Sewing Contractors

Sewing contractors specialize in manufacturing and providing services across diverse industries and applications. Utilizing both simple and advanced machinery, they deliver precision embroidery and large-scale production with exceptional quality. Businesses rely on industrial sewers to produce a wide range of textile products found in homes and workplaces alike. From custom covers and fabric enclosures to uniforms and carrying cases, these contractors play a crucial role in textile manufacturing.

Sewing Contractors FAQ

What do sewing contractors produce?

Sewing contractors manufacture textile products such as uniforms, custom bags, protective covers, tarps, tents, embroidery, and industrial fabrications. They serve industries including fashion, automotive, medical, hospitality, and defense.

Why do manufacturers use contract sewing services?

Manufacturers turn to sewing contractors to scale production, ensure consistent quality, and access specialized expertise in fabrics, stitching, and finishing. This allows businesses to focus on design and innovation while meeting market demand efficiently.

What industries rely on sewing contractors?

Sewing contractors support a wide range of industries, including healthcare, automotive, aviation, hospitality, fashion, restaurants, construction, and military sectors. They produce items like uniforms, seating upholstery, protective covers, linens, and luggage.

What are the benefits of contract sewing for businesses?

Contract sewing offers scalability, professional craftsmanship, and reduced production costs. It ensures high-quality results while freeing businesses from labor-intensive tasks like cutting, grading, sewing, embroidery, and packaging.

What types of sewing machines are used in industrial sewing?

