Wire Baskets

Wire baskets are made from a series of wires that are woven together or welded to form a shape of a basket. They can also be defined as containers that are made by use of an openwork pattern of metal...

Please fill out the following form to submit a Request for Quote to any of the following companies listed on

Here is the most complete guide on the internet to wire forming.

Wire forming refers to the process of reshaping wire by applying force through various techniques such as bending, swaging, piercing, chamfering, and shearing. Using these methods enables the creation of diverse shapes, configurations, and forms. The procedure commences with coiled wire, which is first straightened and then formed into the desired shape.

Commonly utilized metals in wire forming include steel, brass, stainless steel, copper, aluminum, along with assorted alloys. Wire diameters typically vary from 0.5 mm to 6.5 mm (1/64 inch to 0.25 inch) and can be molded into both two-dimensional and three-dimensional structures.

Wire forming equipment can range from basic handcraft tools to sophisticated CNC programmable machinery. Furthermore, the process includes options for finishing techniques like coating to protect and enhance the endurance of the final products against challenging environmental conditions.

Wire forming is an essential process in the metal fabrication and manufacturing industry, used to produce custom wire components, wire parts, and metal forms for a wide range of applications. There are various types of equipment used for wire forming, generally falling into manual or automatic categories. Manual machines include those operated by hand as well as semi-automatic models that, while electronic, require manual wire loading and adjustment.

In modern industrial settings, automatic wire forming machines—often featuring advanced computer numerically controlled (CNC wire forming) programming— handle the entire production process without the need for direct human intervention, greatly increasing efficiency and precision. These automated systems are in high demand in high-volume production environments for creating precision wire forms, springs, fasteners, and intricate wire products.

Before wire forming can begin, the raw metal wire is processed using a wire drawing method to achieve the desired wire diameter, cross-section, and material properties for the final product. This critical wire drawing operation involves pulling the wire through a series of dies, which are typically funnel-shaped and crafted from hardened steel or carbide.

As the wire passes through the die or multiple dies (known as multiple pass drawing), the pressure exerted by the die sides incrementally reduces the wire's diameter, while simultaneously increasing its tensile strength, hardness, material uniformity, and length. This tightly controlled process results in high-quality drawn wire suitable for subsequent forming, bending, coiling, or stamping operations.

Wire forming employs multiple specialized metal shaping processes, each designed to produce specific shapes and configurations. These methods are optimized for high-precision wirework in industries such as electronics, automotive, medical devices, and custom metal fabrication.

Manual wire forming uses hand-operated bending machines equipped with spindles, draw dies, or rotary dies. These machines are commonly used for prototyping or small production runs.

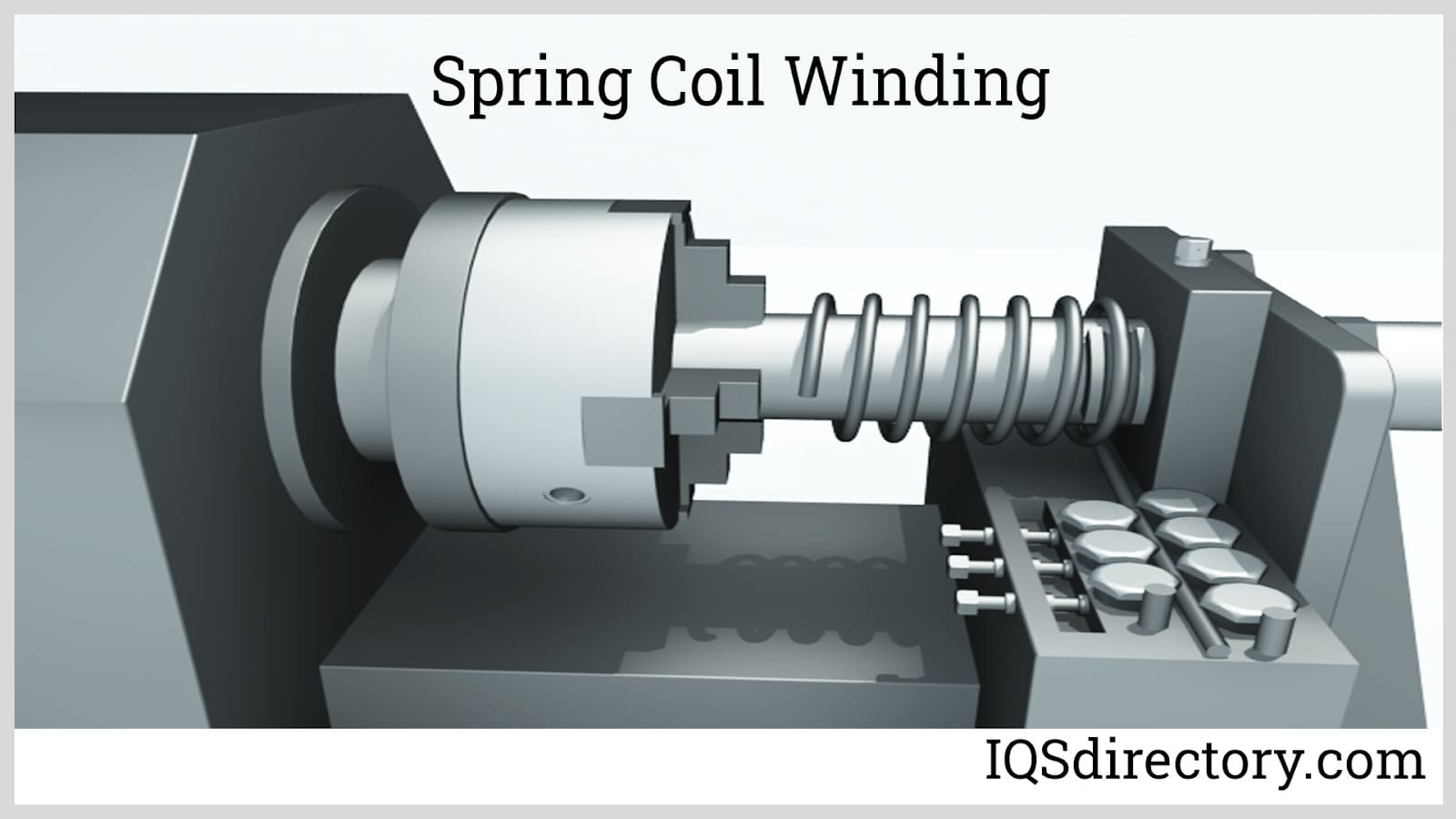

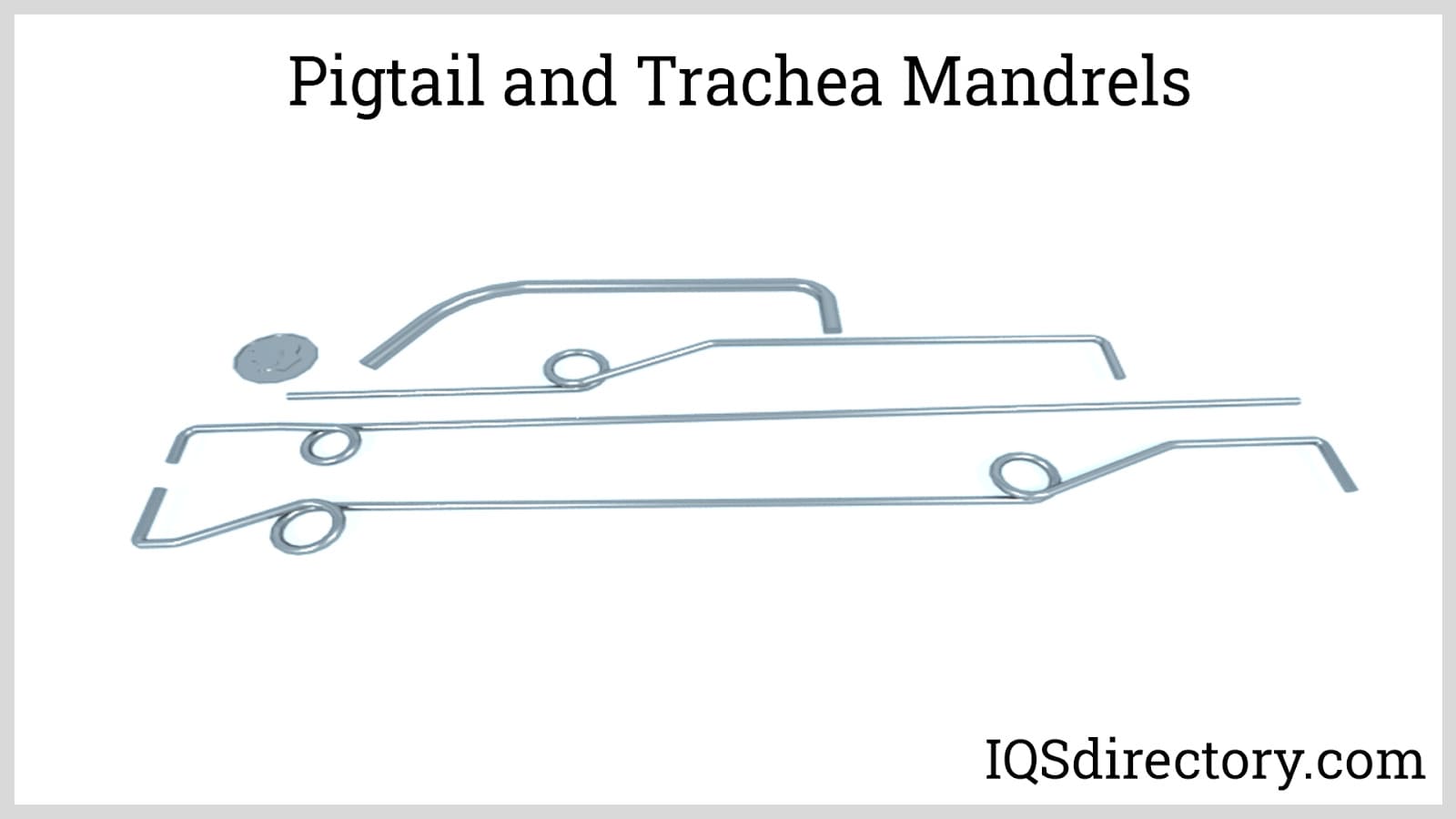

Coil or spring wire forming involves winding wire around a mandrel or core to produce springs and electrical coils. Precision is critical to achieve consistent load and electrical properties.

