Modular Buildings

Modular buildings are prefabricated structures, constructed offsite and assembled on-site. They serve as an economical and efficient alternative to conventional brick and mortar buildings.

Often, you will hear the term "prefabricated building" used interchangeably with "modular building." Modular means "composed of standardized units or sections, for easy construction or flexible arrangement," whereas the verb prefabricate means "to manufacture sections (especially a building or piece of furniture) to enable quick or easy assembly on site." Using these definitions, you can understand that modular structures have been prefabricated, and while prefabricated doesn’t always equal modular, modular always equals prefabricated.

Quick links to Modular Buildings Information

The History of Modular Buildings

Modular building first rose to prominence as a viable alternative to traditional construction in the early 1900s; between the years of 1910 and 1940, Sears Roebuck Co. sold over 500,000 modular homes.

After World War II, modular buildings became even more popular. Part of the reason for this was the Baby Boom, when scores of returning soldiers came home, ready to buy houses and start families. With such a sudden and urgent market for real estate, the pace of traditional construction simply would not cut it. So, builders turned to modular structure construction. Modular construction allowed them to build homes much more quickly and inexpensively than did traditional on-site construction.

The modular built structures of the 1950s were relatively small, but since the 1980s, modular building manufacturers have been able to make them as large and as customized as customers want. Also, in the last 20 years or so, builders have developed much more sophisticated methods of construction of modules, modular building assembly and on-site installation. Today, factory workers ship large modules across the country and assemble them using overhead cranes with lifting capacities upwards of 100 tons.

Modular buildings have become a staple of our constructed world; it is estimated that nearly all Americans have been inside a pre-engineered building, whether or not they realize it. The popularity of using modular and prefabricated buildings will continue to increase due to the benefits in cost reduction, construction speed, portability and range of location possibilities.

Modular buildings can be used permanently or temporarily in spaces, outdoors or built in an existing structure. Especially in areas with limited transportation and where conventional construction supplies may be hard to come by, factory-built modular buildings have proven themselves a logical and effective solution.

Advantages of Modular Buildings

Because of their many benefits, modular buildings are extremely popular. Some of those advantages include: cost savings, speed of occupancy, factory-controlled quality, environmental friendliness and ease of expansion and relocation.

- Assembly Speed

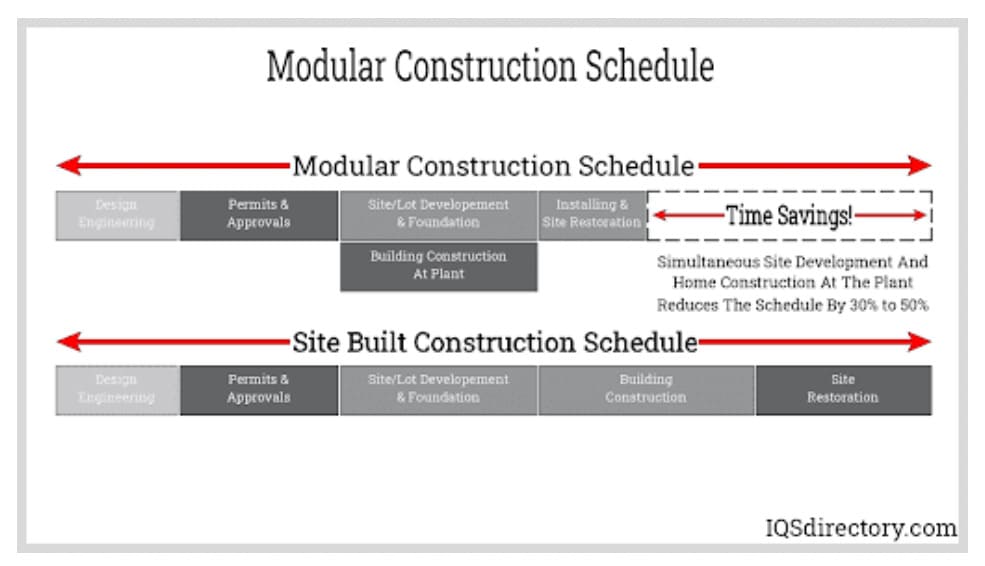

- The most significant advantage of modular construction is the time saved (although actual production times will vary according to the complexity of the design, the skill of the engineers and delivery times). Typically, the process, design to assembly, takes only a matter of weeks.

- Prefab buildings (listed on IQS Directory) go up faster than traditional buildings for a number of reasons. First, because so many modular buildings are fabricated from stock designs, manufacturers don’t have to spend time designing them. Also, during the construction process, the buildings only need to be assembled together instead of actually being constructed onsite. Furthermore, modular buildings are less susceptible to delays due to lack of building materials and labor or due to effects of weather which can stall traditional building schedules. Prefab buildings are typically built according to a carefully monitored timetable within the factory plant, and some manufacturers even guarantee a certain number of weeks until a building is available for installation.