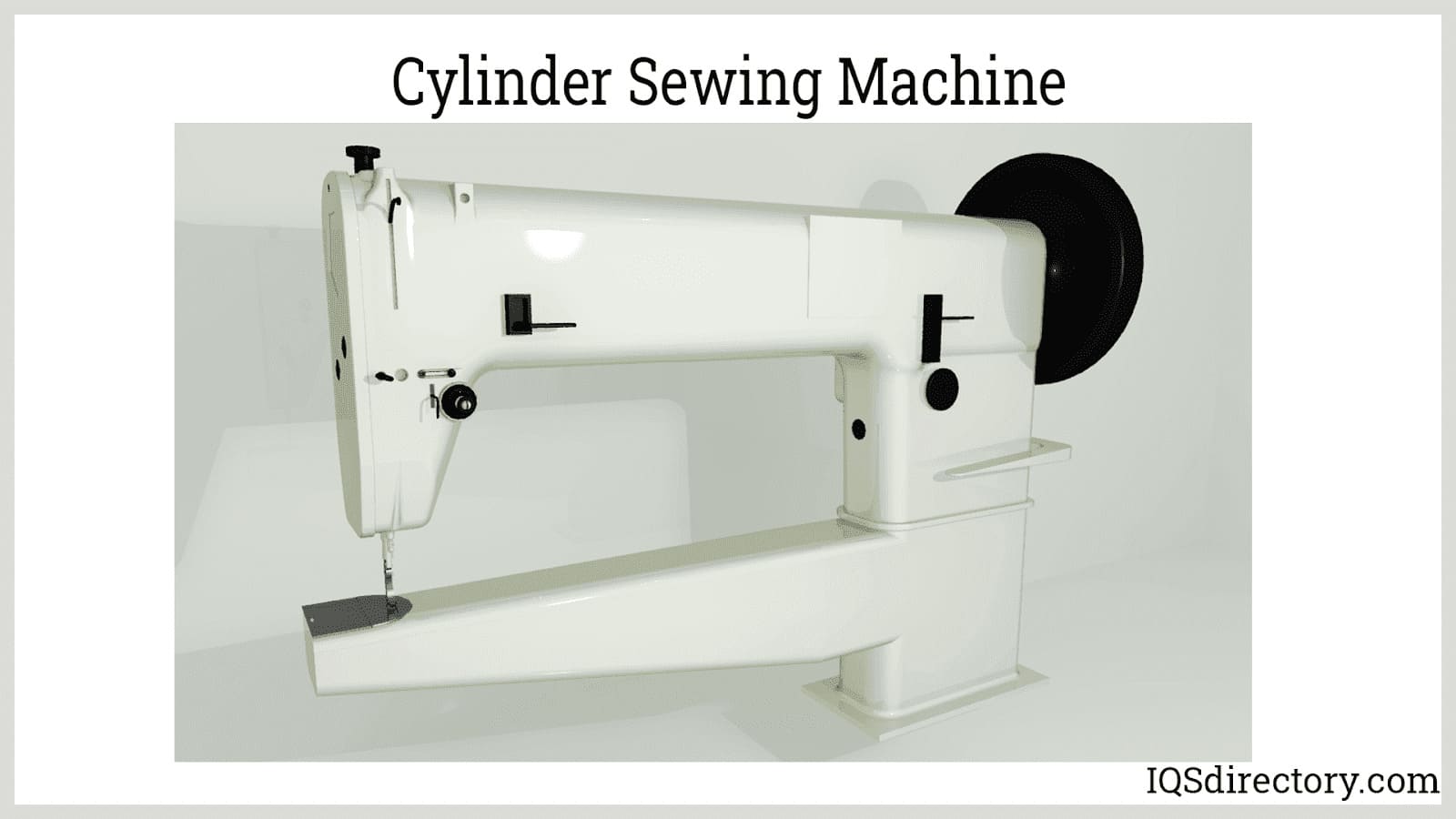

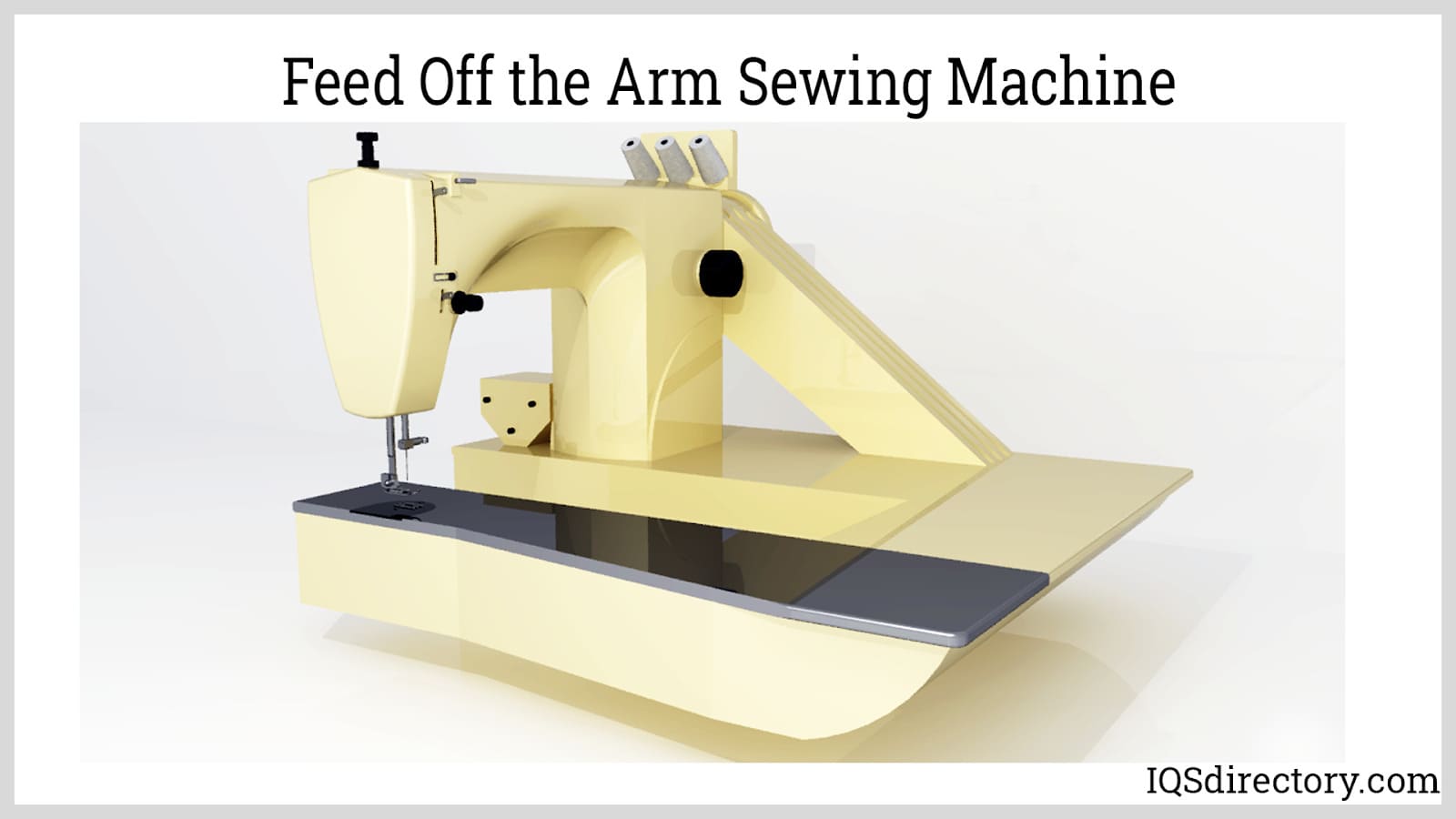

Industrial sewing uses single-needle, double-needle, multi-needle, cylinder bed, post bed, and feed-off-the-arm machines. These machines handle heavy materials, intricate designs, and high-speed production with precision and durability.

