Pressure Gauges

Pressure gauges, alternatively spelled as pressure gages, are instruments used to measure and display the pressure of a gas or liquid inside a closed system or vessel. They are capable of working with various liquids and gases.

Quick links to Pressure Gauges Information

Pressure Gauge Applications

Pressure gauges monitor and indicate the internal pressure of vessels or systems, especially those having dynamic working characteristics that require constant monitoring. They are essential to applications in which the accurate functioning of a pressure vessel or system directly depends on the accuracy of the gauge reading.

Pressure gauges are utilized in a wide variety of industrial systems and products, including: specialty tanks (such as fire extinguishers and medical gas cylinders), high purity semiconductor gas and liquid products, tire pressure gauging, pressure canners, pesticide sprayers and nitrous systems (on nitrous bottles or solenoids).

The History of Pressure Gauges

- Pressure Gauges in the 17th Century

- The history of pressure measurement goes back to the 17th century, with the invention of the barometer. Barometers measure atmospheric pressure. The barometer was invented in the mid-1600s. There is some dispute over who actually invented it, but historians generally give the credit to Evangelista Torricelli, and cite the year of invention as 1643. Torricelli got the idea from his friend, the great Galileo Galilei, who had proposed that water held up in a siphon was being held up by a vacuum. Then, in 1648, Blaise Pascal, a French physicist, used Torricelli’s barometer to demonstrate that air pressure drops at the top of mountains.

- In 1654, a German scientist named Otto von Guericke invented a vacuum pump. He used it to discover and demonstrate the power of air pressure. That same year, he very famously conducted the Magdeburg hemisphere demonstration. During this demonstration, two teams of horses, each consisting of fifteen horses, attempted to pull apart two copper hemispheres joined by the combination of air pressure from the atmosphere. (Before joining them, Guericke had removed the air from them via his pump.) The horses could not make them budge until Guericke neutralized the air pressure.

- In 1662, Anglo-Irish physicist and chemist Robert Boyle published what became known as "Boyle’s Law." It details the relationship between pressure and volume. He confirmed his belief in this relationship via compression and decompression experiments.

- Pressure Gauges in the 1800s

- In 1802, Joseph Louis Gay-Lussac presented Gay-Lussac’s law, which stated that if the mass and volume of a gas are held at a constant, then the gas pressure will increase linearly as temperature increases.

- Between 1849 and 1850, French watchmaker and engineer Eugene Bourdon invented what is now known as the Bourdon tube gauge. His invention revolutionized the pressure sensing world because it could measure the atmospheric pressure of hundreds of different environments. One of the environment operators most commonly used to measure it was that of a steam generator. This gauge, which uses a curved tube as a sensing element, is still quite popular today. Early pressure gauges assisted locomotive operators and machine workers, especially those working around boilers, to be more safe. This is because machines like boilers were so powerful that they exploded, so much so that they caused many horrific deaths. Pressure gauges gave operators an idea of when they were in the danger zone, so they could make adjustments or at least get clear of the machine. In 1893, French physicist Émile Hilaire Amagat (EH Amagat) conducted pressure measurements using dead-weight pistons. Dead-weight pistons in the 1890s were being developed at this time to make calibration pressure gauges.

- Pressure Gauges in the 20th Century

- In the 20th century, scientists and engineers made a number of advances that went along with the technological advances of the day. In 1930, for example, engineers came up with the first electrically-powered gauge products. Also, starting in about 1950, manufacturers began making pressure gauge cases out of stronger materials like plastic or stainless steel.

- Today, because of their widespread usage and critical performance, pressure gauges are continually being improved. As the boundaries of what science and innovation can accomplish continue to be expanded, the abilities of gauges must improve as well. Gauges are becoming more precise and accurate, able to display more specific readings with smaller margins of error. In analogue gauges, the dials themselves are more detailed and often have multiple sets of units displayed on the face. The technology inside the gauges has improved, too. For hydrostatic gauges, different liquids are being tested to determine which most accurately reflects pressure changes. Aneroid gauges use different membrane materials that are more sensitive than previous versions in order to detect even small pressure differences.

Pressure Gauge Design

Pressure gauges vary in style, size and material, depending on the application. Display types include graphical and video displays, digital readouts or analog meters and needles. Pressure gauges can also be equipped with electric contacts to turn on signal lights, sound alarms or operate a pump or valve.

Pressure Gauge Materials

The materials used to make pressure gauges must be strong and durable, and able to stand up to tough environments. The material that manufacturers use most commonly is stainless steel. Stainless steel is perfect for corrosion resistant units, units that require high pressure cleaning and gauges to be used where chemicals or harsh substances need to be looked after and monitored. Also, gauges made of stainless steel can be used in applications that have strict sanitary requirements (sanitary pressure gauges).

