Machine Guards

Machine guards are mechanisms that act as safety barriers between workers and machines used in factories, manufacturing facilities, warehouses and plants. In addition, machine guards control traffic, keep vehicles out of certain areas and contain flying debris.

Almost all machines need safety guards. Any type of machine that shears or impacts, has meshing gears, rotating parts, reciprocating arms, cutting teeth or moving belts, or has the potential to be hazardous must have a safety barrier of some kind.

Quick links to Machine Guards Information

The History of Machine Guards

Machine guarding is a practice that was born out of necessity. Prior to the use of machine guards, machine workers had no protection from injury. Before the Industrial Revolution, this wasn’t much of a problem, since injuries were fairly infrequent. Once electric motors, steam engines and power-driven machinery entered the field, though, that all changed. Factory machinery could be terribly dangerous. Workers sustained injuries and even death from accidents like: being crushed by pulleys, being caught by moving screws, getting fingers caught in the nip point of rolling machine parts and getting pulled into moving gears. Also, young women working in textile factories were losing fingers at an alarming rate. Workers felt rightfully unprotected, and some shared their experience with the press. As newspapers published disturbing stories about their plight, newly formed labor unions began to fight for their safety.

As a result of the tireless efforts of labor unions, lawmakers began to enact changes. In 1877, in Massachusetts, lawmakers passed the first law ever requiring the presence of safety guards in front of dangerous machinery. Within the next 25 to 30 years, the majority of industrialized American states had passed similar laws. While early machining guards were helpful, they still had a long way to go, as they did not make allowances for emergency stopping mechanisms, safe machine arrangement and safe machine control placement.

In the 1940s, the American Standards Association came out with the Safety Code for Mechanical Power Transmission Apparatus. This code required a more thorough thought process in regards to machine guard design.

Another event of huge importance to the machine guarding industry was the 1971 founding of OSHA, or the Occupational Safety and Health Administration. OSHA was founded as a direct result of the Occupational Safety and Health Act of 1970. OSHA did and continues to create and enforce standards that ensure a safe and healthy working environment for all employees.

Today, machine guards are more important than ever. Recently, more manufacturers have begun paying more attention to the ergonomic factor of machine guards. Effectively integrated machinery safety guards can help to prevent worker stress and fatigue. Another new idea that manufacturers have recently had is to integrate the safety of a machine into the control system so that both become one single unit. This helps to save on costs in three areas: installation, materials needed and design.

Advantages of Machine Guards

Machine guards are extremely advantageous. More than that, they’re essential. They keep workers safe, keep operations orderly and maintain the efficient flow of work. Also, by keeping workers safe, they inspire a sense of confidence and well-being in workers.

Machine Guard Design

- Construction

- Manufacturers typically make machine guards using a combination of extrusion, CNC technology and post-extrusion assembly (attaching screws, rivets, bolts, nuts, etc.).

- Materials

- Manufacturers produce machine guards that are made of several different materials. However, metal is usually the top choice. They can come in different forms, such as pipe, bar, panel, wire mesh or sheet metal. In situations where visibility is an important necessity, a strong plastic material called polycarbonate is used to fabricate transparent panels that are shatter proof, can withstand continuous high impact and are stronger than glass. Wood is only used in applications where temperatures aren't extreme and corrosive chemicals are not present.

- Considerations and Customization

- When designing a machine guard, manufacturers must familiarize themselves with and consider factors like: machine point of operation, machine power transmission device (ex. cams, flywheels, glass, belts, connecting rods, spindles, couplings, pulleys, etc.), machine control mechanisms and machine moving parts.

- With the knowledge of such details, machine guard manufacturers will be able construct effective custom guards that meet OSHA standards. Their products come in many different sizes and configurations. To customize machine guards, manufacturers can do any number of things. For example, they can add hinges, add mounting holes, add mounting holes and adjust flange sizes. They can also extrude frames to your exact specifications.

How Machine Guards Work

There are a few different ways in which industrial machine guards actually guard the equipment. These include: point guarding, point of operation guarding and fixed perimeter guarding.

In this setting, when someone refers to "point guarding," they are referring to guarding moving parts on a machine that may be hazardous to machine operators or other employees nearby. Per OSHA 1910.212(a)(2), point guarding guards must be affixed to the machine if possible, and if not, affixed nearby.

Those machinery guards working "point of operation guarding"-style guard the area of the machine that the employees use. The goal here is to make sure that the operator neither comes in physical contact with the machine nor enters the danger zone while working.

