, the weaving process varies quite a bit, based on weaving pattern and crimping pattern.

- The weave in a wire cloth can be plain or twilled. In plain weave, manufacturers weave each weft wire (the wire that runs crosswise) over and under the warp wire (the wire than runs lengthwise). Alternatively, in twilled weaving, manufacturers weave the weft wire over and under two warp wires.

- Manufacturers interlock segments using any number of crimping patterns; to crimp wire is to create corrugations in the wires that secure perpendicular wires to one another. When they’re done putting the final touches on the mesh, they transport it in large rolls until an application has needed it. Then they cut off a length of it and create a wire form.

- Welding Wire Mesh

- When rigid and robust structures are needed, manufacturers electrically weld metal wires together at the intersecting points. The welding is done in such a way that the wires do not fall apart or unravel under pressure or cut.

- Manufacturers give the welded wire cloth its final shape with additional steps, like bending and cutting.

- Finishing Wire Mesh

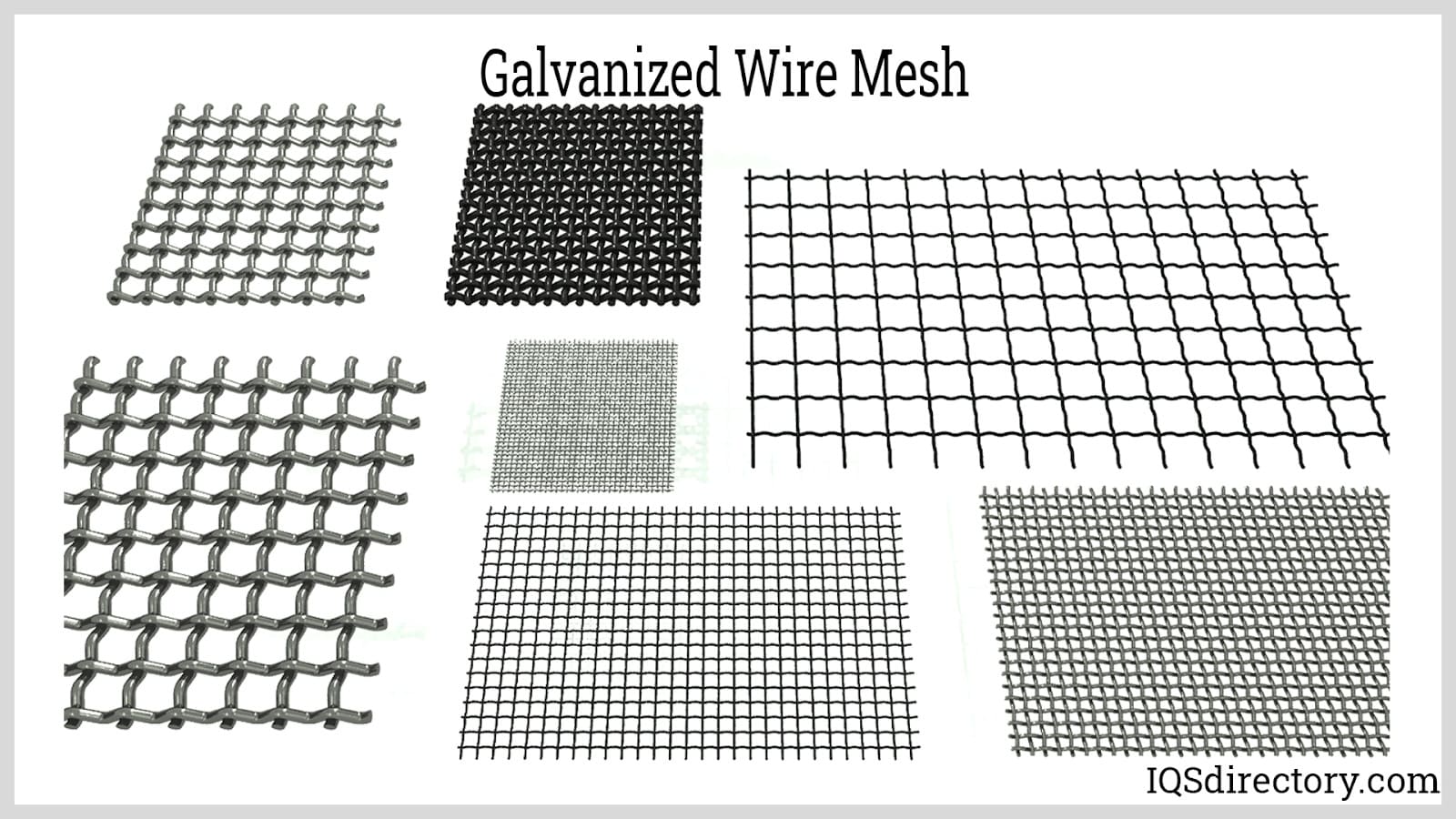

- Wire cloth and wire screen can be finished in a variety of different ways. One of the most common ways they are finished is via galvanization. Galvanized wire mesh is further strengthened and protected against corrosion. Wire cloth made from finer weaves for screens or screen cloths may also require galvanizing to prevent the woven wires coming undone.

