Dryers

An industrial dryer is a piece or system of equipment that utilizes heat, cold, air, infrared light, or chemicals to remove moisture from a substance or product. A wide range of techniques can be employed to facilitate drying of a single batch or for continuous operation. The specific process depends on the type and quantity of material being handled.

Industrial dryers are used to process food, minerals, metals, dyes, pharmaceuticals, textiles, lumber, paper, glass, explosives, fertilizers, sand, gravel, plastic, rubber, and wastewater. Dried products may be powders, solid pieces of any size, or sheet fabrics.

Foods that are dried may be fruits and vegetables in their natural state, or crushed, ground, or flaked. Cereal, pet food, flour, sugar, and instant potatoes are examples of this. Meats may be sliced thinly before, or ground and crumbled after drying, for example, beef jerky or dried sausage and hamburger used for camping and survival meals.

The main process involved in the transformation from wet to dry is evaporation, which is the process by which a liquid becomes a gas and diffuses into the atmosphere. In some cases, sublimation is achieved, and a solid will change state directly into a gas.

Quick links to Dryers Information

The History of Dryers

The history of industrial food drying goes back about fourteen thousand years. It was originally developed as a method of preserving food for the winter. As people began to settle into agrarian societies, preserved food became a trade commodity. Those with an abundance of crops could trade with farmers who grew different crops or with merchants who provided wares, offering variety, and creating commerce.

Primitive methods of drying food included wrapping fruit in dried palm leaves and burying it in hot sand, hanging strips of food over a smoky fire, and in colder climates, freezing vegetables overnight, then squeezing out the moisture as they thawed. The Greeks, Romans, and Persians utilized sun and wind to dry fruits and vegetables. The Chinese and Japanese used smoke to preserve fish and meat. The Inca of Peru developed the art of freeze drying potatoes. Natives of North America freeze dried seal and walrus meat. Mongolians dried herbs, spices, and tea to be traded along the Silk Road. American settlers followed the lead of their native predecessors by sun drying any foodstuff available. Pemmican, a mixture of meat, fruit, nuts, and seeds, that was a highly nutritious staple of Native American diets, was beaten into a pulp and dried on flat rocks or woven mats lying in the sun.

With the moisture content removed, greater quantities of food could be imported and exported, introducing ever more exotic produce and merchandise to Westerners and great profits to the East. As dried products increased in demand, the need for industrial drying grew, and new methods were developed. Most methods of dehydration were low-tech, primarily spreading the product out on trays of some kind, and relying on nature to provide adequately dry conditions. These circumstances could not always guarantee a quality or safe result.

Around the turn of the 18th century, two Frenchmen named Masson and Chollet developed an effective method of mechanically preserving food. They compressed wet vegetable pulp into cakes and fed it through a heated tunnel. Temperatures of 105 degrees F. removed all moisture from the cakes, leaving a lightweight, long lasting food source that was perfect for sailors and soldiers. The flavor was less than stellar, and the general population was happy to leave the rations to the boys in the field.

Drying of food became somewhat passé, with the late 18th Century invention of the zinc-lidded canning jar, the tin can, and, ultimately the refrigerator, but the process experienced a revival when freeze drying by artificial methods was developed in 1906 by Jacques-Arsène d'Arsonval. Five years later, the rabies virus was successfully freeze dried, leading to the development of the rabies vaccine.

Around that time, W. K. Kellogg and C. W. Post were both developing more healthful diets for their respective health oriented institutes. Seeking alternatives to meat-laden nourishment, each began to produce cereal from grain. The grains were made into a paste that was spread thinly on trays and heated in large ovens until it dried into flakes. The health institutes did not succeed, but the breakfast cereal industry flourished, and both men achieved great success. From there, automated food processing developed, creating the need for larger, faster, more complex equipment to keep up with the burgeoning market for powdered and granulated foodstuff.

