Diaphragm Valves

Linear motion valves use flexible closure members, such as discs or diaphragms, to start, stop, and regulate fluid flow. They accurately operate the process stream according to the position of the open/close member.

Diaphragm valves are bidirectional linear motion valves. They start, stop, control, and separate the flow stream from the closure element to ensure contaminants such as flows of slurries, radioactive, corrosive, or other fluid media are contained. The valve diaphragm is a flexible pressure responsive component that forces the valve to open or close. It connects to the seat at the top of the valve body to form a seal.

Quick Links to Diaphragm Valves Information

The History of Diaphragm Valves

Early Romans and Greeks used simple diaphragm valves to control the water flow and temperature of their hot baths. The original control valves were leather diaphragm components manually closed over weirs.

The modern diaphragm valve was patented in 1931 by P.K. Sanders. In the early 1900s, Saunders, a South African mining engineer, rediscovered the diaphragm valve concept used for the Roman baths as a solution for reducing costly power losses caused by failing and leaking seats in the valves used to supply underground air and water in the South African mines.

The Hills McCanna Company was the first (licensee) to manufacture the Saunders patented diaphragm valve in the US. Grinell (ITT Dia Flow), Dow Chemical, and Arco Winn soon followed Hills McCanna. The introduction of elastomeric and plastic materials (i.e.: PTFE diaphragms) used for valve lining increased sales growth. The next realization was the need to perfect a reliable actuator to automate the valve.

In the late 1940s brothers working together in the photographic industry created the reliable and innovative IDV (Iris Diaphragm Valve) flow control solution. They found the powder and granular gelatin used in manufactured photographic film became sticky and jammed traditional slide valves used to control the flow of the gelatin. The slide valve would leak as a result, making the operators’ environment difficult, response time reduced, excess product waste produced, and significant financial loss. Their IDV invention was based on the simple principle of twisting the end of a blown-up balloon so air does not escape. The diaphragm encapsulates product lumps or trapped foreign bodies, particles, or dust. This feature enables the IDV to be effective for a variety of applications.

The initial 1940s prototype was made from cotton shirtsleeves. As new industries began using the IDV flow control solution, valves began being produced in nylon and rubber materials. Today, they are also produced in Terylene, and Polyurethane-coated fabrics for use in manufacturing pharmaceutical and food ingredients. Non-corrosive materials such as stainless steel and alloys are used for explosive or delicate products. Diaphragm solenoid valves, stainless steel solenoid valves, and sanitary diaphragm valves have followed.

Diaphragm Valve Advantages and Disadvantages

- Diaphragm Valve Advantages

- There are distinct advantages of diaphragm valves. They:

- Are very clean.

- Are well-suited to difficult environments (i.e.: hazardous chemicals, radioactive fluids).

- Do not permit contamination of flow medium.

