Compression Springs

Coil springs called compression springs can store mechanical energy when they are compressed. These open-coiled, helical springs provide resistance to compressive loading. When these springs are...

Please fill out the following form to submit a Request for Quote to any of the following companies listed on

This article takes an in depth look at coil springs and their materials.

You will learn more about topics such as:

A coil spring is a helical mechanical element made by winding metal into a spiral form. It functions to store potential energy, which it then uses to mitigate shock. These springs are manufactured by twisting metal wire into a continuous helix, transforming the wire into an energy-storing component.

Available in various sizes, coil springs are engineered to reduce impact and stress on different surfaces. They achieve this by providing flexibility that allows them to deform under external stress and then bounce back to their original shape once the stress is lifted. During compression, the spring holds energy and releases it when returning to its initial form. The energy stored is proportional to the force applied.

When subjected to weight, coil springs compress, storing mechanical energy by reducing in size. After the weight is lifted, the spring expands, releasing the stored energy as it returns to its original state.

Coil springs can be classified into three main categories: compression, extension, and torsion, each serving a unique function. Among these, compression springs are the most prevalent. They are typically produced by hot or cold winding of spring steel and are engineered to absorb force and resist compression.

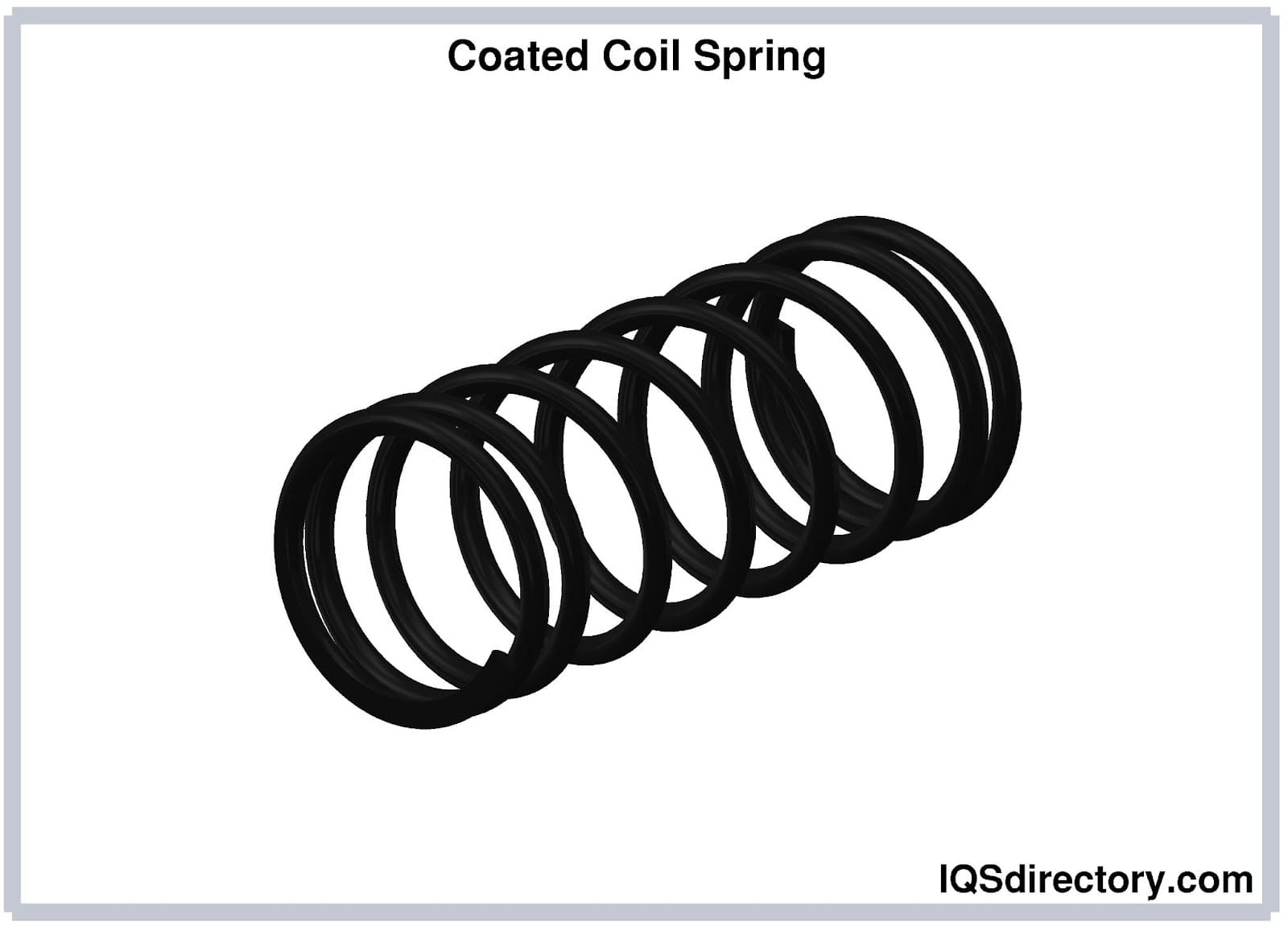

Coil springs may be prone to corrosion and environmental degradation, potentially causing early failure. To improve endurance, they are frequently coated with substances such as powder, epoxy, or polyester. Additionally, some springs are electroplated with zinc or nickel to enhance their protective capabilities.

Coil springs are essential elastic mechanical components engineered to absorb, store, and release energy in a wide range of industrial, automotive, and consumer applications. As fundamental elements in suspension systems, mechanical devices, and precision instruments, coil springs play a pivotal role in maintaining force, shock absorption, and mechanical efficiency. Coil springs can be fabricated from various spring steel alloys, with material selection tailored to the requirements of the load, environment, and application. There are two main types based on coil spacing: close wound coil springs, where the coils are tightly compressed and touch one another, and open wound coil springs, in which spaced coils provide variable deflection and elasticity.

The manufacturing approach for coil springs depends on factors such as production volume, required tolerances, and application standards. For limited or custom runs, manufacturers often use manual or lathe-based methods. However, for mass production of high-performance coil springs, automated spring coiling machines or advanced computer numerical control (CNC) systems are employed to achieve consistent precision, greater efficiency, and tight quality control.

Coil springs are typically constructed from an array of high-tensile and durable metals, each best suited for specific mechanical properties and environments. Common coil spring materials include high carbon steel (such as ASTM A228 music wire), medium carbon steel, chromium vanadium steel, chromium silicon steel, as well as corrosion-resistant stainless steel grades, copper alloys, and nickel-based alloys. Stainless steel coil springs are frequently used when high resistance to oxidation or harsh environments is required, such as in marine or food processing industries. The selection of spring steel or other alloys depends on factors such as fatigue strength, load capacity, resistance to wear, and environmental considerations.

Raw materials for manufacturing coil springs are often provided as bars or rods, which are drawn down into wire of the appropriate diameter. Wire diameter is a critical factor influencing the spring's final physical properties, including its spring constant (rate), load-bearing capacity, and durability. Material quality certifications (such as ISO or ASTM standards) and traceability are especially important for critical engineering applications and OEM (Original Equipment Manufacturer) contracts.

Heat Treatment – The heat treatment of spring wire precedes cold winding and is vital for optimizing wire strength, ductility, and resistance to mechanical fatigue. Cold winding is the preferred process for manufacturing coil springs with wire diameters up to 0.75 inches (18 mm), enabling the production of compression springs and extension springs with precise tolerances and repeatability.

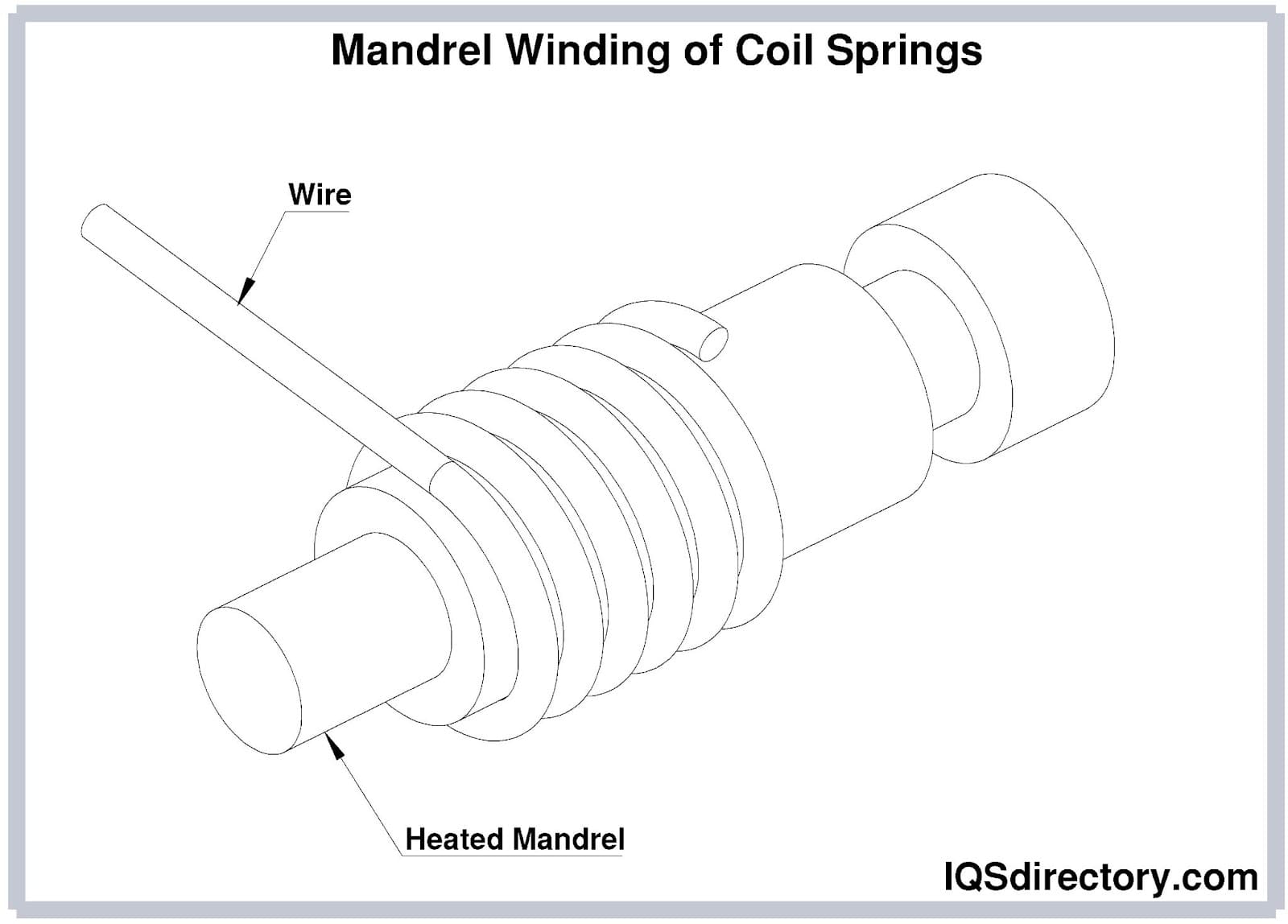

Mandrel – The mandrel coiling process can be performed manually—ideal for prototyping and small batch runs—or using semi-automated winding machines. During winding, the wire is tightly wrapped around a mandrel, guided to ensure the correct pitch and coil alignment. This process determines the spring’s free length, inner and outer diameters, and the number of active coils, key variables in the spring’s load and deflection characteristics.

Computer Numerical Control (CNC) – CNC spring manufacturing represents the pinnacle of automation for coil spring fabrication. CNC machines integrate computer programming and servo-driven actuators, providing unparalleled control of wire feeding, winding, shaping, and cutting. This enables rapid production and high consistency essential for demanding sectors such as aerospace, heavy trucks, and industrial machinery. CNC coiling can handle different wire sizes and complex spring geometries—including barrel, conical, and variable-rate springs—ensuring repeatable precision in custom spring manufacturing projects.

The following diagram details these CNC spring manufacturing components and workflow.