Pressure Gauge Images, Diagrams and Visual Concepts

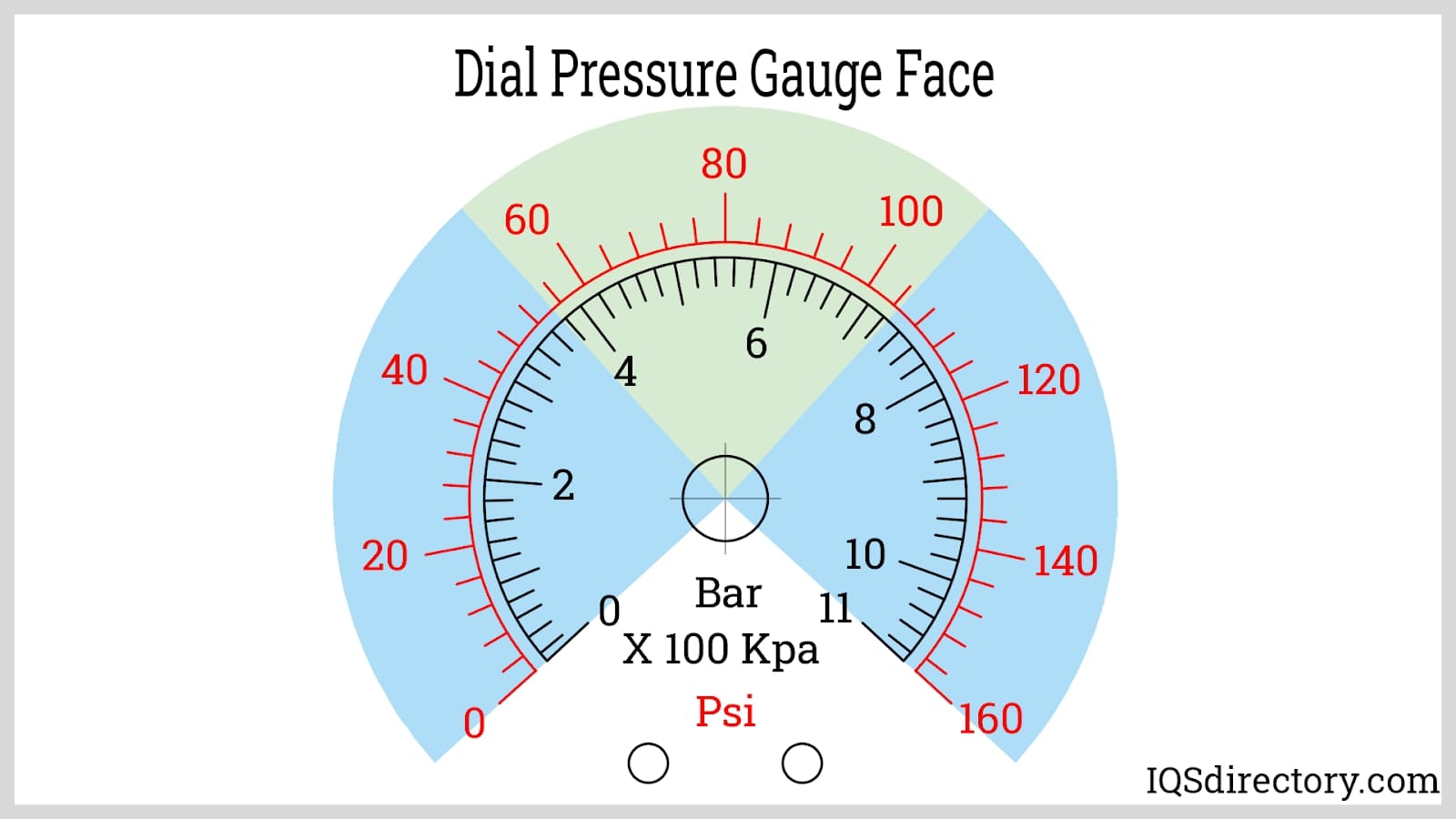

A pressure gauge measures fluid, gas, water, or steam intensity in pressure powered machine to ensure there are no leaks or pressure changes that would affect system performance.

A pressure gauge measures fluid, gas, water, or steam intensity in pressure powered machine to ensure there are no leaks or pressure changes that would affect system performance.

The scale are divided into three sections with the first and third sections being the least accurate and the second section being the most accurate.

The scale are divided into three sections with the first and third sections being the least accurate and the second section being the most accurate.

Cases for pressure gauges are made from plastic, steel, brass, or, stainless steel.

Cases for pressure gauges are made from plastic, steel, brass, or, stainless steel.