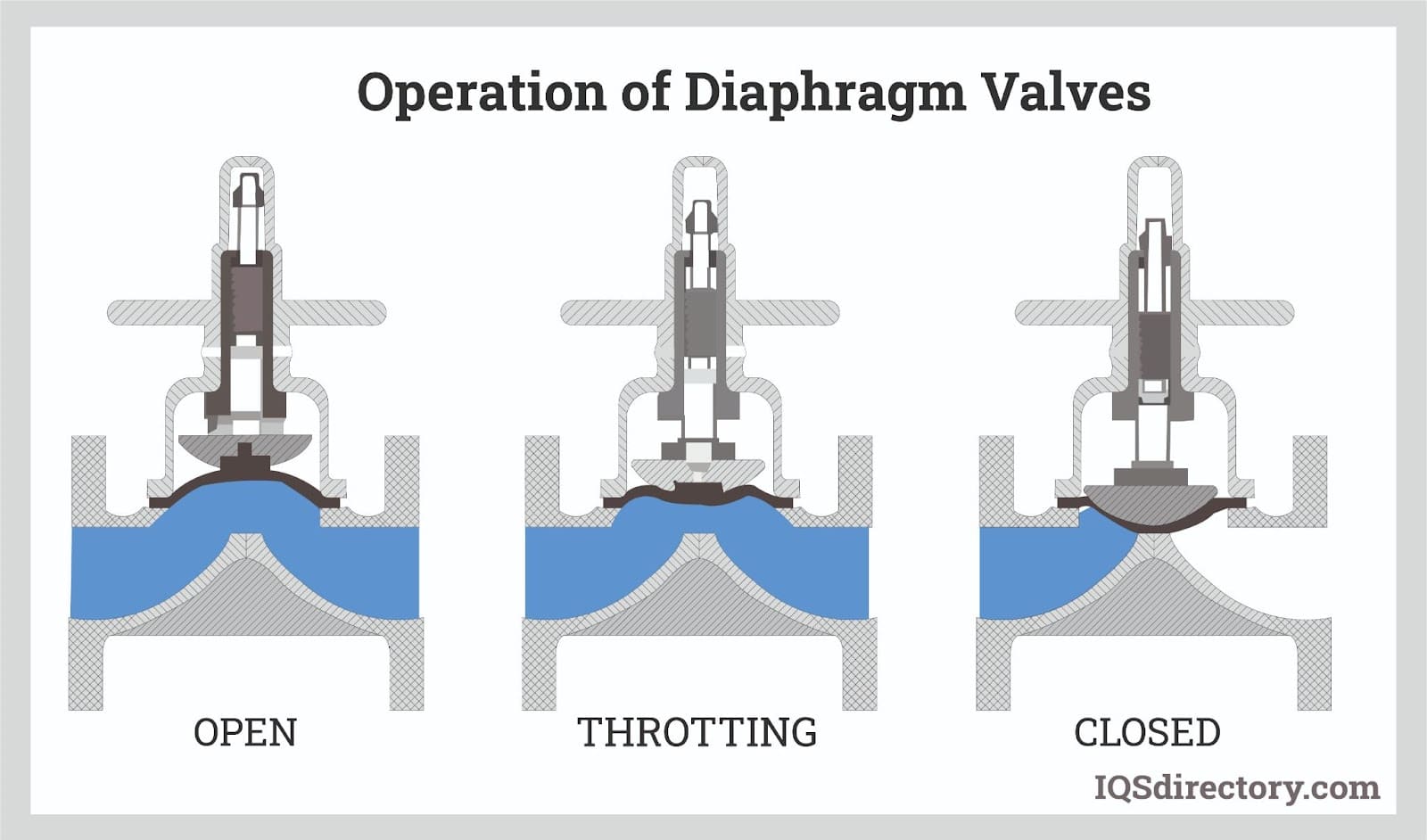

- May be used as on/off and throttling-service valves.

- Have leak-proof seals; stem-leakage is eliminated.

- Have tight shut-off.

- Are easy maintenance; repairs are made without interrupting the pipeline.

- Reduce leakage into the environment.

- Diaphragm Valve Disadvantages

- Diaphragm Valves:

- Can only be used at moderate temps (-60 deg - 450 deg).

- Can only be used at moderate pressures (300 psi).

- Cannot be used in multi-turn operations.

Design of Diaphragm Valves

Diaphragm valves are more cost effective because only the diaphragm and the body need to be chemically compatible with the system fluid/media. Diaphragm valve bodies may be solid alloy- or metal-, or plastic-, rubber-, or glass-lined. The other valve components are sealed from the system.

Diaphragm valve end connections are butt welded, welded end sockets, threaded, flanged, or screwed. They may be clamp or grooved ends, solvent cemented joint ends (for thermoplastic valves), or male sanitary threaded ends.

- Rangeability

- Determine the type of valve by the min./max. flow rate it can control. This is also known as the valve’s rangeability. Rangeability, in turn, calculated on:

- The geometry (seat and closure design) and seat leakage (instability) of the valve.

- The accuracy of the actuator at near-closure of the valve.

- The valve can control more flow rates as the rangeability increases. Higher rangeability indicates sensitivity is lower when the closing element is almost closed, and increases as the valve is opened.

- Flow and Flow Coefficient

- The valve flow coefficient determines the size of the valve opening that best allows the desired flow rate, while providing control of the process fluid. It is the amount of US gal./min. of 60°F. water flowing through a valve at a specified opening, with a pressure drop of 1 psi, across the valve.

- The flow rate may be determined by:

- The linear method (the flow-rate being directly proportional to the amount the disc travels).

- The equal percentage method (the flow rate as it relates to the % valve opening change during an incremental period.

- Pressure Drop

- Calculate the pressure drop (change in pressure between the valve inlet/outlet) to determine the size of the valve opening. For example, if the pressure drop of the fully-opened valve is too small a percentage of the total system drop, there will be minimal fluid flow change until the valve closes, thus requiring a fast-acting valve.

- Valve Sizing a Throttle Device

- The valve’s inlet/outlet ports are typically the same size since there is no pressure drop across an open/close system of the throttle device. The size of the valve is determined by the quantity of fluid/media passing through the system and the flow coefficient. Determine:

- The type of media the valve will control (specific gravity and viscosity affect the flow rate) the maximum inlet pressure, outlet pressure (drop), and temperature at maximum load.

- The maximum capacity.

Types of Diaphragm Valves

A diaphragm valve, is a valve with an elastomeric diaphragm and a seat upon which the diaphragm rests when it is closed which obstructs, controls, or isolates the flow of fluids.

A diaphragm valve, is a valve with an elastomeric diaphragm and a seat upon which the diaphragm rests when it is closed which obstructs, controls, or isolates the flow of fluids.