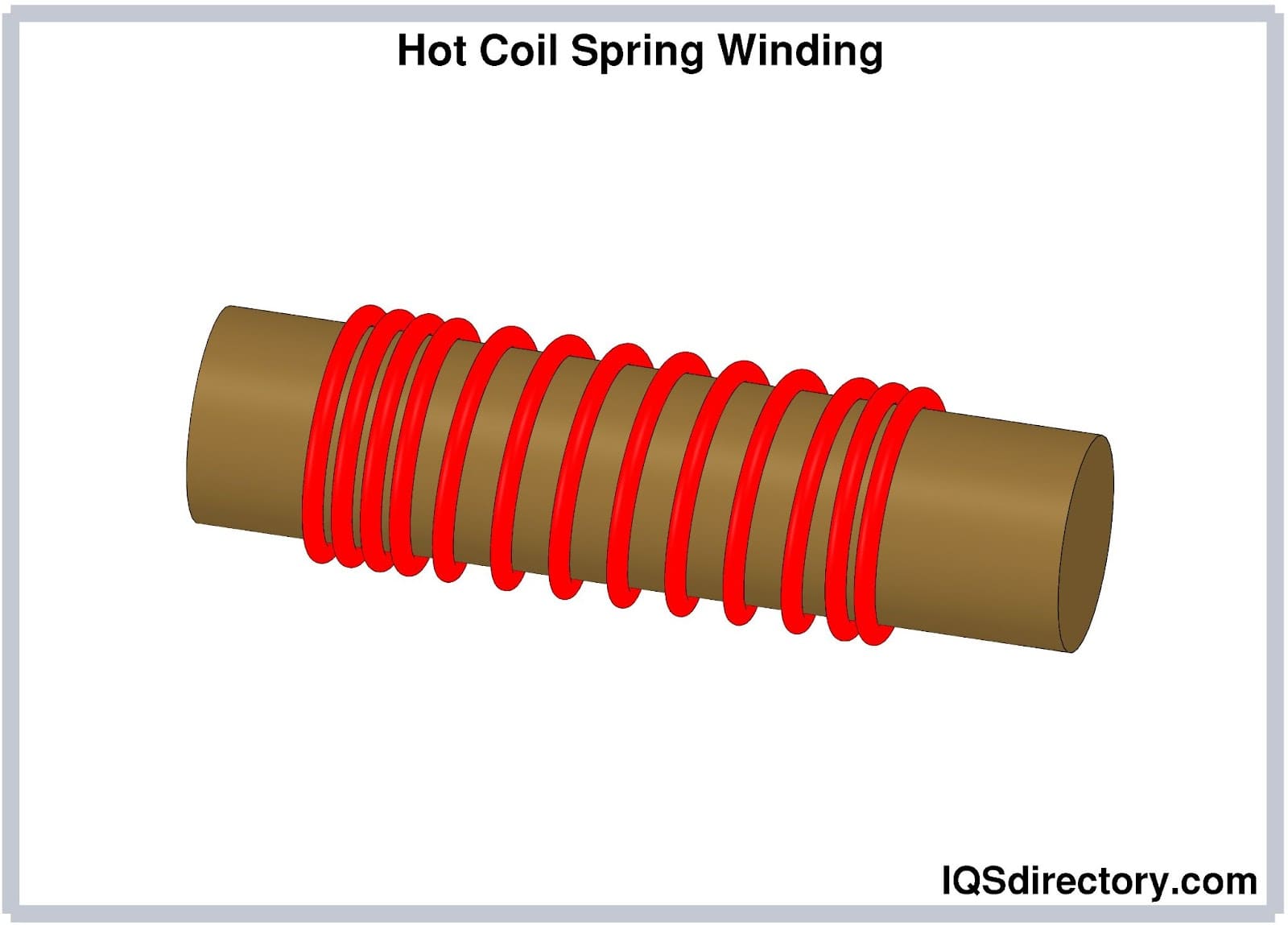

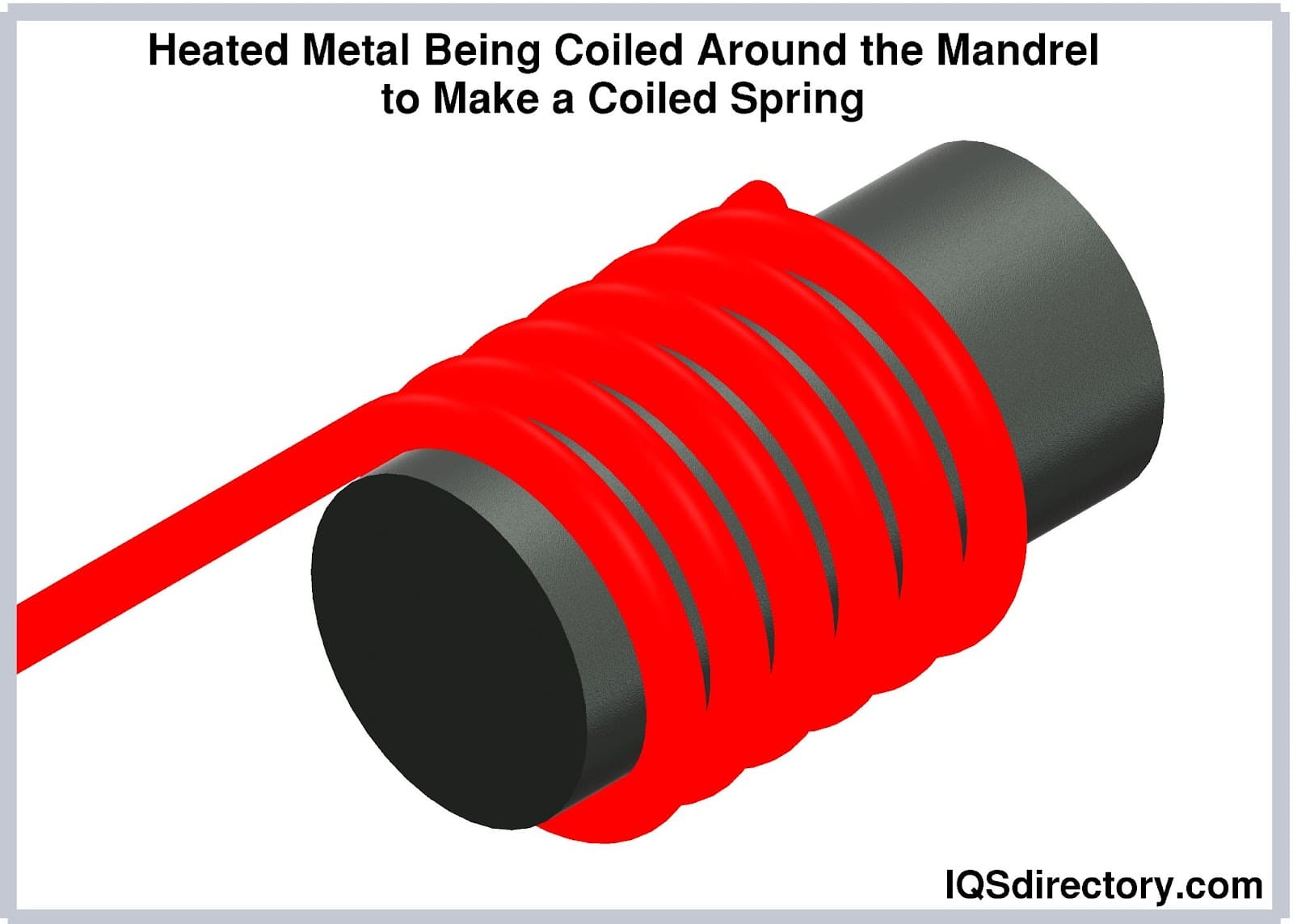

Wire – The hot winding process is recommended for coil springs made from thick wire, usually from 3 inches (75 mm) to 6 inches (150 mm) in diameter, as found in heavy-duty suspension springs, mining equipment, and railroad applications. Coil spring wire is heated in a controlled furnace to approximately 1700°F, greatly increasing its malleability and permitting tight radius winding without cracking or surface defects.

Mandrel – In automated hot coiling, the red-hot wire is wound around a precision mandrel, while CNC robotics ensure exact pitch and coil geometry, even under the stresses of high-temperature deformation. This results in heavy coil springs that meet strict automotive, industrial, or construction-grade performance standards.

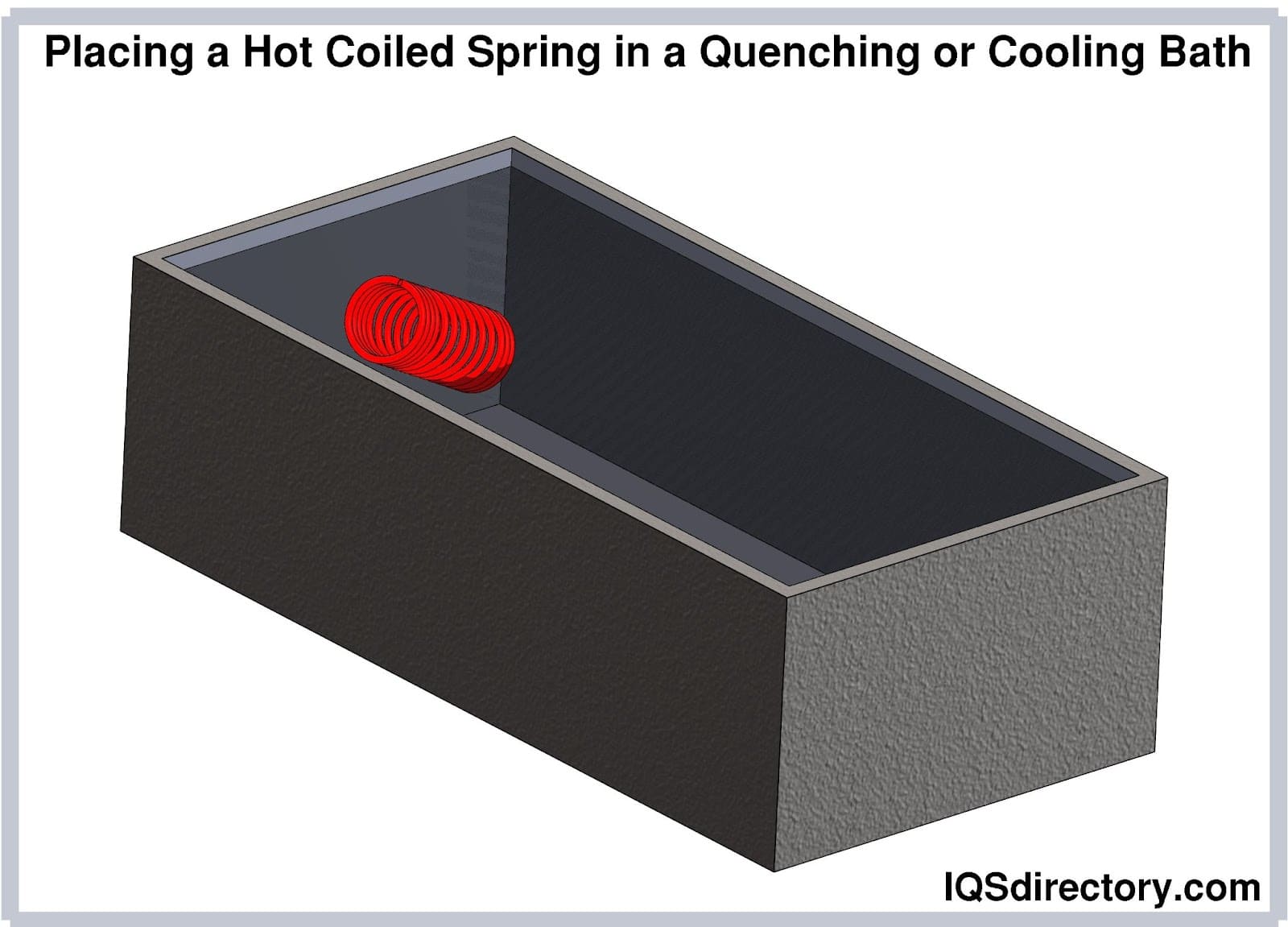

Cooling – Rapidly cooling, or quenching, is a critical post-hot-winding step to harden the newly formed coil and lock in the desired microstructure. Oil quenching is widely used in the spring industry for its speed and ability to minimize metallurgical gradients, which can otherwise cause spring failures due to cracking or embrittlement. Consistent cooling is monitored to establish the final spring hardness and ensure compliance with ISO or SAE spring manufacturing standards.

Throughout quenching, significant changes occur in the steel’s crystalline lattice, resulting in enhanced strength and increased spring life cycles. Using high-quality quenching oils or advanced cooling systems directly impacts coil spring reliability in demanding applications such as vehicle suspension, agricultural machinery, and critical industrial equipment.

The mechanical coil forming process subjects spring wire to high levels of internal strain, resulting in residual stresses that can compromise coil performance, reduce fatigue resistance, or cause premature failure under load. Stress relief is an essential step in the coil spring manufacturing workflow to release these built-in stresses, enhance reliability, and extend service life.

Typically, springs are heated in a controlled oven to temperatures below their recrystallization point, holding them there long enough for molecular rearrangement without altering the spring’s shape. Gradual cooling follows to preserve the optimal physical and metallurgical properties. The exact settings vary by material: for example, chrome silicon and chrome vanadium may undergo stress relief at 700°F–800°F (371°C–426°C), while 17-7 stainless steel requires higher temperatures. Proper stress relief is especially crucial for high-load compression springs and precision extension springs used in automotive, aerospace, and industrial assemblies.

The finishing phase involves surface treatments and machining operations that prepare coil springs for end use and optimize their longevity, corrosion resistance, and precision tolerances.

