Metal Stamping

Metal stamping is a metal forming process in which flat stock sheet metal or metal coils are precisely shaped into metal parts in a stamping press (stamp press). Many different sheet metal forming processes fall under the metal stamp manufacturing umbrella. These include: punching, blanking, embossing, forging, bending, coining, and flanging, among others.

Quick links to Metal Stamping Information

- Cost-Effective

- Metal stamping services are cost-effective because the process can produce parts at production rates that are much greater than what is possible using other traditional methods. Because the process is so fast and accurate, it's well-suited for higher-volumes; as the production level increases, the labor costs and the per piece set-up drop.

- Many parts made through other metal forming processes, such as casting, die casting, forging, machining, or fabricating could just as easily be formed through stamping. Metal stamping dies have a lower tooling cost than the tools of many other processes, such as molds, forging and casting dies, and expendable cutting tools.

- Precise

- Both standard and complex custom metal stamp parts are stamped with precision (including precision tolerances) and high repeatability. Precision stamping offers benefits such as material flow, drawing, tight tolerances, and repeatability that are not possible with other metal fabrication techniques. These benefits become more evident in heavier parts.

- High Quality

- Metal stamping brings a higher level of accuracy, function, wear life, and appearance to parts. Also, metal stamping allows parts to be made of tougher and harder material than other processes allow, including such materials as stainless steel, nickel, cold rolled steel, aluminum, brass, bronze, and galvanized steel.

- Fewer Secondary Processes

- One stamp machine is capable of performing all of the tasks required in advanced stamping. The stamping complements simulation software, so prototype designs can be run on them to approve the concept before investing in dedicated tooling. Because of these advantages, the necessity for secondary processes can be reduced or eliminated altogether. This speeds things up and brings costs even lower.

- Versatile

- Metal stamping presses and fourslide presses are capable of producing two-dimensional and three-dimensional parts with simultaneous or continuous stamping, pressing, cutting, and forming. To make complex shapes, you can incorporate secondary operations within the same press and die system. Many value-added operations can be implemented if required, like nut insertion or automatic stud, in-die welding and assembly, and in-die tapping.

- In addition, if necessary, the stamping process can be highly automated. Such versatility makes metal stamping the method of choice for many.

- More Eco-Friendly

- As a smaller amount of material is required per piece, when you use sheet metal stamping, you help save raw material. Also, metal stamping produces less scrap in manufacturing, making disposal easy.

Manufacturers engage in metal stamp processes because they produce large volumes of products and parts with uniform precision at high speeds and low cost.

Industries in which metal stamping is particularly advantageous include: automotive, aerospace, military and defense, healthcare, electronics, and research and development.

Of all of these, the automotive industry is the largest customer of metal stamp processes. Consumer electronics is where metal stamping is used the second most. The segment is forecasted to go through significant growth; a compound annual growth rate (CAGR) of 5.4% is expected by 2022. The demand for consumer electronics is strong throughout the world, which will aid the market growth over the forecast period.

In addition, the research and development industry is witnessing research and development investments that are improving metal stamping processes. High efficiency metal stamping machines, such as hybrid electromagnetically assisted stamping machines, are available and cut operational costs, as well as reduce failures, like wrinkling and tearing. These technological advancements are critical for industry development and growth.

Metal stamping processes produce shapes that can be worked into countless products.

For example, copper and brass stamp shapes are commonly fabricated into household fixtures, plumbing accessories, or jewelry. In addition, many instruments, from eyelets to gauges, in airplanes can only be made with precision brass stampings and steel stampings are fabricated into a number of larger, three-dimensional parts such as automotive stampings. Deep drawn metal stampings, which are deep three-dimensional parts, are made into products such as pots and pans.

Other products made from metal stamping processes include electronic stampings, medical stampings, metal clips, spring clips, lasers, metal brackets, external panels (bonnets, fenders, deck lids, doors, side panels, and roofs), internal parts (bonnet interiors, mating panels, door interiors or deck lid interiors), dimensionally critical panels, navigation systems, landing gears, and intricate engine parts. Also, almost everything used in modern military warfare depends on precision metal stamping technology, including helicopters, assault weapons, radio systems, and other defense equipment and machines.

History of Metal Stamping

There are not many metal processes that have changed the face of manufacturing the way metal stamping has. In the 20th century, metal stamping design found its major application. However, it has roots in the time when people were exploring different ways to mold metal after figuring out how metal could be extracted from ores.

One of the earliest human attempts at metal stamping was coin striking. Most archaeologists agree that the first coins were struck in the 7th century BC by a group of people living in what is now Turkey, called the Lydians. To create coins, the Lydians created a die with an image to go on one side of the coin and a stamp with an image to go on the other side. Then, they set metal (typically gold or a gold alloy) on the die, placed the stamp on top of it, and struck the whole assembly with a heavy hammer.

This stamping method remained fairly constant throughout the centuries until around 1550 when a German silversmith, Marx Schwab, invented a press to mold metal into coin using a die. His screw press, which could be turned by up to twelve men at a time, spawned modern day precision metal stamping.

Metal stamping became truly popular and viable during the Industrial Revolution; this is when manufacturers started making bicycle parts with this technique. It changed the landscape of manufacturing; the process was much faster and more cost effective. Soon, Henry Ford, inventor of the assembly line, embraced the technology, and the era of affordable cars started with the Model T.

In present day manufacturing, metal stamping is applied in a wide range of products, from spring clips to metal clips. Learn more about current and future market trends below.

Even after the recent decline in manufacturing, the U.S. emerged as the largest market for metal stamping in 2015; the revenue exceeded $35 billion. A large share was attributed to the conventional automotive industry and newly emerging private aerospace industry.

According to a new report by Grand View Research, Inc., the global metal stamping market could exceed $180 billion by 2022, fueled by the metal stamping requirement in infrastructure and other emerging industries' needs. The growth will particularly be in emerging economies.

In the metal stamping industry, the major processes are embossing, blanking, bending, fourslide stampings, flanging, and coining.

The industry at the global level is dominated by blanking, which is closely followed by embossing and bending.

- Blanking Process

- The blanking industry is valued around $30 billion. This industry is expected to go through more significant growth, mainly fueled by the demand growth in the aerospace and automotive industries.

- Embossing Process

- The embossing process accounts for over 21% of total metal stamping. Embossing growth is projected to be aided by the rapid industrialization in China, India, and Brazil.

- Bending Process

- The bending process is expected to follow the growth pattern due to the high demand in end-use industries. This metal process offers many operational advantages including, tolerance to metal thickness variations, easy adjustability, and tonnage requirement for bending.