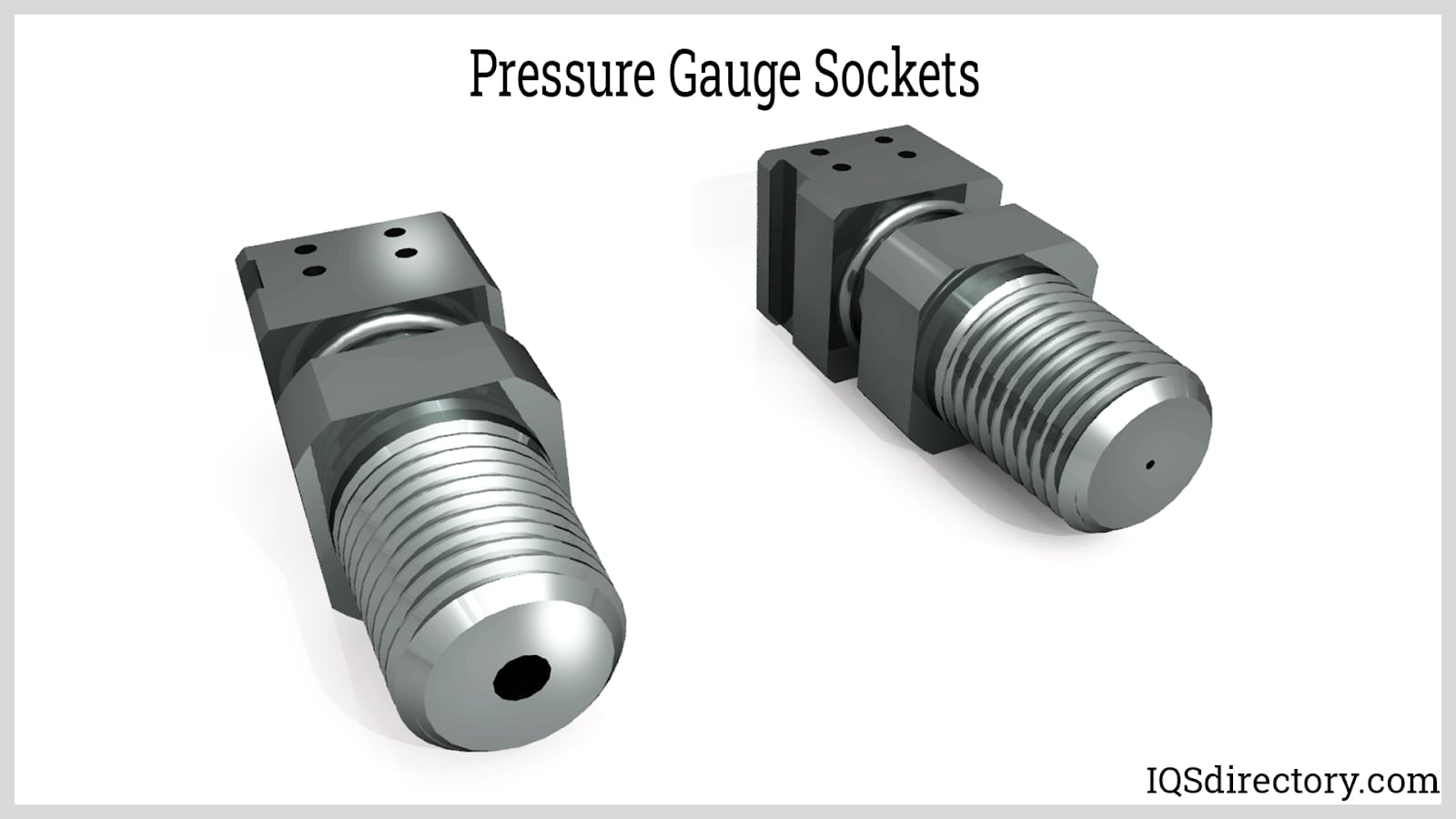

Sockets are the first part of the pressure gauge that pressurized fluid contacts.

Sockets are the first part of the pressure gauge that pressurized fluid contacts.

The placement and size of the connection allows more versatility, a lower mount gauge attached to an upward facing female connection, while backward facing connection makes it harder to read the gauge.

The placement and size of the connection allows more versatility, a lower mount gauge attached to an upward facing female connection, while backward facing connection makes it harder to read the gauge.