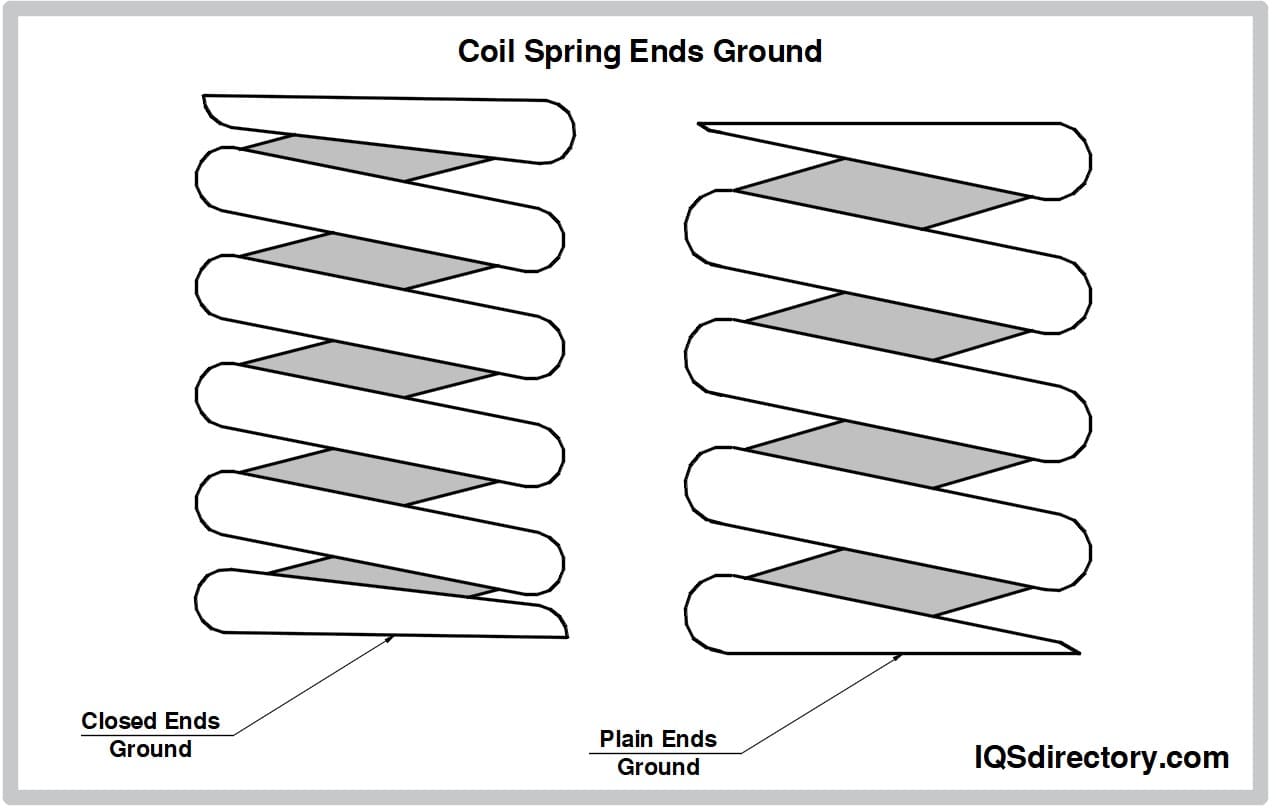

Grinding – End grinding ensures that compression springs or heavy load coil springs have flat, parallel surfaces, allowing stable seating and uniform force distribution in mechanical assemblies. Precise grinding is essential for coil springs in automotive suspensions, valve actuators, and shock absorbers. Lubrication and coolant systems are utilized to maintain dimensional accuracy and prevent thermal warping during high-speed grinding operations.

Well-executed end grinding improves spring fit and functionality, preventing instability and ensuring maximum force transfer. Many OEMs and industrial buyers specify ground ends as a quality requirement for critical spring applications.

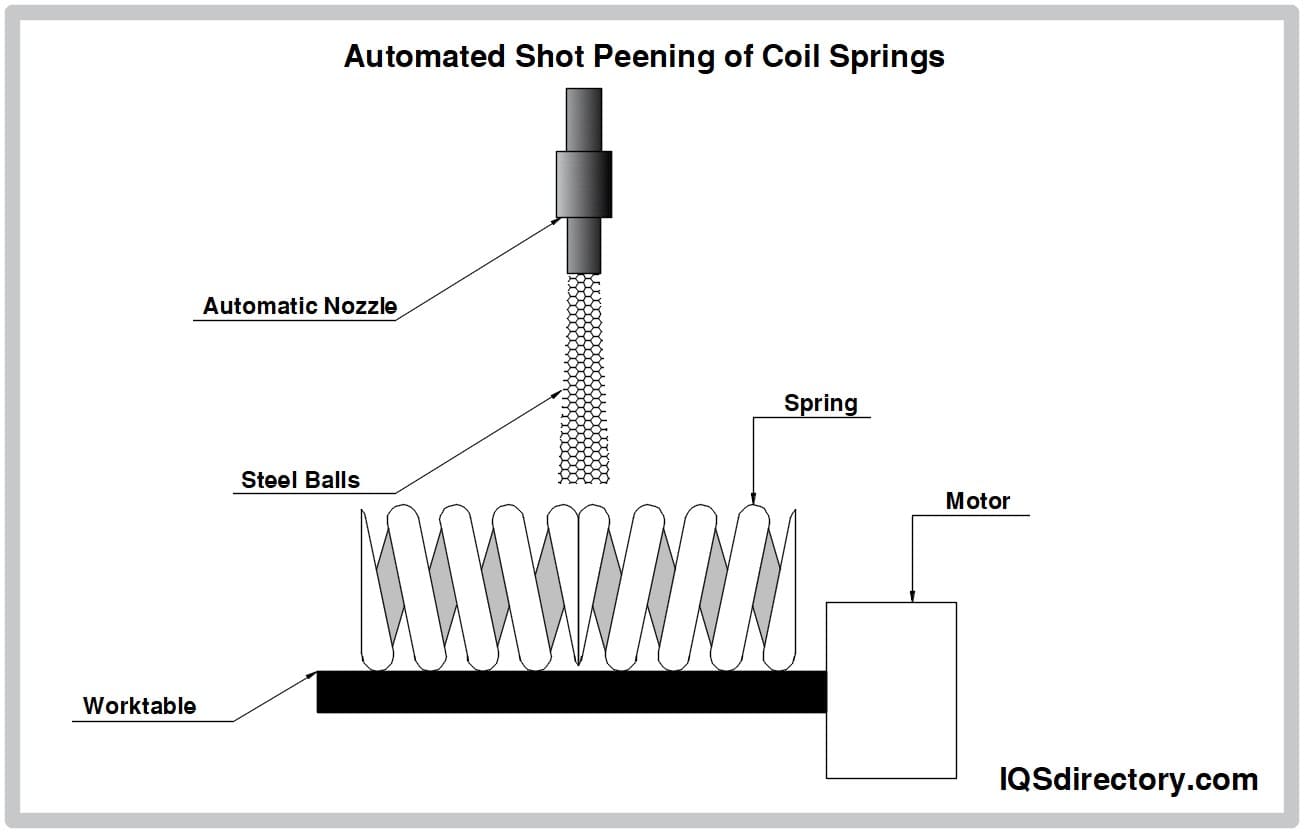

Shot Peening – Shot peening is a high-impact finishing treatment in which spherical media (metal, glass, or ceramic) bombard the coil spring’s surface. This process introduces compressive stresses that greatly improve fatigue strength, resistance to crack propagation, and overall spring longevity—crucial in performance-critical industries such as automotive shock absorbers, industrial automation, and high-cycle machinery.

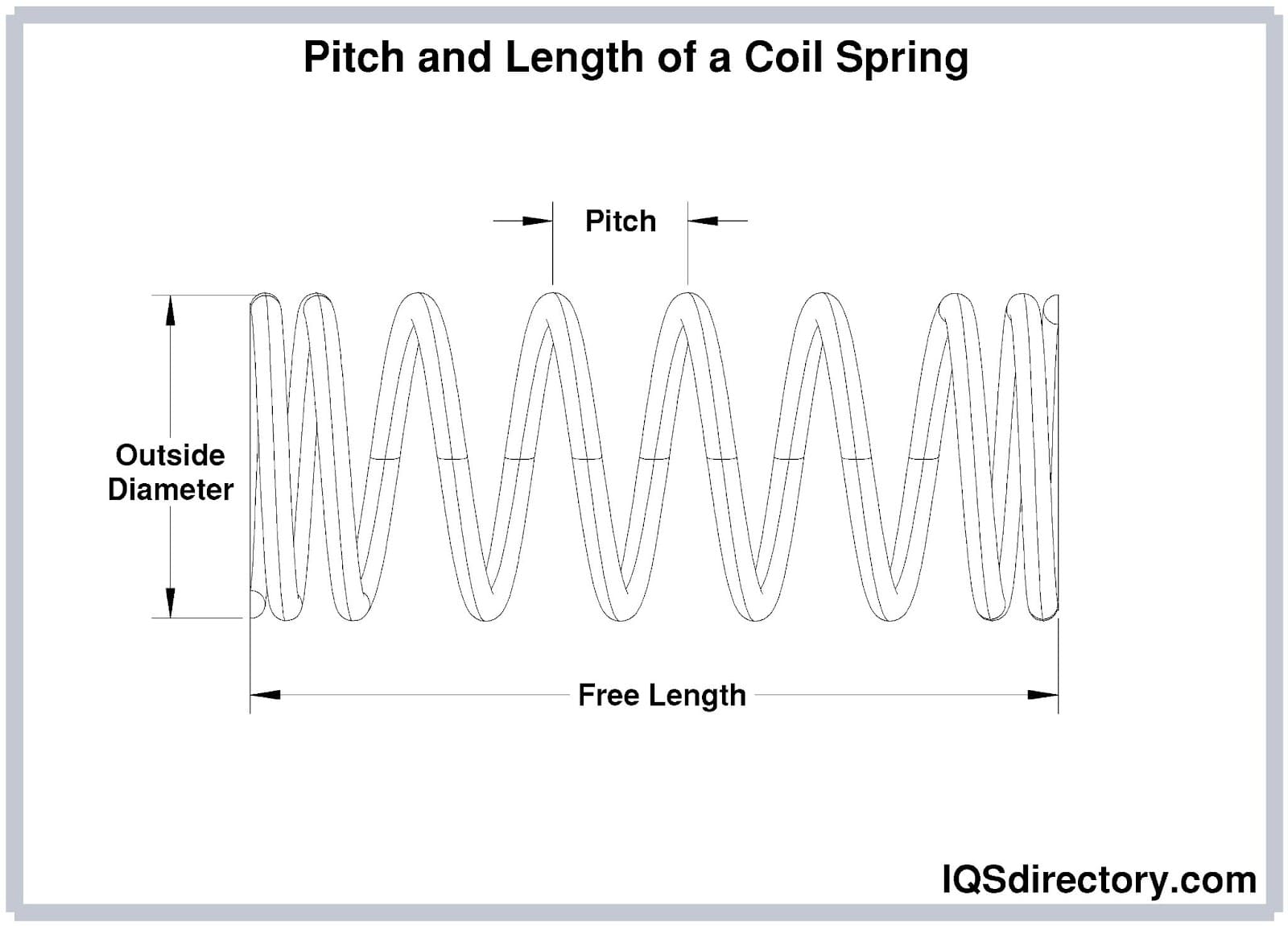

Set Pitch and Length – Custom spring manufacturers often compress and test coil springs to their working length and required pitch, repeating this process to achieve the precise specification demanded by OEM and industrial customers. The spring’s pitch, length, and number of active coils are critical for ensuring engineered load ratings and deflection tolerances. Sophisticated measuring systems and spring testing machines are frequently used to guarantee conformity with design data sheets and application requirements.

Debate exists within the spring manufacturing industry about the most accurate way to characterize spring geometry, with some engineers prioritizing the number of active coils over pitch as a key determinant of spring function in complex assemblies.

Applying Coatings – Applying protective coatings is vital to preventing corrosion, abrasion, and surface fatigue in coil springs, extending their operational lifespan even under exposure to water, chemicals, or salt. The most common coil spring coatings and finishes include:

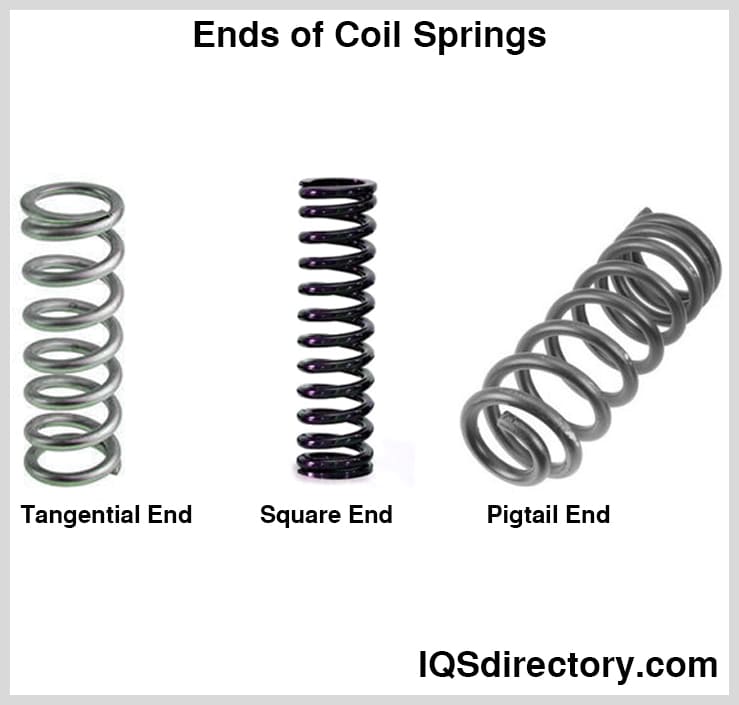

The design of coil spring ends is a critical consideration in spring engineering, as the shape and finish of the spring ends directly impact fit, seating, and performance in the final assembly. Selecting the appropriate end type for a compression or extension spring ensures a secure interface, proper load transfer, and long-term durability. The four most common types are:

The closed end coil spring is the industry standard for stability and even load distribution. The end coil is wound so it sits flat against the adjacent coil, preventing rocking or tilting. Closed end designs are common in automotive coil springs and industrial hardware where precise upright positioning is crucial.