- Building Versatility

- Modular buildings are extremely versatile. Manufacturers can design structures as add-ons to existing buildings, divisions inside existing rooms or separate buildings. Even better, because they are built from modules (standardized parts), customers can rearrange them if and when their needs change.

- Environmentally Friendly Buildings

- Modular buildings are environment-friendly, and modular building construction generates less waste and allows for tighter construction than traditional building construction. As construction is done off-site, the traffic from plant & facility supplies and workers is minimized. Moreover, these portable buildings can be disassembled, relocated or refurbished for further usage, which minimizes the amount of energy used to create a new structure. Dry materials are used in the construction process for improved air quality, ensuring environment friendliness.

Modular Building Design

- Modular Construction Process

- Modular buildings form when the structure is sealed together to become one integrated wall, floor, and roof assembly. Manufacturers use off-site construction, which is done with the use of factory plant and facility equipment. After the modular construction is done, workers complete the assembly on-site by placing modules side-by-side, end-to-end, or stacked, in order to allow different configurations and styles in the building layout.

- Each module is independently engineered to withstand extreme conditions of weather, transportation, and craning.

- Building Materials

- Modular buildings can be built from lumber, polyvinyl or a durable metal such as steel or aluminum. Depending on size, location and intended use, one of these materials might be more suitable than another. Steel building, for example, is popular for large buildings like prefabricated garages, because it is strong, corrosion resistant and able to survive extreme temperatures and weather without deteriorating.

- Modular Building Customization

- Manufacturers can prefabricate a modular building with all the components you require and desire, such as: walls, floor trusses, a variety of windows, complete HVAC systems, plumbing, electrical wiring and lighting and interior finishes.

- While they typically construct prefab buildings according to stock designs, modular building manufacturers can customize yours. They specialize a modular building for you by thinking about your specifications, including: whether or not your building needs a foundation, how much weight the foundation needs to support, what elements the building must withstand (heavy winds, lashing rain, snowstorms, etc.), and how you’d like your building to look (professional office decor, plain, painted to stand out through the use of colors and trims, etc.). Modular buildings can be designed to fit in with external aesthetics and are indistinguishable from their site-built counterparts.

- Common modular construction customizations include: building extensions, space partitions and small booths. In addition, modular building manufacturers often customize the height of the ceiling, the thickness of the walls, and other dimensions according to your needs and requirements.

Modular Building Images, Diagrams and Visual Concepts

Modular buildings are buildings made up of standardized sections and manufactured in a controlled away from the building's future location.

Modular buildings are buildings made up of standardized sections and manufactured in a controlled away from the building's future location.

Relocatable buildings are designed to be repurposed and transported to various sites as needed.

Relocatable buildings are designed to be repurposed and transported to various sites as needed.

Prefabricated shelters provide safe and comfortable outdoor spaces that protects from extreme weather, pollution, and debris.

Prefabricated shelters provide safe and comfortable outdoor spaces that protects from extreme weather, pollution, and debris.

The construction for moldular buildings takes about half of the turnaround time of traditional construction.

The construction for moldular buildings takes about half of the turnaround time of traditional construction.

Modular Building Types

- Aluminum Buildings

- Fabricated from low maintenance, lightweight corrosion resistant aluminum. Their convenience is their durability and flexibility in size and use.

- Booth Manufacturers

- Construct portable enclosed steel structures for applications such as security, revenue and/or access control booths or gate houses.

- Building Systems

- Assemble prefabricated parts to construct permanent buildings.

- Bullet-Proof Structures

- Meet standards for resisting impact from bullets and other fast moving/high powered objects.

- Guard Houses

- Often placed at entrances to secure areas and serve as stations of clearance and general work activity for security or admissions personnel. Sizes will vary by need.

- Metal Buildings

- Composed mainly of select metal material and can be used for anything from storage to protection in various sizes.

- Mobile Offices

- Modular buildings are two types of modular construction, which are done using the same materials that are used in traditional building constructions.

- Mobile offices consist of prefabricated stock buildings; which construction companies utilize as temporary office space.

- Modular Office Building

- Custom-made per customer specifications or requirements. Each section is engineered independently with size ranging from 10 to 18 feet wide to 36 to 76 feet long. However, the module dimensions depend on state shipping regulations.

