Environmental Test Chambers

Anyone interested in a testing chamber for their products should know what they are and how they are used before buying one. An environmental test chamber is a high-quality product that will carefully reproduce a particular environmental condition as a way of testing a product. They can simulate a specific level of humidity, a temperature, or even pressure level to see how the materials of the product react to it.

Environmental testing is done to ensure a company is building a high-quality product. These chambers will test the temperature and humidity in a variety of pressures and provide a wide range of readings that help ensure the product meets quality standards. They can be set to a specific humidity range, temperature range, and pressure range in a straightforward and easy-to-control way.

Environmental chamber manufacturers offer a variety of products, including climate chambers, temperature chambers, and even those that test thermal shock. Understanding these items, including a few items on their spec sheet, will help you decide which is right for your needs and give you insight into how they operate.

Quick links to Enviromental Test Chambers Information

Benefits of Environmental Test Chambers

There are many reasons you should consider installing an environmental test chamber in your facility. They can help you test the quality of your materials and ensure every product you make meets your high standards. They can also help you catch flaws in a design before mass producing an item. In this way, you can avoid losing an excessive amount of money.

Another major benefit of having testing chambers in your facility is you don’t have to hire somebody else to test products for you. This means you can avoid fees typically associated with these types of tests.

Applications of Environmental Test Chambers

There are many reasons that people purchase an environmental chamber for their facility. As mentioned above, they test the characteristics of a product to ensure they meet quality standards. For example, they could test a product's temperature range to ensure that it meets quality standards. However, they often go beyond these standards to find a breaking point for a product. In this way, they can create safety standards for using it.

However, it is also possible to identify flaws and weaknesses in a product before putting it up for sale. Identifying these flaws and fixing them makes the product more efficient and less likely to fall apart. Quality-testing of this type will also help a company avoid paying too much for warranty replacements. Proper testing will help warranty providers feel more comfortable offering this protection and avoid a severe financial loss.

There are a variety of industries that use many types of climatic chamber suppliers to ensure their humidity and temperature protection meet quality standards. These industries include automotive, electronic, construction, medical, pharmaceutical, food, packaging, and even engineering firms. The broad range of environmental condition types these chambers test makes an environmental testing chamber worth consideration.

The History of Environmental Test Chambers

Charles Conrad invented the first environmental testing chamber in 1951. It was built in Holland, Michigan and was designed and crafted literally on the front porch of his home. The aim was to reach a wide temperature range, and the chamber could get as low as -125 degrees Fahrenheit. After inventing and building this item, he started Conrad Inc. and received a patent for his system in 1954.

Conrad's ingenious invention evolved in a variety of ways as the industry of building high-quality environmental testing chamber models grew.

Through the years, these chambers have been improved mostly by expanding the range of temperatures and the humidity levels they can test and by enhancing their portability. Smaller versions are available now that can more easily fit in a laboratory or a manufacturing facility without taking up too much space.

How Environmental Test Chambers Work

Understanding the basics of these chambers can help you operate them more efficiently. Whether you have a walk-in test chamber, a humidity chamber, a climate chamber, a stability chamber, or a temperature test chamber, you should be able to handle the environmental testing needs of most by grasping these basics. They can help you treat a variety of concerns; for example, you can use the humidity test to master the humidity control of your product.

Most tests of this type start with opening up the machine and carefully placing the product you are testing inside. Once the item is inside of the chamber, you close the door and use the controls to set up your environmental testing conditions. If you are using a pressure chamber, you choose the pressure you want the chamber to reach.

You can also control the speed at which the chamber arrives at this environmental threshold. After setting the chamber, you can start the test. The chamber will then adjust its stainless steel interior to meet the conditions you have set. During this process, technicians typically watch the product to gauge how it reacts to these conditions.

Conditions that are often tested include extreme temperatures, thermal shock caused by sudden temperature variations, moisture and humidity, electrodynamic vibrations, electromagnetic radiation, and cyclical corrosion. However, it is also possible to test for weathering elements, such as exposure to sun, sand, dust, salt spray decay, and even rain conditions. In extreme conditions, it is possible to check for the materials in a total vacuum.

The range available in these chambers varies. A temperature chamber can test ranges as large as -120 degrees Fahrenheit to 662 degrees Fahrenheit. Rapid change between extreme temperatures in these chambers creates a thermal shock condition and can cause an item to crack.