Roll forming uses a series of aligned rollers to shape wire into specific profiles, such as grooves, threads, and collars. This process enhances strength and produces smooth, finished surfaces.

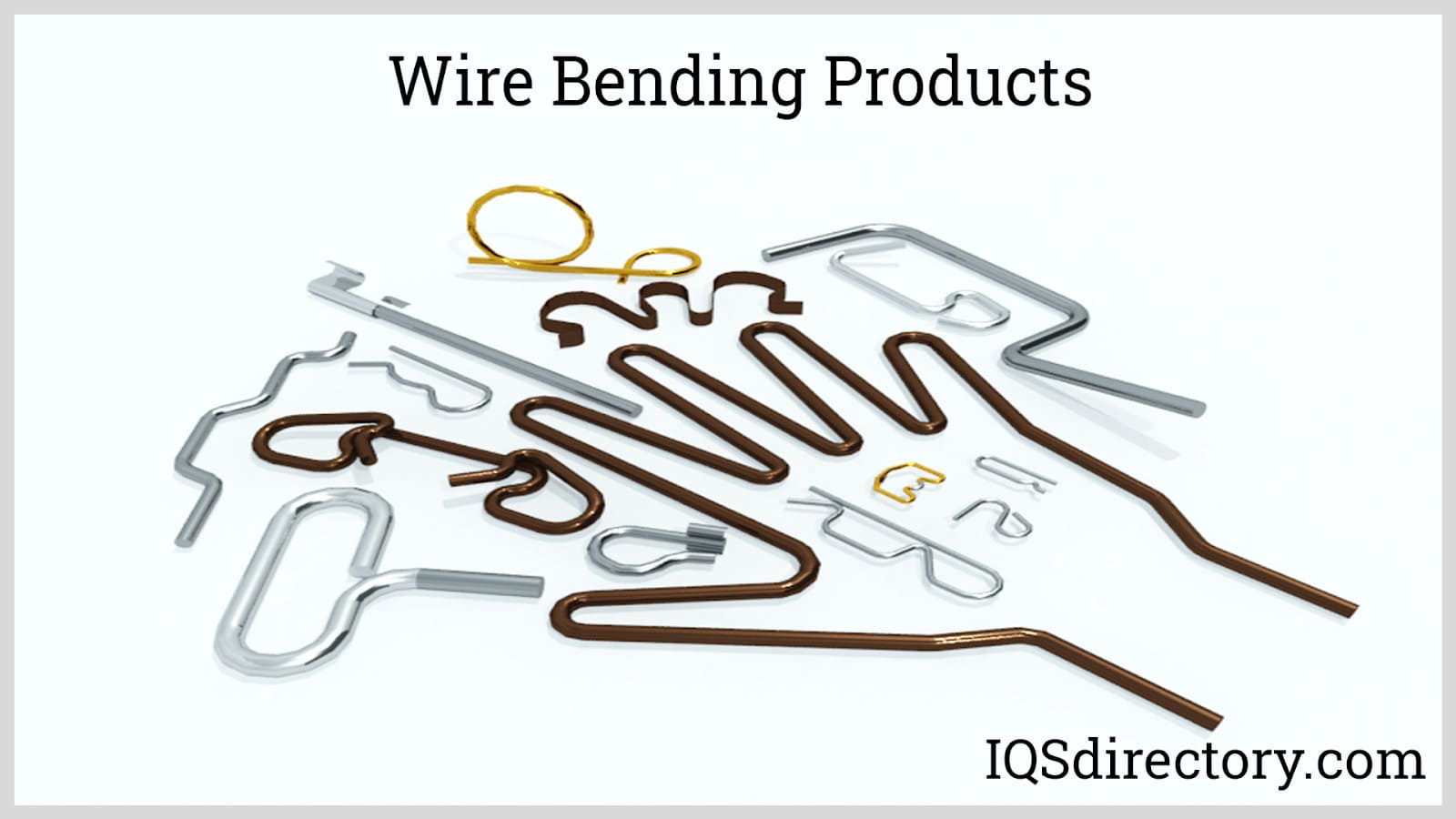

In the wire bending process, wire is shaped into 2D or 3D forms with minimal scrap. Advanced CNC wire benders provide high accuracy and repeatability for complex assemblies.

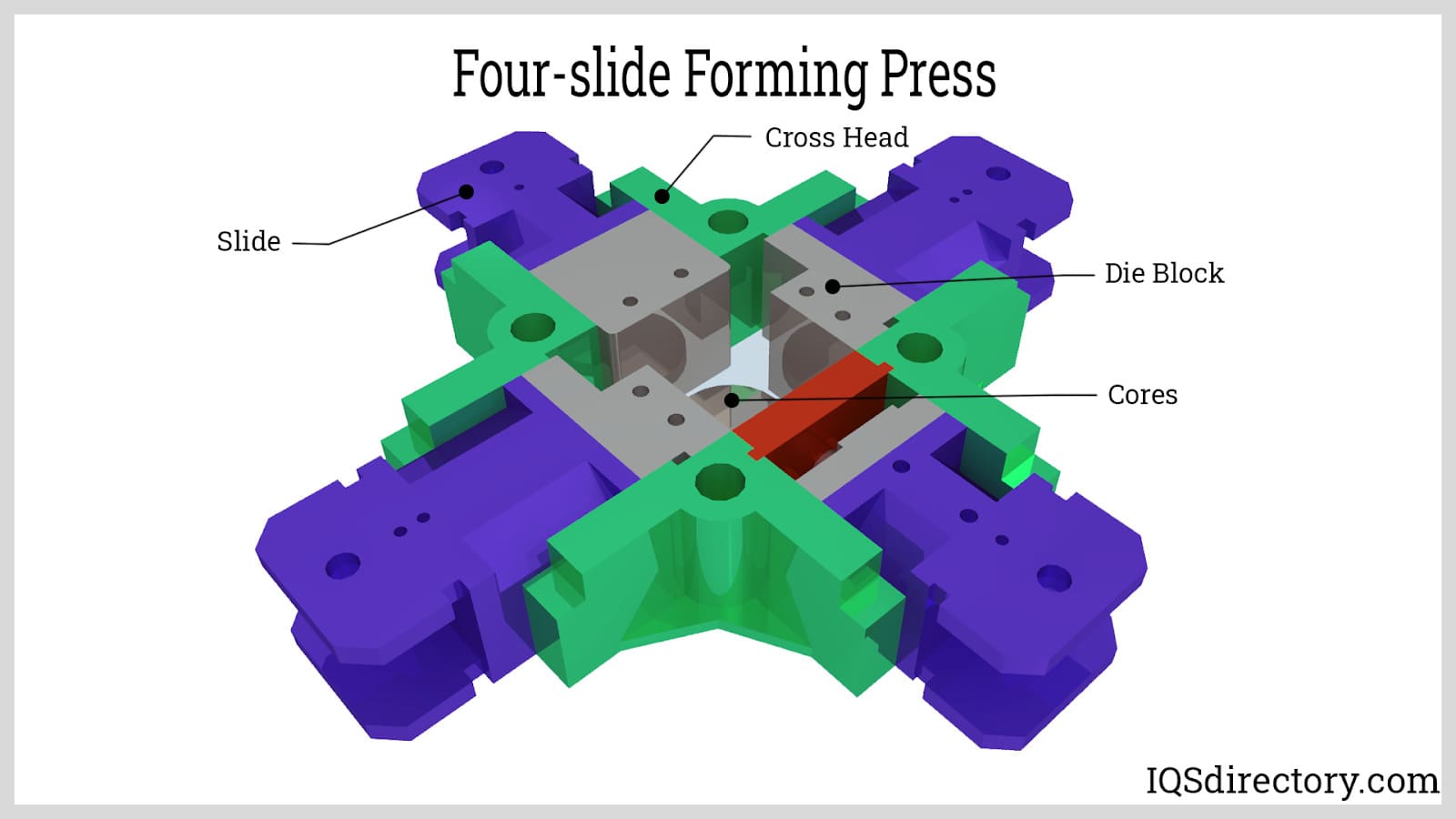

Fourslide forming uses a horizontal press with four synchronized sliding tools to create complex multi-plane wire shapes efficiently and with minimal waste.

