Butterfly Valves

Butterfly valves are mechanisms that control the flow of liquids and gases in pipes. The valves provide complete shut-off capabilities through the use of a disk that rotates on a shaft connected to a lever handle or wheel control. When the actuator is turned, the disk stands upright and blocks the flow line, instead of lying parallel to the pipe.

Quick links to Butterfly Valves Information

History of Butterfly Valves

Butterfly valves can be traced back to the 1870s. They have evolved much since then in terms of the number of valves in a disk and the opening and closing across the disk. Made throughout the 20th century, the development of butterfly valves improves the speed of the rotations and can vary the running speed of the engine.

Historically, typical construction consists of the opener and closer plus two springs of the electric actuators and a moving armature connected to the engine. Most modern electric actuators engines incorporate the hydraulic adjuster to ensure proper valve sealing. The air flowing in the coil creates a force on the valve to overcome the compressive spring and the friction forces in the pneumatic actuators engines. The springs can be adjusted so that they are suitable for any armature position between the opener and closer because these springs are preloaded for a rapid flight time and to minimize the electrical energy simultaneously. During normal operation, the electric actuators' spring forces can accelerate the moving masses while the electric forces attract the armature, unheard of in the history of butterfly valves.

Benefits and Advantages of Butterfly Valves

Butterfly valves have advantages and disadvantages in comparison to other types of flow devices. They are efficient at blocking flow and do not result in leakage, but they are difficult to thoroughly clean and are therefore not appropriate for applications that require sterility, such as in the food or medical industry; although sterile metals, such as stainless steel, are occasionally used.

Butterfly valves are easy and fast to open. A 90° rotation of the handle provides a complete closure or opening of the valve. Large valves are typically equipped with a gearbox, where the gear operator in a handwheel is connected to the stem. This design improves the operation, but at the expense of speed.

Butterfly valves are considered inexpensive to build. Because of the design, they require less material and they are generally less expensive. The wafer type butterfly valve is the most economical. It fits between two pipeline flanges. The lug wafer butterfly valve design is held in place between pipe flanges by bolts that join the two flanges and pass through holes in the valve’s outer casing.

Butterfly valves have less space requirements. Because of the compact design, less space is needed compared to other valves.

Butterfly Valves require less maintenance than other valves.

Butterfly Valve Design

Butterfly valve design is the most important aspect of these valves that control the flow of fluid through a piping system. The butterfly style uses a circular vane or a disc as the shut-off mechanism. They have a quick opening and closing quarter turn function that controls the flow of liquids or gases.

- How a Butterfly Valve Works

- Butterfly valves typically pivot on axis perpendicular to the direction of flow inside the flow chamber and are situated on a spindle that allows for flow in a single direction. They are frequently used as throttling devices, controlling the levels of flow in entirely closed, entirely open or partially open positions.

- Butterfly valve suppliers stock numerous closure types and body configurations, depending on the type of flow control needed and the design. Butterfly valves are designed and sold in many diameters, resulting in different flow rates. Smaller butterfly valve assemblies may be used where space is limited. With recent innovations in fabrication techniques, these valves are made with very few flaws. The metal is even and smooth with a minimum of internal stresses. Bolt holes and flanges are carefully crafted to meet the standards of the valve and to ensure that they are not weak points for the mechanism and the assembly of the seal, disc and shaft is tested before being installed in the enclosure.

- Materials Used in Butterfly Valves

- Because these valves meet potable water, they must be as sanitary and safe as possible, including carefully chosen and appropriate materials. The ability to work with a variety of substances means they can be purchased by more companies and industries. Butterfly valve manufacturers use three main materials when constructing these mechanisms:

- Plastic Butterfly Valves

- The least common. The body and disc are made of thermoplastic materials that are molded into a strong one-piece design. Plastic butterfly valves are a very cost-effective option. However, they should not be used with harsh chemicals that could wear away at the disc, causing an imperfect seal.

