Die Cutting

Die cutting is the manufacturing process of stamping or cutting two dimensional parts out of flat sheets of materials like rubber, fiber, paper, or metals. This process, often used in conjunction with laminating services, is a crucial finishing service for a wide range of parts and products.

Sometimes the term die cutting stems from confusion, as it is quite ambiguous and its meaning differs in different fields. Other than cutting a material, a die can perform other functions as well, such as forming, which involves compression and other stressing methods for producing desired shapes.

Quick links to Die Cutting Information

The History of Die Cutting

The die cut process was born in the mid-1800s, when it was used in the shoe industry. Before cutting, the holes in leather shoes were punched by hand. Die cutting made cutting leather faster and easier; shoemakers cut leather into different shapes by exposing it to a press installed with a cut die, which carved pre-determined shapes.

In the early 1900s, the die cutting industry saw many improvements. For example, this time period saw the invention of the swing arm clicker press, which allowed users to cut different shapes and sizes simultaneously on different dies. Ultimately, this attachment led to the ability of mass production of products like plastic and metal tubing.

During the 1950s, engineers began designing smaller and smaller machine models, including handheld models and tabletop machines.

Since the early 2000s, die cutting has been revolutionized by computers and CAD technology. In addition, modern die cutting processes use sophisticated robots and high-pressure presses that can shear webs even in the thickest hard metal.

Today, die cutting machines don’t just serve commercial and industrial purposes; you can also get them for crafting in the classroom or your home. A great example of this type of die cut machine is the Cricut Expression, which is a small, portable die cut machine you can program with different fonts and shapes. You can get these fonts on a physical or digital Cricut cartridge.

Benefits of Die Cutting

Die cutting, whether you are seeking your own machine or to procure professional services, offer many benefits. First, die cutting works with many different materials, from cardboard to metal sheets. Second, die cutting is highly fast, efficient and precise. Third, the process does not require heat; this will cut down on both injury risks and energy costs.

Furthermore, die-cut machines are incredibly versatile. For example, if you need industrial die cutters, they’re out there; but also, if you want small portable die cutters, those are out there too. Plus, both of these types are available as either manual, hydraulic, pressurized or electric-power models. Finally, your precision die-cut machine can be computerized and use CAD software.

Process and Design of Die Cutting

Die cutting is a cold operation that does not need heat to change the physical properties of a material. Instead, brute force is employed to cut pieces of required shape and size with the help of a press. The first step is to put the material to be shaped on a flat surface with a supportive backing and the help of auxiliary tools that lets the die pass through it. The second step is to press the die against the intended cut surface. Via force, which may be perpendicular or at another angle, the press cuts the part.

When mapping out a die cut design, manufacturers look at the application and decide what type of die and die machine will work best for it.

- Selecting a Die

- Largely, manufacturers decide this based on the function of the die, the function of a die will perform depending on the way a die is tooled; dies can be divided in two sections, one for cutting and other for forming.

- Selecting a Suitable Machine

- Selecting a suitable die cutting machine depends on many factors like the material to be cut, the structure or design to be formed, the volume of cutting requirements, the speed of the machine as well as the method of cutting that will suit the needs.

