Electric Transformers

Electric transformers are inductively coupled electro-magnetic devices that transfer electrical energy from one circuit to another. All electronically operated equipment depends on power transformers to convert electrical currents into voltages that fit a specific application, and current transformers are also required in order to store and transport energy through power lines and grids.

Quick links to Electric Transformers Information

History of Electric Transformers

In the 1830's, Michael Faraday and Joseph Henry discovered the property of induction through their work with electromagnets. Amazingly enough, these two men were on two separate continents, working totally independently of each other, and they made their discoveries within a year of each other.

The Faraday Law, which would lead to the invention of the first transformer about 45 years later, was born when Michael Faraday conducted an experiment to show how an electromagnetic field could provide power. He wrapped two coils around opposite sides of a ring. One side he connected to a galvanometer, and the other side he hooked to a battery. He saw that when he hooked a coil to the battery that it powered, the coil hooked up to the galvanometer, just as he had suspected.

However, when Faraday unhooked the coil from the battery, he noticed that a current still flowed from the coil to the galvanometer, which meant that the battery was still powering the coil even though it was no longer physically connected to the coil or the ring that the coil was wrapped around. This scientific breakthrough laid the groundwork for the creation of the first transformer by Ottó Bláthy, Miksa Déri, and Károly Zipernowsky of the now defunct Austro-Hungarian Empire. Theirs was a toroidal shaped transformer that was used for AC powered incandescent lighting systems.

Even though the first transformer was made in Budapest, Hungary in the mid 1870's, it would be another decade before the first transformers that were considered practical for regular use were introduced. This was done by William Stanley and George Westinghouse. In 1886, it would be the transformer developed by William Stanley that would become the first one used for commercial use to provide power to Great Barrington, Ma. Today transformers are a part of all electronic circuitry. They are on the poles that connect power lines, they are in lamps, and even in flashlights.