What materials are commonly used in contract sewing?

Contract sewing uses fabrics such as canvas, nylon, neoprene, vinyl-coated nylon, leather, polyester, felt, and anti-static materials. Synthetic fabrics like polyester and nylon are often chosen for durability, resistance, and cost efficiency.

How do sewing contractors contribute to product development?

Sewing contractors assist in design refinement, prototyping, custom fitting, embroidery, and label production. They provide multiple mock-ups, quality control, and expertise that help bring concepts to market-ready products quickly and effectively.

History of Industrialized Sewing

Sewing is an ancient craft that predates the invention of the needle and thread, beginning with bone and sinew thousands of years ago. Over time, this essential skill has undergone dramatic transformations, with industrialization standing as the most significant shift in its history.

Like many forms of manufacturing, sewing changed profoundly with the Industrial Revolution. In 1790, London cabinet maker Thomas Saint patented the first sewing machine, though it would take decades before machines could match the skill of a tailor. By 1841, French inventor Barthélemy Thimonnier developed a basic machine to mass-produce military uniforms, only to have angry tailors destroy his workshop in fear of losing their livelihoods. It wasn’t until the 1850s that Isaac Singer introduced a machine capable of stitching as efficiently as hand-sewn work, accelerating the rise of ready-made clothing. While many garments were still sewn at home, machine-made clothing gained popularity among the middle and upper-middle classes, elevating hand-sewn pieces to a mark of craftsmanship.

Beyond revolutionizing textile production, the sewing machine also shaped global fashion. As machine-sewn clothing spread worldwide, Western fashion followed, influencing traditional dress in many indigenous cultures. For some, adopting Western attire became a symbol of modernization or religious conversion.

Today, nearly all textiles are produced by machines, with hand-sewn craftsmanship reserved for luxury or specialty markets. The demand for garments and fabric products has made mass production essential, with designers relying on sewing contractors to deliver high volumes of high-quality products efficiently.

Benefits of Sewing Contractors

From apparel and bedding to outdoor gear and industrial textiles, manufacturers turn to sewing contractors for production. These specialists transform raw materials into expertly crafted products, allowing designers and businesses to focus on innovation and strategy rather than manufacturing logistics.

Contract sewers make design accessible to anyone with an idea. While not all designers have the technical skill to construct their own pieces, experienced contractors provide expertise in fabrics, stitching techniques, and grading—the process of scaling patterns to maintain size consistency. Beyond cutting and sewing, many contractors also handle packaging and even the production of synthetic fabrics, ensuring a seamless transition from concept to market-ready product.

The Rise of Synthetic Fabrics

The technological advancements that enabled mass textile production also drove the creation of new materials. With natural fibers sourced from plants and animals unable to meet industrial demand, scientists developed synthetic fabrics that offered enhanced functionality and performance.

Derived from petroleum-based materials, coal, limestone, and plant-based cellulose, synthetic fibers are formed by heating and extruding them through spinnerets into air or water, where they cool into thread. Popular synthetic fabrics like polyester, nylon, rayon, and dracon emerged for their durability and adaptability.

Unlike natural fibers, synthetics can be engineered for specific properties such as heat resistance, flame retardancy, waterproofing, elasticity, and superior strength. They can also mimic luxury materials like silk, leather, and cashmere, offering cost-effective alternatives without sacrificing quality or style.

Industrialized sewing, powered by both machinery and material innovation, continues to shape global fashion and manufacturing, bridging the gap between artistry and efficiency in ways early tailors could have never imagined.