Designing Wire Mesh

Manufacturers decide how to design a wire cloth based on the application for which it will be used. This is because they know that the way a wire cloth is woven influences many of its characteristics, such as strength, flexibility, the total amount of open area, and mesh count (openings per inch).

In addition, they make design decisions based on whether or not a metal mesh will be used for inclusion or exclusion purposes. During inclusion applications, wire cloth gives liquids or processed fluids passage, while during exclusion applications, a wire cloth restricts the passage of particles.

While manufacturers often custom weave or weld wire mesh products, they also have many weave patterns off of which they can base their work. These include those outlined below. Pre-crimped wire mesh can have one of the following weaves:

- Double Weave

- In this type of weave, each warp wire-the wire that runs vertically-passes over and under two weft wires-the wire that runs horizontally. As wire moves under and over two wires alternatively, it is called double weave.

- Lock Crimp

- The crimps in wire are deep, which are used for locking the wires in place tightly. Typically, the weaving style is plain, where each warp wire moves over and under weft wire.

- Flat Top

- This type of weave gives a smooth surface to wire cloth. The standard weave is used; however, the weft wire is crimped heavily, which locks the wires securely, whereas the warp wire is not crimped at all.

- Intermediate Crimp

- When a wire cloth has more open area than a standard cloth, this type of weave is used. Since the space in between is larger, extra crimp is added to a wire to hold the wires together tightly and securely.

- When a wire is non-crimped, it can have either of the following weaves:

- Plain Weave

- It is the simplest weave, where each warp and weft wires alternate over and under each other; the metal screens fitted in windows and doors to keep flies away has this type of weave.

- Twill

- In this type of weave, each warp wire passes over and under two weft wires. Alternatively, for a staggered configuration, a weft wire goes over and under two warp wires. Twill weave is used when the wire diameter is larger.

- Plain Dutch

- It is a plain weave; the warp wire is oriented in a standard way, but the weft wire is spaced close to each other, as close as possible. The diameter of the weft and warp wire varies, typically, the warp wire has a larger diameter. There is also an alternative to the plain Dutch weave, known as reverse Dutch. In this weave, the diameter of the weft and warp wire varies, typically, the warp wire has a smaller diameter.

- Dutch Twill

- As the name implies, this type of weave hybridizes Dutch and twill weave together. However, there is an exception; unlike twill weave, each warp wire does not alternate over and under weft wire. The resulting weave has a double layer, where weft wires are packed tightly and securely. Just like the plain Dutch weave, in this combination weave, the weft wires are thinner than the warp wires. The weave does not have openings, thus, wire cloths with this weave are for filtering of non-particulate fluids.

- Manufacturers can customize wire mesh products with crimping (for added structural stability and load bearing strength), with specialty weaves, by thickness of wire (measured by mm), overall mesh sizes (measured in mm), mesh count (the number of clear openings between adjacent parallel wires per linear inch), and by material. In addition, they can add coatings. PVC coated mesh offers increased resiliency, corrosion resistance and insulation.

Wire Mesh Images, Diagrams and Visual Concepts

There are a limitless number of shapes, sizes, and configurations of wire mesh made from an assortment of highly durable and resilient materials.

There are a limitless number of shapes, sizes, and configurations of wire mesh made from an assortment of highly durable and resilient materials.