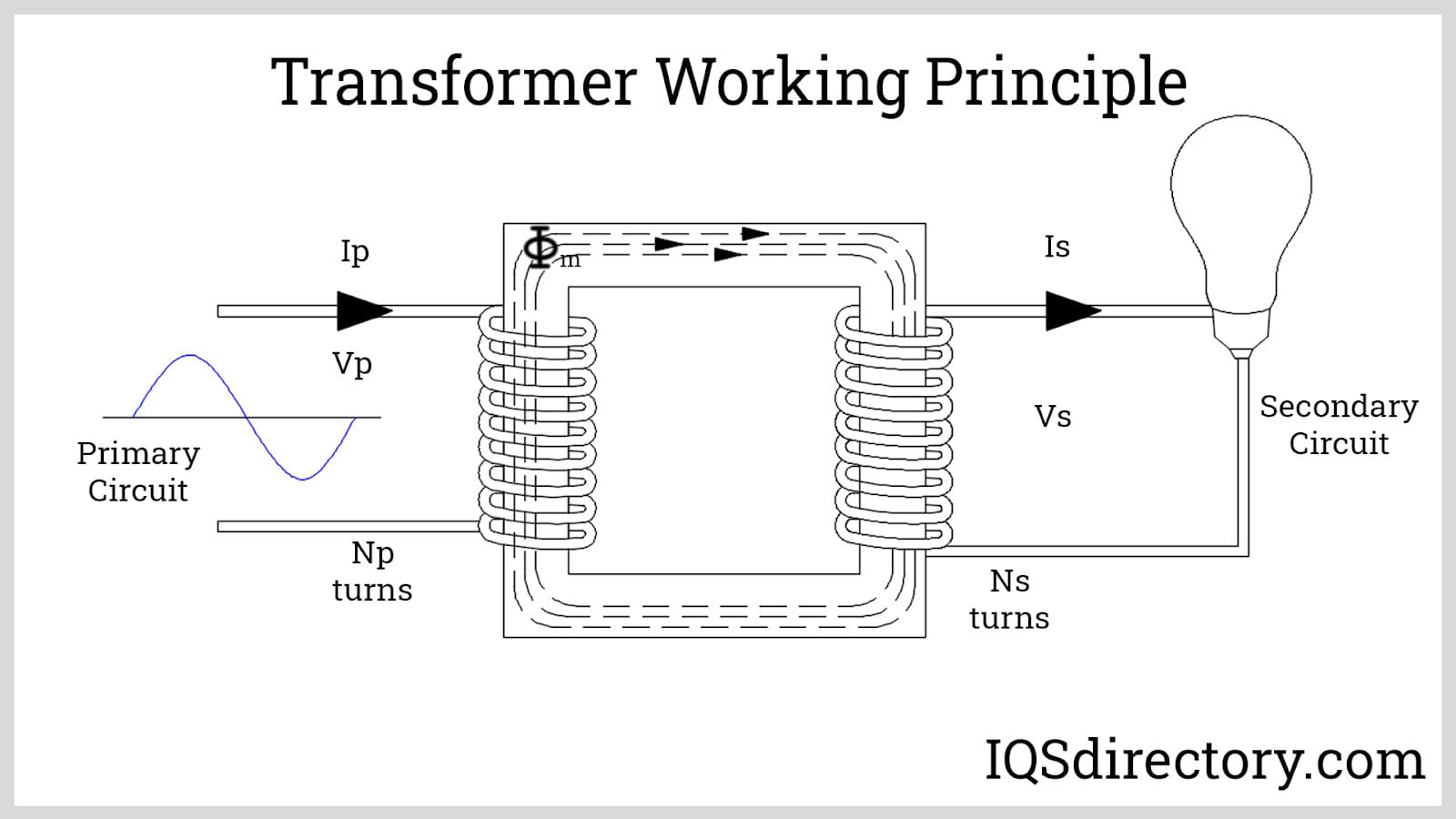

Transformers operate off of the principle of electromagnetic induction. For this to occur, there must be an electromagnetic field. A coil wrapped around a core is charged with an alternate current which is converted into a primary voltage to achieve this. The energy in the coil then permeates an electromagnetic field, also called a magnetomotive force, which will travel through the core to another coil, giving it a secondary voltage.