Square end coil springs, a subtype of closed ends, have their terminal coil ground perpendicular to the spring axis, forming a true 90-degree flat interface for maximum stability in perpendicular mounting scenarios. These spring ends are commonly specified for heavy-load or high-precision engineering contexts where maximum deflection and force transfer are required.

Open end coil springs retain their natural pitch to the very tip, forming a “tangential” end. Frequently deployed in situations where the spring is seated in a recessed cup or groove, open end designs are popular in both automotive and mechanical equipment—especially where custom mounting and cost control are important. These springs must be supported by a compatible spring seat to ensure correct operation.

Pigtail coil springs, marked by a terminal coil with a smaller diameter, are engineered for attachment via screws or bolts—common in certain automotive suspension spring designs and industrial machine components. This specialized end allows for direct mechanical fastening, simplifying installation in complex assemblies.

How to Select the Right Coil Spring? When sourcing or specifying coil springs, consider key factors such as load capacity, spring rate, operating environment, fatigue life, installation constraints, and finishing requirements. Collaborate with reputable spring manufacturers who offer engineering support, material traceability, quality testing (including fatigue and load testing), and advanced manufacturing capabilities (manual, CNC, and custom solutions) to achieve the optimal balance of performance, price, and durability for your application.

Whether you are specifying automotive coil springs, industrial compression springs, or custom extension springs, partnering with knowledgeable spring suppliers ensures access to technical consultation, certified materials, and tailored design options that meet regulatory and performance standards.

The initial step in coil spring manufacturing is selecting the appropriate metal for fabrication. A key factor in this selection is the tensile strength of the metal, which must meet the application's load and durability requirements. Most coil springs are made from steel alloys, such as high carbon steel, chrome vanadium, and stainless steel, due to their widespread availability, high performance, and cost-effectiveness. However, copper-based and nickel-based alloys are also utilized in specialized spring designs where properties like corrosion resistance, non-magnetism, or enhanced electrical conductivity are required.

The chosen spring material must be capable of holding and releasing mechanical energy over an extended period without fatigue or failure. High-quality coil springs are engineered for their ability to efficiently exert force between surfaces and to absorb or dampen shock, vibration, and stress, which is vital for optimal performance and extended service life in demanding applications.

High carbon steel is widely used for manufacturing coil springs thanks to its high strength, durability, and economical price point. Industry-standard spring wire grades include 1045 and 1095 alloys, featuring approximately 1% carbon and 0.9% manganese content. The very fine pearlite layer structure of high carbon steel provides excellent hardness and fatigue life, though it results in decreased ductility and increased brittleness.

Music Wire – Also known as piano wire, music wire is regarded as one of the toughest and most reliable materials for spring wire production. This type of high carbon spring steel is known for uniformity, high tensile strength, and remarkable resilience, enabling it to endure repeated load cycles. Music wire springs offer outstanding performance in applications subject to fluctuating or dynamic loads. Their elevated heat resistance makes them ideal for high temperature environments, including foundries and refractory furnaces, as well as general industrial machinery.

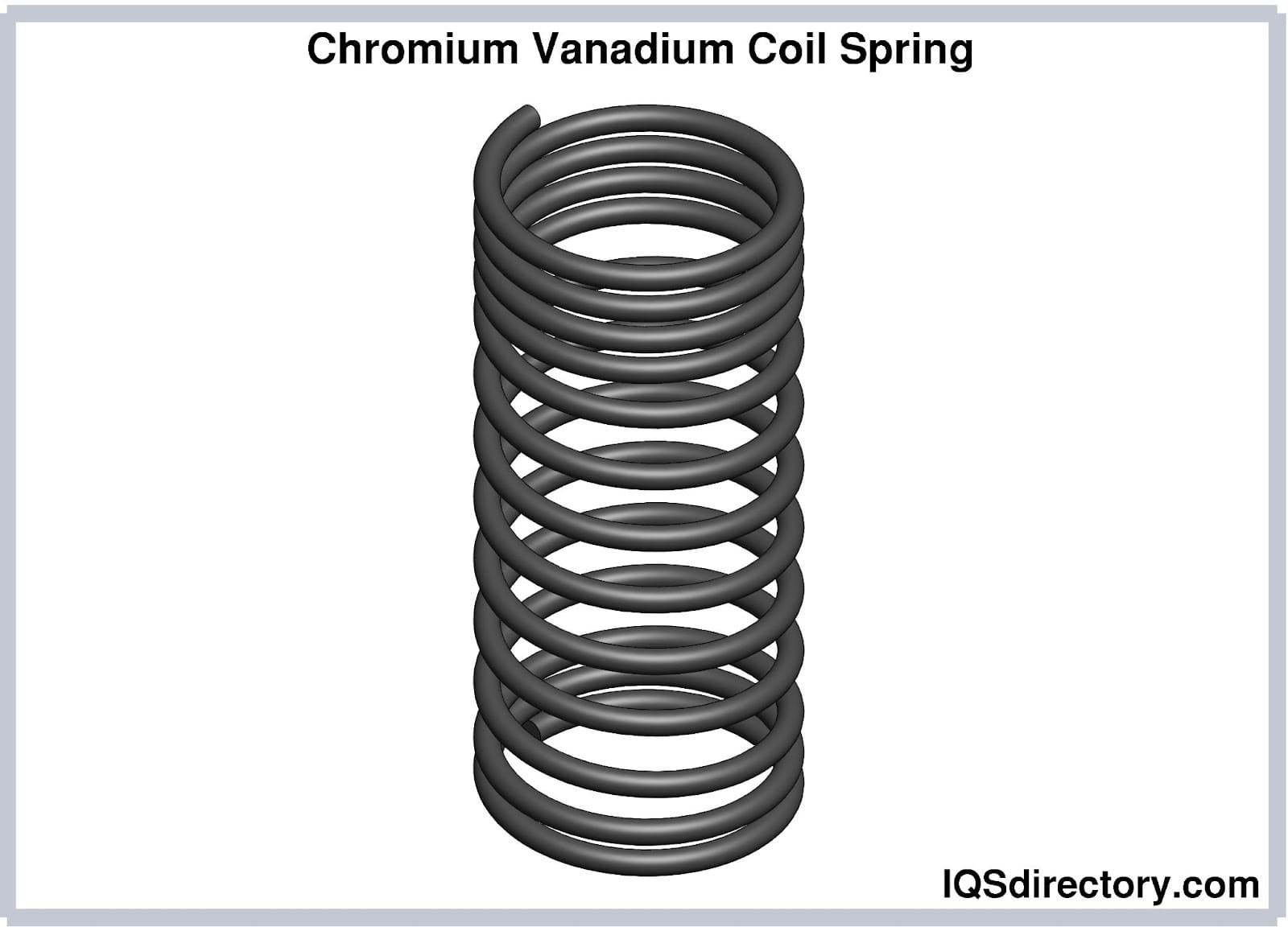

Chromium vanadium steel is renowned in the spring manufacturing industry for its outstanding strength, flexibility, and superior fatigue resistance. The alloy's medium carbon content delivers excellent toughness and wear resistance, essential in heavy-duty spring applications. Addition of vanadium enhances machinability and reduces the risk of crack propagation during wire forming processes. The heat-treatment process further improves its resistance to wear, fatigue, and moderately high temperatures, making chromium vanadium steel ideal for automotive suspension springs, industrial machinery, and high-stress assemblies.

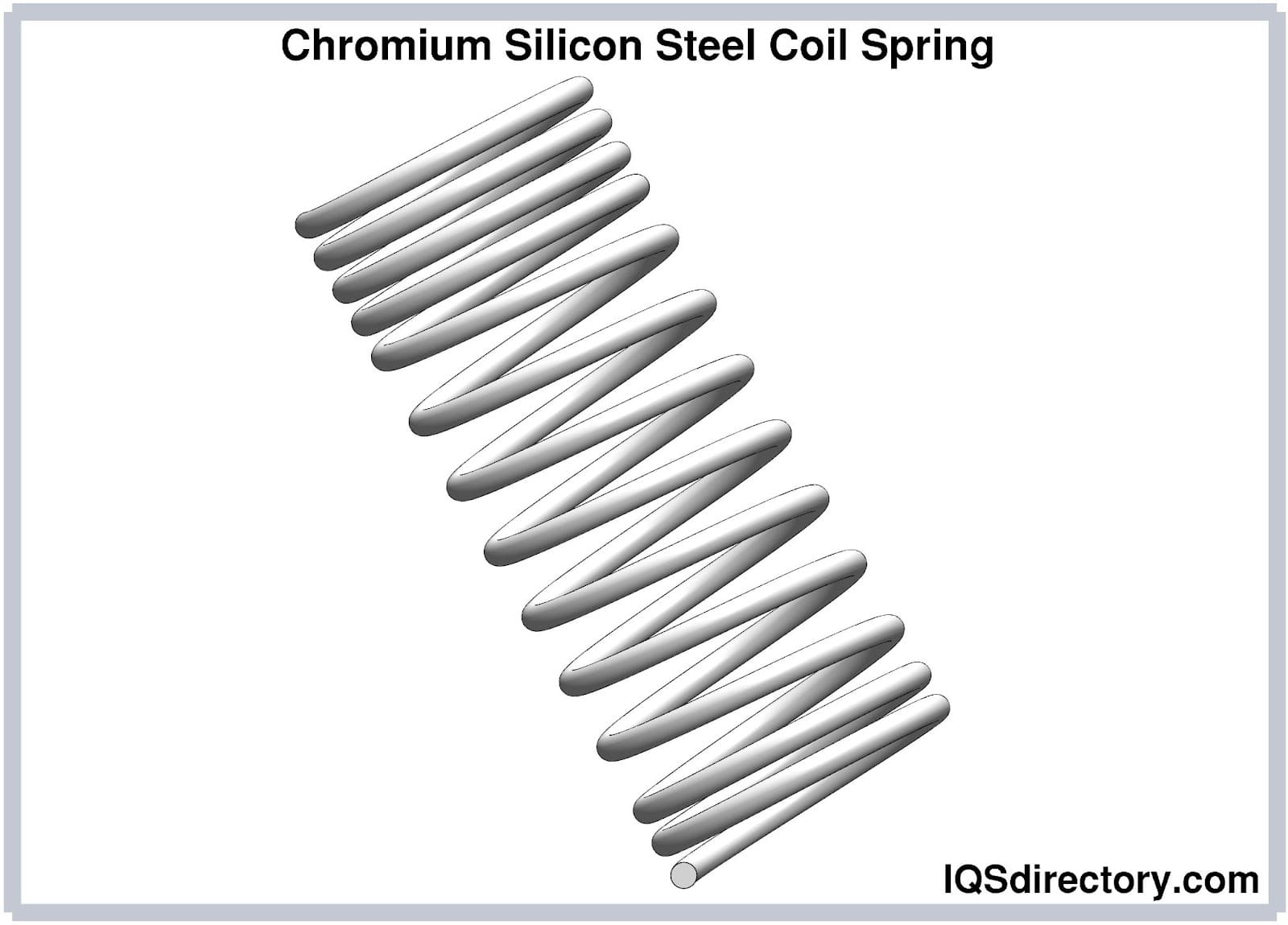

Chromium silicon steel is recognized among spring steel alloys for its exceptional hardness and the capacity to endure high stresses and repeated shock loads. This material provides both high tensile strength and excellent heat resistance, enabling reliable performance in temperatures exceeding 275°F. Originally developed for anti-aircraft weapon springs, its primary characteristics include the ability to handle significant shock, vibration, and operating demands, making it ideal for performance coil springs in transportation, agriculture, and defense industries.