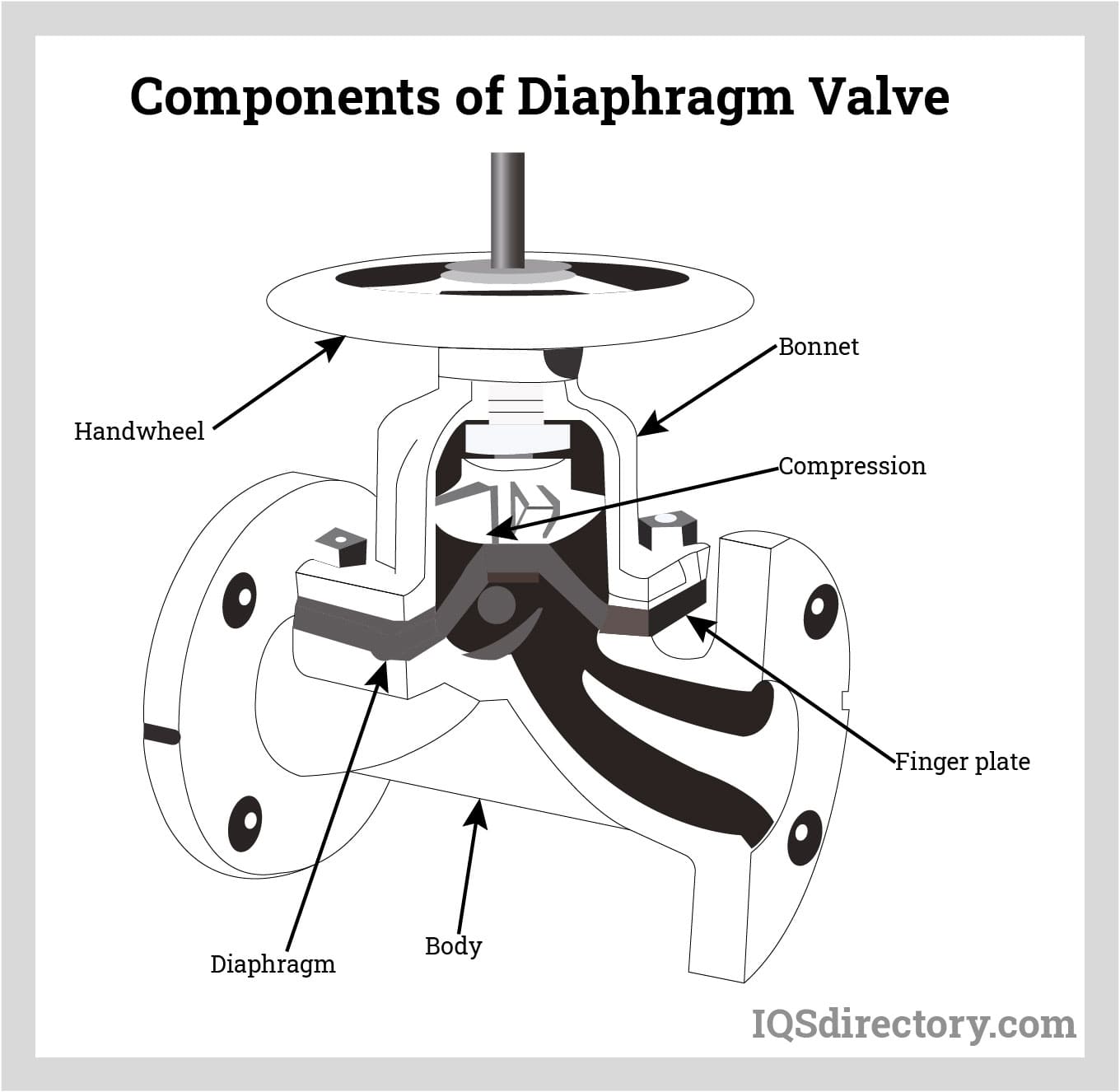

Diaphragm valves includes a stem, bonnet, compressor, diaphragm, and actuator which the material depends on the function of the valve.

Diaphragm valves includes a stem, bonnet, compressor, diaphragm, and actuator which the material depends on the function of the valve.

