Vibratory Feeders

The vibratory feeder, also known as a bowl feeder, is one of three main parts feeders on the bulk material handling market; the other two are the centrifugal feeder and the pneumatic feeder. Vibratory feeder systems feed parts or bulk material through various stages of finishing, packaging and recycling by means of vibration.

Unlike pneumatic conveying, screw conveying and standard belt conveying, vibratory conveying offers solutions for moving delicate or sticky food materials without causing liquefying or damage due to shearing or rough handling.

Quick Links to Vibratory Feeders Information

History of Vibratory Feeders

Vibratory feeders were first patented in the USA in 1950, by Mario Thomas Sgriccia. During that time through the 1960s, vibratory feed machines were used primarily in the mining industry. Sgriccia’s model was durable and simple, but it also consumed a large amount of energy, was heavy and produced uneven piles of fed material. In the 1960s, engineers introduced an improved model, the electromagnetic vibrating feeder. This offered more energy efficiency, more even processing and was lighter. However, it was still quite loud and not terribly durable.

Since then, vibratory feed machine manufacturers all over the world have tweaked the bowl feeder, with improvements like the optional sound enclosure, which is one of the reasons we have so many feeder types available to us today. Contemporary feeders are durable, efficient and much quieter than the early types. They no longer serve just the mining industry, but any industry that requires sifting and sorting.

Benefits of Vibratory Feeders

Benefits of vibrating feeders include their low maintenance and easy material handling, lack of moving parts (aside from the vibrating drive), cost-effectiveness, automated functioning, versatility, effectiveness, accuracy and ergonomic design.

In addition, vibratory feeding systems are highly adaptable; parts that vary in shape, size, geometry, and weight can be easily fed in the feeder without any modification or the addition of an auxiliary system.

Plus, you can easily change the feed rates according to your application needs.

Design of Vibratory Feeders

When designing a vibratory feeder system, manufacturers must consider application needs and factors, such as: load volume, material feed rate, material texture, material size, and vibration intensity and amplitude.

The standard vibratory feed design is a bowl feeder; manufacturers typically make bowl feeders from stainless steel, silicone or plastic, and equip them with a vibrating drive beneath the bowl, where it is mounted to a base.

Manufacturers can create a quiet custom vibratory feed system by enclosing the feed machine in a sound enclosure. They can also customize a system in terms of all of those standard design factors, like feed rate, vibration intensity and amplitude, etc.

How Vibratory Feeders Work

While each type is a little bit different, in general, vibratory feeders feed material into another machine or process using a combination of gravity and vibrations. First, gravity determines the direction of flow of component parts; this flow is either down and to the side, or just down. Second, vibration moves the material or parts. The vibrations are usually created by a vibratory drive unit that sits below the vibratory feeder bowl.

The bowl and the drive unit vibrate the parts in a circular motion, driving them up a ramped, spiral ridge along the edge of the bowl until they reach an outfeed area. Once there, parts and materials are forced to form a single-file line.

When working with loose materials, vibratory feed machines work in conjunction with equipment like vibratory screens, vibratory conveyors or trommels, which help them sift and separate materials.

Vibratory Feeders Images, Diagrams and Visual Concepts

A vibratory feeder is a conveying system designed to feed components or materials to an assembly process using controlled vibratory forces, gravity, and guiding mechanisms to position materials.

A vibratory feeder is a conveying system designed to feed components or materials to an assembly process using controlled vibratory forces, gravity, and guiding mechanisms to position materials.