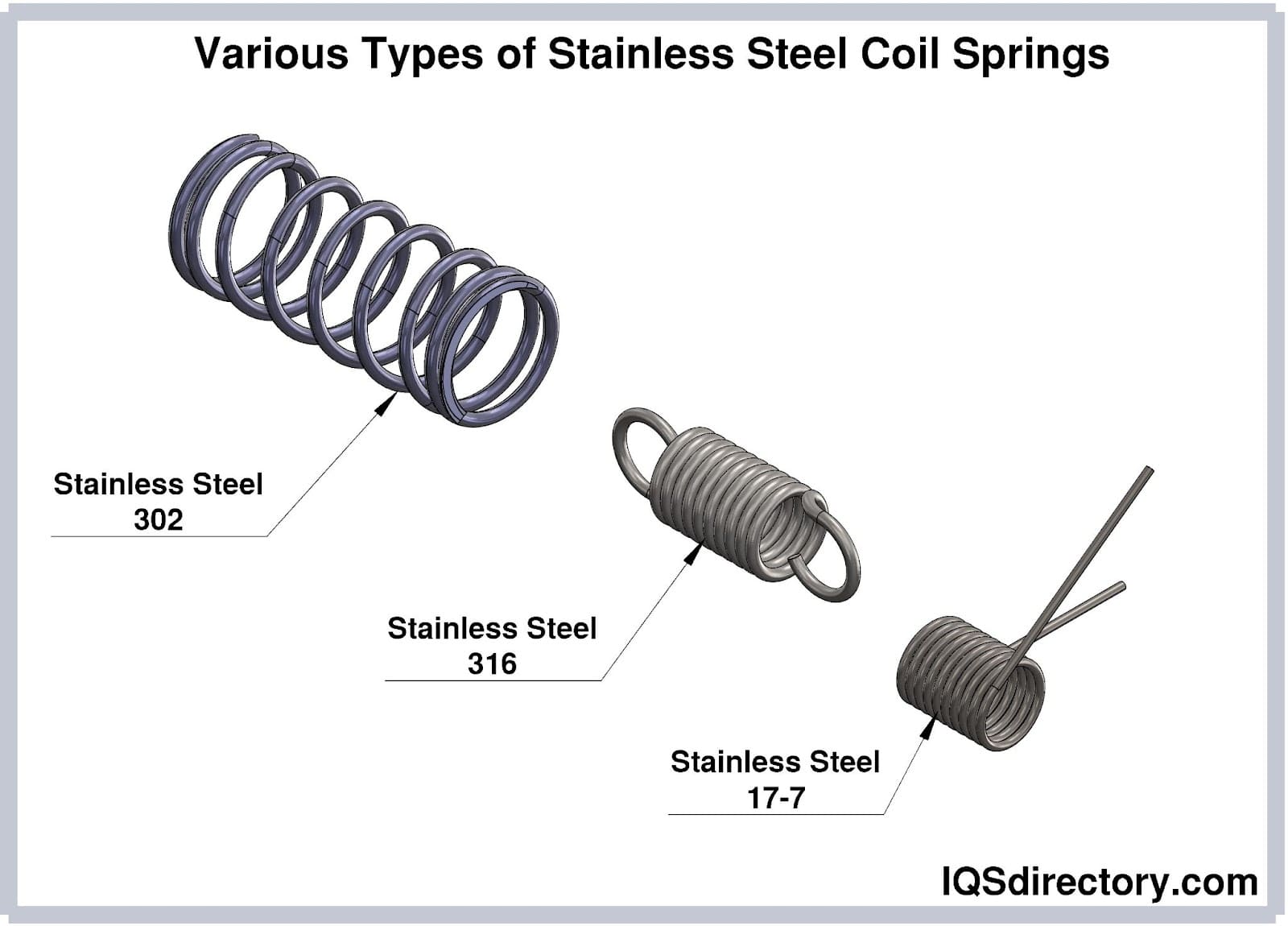

When discussing stainless steel springs, it is critical to specify the grade, as each alloy possesses unique properties and is engineered for specific industrial or environmental requirements.

Stainless Steel 302 is the most widely used stainless steel for coil spring manufacturing owing to its combination of corrosion resistance, toughness, and cost-effectiveness. It performs exceptionally well in environments exposed to moisture, chemicals, or salt air, and can handle working temperatures up to 550°F (228°C). Its flexibility and formability make it suitable for a variety of spring types, including compression springs and extension springs, while maintaining high tensile strength.

Stainless Steel 316 is known for its exceptional corrosion resistance, especially in marine or chemical-processing applications. While it shares similar benefits with 302, it is considered the least strong of the three main stainless spring grades, but offers superior resistance to pitting and crevice corrosion, which is critical for harsh operating conditions.

Stainless Steel 17-7 alloy provides the highest strength and hardness out of the three main grades, as well as excellent resistance to moisture and corrosion. Its increased stiffness and the ability to maintain force under load make it ideal for heavy-duty applications such as aerospace, defense, and industrial valve springs. Stainless Steel 17-7 maintains integrity up to working temperatures of 650°F (343°C).

Silicon manganese steel is favored in the automotive, rail, and heavy-duty equipment industries for its superior hardness, fatigue resistance, and toughness under extreme load conditions. This alloy manages steel decomposition during tempering, strengthens the ferrite matrix, and increases resilience due to the combined effects of silicon and manganese. Coil springs formed from silicon manganese steel are typically hot-forged at 900°C (1652°F) to reach optimal hardness (225 BHN), and are widely used in torsion bars, railway car suspensions, leaf springs, and automotive stabilizers.

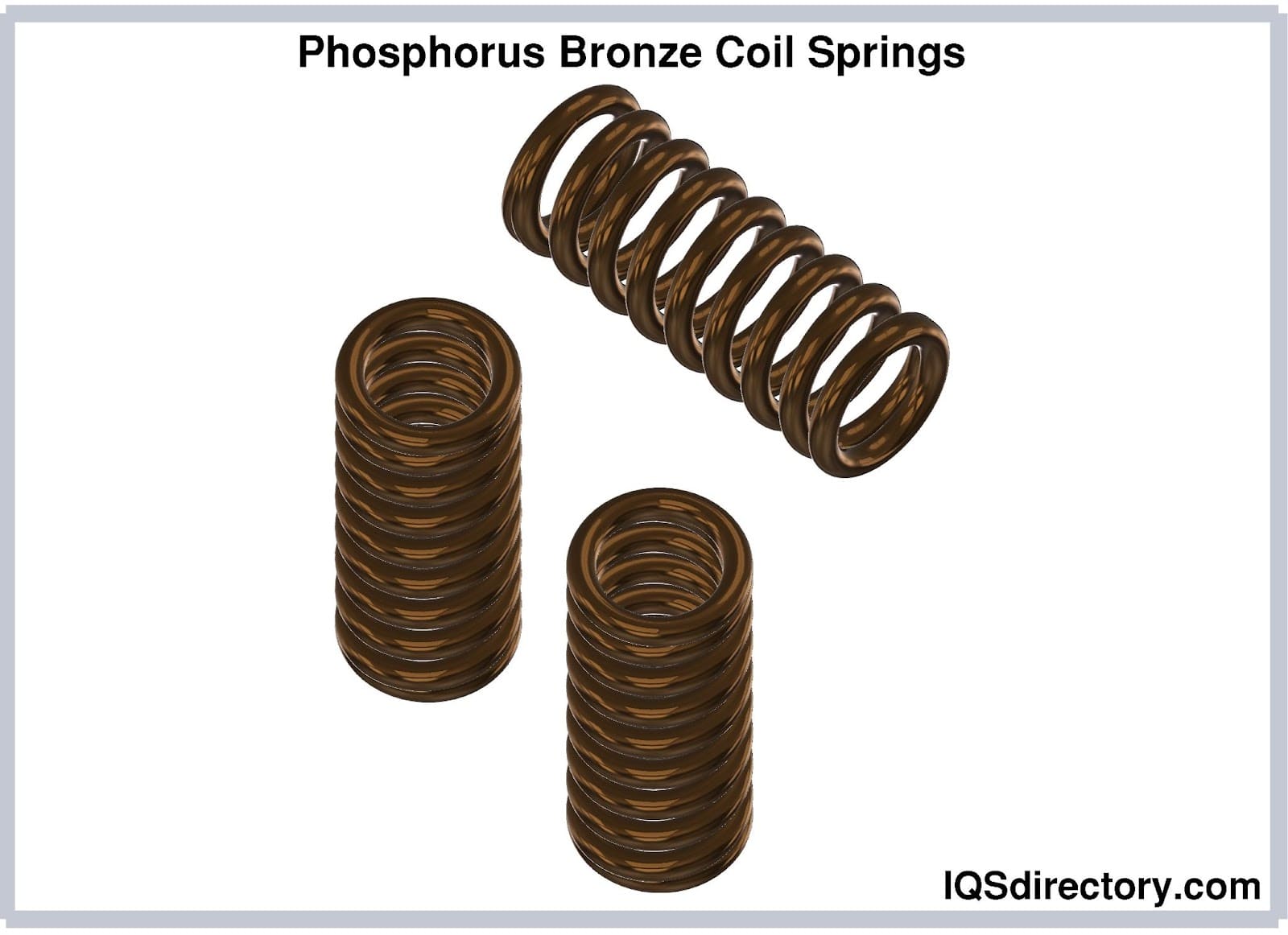

Copper-based spring alloys are prized in electrical engineering, marine, and cryogenic applications for their exceptional electrical conductivity, thermal conductivity, and superior corrosion resistance. While generally more expensive than steel alloys, their value lies in environments requiring enhanced performance, non-magnetic properties, or excellent fatigue resistance at low or fluctuating temperatures.

Beryllium Copper exhibits a rare combination of properties, including high electrical and thermal conductivity, marine-grade corrosion resistance, and exceptional mechanical integrity. With excellent fatigue and stress relaxation resistance, this non-magnetic alloy finds uses in medical devices, MRI components, oil and gas drilling equipment, aerospace, and electronics. Its ability to retain ductility and strength in cryogenic and high-pressure environments sets it apart from other copper-based alloys.

Phosphorus Bronze, an alloy of copper, tin, and phosphorus, is valued for its superior corrosion resistance—especially in marine atmospheres—and increased hardness and spring stiffness. Its ability to withstand repeated flexing and its excellent machinability make it ideal for marine fuel pumps, oil rig valves, and precision instrumentation. The addition of tin imparts strength, while phosphorus increases wear resistance, ensuring longevity in mission-critical spring components.

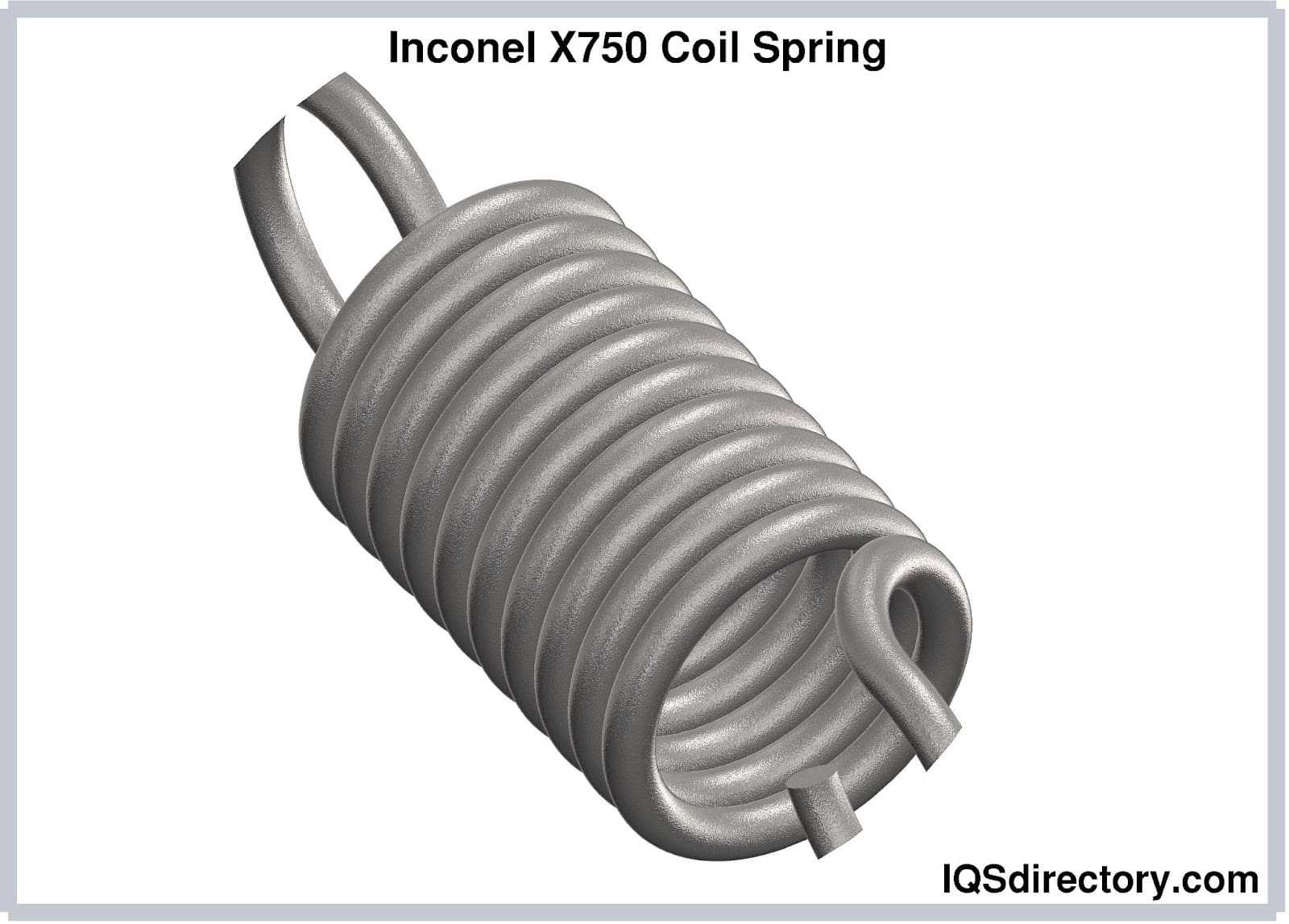

Nickel-based alloys are an industry standard for high-performance coil springs requiring superior corrosion resistance, temperature endurance, and non-magnetic properties. These specialty alloys maintain mechanical properties at extremities—whether exposed to sub-zero cryogenics or elevated heat—making them essential for aerospace, petrochemical, and instrumentation applications. Nickel-based springs are also chosen for environments where resistance to electrical interference and stability in aggressive chemical settings are critical.