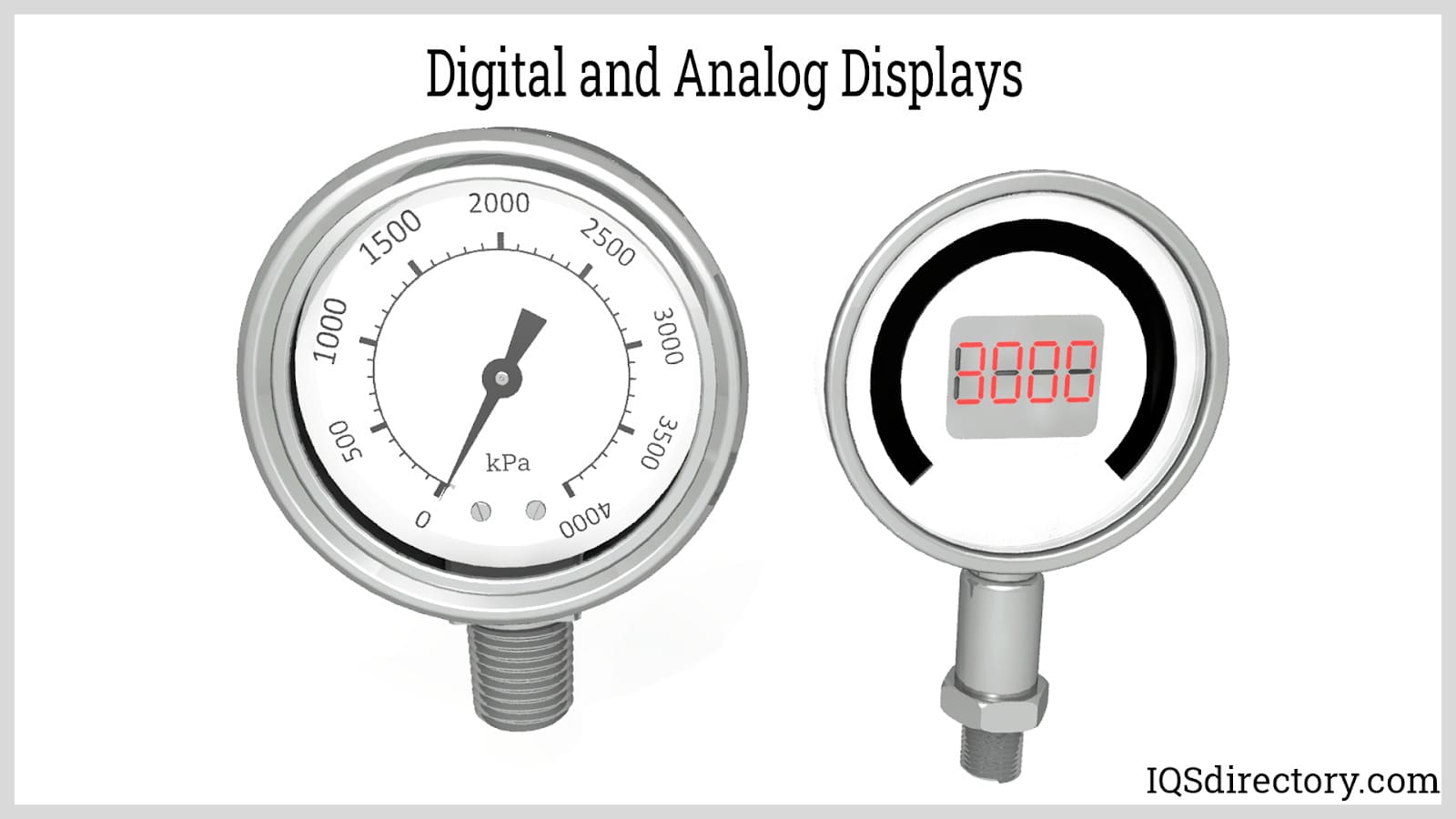

Displays for pressure gauges uses either analog or a digital display each with there benefits of usage.

Displays for pressure gauges uses either analog or a digital display each with there benefits of usage.

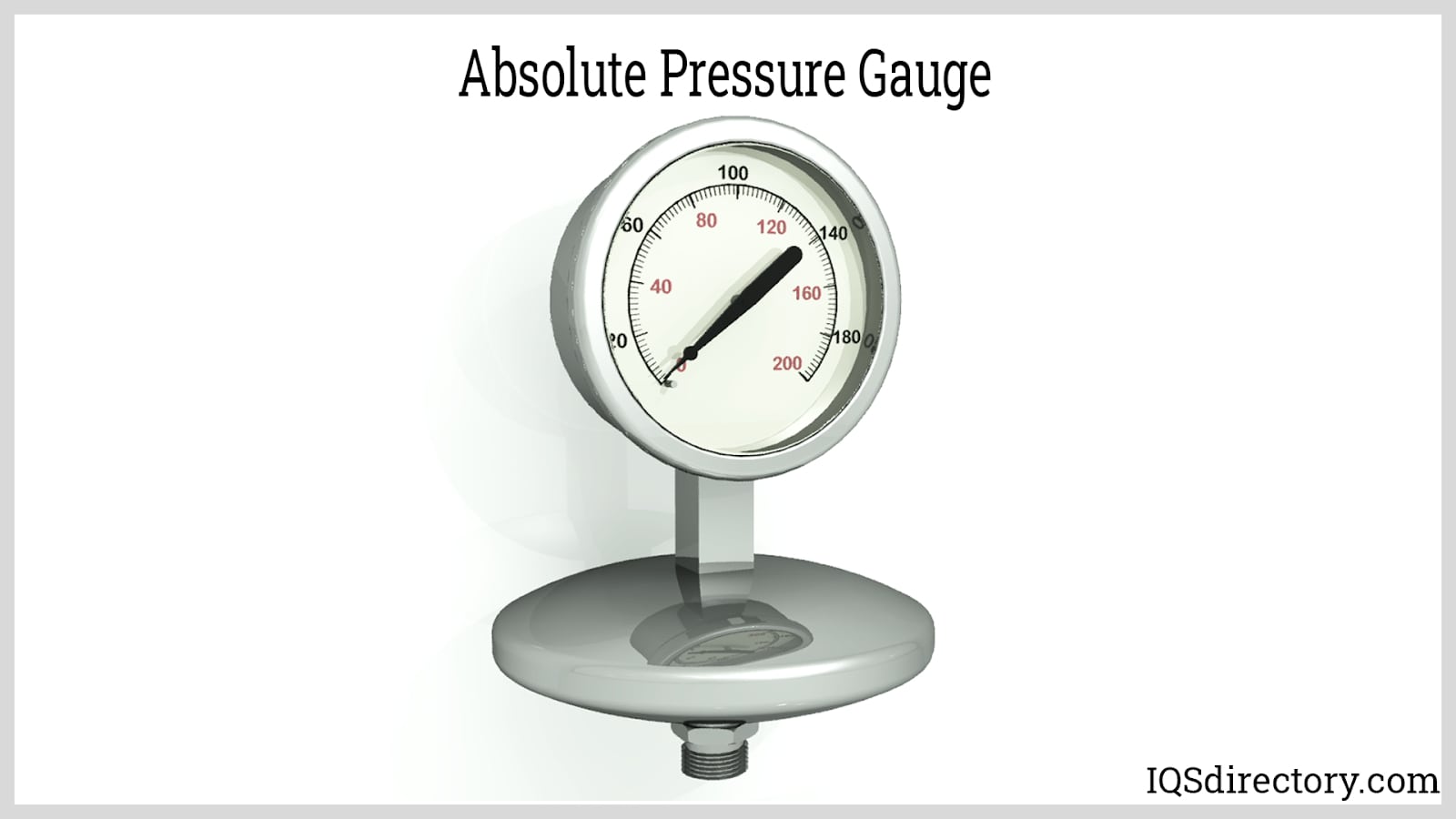

Absolute pressure gauges are used to measure pressure independent of the natural fluctuations in atmospheric pressure.

Absolute pressure gauges are used to measure pressure independent of the natural fluctuations in atmospheric pressure.