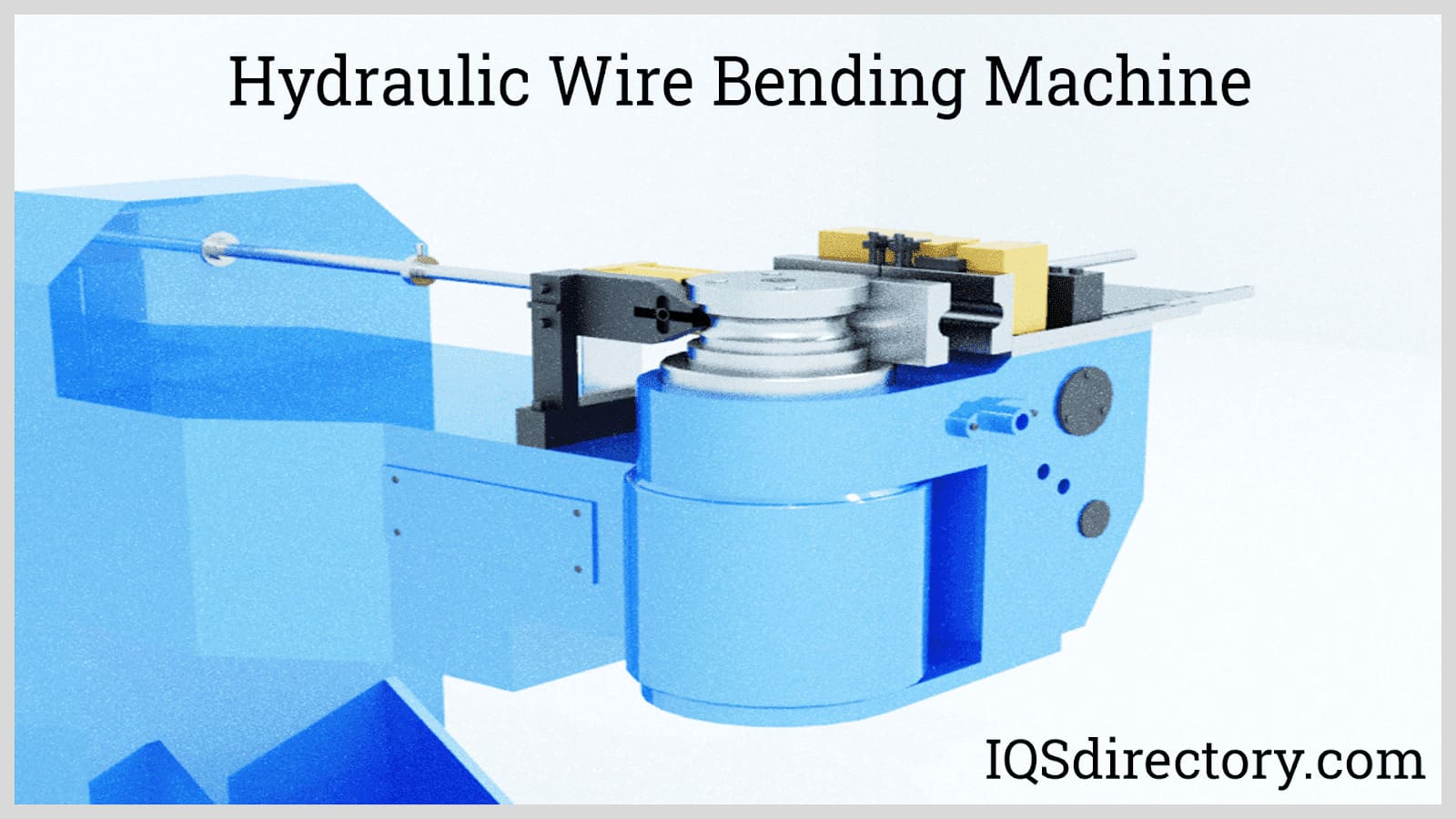

Hydraulic wire forming machines use high-torque motors and CNC controls to form heavy-gauge wire for demanding industrial applications.

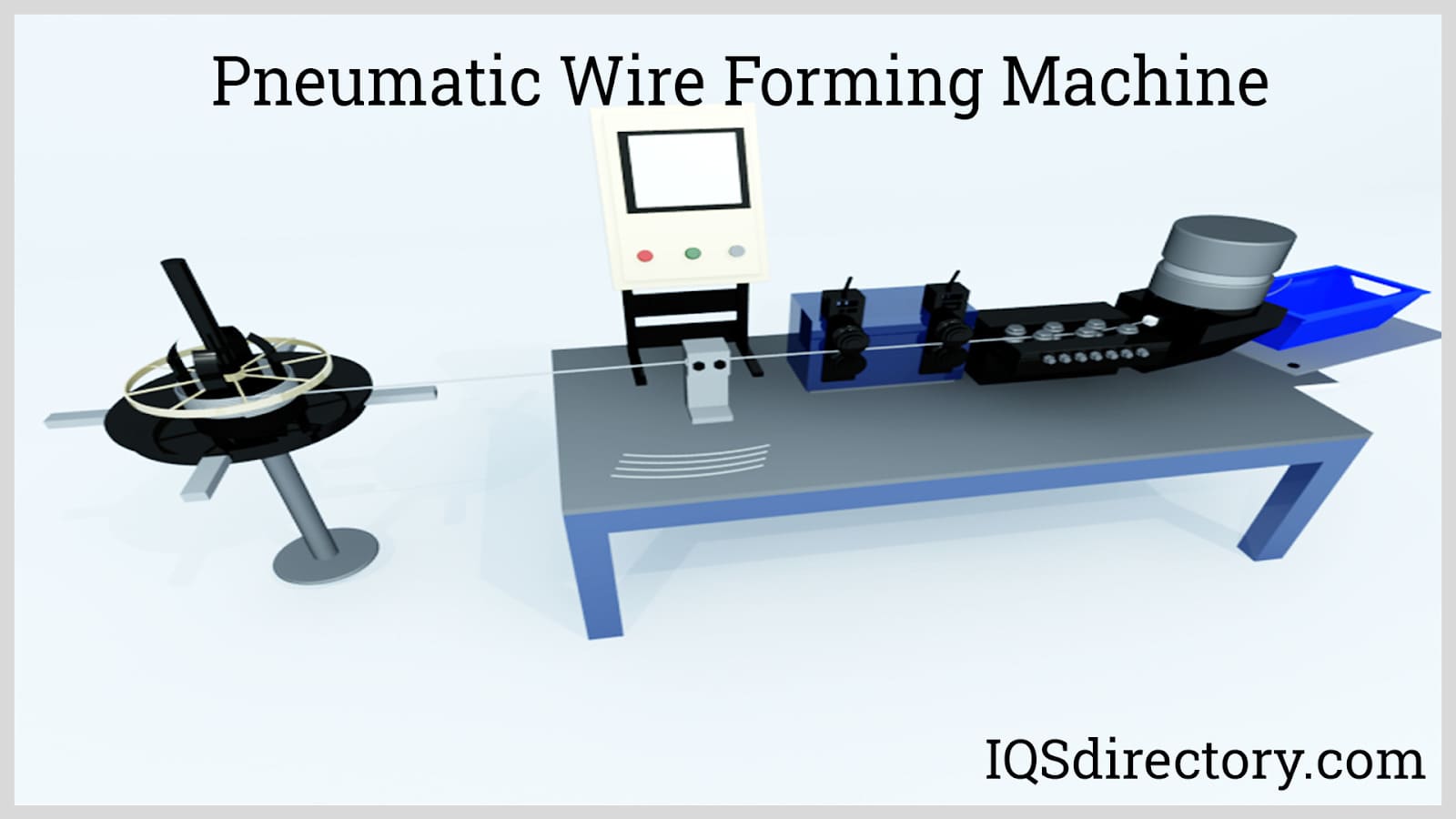

Pneumatic wire forming uses compressed air to feed, form, and cut wire rapidly, making it ideal for repetitive, high-speed production.

CNC wire bending machines provide exceptional precision and flexibility for custom wire forms, prototypes, and low-to-medium volume production runs.

Finishing wire ends and forming internal geometries are critical steps that affect fit, safety, and performance in custom wire components.

Wire ends can be straight-cut, angle-cut, or quill-cut depending on the application.

Chamfered ends remove sharp edges and improve safety and ease of assembly.

Winging, also known as swaging, forms a wing-like shape on the wire end for improved retention.

Pierced swaging expands the wire end and punches a centered hole for electrical or mechanical connections.

Custom-shaped holes are created using specialized punches for unique mounting requirements.

Chisel points are formed by diagonal cutting and are commonly used in pins, stakes, and probes.

Ball ends are formed using lathes or turning machines for decorative or functional purposes.

Grooves are machined or pressed into wire ends to assist with locking and assembly.

Cold heading forges wire ends into strong, uniform heads used in fasteners and rivets.

Wire forming tolerances are typically ±0.01 per bend or ±0.06 on an assembly. Tighter tolerances require advanced CNC equipment, specialized tooling, and additional quality control.

| Wire Diameter Tolerances | ||||||

|---|---|---|---|---|---|---|

| (mm) | (inch) | |||||

| Wire Diameter | Up To But Excluding | Tolerance | Wire Diameter | Up To But Excluding | Tolerance | |

| 0.0254 | 0.203 | ±0.0051 | .001 | .008 | ±.0002 | |

| 0.203 | 0.376 | ±0.0076 | .008 | .015 | ±.0003 | |

| 0.376 | 0.813 | ±0.0100 | .015 | .032 | ±.0004 | |

| 0.813 | 1.220 | ±0.0127 | .032 | .048 | ±.005 | |

| 1.220 | 2.030 | ±0.0152 | .048 | .080 | ±.0006 | |

| 2.030 | 3.250 | ±0.0254 | .128 | .176 | ±.0010 | |

| 4.470 | 5.890 | ±0.0381 | .176 | .232 | ±.0015 | |

| 5.890 | 8.000 | ±0.0510 | .232 | .315 | ±.0020 | |

| 8.000 | 10.00 | ±0.0635 | .315 | .395 | ±.0025 | |

| 10.00 | 21.00 | ±0.0762 | .395 | .827 | ±.0030 | |

When seeking a wire forming partner or sourcing custom wire forms, buyers should also consider factors such as material selection (e.g., stainless steel, carbon steel, copper, titanium), surface finishing, secondary processing (such as threading, welding, or assembly), production capabilities (including short-run vs. high-volume), in-house engineering support, quality certifications (e.g., ISO 9001), and lead time. Leading wire forming companies invest in advanced automation, state-of-the-art tooling, and stringent quality control measures to meet the diverse needs of industries like aerospace, medical, electronics, and industrial equipment manufacturing.