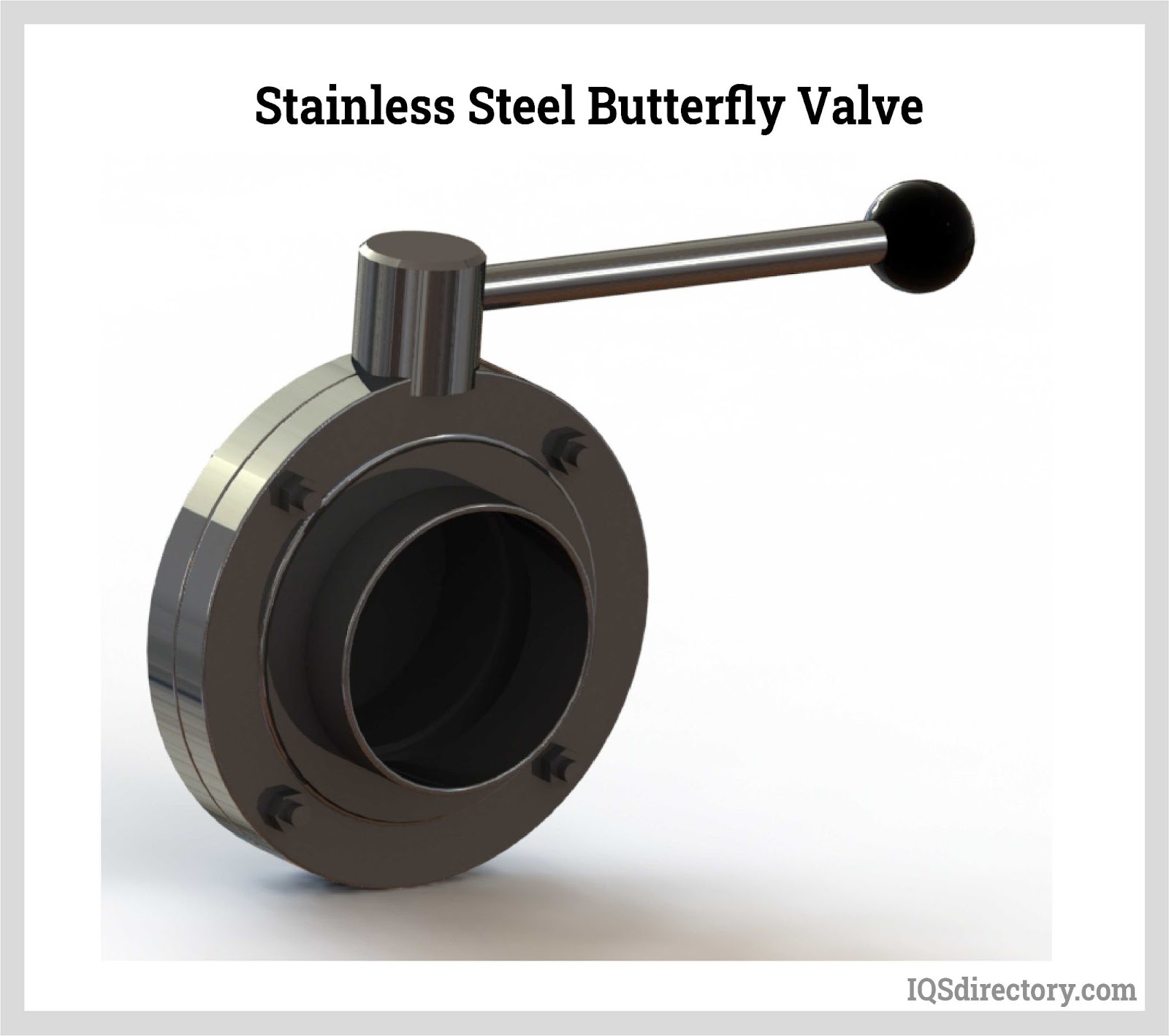

- Stainless Steel Butterfly Valves

- Made of stainless steel materials. Stainless steel is a metal that is resistant to corrosion and oxidation. It is chosen over traditional steel and other metals and traditional steel because it requires less maintenance and has a longer life. Stainless steel is also highly sanitary and easy to clean therefore making it the best option for applications involving food products and drinkable liquids.

- Cast Iron Butterfly Valves (Ductile Iron)

- Used in heavy duty scenarios because the casting process toughens and hardens the iron into a very durable material.