Sewing Contractors Images, Diagrams and Visual Concepts

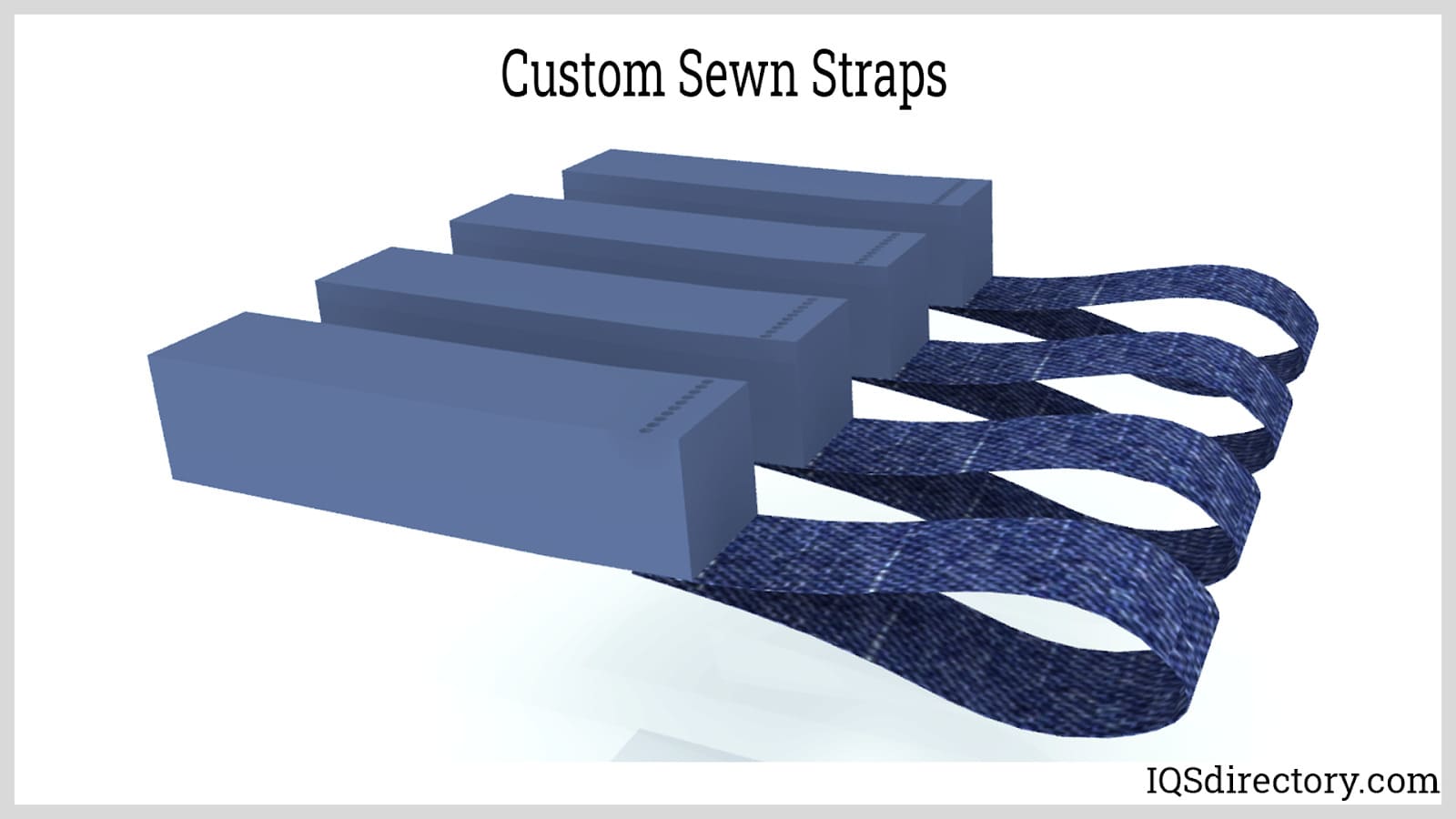

Contract sewing, a specialized industry which provides services to manufacturers for production of a wide range of products.