Common nickel-based spring alloys include:

Inconel X750 is a nickel-chromium alloy prized for its prolonged high-strength integrity at temperatures up to 1300°F (704°C) and excellent oxidation resistance at even higher temperatures (up to 1800°F/982°C). Its distinctive relaxation resistance means Inconel X750 springs maintain their mechanical properties under sustained thermal or fluctuating loads, making them ideal for turbine engines, exhaust systems, and industrial furnaces.

Inconel 600 is a nickel-chromium-iron alloy renowned for its exceptional resistance to oxidative and reductive corrosion environments. High nickel content imparts remarkable stability against chloride-induced stress cracking and prevents embrittlement at sub-zero temperatures (as low as –300°F). Capable of withstanding both organic and inorganic chemical exposure, Inconel 600 is favored in chemical processing, nuclear plants, and environments requiring a tensile strength of 220 Ksi, where springs are cold-worked for improved elasticity and load bearing.

Inconel 625 combines nickel, chromium, molybdenum, and niobium, endowing the alloy with unparalleled corrosion and oxidation resistance even at elevated operating temperatures. Its strength results from the synergistic effects of molybdenum and niobium. Coil springs crafted from Inconel 625 excel in aggressive marine, seawater, and aerospace environments where performance, reliability, and longevity are non-negotiable.

Inconel 718 is a high-strength, precipitation-hardened nickel alloy designed for service in extreme condition environments. Its high fatigue strength, outstanding creep resistance, and rupture properties make it a go-to option for heavy-duty industrial, aerospace, and oilfield spring applications where both high and low temperature performance is vital.

The metals listed above represent some of the most commonly used materials in modern coil spring design and fabrication. However, ongoing research and engineering in spring technology has led to the consideration of alternative metals and advanced alloys, such as lightweight aluminum and titanium, particularly in industries where weight reduction and custom spring characteristics are demanded. Selecting the right coil spring metal is essential for achieving the optimal balance of strength, flexibility, corrosion resistance, and cost-effectiveness for your unique application.

Key factors to consider when choosing a spring alloy include expected service environment, operating temperature, required mechanical strength, and any regulatory or industry-specific material standards. By working with experienced spring manufacturers and engineers, you can tailor your custom spring solutions to best fit your operational needs, ensuring reliability and long-term performance.

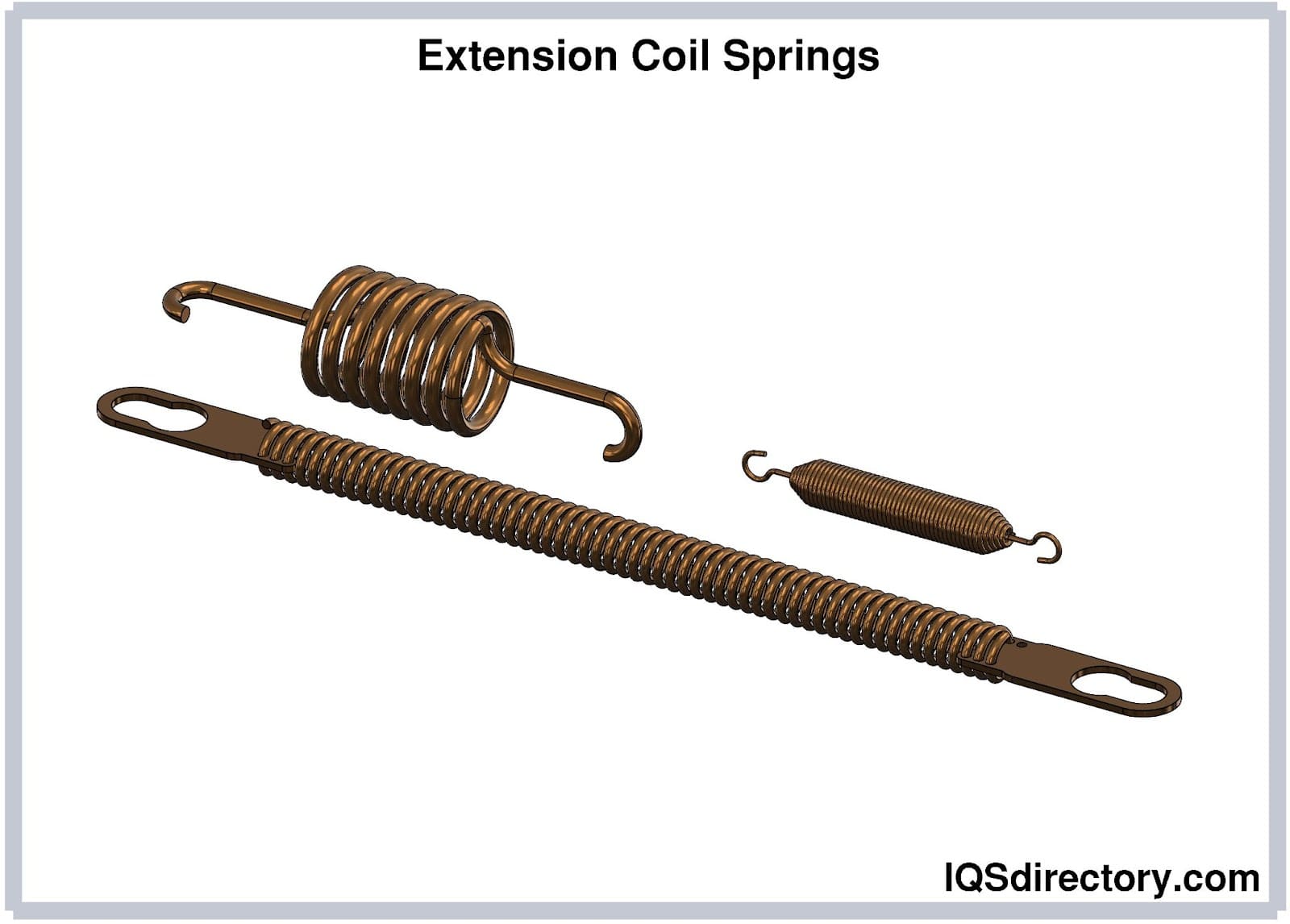

The main types of coil springs are compression, extension, and torsion. Compression springs absorb force and resist compression, extension springs stretch under load, and torsion springs store rotational energy. Compression springs are the most commonly used.

Coil springs are made by winding steel wire into a helix, using either cold winding for thinner wires or hot winding for thick wires. Key steps include heat treatment, coiling, stress relief, grinding, and applying protective coatings for durability.

Common coil spring metals are high carbon steel, chromium vanadium steel, chromium silicon steel, stainless steels (302, 316, 17-7), silicon manganese steel, copper alloys (beryllium copper, phosphorus bronze), and nickel-based alloys like Inconel for specialized requirements.

Finishing treatments like grinding, shot peening, zinc coating, electroplating, powder coating, and using pre-plated wire increase corrosion resistance, fatigue life, and performance. These treatments help springs withstand harsh environments and heavy use.

Select coil springs based on load capacity, spring rate, operating environment, fatigue life, space constraints, and finishing requirements. Consult with manufacturers for engineering support and to meet specific regulatory or performance standards.

Yes, stainless steel coil springs—especially grades 302 and 316—are ideal for marine and food processing environments due to their high corrosion resistance, durability, and compliance with hygiene and endurance requirements.

Springs are classified into coil and non-coil types based on their design. Coil springs have a helical shape and are made from a single metal strand wound into a coil. The typical manufacturing process involves wrapping or winding the spring material around an arbor and coiling point.

Different types of coil springs have distinct characteristics that set them apart. Generally, coil springs are engineered to withstand various types of stress, such as compression or extension.

Volute springs are created from flat material coiled around an arbor to form a spiral scroll shape, known as a volute. These springs often resemble a tube with a smaller end, and some designs feature small ends at both extremities. After coiling, the material sheets are heated, which affects the spring's gap, shape, dimensions, and load characteristics. During compression, the overlapping flat sheets guide each other radially, enhancing the stability of the volute spring.

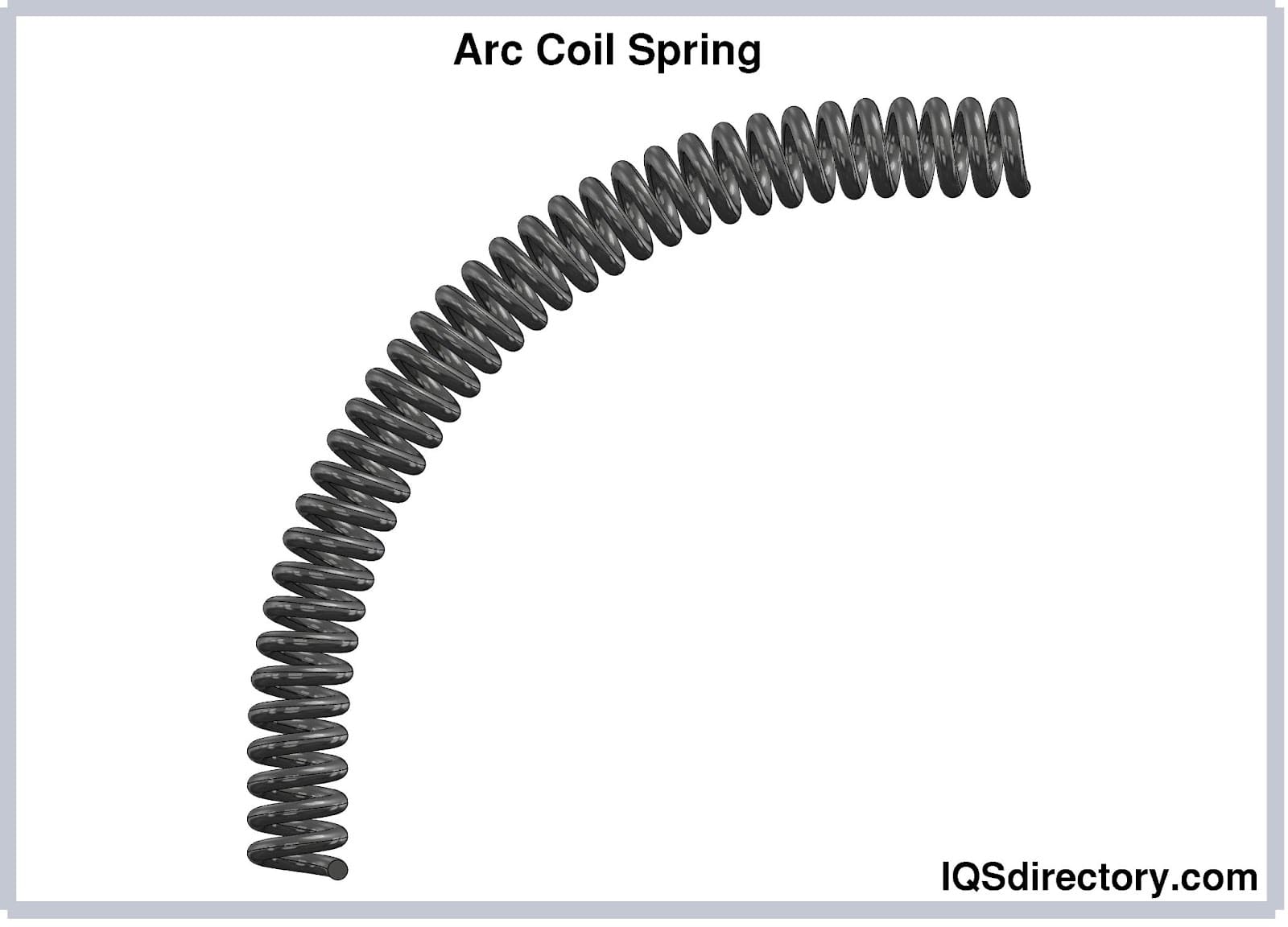

Arc coil springs, or bow springs, feature a curved shape resembling the arch of a bow. Unlike traditional springs that run straight from end to end, these springs have a central curve. Initially designed for use in dual mass flywheels within drive trains, arc coil springs apply force from both ends to bring objects closer together.