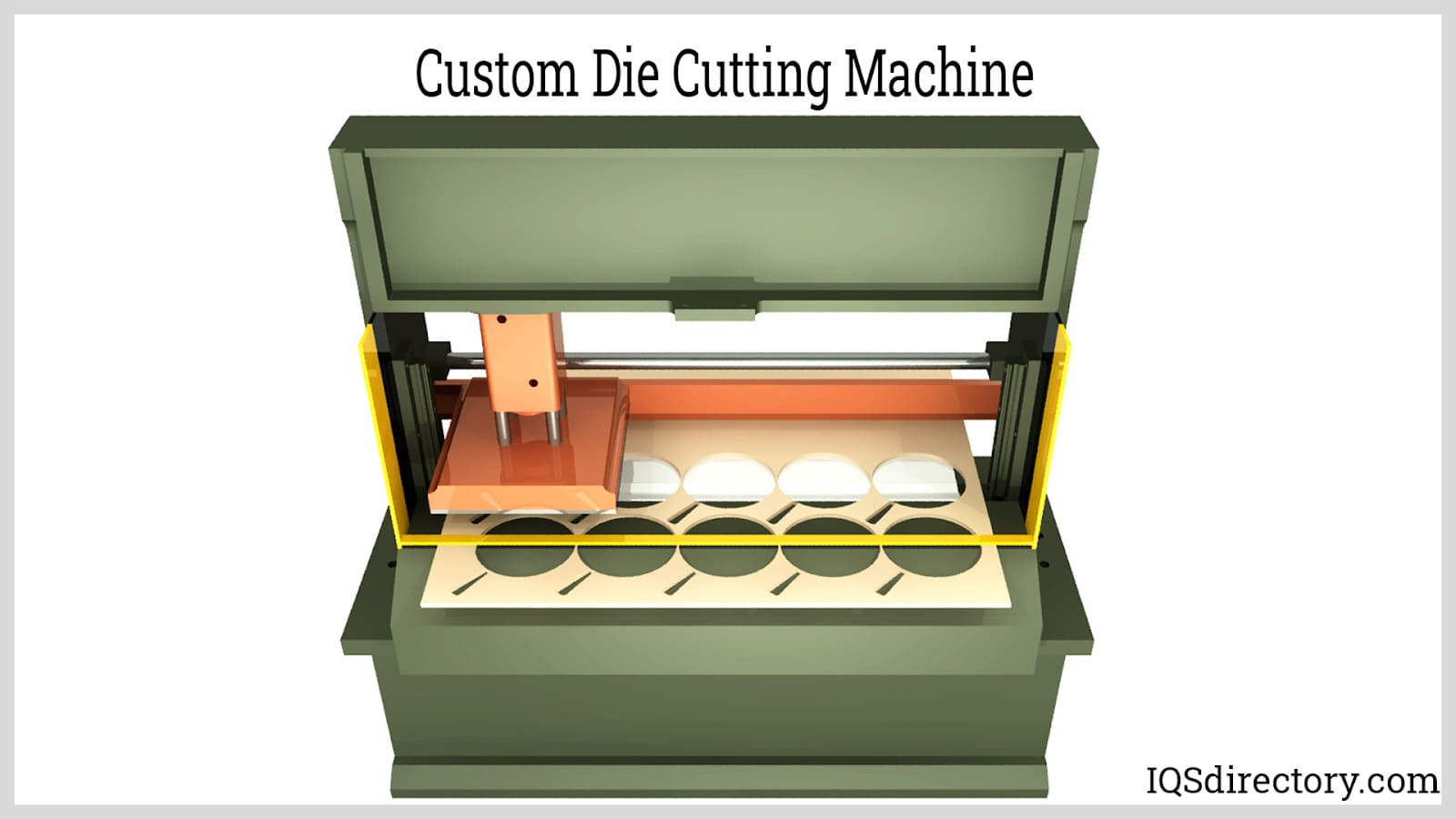

- Custom Die Cutting

- To make sure you get the perfect shapes, your die cut service provider offers both custom die and custom die cut options. For example, they can use blades shaped just for your precise cutting application, as well as dies tooled just for your unique shape. Also, depending on the type of material to be cut, manufacturers can program machines to either cut and form a piece of material, or slice multiple pieces of materials stacked one over the other.

Cutting Machinery Used

Die cutting machines come in a variety of configurations, each specialized for creating different types of die cut shapes. Below are some examples of the various presses, dies and machines used during the many different types of die cutting.

- Rotary Press

- Works continuously, cutting pieces as it rotates. It offers a fast and efficient operation experience. Most often, rotary presses are paired with rotary dies.