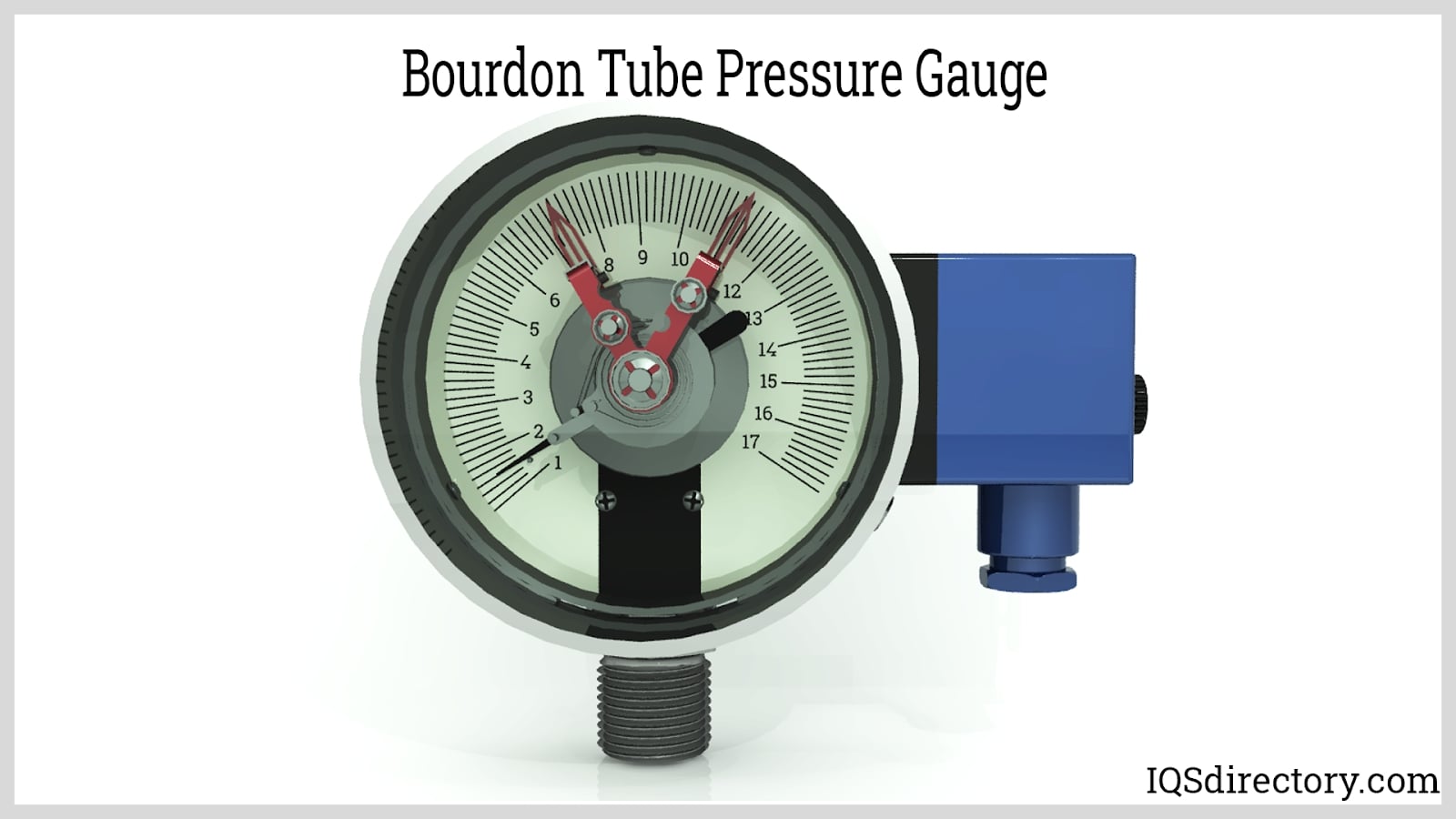

A Bourdon tube pressure gauge measures pressure up to 1000 bar and down to -1 bar.

A Bourdon tube pressure gauge measures pressure up to 1000 bar and down to -1 bar.