As the temperature increases or decreases in the chamber, technicians gauge the effects it has on the item. At some point, it is likely to burn in the heat or freeze in the cold. Engineers can use this information to understand the limits of their design and make adjustments if they are necessary.

Other chambers work in similar ways. In humidity chambers, the range is from about 10 to 98% RH. Testing this environmental condition is crucial to ensure the standards of your materials. In electronics, most items have a maximum humidity rating around 20-30%. However, testing them for higher capabilities helps manufacturers create higher-quality items.

It is a good idea for manufacturers to put their items to the test using a variety of testing chambers. A bare minimum of temperature and humidity tests should be conducted. However, stability testing and stress testing is also wise.

Stress testing gauges how much force an item can suffer before it breaks. The testing range for this chamber typically lies within a few pound-feet per square-inch all the way up to hundreds. When the item cracks, the engineer has found the breaking point and can either adjust the design to make it stronger or release the product.

Types of Environmental Chambers Available

There is a wide range of chamber types available for your use. Some chambers are designed for specific types of environmental conditions. A humidity chamber focuses solely on controlling the humidity in the testing area. A temperature chamber can reach a broad range of temperature levels and can often induce thermal shock in a product.

However, there are also temperature and humidity chambers that can perform a variety of processes. Other chamber types include a climatic chamber, a pressure chamber, and a stability chamber. The last type tests how well a product reacts to the vibrations caused by using it. While not as common as other types of chambers, they do have their use.

In addition to different environmental conditions tested by chambers, there are variations in size for different product types. A walk-in chamber is typically the best type if you plan on working with a lot of delicate items and need a lot of storage space. However, table-top testing chambers are ideal for smaller facilities that test individual items of a slighter size.

Many of these products are built by a variety of manufacturer groups. Choosing the right one requires considering why you need one in the first place and researching manufacturers who can best meet all your needs. Electronics manufacturers typically do well with pressure and temperature chambers.

Method of access to your chamber is an important consideration. A large number of people prefer a walk-in chamber because they hold a more substantial number of materials. However, they can be more expensive and harder to install. That's where bench-top models come into play. They can be fitted in a small area to test smaller items. You typically see these examples right in the manufacturing facility, used by engineers or factory workers to quality-test their products.

Important Components of Environmental Test Chambers

Several items make up the build of an environmental test chamber. A few include the electronic elements that help control the changing environment inside of the chamber. These typically include various conductors and wires that are well-insulated and protected from the environmental changes occurring inside of the chamber.

In addition to these electronics, test chambers contain the item that changes the environmental conditions. There are heaters and freezers in temperature chambers to reach extreme temperatures quickly and efficiently. For pressure chambers, there are vacuums and other items that help adjust the pressure inside of the chamber to the level required.

There are many other interesting components in these chambers that make them worth considering. Some have video feeds that make it easier to gauge what is happening to the sample during the testing process. Others simply have a viewport that can be opened up after the process is done. Higher-quality chambers include a reach-in glove that allows you to handle test subjects.

Beyond these viewing components, you have a variety of possible control systems you can utilize. For example, older chamber models often use simple analog control methods to achieve their environmental changes. In some instances, it is possible to use a small wheel to adjust the humidity on these old chambers. However, more modern ones use digital readouts and LCDs.

Design of Environmental Test Chambers

Can you customize a testing chamber for your facility? Absolutely. Many design elements can be adjusted to meet your needs. For example, you can change the size of the unit to get a testing chamber that fits more comfortably in your facility. While the size adjustments are limited by the reality of the product operation, you can adjust many aspects of its design to minimize its width and length.

You can also get new inspection equipment installed, change the viewing port, add a stainless steel interior, add computer components, and even request web-enabled capabilities. All of these updates are available and help to make your testing chamber more efficient for your specific needs.

It is also possible to get computer programming installed on your testing chamber. This extra makes it possible to change your testing so that it is more efficient; with this feature, you can set up automatic testing cycles while your workers are away from the office.

Safety Standards of Environmental Test Chambers

There are many safety standards for these types of units. They must pass the OSHA standards for insulation on freezing chambers and also pass their own stress test needs. Interestingly, a walk-in chamber is not considered a constricted area because it is not designed for continuous employee use. As a result, the interior size can often be quite small. However, the interior space does require a permit because it could contain a hazardous atmosphere capable of impacting employees. Understanding of these safety standards requires discussion with OSHA representatives and review of an updated copy of their considerations.