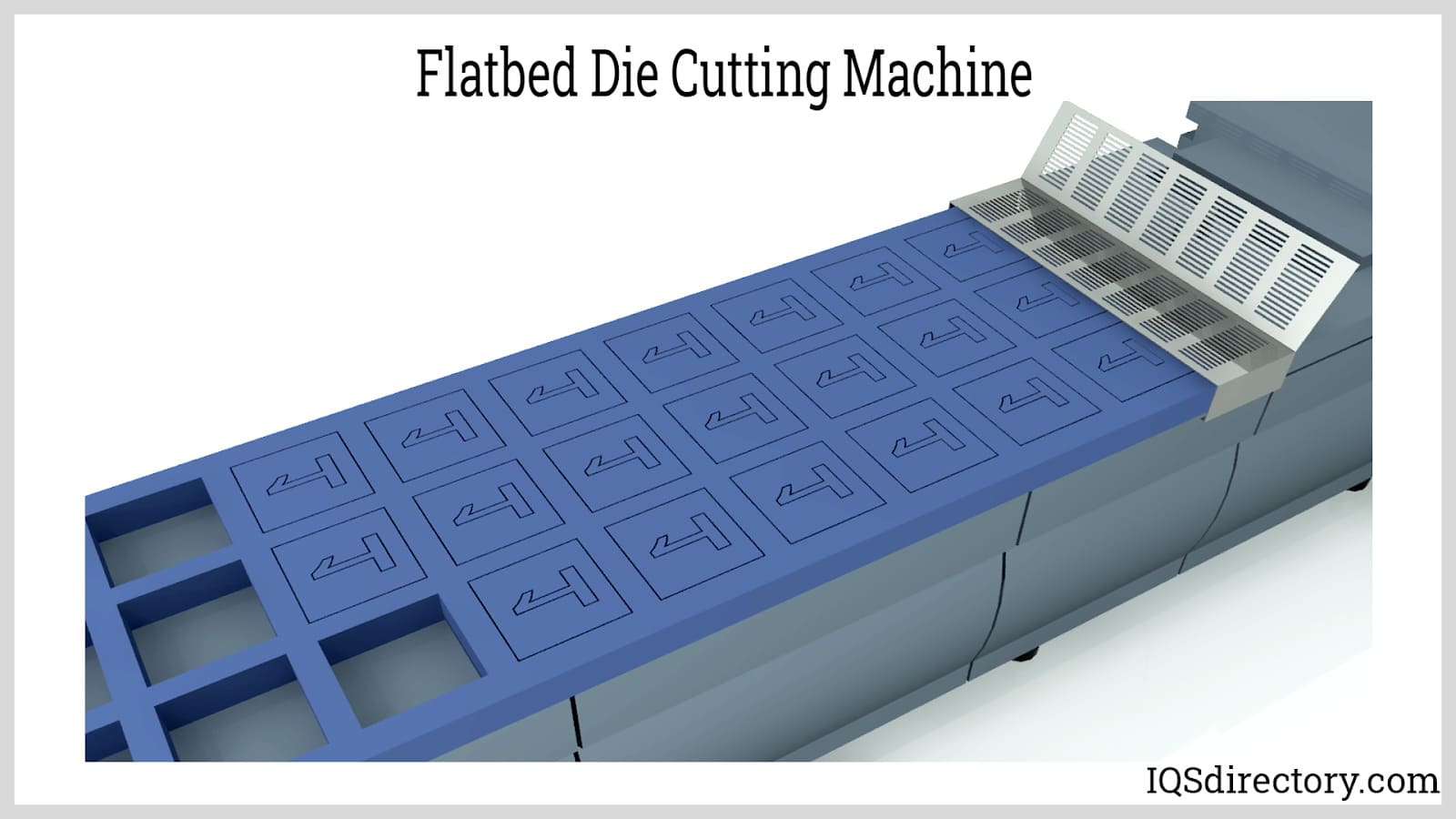

- Flatbed Die Cutting Machine

- Exert force perpendicularly to material that needs to be fabricated. They are usually driven hydraulically, but manufacturers often stock or custom make mechanical models as well. While flatbed presses are not as fast as rotator presses, their tooling costs are much lower. Flatbed die cutting machines are best for cutting stamps and stickers.

- When it comes to cutting materials involving different types of shapes and get high design flexibility, then selecting flatbed die cutters is the best bet. This machine uses steel rule dies with a hydraulic press that can make precise kiss-cuts and die-cuts into sheets and laminates.

- Laser Die Cutting Machine

- Operated by CNC, are driven by a 3-axis table. They come in two types: flat cutters, which laser cut flat sheets of material, and rotary cutters, which laser cut material from a web.

- Rotary Die

- Cylindrical and made to fit on a rotary press. Typically, they’re bought in sets, as manufacturers put them together as continuously working rolling calendar dies. Rotary dies are typically used in the corrugated box industry, but they are also commonly utilized for plastics, foam, rubber and textiles.

- Steel Rule Die

- Cut single or multiple sheets in batches. Steel rule blade dies are sharpened and thin, embedded in rubber and mounted on a solid wood block. The rubber surrounding the steel rule's cutting edge serves to eject punched out pieces, while the die and rubber pad crush sheets of foam, plastic, or rubber between them with several tons of force.

- Heavy Duty Steel Rule Die

- Such as the clicker die, have thicker blades (.056"-.112") to cut through thicker, tougher materials. Examples include: plastics, Kevlar, fabric, rubber, leather and composites to make a range of gaskets, vibration absorbers and plastic parts.

- Conventional Die

- Can attain the highest accuracies and the most intricate of forms as well as fold lines, scores and perforated or partial cuts. These dies are typically used to cut corrugated boxes, folding cartons, gaskets, plastics, fabric, rubber, foam and composites. The blades are held in place by high density plywood; the thickness of the blade is usually between .028" and .056".