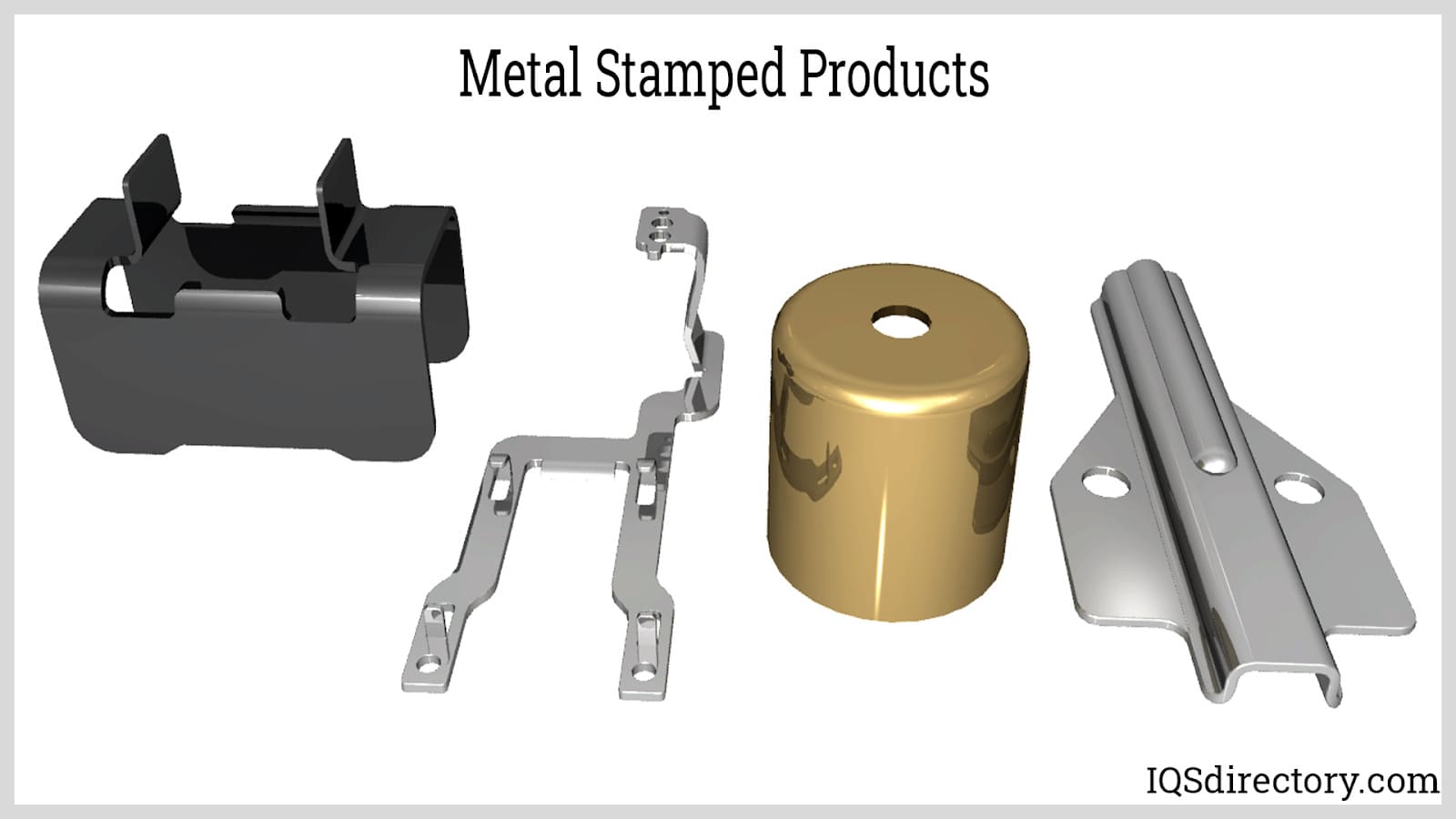

Examples of proedust made from metal stamping.

Examples of proedust made from metal stamping.