Fixed perimeter guarding is a type of guarding during which manufacturers create a machine border or a machine enclosure around the entire workspace.

Machine Guard Images, Diagrams and Visual Concepts

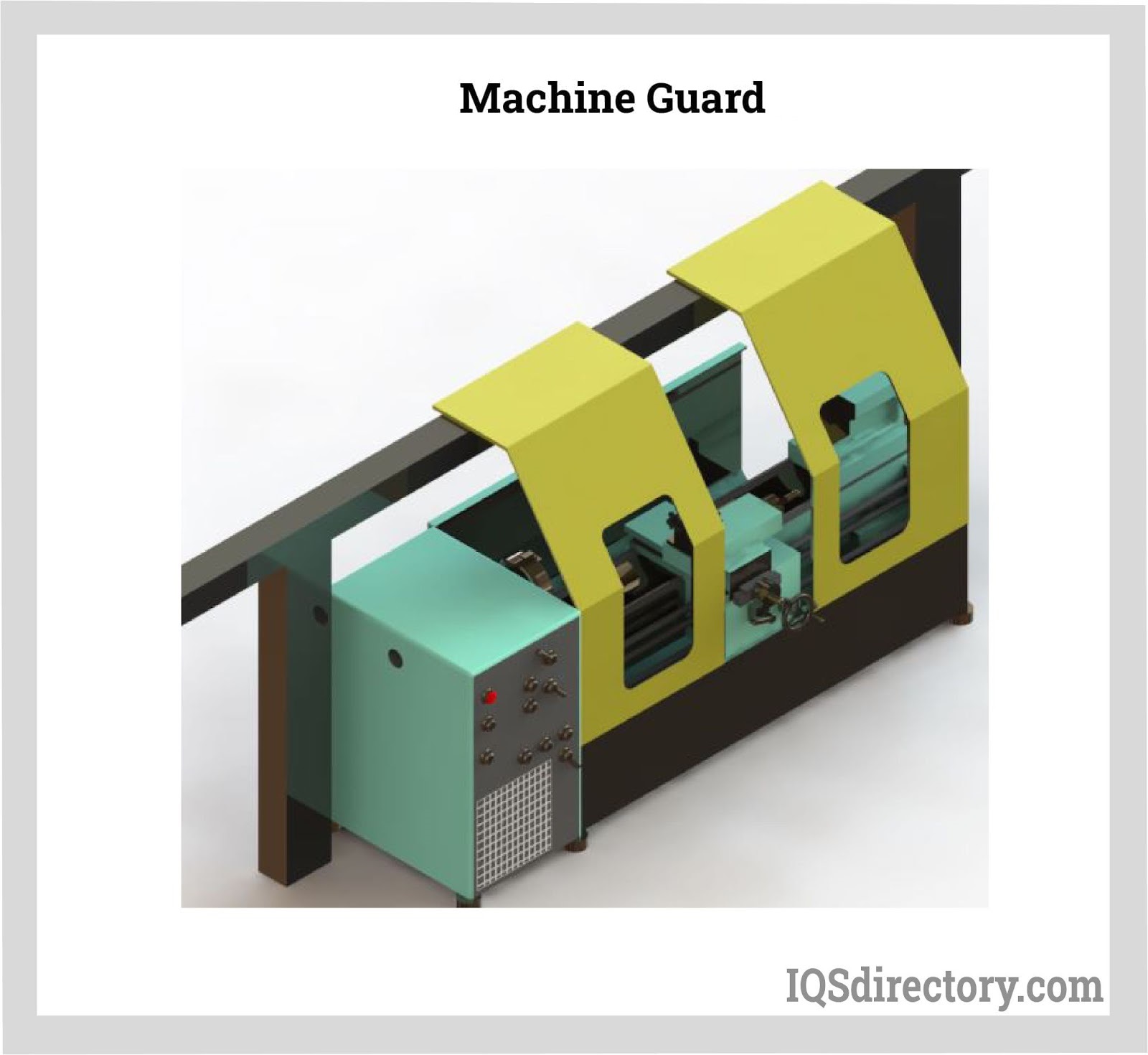

Machine guard act as a safety barrier between workers and machines.

Machine guard act as a safety barrier between workers and machines.