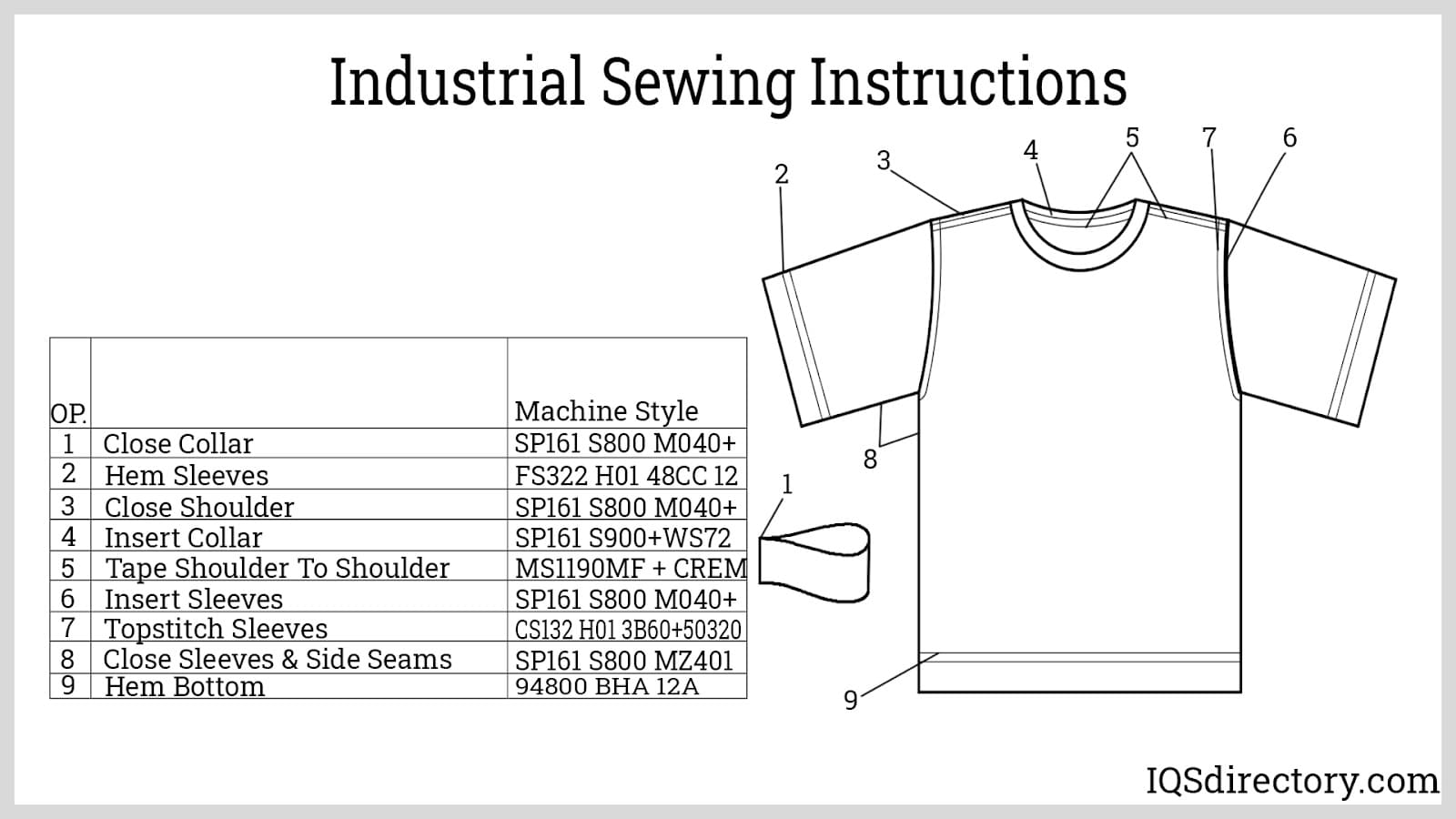

Designing and prototyping allows to catch errors before production.