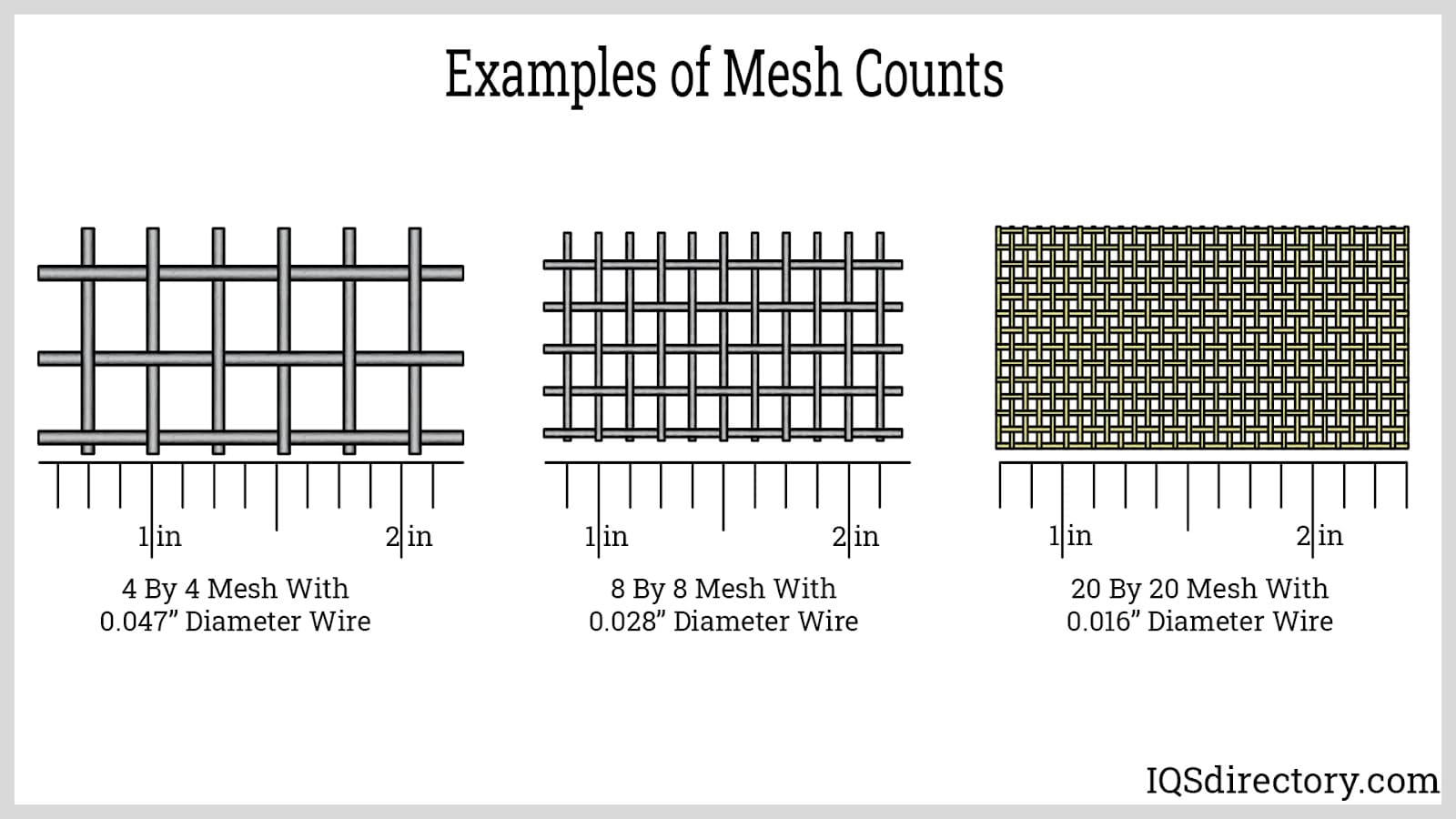

Mesh count refers to the number of openings per linear inch in wire mesh and is determined by counting the number of openings in one linear inch from the center wire of a wire mesh.

Mesh count refers to the number of openings per linear inch in wire mesh and is determined by counting the number of openings in one linear inch from the center wire of a wire mesh.