- Swing Arm Cutting Press

- Also known as a clicking press, the swing arm cutting press draws its name from the cutting action it performs. With the help of a hydraulic arm, this press efficiently cuts small parts in productions large and small.

- Travelling Head Cutting Press

- Named as such because it has a motorized cutting head that travels on a frame. It is typically automatic.

Die Cutting Applications

Die cuttings are produced to act as important elements of all sorts of applications. Customers turn to die cutting because it gives a perfect finish to stamped paper, plastic, or metal products.

Die cut products, including die cut foam, is used extensively in medical, craft, packaging and shipping, hydraulic, electronic and consumer industries.

Products commonly produced via die cutting include: die cut gasket hardware, vibration absorbers, bandages and adhesives and die cut plastic handle bags. Die cutters can also be used to make circuit boards, ID cards, credit cards and other flat plastic pieces, labels and stickers, adhesive tapes and stamps, corrugated envelopes, cartons, fabric and metallic products. They can even make keys.

Various die cutters are used that are specialized to cut different products like furniture, plastic, paper or metals in specific designs and patterns.

Variations and Similar Processes to Die Cutting

- Rotary Die Cutting

- Sheets of material are crushed between the angled blades on a cylindrical die and an anvil. Typically, the material is cut in continuous roll form. Rotary die cut parts are consistently within a tolerance as tight as .02", slightly higher than typical steel rule die cutting, which must be carefully aligned by hand and is more error prone.

- Rotary Steel Drum Cutting

- A combination of rotary and steel rule die cutting, which is used to cut large parts such as boxes or garments with a high degree of accuracy.

- Ultrasonic Die Cutting

- A relatively new technology that uses ultrasonic vibrations from a metal horn to cut and heat seal edges simultaneously. Ultrasonic waves are below the level of human hearing.

- Ultrasonic die cutting is ideal for cutting thermoplastic materials that tend to easily fray. However, this type of die cutting is limited in that only relatively thin materials can be cut, and parts have a small maximum width.

- Laser Die Cutting

- Very useful for cutting materials that are impossible for conventional steel rule dies to cut, like steel thicker than .5", as well as ABS, acrylics, aluminum, brass, composites, copper and cured fiberglass. Laser die cut parts can be cut intricately, with very precise tolerances.

- Laser die cutting does not use dies. Thus, it requires none of the initial tooling costs that all other die cutting methods require. Also, because it has such high tolerance capabilities, it creates less waste than other processes.

- Laser die cutting is ideal for prototyping and short runs, but laser die cutting cannot cut parts at the speed and volume rotary and steel rule die cutters can, and so, most typical long run projects are still performed by traditional dies.

- Crush Cutting

- Both rotary and steel rule die cutting can perform either kiss cutting or crush cutting. Crush cutting, contrary to what its name suggests, makes clean, complete holes all the way through the material sheet. Typical crush cut products include: foam pads, adhesive bandages, gaskets and rubber parts.

- Kiss Cutting

- Used only on adhesive-backed materials, cuts through the top layer of the material without cutting through the backing. Common kiss cut products include: sheets of stickers, foam adhesives, bumpers and many other products meant to be peeled off a backing sheet.

- Blanking Operations

- Via the single movement of a press, a flat or processed profile is cut entirely from a flat material. During this single movement, the die compresses the material uniformly at all contact points. Blanking is considered a dual-purpose operation and performed at a larger scale.

- Trimming Operations

- Manufacturers trim away the perimeter of a pre-processed or flat sheet material in order to create a certain profile. They recycle any leftover materials.

- Notching Operations

- Manufacturers use progressive dies to notch out the edges of a material sheet. This progressive process is also used to create a desired shaped.

- Die Cutting Through Bending

- Involves giving shape to a material by exerting pressure from a die. For instance, in a typical operation, the forming part of a die exerts pressure on a material and bends the material at a 90-degree angle.

- Die Cutting Through Piercing

- Also known as perforation. This operation produces specific shapes from flat material; the material is pierced with holes by a die. The die design can be a circle, a square, or a custom shape.

- Lancing Operation

- Manufacturers turn to lancing to slit or slice a part of a material without severing it completely from the strip. This type of operation is done on a progressive die.

- Die Cutting Through Shearing

- Shearing is the simplest die cut slicing operation. It involves slicing the material strip in a straight line. Through shearing, manufacturers produce rectangular and square-shaped blanks.