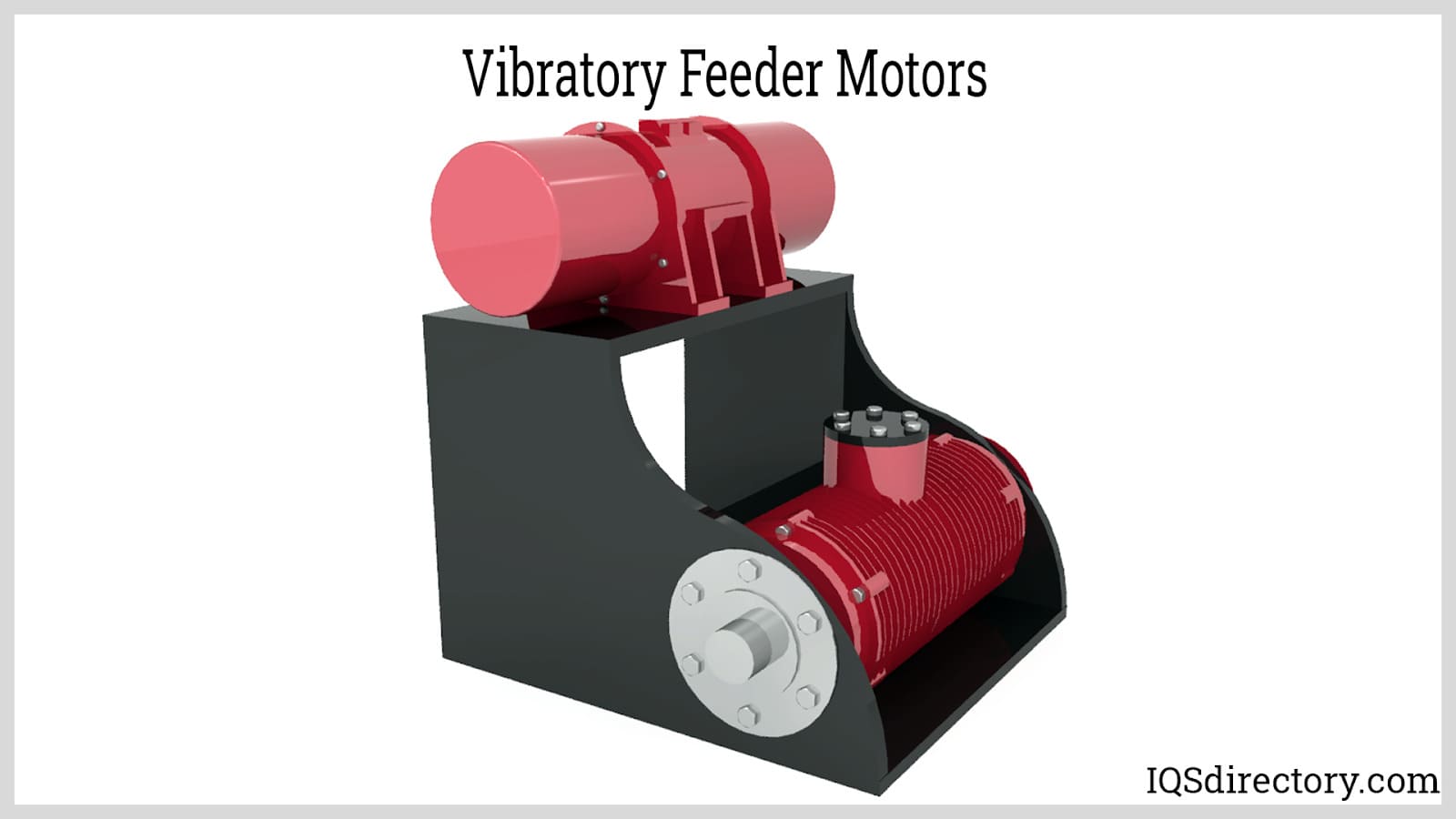

The motors causes vibrations with both horizontal and vertical.

The motors causes vibrations with both horizontal and vertical.

The primary springs continuously store and release energy during operation.

The primary springs continuously store and release energy during operation.

Material added to cover the surface of the trough to resist wear, temperature, reduce noise, reduce friction,and prevent material buildup in the trough.

Material added to cover the surface of the trough to resist wear, temperature, reduce noise, reduce friction,and prevent material buildup in the trough.

A Grizzly Screen heavy-duty screen consisting of rails or bars running in the direction of material flow and separtes fine particles form the material.

A Grizzly Screen heavy-duty screen consisting of rails or bars running in the direction of material flow and separtes fine particles form the material.