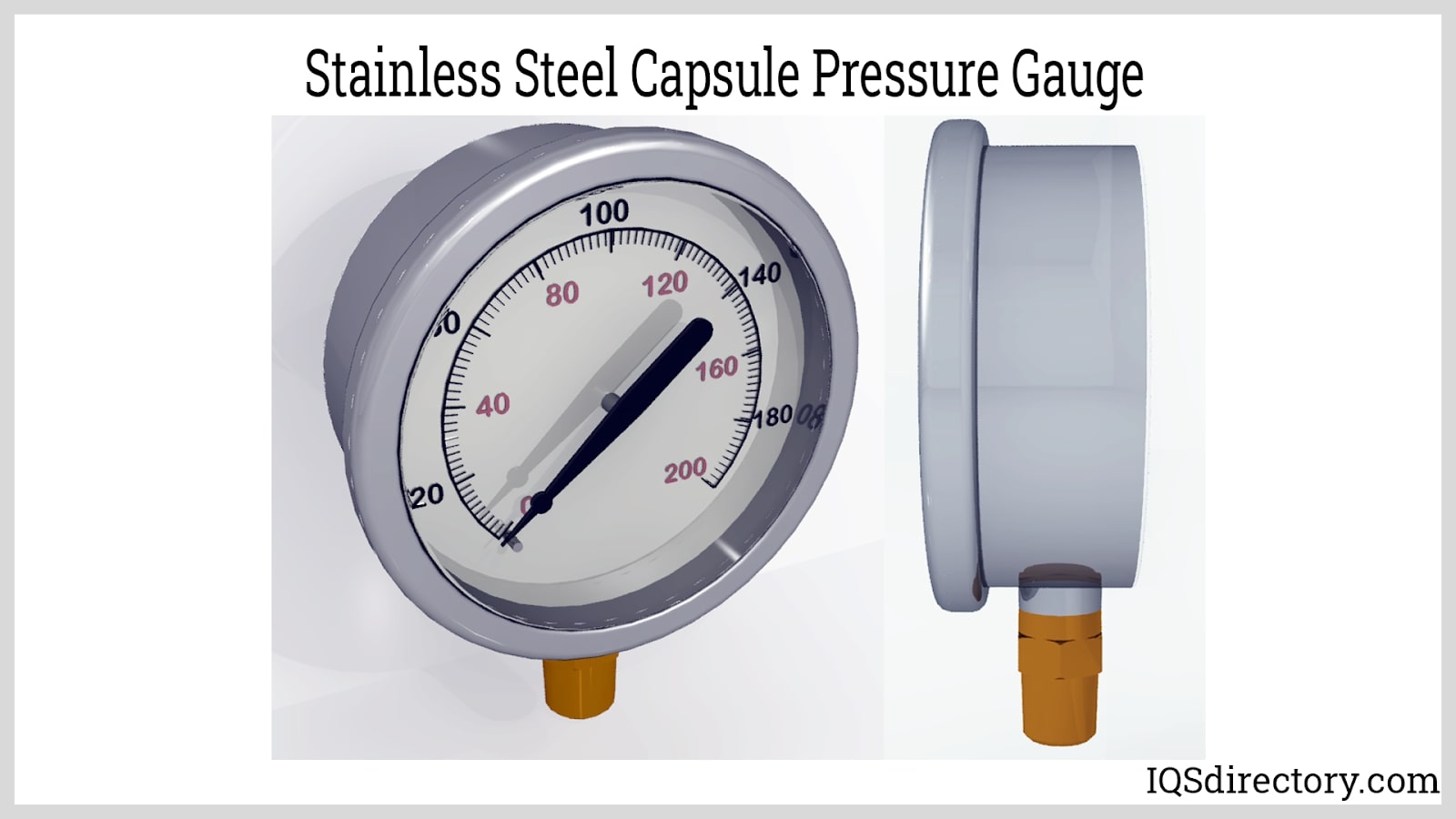

A capsule pressure gauge has two thin, concentric corrugated diaphragms that are sealed tightly together around their circumferences.

A capsule pressure gauge has two thin, concentric corrugated diaphragms that are sealed tightly together around their circumferences.