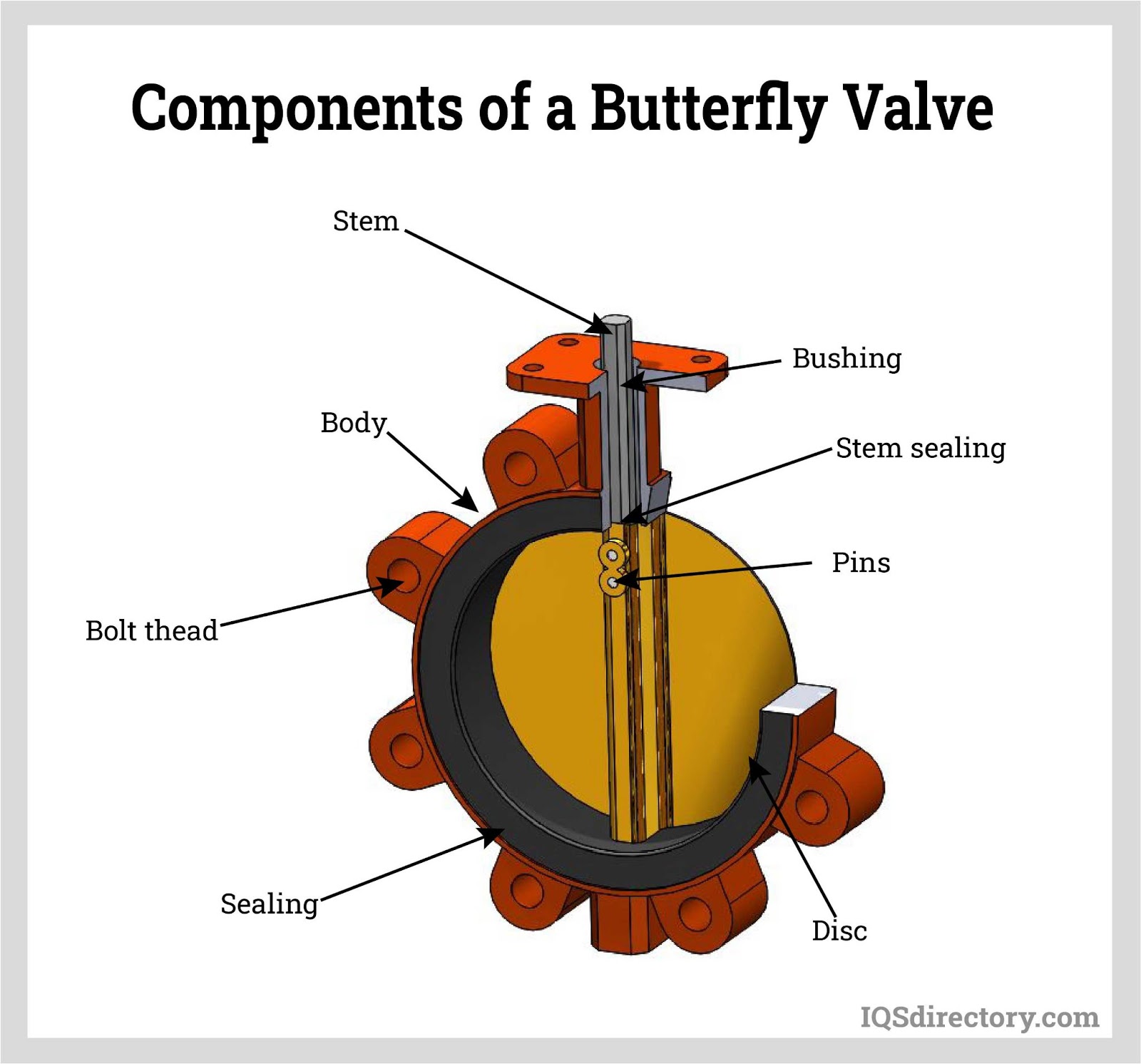

- Butterfly Valve Components

- The most important aspect of all the varying kinds of valves is the butterfly valve design. The winged and raised edges of flanged butterfly valves allow them to be attached between pipes, creating a leak resistant seal, while there are triple offset valves that seal the pipe in three different places, ensuring no leak will occur.