Choosing the Right Environmental Test Chamber Manufacturer

When it comes time to choose the right environmental testing chamber designer for your company, you need to do a lot of research. What kind of chambers does the company build? Are these products regarded highly by others? Gauging a company's reputation helps you find one that meets your unique needs.

The right manufacturer for you may not always be the best manufacturer. Those with limited funds may require a bench-top model that the highest-rated manufacturer doesn't provide at a reasonable price. In this instance, it is a good idea to talk to a variety of budget-oriented designers who understand your needs and who can work with you to achieve your goals.

Make sure to check with OSHA and the Better Business Bureau to get a good idea of the quality of a manufacturer and their products. OSHA can help you better grasp the safety standards behind these products while the BBB can give you a rating of the company based on real customer reviews and their independent investigation.

Environmental Test Chamber Images, Diagrams and Visual Concepts

An environmental chamber is an enclosure used to test the effects of a variety of conditions on a product, component, part, or assembly.

An environmental chamber is an enclosure used to test the effects of a variety of conditions on a product, component, part, or assembly.

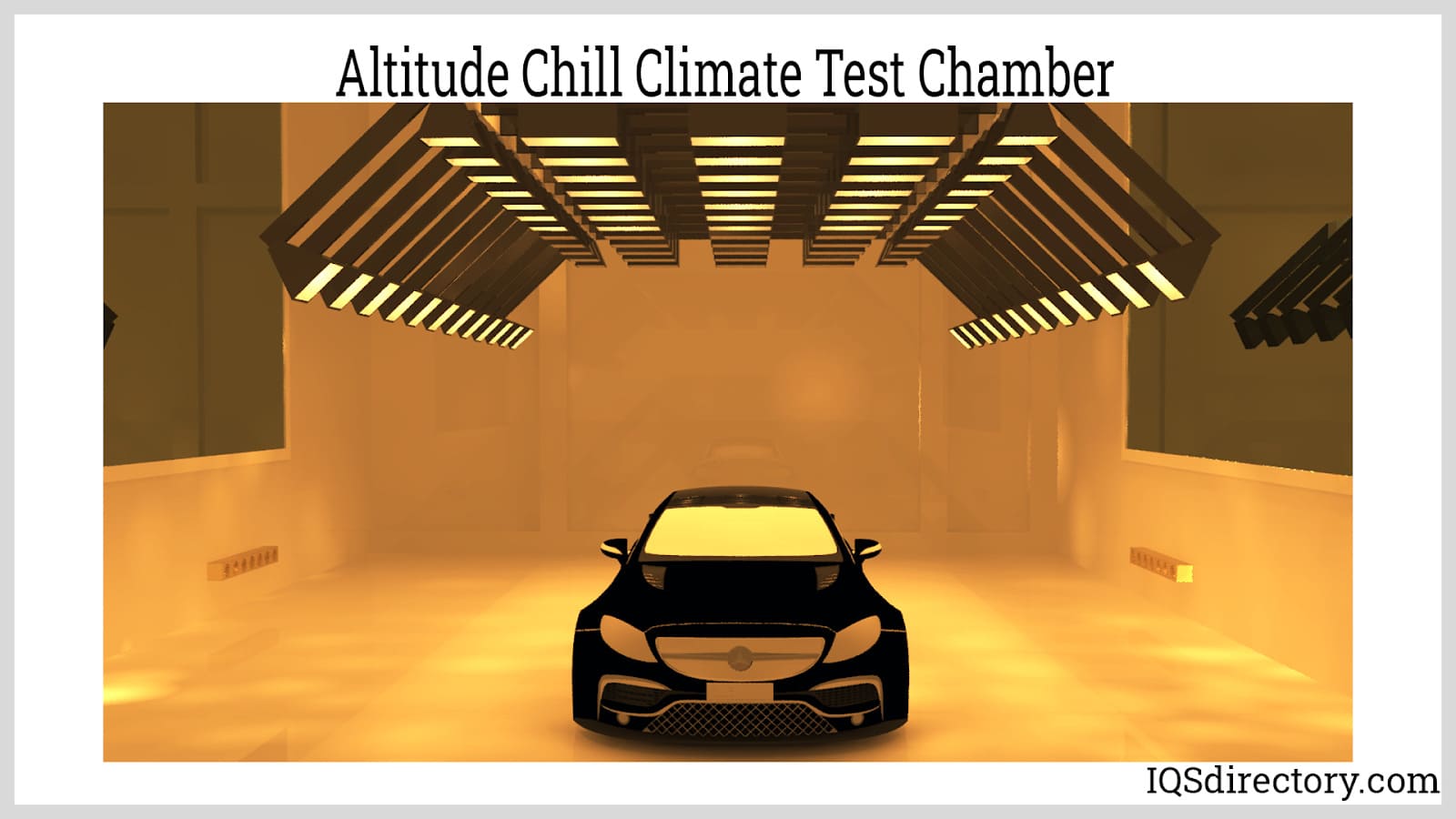

An example of testing a car to certain environmental conditions that might be experienced.

An example of testing a car to certain environmental conditions that might be experienced.

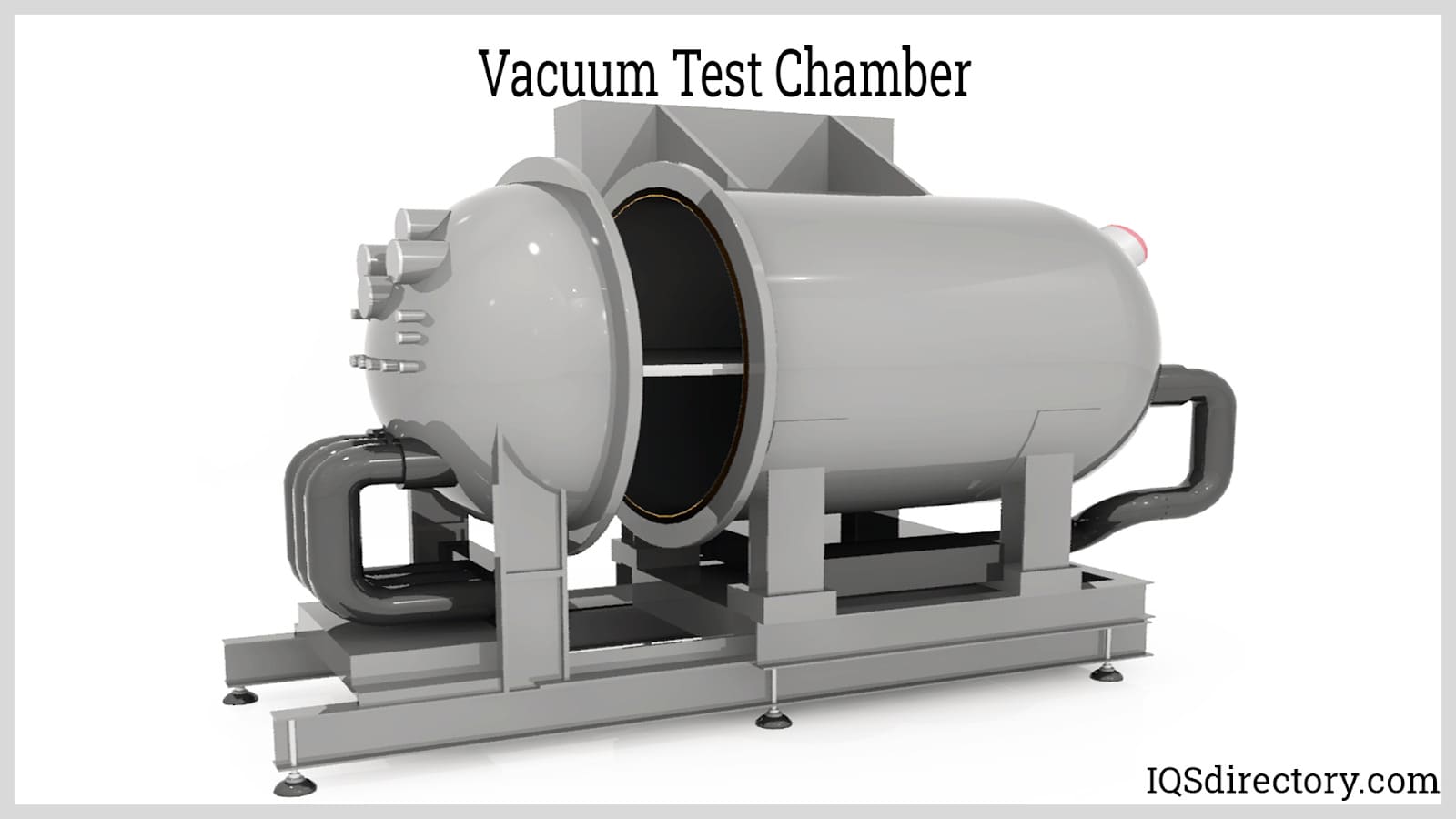

Vacuum chambers creates a low pressure environment by removing air and other gases from an enclosed space.