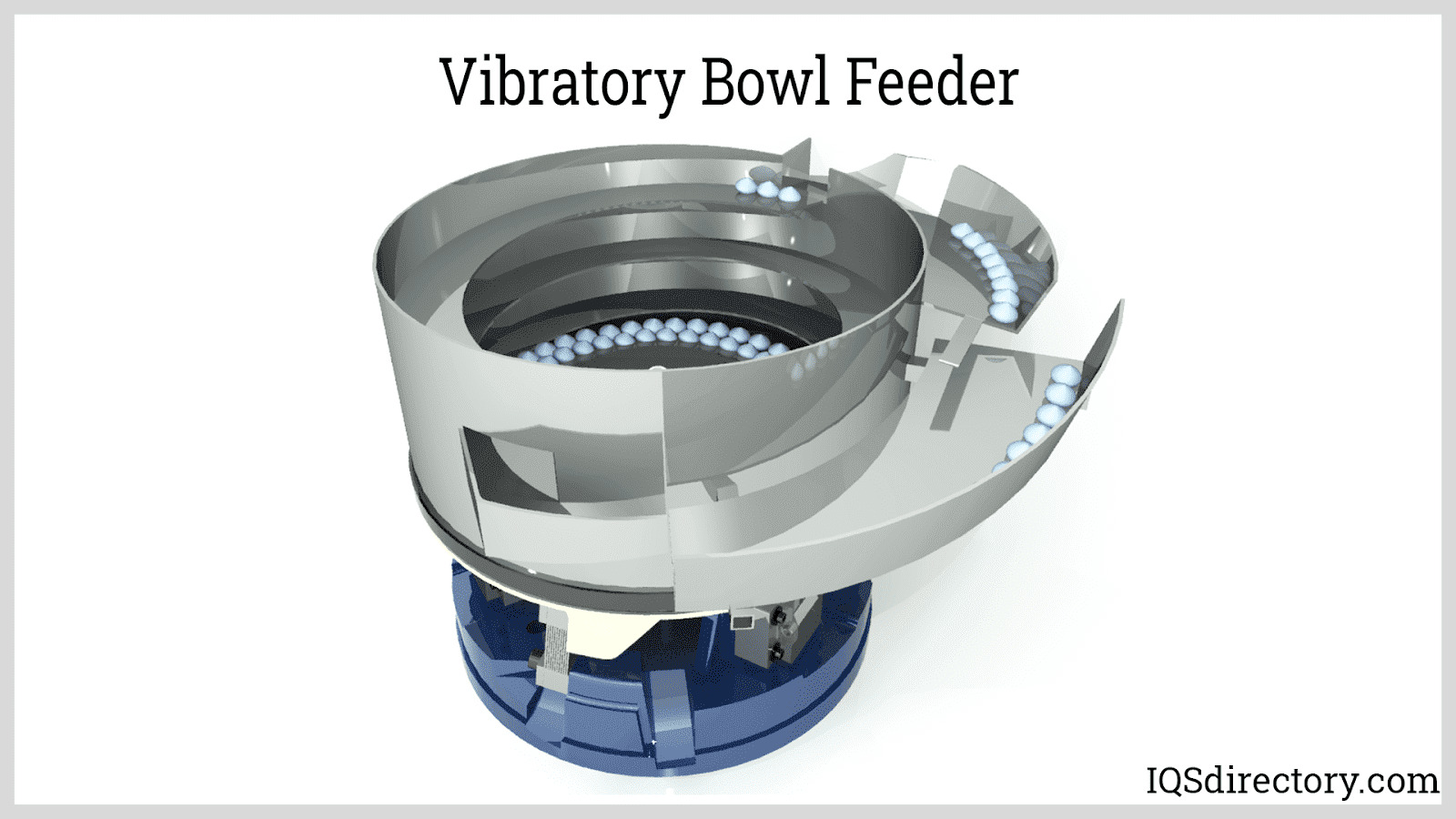

Vibratory bowl feeders have helical trough which uses vibrations to toss and shuffle materials along a slightly slanted surface of the helical trough.

Vibratory bowl feeders have helical trough which uses vibrations to toss and shuffle materials along a slightly slanted surface of the helical trough.

Types of Vibratory Feeders

- Vibratory Bowl Feeder

- Also known as vibratory bowls, are a type of parts feeder composed of a bowl top and an inclined spiral track on which components are guided. From the track, parts move to a line that takes them to the bottom of the bowl feeder.

- They’re used extensively by small parts manufacturers as an extremely efficient means of orienting products for further finishing or for distribution. Originally designed by pharmaceutical companies to count, sort and organize pills, bowl feed machines also orient small parts, like fasteners, ammunition, O-rings, molded rubber parts and toothpaste caps.

- Vibratory Conveyor

- Also known as step feeders, are metal troughs which vibrate in one direction, conveying powder bulk solids or heterogenous mixtures from one process to another. Some vibratory conveyors have ultra-low vibrations designed specifically for solids which are delicate, sticky or may liquefy, such as gummy bears or lettuce.