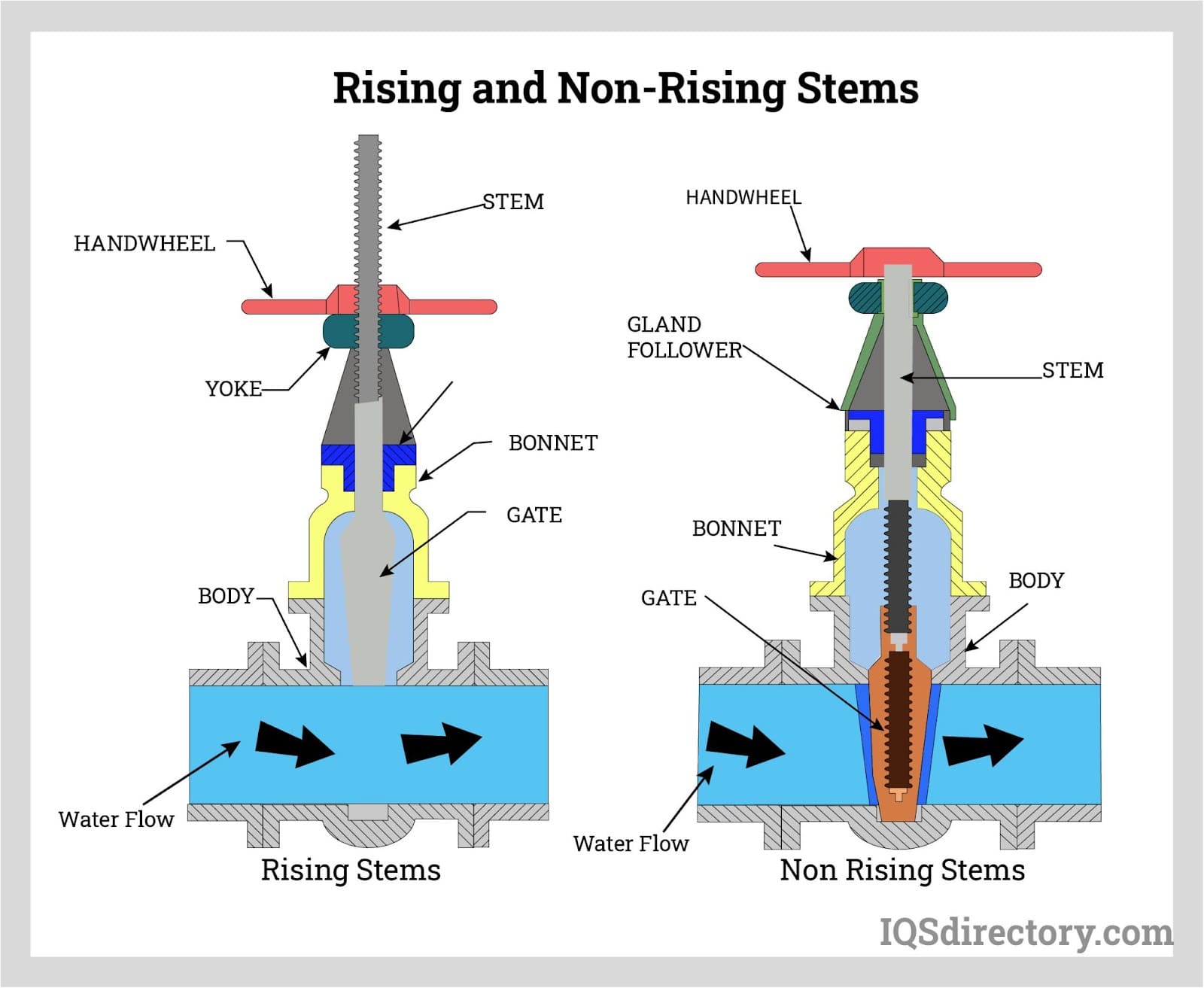

Rising stems, extend their length up to the handwheel, as the handwheel is turned the stem to open or close the valve. Non-rising stems rotate to open or close the valve without the stem move up or down.

Rising stems, extend their length up to the handwheel, as the handwheel is turned the stem to open or close the valve. Non-rising stems rotate to open or close the valve without the stem move up or down.