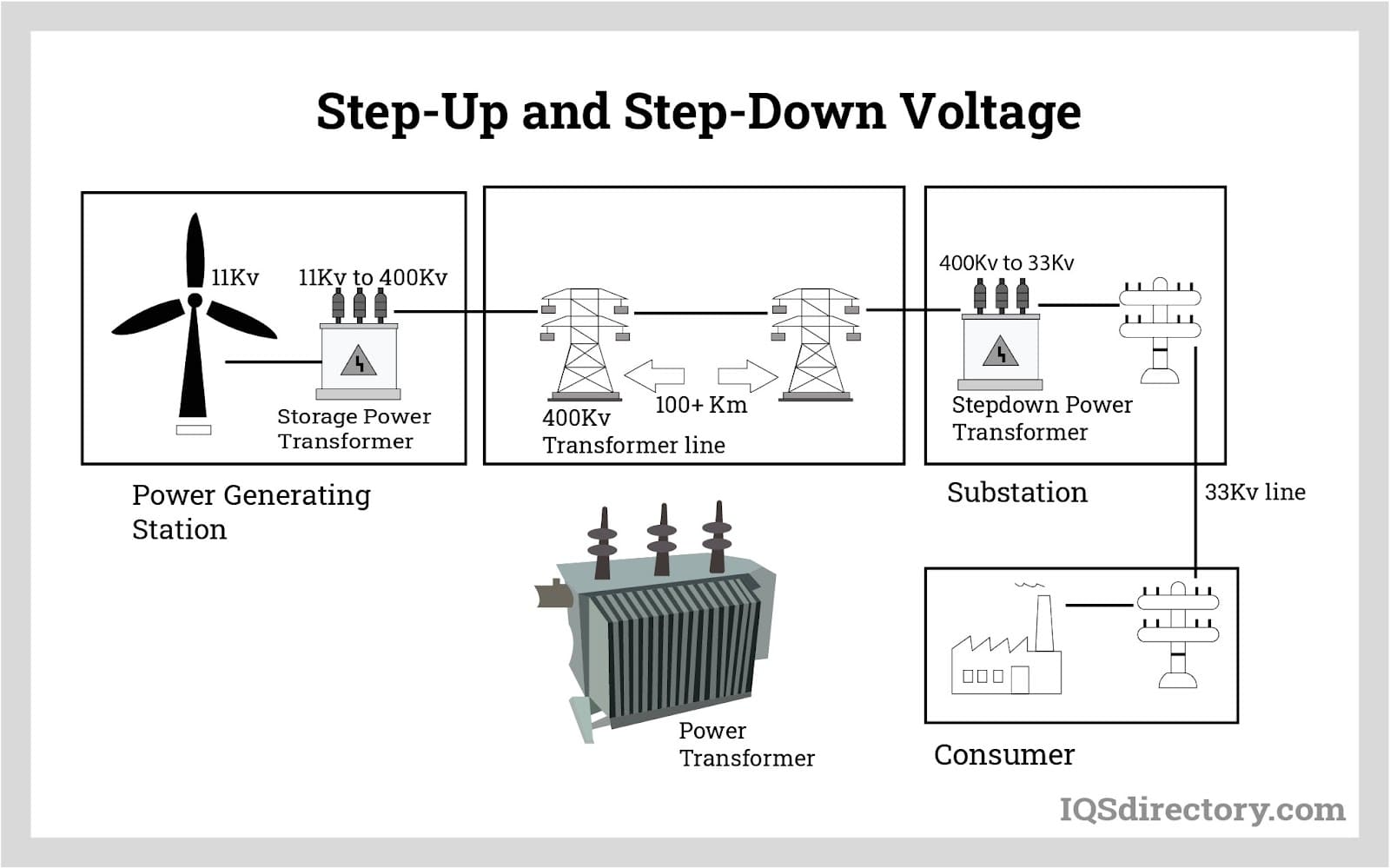

The input voltage is determined by the power source itself. However, the voltage that the actual transformer will output is determined by the second coil that the electricity passes through. If the second set of windings, or coils, is equal to the first set, then the voltage output will be the same as the input. However, if the secondary coil has fewer windings than the primary coil then the secondary voltage will be less than the primary voltage. This is called a step-down transformer. If the secondary coil has more windings than the primary one then it will increase the voltage; this type of transformer is called a step-up transformer.

There is energy lost in the magnetic field of the transformer. This lost energy resonates in the form of heat. To lessen the loss of energy, oftentimes the coils are in a cooling agent within the transformer. Many manufacturers utilize a concentrical configuration in which both the primary and secondary coils are wrapped together around the coil. This configuration is most popular in three step transformers. From the transformer, electricity is then transported through power lines and power grids. The transformer does the job of regulating the voltage of the electricity to be transferred. Step-up transformers increase the voltage, and step-down transformers decrease the voltage. This process ensures that the end device that is being powered receives the proper voltage. Too little voltage will not power a device, and may affect its functionality long-term. Too high a voltage could destroy the device that is being powered, and could potentially cause fire and electric shock if it exceeds the peak voltage of a device.

- 3 Phase Transformers

- Tools used to change the voltage of 3 phase electrical transmission systems. The three primary windings are connected to each other, and the three secondary ones are connected to each other.

- Auto Transformers

- Electrical transformers with one winding that is common between both circuits and does not have any isolation between the two circuits. Automatic transformers are one of the more cost-efficient types of transformers, as well.

- Current Transformers

- A primary winding linked in with the circuit to make the current measurable; they are used to change electrical currents.

- Distribution Transformers

- Rated between 3 and 500 KVA with 601 volts or more.

- Dry Type Transformers

- Do not use liquid to cool or insulate.

- High Resistance Transformers

- Have high leakage-to-reactance to limit the output current to a designated value in the event of a fault.

- High Voltage Transformers

- Designed to handle electrical energy in high voltage levels. Instrument transformers accurately measure and monitor power voltage as it is transmitted proportionally through the primary and secondary coils.