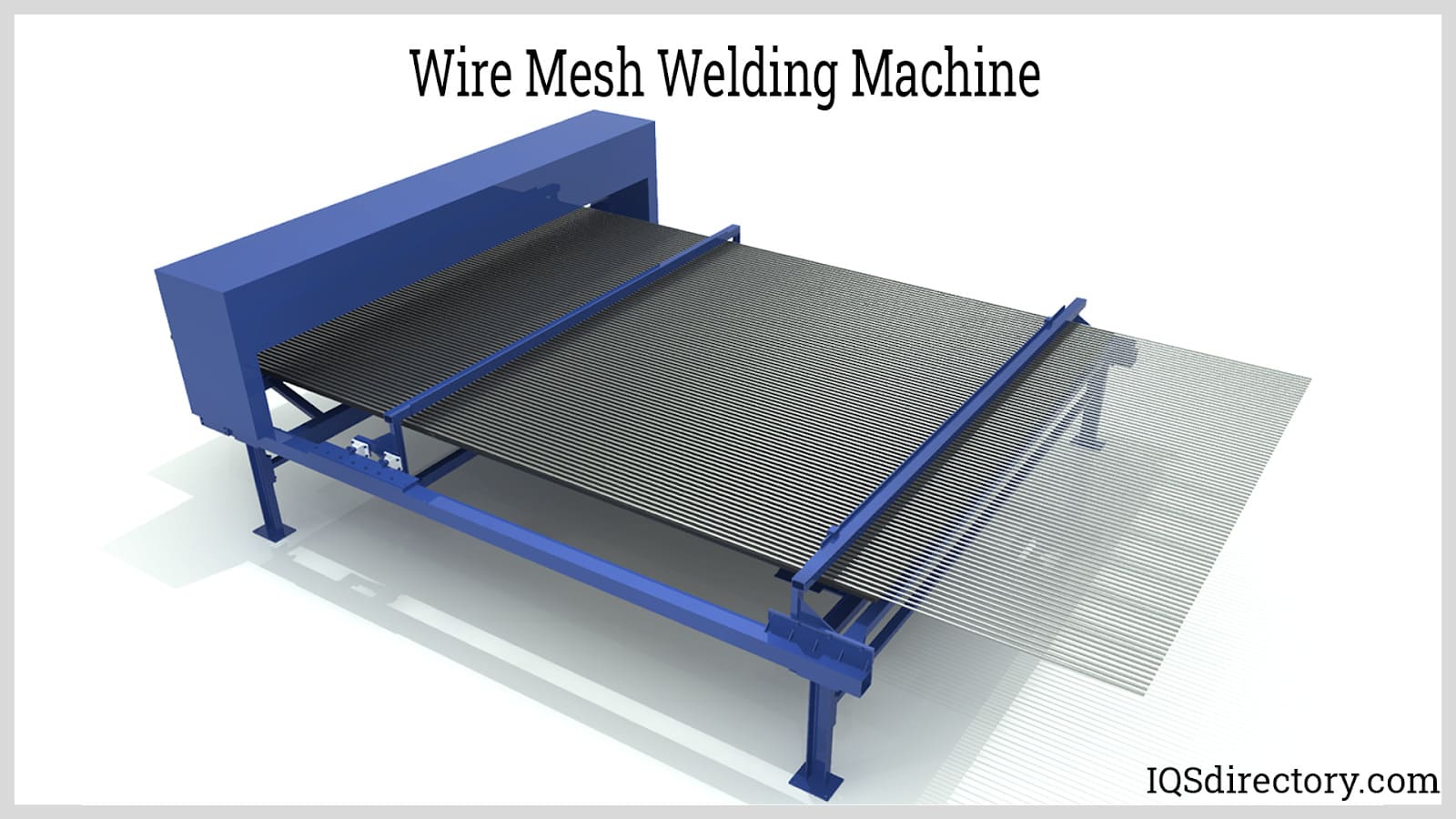

Wire mesh uses a semi-automatic process that welds the intersections of the woven wires at horizontal and vertical aligns.

Wire mesh uses a semi-automatic process that welds the intersections of the woven wires at horizontal and vertical aligns.

Wire looms weave meshes of standard and custom patterns by cutting varying lengths depending on the specifications.

Wire looms weave meshes of standard and custom patterns by cutting varying lengths depending on the specifications.