Vacuum chambers creates a low pressure environment by removing air and other gases from an enclosed space.

Humidity Chambers producing environmental conditions to test products or components when affected by both heat and moisture.

Humidity Chambers producing environmental conditions to test products or components when affected by both heat and moisture.

Stability test chambers are used to determine a products shelf life and the conditions that causes the products to deteriorate.

Stability test chambers are used to determine a products shelf life and the conditions that causes the products to deteriorate.

Used to test components for conditions that could be experienced during the usage of the component.

Used to test components for conditions that could be experienced during the usage of the component.

Environmental Test Chamber Types

- AGREE Chambers

- Can produce fast temperature changes of 41-104°F (5-40°C) per minute, even with large loads. Vibration test systems can be integrated within AGREE chambers, as they have removable floors.

- Altitude Chambers

- Test the effects of low pressure on an object and are capable of replicating low-pressure environments found at altitudes of up to 200,000 feet above sea level.

- Benchtop Test Chambers

- Reduce test time when testing small items.

- Cryogenic Chambers

- Replicate extremely low temperatures, from -238 degrees F to absolute zero.

- Drive-In Chambers

- Accommodate large items, such as vehicles, and are useful when performing batch testing.

- Engineering Stress Screening (ESS) Chambers

- Change the temperature of a product at a highly accelerated rate through high air velocity conditioning.

- Environmental Chambers

- Replicate environmental conditions for engineering tests.

- High Altitude Simulation (HAS) Chambers

- Replicate environmental extremes that an airplane typically endures when in operation.

- Humidity Chambers

- Able to simulate a variety of humidity conditions in order to test the effects of humidity on an object. They are used for specific testing in industrial and biotechnology applications.

- Mixed Flowing Gas (MFG) Chambers

- Used to expose electronic equipment to a mixture of pollutant gases in an environment in which the temperature and humidity are controlled.

- Reach-In Chambers

- Often contain shelves and other amenities for easy storage and user convenience.

- Salt Spray

- Or fog chambers test the corrosion resistance of an object. The object usually hangs from a rod while the chamber introduces a salty residue; this creates a foggy atmosphere, but the object remains visible throughout the process.

- Temperature Chambers

- Test the effects of temperature on an object. Temperature cycling is performed alone or in conjunction with other tests, such as altitude and vibration tests.

- Thermal Cycling or Stress Screening Chambers

- Involve the subjection of an object to extreme changes in temperature within a single chamber; the temperature alternates between cold and hot for a given number of cycles.

- Test Chambers

- Enclosures designed to provide controlled environments for tests and experiments.

- Thermal Shock Chambers

- Initiate automatic changes between two compartments; one compartment contains an extremely cold environment and one compartment contains an extremely hot environment. The rapid transference of the object between these two compartments of extreme temperatures causes a shock to the object.

- Thermotron Chambers

- Used for thermal and dynamic testing and have shock and vibration capacity.

- Vacuum Chambers

- Chambers from which almost all matter, especially air, has been removed.

- Vibration Chambers

- Apply shock vibrations of varying frequencies to an object, including bumping, shaking, and bouncing; this testing can be administered in conjunction with temperature and humidity testing. Vibration chambers have sensors that perceive and monitor the object’s reaction to the vibration.

- Walk-In Chambers

- Vary in size and can usually accommodate one or more persons. Walk-in chambers are useful when testing large objects and performing batch testing.

Environmental Test Chamber Terms

- Absolute Humidity

- The amount of water vapor, or moisture, in a unit of air.

- Absolute Vibration

- The measurement of an object’s vibration in comparison to a fixed point in space.

- Accelerated Life Testing

- The subjection of a product to stress during the development phase in order to gauge the quality of the product. The stress applied to the product often exceeds that which the product would sustain during normal use.