- Inverters

- Convert between AC and DC power.

- Isolation Transformers

- Transformers that insulate the primary circuit from the secondary circuit. These transformers decouple two circuits, allowing AC power to move from one device to another without the two circuits connecting; this is achieved by having the primary and secondary coils not directly connected.

- Laminated Core Transformers

- Among the most commonly used types of transformers. These transformers are commonly used in appliances to convert voltages to low voltages. The laminated core prevents eddy current losses in the core.

- Low Voltage Transformers

- Convert into lower voltages.

- Polyphase Transformers

- Can be connected either to multiple single-phase transformers or just one polyphase transformer. Many polyphase transformers use the zigzag configuration, especially if it is a grounded system.

- Power Transformers

- Devices that convert voltage to lower levels.

- Pulse Transformers

- Wide-band devices that are mainly intended for waveform transmission. They transmit rectangular electrical pulses, meaning that the pulses have fast rise and fall times with a fairly constant amplitude.

- Step Down Transformers

- Have the power to convert higher voltages to lower voltages by means of transferring electrical energy through two coil stages, the second coil stage having fewer coil windings.

- Step Up Transformers

- Transformers that have a high voltage winding connected to the output load and a low voltage winding connected to the power source. Toroidal transformers have copper wire around a cylindrical core so the magnetic flux is contained.

- Toroidal Transformers

- Similar to the one invented in Hungary by Ottó Bláthy, Miksa Déri, and Károly Zipernowsky. It is more expensive to make because the winding process is slow and requires special equipment. Toroidal transformers are donut-shaped transformers that are highly space efficient and excellent for reducing electromagnetic interference; inductors limit the amount of AC flow to an appliance or transient application while suppressing high frequency noise, similar to toroids.

- Zig Zag Transformers

- Special-purpose three-phase transformers that are intended for use in providing earthing for ungrounded electrical systems as well as filtering and controlling harmonic currents. In addition, zig zag transformers are special-purpose 3-phase transformers that are intended for use in filtering and controlling harmonic currents.

Transformers are regulators. They make sure that enough, but not too much, voltage is supplied for specific use. If too high a voltage is used on an electronic device then it could destroy the device, cause a fire, and even send out sparks of electricity in arch form. If a device receives too low a voltage, it could cause the device to malfunction. For these reasons, it is important that the voltage level is regulated before it is transferred to the device that is to utilize the electricity.

Power transformers are utilized in every electronically powered device or equipment. They are necessary to convert the current into the proper voltage so that the electricity can be used by the device. Whether it’s a computer, hair clippers, or a remote-control car, there is a transformer in it that regulates the way and amount of electricity is transferred to where it will be used. Use IQS Directory to find the power transforming equipment you need. In addition to converting currents to a higher or lower voltage, electric transformers can serve to isolate parts of circuits from others.

Electric transformers are static electrical machines that transform electric power from one circuit to the other without changing frequency.

Electric transformers are static electrical machines that transform electric power from one circuit to the other without changing frequency.

The electric transformers usage of the properties of the electricity to change the voltage of the electricity either making it high or to a lower degree.

The electric transformers usage of the properties of the electricity to change the voltage of the electricity either making it high or to a lower degree.