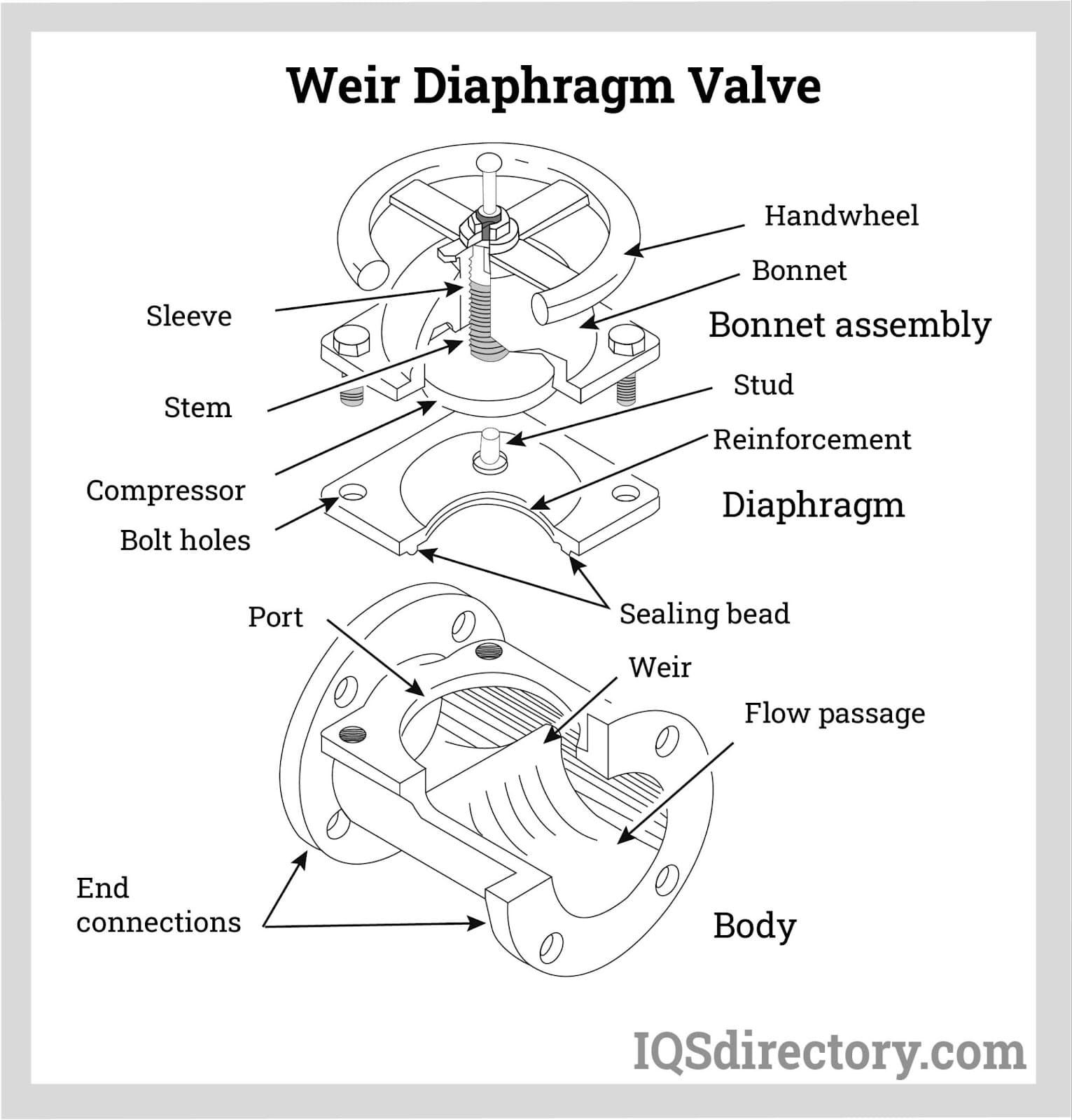

Weir diaphragm valves have a raised lip or saddle into which the diaphragm presses to create a sealing action.

Weir diaphragm valves have a raised lip or saddle into which the diaphragm presses to create a sealing action.