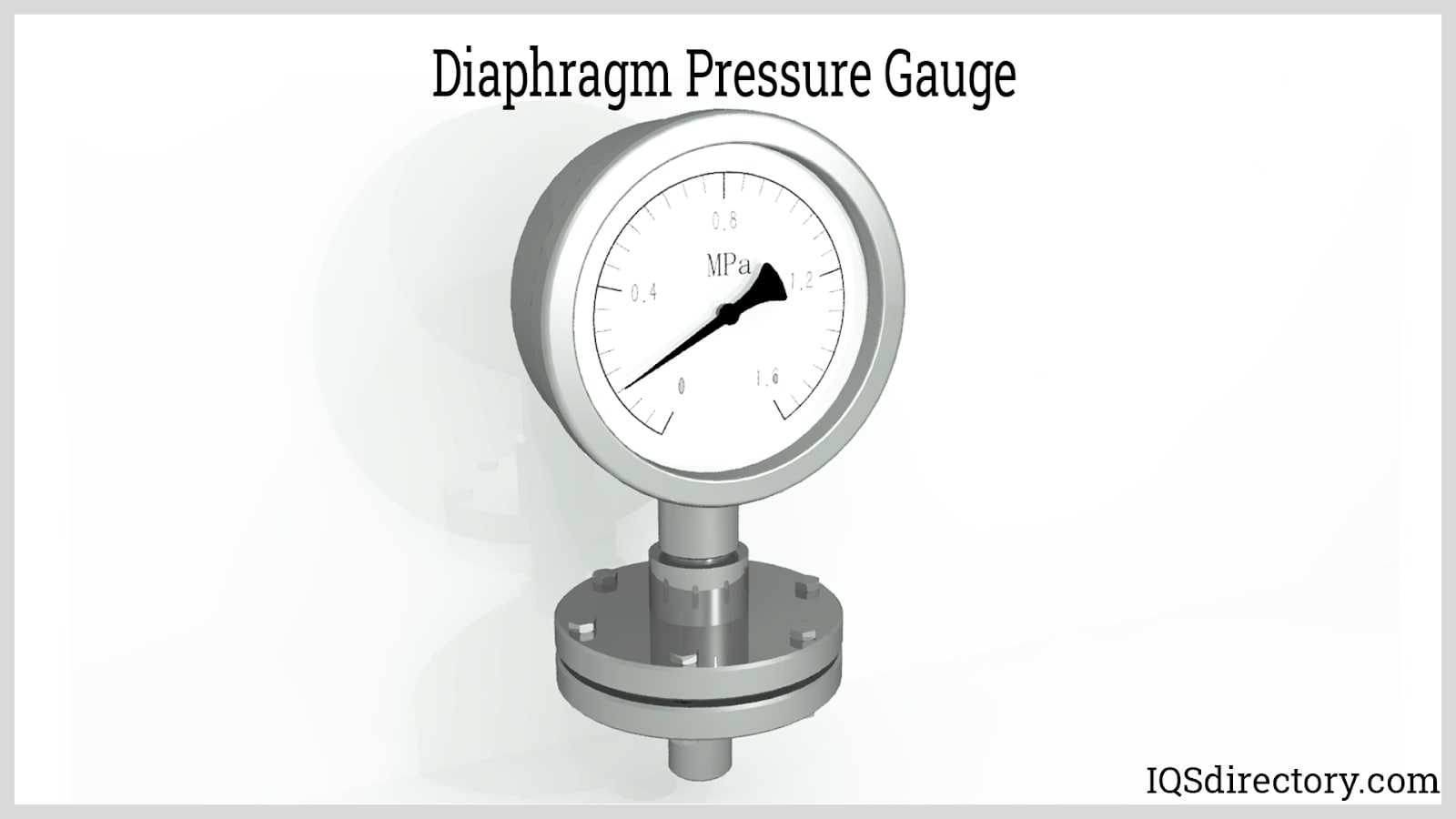

Diaphragm Pressure Gauges measures pressure up to 40 bar to -1 bar.

Diaphragm Pressure Gauges measures pressure up to 40 bar to -1 bar.

Types of Pressure Gauges

There are many different kinds of pressure gauges, and they are applied in all kinds of contexts.

- Air Pressure Gauges

- Measure pneumatic pressure in any air-operated equipment and can feature analogue or digital displays, as can most gauge varieties.

- Differential Pressure Gauges

- Instruments that measure the difference in pressure of a gas or liquid between two points. This eliminates the need for an operator or computer system to watch two gauges and perform the math. Differential pressure gauges are fast and efficient and immediately and constantly display information in one location.

- Water Pressure Gauges

- Monitor the pressure of any water-based system. These type pressure gauges are commonly attached to tanks that require monitoring of the liquid within.

- Fuel Pressure Gauges

- Instruments that specify the pressure of the fuel supply to the intake manifold in a combustion engine vehicle. This display represents how much gas is left in the tank.

- Oil Pressure Gauges

- Tools that measure the pressure of oil circulating in any lubricating system. Maintaining the correct amount of oil in a vehicle can increase its longevity; the same is true in machinery.

- Gas Pressure Gauges

- Measure and display the pressure of a gas. They are widely used by manufacturing plants or industrial companies where it is important to monitor any changes in pressure in order to control the rate of flow of gases such as propane or natural gas. They are used to measure very high pressures as well as low pressures.

- Vacuum Gauges

- Instruments used to measure and display sub-atmospheric or vacuum pressures within a system or vessel. Vacuums are frequently used to create cold temperatures for certain processes.

- Temperature Gauges

- Take measurements in a variety of materials including air, oil and water. They are used for home purposes as well as in scientific processes.

- Digital Pressure Gauges

- Attached to an instrument that measures the pressure of a gas or liquid and gives numerical readings. They display readings in digital, rather than analog, form. Digital readouts are typically easier to read and provide greater accuracy. They usually run on batteries and are available on most kinds of pressure gauges.

- High Pressure Gauges

- Instruments that measure and display the pressure of gases and liquids moving at high velocities. When the temperature rises or more gas and liquid is added to the container, the pressure increases even more. High pressure gauges are manufactured for industrial and manufacturing applications, mainly for high pressure hydraulic technology including water cutting machines, hydroblasting pumps and hydro-demolition. Some high pressure gauges are specifically designed for use in high purity semiconductor gas and liquid applications; they feature pressure ranges from less than 15 PSI to as high as 10,000 PSI.

- Low Pressure Gauges

- Generally measure pressures of 10 to 15 PSI. Gauges designed for low pressure are extremely sensitive and accurate out of necessity; many processes depend on the correct pressure to function properly and safely.

- Gauges

- Used in environments where the pressure tends to fluctuate frequently and so requires constant monitoring.

- Absolute Pressure Gauges

- Measure any pressure above zero pressure. It is impossible to create a perfect vacuum artificially, and no perfect vacuums exist on earth or anywhere in space. Absolute pressure gauges measure pressures on a scale that begins with zero, though a pressure of zero is impossible to achieve.

- Ambient Gauges

- Also called "sea level gauges," are the most commonly used gauge. They are used in meteorology. Ambient gauges are preset to read zero pressure at standard atmospheric pressure (~14.7 psi).

- Combination Gauges

- Measure both pressure and vacuum.

- Commercial Gauges

- Also referred to as "general purpose gauges" or "equipment gauges," are low-cost measuring instruments designed for applications that do not have severe conditions. Commercial gauges may be ruggedly constructed but are not typically economical to repair.

- Fuel Pressure Gauges

- Instruments that indicate the pressure of the fuel supply to the intake manifold in a combustion engine.

- Gas Pressure Gauges

- Instruments designed to measure and display the pressure of a gas.

- High Pressure Gauges

- Instruments that measure and display the pressure of gases and liquids moving at high velocities, up to 10,000 PSI, a very high pressure when compared to the atmospheric pressure of ~14.7 PSI.

- Industrial Gauges

- Have heavy-duty sensing elements and case designs and higher accuracy requirements than general purpose gauges. They are built for extended life and are designed for use in harsh environments.