- Stamping or Pressing

- Also known as pressing, is a die cutting process during which sheet metals are stamped into a net shape. This process relies on blank or coil metals and a stamping press.

Die Cutting Images, Diagrams and Visual Concepts

Rotary die cutting machines operate in continuous production mode at a lower cutting pressure and constant speed.

Rotary die cutting machines operate in continuous production mode at a lower cutting pressure and constant speed.

The retail items made from die cutting.

The retail items made from die cutting.

Kiss cutting is a method for cutting into a material where the upper layers are pierced, but the back layer is left intact.

Kiss cutting is a method for cutting into a material where the upper layers are pierced, but the back layer is left intact.

The flatlbed die cutting is suitable for cutting thicker sheets or multiple sheets as the machine is capable of exerting a considerably amount of force.

The flatlbed die cutting is suitable for cutting thicker sheets or multiple sheets as the machine is capable of exerting a considerably amount of force.

Things to Consider When Choosing Die Cutting

The first thing you need to consider is whether you would like a die cut company to perform services for you or you would like to invest in your own die cutter.

If the former, we recommend you conduct your search using this page as your home base. Scroll up to the top of this page and find our list of our top company picks. Browse their respective websites and pick three or four that you think could fulfill your requirements. Then, reach out to all of these manufacturers. Tell them your specifications, and make sure to ask lots of questions, like about the lead time they can achieve, and if they can work within your timeline, your budget and any standard requirements that you have. After you’ve talked to all them, compare and contrast their answers. You want to choose the one that you believe will do the best work for you.

If, on the other hand, you would like to buy your own die cutter, consider these essential factors; they will go a long way to help you make the right choice.

- Cutting Requirements and Machine Type

- Although the basic functionality of all types of die cutting machines is the same, there is a great difference in the usability and cost of the machine. Based on material, shape and quantity cutting requirements, select a die cutter that is specialized for your cutting requirements.

- Requirements for Die Type

- Because dies come in various shapes and sizes, it is important to check the compatibility of dies with your machine.

- Installation Requirements and Machine Portability

- Setting up a die cutting machine may be time consuming, so it’s important that buyers check how much time it takes to install the machine. It’s also important you check the portability of your machine, as that will impact your ease of installation. Small and portable machines are the easiest to install.

- Storage of the Die Cutting Machine

- Check your available storage space. This will give you a fair idea about how big or small your machine must be in order to be usable, as well as how difficult it will be to store your die cutting machine properly without risking damage.

- Cost Requirements

- Consider your die cutting requirements and long term budget, and remember that a die cutter purchase is an investment. Work with a reputable supplier, compare prices and do proper research before purchasing a die cutting machine.

Die Cutting Terms

- Air Holes

- Holes in die cutters that aid in the prevention of deformations in die cut materials by allowing the release of air from the die cavities.

- Anvil

- The surface upon which the materials to be die cut rest.

- Automated Feed Systems

- Components of certain die cutting machines that provide the continuous, automatic supply of material to the die cut machine.

- Capacity

- The widest part that can be cut on the equipment.

- Chisel Punches

- Blades located either on the die or another part of the press that produce a separation in die cut materials.

- Composite

- A material obtained by layering and bonding with resin sheets of woven material to obtain specific characteristics and properties. The materials are not completely blended and so remain physically identifiable.

- Deflection

- Unwanted deviation from parallelism in the top die plate.

- Die Blade

- A steel blade attached to the die that performs the cutting procedure by penetrating through the die cut substance.

- Dieboard

- Steel rule die component, often consisting of plywood, in which the die blades are inserted.

- Kevlar

- DuPont’s trade name for aramid fibers that are strong, tough and stiff, have a high melting point and are used in composite construction. Kevlar is lighter, stiffer and more costly than glass fiber.

- Kiss Cut

- A die cut that penetrates the upper layer(s) of the die cut material instead of penetrating through the material.

- Knifing

- The process of fitting the steel die blades into the die board of a steel rule die.

- Nicks

- Indentations in a die rule that stop the cutting.

- Plastic Die Cutting

- The process of pushing a flat plastic sheet against a die-formed cutting edge, resulting in a plastic piece that resembles the shape of the die with which it was cut.

- Punch

- The die component that actually forms, or punches, a shape from the die cutting material.

- Through Cutting

- Die cutting in which the die cut material is penetrated all the way.

- Ultrasonic

- A frequency usually higher than 20 kHz, which is too high to be heard by the human ear.

- Web

- Continuous roll form.