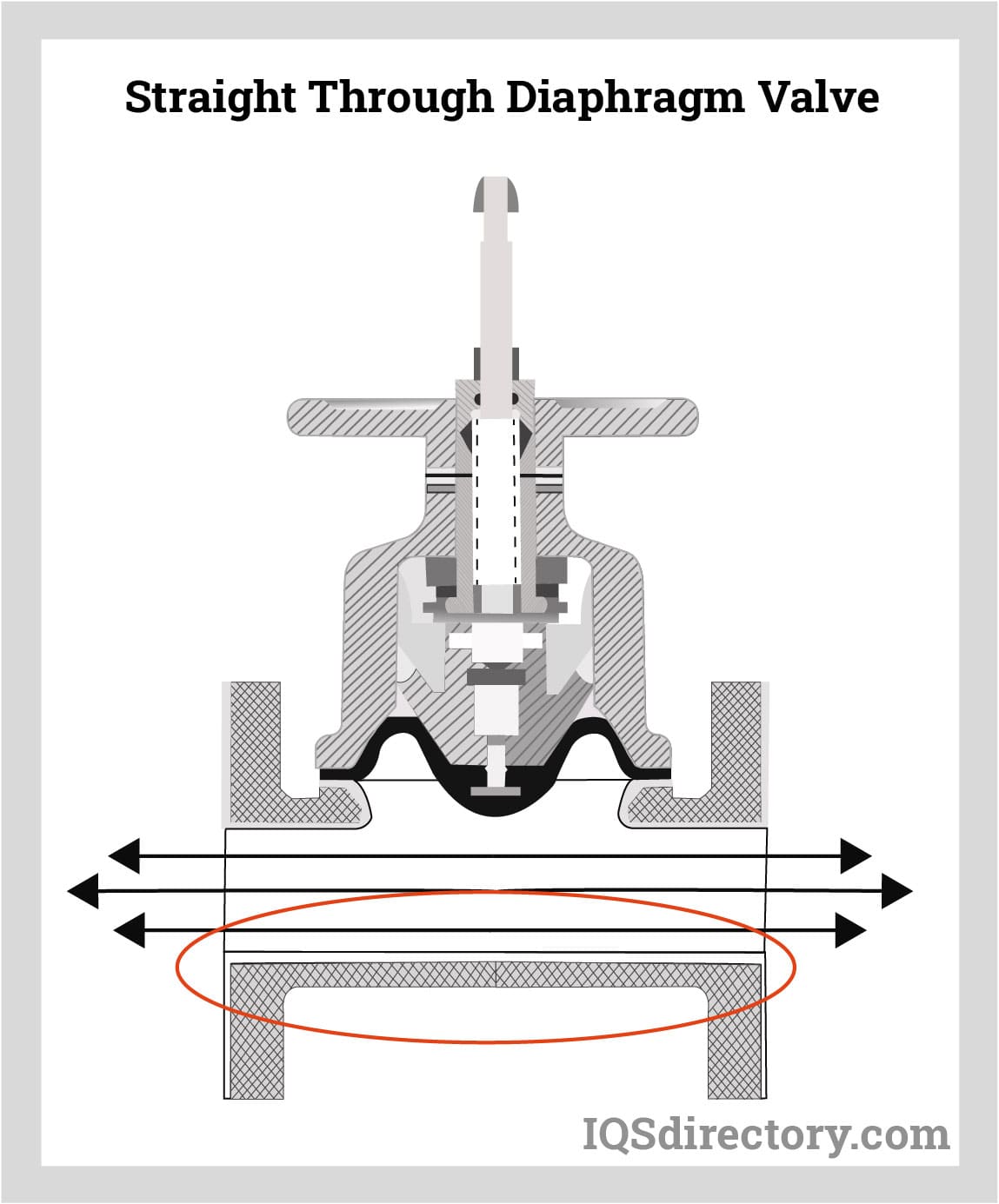

Straight through diaphragm valves have a flat bottom valve body to reduce the impediment of fluid flow giving the fluid a straight pathway.

Straight through diaphragm valves have a flat bottom valve body to reduce the impediment of fluid flow giving the fluid a straight pathway.

Types of Diaphragm Valves

Diaphragm valves consist of:

- A Rigid Body

- A Weir Placed in the Flowpath

- A Flexible Diaphragm (forming the valve’s upper pressure boundary)

- A Compressor (that forces the diaphragm against the weir)

- The Bonnet and Handwheel (that secure the diaphragm to the body and actuate the compressor)

- The valve’s rated design life and maximum pressure that these valves can endure depends on the service temp and the diaphragm material. It is imperative that the system hydrostatic test pressure never exceeds the maximum diaphragm pressure rating.

- Biotech Valves

- Intended to be used in the biotechnology fields — agriculture, food science, pharmaceuticals and medicine. Biotech valves must be sanitary.

- Diaphragm Check Valves

- Process stream regulation devices that maintain the unidirectional flow of a system through the use of a flexible membrane.

- Diaphragm Control Valves

- Employ a membrane or elastomer film to regulate the process stream of various manufacturing operations. Everything from rate, pressure and temperature to liquid level can be regulated with the application of these valves.

- Diaphragm Diverter Valves

- Can be used to divert flow from an inlet to two or more outlets; they can also be used in reverse to feed flow from one line into two or more lines.

- Diaphragm Tank Bottom Valves

- Designed for use at the bottom of a tank or vessel, to drain or sample from the tank.

- Diaphragm Valves

- Inline devices that utilize a membrane to transect a pipe completely or partially in order to regulate the flow of liquid, gaseous or semi-solid process streams.

- Hygienic Valves

- Specially designed to be used in sanitary and aseptic (sterile) applications.

- Plastic Diaphragm Valves

- Process stream regulation devices that use an elasticized polymeric membrane to transect conduits either fully or partially as needed to maintain optimal flow and pressure rates. Included in this material category are those diaphragm valves made entirely of plastic components as well as those that employ plastic elements in conjunction with metal parts and forms.

- Pneumatic Diaphragm Valves

- Convert the energy of compressed air in order to engage an elastomeric membrane thereby maintaining and regulating the flow of a given process stream.

- Process Valves

- Include any type of mechanical device that can stop, start or regulate the flow of liquid, gas, solid material or steam.

- Straight-Through Diaphragm Valves

- Commonly used where the flow direction tends to change within the system. The body has a flat bottom that runs parallel to the flow stream to ensure the stream through the valve is unobstructed. The diaphragm must be constructed from a flexible material so the mechanism can reach the bottom of the valve body. Straight-through diaphragm valves are recommended for use with slurries, sludge, and other viscous fluids. They are not recommended for high temperature fluids.

- Sanitary Diaphragm Valves

- Process flow regulation devices constructed of sterile materials and designed to create an aseptic environment for liquid, gaseous and semi-solid material flows.

- Tank Bottom Valves

- Designed to eliminate deadlegs or areas where bacteria might become trapped in the valve.

- Weir Valves

- Have a raised section, or "weir," on which the diaphragm presses to create a seal.The most commonly used diaphragm valve is the weir-type. It is a large, general-use, two-piece compressor unit valve that is best-suited for controlling small flows. The weir-type diaphragm valve is made to endure corrosive and abrasive environments. They are typically made from heavier material so they can be used for vacuum and high-pressure purposes. It requires less material due to its smaller diaphragm.