- The general design of butterfly valves has not changed much since they were first developed. The concept behind them is simple; a disc rotates to plug the width of the pipe. There have been advancements in materials, machining processes and fabrication techniques.

- The butterfly valve consists of only four main components:

- Butterfly Valve Body

- Generally have bodies that fit between two pipe flanges. Lug and wafer body design are the most common.

- Butterfly Valve Disk

- Equivalent to a plug in a plug valve, a gate in a gate valve or a ball in a ball valve. The disk design and orientation have variations in order to improve flow, sealing and/or operating torque have variations.

- Butterfly Valve Stem

- May be a two-piece (split-stem) or a one-piece shaft or design.

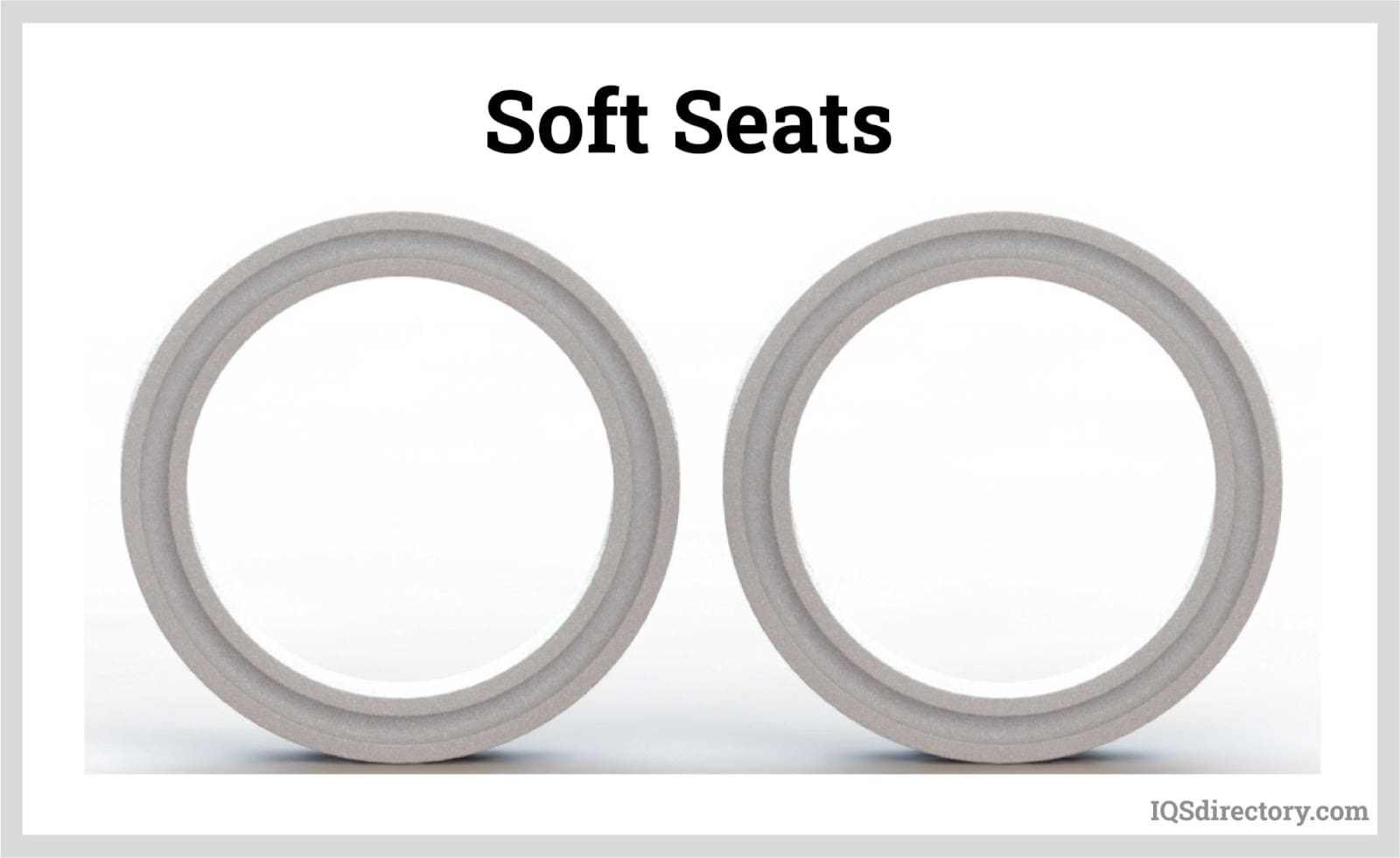

- Butterfly Valve Seat

- Utilizes an interference fit between the seat to provide shut-off and the disk edge. The material of the seat can be made from many different elastomers or polymers. The seat may be pressed, locked in, or be bonded to the body.