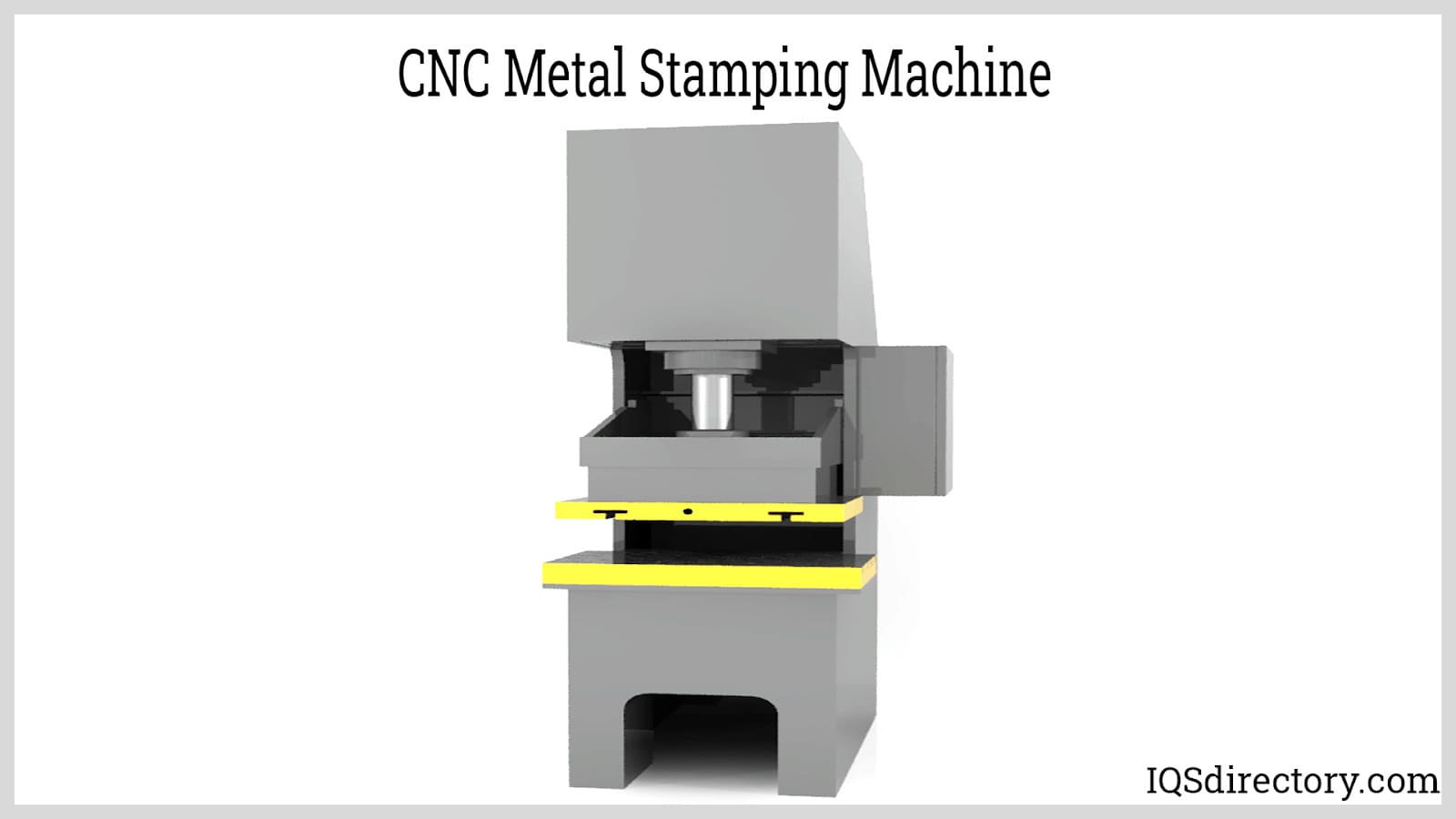

Metal stamping machines can cast, punch, and deform metals using a computer program or computer numerically controlled (CNC) for accurate parts.

Metal stamping machines can cast, punch, and deform metals using a computer program or computer numerically controlled (CNC) for accurate parts.

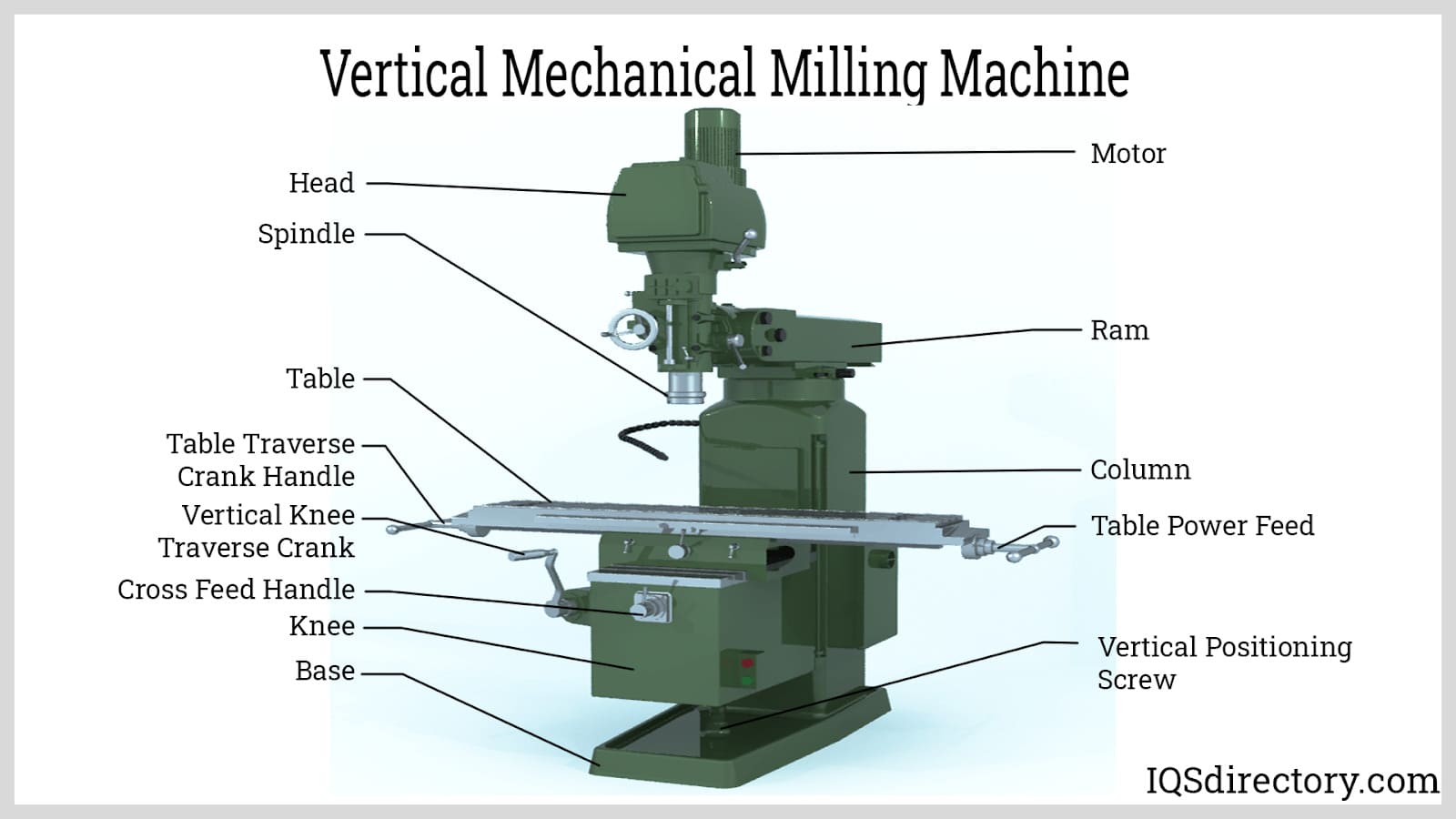

Vertical milling machines uses precision to shape metallic material.

Vertical milling machines uses precision to shape metallic material.