Food was not the only commodity to be dried industrially. During World War II, biologists discovered that freeze dried blood would remain chemically stable and viable for use without refrigeration. It was subsequently discovered that penicillin and bone tissue could also be freeze dried, dramatically advancing medical support to the troops. As humanity, industry and technology advanced, so did the need for commercial laundries. A hand cranked clothes dryer for home use was invented in 1800, although not much is known about it. The first electrically powered clothes dryer came into use in 1938. Several years later, a glass viewing door was made available on commercial tumble dryers. As technology developed and industry grew, more and more materials of every imaginable sort were being processed. Many of these products entered the process with an undesirably high moisture content or passed through a wetting process and thereby required a drying process. Drying equipment developed accordingly.

Natural matting and trays were replaced by sterile stainless steel screens and drums. Methods used to compress air for processing became cleaner and more efficient, making food processing faster, more efficient, and safer for manufacturers and consumers alike. Kilns for drying lumber, ceramics, and mineral products, such as gypsum, asbestos, and cement additives allowed the construction industry to boom.

Industrial Dryers Images, Diagrams and Visual Concepts

Industrial dryer are high powered device designed to remove moisture from machinery, products, materials, food products, and mixtures.

Industrial dryer are high powered device designed to remove moisture from machinery, products, materials, food products, and mixtures.

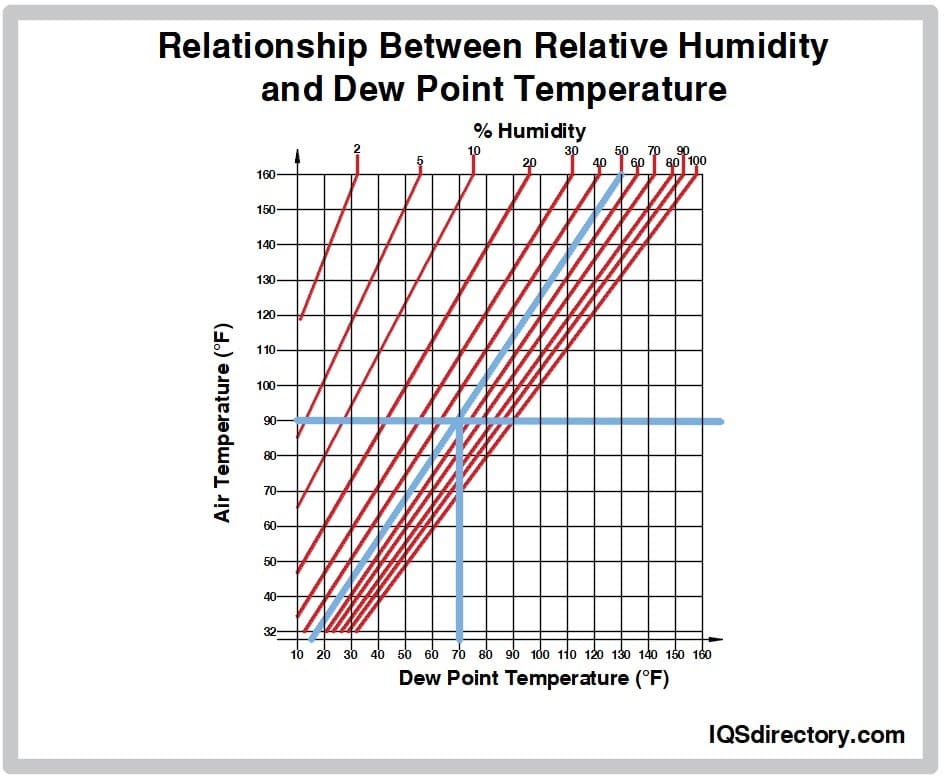

Relative humidity can be manipulated by increasing or decreasing the temperature, the amount of water vapor and the dew point temperature is still the same.

Relative humidity can be manipulated by increasing or decreasing the temperature, the amount of water vapor and the dew point temperature is still the same.