- Size of Butterfly Valves

- The characteristics of steel and iron alloys when they encounter certain pressures, temperatures and substances have been widely researched so that there are no surprises when the actual valve is installed in the pipeline. Better machining such as CNC (computer numeric controlled) processes allow the discs and enclosures to be cut to very precise measurements for the tightest fit with minimal clearance. A large range of sizes is now available that can be used in standard and custom sizes, which allows more industries to benefit from using butterfly valves.

Butterfly Valve Images, Diagrams and Visual Concepts

The main components of a butterfly valve.

The main components of a butterfly valve.

Double-flanged butterfly valves have a pair of flanges built on each side of the valve body.

Double-flanged butterfly valves have a pair of flanges built on each side of the valve body.

Metal butterfly valves have high toughness and withstand intense pressure.

Metal butterfly valves have high toughness and withstand intense pressure.

Softs seats are made from plastic or elastomeric materials with a low coefficient of friction and have self-lubricating properties.

Softs seats are made from plastic or elastomeric materials with a low coefficient of friction and have self-lubricating properties.

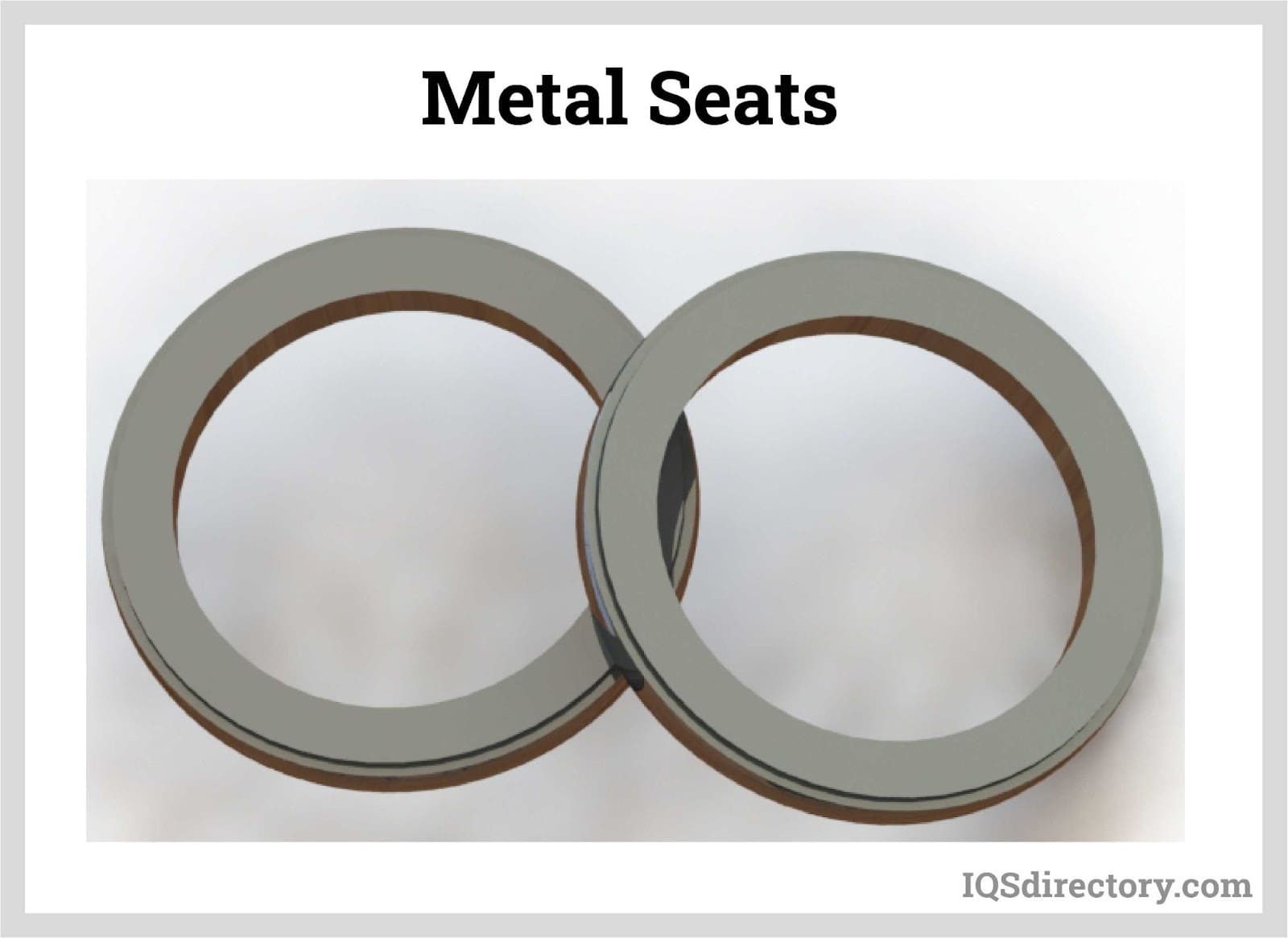

Metal seats can withstand and retain their strength at high temperatures.

Metal seats can withstand and retain their strength at high temperatures.

Butterfly Valve Types

- Aluminum Butterfly Valves

- Use various grades of aluminum for their makeup. Aluminum is commendable for its ultra-lightweight and above average strength, but unlike stainless steel, aluminum is prone to corrosion over time.

- AWWA Butterfly Valves

- Meet standards put in place by the American Water Works Association because they are used to transport potable water.

- Cast Iron Butterfly Valves

- Frequently used in heavy duty environments with harsh conditions because of the metal's strength.

- Electric Butterfly Valves

- Use an electric actuator to open and close the valve instead of a hand operated lever or crank wheel.

- Flanged Butterfly Valves

- Have raised outer rims that allow them to be installed in between two pipes so one side may be disconnected without having to disrupt the entire piping system.