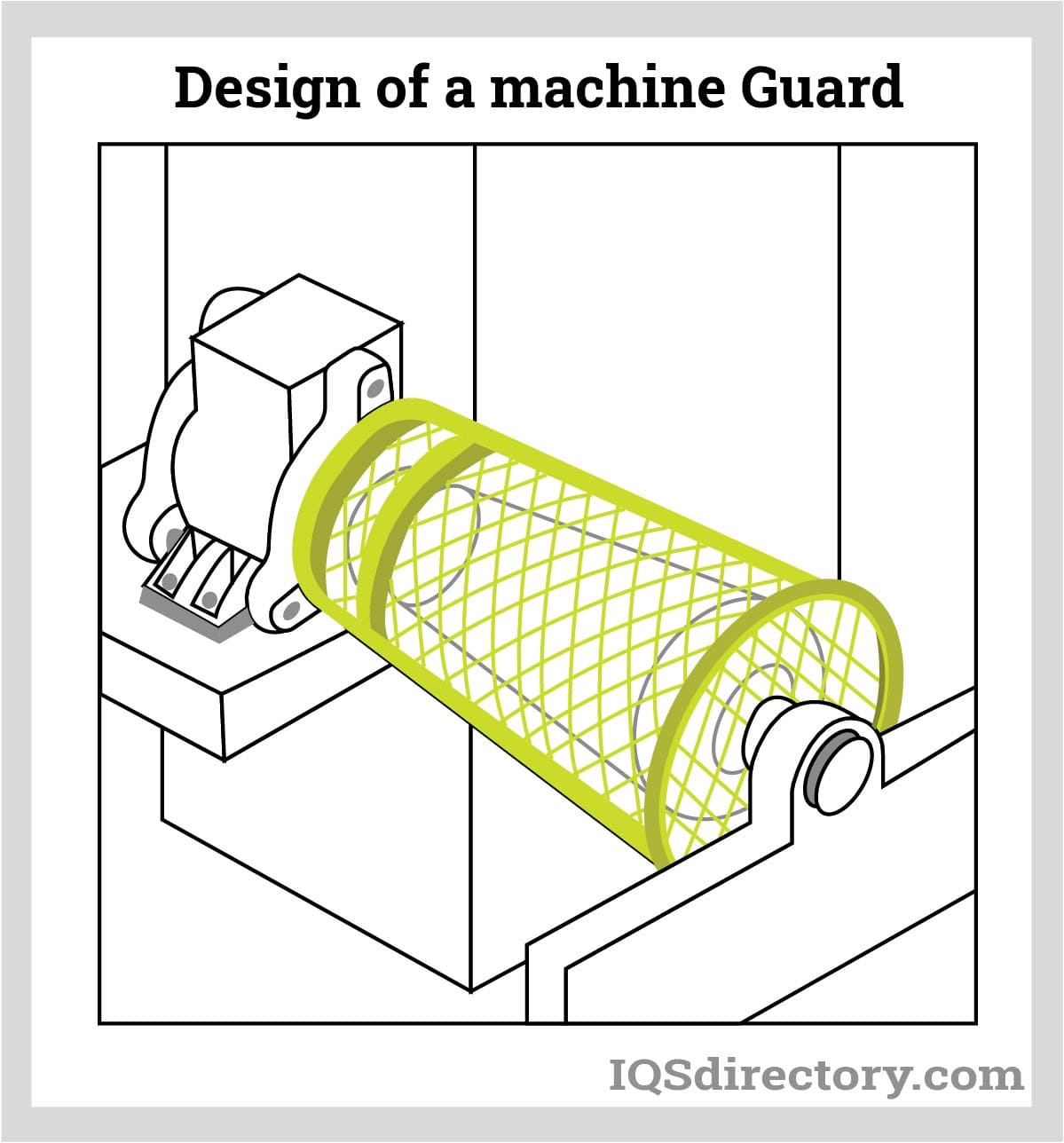

Manufacturers usually make machine guards by combining CNC machining, extrusion, and post extrusion processes.

Manufacturers usually make machine guards by combining CNC machining, extrusion, and post extrusion processes.