- Weir-type diaphragm valves are designed with a large shutoff area beside the seat, which makes it better at throttling (than a straight-through diaphragm valve). The weir-type body has a raised lip that decreases the amount of diaphragm travel from the completely-open to the completely-closed position, thus reducing the amount of stress on the diaphragm. The diaphragm functions as a valve gasket seal between the body and the bonnet cap. The shut-off valve operates like a quick-opening valve. The weir is an important part of the valve body that performs like the valve seat. Essentially, the diaphragm compresses against the weir to stop the flow.

- Bonnet assemblies are recommended for managing hazardous gases or liquids, in the event the diaphragm fails. The bonnet cap ensures the hazardous material does not escape into the system. Bonnet assemblies are also recommended for food processing applications since the body is self-draining.

- Variations of the weir-type diaphragm valve:

- The full-bore valve type is mostly used in the beverage industry. It permits ball valve cleaning (with steam or caustic soda) without opening the valve or removing it from the line.

- The straightway valve’s diaphragm lifts up for full bidirectional streamline flow when it is opened. When it is closed, the diaphragm seals tightly.

- Zero Static Valves

- Multiport diaphragm valves that serve to promote drainage and eliminate dead-leg, or process stream stagnation. These valves accomplish both measures not only by reducing the number of recesses where materials may be caught, but also providing an exhaust or purge port for materials that do become trapped.

Valve Features

The diaphragm valve has retaining rings at each end that a flexible diaphragm attached to a compressor closes. The compressor is moved by the valve stem to start or increase the flow. One end is held in position while the other end is rotated 180 deg. To stop or slow the flow, the 180 deg. rotation closes the opening completely, providing an equal load support of the steel plate slide valve.

- Valve Position Indicator

- The on/off or open/closed indicator feature on the valve identifies the position of the valve. It may be a switch, light, stem, or other visual characteristic. Piston indicators, for example, are on the top of the ball to indicate the flow direction.

- Valve Body

- Diaphragm valve body construction is basic. The diaphragm valve manufacturer sizes diaphragm valves according to specified use. They also typically have diaphragm valves with different features to fit a desired application.

- Diaphragm valves come in a variety of body, diaphragm, and lining materials suitable for just as wide a variety of media. Diaphragm valves designed for corrosive applications, for example,are made of PVC or stainless steel, or they may be lined with lead, rubber, glass, plastics, titanium, or other durable, non-corrosive materials.

- The Stem

- The diaphragm stem does not rotate. A non-indicating stem" is a handwheel that rotates the stem bushing, which engages the stem threads that move the stem and the attached compressor, which in turn, is attached to the diaphragm. Non-indicating bodies use a sealed bonnet w/seal bushing. "An indicating stem" has a longer stem that extends through the handwheel. It operates the same as a non-indicating stem. Indicating bodies use a sealed bonnet w/seal bushing and O-ring.

- The Bonnet

- The bonnet bolts to the body and covers the top of the valve. It contains the non-wetted portion of the valve, the compressor, and the handwheel. It opens quickly, is lever-operated, and is interchangeable with the standard bonnet on weir-type bodies. Diaphragm valves are used in vacuum services using a max. 4" bonnet construction. Larger valves should use a sealed, evacuated bonnet.

- The Compressor

- It is needed for the diaphragm to operate. It is round and located above the diaphragm and below the handwheel-stem.

- Travel Stops

- Adjustable travel stops prevent excessive diaphragm compression. Temper-proof housing prevents changes after the travel length is set.

Applications of Diaphragm

Diaphragm valves are considered the "cleanest valves" because their passages and media have minimal contact with contaminants. The fluid stream does not come in contact with the valve’s working parts, which prevents fluid contamination and corrosion of the operating mechanism. As a result, diaphragm valves are widely used in the food processing, pharmaceutical, and water treatment industries.

Originally developed for industrial applications, the modern diaphragm valve has been adapted for the bio-pharmaceutical industry. Compliant materials such as stainless steel withstand sterilization methods. Sticky and viscous fluids that clog other valve systems may utilize the smoothly-lined diaphragm valves.

Diaphragm valves are successfully used as on/off and throttling valves due to their superior leak-tight characteristics during conveyance of liquids that contain suspended solids. They are well-suited for low pressure applications when other types of valves are not. The smooth/streamlined passages minimize pressure drops. The valve is effectively leak-proof since there is no valve stem leak path.

Diaphragm valves are well-suited for harsh environments transmitting slurries, corrosive chemicals, and radioactive fluids and wastes. Other industries and uses include:

- High-Purity and De-Mineralized Water Systems

- Vacuum Services

- Food Processing, Pharmaceutical, and Brewing Systems

- Electronics Industry Applications

- Pulp and Paper Industry Applications

- Power Industry Applications

- Photographic Industry Applications

Use and Installation of Diaphragms

- Diaphragm Install

- The diaphragm is connected to a compressor by a stud molded into it. The compressor is moved up by the valve stem to start. The compressor is lowered, and the diaphragm pressed against the bottom of the valve to slow or stop the flow.