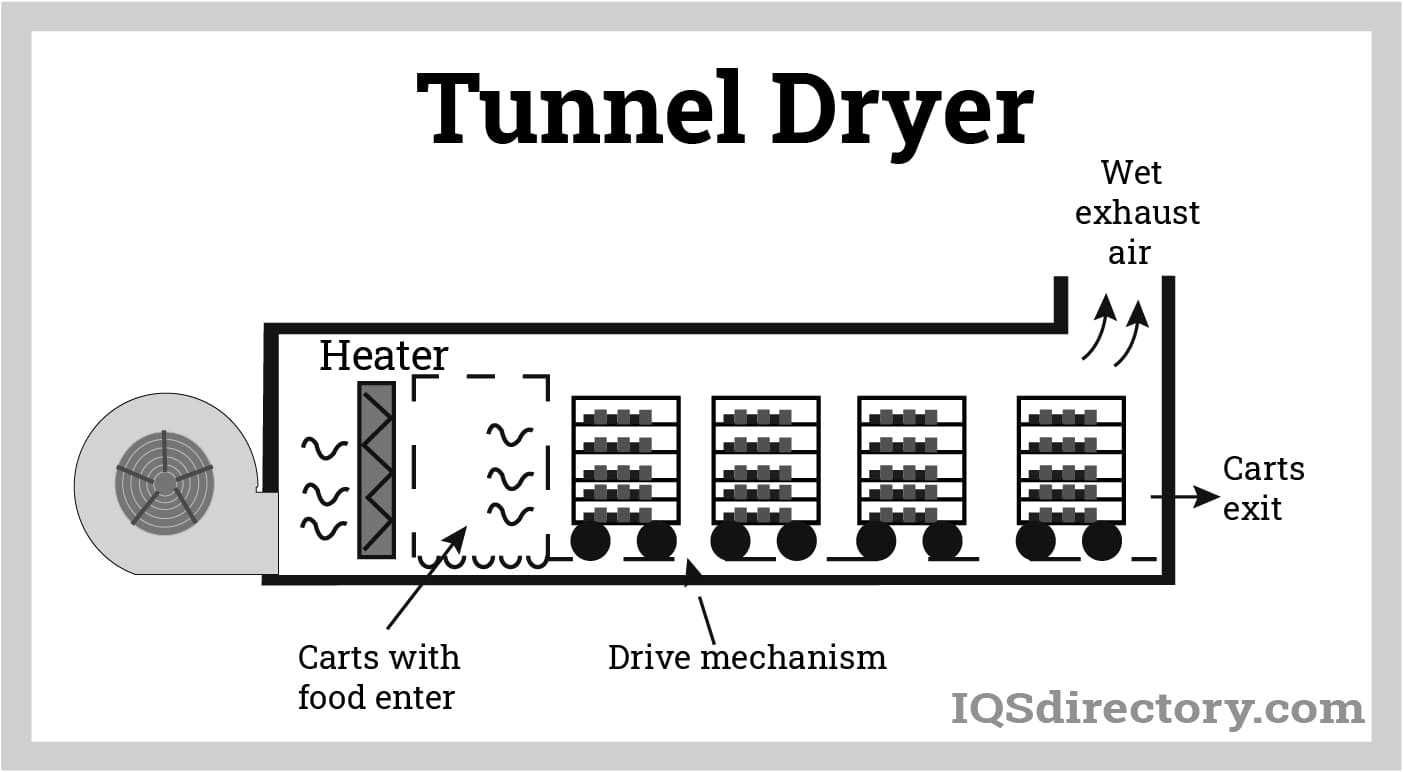

Tunnel dryers, the materials to be dried are loaded in trays attached to a trolley.

Tunnel dryers, the materials to be dried are loaded in trays attached to a trolley.

Freeze-drying involves freezing the material to be dried and subjecting it under vacuum pressure.

Freeze-drying involves freezing the material to be dried and subjecting it under vacuum pressure.