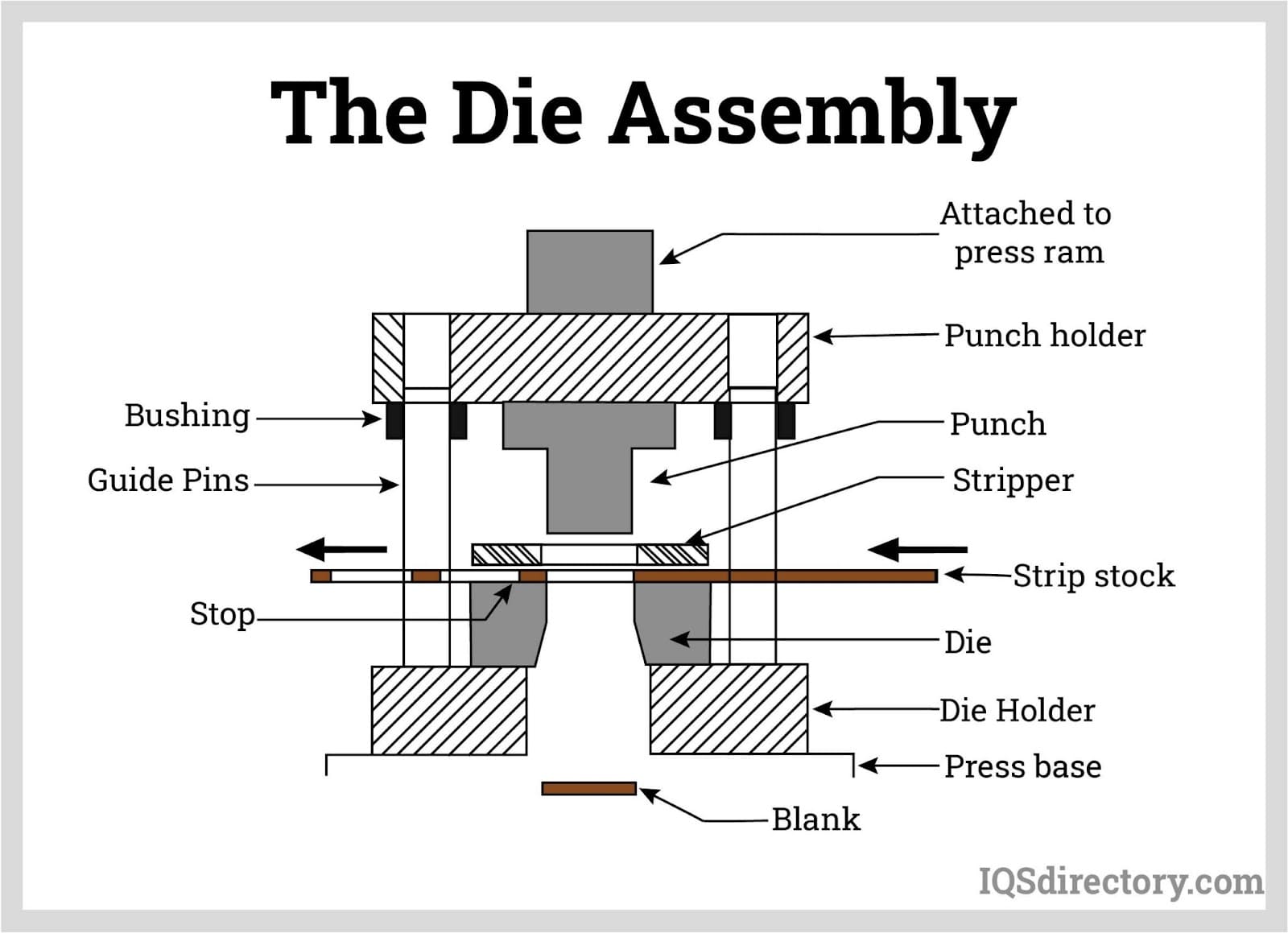

Dies are sets of tooling used to shape material to create specific customized parts.

Dies are sets of tooling used to shape material to create specific customized parts.

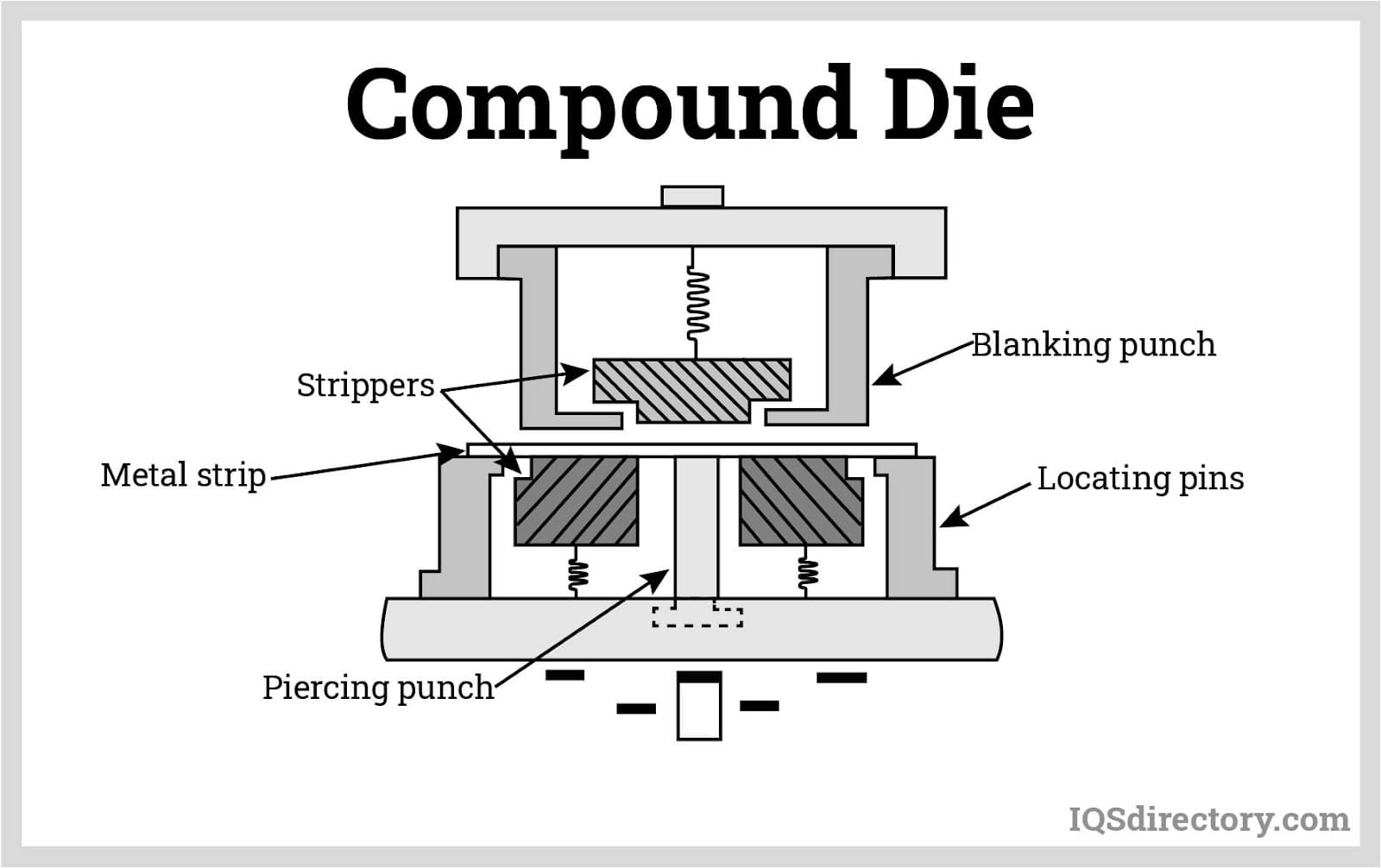

Compound dies perform more than one cut per stroke.