- Accelerated Stress Testing

- The subjection of a product to stress after production in order to identify production flaws before the product reaches retailers and consumers.

- Aggravated Testing

- The process of applying greater stress to an object than the object would sustain during normal use; the purpose of this is to identify guidelines by which the product may be used.

- Air-To-Air Thermal Shock

- Also called “two-zone thermal shock,” this process is the transferring of a product from a hot chamber to a cold chamber, or it is other sudden changes of the air temperature.

- Ambient Environment

- The given temperature and humidity content of an indoor (internal) or outdoor (external) environment.

- Atmospheric Pressure

- The amount of force the atmosphere exerts upon the earth’s surface, measuring 14.7 psi at sea level.

- Batch Testing

- A test procedure in which multiple items are tested at the same time.

- Burn-In

- The hastening of a product’s aging process through the continuous operation of the product, usually at higher than moderate temperatures, in order to evaluate product quality.

- Calibration

- The process of comparison between the current operation of an object or a system and the operating standards of that object or system. Calibration determines the efficiency of an object and identifies errors and the manner in which the system can improve.

- Corrosion

- The gradual deterioration of a metal caused by oxidation or chemical reaction.

- Critical Frequency

- The frequency level at which the destruction of the object subjected to such frequency begins.

- Damping

- Decrease in the vibration of an object.

- Dew Point

- The temperature of a given unit of saturated (containing the maximum amount of water vapor) air.

- Dry Room

- An environmental chamber in which the humidity level remains below a 14° F/-10° C dew point.

- Environment

- The internal and external conditions, regardless of the source, which affect a given object. The environment includes temperature, humidity, electricity, precipitation, etc.

- Environmental Stress Screening

- The determination of the working efficiency of an object or system through the identification of the effects of thermal changes upon the object or system.

- Frequency

- The rate of movement, measured in cycles, of a wave within a set time frame, usually one second. Frequency is often measured in hertz (Hz), which equals one wave cycle per second.

- Highly Accelerated Life Test (HALT)

- A test that assesses the lifetime of a product, reduces its development cycle time, and increases confidence in the life-cycle reliability of the product.

- Highly Accelerated Stress Test (HAST)

- Product reliability test in which an object is subjected to high temperature, humidity, and pressure. HAST has also come to be called Autoclave or Pressure Cooker Test (PCT).

- Hermetic

- The airtight sealing of an object.

- Life Cycle Testing

- The subjection of a product to stress comparable to that which the product will sustain during use in order to determine product quality.

- Liquid-To-Liquid Thermal Shock

- Alternating immersion of an object in hot and cold liquids.

- Product Recovery Time

- The recovery time of a physical product after it has been subjected to testing. Product recovery time is dependent upon the location of the sensor in the load.

- Psi (Pounds Per Square Inch)

- Unit that measures the amount of pressure applied to an object.

- Relative Humidity

- The ratio of the current amount of water vapor in a given unit of air at a given temperature to the greatest amount of water vapor the unit of air could hold at that temperature.

- Relative Vibration

- The measurement of an object’s vibration in comparison to a fixed point on the object.

- Remote Conditioners

- Are used for testing hard to reach, non-accessible, or large products. They are designed to promote flexibility in temperature testing applications by delivering temperature-conditioned air to secluded sites. Remote conditioners provide unique solutions for unusual requirements and can be used in many different industries.

- Saturation Humidity

- The maximum amount of water vapor a given unit of air can hold at a given temperature. Air becomes saturated when relative humidity reaches 100%.

- Stress

- Condition or force applied to an object that may impair the object’s quality and performance.

- Temperature/Humidity/Bias (THB) Test

- Product reliability test in which an object is subjected to high humidity under a constant temperature. Test time greatly exceeds that of HAST test time.

- Thermal Cycling

- Subjecting an object to extreme changes in temperature within a single environmental chamber.

- Thermal Shock

- Stress sustained by an object as a result of rapid temperature changes.

- Three-Zone Thermal Shock

- Moving the object from a hot to a cold chamber, and vice versa, with an intermediate step of exposure to room temperature.

- Transfer Time

- The amount of time it takes for an object to be moved from one chamber to another.

- Upstream Recovery Time

- Also called “downstream recovery time,” this is the time required for the air temperature to recover in the new zone. Upstream recovery time can be measured in the air stream prior to or following the test load.

- Vibration

- Motion of an object around a position of equilibrium.