- Uses of Diaphragm Valves

- Diaphragm valves connect to a compressor molded into the diaphragm. The diaphragm is pushed into the bottom of the valve body to provide shut-off to control the flow.

- Manual diaphragm valves provide a variable and precise opening for controlling pressure drop through the valve. The handwheel turns (similar to a butterfly valve) until the compressor pushes the diaphragm against the bottom of the body or lifts the diaphragm off the bottom until flow is able to pass through.

- Diaphragm valves control fluids containing suspended solids. Weir-type diaphragm valves are better at throttling.

Actuators

The actuator operates the disc and stem that opens and closes the valve. Depending on the system, speed and torque needed to operate the valve must be determined. Actuators may have adjustable openings, flow control positioners, or valve position electric relays.

- Manual Actuators

- Use a handwheel or crank to open or close the valve. They are used in remote systems (without power). They are not recommended for larger valve applications.

- Electric Actuators

- Permit higher-speed manual, semi-, and automatic open/close control valve operation. The motor is typically reversible. The actuator is connected through a gear train to increase the torque which runs the actuator. It may also be operated by the position of the valve. A limit switch that automatically stops the motor at fully open/closed may be added.

- Pneumatic Actuators

- Automatically or semi-automatically operate pneumatic diaphragm valves. Air pressure acting on a piston stem or diaphragm transmits an air signal into the pneumatic diaphragm valve stem motion. These use a spring and can be programmed to open/close the valve. They are fast-acting for throttle valves and for open/close positioning.

- Hydraulic Actuators

- Permit semi-, and automatic open/close valve operation when a large force is needed to open the valve (i.e.: mainstream valve). The spring force holds the valve in the closed position as fluid enters the chamber (changing the pressure). When the force of the hydraulic fluid increases, the piston moves, and the valve opens. The valve closes when the hydraulic fluid is pushed to either side of the piston while the other side is bled/drained.

- Thermal Actuators

- Activated when the preset media temperature/pressure changes. The valve opens/closes to adjust to the preset specifications.

Proper Care for Diaphragm Valves

Diaphragm valve connections should be selected based on system requirements and seal type, such as:

- Simple threaded ends that fit standard piping systems.

- Compression fittings that seal a connection without soldering or threading.

- Bolt flanges that connect inlet or outlet valve ends.

- Clamp flanges (spring-hinge flanges) that wrap around a pipe to make the connection.

- Tube fittings that allow a direct connection from a tube to a valve.

- Metal face seals sandwich a metal gasket between two fittings parts.

Compliance and Standards for Diaphragm Valves

Diaphragm valve performance standards/specifications may be found in the following:

- ANSI B16.34

- Defines pressure-temperature rating, materials, design requirements, and wall thicknesses for process valves.

- MSS Standards

- Steel and alloy valves of 1" nominal pipe size and smaller; at 10,000 psi and lower at 100°F.

- API Standards (API 598)

- Inspection and test requirements for valves purchased under API valve standards; used in the petroleum and chemical industry.

- NACE Standards

- Valves handling corrosive materials.

- ASME Standards

- Codes, design, construction, materials, etc. for pressure vessels and piping systems.

How to Choose the Right Manufacturer

The "right manufacturer" provides quality products (and warranties) that meet the client’s needs.

Diaphragm Valve Terms

- Actuators

- Controls that switch the position of a valve from open or partially open to partially or completely closed. Actuator operation may be manual, pneumatic or hydraulic.

- Back Pressure

- The pressure at the outlet of a relief valve, caused by pressure in the discharge system. Pressures may be constant or variable.

- Bellows

- A sealing device that prevents leaks between the valve stem and the body of the valve.

- Bonnet

- A cover fitted over the valve body, which may be removed for valve maintenance.

- Cracking Pressure

- The pressure at which leaks start to flow through a valve.

- EPDM

- Ethylene propylene diene monomer. EPDM is a commonly used rubber seal material that is compatible with many chemicals.

- Flange

- A type of pipe fitting that attaches with nuts and bolts.

- Flare

- A pipe fitting that uses a socket and a union nut to form a connection. Flares are one of the most crevice-free pipe fittings and may be used for ultrapure processes.

- GPM

- Gallons per minute. Used to measure flow through a pipe, valve, inlet or outlet.

- O-Ring

- A rubber seal with an "o" shape, used to seal connections between pipes and valves.

- Ports

- Passages that allow flow into and out of a valve.

- Set Pressure

- The pressure from an inlet that a valve is adjusted to open, maintain or control under service conditions.

- Stem

- A rod that spans the inside and outside of a valve, transmitting motion to control the internal disc, which moves to seal or unseal the valve.

- U-Cup

- A seal formed into a u-shaped channel. This type of seal may be used when an O-ring is not desirable.