- The big advantage of the step feeder is the fact that it eliminates the issue of jamming parts, associated with standard bowl feeders. This unique design makes operation smooth, which in the long run brings cost down, by decreasing downtime.

- Grizzly Screen

- A particularly powerful type of vibrating screen is a grizzly screen, which is most often used in the mining industry.

- Electromagnetic Vibratory Feeders

- A sub-resonance tuned two mass system is used to create vibration. Its working principle is simple; an electromagnet fitted in the machine attracts an armature bracket, which is connected, through a leaf spring set, to the second mass that creates linear vibration. This vibration pushes material to the feeder pan that creates controlled movement of the materials along the pan. A controller is fitted that varies the AC supply to regulate the feed rate.

- Electromagnetic feeder systems offer excellent control and are considered ideal for batching applications.

- Electromechanical Vibratory Feeders

- Use rotary electric vibrator drives to produce fully adjustable, and uniform volumetric flow. They are corrosion resistant equipment, rugged and low maintenance, and can be fixed with Isolators to limit noise levels. Since the design has controls for vibration intensity, force and frequency, they have application in a wide range of industries. Electromechanical feeders can be installed with additional parts, such as single, dual or multiple drives, to work as vibrating conveyors. This versatility is hard to come by in other vibratory equipment.

- Trommel

- Or trommel screens, are vibrating screens which help sort small particles from large particles. They cut down on the huge amount of labor required to sort recyclable materials, an important step in making recycling a cost-effective part of manufacturing processes.

- Rotary Trommel

- Large tumbler design, aid in gravel processing and recycling; trommel magnets are often used in conjunction with metal recycling rotary trommels to help sort ferrous materials from non-ferrous materials.

- Continuous Flatbed Trommel

- May have screens or filtering devices which sort particles of different sizes as large particles are conveyed to containment or further processing.

- Pneumatic Feeder

- Specialized feeders designed for laboratory environments; they are both water and explosion proof in compliance with the standards of a laboratory. As the name suggests, the feeders have a pneumatic drive unit with a piston engine producing vibrations.

- Whatever the load is, they are designed to produce constant speed, which makes them appropriate for lab settings. They are also valued as environmentally friendly, reliable and low maintenance.

Types of Non-Vibratory Feeders

- Screw Feeder

- This part feeder type is designed specifically for use with screw conveyors. Screw feeders are especially useful with screw conveyors because you can program them to volumetrically meter material at a controlled rate.

- Belt Feeder

- Composed of a conveyor belt and rollers upon which the belt moves. They’re used to feed materials that don’t need to be pre-sifted into bulk handling machines.

- Storage Hopper

- Storage containers used to collect granular materials, then dispense them onto a conveyor or another material handling component, using gravity.

- Linear Feeder

- Also known as inline feeders, were developed and designed as an alternative to vibratory feeders. As the name suggests, the design involves horizontal conveying components. They are specifically created for applications when oily or irregular parts, which vary in size, shape, and other physical characteristics, are involved. The alternative horizontal design requires minimal maintenance and is relatively easy to setup. Install and forget about them, they still will serve you well for a long time.

- Centrifugal Feeder

- Also known as rotary feeders, work with screw conveyors or vibratory conveyors to provide air-tight bulk material feeding. In this system, an electric motor runs an angled rotating disk that puts centrifugal forces on the component parts. The parts then start to move to the outer edge of the bowl. They are fitted with specialized tools to deliver and orient the parts before they are fed to the processing line. Centrifugal feeders are used mostly when high-speed and gentle handling is required for a production line. However, only those component parts that have no tendency to tangle at a high feed rate, like caps and medical devices, can be fed using this system.

- Most often, they’re used with powder bulk material conveying or dust collecting systems. Centrifugal feeders do not use electromagnetic vibrations or gravity like vibratory feeders do; instead, they work by centrifugal force. They use a central motor that moves parts in a circular motion, and under the centrifugal force, aligns them across the outer edge of the bowl. Before being fed onto the processing line, they are oriented by specialized tools. You can set a predetermined speed based on your requirement.

- The rotary feeder is used when the application requires the high speed of centrifugal force, which cannot be reached with vibrating feeders. It’s also suitable for gentle processing, strength, and hygiene. However, only those component parts that do not tangle at high feed rates, like caps and medical devices, can be fed using this system.