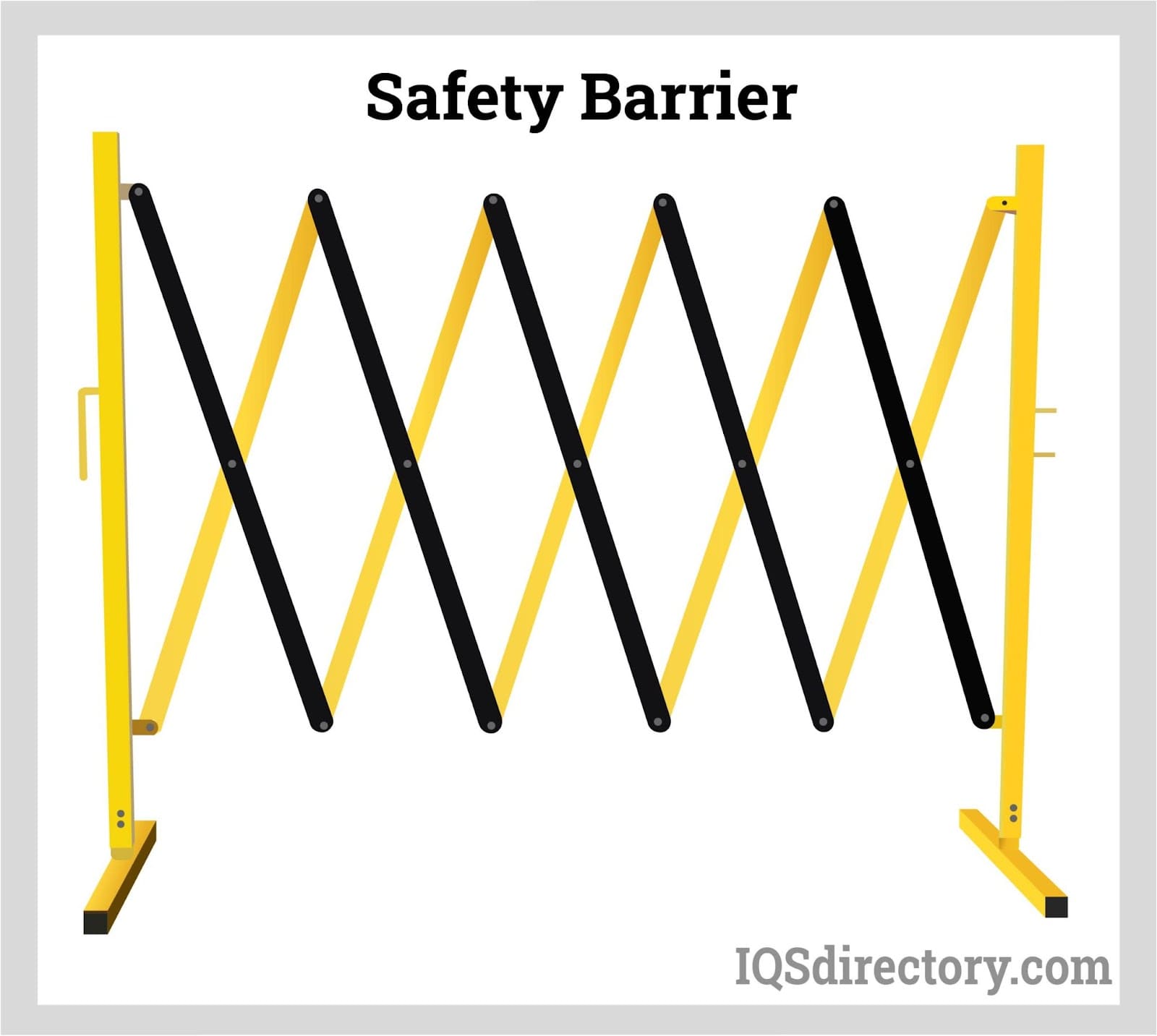

Safety barriers keeps employees away from potentially hazardous machines and keep vehicles away from restricted areas.

Safety barriers keeps employees away from potentially hazardous machines and keep vehicles away from restricted areas.