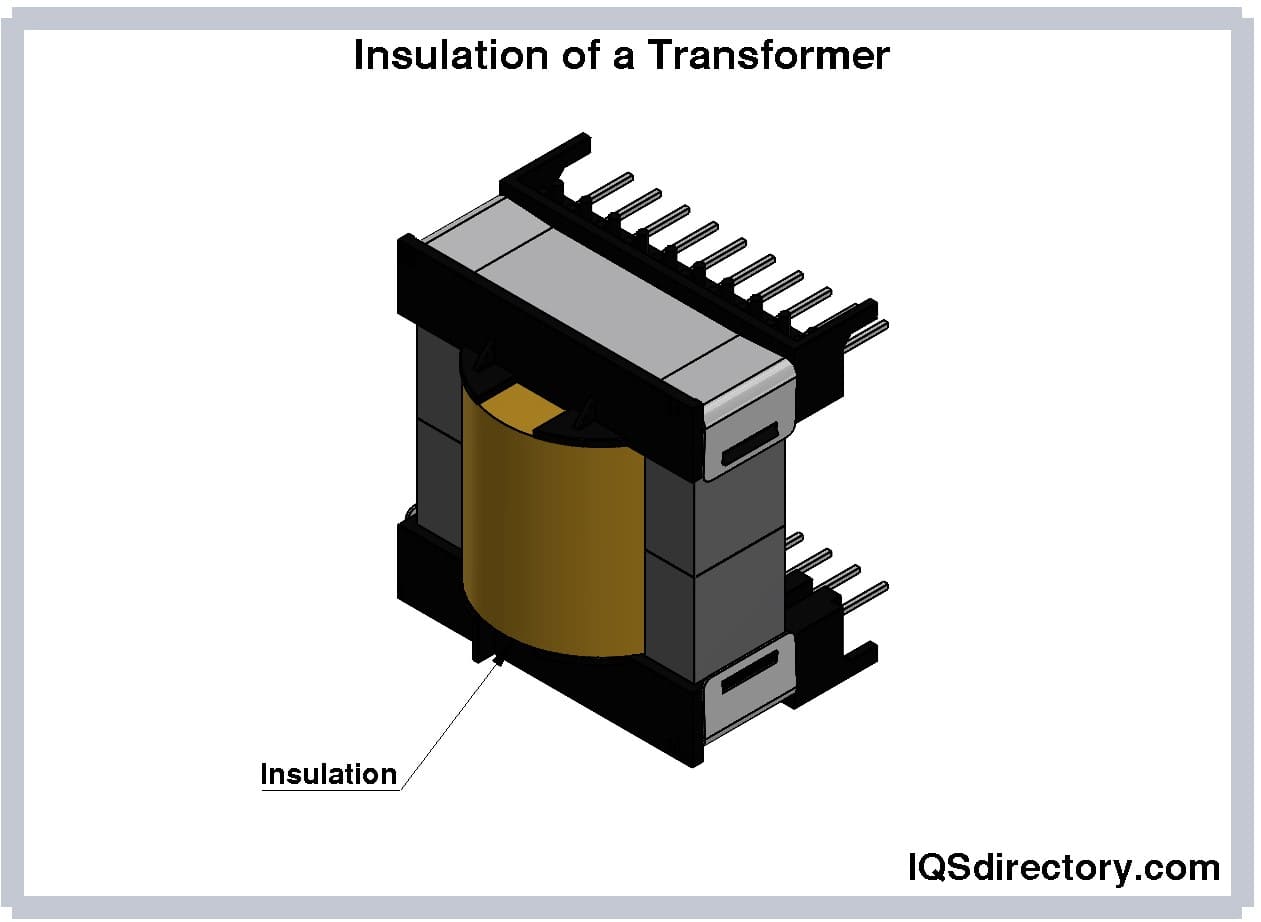

Insulation is the most important requirement for transformers and in case of failure, severe damages to the transformers can occur.

Insulation is the most important requirement for transformers and in case of failure, severe damages to the transformers can occur.

The transformer either step up or step down voltage levels ensuring a safe and efficient power system.

The transformer either step up or step down voltage levels ensuring a safe and efficient power system.

When it comes to transformers, it is Faraday's Law that is in operation, and they are perfect for storing and transporting electrical power. Ever since transformers were introduced for commercial use in 1886, when they were used to power Great Barrington, Maine, they have been in constant use in some incarnations. Transformers are the safest way to transport electricity between circuits. Many of them are capable of providing electrical power to whole towns and large sections of big cities.

Transformers can be customized to suit specific needs. There are a wide variety of types of transformers, but in the case that you need something suited specifically to your needs there are manufacturers who can help you. The key is finding the right manufacturer. A good manufacturer and the right manufacturer are by no means the same thing.