- Vertical Mast-Step Feeder

- Offer even more value, as they save you floor space. They collect the component parts from the hopper and use elevated plates or a conveyor to get the height they need. They operate quietly and without vibration; therefore, their maintenance remains low.

Applications of Vibratory Feeders

Vibratory feeders offer feeding, sifting and sorting solutions for delicate materials, such as powder. Examples of materials they frequently deal with include: plastic, wood, crushed cement, metals, gravel and sand. They also process and align small parts like washers, O-rings, Legos and coins.

Vibratory feed machines are relied upon by operators in a wide variety of industries, including recycling (to convey and sort materials for reclamation), fertilizing, sand and gravel, pharmaceuticals, agriculture, food processing, mining and pulp.

Things to Consider When Purchasing Vibratory Feeders

When you’re considering purchasing a vibratory feeder, you need to consider both your application requirements and your manufacturer. Important application aspects include: the type of material (Is it loose? Is it compact? Small parts? Etc.), the weight of the material, the speed at which you need to move it, whether or not it requires sanitary conditions, and how often you’ll be changing your materials.

Prepare the answers to these questions and then take them to a reputable manufacturer. How do you find a reputable manufacturer? The best way is by going straight to a directory, like this one. IQS has done the legwork for you by searching the crowd and finding the best manufacturers around the USA and Canada. To learn more about our top picks, check out the list that we’ve provided near the top of the page. Browse their respective websites and pick out three or four companies you think could work for you. Then, reach out to each of them and discuss your specifications. Compare and contrast their answers, bearing in mind that the right one for you will be the one that can deliver quality results on all of your requirements within your budget and timeframe.

Vibratory Feeder Equipment Components

Vibration feeder equipment components include: an electromagnetic system or electromechanical system, a set of springs, a bowl, a spiral rack and, often, a control box.

With an electromagnetic system, the springs, which are connected to it, are used to convert electromagnetic vibrations into wavy movements in the bowl. With an electromechanical system, rotary electric vibrator drives deliver the movements to the bowl. The spiral track is used to move parts around the feeder. The control box, also called a cycle control, is installed to adjust the intensity and amplitude.

Vibratory Feeders Terms

- Approach

- The location in the parts feeder bowl at which the parts begin to ascend the bowl feeder track.

- Backpressure

- The exertion of force when parts emerge from the vibratory feeder.

- Cascade Bowl

- A bowl feeder that consists of basic tooling on its inside track. Cascade bowls are advantageous when orienting larger, standard parts.

- Depth of Bed

- Also known as "material depth (mat. depth)" it is the thickness of the layer of material that is being carried on the conveyor or vibratory feeder surface.

- Discharge End

- The vibratory feeder exit where the parts emerge from the vibratory feeder system.

- Drive Unit

- Also referred to as the "drive base unit" it is the device that provides power to the vibratory feeder system.

- Explosion Proof

- Equipment that meets the standards of operation in a specific hazardous environment as set by recognized organizations such as Underwriters Laboratories (UL).

- Feed End

- The feeder entrance through which the parts enter the vibratory feeder system.

- Grizzly

- A hard wearing screen used in the sizing of bulk material.

- Hanger

- Also called "suspension assembly" or "bail assembly" it is a support device for vibratory feeders.

- Head Load

- A term referring to the weight of the material supported by the vibratory feeder, which is located in the trough and hopper/bin.

- Hopper

- Large, bulk container that stores material and regulates parts flow into the vibratory feeder system.

- Isolation

- Also referred to as a "vibration absorber" it is a device that separates the vibration between the machine and the structure. Examples of isolations include coil springs and rubber.

- Load Sensitivity

- The difference in performance as the vibratory feeder empties.

- Orientation

- The act of setting or arranging in a determinate position from random positions. Vibratory feeders usually have three types of orientation: simple, moderately complex and complex.

- Outside Track Bowl

- A bowl feeder that consists of complex tooling for parts, which have intricate part configurations.

- Rotation

- The direction, either clockwise or counterclockwise, in which the drive base unit shifts the bowl feeder and parts.

- Singulation

- The separation of a mass of parts into individual parts.

- Sound Enclosure

- A foam-lined structure that absorbs the noise created by the vibratory feeder.

- Spring

- Device that generates vibration or isolates vibration between the machine and the structure.

- Trough

- Also called a "pan" it is the tray on which the material is loaded into the vibratory feeder system.

- Vibratory Separators

- Devices commonly used to separate materials or particles across a number of different applications and industries.