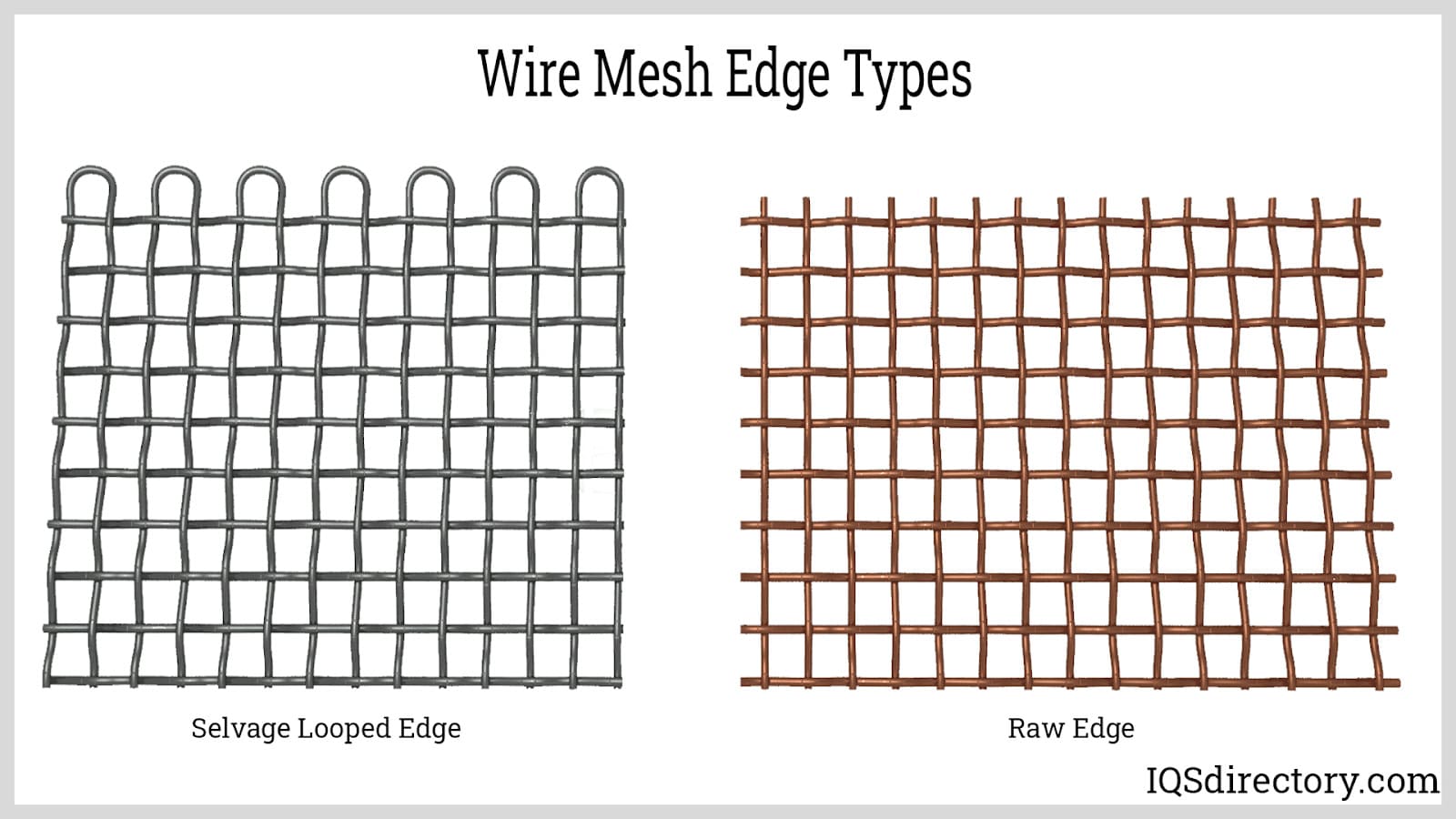

When wire mesh cloth is woven, the weft wires forms an edge along the length of the roll which prevents the mesh from unraveling.

When wire mesh cloth is woven, the weft wires forms an edge along the length of the roll which prevents the mesh from unraveling.

Carbon plain steel is mainly iron with a small amount of carbon which makes it low-cost and versatile.

Carbon plain steel is mainly iron with a small amount of carbon which makes it low-cost and versatile.

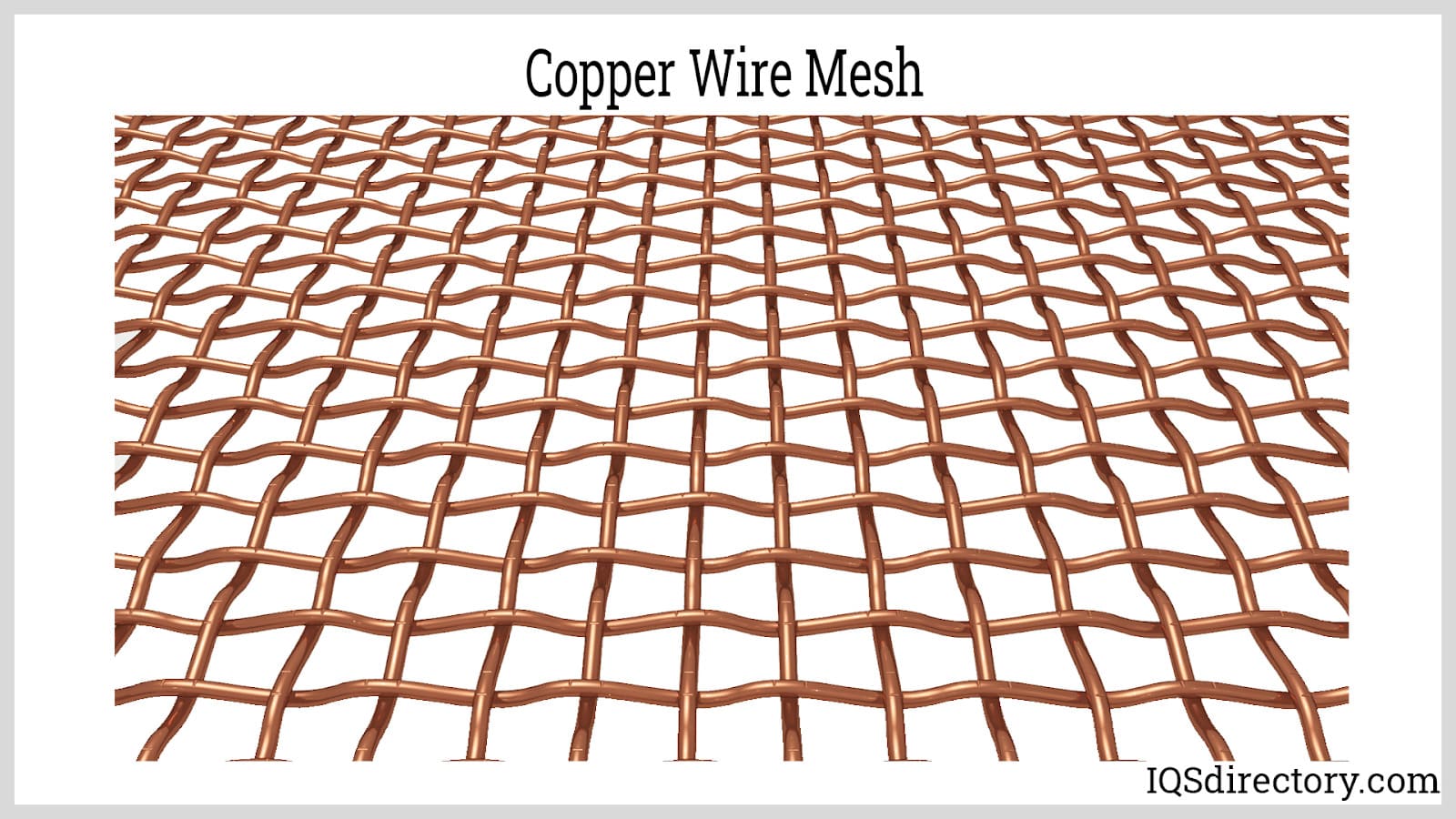

Copper wire mesh has exceptional thermal and electrical conductivity and is ductile and bendable.