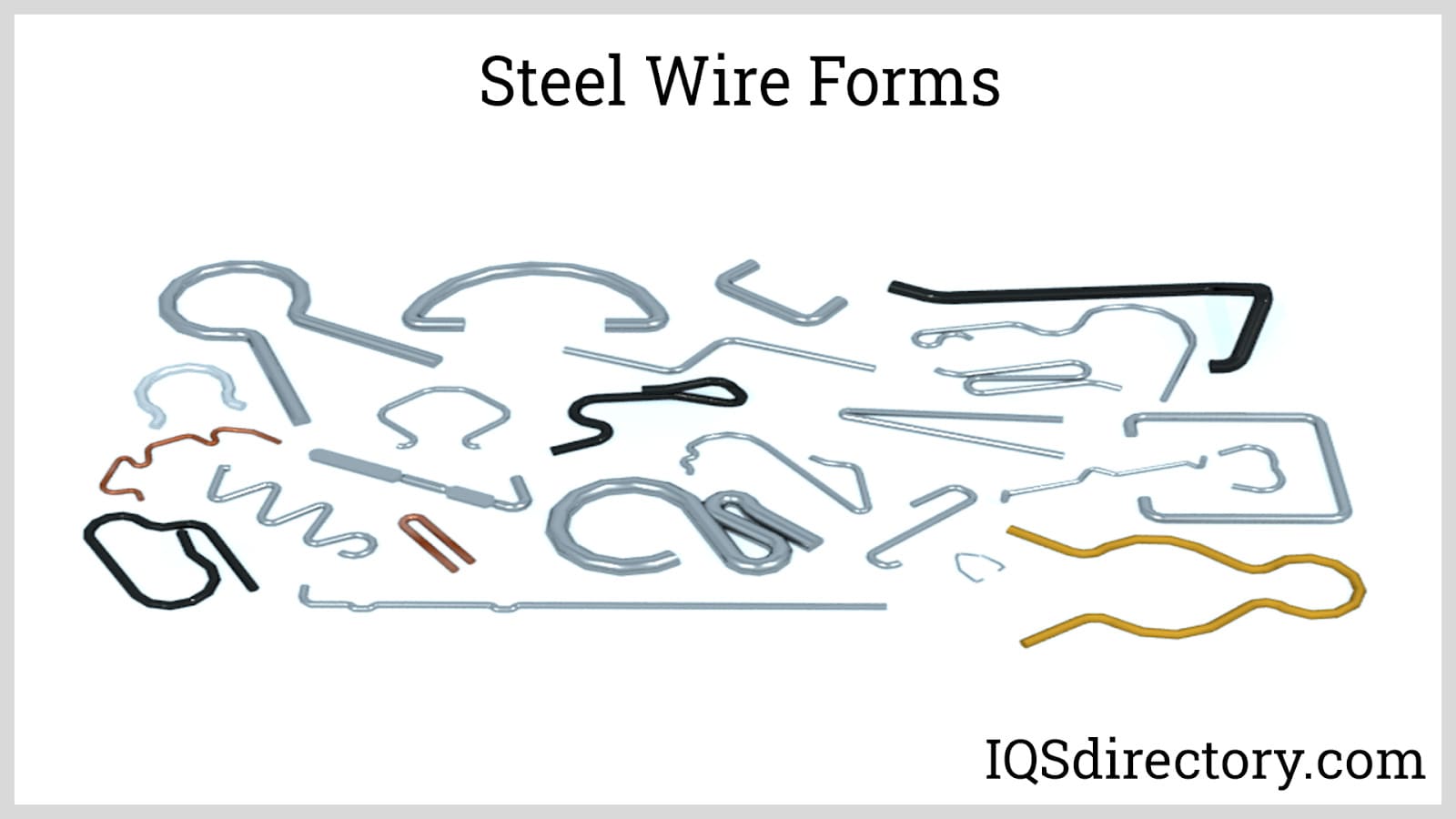

The range of wire shapes, configurations, and forms is virtually limitless, with new wire form designs continually being developed to meet evolving industrial needs. Wire forming is an advanced manufacturing process that can create anything from complex, intricate three-dimensional components for automotive assemblies and medical devices to simple hooks and springs for everyday applications. Many of the products and hardware we use daily—ranging from storage solutions and display racks to safety fasteners and mechanical linkages—incorporate some type of precision wire forming.

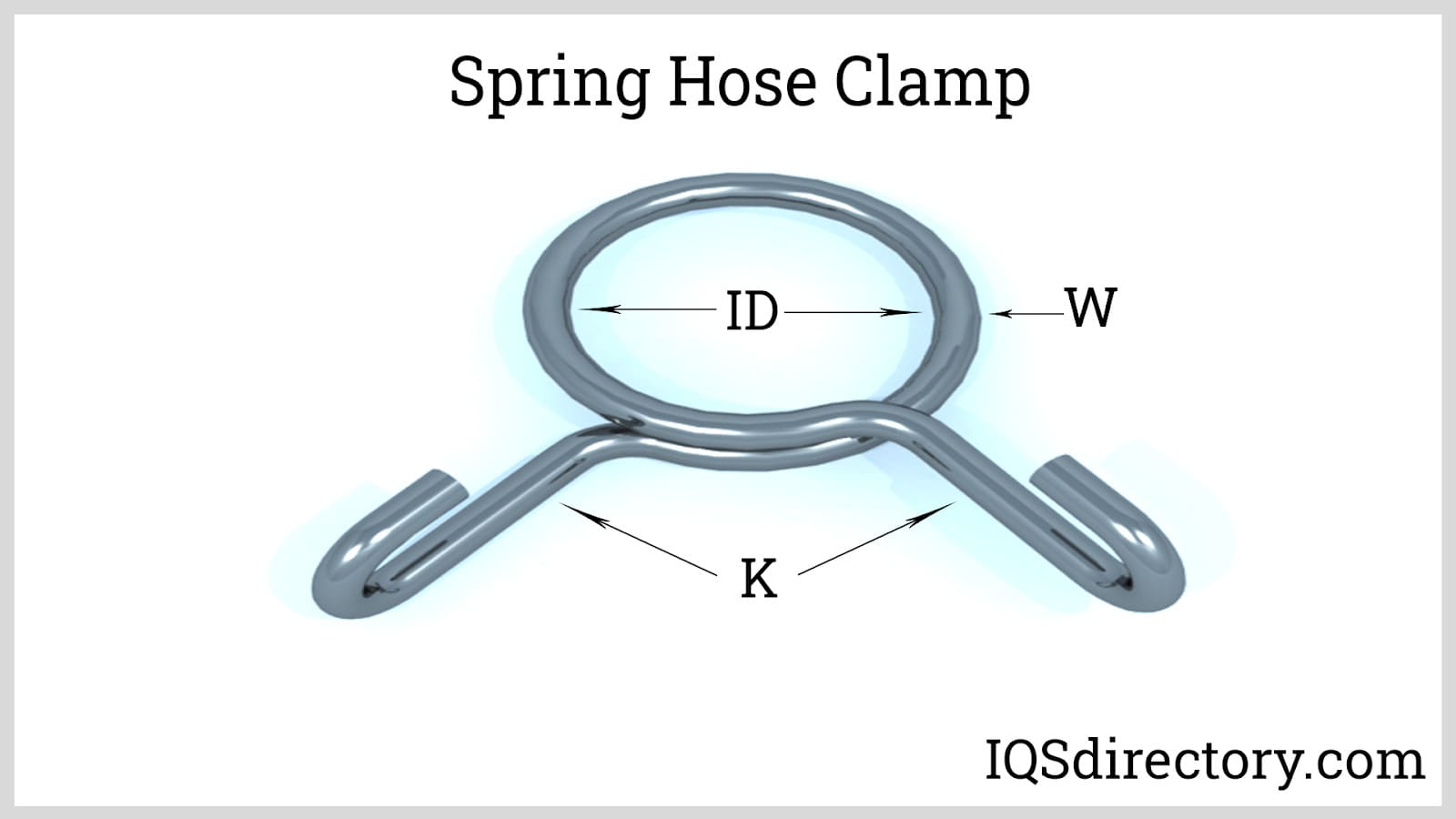

Wire hose clamps are made from heavy-duty wire bent into a U shape and then formed into a continuous ring, with one end overlapping the other. The ends are bent upward to allow for easy opening and secure installation. When the ends are pushed apart, the clamp tightens around the hose, applying uniform compression and ensuring a leak-proof seal—an essential feature in plumbing, automotive, and industrial hose applications.

To loosen the clamp, the ends are simply pressed together, allowing for fast adjustment or removal. Stainless steel and galvanized steel are often used for corrosion-resistant hose clamps in demanding environments.