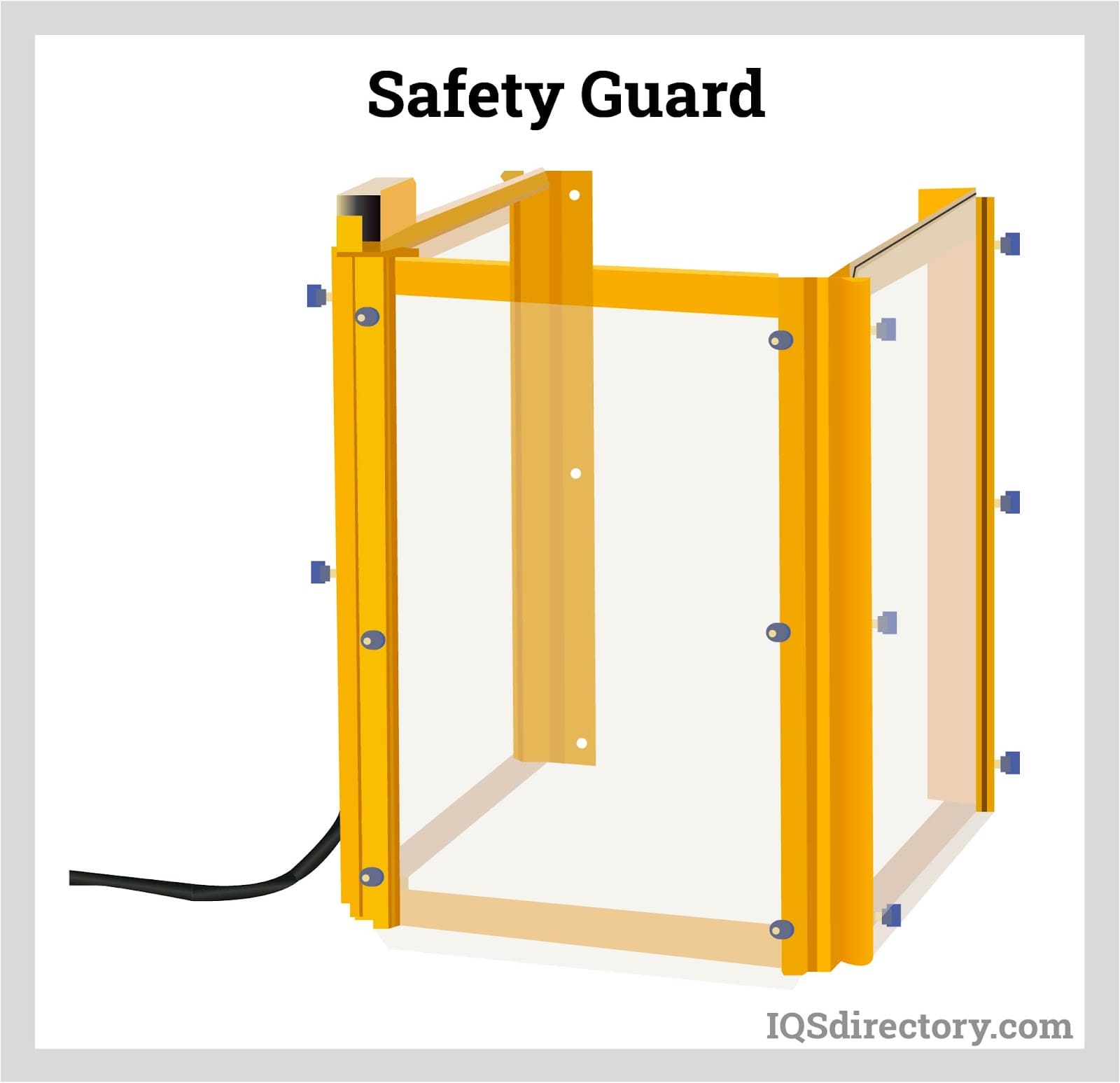

Safety guards are physical barriers built around potentially hazardous machines and mobile parts.

Safety guards are physical barriers built around potentially hazardous machines and mobile parts.

Wire guards direct traffic and prevents big debris from flying.

Wire guards direct traffic and prevents big debris from flying.