Compound dies perform more than one cut per stroke.

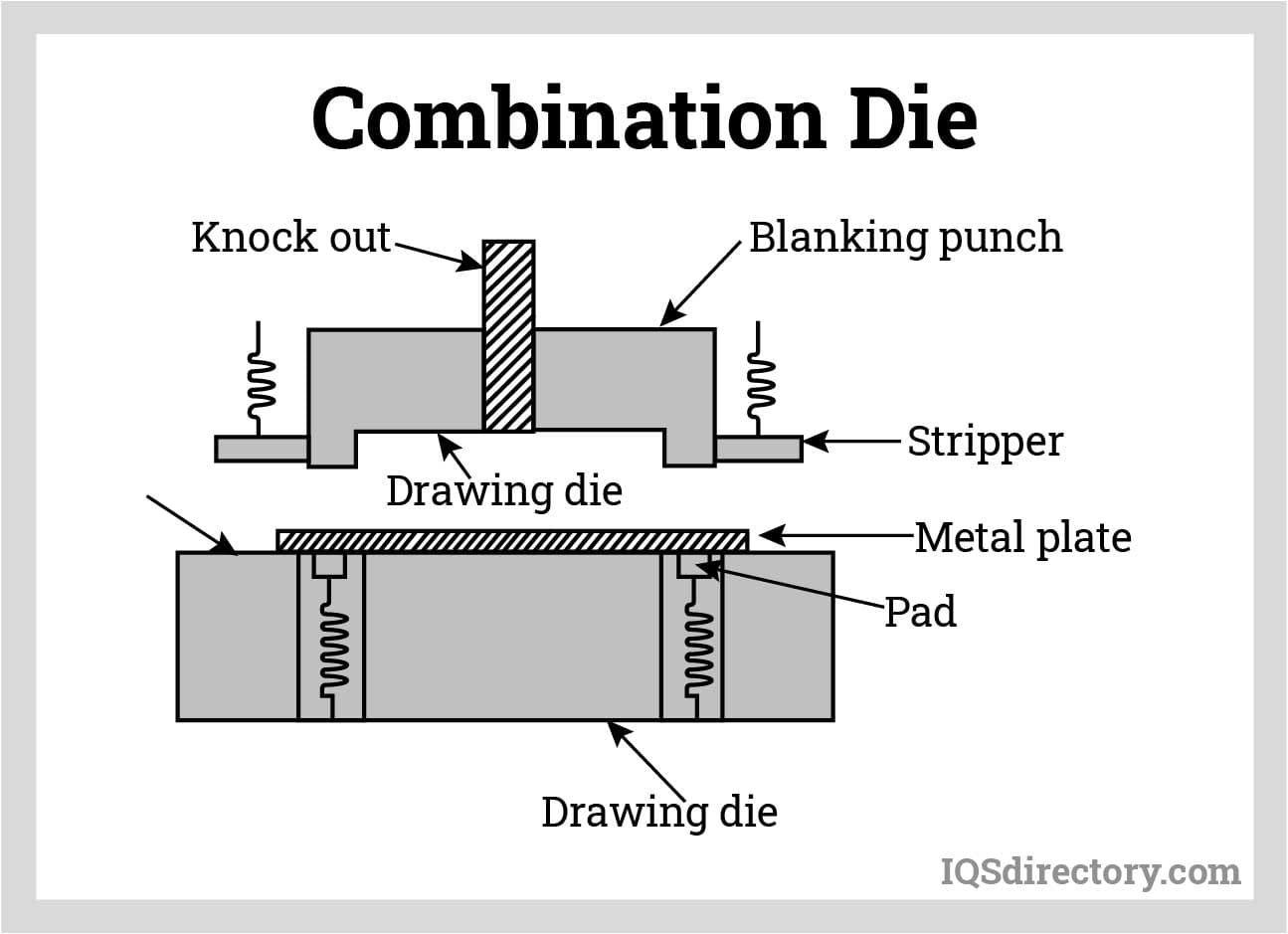

Combination dies are capable of performing more than one cutting and forming operations with a single stroke.

Combination dies are capable of performing more than one cutting and forming operations with a single stroke.