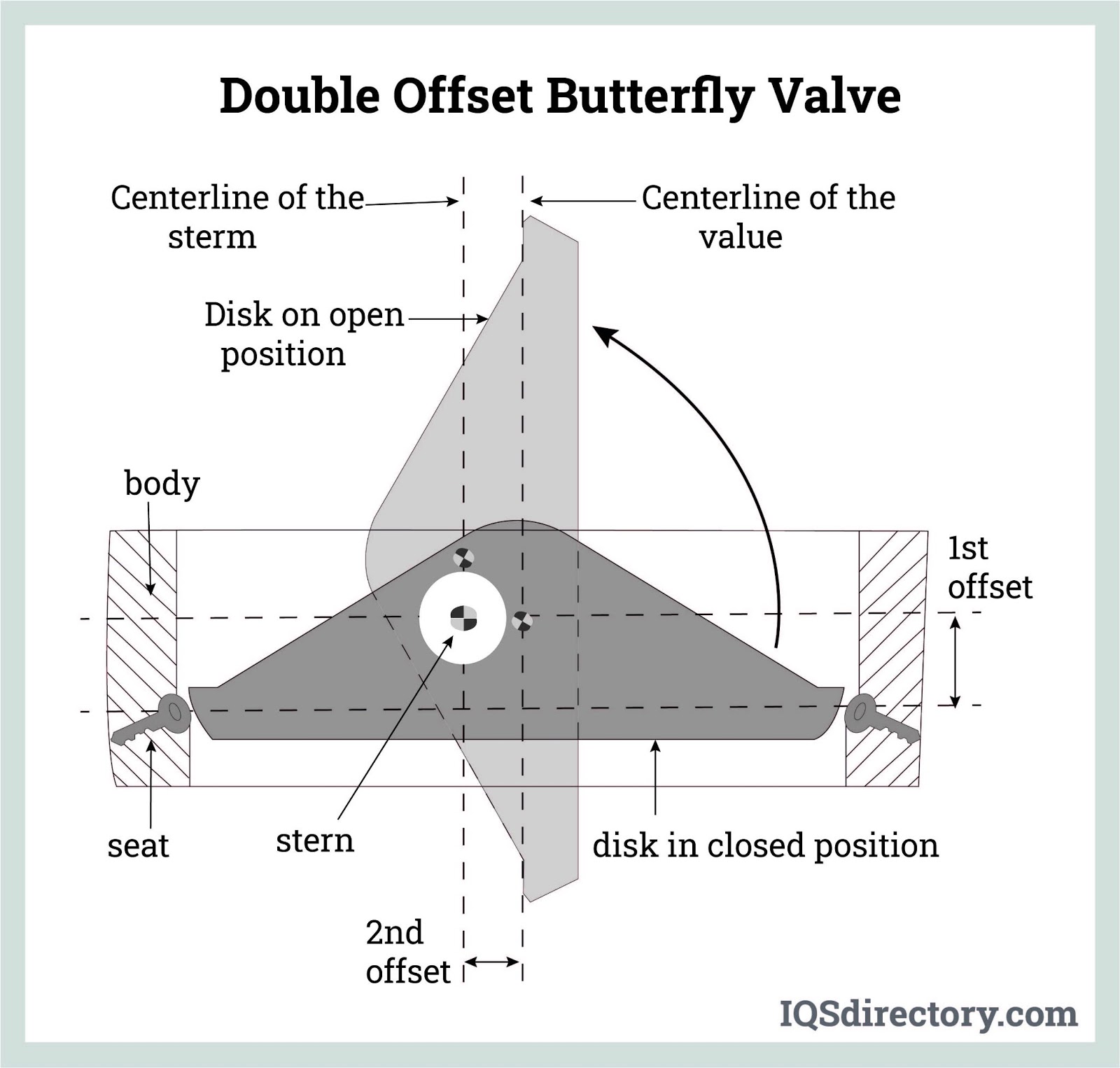

- High Performance Butterfly Valves

- Typically double offset valves that can withstand both high temperatures and pressure.

- Lug Butterfly Valves

- Valves that have threaded metal inserts in the bolt holes that allow a system to use two sets of bolts without nuts. Lug valves are installed between two flanges and are used to disconnect one side of the piping system without distributing the other.

- Plastic Butterfly Valves

- Cheap and offer higher flexibility than their metal counterparts. With these benefits, a lower maximum pressure and temperature stability are to be expected.

- Pneumatic Butterfly Valves

- Used to shut off pipes that transport compressed or pressurized air.

- Stainless Steel Butterfly Valves

- The most common type of butterfly valves. Stainless steel is used for its strength and anti-corrosive properties.

- Triple Offset Butterfly Valves

- Mounted eccentrically in three places to help create a tighter and stronger seal.

- Wafer Butterfly Valves

- Installed between two flanges and are secured using bolts or nuts and studs.

Installing Butterfly Valves

It might be better to install butterfly valves over gate valves for the following reasons:

Because of their light weight and reduced space requirements.

Butterfly valves, compared to Gate valves, have significantly smaller dimensions for small spaces.

They open fully faster and shut-off easier, requiring only a quarter turn.

The shorter shafts, for butterfly valves than gate valves, potentially lead to fewer problems with access.

Butterfly valves are generally cheaper due to less expensive requirements and less weight.

Applications for Butterfly Valves

Butterfly valves are used in a range of environments partly because they can act as throttles to control the flow of fluid without completely closing the pipe. They can block and control the flow of gases such as air, liquids such as water or petroleum, and mixtures of solids such as slurries.

Specific applications include chemical transport, underground piping systems, high pressure water lines and carburetors. Industries that utilize butterfly valves include pipe fabricators, automotive, waterworks companies, irrigation industries, food processing and industrial manufacturers.

Butterfly valves are used in many food transporting and chemical plants where controllable product flow is required. Other specific applications include HVAC, petroleum recovery and industries that use high-pressure water. Butterfly valves can be used for a range of applications:

- Air, Cooling Water, Gases and Fire Protection

- Slurry and Similar Services

- Vacuum Service

- High-Temperature and High-Pressure Water and Steam Services

- Compressed Air or Gas Applications

Valve Standards and Specifications

Many applications throughout the industrial, commercial, and residential industries use Valves including Butterfly Valves. Due to this, there are several major regulatory organizations to ensure proper functionality, compatibility, and safety for users.