- Liquid Filled Gauges

- Can be filled with various fluids, such as silicone oil, mineral oil and glycerin. The liquid fill provides protection to internal components of the gauge in severe environments in which the gauge may encounter excessive vibration and pulsation.

- Liquid filled gauges are utilized in nitrous systems on nitrous bottles or solenoids.

- Low Pressure Gauges

- Designed to accurately measure pressures less than 15 PSI using a capsule sensing element.

- Oil Pressure Gauges

- Instruments that measure and display the pressure of the oil in an enclosure, particularly oil circulating in a lubricating system.

- Precision and Test Gauges

- Extremely sensitive and highly accurate instruments that are used in applications that demand precision and consistent results, such as instrument shops, gauge repair and calibration shops and testing laboratories.

- Process Gauges

- Made from corrosion resistant material to meet the demanding heavy-duty operating and construction requirements of the chemical and petroleum industries. Process gauges are also designed to fulfill the exacting accuracy and service life needs of a variety of process applications.

- Retard Gauges

- Have a scale that is compressed at either one or both of its ends.

- Temperature Gauges

- Instruments that indicate the temperature of an item or substance being measured. The results may be displayed through an analog dial or digital readout.

- Vacuum Gauges

- Indicate negative atmospheric pressure or the degree of rarefaction below atmospheric pressure.

- Water Pressure Gauges

- Designed to determine and monitor the pressure of any system that uses water.

Pressure Gauge Accessories

Common accessories include: diaphragm seals, pressure gauge valves, panel mounts, siphons, test plugs, snubbers and pulsation dampeners.

Pressure Gauge Installation

When you install your pressure gauge, it’s best to isolate it from potentially disruptive forces, such as vibration, dampening, moisture and extreme temperatures. Mount your pressure gauge on a stable wall, panel or surface that is away from piping strains. We recommend you install a shut-off valve between the pressure gauge and the system it is monitoring, so that you can shut down the gauge if you need to, without shutting down the related system. For more details, talk to your provider.

Standards and Specifications for Pressure Gauges

We recommend that any pressure gauges used in the United States meet the safety and quality standards of ANSI (American National Standards Institute) or ASME (American Society of Mechanical Engineers). For more specific information, contact your industry leaders.

Things to Consider When Purchasing Pressure Gauges

If you’re in the market for a great pressure gauge, you need to work with a high quality manufacturer that you can trust. Find an experienced pressure gauge provider by browsing the list we’ve provided towards the top of this page. As you browse, consider all of your application specifications, including: your required lead times, your budget, your standard requirements, your delivery preferences and your post-delivery support preferences (installation, calibration services, maintenance, etc.). Keeping those things in mind, pick out three or four pressure gauge service companies that you believe to hold the most promise. Then, reach out to each of them to discuss your application. After you’ve talked to each of them, compare and contrast your conversations and pick the right one for you.

When designing a custom pressure gauge for a customer application, pressure gauge manufacturers consider things like: the environment in which the gauge will be used, the substance the gauge will monitor, how often the gauge will run, how much space the customer has available, etc.

To improve the gauge for customer applications, manufacturers may combine a pressure gauge with other similar instruments, such as: pressure transducers, strain gauges, pressure sensors, pressure transmitters and switches. They may install them in the same location or contain them in the same enclosure. Also, they can manufacture them in any size you need, whether they need to fit in tight spaces or work on very large tanks.

Proper Care for Pressure Gauges

To make sure your pressure gauges are working safely and accurately, you need to occasionally inspect them. Checking your gauges will ensure that you stay on top of any potential problems and take care of them before they snowball. The frequency with which you need to do this depends on your application. You should decide on your maintenance schedule with the help of your manufacturer. Always watch out for problems like excessive wear, damaged sockets and damaged threads. If you notice these, you’ll have to replace those parts.

Pressure Gauges Terms

- Bourdon Tube

- A thin walled elastic tube of metal that is flat and formed into a circular shape, which tends to straighten in response to increases in pressure and is fixed to a pressure recording or indicating device such as a gauge.

- Pointer

- The part of the gauge that works with the dial to indicate the pressure level.

- Pointer Indication Adjustment

- A way of making a modification in indication with an adjustable needle with the change being the same over the whole scale.

- Pressure Relief Plug

- The insertion of a plug in the wall of the gauge that vents when there is an element leak to prohibit excess pressure build up in the case.

- Proof Pressure

- The highest pressure a gauge can maintain with no apparent alteration in accuracy.

- Pulsation

- A periodic pressure swell.

- Repeatability

- The highest difference from any two or more successive indications for identical working conditions and applied pressure.

- Restrictor

- The apparatus that limits the flow of fluid between the pressure element and the source of pressure.

- Retard Gauge

- The scale of this gauge is compressed at either one or both ends.

- Ring

- The part that firmly fixes the window to the case.

- Rupture Pressure

- The point at which a vessel's capacity to contain pressurized material is exceeded.

- Scale

- The markings on the dial comprised of gradations, related numbers and units of measure.

- Snubber

- An apparatus for the reduction of the effect of pressure variations and surges.

- Socket (Stem)

- The major supporting element of the pressure component assembly that the elastic component is fixed.

- Temperature Error

- The alteration of pressure indication that is caused by the difference of temperature in the components from the temperature at which they were calibrated.

- Wetted Parts

- Any element of a gauge that comes in direct contact with pressure media.

- Window

- A clear component made of glass or plastic closing the front of the case.