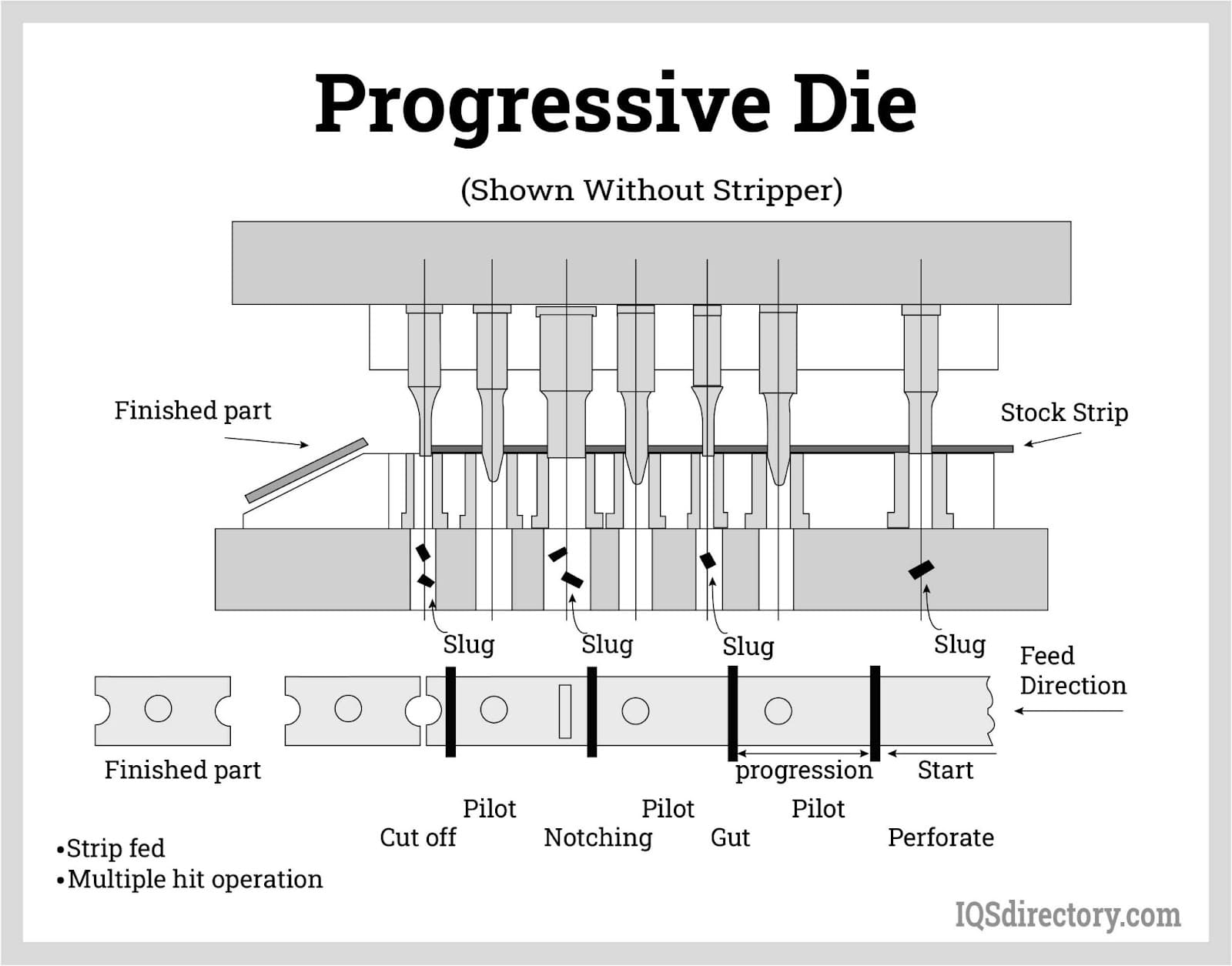

Progressive dies are used to gradually form a workpiece by passing through the series of stations arranged within the die according to the sequence of steps.

Progressive dies are used to gradually form a workpiece by passing through the series of stations arranged within the die according to the sequence of steps.

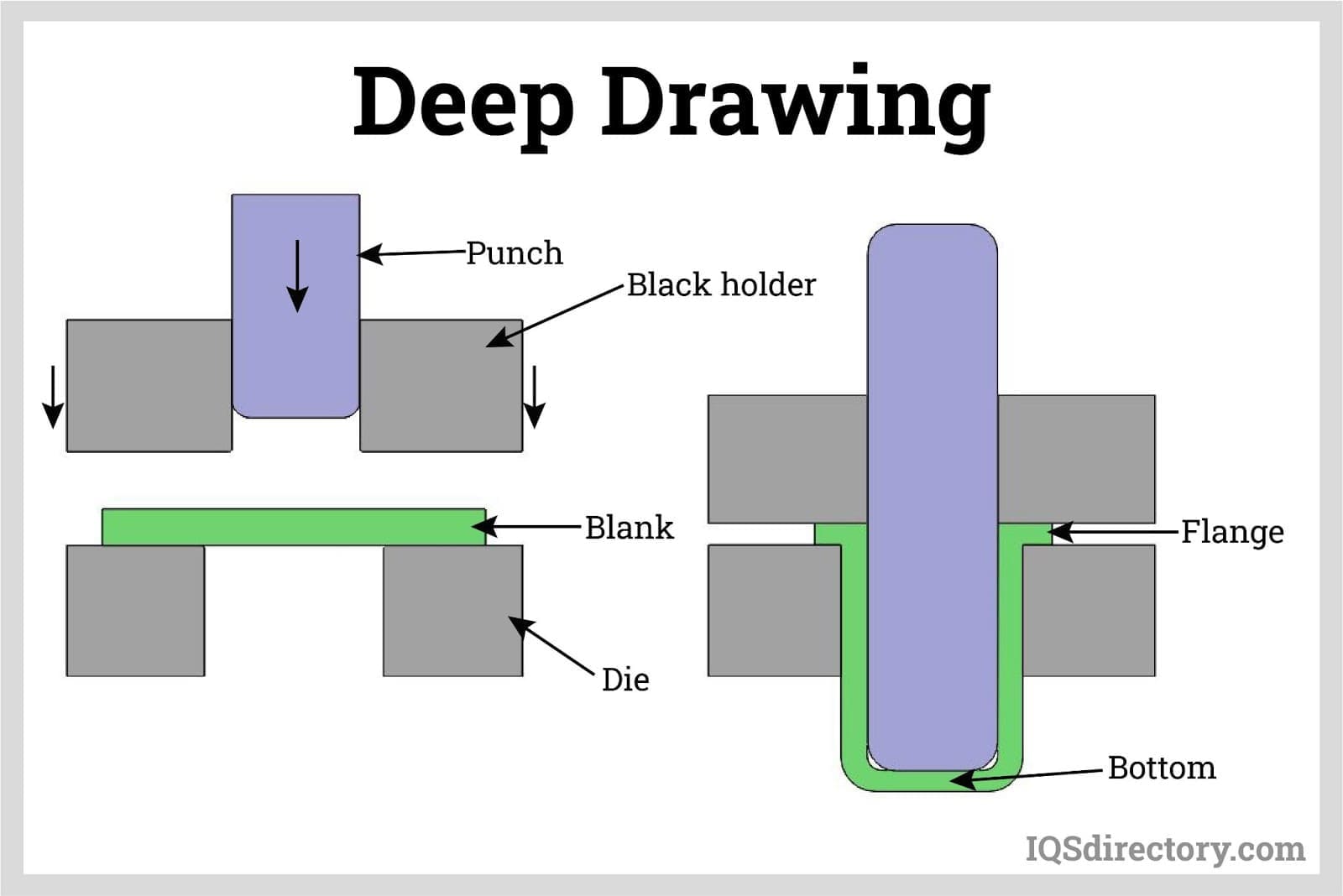

The Drawing process forms a blank into a hollow edge with a seamless edge and parts with several diameters.

The Drawing process forms a blank into a hollow edge with a seamless edge and parts with several diameters.

Materials most commonly used in the metal stamping process include steel, aluminum, zinc, nickel, titanium, brass, copper, and a number of alloys, such as beryllium copper.