- Modular Buildings for Mining

- The Denali Building System, used to make buildings in portable construction and mining, combines traditional modular structures with fabric buildings. The goal of this type of modular construction is to provide mining colonies with housing and office solutions. The main benefit of this modular building system is that it combines the best aspects of soft-walled and hard-walled structures. The buildings are portable, require minimal assembly and tools, and are easy to install. The buildings also have other benefits, like small shipping volume, a low per-person cost, larger rooms, no hard wiring required, and installation included in the base price. The buildings even have wood floors covered in vinyl and glass windows. Multiple bathroom layouts make these buildings ideal for a variety of uses.

- Portable Buildings

- Buildings that can be easily moved or relocated. They are designed to be moved without significant structural modification; examples include portable hospital facilities, classrooms, offices, etc.

- While portable buildings can be both portable and modular, modular buildings do not have to be portable. Portable, or relocatable, buildings are designed to be temporary and easy to break down and move. The basic layout consists of a frame and wall panels, as well as a roof and installed floor. Portable buildings are extremely versatile and are useful for installation in many different fields, including in remote and rural locations.

- Pre Engineered Buildings

- Built of or with prefabricated sections or parts and are similar to prefabricated structures in use and variety.

- Prefab Buildings

- A type of modular building built with prefabricated parts.

- Prefabricated Buildings

- Different from modular buildings in that they are delivered fully assembled to site. Sizes and uses are varying.

- Prefabricated Garages

- Modular structures often used to add on to a previously existing garage.

- Steel Buildings

- Fabricated primarily of steel and are often found in industrial settings as well as for outdoor use. Size possibilities are unlimited.

- Storage Buildings

- Can be made from prefabricated parts, usually those composed of steel materials.

- Walk-In Enclosures

- Enclosed areas, which can be entered and worked in. Guard houses, x-ray rooms and communications rooms are examples of these.

Modular Building Applications

Modular buildings are built to provide long-term temporary or permanent shelter. They can be found in the form of complete standalone buildings, space partitions, building extensions or small booths and guard houses.

They serve as facilities and structures for all sorts of applications, including: church, school and university, modular home, classroom, cleanroom, gym, hospital, construction site office, inplant office, commercial modular building, disaster relief housing, storage building, medical/dental office, emergency medical center, security guardhouse and military barrack.

Modular Building Installation

Once the specifications and layouts are decided by you, your supplier will manufacture the building. After the manufacturing process is completed, the modular building will be delivered and assembled on site. The installation will not take more than a few days, and after that, the building will be handed to you.

Standards and Specifications for Modular Buildings

Modular buildings are built with the same building code and architectural code specifications as conventional buildings. So, before installing your prefabricated structure, you need to look into things like national and local electrical and construction standards. You also need to make sure to adhere to industry and application specific standards, such as ADA or FDA building code. In addition, always check with local authorities to see if you need to get a building permit for your structure.

Choosing a Supplier of Modular Buildings

To make sure you end up with a modular building that is serviceable, durable and attractive, you must choose the right manufacturer. Note that a good supplier you choose will provide you with free, no obligation proposals and designs. In addition, any supplier you select has to come on-site for installation, so it is important that the supplier has a good reputation in the market. The best way to find the right modular building manufacturer is by checking out the list of quality companies we’ve curated above. Using this list, you eliminate the uncertainty of a Google search, as all of those with whom we work are verified and reliable.

Of course, from among these manufacturers, you still need to pick the one for you. We recommend that you browse their respective websites, get a feel for what they offer and their prices, and then contact three or four in whom you are most interested. Gather your questions, concerns and requirements, and learn more about what each company offers. Keep an eye out not only for good prices, but good customer service. You want to choose a manufacturer looking not simply to make a profit, but rather to make a difference.

Once you choose the supplier, sit and discuss the design or layout you want. Give information to your supplier so that they can propose a suitable modular design for you. They will help you by providing you with different layouts, specifications, and a quote. From there, you’ll have your custom modular building in no time.

Accessories for Modular Buildings

Per their nature, modular buildings can have many accessories. All sorts of features count as accessories. Examples include: plumbing and sinks, roof vents, a separation wall, windows, outlet strips, ADA compliant restrooms and more.

Modular Building Terms

- Accessory

- Products for modular buildings that add to a fundamental solid panel building like a window, door, roof vent, etc.

- All-bolted Steel Floor

- Floor joists of galvanized steel that reach across each module from both sides as well as being bolted to both floor side beams.

- Aluminum

- A light, corrosion and oxidation resistant, metallic material with high electrical and temperature conductivity. This metal is commonly used in construction of modular buildings.

- Anchor

- Construction for assisting the stabilizing of modular buildings or portable buildings to the ground, combined with straps or cables and turnbuckles or split bolts.

- Anodized

- Material that has a metal oxide finish formed by a process that produces a durable semi-translucent finish in varying colors.