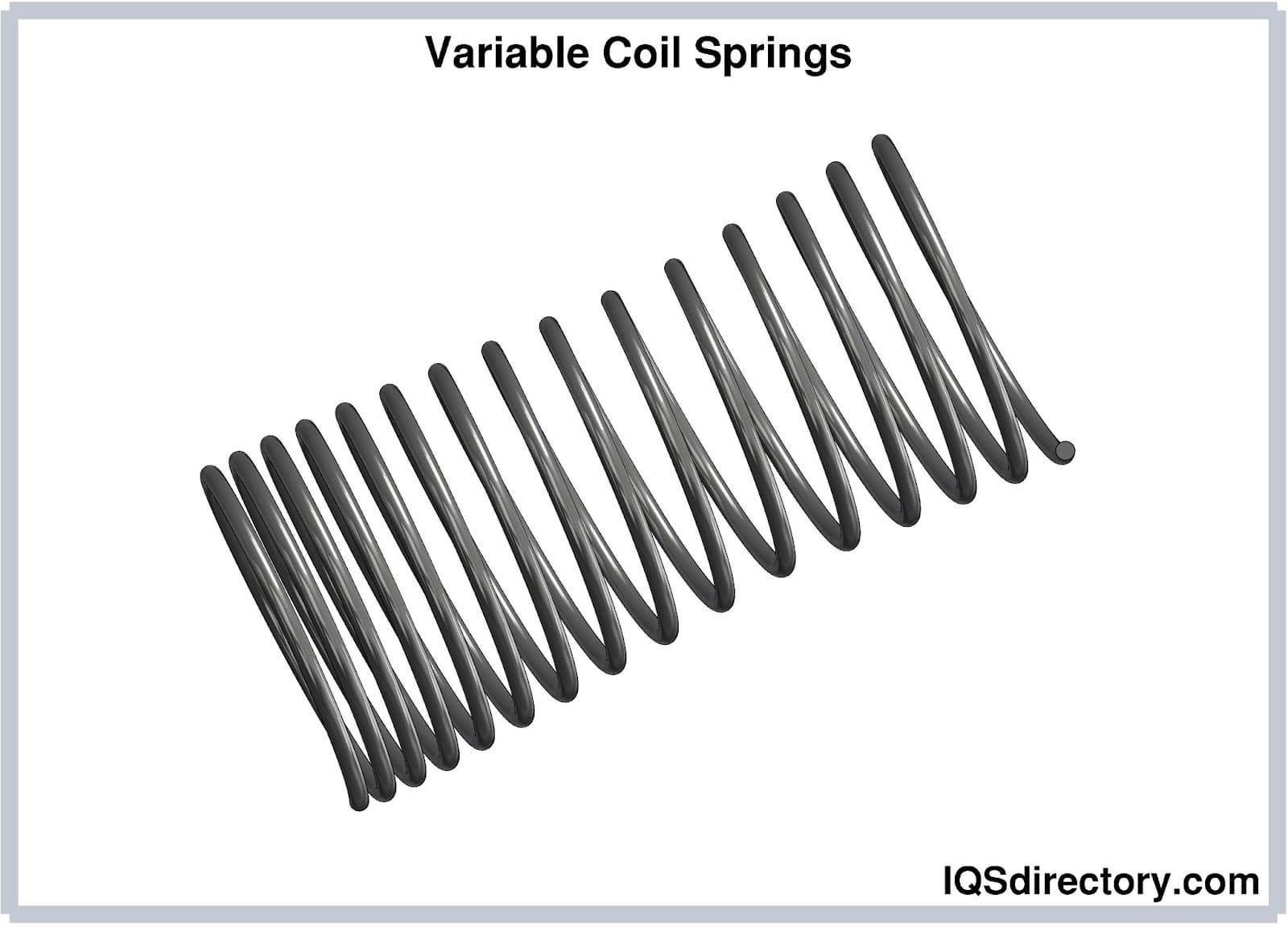

Variable coil springs feature varying distances between their turns, which affects how the spring compresses at different points. As the spring is compressed, the energy required changes with each turn, often following an exponential curve. This design enhances performance in several areas, including easier unlocking, better recoil energy storage, improved dampening, and more effective feeding, breaching, and lockup.

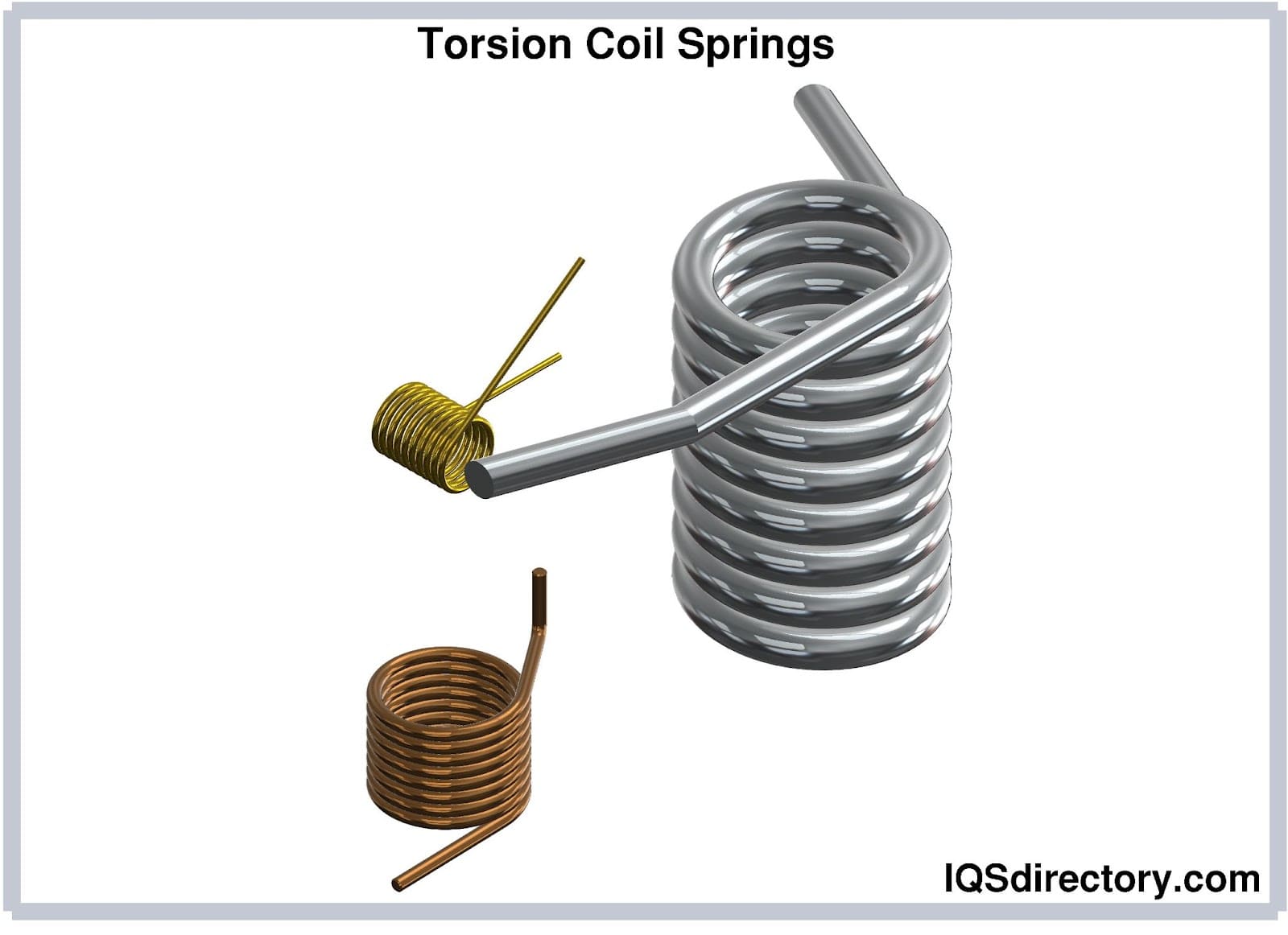

Torsion coil springs are a flat spiral coil that is used to apply torque or store rotational energy. They store and release rotational energy via torque, which causes the spring to rotate on its axis to apply or resist a load. Torsion springs are attached to components that will rotate around their axis. In most cases, they are very tightly wound but also have versions that have pitch to reduce friction between the coils.

Torsion springs, like many other springs, can be oriented at various angles, either horizontally or vertically, and can rotate along or against their axis. When a torsion spring rotates, its coil tightens to either store or release energy. They are commonly used in applications such as mouse traps and self-closing screen doors.