Disc dryers consist of multiple vertical discs mounted on a shaft heated by steam or hot oil, all contained in a horizontal cylinder.

Disc dryers consist of multiple vertical discs mounted on a shaft heated by steam or hot oil, all contained in a horizontal cylinder.

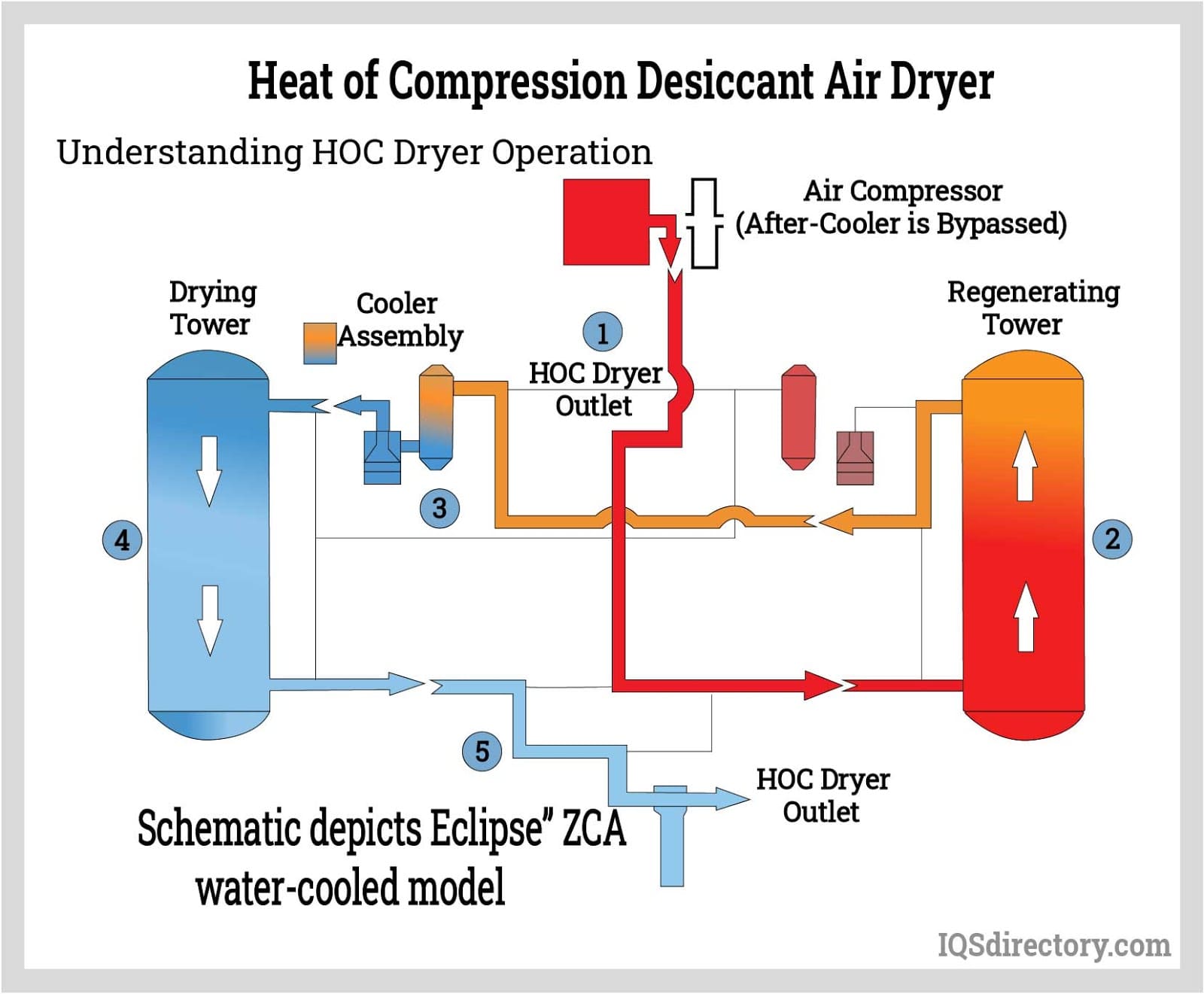

Compression desiccant dryer redirects some of the dried air from the compressor discharge is used.