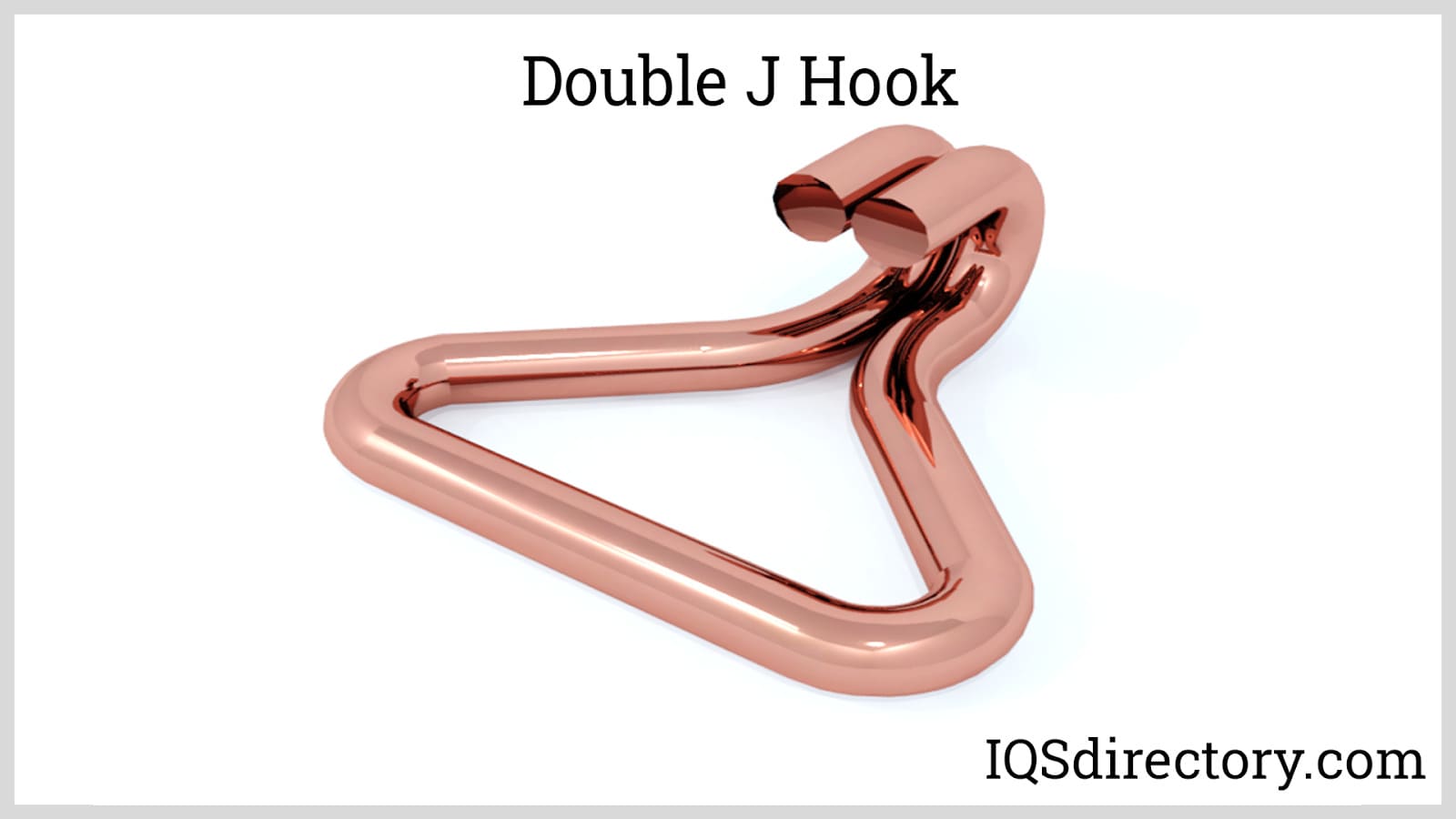

There are many types of J hooks, which are essential hardware in construction, electrical wiring installation, and material handling. The fishhook is one of the most common variants. J hooks can be coated with rubber or vinyl to protect the surfaces of the items they hold and often feature notched design elements for easy, secure hanging.

Heavy-duty double J hooks, when attached to webbing or straps, are engineered to support substantial loads, making them ideal for cargo control and transportation applications.

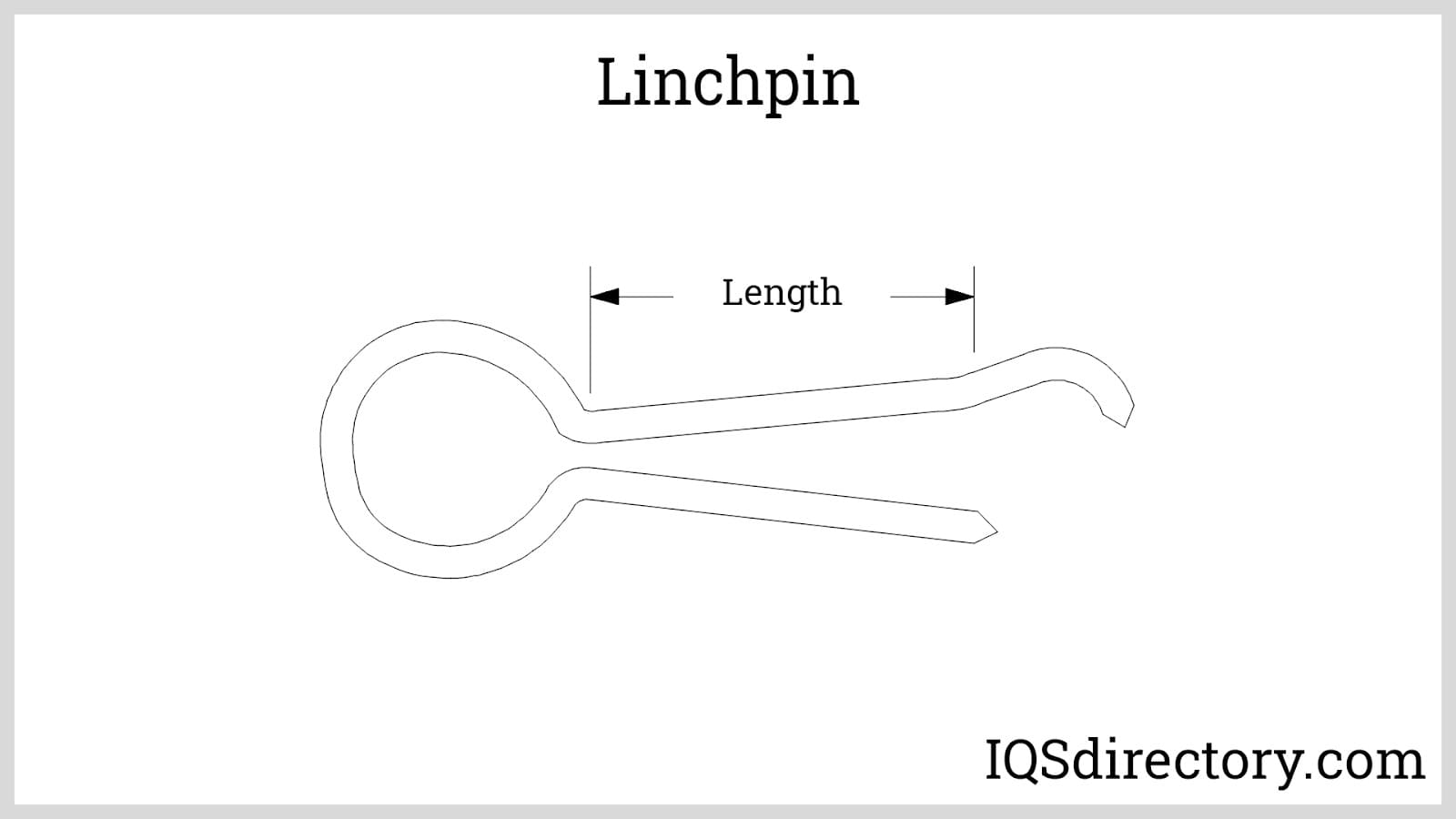

Linchpins are precision wire fasteners that are inserted into the end of an axle or shaft to prevent wheels or rotating parts from coming off. These critical components are fabricated from materials such as aluminum, zinc, brass, and stainless steel for enhanced durability and resistance to wear in agricultural machinery, trailers, and automotive assemblies.

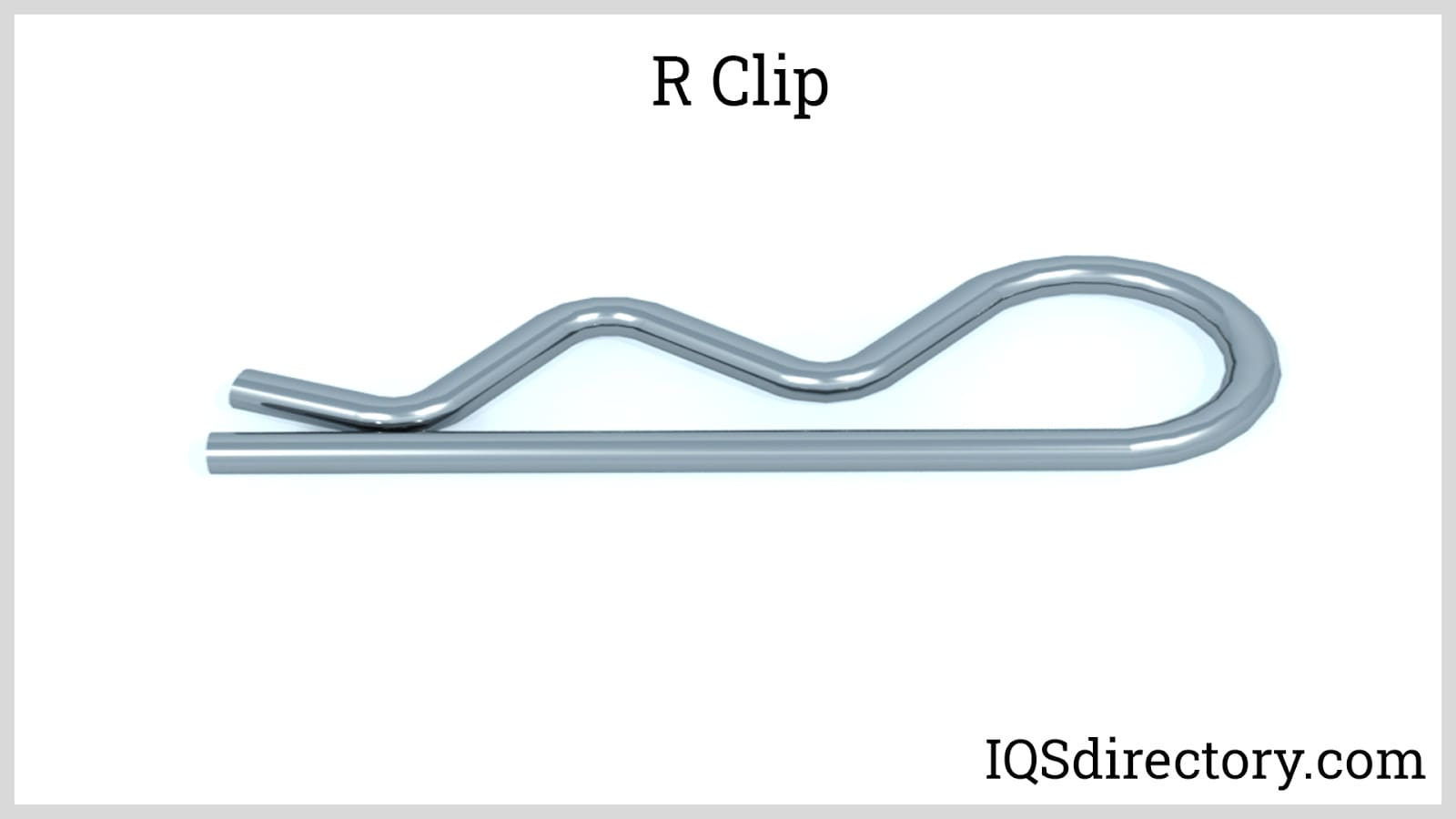

R-clips—commonly referred to as retaining clips, hairpin cotters, or spring cotter pins—are versatile metal wire fasteners shaped like the letter R. They function similarly to linchpins, securing the end of an axle, pin, or rod with a wheel.