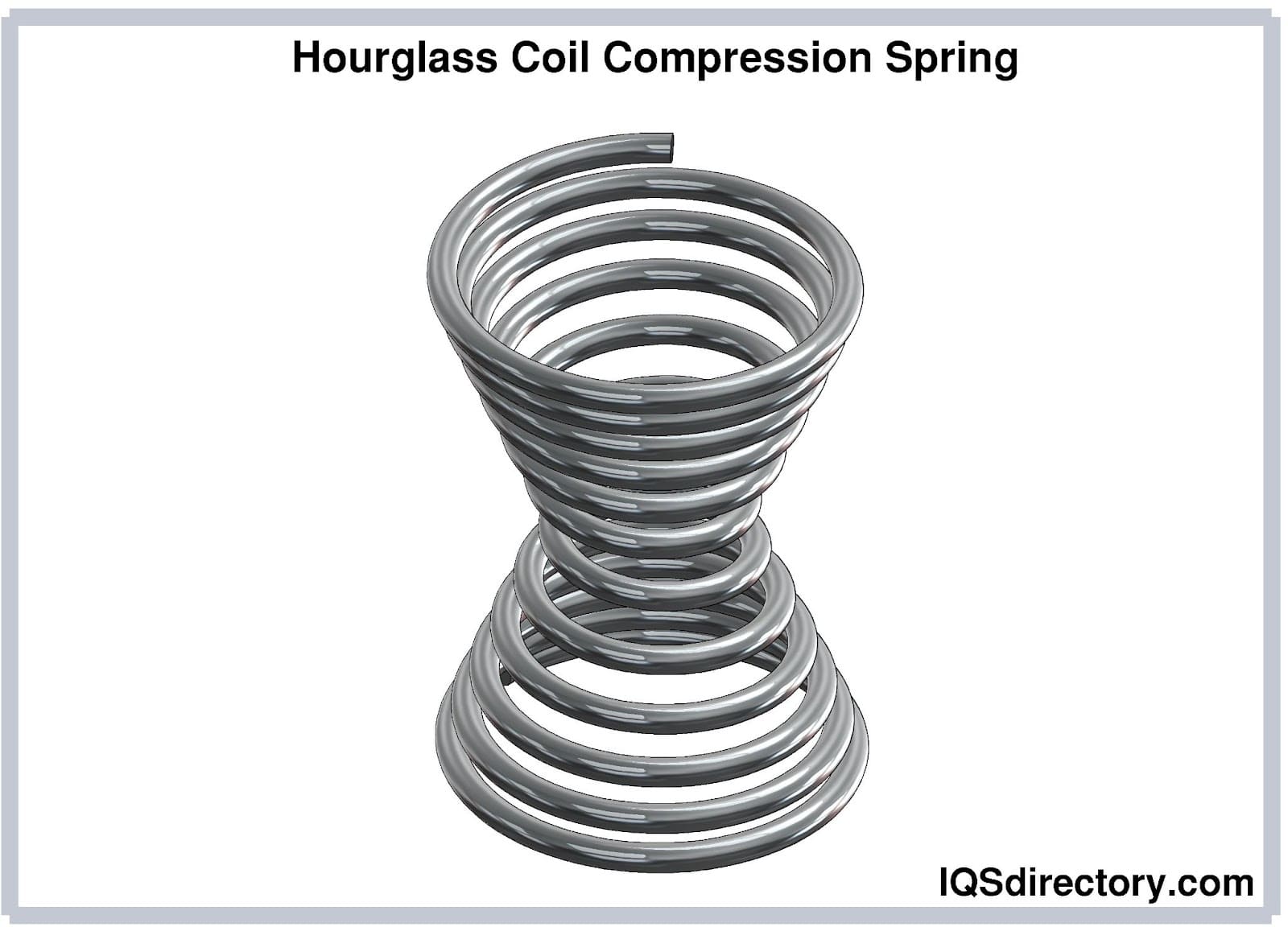

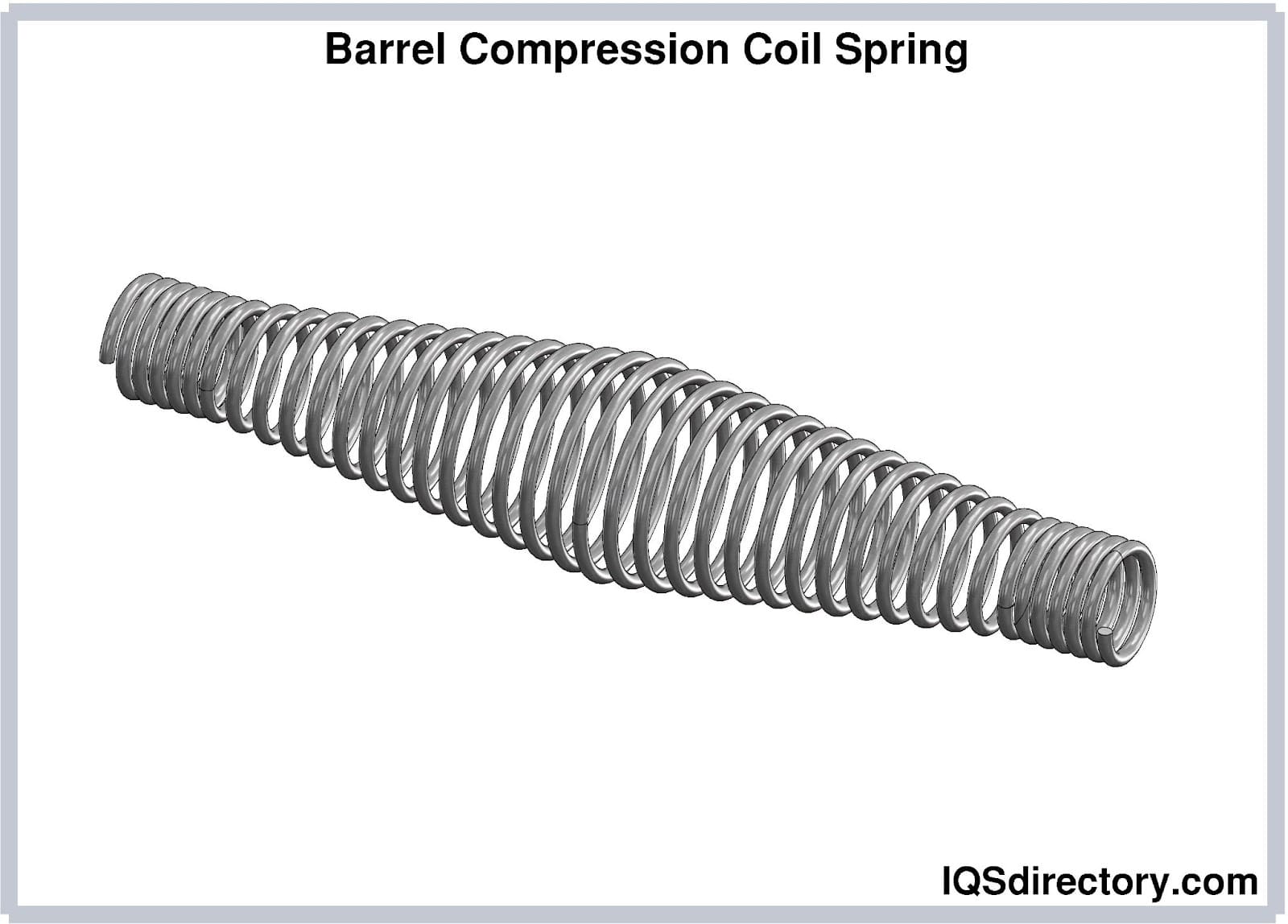

Compression coil springs are designed with a helical shape to resist forces applied along their axis. They are highly versatile and come in various sizes, ranging from those used in retractable pens to those found in automobile suspension systems. Compression springs come in different forms, including helical, conical, volute, barrel, and hourglass types.

Straight Coil compression springs feature coils that maintain a consistent diameter throughout their length. This type is the most commonly used compression spring.

Hourglass compression springs feature a tapered middle that narrows to a smaller diameter compared to the rest of the coils. This design ensures that the spring remains centered within a larger diameter hole. Hourglass springs combine some benefits of conical springs while offering symmetrical characteristics.

Barrel compression springs feature smaller diameters at the ends and a larger diameter in the middle. This design addresses a common issue with standard compression springs, which can buckle or bow under pressure. The barrel shape enhances flexibility, allows the spring to fit various designs, and distributes pressure more evenly due to its wider middle section, resulting in improved stability.

Extension springs are like compression springs but are tightly wound and loaded with tension. They have hooks or loops at either end to apply pull force. Extension springs are attached at both ends to components. When the components move apart, the extension spring attempts to bring them back together. The initial tension in the spring determines how tightly coiled it is and can be changed to meet the needs of an application. The tight winding of extension springs is designed to oppose extension. In essence, they provide return force for components that have extended to the actuated position.

Coil springs are extensively utilized in a vast range of components, machines, devices, instruments, and vehicles. They play a crucial role in medical equipment, automobiles, heavy lifting machinery, and small delicate tools. Their capacity to store and release energy is essential for supporting and ensuring the efficient operation of these applications.

In trucks and cars, coil springs are a vital component of the suspension system, working in conjunction with struts and shocks. They absorb road impacts, support the vehicle’s weight, ensure a smooth ride, and maintain wheel contact with the road. In smaller applications, coil springs hold the hood open and regulate engine valve movement. Additionally, they contribute to the comfort of car seats.

Coil springs are extensively used in doors to facilitate opening and closing mechanisms. In garage doors, they are crucial for bearing the door's weight and keeping it in place until it is manually moved or closed. The design of coil springs for doors is tailored to the weight and size of the door to ensure reliability and prevent failure. For automatic doors, coil springs apply resistance to keep the doors closed but release their tension when the opening sensor is triggered.

Coil springs play a crucial role in construction projects, from anchoring new constructions to reinforcing existing foundations. They provide essential support for sidewalks, managing movement and motion. Additionally, coil springs are integral to safety release valves, facilitating the opening and closing of pipelines and pressure release systems. They also support railroad cars and engines, and are used in bridges and overpasses. In environments prone to vibrations or motion, coil springs function as dampeners and sound-absorbing devices to protect and enhance the durability of applications.

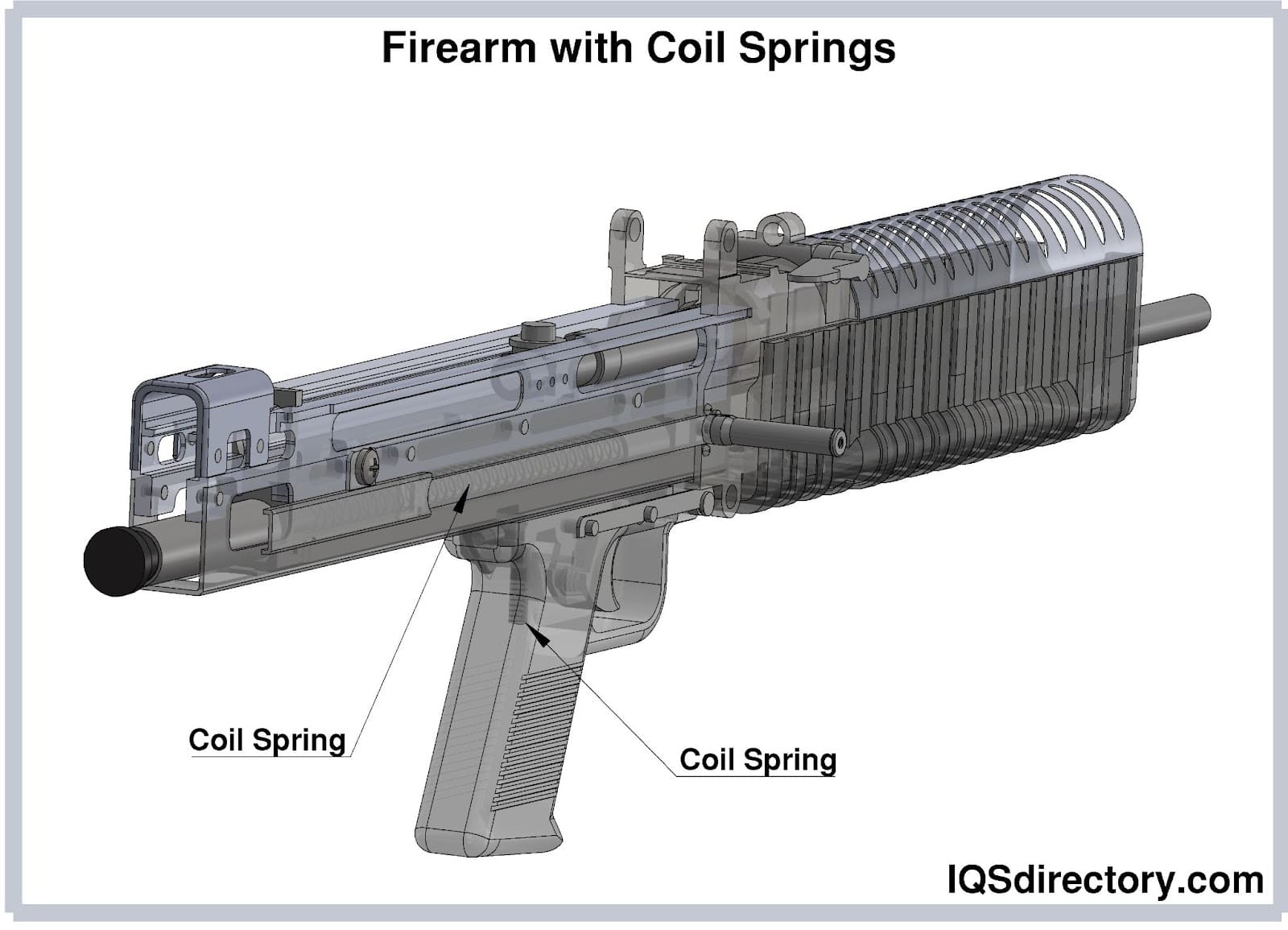

Coil springs are essential components in firearms, found in magazine springs, trigger springs, and recoil springs. In detonators, they are compressed and held in a flattened state until activation. Their reliability and durability make them suitable for the constant use demanded by loaded weapons.

The average home contains a multitude of coil springs in nearly every room. They are found in mattresses, chairs, and couches to provide support and absorb impact. Modern children’s toys use springs to activate their functions and keep them operational. Coil springs are also crucial in switches, garage door openers, cabinets, appliances, and countless other applications. In many ways, homes rely heavily on coil springs for smooth and effortless living.

Compression coil springs are employed to extend and retract the ballpoint of a pen. These springs need to be elastic enough to compress to a solid height. For proper functionality, the spring must have a suitable index and an adequate number of coils relative to its free length and wire diameter. Generally, a larger diameter and more coils result in a lighter spring.

Coil springs called compression springs can store mechanical energy when they are compressed. These open-coiled, helical springs provide resistance to compressive loading. When these springs are...

Extension springs are helical wound springs that are so closely coiled together to create initial tension in the coils. This initial tension creates resistance against the force applied to its ends for extension. The initial tension helps determine how closely and...

Springs are a flexible machine element that store mechanical energy when subjected to tensile, compressive, bending, or torsional forces. When the spring is deflected, it stores energy and at the same time exerts an opposing force...

A torsion spring is a mechanical device that stores and releases rotational energy. Each end of the torsion spring is connected to a mechanical component. As the spring is rotated around its axis on one end, the winding of the spring is tightened and stores potential energy...

Wire mesh is fabricated by the intertwining, weaving, or welding of wires of various thicknesses to create proportionally equal parallel rows and intersecting columns. Also known as wire fabric, wire cloth, or...

Contract manufacturing is a business model in which a company hires a contract manufacturer to produce its products or components of its products. It is a strategic action widely adopted by companies to save extensive resources and...

Hardware cloth is a woven mesh made by interlacing various sizes of wire to form a metal fabric that can be used for animal cages, fence material, strainers, and filtering screens. The differences between the various types of hardware cloth...

The phrase "wire mesh" describes two- or three-dimensional structures constructed of two or more metallic wires connected by various techniques. In a wide range of settings, wire mesh products are...

Welded wire mesh is a series of wires that are welded where the individual wires cross. The openings of the mesh varies depending on the type of wire used and the function of the mesh. Regardless of size and wire, welded wire mesh is permanent and...

Wire baskets are made from a series of wires that are woven together or welded to form a shape of a basket. They can also be defined as containers that are made by use of an openwork pattern of metal...

Wire cloth is a woven (or nonwoven) sheet or web material with a series of openings across the surface. Wire cloth is also known as: Metal Fabric or Metal Cloth; Wire Mesh, Metal Mesh, or Alloy Mesh...

Wire shaping is a complex method that encompasses a wide range of dimensions, forms, and textures. The technique of creating a usable product by wire bending and shaping is known as custom wire forms...

Wire forming is a method for applying force to change the contour of wire by bending, swaging, piercing, chamfering, shearing, or other techniques. The various techniques for wire forming can produce any type of shape, form, or configuration...

A wire handle is attached to a bucket, pail, or other type of container to make it easy to lift the container and transport it. They are made of durable and sturdy metals capable of lifting several pounds...

A wire rack is a level wire form utilized to stock and exhibit a number of products, usually retail. The bottom surface on which such goods are stored is made of several latticed or interlaced metal strands...