Compression desiccant dryer redirects some of the dried air from the compressor discharge is used.

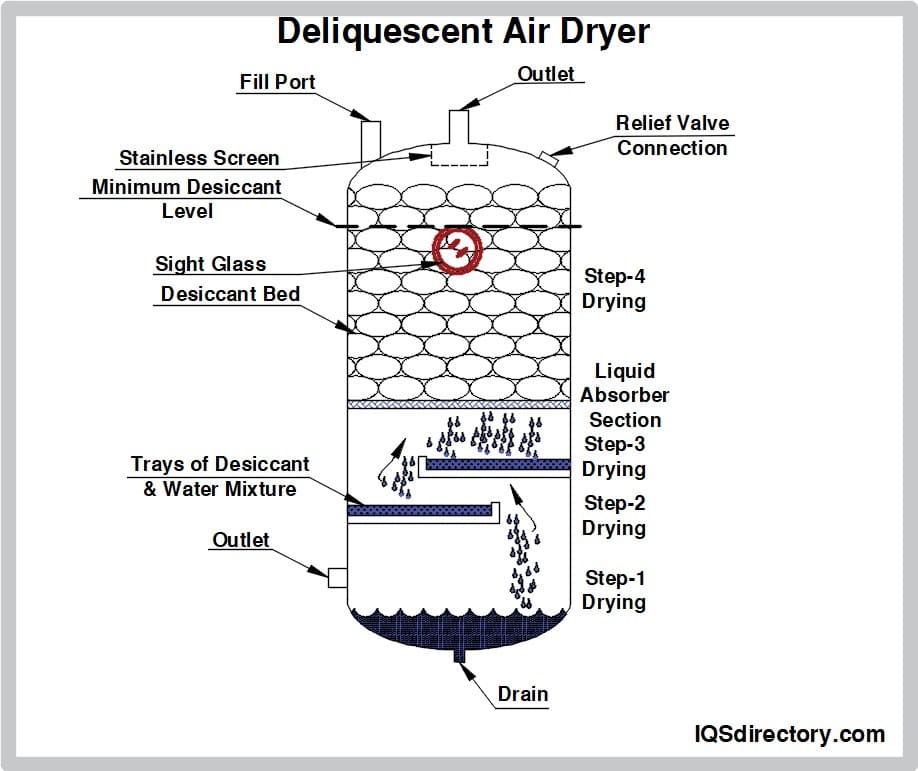

Desiccant dryers use hygroscopic materials to capture moisture from the air.

Desiccant dryers use hygroscopic materials to capture moisture from the air.

Types of Industrial Dryers and Their Uses

- Fluid Bed Dryer

- Incorporates air, blown up, through a permeable membrane, to "pick up and drop" particles in a closed chamber, to facilitate the drying process. The medium becomes a dry fluid mass as hot air blows the wet material around the chamber. The intake air used in this process must maintain thermodynamic equilibrium to keep the medium from forming a crust that traps moisture in the mix. The fluid bed drying process is best suited for granulated or powdered solids with uniform particle size, such as those found in pharmaceutical powders, food products such as dried grains, cereal, and granulated or powdered ingredients. Specialty chemicals, minerals, and metals are processed in a fluid bed dryer. Fluid bed dryers are thermally efficient, cutting oven drying time to a fraction of the time for tray drying. The machinery is compact and may be modular, linking steps in processing via conveyor systems. They provide controlled, even heating and drying of a product, ensuring consistency. They have made tray dryers virtually obsolete, except for small applications.