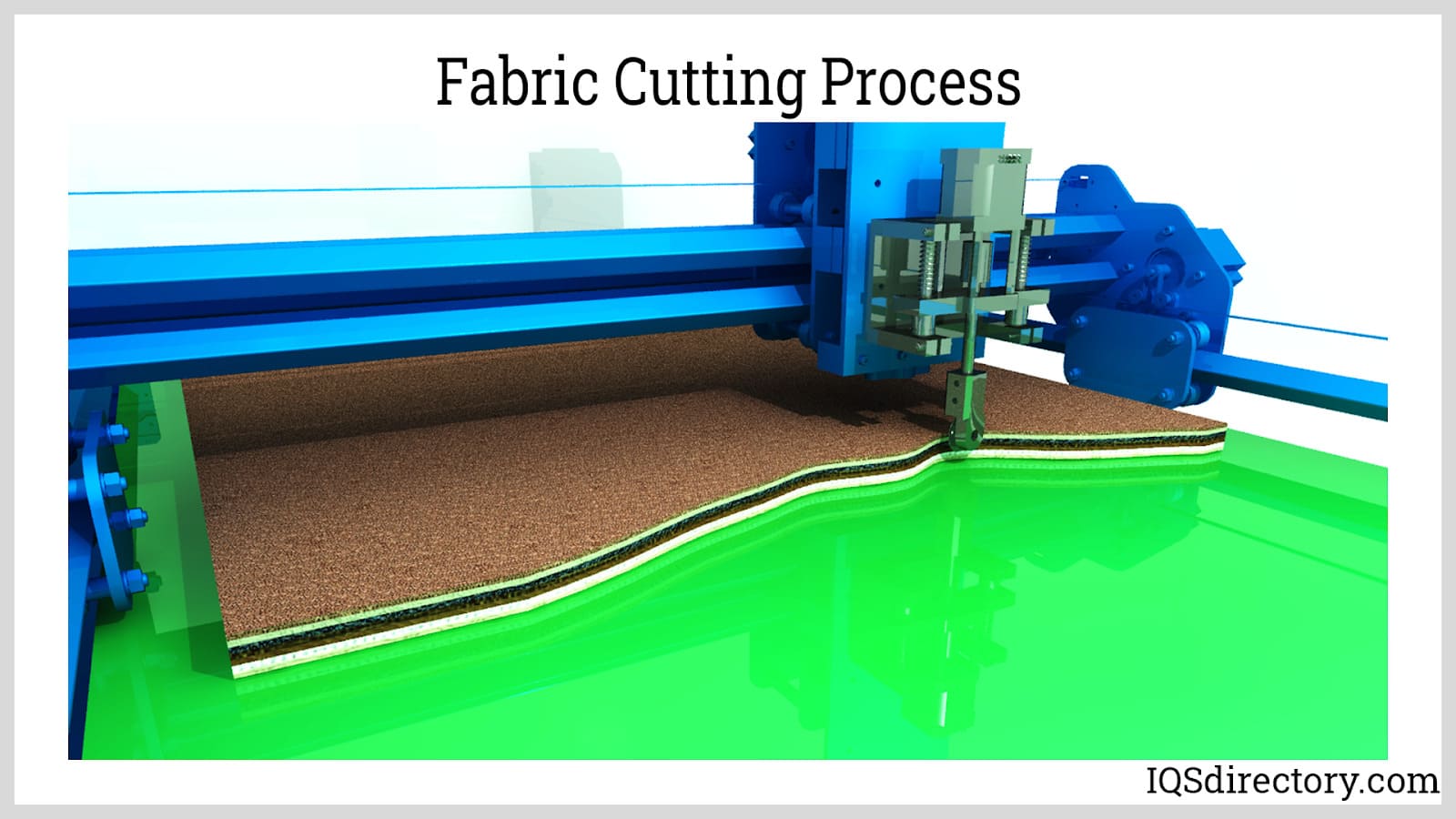

The cutting process involves having the pattern lain out on the material then using cutting tools to cut through the several layers of fabric.

Contract sewing allows for the production of large quantities of sewn products in short amounts of time, regardless of the size.

Fabric canopies are examples of products produced be contract sewing.

Cylinder sewing machines is use for making parts of materials sewn in a circular fashion.

Post sewing machines use three dimensional sewing and allows for more space for creating specialty items.

Feed off the arm machines are multi-functional that uses two or three needles allowing sewing to be completed by four threads.

Types of Sewing Contractors

Canvas Bags

Durable and versatile, these sturdy bags are perfect for carrying groceries, books, art supplies, or promotional materials.

Commercial Sewing

Mass production of fabric-based products using heavy-duty sewing equipment to ensure efficiency and consistency in manufacturing.

Contract Sewing

Specialized businesses providing a broad range of custom sewing solutions tailored to various industry needs.

Custom Bags

Designed to meet unique customer specifications, these bags are crafted for specialized applications rather than mass production.

Carrying Cases

Custom-built containers designed to accommodate specific consumer requirements, ensuring protection and functionality.

Custom Embroidery

Personalized decorative stitching applied by hand or embroidery machines, enhancing fabrics with unique designs and branding.

Custom Sewing

Production of sewn goods tailored to unique consumer demands, incorporating specialized designs and specifications.

Custom Tents

Temporary shelters crafted to meet individual specifications, providing customized solutions for outdoor and industrial applications.

Industrial Sewing

Expert stitching of heavy-duty materials, ensuring durability and strength for demanding applications.

Instrument Cases

Precision-crafted covers designed to protect delicate and sensitive equipment from damage.

Medical Sewing

Production of sewn products specifically designed for healthcare environments, meeting strict industry standards.

Nylon Bags

Constructed from strong, elastic synthetic materials, these bags offer resilience and long-lasting durability.

Pouches

Compact fabric containers designed for carrying and organizing various items securely.

Protective Covers

Fabricated to shield objects from environmental elements and impact, preserving their condition and longevity.

Soft Cases

Flexible and padded protective covers that safeguard items from impact, weather, and wear.

Soft Luggage

Lightweight yet durable travel bags, designed with high-denier fabric for enhanced strength and longevity.

Tarps

Sewn from materials like nylon, vinyl, or canvas, these versatile covers are used for machinery protection, waste hauling, and industrial applications.