Copper wire mesh has exceptional thermal and electrical conductivity and is ductile and bendable.

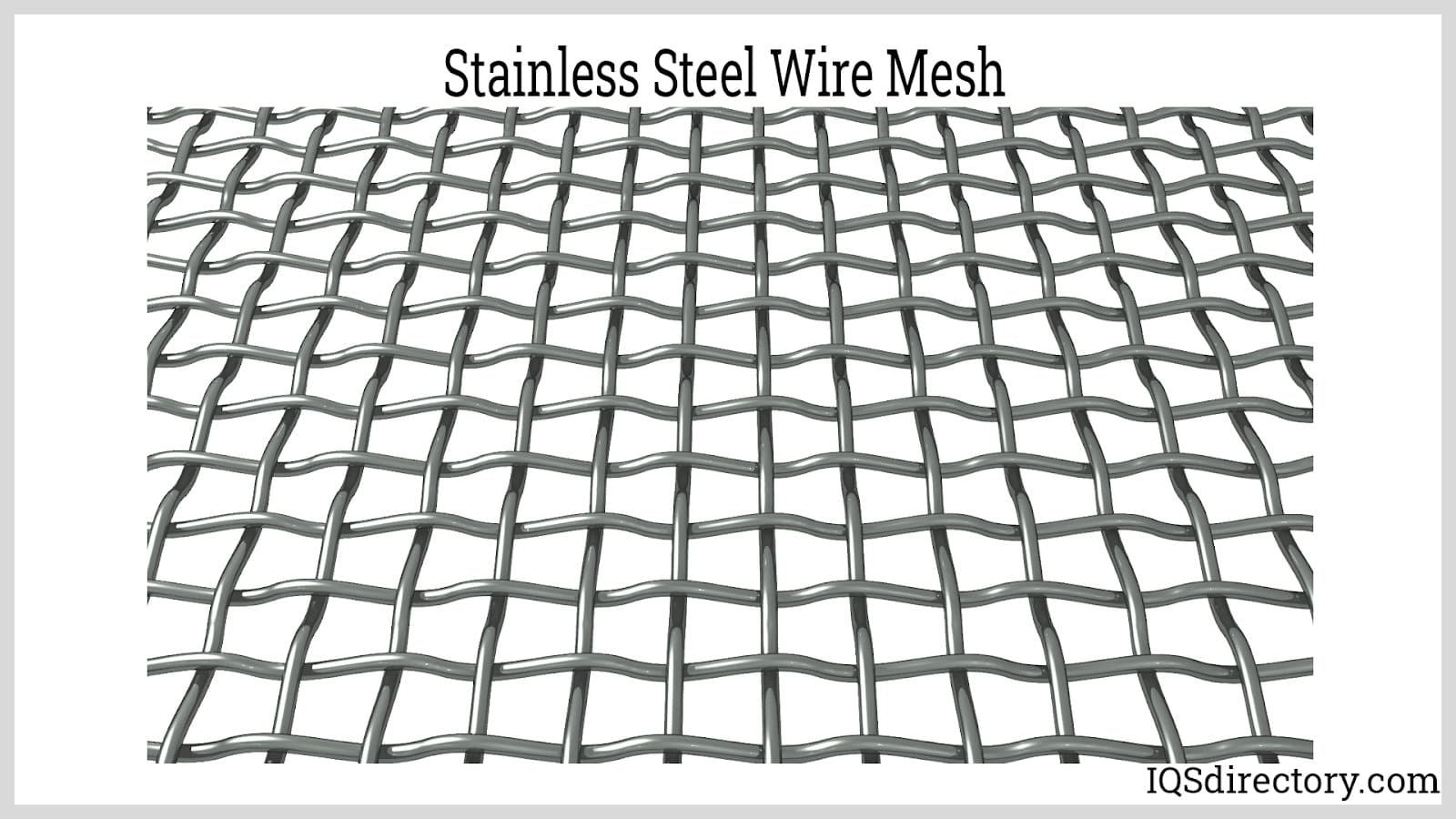

Stainless steel wire mesh is dependability, sturdy, and rust resistant.

Stainless steel wire mesh is dependability, sturdy, and rust resistant.

Galvanized wire mesh is coated with zinc to prevent corrosion and rust.