- Steel

- This material is known to make products with high tensile strength, high yield strength, good corrosion resistance, good thermal conductivity, and overall durability.

- Aluminum

- Lightweight, corrosion resistant, nonmagnetic, electrically and thermally conductive, malleable, and soft.

- Zinc

- On its own, zinc tends to be brittle and hard to work with. However, it makes a great alloy element. In alloys, it boosts corrosion resistance and galvanization resistance abilities.

- Nickel

- Most well-known for its corrosion resistance. However, it has other favorable characteristics as well, such as ductility and magnetism. It is also an important component of alloys such as brass.

- Titanium

- An extremely strong and lightweight metal element with an excellent strength-to-density ratio. It is also highly resistant to corrosion and can be alloyed with other metals in order to create metal stamp products for aerospace, medical, and military purposes among others.

- Brass

- Primarily made up of copper and zinc. It’s mostly used when manufacturers want to create decorative metal stampings. While it can be made more corrosion resistant with aluminum, it is not the best metal for heavy duty industrial or outdoor applications.

- Copper

- Soft, malleable, and formable. It can be used to make excellent alloys, such as brass and beryllium copper. As a stamp metal, it offers thermal conductivity and electrical conductivity.

- Beryllium Copper

- This alloy is ductile, weldable, and machinable. It is resistant to non-oxidizing acids like hydrochloric acid, galling, abrasive wear, and plastic decomposition products. In addition, manufacturers can heat treat it for increased strength, durability, and electrical conductivity. Of all the copper-based alloys, beryllium copper is the strongest.

In metal stamping, manufacturers press a flat sheet of metal into various shapes based on the stamp die they use.

- During press operation, the slide, or ram, maintains movement to and from a motionless table called a press bed. The stamp die (or die stamp), a press tool consisting of a specially designed cavity, shapes metal parts from the inserted sheet metal. The upper component of the die connects to the press slide, and the lower component connects to the press bed.

- A die component called the punch, or punch press, performs the necessary shaping operation by pushing the sheet metal through the die. The punch part of the process can be single stage or multistage depending on the requirement. In single stage operation, every stroke of the press results in a desired metallic form. In multi stage, using progressive stamping, the metal sheet is pressed at various angles to give the final shape.

- After the metal stampings are formed, they are typically subjected to one or more secondary processes, such as plating, cleaning, heat treating, or deburring.

Plating increases the corrosion resistance, solderability, and wearability of the part. The most common plating materials include gold, palladium, nickel, and tin; metal can be pre-plated to avoid this secondary process.

Cleaning removes oils and films from the metal stampings. This type of cleaning is also called degreasing.

Heat treating processes increase the strength of the product. The part is stamped in the soft state before it is hardened by heat treating in order to circumvent its tendency to crack when formed or coined.

Sharp corners are removed by the deburring process, which can be done by either abrasives or chemicals.

When putting together a metal stamping process, manufacturers consider several design aspects. These include: desired shape and size, desired material thickness, required tolerances, standard requirements, and property preferences (hardness, corrosion resistance, etc.).

Many companies, before constructing their metal stampings, use stamping simulation as part of their preliminary processes.

Stamping simulation technology works by calculating the process of a specific sheet metal stamping project and predicting defects that may be likely to occur, such as wrinkles, splits, material thinning, and springback. This state-of-the-art technology simulates the sheet metal part form process in the virtual environment of a PC, and allows tool and die makers to see the likelihood of success for a particular sheet metal part without the expense of making an actual tool. Tool makers use the results to quickly compare alternative designs and enhance their part; this lowers manufacturing costs.

After stamping simulation, to get the shape they want, manufacturers carefully create a metal mold, or die, with its exact dimensions and bends. Dies can be used over and over again. If the stamping needs certain properties that it doesn’t already have after the initial machining, manufacturers can choose any number of secondary processes. For example, if a part needs to be more corrosion resistant, manufacturers can plate it after they’ve stamped it.

- Stamping Press

- A stamping press completes metal forming with force, speed, and precision. This stamp tool can be designed to work as a mechanical or a hydraulic press (or both). (Mechanical presses produce energy in the flywheel, which is then transferred to the crankshaft, electric shaft, or eccentric gear.) Both types are available for customization in a wide variety of sizes, ton capacities, stroke lengths, and operating speeds.

- Gap Frame

- A type of mechanical press often utilized in applications where the stock metal form is fed by hand. Straight frames are ideal for progressive die and transfer die forming applications.

- Hydraulic Press

- A controlled force is actuated by hydraulic pressure, which is used to move one or more rams in a preset sequence. Hydraulic presses, which have a variety of frame types including C-frames, straight sides, H-frames, and four columns, have the ability to deliver full power at any point in the stroke. These presses are ideal for deep draw projects, short runs, precision metal stampings, lower-speed high-ton blanking with long feed lengths, and work requiring repeatable pressure rather than repeatable depth of stroke.

- Progressive Press

- Have multiple stations that stamp different attributes into parts as a metal coil moves through the press; parts are cut and separated on the final step.

- Transfer Press

- Similarly, transfer presses have multiple stations for the completion of a part, but parts are separate sheet metal pieces rather than parts along a continuous coil.

- Fourslide Press

- Have four moving slides; this allows the automated press to manipulate parts along both axes, completing multiple aspects of stamping, cutting, and shaping on parts at one processing stage.

- Variations and Similar Processes

- Squeezing

- In this processing method, a metal plate is molded into the desired shape by applying pressure or squeezing metal in a die. It eliminates other secondary machining operations. Traditional stamping results in high wear and tear of a die, whereas the modern squeezing technique is cost effective, producing vertical, smooth, accurate sides with no tear.

- Pinch Trimming

- In a stamping operation, pinch trimming is used to cut the vertical walls of stretched or drawn vessels. The metal is cut when it is pinched between two hardened tool die sections. The product has no shearing or fracturing; deep-drawn cans are normally pinch trimmed.

- Bending

- The metal processing operation in which the metal is reformed or deformed along a straight axis. There are several types of bending methods, including V bending and wipe bending. Wipe bending is one of the most common methods to make metal clips; however, it is not suited for high-strength metals or parts that require precision bending. V bending is used for obtaining a given v angle and requires less force to bend in comparison to conventional wipe bending.

- Forging

- Also known as crushing, this metal stamping process shapes metal using the compressive forces of a powered hammer or a die. It is one of the oldest ways of shaping metal, used for millennia. A product constructed with forging is stronger than one made with casting or machining. Forging is classified by the temperature the metal is processed under; it can be cold, warm, or hot. For example, a forging process that uses heat is hot forging.