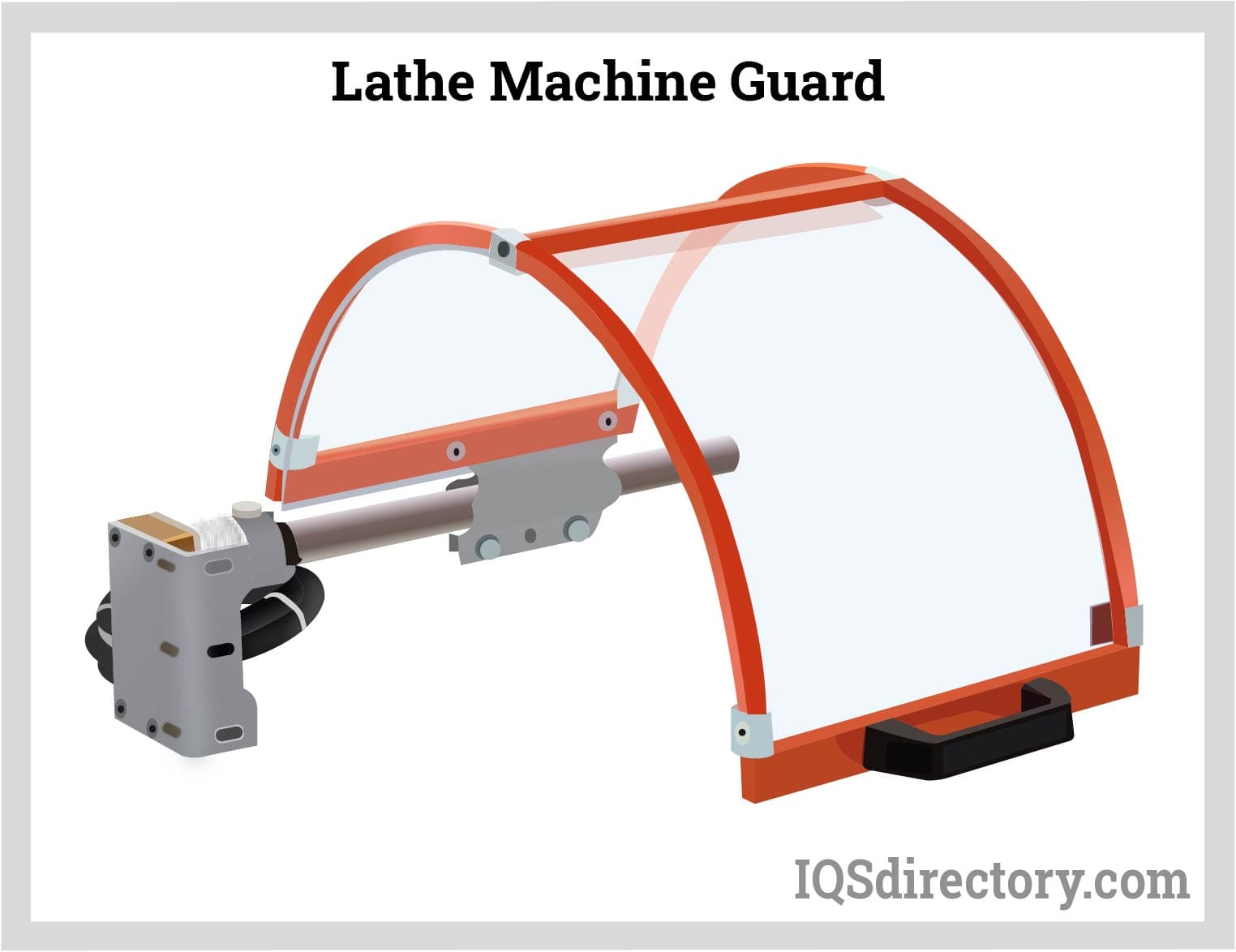

lathe guard, a visor or shield that serves as a point-of-operation protective barrier for the operators.

lathe guard, a visor or shield that serves as a point-of-operation protective barrier for the operators.