Applications of Sewing Contractors

Sewing contractors transform designs into finished products, playing a vital role in manufacturing across industries. Many of the world’s most recognized brands depend on contract sewing services to produce their products or the protective packaging that ensures safe delivery. Beyond fabrication, sewing contractors often contribute to product development and maintain stringent quality control to meet the highest industry standards. By outsourcing production to skilled professionals, businesses can focus on innovation and market growth while ensuring their products meet expectations.

One of the key advantages of working with a sewing contractor is the ability to scale production in response to consumer demand. As customer needs evolve, in-house production may struggle to keep pace. Contract sewers provide the flexibility to expand capacity, preventing supply shortages that could drive customers elsewhere. Additionally, producing sewn goods in-house can be labor-intensive and time-consuming, diverting attention from other critical business operations.

Sewing contractors handle projects of all sizes, from sewing labels onto uniforms and producing custom embroidery to full-scale manufacturing of apparel, accessories, and industrial fabrications. By managing the production process, they allow businesses to focus on expanding their customer base, refining product designs, and strengthening brand presence.

Their services extend across a wide range of industries, supplying products to hospitals, the military, fashion houses, automotive manufacturers, restaurants, and packaging companies. They manufacture high-visibility gear for outdoor workers, canvas mailbags for postal services, linens for hotels and healthcare facilities, interior components for automobiles, industrial tarps, uniforms, and soft luggage. Many top fashion brands rely on sewing contractors to bring their designs to life. The reach of contract sewing is vast, with nearly every industry benefiting from its expertise.

Contract sewing services include prototype development, custom fitting, embroidery, and label production. Sewing contractors create fabric-based products such as custom bags, soft luggage, and protective covers. These include durable canvas pouches for tools and equipment, transit bags for banks and retail stores, and weather-resistant covers for machinery and vehicles. The aviation industry also relies on contract sewing for seating upholstery, carpets, blankets, and ground service covers. Restaurants utilize sewn products for umbrellas, slipcovers, window treatments, and booth cushions, while the military, hospitality, and healthcare industries require custom-fitted fabric solutions for their operations.

The equipment used in contract sewing ranges from traditional single-needle machines to advanced computer-programmable systems. Additional tools such as riveters, zipper fabricators, snap setters, and heat sealers ensure precision and efficiency in production.

Custom bags remain a staple of contract sewing, designed to meet specific size, durability, and material requirements. Canvas pouches, often used for tools, cables, cameras, and manuals, offer a soft yet durable carrying solution. These pouches come in a variety of materials, including nylon, neoprene, leather, felt, and polyester, ensuring suitability for different applications. Soft luggage, another key product, is crafted from durable fabrics such as canvas, leather, or plastic. These bags, including backpacks, briefcases, and sports bags, provide a lightweight alternative to hard-shell luggage while offering secure closures with buttons, clasps, or zippers.

Protective covers, built for durability and weather resistance, shield equipment, furniture, and vehicles from harsh elements. Made from nylon or canvas coated with waterproofing agents, these covers can be custom-fitted for grills, machinery, outdoor furniture, and dumpsters. Larger, unfitted covers, such as tarps, provide protection for swimming pools, vehicles, and industrial equipment during transport or storage. Their versatility makes them essential for applications ranging from construction sites to camping trips.

Sewing contractors serve as essential partners in product manufacturing, offering scalable production, expert craftsmanship, and high-quality sewn goods that support businesses across industries. Their ability to meet diverse demands with precision and efficiency makes them a vital component of the modern supply chain.

Textile Production Process

Every textile product begins as an idea and transforms through a meticulous process into a market-ready commodity. Meeting the demands of consumers requires precision, expertise, and efficiency—qualities that define contract sewing specialists. The right partner in production not only meets demand but enhances the final product, ensuring durability, functionality, and aesthetic appeal.

The journey starts with careful planning. A pattern designer translates an initial concept into a precise blueprint, breaking it down into sections with scaled dimensions to accommodate different sizes. During this stage, opportunities for improvement emerge, allowing refinements that enhance performance, appearance, and manufacturability.

Once the pattern is established, attention shifts to material selection. The choice of fabric is critical, influencing durability, comfort, and overall quality. A prototype is then created, offering clients the chance to review, refine, and customize their product before full-scale production begins. From adjustments in stitching to enhancements in embroidery, every detail is fine-tuned at this stage.

Sewing contractors often produce multiple mock-ups, giving clients options to evaluate before the final selection. Once approved, the production phase moves swiftly, with the first finished batch typically ready within weeks.