- Rotary Dryer

- Also known as a drum dryer, utilizes a single or multiple chambered rotating cylinder through which air passes, as the material to be dried is tumbled. It may be gas fired or equipped with an electric motor and heating element. The air may be heated, cooled, or simply passed through the system at ambient temperature. The most familiar type of rotary dryer is the basic clothes dryer found in all laundromats and many homes. They are also used for drying of heavy materials or products with inconsistent particle size, such as those in aggregates and fertilizers. Because the particles are rolled in the drum, the edges are worn down, and they become polished. Drum dryers can be custom manufactured for any purpose. They tend to be heavy and bulky, but make efficient use of energy and are comparatively inexpensive to purchase and install.

- Freeze Dyer

- Utilizes a four step process. The process material may be pretreated to facilitate free flow or to add ingredients that improve appearance, stability, or processing. It is then frozen by mechanical refrigeration, dry ice, methanol, or liquid nitrogen. Once it reaches its triple point--the state where liquid, solid, and gas coexist--the primary drying step begins. The air pressure drops slightly and heat is added to sublimate water from the product. This step removes up to 95% of the water content. A secondary drying process provides adsorption of remaining water molecules, leaving only 1% to 4% moisture content. Foods that are freeze dried have a long, stable shelf life. Microorganisms that could contaminate or spoil the food are rendered inert. The color, flavor, and smell are not compromised, and they may be rehydrated readily.

- Air Dryer

- Removes water vapour from compressed air systems. They are distinguished by their dew point rating. Desiccant dryers, or regenerative dryers, use a desiccant, such as silica gel or activated alumina, to adsorb the moisture from compressed air. Refrigerated dryers utilize a mixed thermal system to prevent condensation within the compressed air lines. Deliquescent dryers utilize a hygroscopic medium in a pressure vessel to absorb moisture as the air passes through. Membrane dryers physically filter out water molecules and retain them until an air sweep clears the membrane.

- Flash Dryer

- Uses hot gas or infrared light to remove water vapour from material as it passes through the stream. It can be used to set ink for screen printing or to dry massive quantities of powdered process materials. Flash drying requires a large quantity of heat and gas exchange, but the process material is retained in the heat chamber for a minimal amount of time, making it thermally efficient. Gas dryers use gas to heat and dry a product as desired. These dryers are quite common.

- Cyclone Dust Collector

- A type of flash dryer. The wet material flows from the top into a rotating vortex of hot air or gas. As the material spins, centrifugal and gravitational forces push the dry, solid particles outward and downward into a bag filter where they can be harvested for use or disposal.

- Double Cyclone

- Utilizes a secondary vortex to keep the particles from impacting the outer walls, thus retaining their particulate structure. Because the secondary vortex overrides gravitational forces, the double cyclonic system may be used horizontally. Wastewater, refinery products, and sawdust from sawmills may be treated in a cyclonic flash dryer.

- Sludge Dryers

- Are used to remove up to 90% moisture content from wastewater, industrial slurry, or urban sludge with high viscosity. The sludge is filtered down to a wet cake which is passed through a heated chamber, often a double cyclone, where the remaining dust is separated from the water. The clean water can then be returned to its natural channels.

- Spray Dryers

- Atomize the slurry to be dried and spray it into a heated chamber where the water is vaporized, leaving the dried process medium to fall into a hopper for collection. Air is typically used in the spray process, although ethanol or nitrogen may be used in the case of flammable or oxygen sensitive materials.

- Continuous Dryers

- Remove moisture from a constant flow of substances or items that enter the dryer, are dried and then exit, all without stopping.

- Conveyor Dryers

- Use a belt to move materials through the dryer at a continuous feed. Agricultural products are often dried on a belt or similar conveyor dryer system.

- Compressed Air Dryers

- Remove water and other contaminants from compressed air and the lines that carry it. This is done via refrigerant or desiccant processes.