There are many good manufacturers, but the right manufacturer can only be determined by you. A good place to start when looking for the right transformer builder is of course pricing, but also understand that you may get the quality that you pay for. Also, the right manufacturer will work cooperatively with you to find the electrical power solutions that best suit your company rather than just trying to push their most expensive transformer.

It is important to know what it is you need in a transformer, and even if you aren't 100% sure what is best for your particular powering needs, capable manufacturers can provide you with the best options for your unique situation. Mechanical and electrical systems can be tough fields to navigate, but the good news is that you don't have to go it alone. You can return to the top of this page to find a convenient list of electric transformers who can fulfill your needs.

- Air Cooled

- A transformer that uses air to cool by use of fans or normal ventilation.

- Auto Transformer

- A transformer with one winding per phase.

- Banked

- Describes multiple single phase transformers connected together to provide power to a three phase load.

- Core

- The transformer’s central part or inductor that enhances the power of the magnetic field.

- Core Saturation

- A condition that results from a transformer or inductor reaching highest magnetic strength.

- Delta

- In a three phase connection the windings all connect to form a loop.

- Duty Cycle

- Proportion of time for a transformer to provide full rated power to the load. This measurement greatly affects the actual size of the transformer.

- Electrostatic Shielding

- A component that sits between windings – typically the primary and secondary – to supply the most isolation; more of these can be placed between secondary windings as needed. It is normal to connect the shielding to the core.

- Encapsulated

- A dry transformer with an enclosed core and coil assembly.

- Exciting Current

- The amount of current a transformer draws at nominal voltage input in an unloaded state.

- Ferroresonance

- Resonance results from the saturation of a ferrous core of an inductive component, which increases the inductive reactance relative to the capacitance reactance.

- Filter

- A complex system within the transformer that consists of capacitors, inductors and a resistor; it provides a relative small opposition to specific frequencies or direct current, as it blocks or attenuates other frequencies.

- Flexible Connector

- A conductor that can handle thermal expansion and contraction as well as reduce noise.

- Impedance

- That the forces that resist the flow of current in AC circuits like resistance or inductive or capacitive reactance.

- Inductance

- The capability of a coil for storing energy and resisting changes in the flow of current; it is a function of the core material, amount of turns of the coil and the cross section.

- Inrush Current

- This is when the transformer has a short current surge through it from residual flux, occurring at the moment energy is applied to the transformer.

- Isolation Transformer

- This transformer has physical separation from the primary and secondary windings in order to allow magnetic coupling between isolated circuits and minimize electrostatic coupling.

- KVA

- Kilovolt Ampere rating is a measurement of the output of a transformer without exceeding a certain temperature.

- Load

- The quantity of electric power supplied or necessitated at any particular spot in the system. Also a requirement of the KVA or VA from the transformer; light bulbs are loads.

- Magnetic Shielding

- This conductive material attenuates stray magnetic fields by its positioning around a transformer’s coils.

- Polarity

- The direction of the current between two leads. If the directions are the same, the leads have the same polarity. In electric transformers the polarity is classified as either additive or subtractive.

- Power Factor

- Watts divided by volt amps, KW divided by KVA - the leading and lagging of voltage versus current caused by inductive or capacitive loads. Harmonic power factor relates to nonlinear current.

- Rated Power

- The total of the Volts and Amps derived from all the secondary windings.

- Reactance

- The opposition to variations of alternating current; capacitive reactance relates to capacitors, and inductive reactance is the opposition to change from an inductor or coils.

- Resonance

- A condition of an AC circuit in which capacitive and inductive reactances interact, resulting in a maximum or minimum circuit impedance.

- Secondary Winding

- On the load or output side, the connected transformer winding.

- Sudden Pressure Relay

- Pressure switch device that detaches the transformer from the line.

- Voltage

- The measurement of the amount of force on a unit charge because of the surrounding charges.

- Voltage Regulation

- The change, in percentages, of the output voltage from no load to full load.

- Voltage Taps

- Supplemental connections to a winding that permit varying voltages from the same winding; typically utilized on the primary winding to permit the transformer to be used in different countries with varying line voltages.