Galvanized wire mesh is coated with zinc to prevent corrosion and rust.

Aluminum wire mesh is inexpensive, lightweight, malleable, flexible, and resistant to corrosion.

Aluminum wire mesh is inexpensive, lightweight, malleable, flexible, and resistant to corrosion.

Wire Mesh Types

- Backing Cloth

- Wire cloth or mesh that supports the surface of a screen.

- Bolting Cloth

- A stainless steel mesh with a plain weave construction and a small wire diameter, resulting in a high percentage of open area.

- Cloth Baskets

- Baskets formed from wire cloth and may have a round or rectangular frame and be constructed from rod, flat or angle stock. Cloth baskets used for small parts may have a heavy screen outer lining for protection and strength.

- Copper Screens

- May be used for Faraday cages, electromagnetic shielding, papermaking and insect screens. Copper mesh is quite ductile and has very little springback after being bent or formed.

- Filter Cloth

- Cloth with differing wire diameters designed for the express purpose of filtering or straining. Filter cloth is woven in both plain and twill patterns with a higher number of wires in one direction.

- Galvanized Wire Mesh

- A wire product made of interlocking metal that is coated with zinc.

- Hardware Cloth

- A type of wire mesh that is welded and galvanized.

- Metal Screening

- A mesh material.

- Screen Cloth

- A type of wire cloth used for filtration and straining.

- Sieves

- Implements with mesh baskets that are used for straining.

- Square Mesh Cloth

- Woven with uniform mesh count and wire diameter in either direction.

- Stainless Steel Screens

- Used for sifting, especially in food service and plumbing applications where its corrosion-resistant quality is needed.

- Stainless Steel Screen Cloth

- The most common material and has high strength and corrosion resistant properties. The mesh pattern consists of square openings.

- Steel Mesh

- And wire cloth made of standard steel is inexpensive, tough, temperature resistant and fares well over long periods of time. If uncoated, regular steel mesh should not be exposed to water for long periods of time or on a regular basis because it will rust and oxidize; stainless steel mesh is water resistant and ideal for these applications.

- Strainers

- Products made from woven wire cloth that are used for clog prevention, filtering, draining, straining and sifting of liquid materials.

- Test Sieves

- Come in a wide variety of styles, including half-height, microplate, wet washing, extra depth, air jet and grain sieves. Test sieves are totally sealed and have precision frames, structured rims and evenly tensioned mesh.

- Welded Wire Mesh

- A product made from perpendicular metal wires that have been welded at their 90 degree angle cross points and are used in the construction, fencing and engineering industries.

- Wire Screens

- Thin, finely woven metal wire mesh with a square weave that provides open yet protected barriers.

- Woven Wire Mesh

- The main alternative to welding and is composed of perpendicular wires that are interlaced with each other.

Wire Mesh Applications

The purpose of wire mesh manufacturing is to create products that can be used for all kinds of applications. Most often, these applications are related to separating, filtering, screening, structuring and shielding.

Wire cloth also has applications in the watermarking of bills and notes, the shielding of micro and radio waves, plastic extrusion, optical lens manufacturing, transportation belt manufacturing, and the diffusion of light, heat and flames.

Wire mesh services are valued by a wide variety of industries, including: food and beverage processing, petrochemical processing, pharmaceutical manufacturing, screen printing, automotive manufacturing, pulp and paper, flooring, home appliance, HVAC, mining, battery manufacturing, and industrial manufacturing.

Manufacturers weave and shape wire into many products. All final products start out as generic products, including: wire forms, woven wire mesh, square mesh, welded wire mesh (hardware cloth), fine wire cloth, strong wire cloth and diamond mesh.

These products serve as blank canvases, by which manufacturers make more specific products, such as: window screen, decorative mesh, flour sifters and cooking strainers, wire cloth filter products, wire strainers, animal cages, chicken wire, sieves and screens, catalytic converters, protection equipment and barriers, screen mesh cloth and floor grating.

Materials Used in Wire Mesh

The most common metals and alloys used for making wire cloths are:

- Low-Carbon Steel

- Also known as plain steel, is marginally resistant to corrosion and abrasion. Wire cloth made from it is considered low quality for application in a moist environment. However, low carbon steel has high impact resistance and tensile strength, which makes it suitable for most applications, including metal mesh and hardware cloth. Galvanized steel is even stronger.

- High-Carbon Steel

- More naturally resistant to abrasion and corrosion. With this type of steel, galvanization is not necessary. High-carbon steel is used for making vibrating filter screens for sorting and sifting of abrasive materials, such as stone, gravel and coal.

- Stainless Steel

- For the highest quality, manufacturers make products from stainless steel wire mesh, since stainless steel wire cloth is virtually resistant to a variety of corroding elements. If application demands, stainless steel can be preprocessed to be magnetized or unmagnetized. Moreover, metals like titanium, chromium, nickel, and molybdenum are added to stainless steel for custom-made mesh material, as these metals can change properties, such as heat and moisture resistance, shock absorbency, for a given need.