The long, straight portion of the R clip fits through a pre-drilled hole at the end of the shaft, while the springy loop snaps snugly around the shaft, ensuring a secure hold. The semi-circular, bent section of the clip facilitates easy installation and removal, making them a preferred choice for quick assembly and maintenance.

Both ends of an S hook are precisely bent to form the characteristic S shape, enabling effortless hanging and lifting. S hooks are widely used for hanging storage, organizing cables, hoses, chains, and cords, and enhancing workplace or home safety.

Among the various categories of wire forms, springs are the most common and widely utilized components in countless industries. These mechanical devices consist of a coiled wire wound into a tightly wrapped spiral to achieve precise tension, compression, or torsion requirements.

Types of springs include compression springs, extension springs, torsion springs, and wire coil springs, each engineered for a specific function.

In the wire form threading process, a metal rod is passed through a set of threading dies that shape the threads with precisely engineered peaks and valleys. Rolled threading displaces material, while cut threading removes material to form the thread profile.

Utility hooks feature a threaded end and a hook, allowing for straightforward installation into wood, metal, and masonry surfaces. They are commonly used in garages, warehouses, and storage systems for organizing tools, hoses, bicycles, and equipment.

Wire baskets are essential for bulk storage and material handling of parts, equipment, and components. Fabricated from heavy-gauge welded wire mesh, they provide strength, ventilation, and visibility.

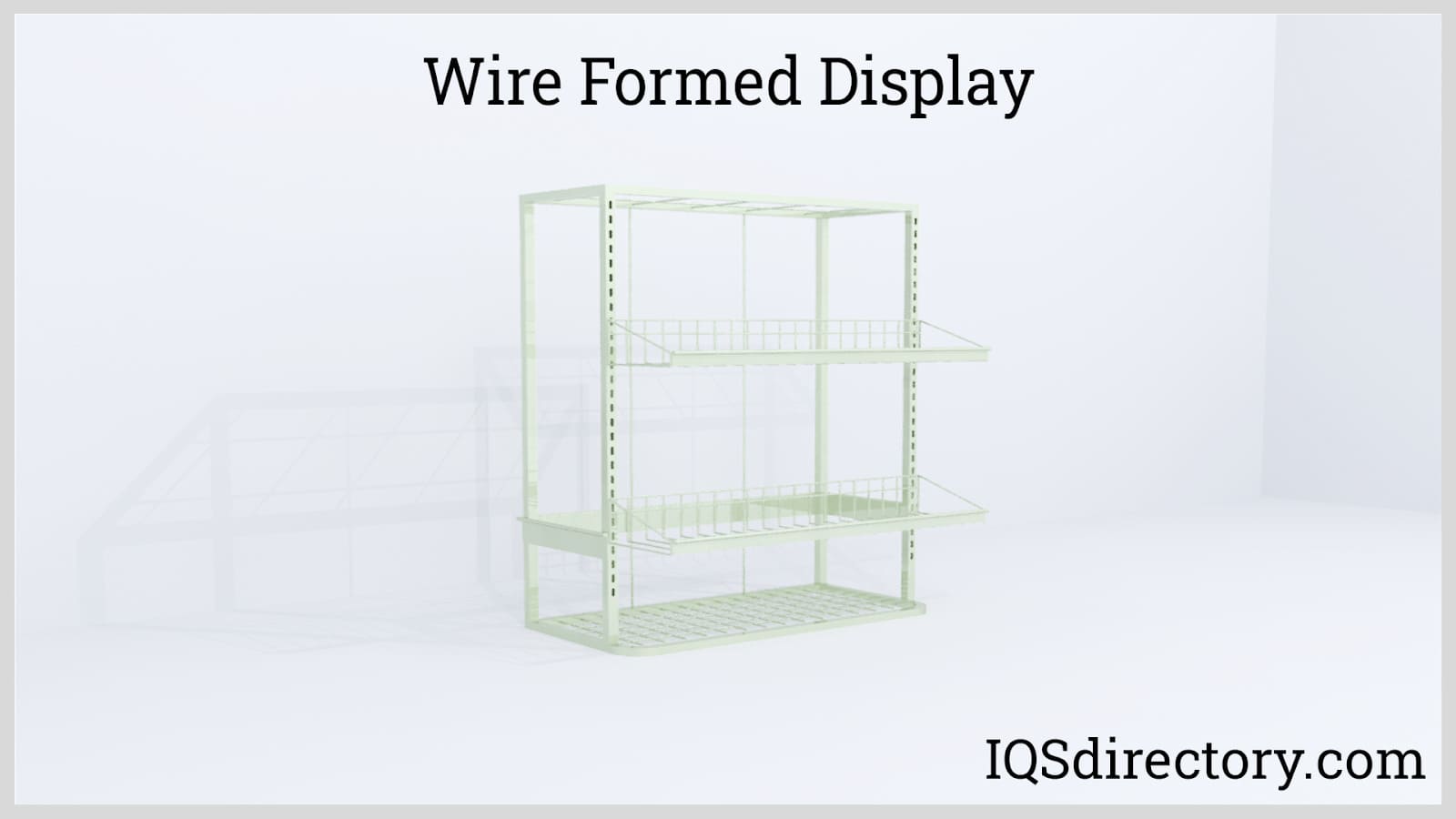

Wire displays are a durable and cost-effective solution for showcasing retail products and promotional items. They can be powder coated, plated, or painted for enhanced appearance and durability.

Wire guards are engineered to provide reliable protection and prevent unauthorized access to equipment, passageways, and electronic devices. Hinged wire guards and open-face designs are commonly used in industrial and public environments.

Wire screens are fabricated by weaving or welding thin metal wires into mesh patterns for filtering, sieving, and flow control in industrial applications.

Z clips are wire fastening components engineered to securely lock panels, signage, or assemblies in place. They are valued for their strength, adaptability, and corrosion resistance.

Choosing the Right Wire Form for Your Application

Selecting the proper wire form involves evaluating material composition, wire diameter, load capacity, corrosion resistance, finishing options, and the operating environment. Industries such as automotive, aerospace, electronics, medical device manufacturing, and construction rely on custom wire forming for precision and durability.

Wire forming is the process of reshaping wire using techniques like bending, drawing, and coiling. Common metals include steel, brass, stainless steel, copper, aluminum, and various alloys.

Key methods include drawing, manual and CNC bending, coil forming, roll forming, fourslide forming, hydraulic forming, and pneumatic forming.

Tight tolerances ensure proper fit, function, and reliability, especially in high-precision industries such as aerospace and medical devices.

Options include machine cut, chamfered ends, winging, pierced swaging, chisel points, ball ends, grooves, and cold heading.

Automotive, aerospace, electronics, medical device manufacturing, and construction industries commonly rely on custom wire forms.

Automation increases speed, accuracy, and repeatability, making it ideal for high-volume production of complex wire components.

Wire forms can be manufactured from a broad range of metals and alloys, allowing manufacturers to tailor strength, corrosion resistance, conductivity, and formability to the requirements of the final application. Common wire forming materials include aluminum, copper, steel, brass, and stainless steel grades such as 304, 316, and 434, along with specialized alloys engineered for performance in demanding industrial environments.

Bright basic wire (BBW) is a low-carbon steel wire known for its smooth, polished surface finish and excellent workability. It is cold drawn to improve tensile strength, dimensional consistency, and mechanical performance, making it ideal for precision wire forming. BBW offers reliable bendability, straightening capability, weldability, and compatibility with surface finishes such as epoxy coating, plastic coating, galvanization, and powder coating. The most commonly used grades for wire forming applications are 1008C and 1018C.

Galvanized wire is carbon steel wire that has been coated with zinc through either electroplating or hot-dip galvanization. This protective zinc layer significantly enhances corrosion resistance and extends service life in outdoor, humid, or corrosive environments. In hot-dip galvanizing, the wire is submerged in molten zinc, forming a metallurgical bond that protects the steel from oxidation and rust. Galvanized wire is widely used in fencing, baskets, guards, fasteners, and structural wire forms where durability and environmental resistance are critical.

Stainless steel grade 304 is one of the most widely used materials in wire forming due to its excellent corrosion resistance, durability, and strength. With a tensile strength of approximately 621 MPa, it performs well in environments exposed to moisture, chemicals, and moderate heat. Grade 304 can withstand operating temperatures exceeding 1500°F (815.5°C) and is non-magnetic, which is important in applications involving electronics, medical devices, and food processing equipment. Its balance of strength and formability makes it a versatile choice for long-lasting wire components.