- Architect of Record/Engineer

- Architect or engineer who oversees the entire modular buildings projects. This is not the same as the manufacturer's engineer.

- Beam

- A modular building component that has bending loads subject to it. The three types are continuous, simple and cantilever.

- Bottom Board

- Material placed beneath the floor joists of a modular building or portable building for the protection and keeping in of insulation as well as keeping the building weathertight. Bottom board is typically composed of paper that is fiberglass reinforced, asphalt impregnated or asphalt board.

- Bracing

- The use of angles, cables or rods in the roof's plane and walls to convey loads to the foundation like seismic, crane thrusts and wind.

- Building

- A structure that forms an enclosed, partially enclosed or open area made through a process of planning using components, materials and subsystems to achieve particular usage conditions.

- Building Code

- Industry recognized agencies establish specific regulations pertaining to building designs such as design loads, procedures and construction details for structures, typically as applied to certain political jurisdictions like city, county, state, etc.

- Cantilever Beam

- A type of beam that provides support at only one end allowing the other end to move freely.

- Cladding

- Outer wall paneling and exterior metal roof of the metal building system found in prefabricated steel buildings.

- Clear-Span

- Interior free of columns.

- Collateral Loads

- Weight caused by further permanent material necessitated by the building contract beyond the building system, like mechanical and electrical systems, sprinklers, ceilings and partitions.

- Column

- A primary building component designed to convey the load from the main roof trusses, beams or rafters to the foundation.

- Composite

- Substance consisting of more than one material with each retaining their distinct beneficial characteristics.

- Cool Roof

- A metal roof meeting standards for Solar Reflectance and Infrared Emittance as determined by the CRRC. Cool roofs are sometimes painted white or made from specific reflective materials.

- Elastic Design

- Conception of design using the property of the materials permitting for temporary shape deformation in a predetermined load range.

- Fabrication

- Process of manufacturing done in the plant to transform raw material into completed components for prefabricated steel buildings. The fundamental processes are welding, cold forming, punching, painting and cleaning.

- Fiberglass

- Filaments of glass used in a process with polyester resins, catalysts and hardeners to be molded into shapes.

- Gable

- Building style, which usually includes one peak with the roof sloping at each side of modular buildings.

- Galvanized Steel

- Steel covered with zinc metal.

- Girt

- A horizontal structural component mounted to endwalls or sidewall columns of modular buildings, which serves to support paneling.

- Hardwall

- Walls of modular buildings that are constructed of masonry, block, tilt-up or precast.

- Installation

- The construction of prefabricated buildings components of a metal building to produce a finalized portable building - done on location.

- Joist

- A light weight beam that serves to support a roof or floor.

- Magnetic Shielding

- When magnetic fields, electromagnetic or radio frequency interference are deterred and safeguarded from structure.

- Manufacturer's Engineer

- The engineer under the employ of the manufacturer, who is responsible for the structural design of prefabricated steel buildings systems formed by the manufacturer.

- Multi-Span

- The interior of the building includes columns.

- Purlin

- The horizontal structure that serves to support the roof covering transferring loads to the main framing members of modular buildings.

- Prefab Office

- Prefabricated, built largely, if not completely, off-site. They serve as office buildings but are not actually connected to a permanent foundation on the ground.

- Prefab Shelters

- Modular buildings built to provide shelter of some sort.

- Portable Offices

- Often seen at construction sites and other locations where temporary events are taking place.

- R-Value

- R-value measures insulation's resistance to heat flow; it is important for temperature control issues.

- Rigid Frame

- Structural frame composed of components attached with moment connections causing stability in the frame relative to the design loads, removing the need for bracing in its plane.

- Roofing

- Modular buildings component that is attached to the frame of the roof covering the building, protecting against weather and fire.

- Relocatable Buildings

- Prefabricated, modular structures consisting of a room, or rooms that are constructed in a factory either wholly assembled, or ready to be assembled quickly on site.

- Single Slope

- A peak with one slope.

- Sound Attenuation

- Designed specifically to reduce noise from inside modular buildings to the outside.

- Stainless Steel

- Resistant to chemicals and corrosion.

- Steel

- Iron that contains carbon as an essential alloying component up to 1.8% and is workable in certain circumstances.

- Structural Insulated Panels (SIPs)

- Also known as foam core panels. SIPs are prefabricated insulated structural elements consisting of an engineered sand laminate with a solid foam core four to eight inches thick.

- Truss

- Designed to perform as a beam since it consists of three or more members that each carry a compression or tension force.

- Turnkey

- A product which has been completely outsourced for fabrication, leaving all aspects of manufacturing, material acquisition, assembly, installation and testing to the subcontractor. Turnkey systems are delivered and installed to the purchaser ready to use.