Materials in Contract Sewing

Sewing contractors work with a wide range of fabrics, each selected based on the intended application. Vinyl-coated nylon offers durability and weather resistance, making it ideal for bags, protective covers, and presentation cases . Neoprene and Hypalon, valued for their chemical and abrasion resistance, serve industrial needs. Canvas, a breathable and versatile fabric, finds use in bags, curtains, and various industrial applications. The technology industry often requires anti-static materials for computer and electronic components, while suede, leather, felt, webbing, plastic, cotton, and polyester serve diverse commercial and industrial purposes.

Customization plays a significant role in textile production, with embroidery providing a decorative yet professional touch. Whether adding logos to uniforms or branding products with custom stitching, embroidered details elevate the visual appeal and marketability of textile goods. Additionally, clothing labels—woven, embroidered, or printed—convey essential information such as material composition, care instructions, and brand identity.

Advanced Sewing Machinery

Industrial sewing relies on a variety of machines, each designed for a specific purpose. These range from light-duty to heavy-duty models and may include single-needle, double-needle, or multi-needle machines, each contributing to different stitching techniques.

Lock stitching, known for its superior durability, is commonly used for textiles requiring strength, such as military-grade bags and protective fabrics. Double-needle machines create chain stitching, offering efficiency but slightly less resilience than lock stitching. Multiple-needle machines handle intricate patterns, often found in quilted designs and decorative applications.

Industrial sewing machines operate at significantly higher speeds than consumer models, handling thicker materials and multiple layers with ease. Many are equipped with self-lubricating systems and robust motors built for continuous operation. Some machines, particularly those used in large-scale manufacturing, are computerized, automating both cutting and stitching processes. These high-tech systems enhance precision, allowing for complex patterns and detailed embroidery, all while streamlining production.

Finding the Right Company to Contract

Selecting the right contract sewing company requires careful consideration. Not all sewing specialists are suited for every type of product. A manufacturer specializing in tactical gear, such as military rucksacks and camping equipment, will not be the best choice for high-fashion apparel or luxury bedding. Likewise, a company producing pre-cut fabrics for hobbyists would not be the ideal partner for manufacturing industrial-grade parachutes.

Beyond technical expertise, the best sewing contractors operate as true partners, offering insights, refining designs, and ensuring product success. Their role extends beyond production—they provide invaluable support that allows clients to focus on expanding their businesses.

The impact of contract sewing on the textile industry is immeasurable. From household essentials to high-performance industrial textiles, these manufacturers make quality, affordability, and accessibility possible, shaping the products that fill homes, businesses, and industries worldwide

Sewing Contractors Terms

Air Porosity

The measure of how easily air passes through a material. This characteristic influences the air resistance of parachute fabrics, the efficiency of filtration media, and the wind resistance of sailcloth.

Autoclave

A specialized chamber that applies heat and pressure, often in a steam environment, to perform finishing processes such as pleating and heat setting.

Bicomponent Yarns

Filament threads composed of two distinct fibers or variations of the same fiber type, offering unique performance properties.

Broad Goods

Woven fabrics that exceed 18 inches in width.

Broadcloth

A tightly woven fabric manufactured in widths greater than 29 inches.

Calender

A machine equipped with multiple heavy rollers—sometimes heated—that applies pressure to fabric, enhancing surface texture and finish.

Cloth

A general term encompassing all materials made from textile fibers, wire, or felt.

Coated Fabric

Fabric treated with an adherent layer of lacquer, varnish, resin, plastic, or rubber to enhance properties such as water resistance.

Denier

A thread measurement system primarily used for continuous filament threads. A higher denier indicates a stronger, thicker thread, while a lower denier results in a finer thread.

Embroidery

A decorative stitching technique used to embellish fabric with intricate designs.

Greige Goods

Unfinished and un-dyed woven or knitted fabrics, serving as the raw material for further processing.

Hem

The folded and sewn edge of fabric, designed to create a clean finish and prevent fraying.

Nap

The textured, raised surface of fabric that often follows a particular direction, commonly found in materials like velvet and suede.

Non-Woven Fabric

A fabric produced without weaving or knitting, often used in faux leather, suede, and felt applications.

Sailcloth

A durable, heavy-duty woven canvas designed for constructing boat sails.

Seam Allowance

The margin of fabric between the stitching line and the fabric’s edge, typically ranging from ¼ inch to ⅝ inch.

Textile

A term referring to fabrics or cloths created through knitting or weaving, as well as the raw materials like yarn and fiber used in their production.

Upholstery

The combination of fabric, cushioning, springs, and stuffing used in furniture design and construction.

Weaving

The process of interlacing yarns at right angles to form a structured, woven fabric.

More Sewing Contractors Information