Grade 316 stainless steel offers enhanced corrosion resistance compared to 304, particularly against chlorides, salts, and harsh chemicals. With a tensile strength of approximately 579 MPa, it is well suited for heavy-load applications in marine, chemical processing, and pharmaceutical environments. Grade 316 is commonly used where exposure to caustic substances or saltwater is unavoidable and maintains performance at temperatures up to 1400°F (760°C).

Stainless steel grade 434 is a ferritic alloy that provides strong resistance to oxidation, corrosion, and pitting while containing no nickel, making it a cost-effective alternative to austenitic stainless steels. Its maximum operating temperature is below 1500°F (815.5°C), which limits its use in high-heat applications but makes it suitable for industrial wire baskets, racks, and structural wire forms requiring durability and corrosion resistance without premium material costs.

Brass wire is an alloy composed primarily of copper and zinc, typically in a 67% copper and 33% zinc ratio. It retains copper’s electrical and thermal conductivity while offering improved strength and rigidity. Brass is highly formable and visually appealing, making it suitable for decorative wire forms, electrical components, and precision hardware. Certain brass alloys incorporate elements such as tin, iron, antimony, or arsenic to enhance hardness, wear resistance, and overall mechanical performance.

Copper is a soft, ductile, and highly conductive metal valued for its superior electrical and thermal conductivity. Its ease of forming and resistance to corrosion make it ideal for wire forming in electrical, grounding, and heat-transfer applications. Over time, copper develops a natural green patina when exposed to the atmosphere, which further protects the material from corrosion while maintaining structural integrity.

Aluminum is a lightweight, non-magnetic, and corrosion-resistant metal commonly used in wire forming applications where weight reduction is important. Derived from bauxite ore, aluminum is alloyed with elements such as copper, magnesium, zinc, manganese, or silicon to improve strength and resistance to deformation. Aluminum wire forms are frequently used in aerospace, automotive, and consumer product applications where strength-to-weight ratio is a critical factor.

Steel wire is an alloy of iron and carbon engineered for strength, toughness, and cost efficiency. The addition of carbon and other alloying elements significantly increases hardness and tensile strength compared to pure iron. Steel wire is widely used in structural wire forms, fasteners, guards, frames, and industrial baskets due to its durability, load-bearing capability, and affordability.

Wire forming plays a vital role across a wide range of industries by enabling the production of both standardized and highly customized wire components. The flexibility of wire forming allows manufacturers to design parts that meet precise mechanical, dimensional, and environmental requirements, making wire forms essential in applications where reliability, repeatability, and strength are required.

Medical wire-formed components must meet strict standards for cleanliness, durability, and precision. Stainless steel is the preferred material due to its ability to withstand repeated sterilization, high temperatures, and chemical exposure. Smooth finishes reduce the risk of glove punctures or contamination, making wire forms suitable for surgical instruments, mandrels, trays, and medical device components.

In industrial manufacturing environments, wire forms support efficient material handling, assembly, and workflow organization. Wire baskets, racks, and fixtures are commonly used to transport, stage, and store parts throughout production lines, improving operational speed, safety, and consistency.

Automotive wire forms include springs, clips, retainers, battery contacts, and suspension components. Compression, torsion, and conical springs are engineered to absorb vibration, support loads, and enable mechanical movement in vehicles. Precision wire forming ensures these components perform reliably under constant stress and temperature fluctuations.

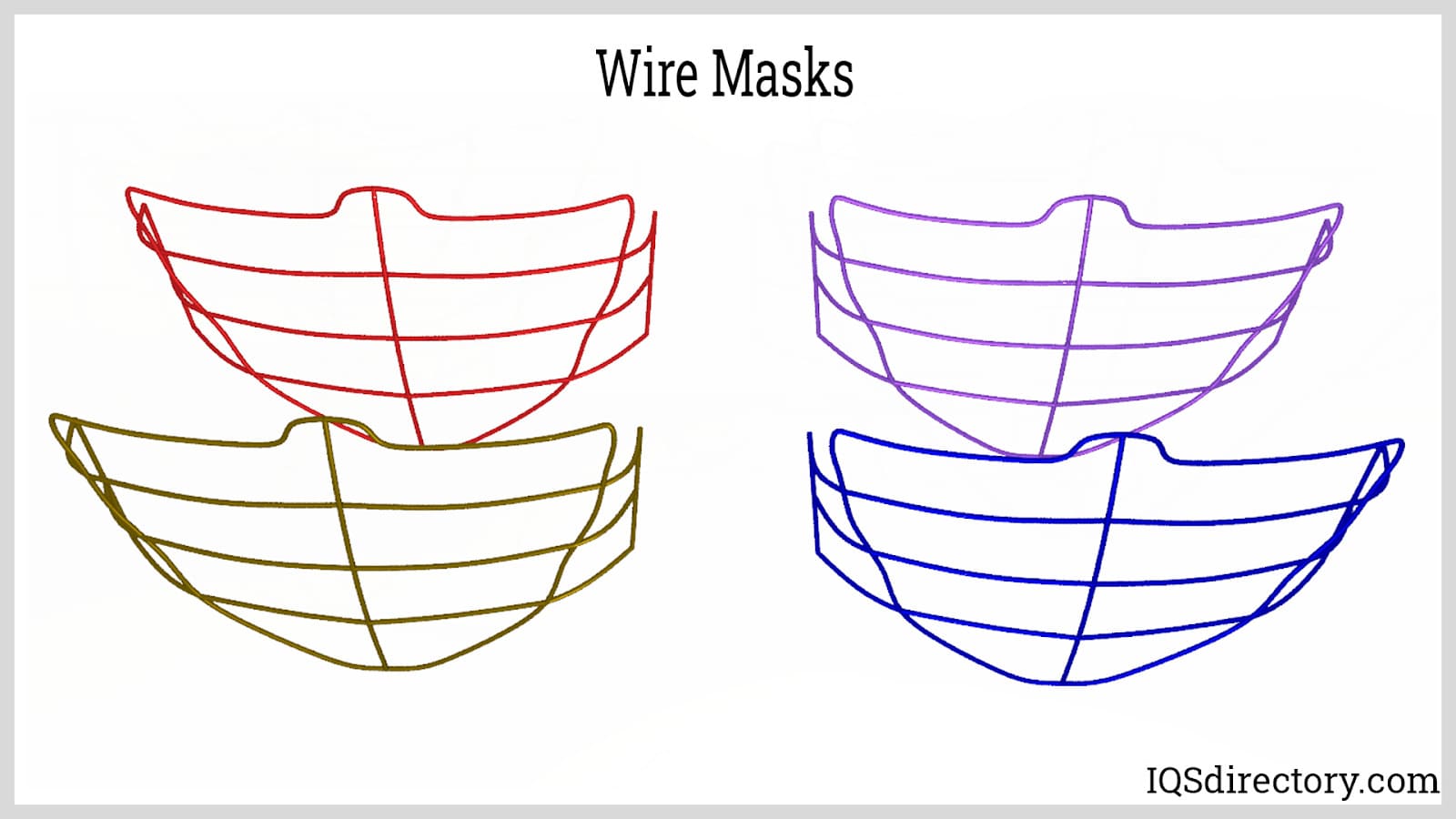

Wire-formed protective masks and guards are used in contact sports to enhance athlete safety. These components are designed and manufactured to comply with standards set by organizations such as the National Operating Committee on Standards for Athletic Equipment (NOCSAE), ensuring consistent protection and durability.

Wire forms are widely used in telecommunications infrastructure for cable management systems, including trays, guides, routing rings, and support frames. Their open design allows for easy access during installation, inspection, and upgrades, while steel construction provides strength and long-term reliability.

In retail environments, wire-formed display racks provide lightweight yet durable solutions for showcasing merchandise. These racks are easily repositioned to adapt to changing store layouts and high-traffic areas. Wire racks are also used for backroom storage and inventory management, supporting efficient merchandising and restocking operations.

Food processing and storage applications require wire forms that meet FDA sanitation standards. High-grade stainless steel wire racks and baskets resist corrosion, tolerate frequent washing, and maintain hygiene in food production, preparation, and storage environments.

Wire forms are essential in construction for reinforcing structures, supporting electrical systems, creating guards and screens, and forming architectural accents. From functional frameworks to decorative fencing and railings, wire-formed components provide strength, versatility, and aesthetic appeal.

The wire forming process consists of several critical steps that ensure the final product meets design, performance, and quality requirements. These steps include wire selection, straightening, forming through applied force, and determining whether secondary finishing operations are required.