- Copper

- When wire clothes need good heat and electrical conductivity, manufacturers use copper. Copper naturally has high conductivity and shows resistance to salty and briny environments, which makes it suitable for making wire cloth that will be used in a chemically corroding environment. However, copper is a soft metal and shows poor resistance towards abrasive materials and has poor tensile strength. To supplement the abrasion resistance, copper wire mesh is alloyed with zinc; however, the resulting copper mesh has low heat and electrical conductivity.

- Aluminum

- When an application needs wire cloth to be light, aluminum is used. Since aluminum has natural anti-corrosion properties and high strength-to-weight ratios, aluminum is used for making wire cloth, which is used in marine environments. However, usually, alloys of aluminum, such as 5056, are utilized rather than standard aluminum.

- Nickel

- Pure nickel is rarely used for making wire screens or wire forms, since it shows low resistance to corrosion; a layer of oxide develops over the surface over time. Therefore, alloys like monel, hastelloy B, hastelloy C and Carpenter 20 CB-3 are preferred.

Machinery Used For Wire Mesh Creation

Manufacturers weave wire using looms. They are automated and can be customized based on the following parameters: scope of weaving, scope of mesh counts, square holes range, crankshaft rotating speed, power of motor, total weight and total measurement.

In addition, some are designed for fine mesh, while others are made to weave coarse mesh. Furthermore, some are designed specifically for weaving wire mesh stainless steel.

Variations to Wire Mesh

Similar to mesh metal is perforated metal, perforated metal is sheet metal that has a pattern of holes, slots or decorative shapes. Unlike wire mesh manufacturing, which uses weaving and welding of wires to create hole patterns, perforated metal manufacturing relies on stamping machines, punch presses and lasers to mechanically stamp in the holes.

Things to Consider When Purchasing Wire Mesh

To find the best wire mesh product, work with an experienced wire mesh supplier. The right supplier will know the best actions to take, from whether to weld mesh or weave mesh, to what patterns to use. The right manufacturer will make sure that you get the best product possible; they will do everything they can to deliver timely, cost-effective and better than requested results. To find a manufacturer like this, browse those we have listed above. Check out their respective websites; choose three or four with whom you’d like to speak, and then reach out to them. Offer them all a detailed explanation of your application requirements; don’t forget to ask lots of questions! Then compare and contrast what they tell you. From the group, pick the one that you believe will provide you with the best customer service.

Wire Mesh Terms

- Aperture

- The space between contiguous parallel wires, expressed in millimeters.

- Bands

- Steel, galvanized steel or stainless steel material that is used to reinforce the screen edge.

- Bend Test

- A test in which wire is bent over a specified diameter through a certain angle and for a preset number of cycles, in order to determine its relative ductility, soundness and toughness.

- Blinding

- The blocking of apertures of wire mesh caused by particle entrapment of the process material.

- Bubble Point Test

- A method used to test the average aperture size. The pressure needed for air bubbles to pass through the mesh, which is covered by a test liquid, is measured, and surface tension, liquid density, temperature and immersion depth are taken into account in the calculations.

- Calender

- Also known as “rolled,” it is the process of passing wire cloth between two rollers to reduce the thickness or flatten intersections of wires and to supply a smooth surface.

- Coin

- To stamp wire cloth in order to prevent unraveling and to shape or compact the wire mesh.

- Count

- A term used only in reference to mesh wire cloth, referring to the amount of openings per linear inch as measured from the center of the wire.

- Crimp

- Corrugations in the wires for the purpose of securing the wire in place when perpendicular to each other.

- Double Crimp

- Crimping of wires prior to weaving. The shute and warp are in each crimp.

- Feather Edges

- Non-crimped, straight wire edges sticking out all around a section of screen cloth on the same plane.

- Gauge

- The diameter of the wire prior to weaving.

- Heated Deck

- A screen surface that is heated by a screen cloth, which is used as a heating element and is typically made of stainless steel material.

- Intermediate Crimp

- Shute and warp wires occurring in every other crimp.

- Market Grades

- The most commonly utilized sizes of industrial wire cloth specifications chosen for general-purpose work and typically ready for shipment upon order from companies.

- Mesh Count

- The number of openings between interlocked wires per linear inch. Mesh count indicates the size of the weave, therefore indicating filtering capabilities.

- Offal

- Excess wire screen material that, in the slitting or fabricating process, is cut from a standard roll.

- Open Area

- The proportion of open space to the total area of a wire screen, expressed as a percentage.

- Selvage

- The finishing of edges along the length of a roll of wire mesh to prevent unraveling.

- Shute Wires

- Also called “weft,” “shot,” “shoot” or “fill” wires, they are the wires going across the width of the woven cloth. Shute wires are moved back and forth by the shuttle.

- Warp Wires

- Wires going lengthwise across the wire cloth. In the weaving process called "warping the loom," the warp wires are placed first at the preferred spacing.