- Metal stamping processes can also be classified into three methods based on the dies: line dies, transfer dies, and progressive dies.

- Line Die Method

- This manufacturing process is used to make large parts that typically cannot be manufactured efficiently in one press. In this method, tools are typically loaded by hand or robotics. Hand-loaded line dies are commonly used for low-production parts and for those parts too bulky to handle with an automated system.

- They cost less than complicated dies.

- Its operation is simple, which allows the part to be handled or rotated at various axes.

- Complex geometries can be created with this method.

- Transfer Die Method

- In this method, uniquely designed line dies are assembled in a predetermined structure in a single press. Unlike with conventional line dies, the traveling rails assist the movements of metal parts. The rails are mounted in the press boundaries. During a press cycle, each rail moves inward to grab the metal part with specialized finger-like structure, which transfers metal parts to the next die.

- With this method, large parts are handled rapidly.

- Based on the requirement, stamped parts can be rotated, if necessary, during the transfer process.

- Can be programmed to accommodate a large variety of parts for different press speeds and stroke lengths.

- Progressive Die Method

- Also known as progressive stampings, this is the fastest method to produce metal parts. In this method, progressive dies tie the metal parts together by a strip carrier, which is actually a portion of the original strip. Unlike the transfer or line die methods, a single common die set mounts necessary stations that are sequenced and timed to feed the metal part.

- A great volume of parts can be produced rapidly.

- They can run without assistance if necessary.

- Only one press is required for whole operation.

- These are the most common production methods. Choose one carefully by considering factors like labor rates, the required volume of parts, and existing equipment.

For the best metal stamping experience, you need the right manufacturer. But there are so many out there. The right manufacturer is the one that suits your needs. This manufacturer will be willing and able to deliver you high quality metal stamping work within a reasonable lead time and do so while keeping within your budget. They won’t cut corners for a profit; rather, they’ll work to ensure you’re satisfied.

Of course, it’s also important that your manufacturer be knowledgeable, experienced, and close enough to ship to you. Find a manufacturer that has all the qualities and know-how you’re looking for by perusing those we’ve listed at the top of this page. Everyone we partner with has proven to be a quality stamp service provider who is willing to work hard for their customers.

- Alloy

- A compound consisting of more than one metal or the combination of a metal and a nonmetal. The resulting compound consists of properties different from those of the components.

- Annealing

- The metal stamping procedure wherein a metal is softened through heating and cooling treatments.

- Base Metals

- Common metal stamping consisting of inexpensive metals, such as aluminum, zinc, lead, nickel, and tin, that are easily oxidized.

- Blankholder

- A metal stamping mechanism that ensures that the blank does not move during the drawing process.

- Blanking

- The process of punching, cutting, or shearing predetermined shapes out of metal stampings stock.

- Bottoming Stamp

- A metal stamp or weld mark that signifies the form die stampings are on the bottom.

- Brazing

- Metal stampings that join two metals by filling the space between the metals with a nonferrous metal, the melting point of which remains lower than the two metals joined together.

- Burrs

- Jagged edges or protuberances on the surface of metal stampings created by metal stampers during metal stamping, die stamping, or other industrial applications.

- Cam

- A mechanism that moves or works at an angle to the metal stampings press stroke.

- Column Press

- A four-post, single slide press.

- Compound Die

- A stamping die that performs multiple stamping operations, such as blanking, piecing, and forming in one press stroke.

- Crank Press

- A mechanical press whose slides are activated by a crankshaft.

- Cup

- A cylindrical sheet metal part or shell that is closed on one end. Cups are the product of the first step in deep drawing.

- Deburr

- The removal of jagged edges and protuberances on metal surfaces, known as burrs, through abrasive or chemical means.

- Dope

- A compound used to lubricate the stock during the forming portion of the drawing process.

- Draw Bead

- A rib-shaped projection on the draw ring or hold-down surface that is useful in controlling the rate of metal flow during deep draw processes, especially in the manufacturing of irregularly shaped stampings.

- Ductility

- The ability of an object to accept bending or reforming without fracture.

- Deep Drawn Stampings

- Involves the fabrication of a metal sheet into a three-dimensional configuration. In order for a certain metal part to be categorized as a deep drawn stamping, it needs to have a certain set of specifications.

- Eyelets

- A metallic ring used to strengthen or reinforce holes punched in thin materials.

- Ferrous Metal

- A metal such as steel that contains a significant portion of iron.

- Fourslide Stampings

- Refers to a particular stamping process that is used to produce complex stamped parts requiring a bend greater than 90°. A fourslide is a mechanism that guides a forming tool into the correct position. The fourslide does this action quickly and repeatedly, time and again, producing a large quantity of identical products in a short period of time.

- Ferrules

- A device used to cover, join, fasten, reinforce, or shield many different objects.

- Hard Tooling

- Also called “dedicated tooling,” it is a procedure involving the production of one specific part.

- Heat Treating

- A secondary operation in the metal stamping process in which the strength and hardness of a metal part is increased through controlled cycles of heating and cooling.

- Insert Molding

- The injection of molten plastic into the surrounding area of metal stamping parts in order to combine the stamping parts into a single piece.

- Lead Time

- The amount of time from product order to product availability that it takes to complete product manufacture.

- Mechanical Press

- A press that uses mechanical means to complete stamping operations. In mechanical presses, a shaft conveys motion to the punch.

- Metal Washers

- Devices used primarily to distribute the load of a fastener over a greater surface area. Most washers are disk-shaped metal plates with a hole through the middle to allow a fastener like a bolt or screw to pass through.

- Non-Ferrous Metal

- A metal, such as aluminum or zinc, in which iron is not a main component.

- Notching

- The removal of the edges and corners of a metal blank.

- Plating

- Also called “electroplating,” it is a secondary operation in the stamping process that involves coating a metal part with another metal substance by electrical means to increase the corrosion resistance of the part.

- Precious Metals

- Also called “noble metals,” they are expensive metals, such as gold, silver and platinum, which remain resistant to oxidation and corrosion.

- Punch Press

- A standard stamping press that reshapes material through the application of compression.

- Secondary Operations

- Treatments, including cleaning, heat treating, plating and deburring, performed after the initial metal stamping process to refine the stamped part.

- Soft Tooling

- Tooling procedure involving the production of multiple part configurations.

- Stroke

- The completion of one full movement of the stamping press.