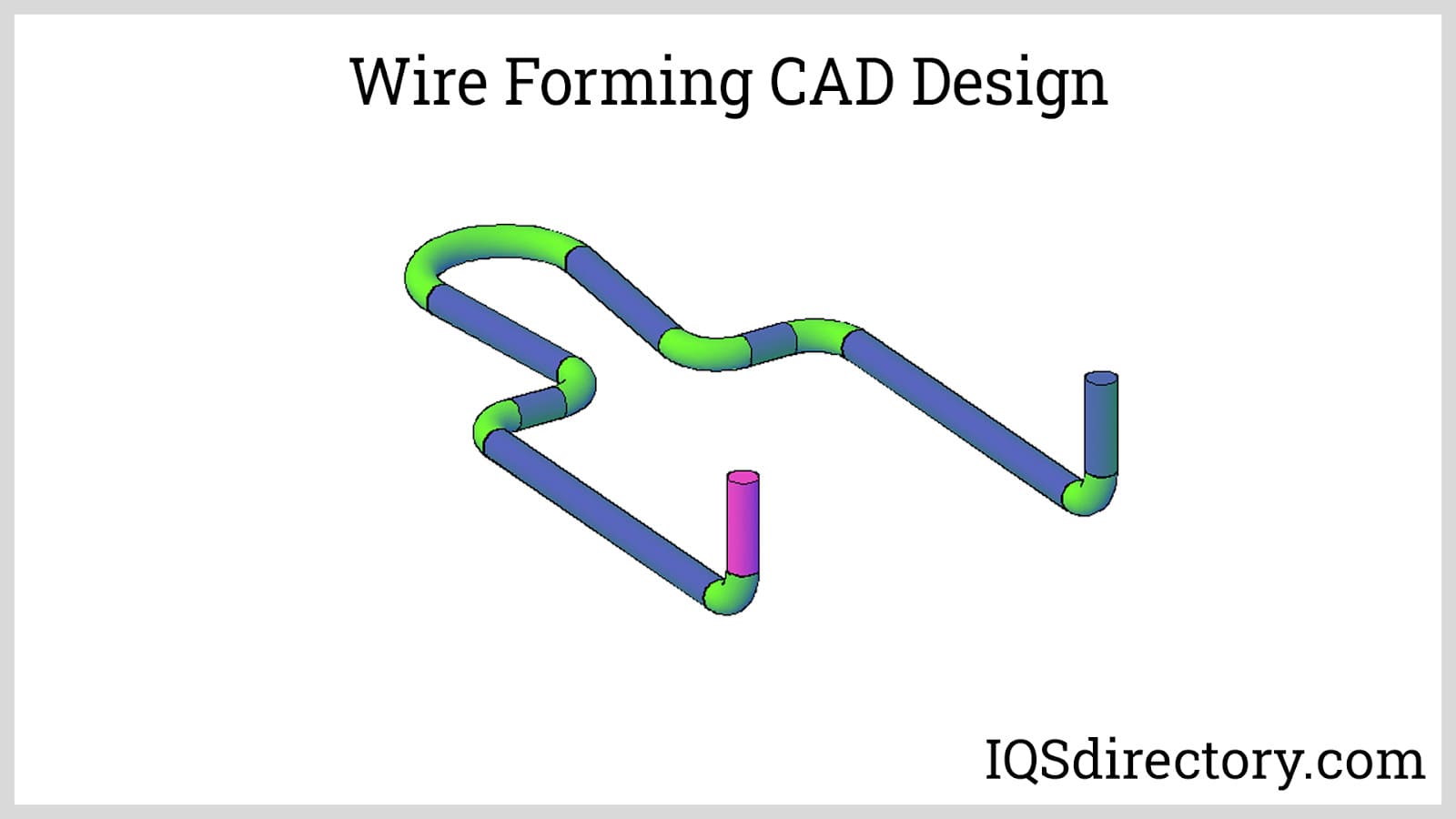

Wire selection is guided by CAD designs and engineering specifications, which define the required diameter, gauge, material type, and mechanical properties. Steel and stainless steel are commonly selected for strength and durability, while aluminum and copper are used in applications requiring reduced weight or high conductivity.

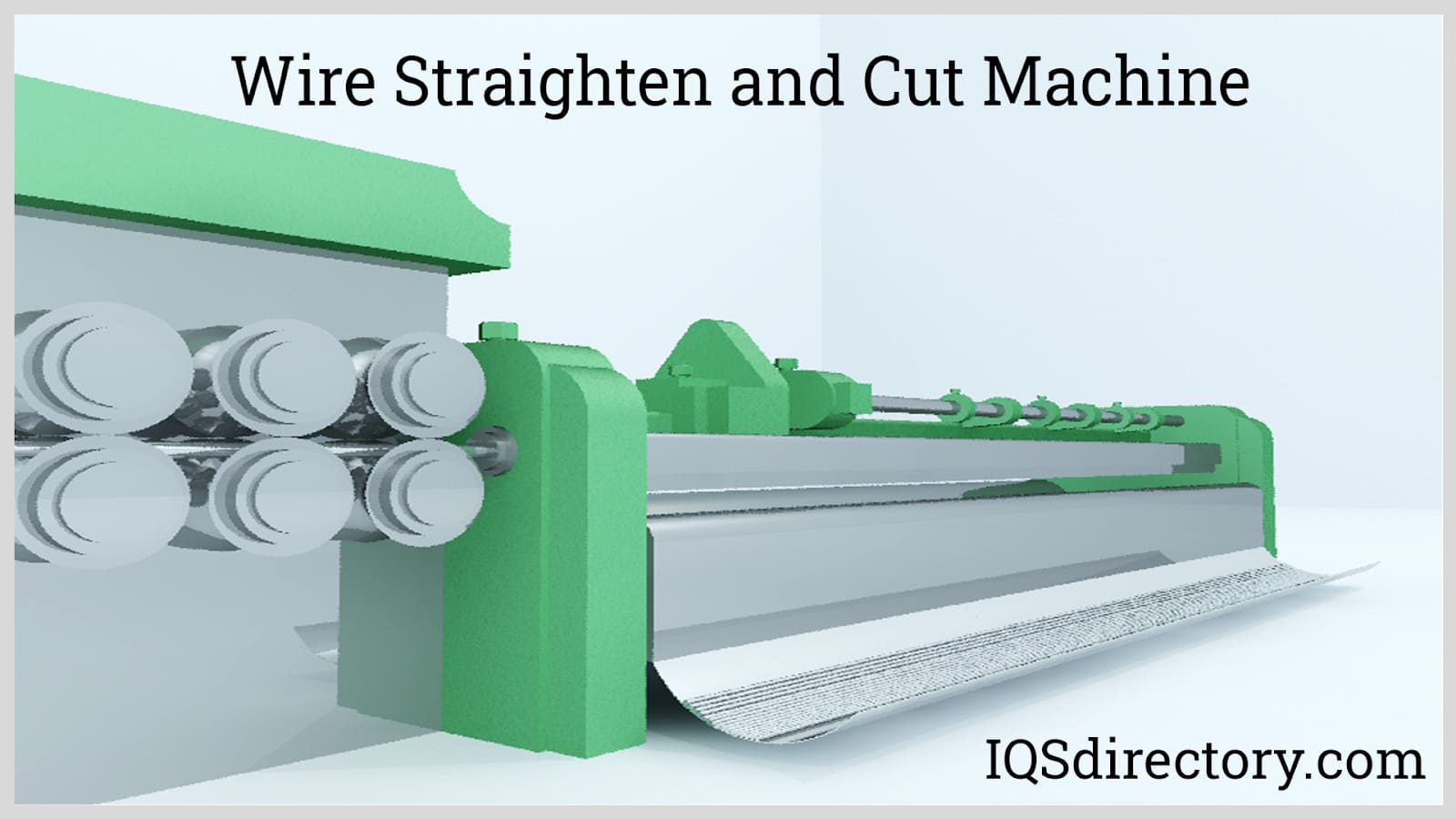

Wire is typically stored in coils and must be straightened prior to forming. Straightening removes residual stresses and irregularities that could compromise dimensional accuracy. This process is performed using precision straightening machines that roll and align the wire before cutting or forming.

During wire forming, controlled force is applied to bend, shape, or contour the wire into its final configuration. This force may be applied manually or through automated systems such as CNC wire benders, hydraulic presses, or fourslide machines. Automated equipment is preferred for high-volume production due to its precision, speed, and repeatability.

Finishing requirements depend on the design and intended use of the wire form. Some components require no additional processing, while others undergo secondary operations such as cutting, grooving, heading, coining, swaging, or coating. The primary goal of finishing is to eliminate burrs, smooth sharp edges, and enhance safety, appearance, and functionality.

Wire baskets are made from a series of wires that are woven together or welded to form a shape of a basket. They can also be defined as containers that are made by use of an openwork pattern of metal...

Wire shaping is a complex method that encompasses a wide range of dimensions, forms, and textures. The technique of creating a usable product by wire bending and shaping is known as custom wire forms...

A wire handle is attached to a bucket, pail, or other type of container to make it easy to lift the container and transport it. They are made of durable and sturdy metals capable of lifting several pounds...

A wire rack is a level wire form utilized to stock and exhibit a number of products, usually retail. The bottom surface on which such goods are stored is made of several latticed or interlaced metal strands...

Wire mesh is fabricated by the intertwining, weaving, or welding of wires of various thicknesses to create proportionally equal parallel rows and intersecting columns. Also known as wire fabric, wire cloth, or...

A coil spring is an elastic element made of metal or heavy plastic in the form of curls or ringlets of round wire or cord that is wrapped around a cylinder. The winding of a coil spring can be loose or tight in a helical shape depending on the application for which it is made...

Coil springs called compression springs can store mechanical energy when they are compressed. These open-coiled, helical springs provide resistance to compressive loading. When these springs are...

Contract manufacturing is a business model in which a company hires a contract manufacturer to produce its products or components of its products. It is a strategic action widely adopted by companies to save extensive resources and...

Extension springs are helical wound springs that are so closely coiled together to create initial tension in the coils. This initial tension creates resistance against the force applied to its ends for extension. The initial tension helps determine how closely and...

Hardware cloth is a woven mesh made by interlacing various sizes of wire to form a metal fabric that can be used for animal cages, fence material, strainers, and filtering screens. The differences between the various types of hardware cloth...

The phrase "wire mesh" describes two- or three-dimensional structures constructed of two or more metallic wires connected by various techniques. In a wide range of settings, wire mesh products are...

Springs are a flexible machine element that store mechanical energy when subjected to tensile, compressive, bending, or torsional forces. When the spring is deflected, it stores energy and at the same time exerts an opposing force...

A torsion spring is a mechanical device that stores and releases rotational energy. Each end of the torsion spring is connected to a mechanical component. As the spring is rotated around its axis on one end, the winding of the spring is tightened and stores potential energy...

Welded wire mesh is a series of wires that are welded where the individual wires cross. The openings of the mesh varies depending on the type of wire used and the function of the mesh. Regardless of size and wire, welded wire mesh is permanent and...

Wire cloth is a woven (or nonwoven) sheet or web material with a series of openings across the surface. Wire cloth is also known as: Metal Fabric or Metal Cloth; Wire Mesh, Metal Mesh, or Alloy Mesh...