- Food Dryers

- Remove moisture from fruits, vegetables, meats and other edible substances. Dried foods preserve nutrients, color and flavor while reducing weight and volume, making them easy to pack and transport.

- Gas Dryers

- Use gas to heat and dry a product as desired. These dryers are quite common.

- Industrial Dryers

- Used for removing moisture from substances, products or materials in a business or manufacturing capacity.

- Infrared Dryers

- Used most often for the curing of water-based inks and coatings found in the painting and the screenprinting industries. These use infrared radiation to quickly dry or set the material.

- Parts Dryers

- Remove moisture from machined components by use of blown air or heat.

- Thermal Oxidizers

- Used during a certain method of pollution control. They take air polluted with small particles or combustible solids and liquids and oxidize the organic parts before destroying them.

- Vacuum Rotary Dryers

- Used to provide low temperature drying of materials in the chemical and pharmaceutical industries.

Things to Consider When Purchasing a Dryer

The right industrial dryer depends on the quantity and substance of the materials to be processed. There are many standard models to choose from. Custom dryers can be manufactured to suit specific needs. Whether you are in the food processing, mining, or chemical business, a good industrial dryer manufacturer will know which system works best for your applications.

Consideration will be given to the physical qualities of the medium being dried, the size of the operation, and whether you are drying single batches or if the system needs to be in continuous operation. If there are legal requirements for safety of product or equipment, the manufacturer will be able to meet and exceed those standards.

Some operations require follow-on procedures that can be facilitated by a conveyor system. Some require multiple phases of processing. The right manufacturer can direct you through a myriad of options to find what will provide maximum production with minimal effort and cost. They should be able to supply you with or connect you to an appropriate supplier of pre- and post- drying equipment to complete or upgrade your system.

Your industrial dryer manufacturers should be able to answer any questions you have, provide maintenance tips, or perform the actual maintenance, upon request. They should stand behind their products after the sale, and direct you to associated resources that you might need.

Dryer Terms

- Agglomeration

- Adherence of particles to a small mass due to moisture, static charge or chemical or mechanical binding.

- Bag Filter

- A bag that filters air by catching air-borne particulates.

- Boiling Point

- A bag that filters air by catching air-borne particulates.The temperature at which particles within a liquid move rapidly enough to escape the surface and become gas or vapor.

- Bulk Density

- The weight per unit volume of solid materials, expressed as pounds per cubic foot or grams per cubic centimeter.

- Conductive Drying

- Heat transferred by conduction through a solid (the steel shell) of industrial dryers, separating the heating medium (steam/oil) and the material being heated. Vapor is usually removed by a combination of a condenser and a vacuum pump.

- Contactive Drying

- Direct contact between the material and the air heated industrial dryers.

- Diffusion

- The movement of molecules away from the center of concentration of a substance.

- Dry Gas

- Any gas or gas mixture that contains no water vapor and/or in which all of its constituents are substantially above their respective saturated vapor pressures at the existing temperature.

- Evaporation

- The process of extracting moisture.

- Flash Point

- The minimum temperature at which vapor forms at the surface of a liquid.

- Humidity

- The moisture content of air.

- Latent Heat

- The energy required by industrial heaters to change a substance from one state to another.

- Manometer

- An instrument for measuring fluid pressure.

- Non-Hygroscopic Material

- A material that contains only unbound moisture.

- Oxidation

- Increasing the amount of oxygen within a molecule.

- Quench

- The rapid cooling of combustion exhaust with showers of water.

- Radiation

- Heat transfer from industrial dryers by infrared radiation through space (air or vacuum), from a warmer mass to a cooler mass.

- Sublimation

- The direct vaporization of a solid by heating using industrial heaters, without passing through the liquid state.

- Throughput

- The maximum potential of industrial heaters, devices, or other industrial machines, expressed in amount per time.

- Vapor

- A visible suspension in the air of a substance's particles.

- Vitrification

- A high-temperature combustion process that melts and converts non-combustible inorganic materials.