The major standard organizations include the following:

- American Petroleum Institute

- American Society of Mechanical Engineers

- American National Standards Institute

- ASTM International

- Manufacturers Standardization Society

They are all headquartered in the U.S. They have international reach used around the world.

Engineers designing or using a valve for global use, should review the standard documents for the following applicable national standard organizations to name a few:

- International Organization for Standardization

- European Committee for Standardization

- ANSI Valve Standards (United States)

- BSI Valve Standards (United Kingdom)

- CSA Valve Standards (Canada)

- DIN Valve Standards (Germany)

- EEMUA Valve Standards (United Kingdom)

- JSA Valve Standards (Japan)

Things to Consider When Purchasing a Butterfly Valve

Majority of the industrial companies that employ butterfly valves are manufacturing companies, chemical and water-based companies, and anything that has to do with pipes. Depending on the size and shape of the pipe where the butterfly valve will be placed, the manufacturers may need to create a customized butterfly valve design. Manufacturers must consider the properties of the material and how they fabricate the pieces of the valve.

If the environment is going to be high or low pressure, specific types of butterfly valves will be used, as is the case with different types of piping connections. Find butterfly valve companies that can design, engineer, and manufacture butterfly valves to your specifications. Whatever the piping needs, there is a butterfly valve to meet it.

Peruse our website to review and discover top butterfly valve manufacturers with roll over ads and complete product descriptions. Connect with the butterfly valve companies through our hassle-free and efficient request for quote form. You are provided company profiles, website links, locations, phone numbers, product videos, and product information. Read reviews and stay informed with product new articles.

Whether you are looking for manufacturers of stainless steel butterfly valves, high performance butterfly valves, and triple offset butterfly valves of every type, IQS is the premier source for you.

Butterfly Valves Terms

- Actuator

- The part of a valve that converts electrical, fluid or thermal energy into mechanical energy in order to open/close the valve.

- Aeration

- The process of mixing air with a high content of oxygen into a liquid. Carburetor butterfly valves go through aeration when mixing oxygen with fuel.

- Back Pressure

- Force on the upstream part of a butterfly valve or valve seat.

- Bearing

- A support typically used in conjunction with butterfly valves to hold the revolving shaft in its appropriate position.

- Blind Flange

- A solid plate-like fitting used to seal a flanged end pipe’s end.

- Bonnet

- The part of a valve that connects the body to the valve actuator. The bonnet sometimes includes the stem packing.

- Breakaway (Unseating) Torque

- The turning force required to rotate the closure element of a butterfly or rotary valve.

- Flange

- The rim at the end of a fitting, pipe or valve that allows for bolting onto an additional pipe element.

- Flow Meter

- A measuring device used to read and signify the flow rate of a material.

- Flow Rate

- The weight, mass or volume of a gas, liquid or solid through a medium per unit of time.

- Gate Valve

- A valve similar to a butterfly valve. Gate valves are not used in throttling applications because they are either entirely open or entirely closed.

- Inlet

- Area of a valve through which fluid enters.

- Leakage

- The amount of fluid that passes through a valve while it is in the off position. The most common unit for measuring leakage is in volume/time.

- Outlet

- The opening in a valve through which fluid exits.

- Pounds per Square Inch (PSI)

- A unit of measurement that signifies the level of pressure of a liquid, solid or gas in a valve system.

- Recovery

- The amount of pressure in a flow stream that is reduced as a direct result of the design of the control valve. Recovery is also described as the ratio of maximum downstream pressure to upstream pressure.

- Seating Torque

- The value of the turning force that is needed to close a valve.

- Slip on Flange

- A flange that slides over the end of piping and is then welded in place.

- Throttling

- Regulation of flow or current through a valve.

- Trim

- The inner parts of a valve that are in contact with the flow stream.

- Valve Body

- The main part of a valve that contains passages for the flowing material.

- Variable Speed

- Term for when an actuator is able to provide a slower operating time over the entire range of operation.

- Vena Contracta

- The area of a valve at which the flow stream is the slowest, usually downstream of the physical constriction.