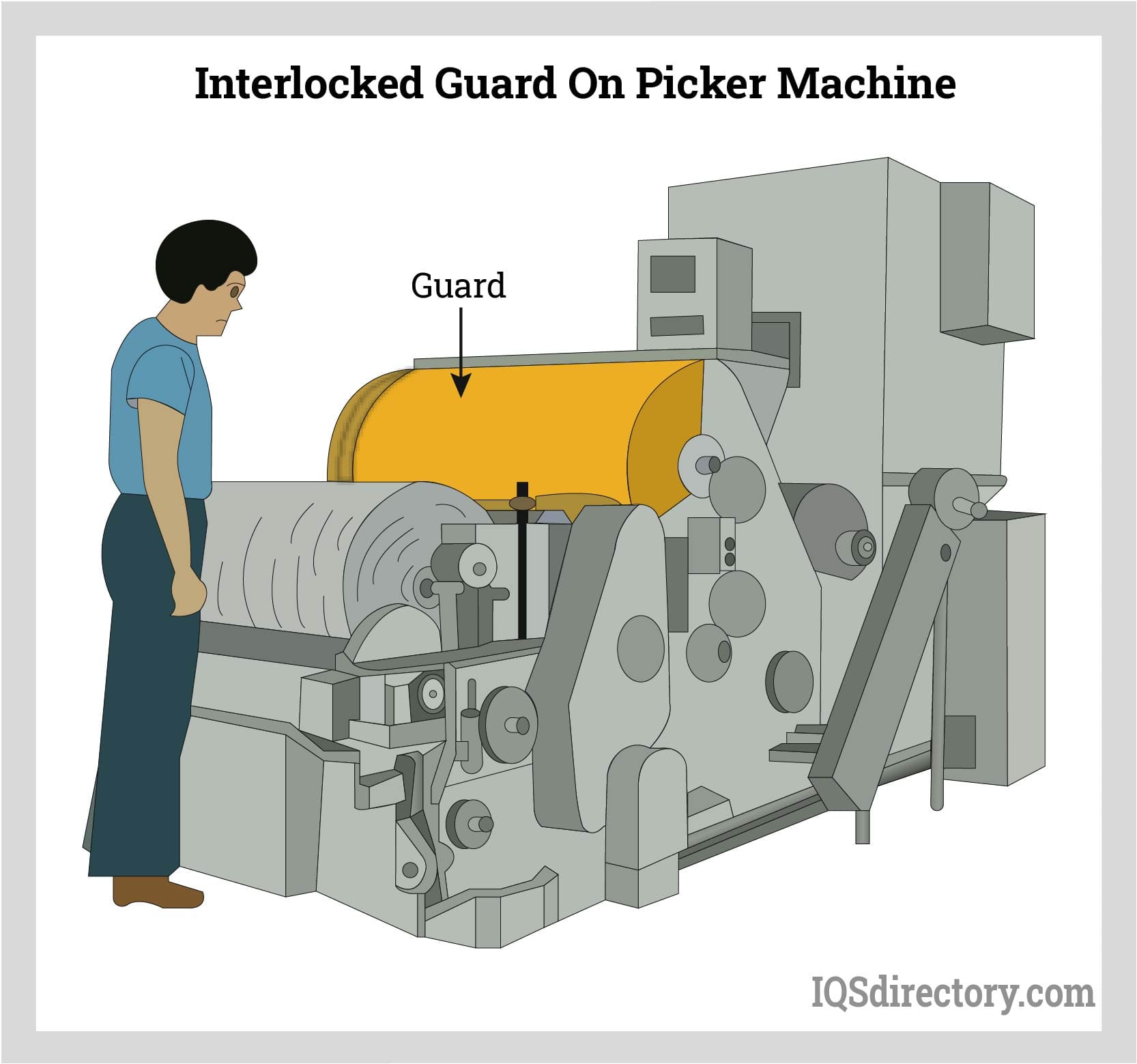

Interlocking guard allows the barrier to be opened or closed, while open the power supply is automatically disengaged.

Interlocking guard allows the barrier to be opened or closed, while open the power supply is automatically disengaged.

Types of Machine Guards

There are four different types of machine guards, as defined by OSHA. These include: fixed machine guards, interlocked machine guards, adjustable machine guards and self-adjusting machine guards.

- Fixed Machine Guards

- An integral part of the machinery. Fixed guards are permanent components made from sheet metal, wire mesh, bars or plastic panels. Fixed guards like guardrail machines create a barrier by surrounding the perimeter of the machinery.

- Interlocked Machine Guards

- Also known as electrical interlocks, are electronically connected to the machinery. Their goal is to regulate access to the hazard zone. As an added safety feature, if and when the guard opens, the machinery it is guarding automatically shuts down immediately.

- Adjustable Machine Guards

- Manually adjustable guard types that allow workers to move them around. They are quite useful not only for this reason, but also because they permit configuration flexibility. This way, operators can handle a wide variety of material sizes and loads. Plus, they protect the point of operation or section of blade even when it is not being used. Adjustable machine guards are useful on equipment like band saws.

- Self Adjusting Machine Guards

- Automatically alter their positions when workers feed new material into the machine. They are also quite commonly used with saws. They move away from the point of operation and open up just enough to let material into a blade’s cutting zone. They cover the other portion of the blade when it is not in use.

- In addition to these, there are a wide variety of machine guards specifically meant to encase certain types of machinery, such as lathe guards and chuck guards, wire guards, drill press guards, milling machine guards, safety light curtains and brake monitors.

- Lathe Guards and Chuck Guards

- Protect machinists from flying tool bits and shards of excess material.

- Wire Guards

- Which are one example of a safety barrier, usually form a partition around a machinery area and acts as machine guard fencing.

- Drill Press Guards and Milling Machine Guards

- Designed to fit around machines that require workers in close contact with potentially dangerous components, like blades or powerful presses.

- Safety Light Curtains

- Rather than form a physical barrier, are invisible and shut down a machinery system when a certain partition has been breached. They use infrared lights to form a barrier around dangerous machinery.

- Brake Monitors

- Also non-physical guards, and signal workers or shut down systems when a brake system is failing or in need of repairs.

- In addition, in place of these basic machine guards, workers can use different aids, such as awareness barriers.

- Awareness Barriers

- Like safety light curtains, call attention to the danger zone, but do not physically prevent the operator from entering it. Instead, if the worker does walk through the barrier, the system automatically and immediately shuts down. The mechanics involve a transmitter that emits infrared lights surrounding the object or machine that is dangerous, which are connected by the receiver that comes in the form of many photoelectric cells. When any of the connections between the transmitter and the receivers are broken, that is when the system is shut off.

- Electromechanical Sensors

- Have a probe or contact bar that moves a predetermined distance as the operator starts the machine, and if there is something blocking the bar, the machine will not begin.

- Gate Barriers

- Used to protect the operator at the point of operation. If the gate is not in place, the machine will not begin its cycle.

- Radiofrequency Devices

- Use radio beams to interrupt or prevent the machine from starting.

- Two-Hand Control Guards

- Require the operator’s hands to be safely located on the controls while the machine is running. Once the pressure from the hands is released, the machine will stop.

Machine Guard Applications

Presses, milling machines, automated assembly line machinery, roll form machines, robotics, saws and feeders, among others, have potentially dangerous components that require a machine guard to operate safely. Machine safeguards are crucial to these types of machines because they prevent crushed fingers or hands, loss of limbs, burning, blindness, or death. More and more often, machines are manufactured with integral machine guards, but some need to be analyzed before the proper user-built guard can be installed at the point of operation. Robots also need proper machine guarding.

Finding the Right Machine Guard Manufacturer

Worker safety and OSHA compliance are two incredibly important applications for those employing industrial machinery. To make sure that your systems, equipment and devices receive proper guarding, you need to work with a professional you can trust. To help you in that endeavor, we have put together a list of several industry leaders.

Find machine guards manufacturers and machine guards suppliers by perusing the list of companies on IQS Directory. Refine your search below by location, company type and certification to find machine guards manufacturers and suppliers. Use the time-saving Request for Quote tool to submit your inquiry to all the machine guards companies you select.

Accessories for Machine Guards

In a sense, machine guards themselves are accessories, since they accompany the main machine. Nevertheless, they have many accessories of their own. Examples of machine guard accessories include: motor controls, machine lamps, safety tape, belt covers and fittings.

Standards and Proper Care for Machine Guards:

Because of the vast dangers of certain machinery, machine guards are regulated by OSHA standards, to ensure that every worker is protected by a product that is sound and strong. (The European equivalent to OSHA standards is the Machinery Directive (MD).)

All machine guards, regardless of application, must adhere to the following five OSHA requirements:

First, they must prevent all contact with the dangerous components of the machinery.

Second, they must always be secured. If the machine guard is not secured to the machine itself, then it must be secured to the walls or ground.

Third, all guards must have high impact strength to stay in place at all times. They must all protect workers from falling and flying objects and create no new hazards.

Fourth, machine guards must not create an interference that could slow down the manufacturing or fabrication process, or create difficulty for any workers.

Fifth and finally, since many machines must be regularly lubricated to work properly, machine guards cannot inhibit, but should rather allow plenty of room for a machine to be safely and easily lubricated.

Machine Guard Terms

- Belts

- Moving parts of a machine such as transmission belts, flat belts, V-belts or round belts.

- Brake

- Stops and holds the crankshaft on a mechanical press when the clutch is disengaged.

- Danger Zone

- The part of the machine where action is taking place that could potentially injure the operator.

- Device

- An attachment to a press that can either stop the press from operating if the worker’s hands are near the point of operation, or prevent the operator of the machine from reaching into the point of operation.

- Enclosures

- Mounted barriers preventing access to machine parts or equipment that is in motion.

- Guard

- Barrier that restricts entry of any body part or object into the point of operation.

- Hand Feeding Tool

- Hand held tool used to place or remove material being processed within or from the point of operation.

- Mill

- Machine with two metal, horizontal rolls revolving in opposite directions.

- Nip Points

- Caused by rotating parts that are either touching or close to each other. Nip points may cause injury if something is caught in them and the machine does not stop.

- Point of Operation

- The area where work is performed on a machine.

- Power Transmission Apparatus

- Mechanical system parts transmitting energy to the section of the machine performing work.

- Components may include cams, gears, pulleys, connecting rods, coupling belts, flywheels, chains, cranks and spindles.

- Press

- Mechanically powered machine built to shear, punch, form or assemble material by means of shaping, cutting or using various dies attached to slides.

- Press safety

- Refers to the area of manufacturing that deals with protecting workers from bodily damage caused by industrial presses.